light DODGE NEON 1999 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 258 of 1200

ply circuit shorts to ground, neither sensor will pro-

duce a signal (output voltage to the PCM).

When the ignition key is turned and left in the On

position, the PCM automatically energizes the Auto

Shutdown (ASD) relay. However, the controller de-en-

ergizes the relay within one second because it has

not received a camshaft position sensor signal indi-

cating engine rotation.

During cranking, the ASD relay will not energize

until the PCM receives a camshaft position sensor

signal. Secondly, the ASD relay remains energized

only if the controller senses a crankshaft position

sensor signal immediately after detecting the cam-

shaft position sensor signal.

(1) Check battery voltage. Voltage should approxi-

mately 12.66 volts or higher to perform failure to

start test.

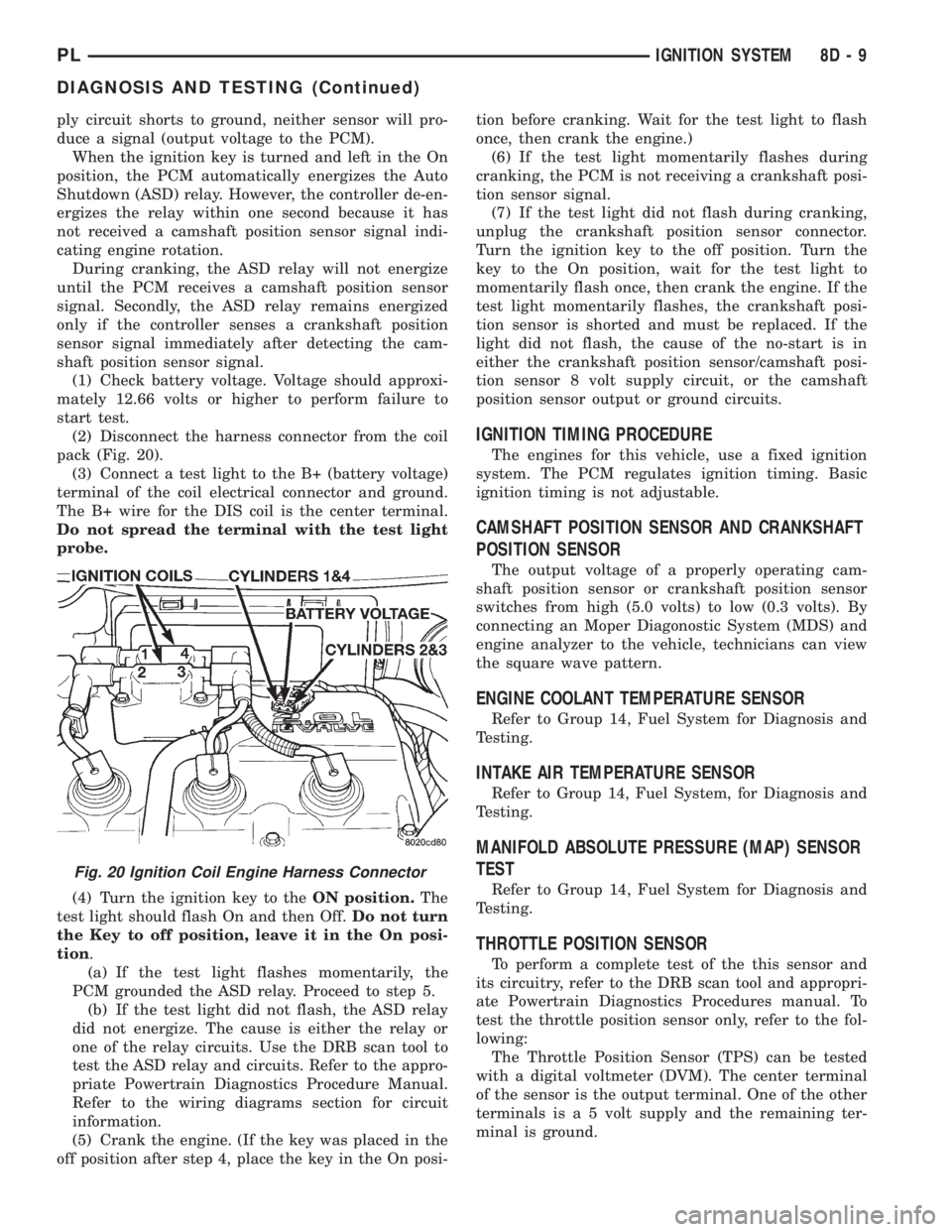

(2) Disconnect the harness connector from the coil

pack (Fig. 20).

(3) Connect a test light to the B+ (battery voltage)

terminal of the coil electrical connector and ground.

The B+ wire for the DIS coil is the center terminal.

Do not spread the terminal with the test light

probe.

(4) Turn the ignition key to theON position.The

test light should flash On and then Off.Do not turn

the Key to off position, leave it in the On posi-

tion.

(a) If the test light flashes momentarily, the

PCM grounded the ASD relay. Proceed to step 5.

(b) If the test light did not flash, the ASD relay

did not energize. The cause is either the relay or

one of the relay circuits. Use the DRB scan tool to

test the ASD relay and circuits. Refer to the appro-

priate Powertrain Diagnostics Procedure Manual.

Refer to the wiring diagrams section for circuit

information.

(5) Crank the engine. (If the key was placed in the

off position after step 4, place the key in the On posi-tion before cranking. Wait for the test light to flash

once, then crank the engine.)

(6) If the test light momentarily flashes during

cranking, the PCM is not receiving a crankshaft posi-

tion sensor signal.

(7) If the test light did not flash during cranking,

unplug the crankshaft position sensor connector.

Turn the ignition key to the off position. Turn the

key to the On position, wait for the test light to

momentarily flash once, then crank the engine. If the

test light momentarily flashes, the crankshaft posi-

tion sensor is shorted and must be replaced. If the

light did not flash, the cause of the no-start is in

either the crankshaft position sensor/camshaft posi-

tion sensor 8 volt supply circuit, or the camshaft

position sensor output or ground circuits.

IGNITION TIMING PROCEDURE

The engines for this vehicle, use a fixed ignition

system. The PCM regulates ignition timing. Basic

ignition timing is not adjustable.

CAMSHAFT POSITION SENSOR AND CRANKSHAFT

POSITION SENSOR

The output voltage of a properly operating cam-

shaft position sensor or crankshaft position sensor

switches from high (5.0 volts) to low (0.3 volts). By

connecting an Moper Diagonostic System (MDS) and

engine analyzer to the vehicle, technicians can view

the square wave pattern.

ENGINE COOLANT TEMPERATURE SENSOR

Refer to Group 14, Fuel System for Diagnosis and

Testing.

INTAKE AIR TEMPERATURE SENSOR

Refer to Group 14, Fuel System, for Diagnosis and

Testing.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

Refer to Group 14, Fuel System for Diagnosis and

Testing.

THROTTLE POSITION SENSOR

To perform a complete test of the this sensor and

its circuitry, refer to the DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the throttle position sensor only, refer to the fol-

lowing:

The Throttle Position Sensor (TPS) can be tested

with a digital voltmeter (DVM). The center terminal

of the sensor is the output terminal. One of the other

terminals is a 5 volt supply and the remaining ter-

minal is ground.

Fig. 20 Ignition Coil Engine Harness Connector

PLIGNITION SYSTEM 8D - 9

DIAGNOSIS AND TESTING (Continued)

Page 259 of 1200

Connect the DVM between the center and sensor

ground terminal. Refer to Group 8W - Wiring Dia-

grams for correct pinout.

With the ignition switch in the ON position, check

the output voltage at the center terminal wire of the

connector. Check the output voltage at idle and at

Wide-Open-Throttle (WOT). At idle, TPS output volt-

age should be approximately 0.38 volts to 1.2 volts.

At wide open throttle, TPS output voltage should be

approximately 3.1 volts to 4.4 volts. The output volt-

age should gradually increase as the throttle plate

moves slowly from idle to WOT.

Check for spread terminals at the sensor and PCM

connections before replacing the TPS.

SPARK PLUG CONDITION

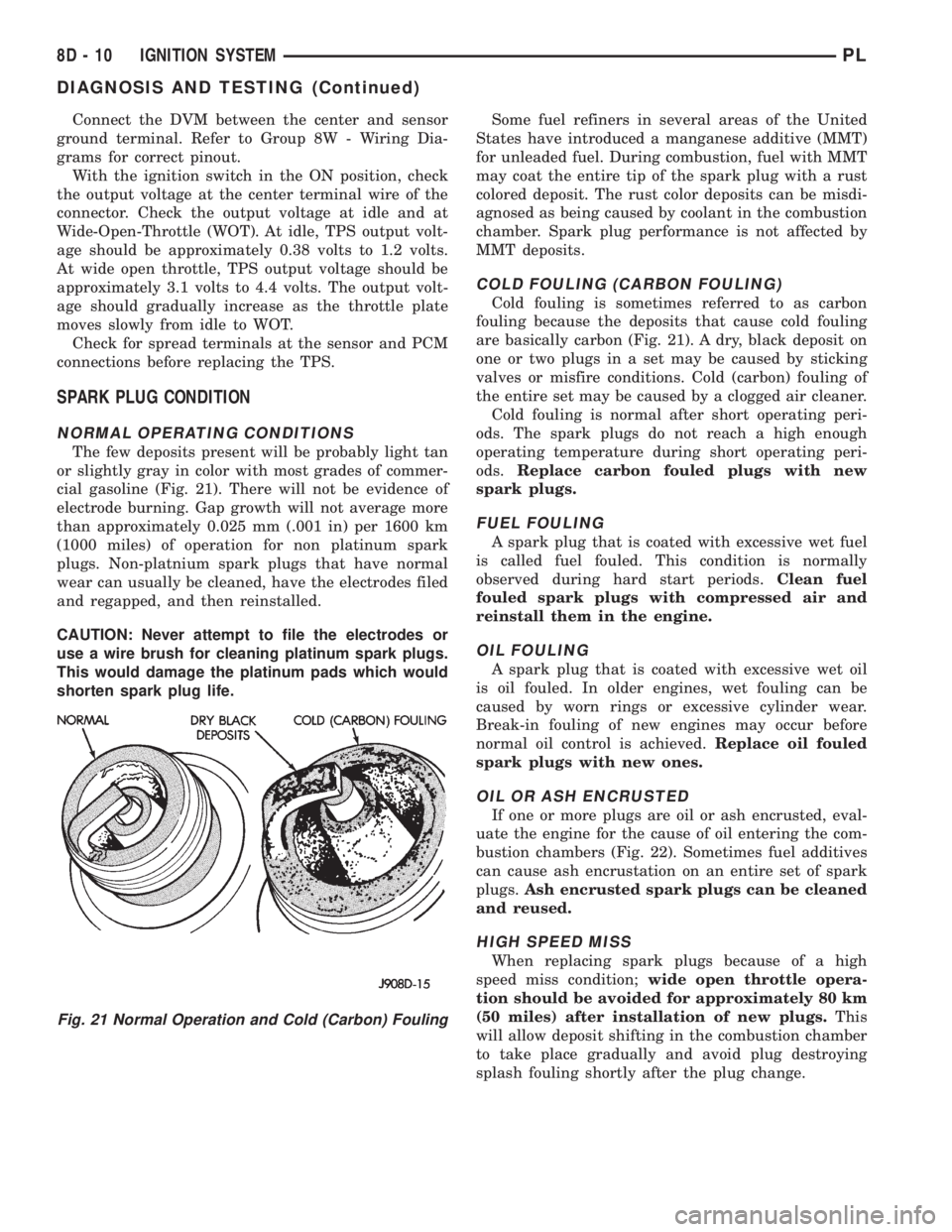

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 21). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation for non platinum spark

plugs. Non-platnium spark plugs that have normal

wear can usually be cleaned, have the electrodes filed

and regapped, and then reinstalled.

CAUTION: Never attempt to file the electrodes or

use a wire brush for cleaning platinum spark plugs.

This would damage the platinum pads which would

shorten spark plug life.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

may coat the entire tip of the spark plug with a rust

colored deposit. The rust color deposits can be misdi-

agnosed as being caused by coolant in the combustion

chamber. Spark plug performance is not affected by

MMT deposits.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling because the deposits that cause cold fouling

are basically carbon (Fig. 21). A dry, black deposit on

one or two plugs in a set may be caused by sticking

valves or misfire conditions. Cold (carbon) fouling of

the entire set may be caused by a clogged air cleaner.

Cold fouling is normal after short operating peri-

ods. The spark plugs do not reach a high enough

operating temperature during short operating peri-

ods.Replace carbon fouled plugs with new

spark plugs.

FUEL FOULING

A spark plug that is coated with excessive wet fuel

is called fuel fouled. This condition is normally

observed during hard start periods.Clean fuel

fouled spark plugs with compressed air and

reinstall them in the engine.

OIL FOULING

A spark plug that is coated with excessive wet oil

is oil fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur before

normal oil control is achieved.Replace oil fouled

spark plugs with new ones.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or ash encrusted, eval-

uate the engine for the cause of oil entering the com-

bustion chambers (Fig. 22). Sometimes fuel additives

can cause ash encrustation on an entire set of spark

plugs.Ash encrusted spark plugs can be cleaned

and reused.

HIGH SPEED MISS

When replacing spark plugs because of a high

speed miss condition;wide open throttle opera-

tion should be avoided for approximately 80 km

(50 miles) after installation of new plugs.This

will allow deposit shifting in the combustion chamber

to take place gradually and avoid plug destroying

splash fouling shortly after the plug change.

Fig. 21 Normal Operation and Cold (Carbon) Fouling

8D - 10 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 270 of 1200

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

DOME LAMP............................ 1

ELECTRONIC DIGITAL CLOCK.............. 1

INSTRUMENT CLUSTER................... 2

WARNING AND INDICATOR LAMPS......... 2

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM............... 2

BRAKE SYSTEM WARNING LAMP TEST...... 2

FOG LAMP SWITCH TEST................. 2

FUEL TANK SENDING UNIT TEST........... 3

HEADLAMP SWITCH TEST................. 3

HEATER A/C BLOWER SWITCH TEST........ 3

HEATER BLOWER SWITCH TEST............ 3

INDIVIDUAL GAUGE INOPERATIVE.......... 4

INSTRUMENT PANEL AND COMPONENTS.... 4

LOW OIL PRESSURE WARNING LAMP TEST . . 4

MULTIPLE GAUGE INOPERATIVE TEST....... 4

SEAT BELT REMINDER SYSTEM TEST....... 6

SENDING UNIT......................... 6

SERVICE ENGINE SOON INDICATOR......... 6

VEHICLE SPEED SENSOR TEST............. 6

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP....... 6

CENTER BEZEL.......................... 6

CIGAR LIGHTER RECEPTACLE.............. 6

CLUSTER LAMP......................... 7

CLUSTER PRINTED CIRCUIT BOARD........ 7CLUSTER.............................. 7

DOME LENS/LAMP....................... 8

FLOOR CONSOLE........................ 8

GAUGE................................ 8

GLOVE BOX DOOR/BIN................... 8

GLOVE BOX SWITCH/LAMP................ 9

HEADLAMP SWITCH..................... 9

HEATER A/C CONTROL BLOWER SWITCH . . . 10

HEATER A/C CONTROL LAMP............ 10

HEATER A/C CONTROL................... 9

HEATER CONTROL BLOWER SWITCH....... 10

IGNITION KEY LAMP.................... 10

INSTRUMENT PANEL.................... 10

LEFT TRIM PANEL...................... 10

ODOMETER............................ 10

RADIO................................ 12

REAR WINDOW DEFOGGER AND/OR FOG

LAMP SWITCH....................... 12

RIGHT TRIM PANEL..................... 12

SHIFTER KNOB......................... 13

STEERING COLUMN COVER LINER......... 13

STEERING COLUMN COVER.............. 13

STEERING COLUMN SHROUDS............ 13

TOP COVER AND CLUSTER BEZEL

REMOVAL........................... 14

TRANSMISSION RANGE INDICATOR LAMP . . 14

TRUNK LAMP/LENS..................... 14

VEHICLE SPEED SENSOR................ 14

GENERAL INFORMATION

INTRODUCTION

The purpose of the dash gauges and indicator

lamps is to keep the driver informed about the oper-

ating condition of the vehicle. If an abnormal condi-

tion occurs, the driver is informed by indicator lamp.

The driver can seek service before damage occurs.

Indicator lamps use ON/OFF switch functions for

operation, while gauges use a sending unit or sensor.

DESCRIPTION AND OPERATION

DOME LAMP

The Dome Lamp operates when a door is open or

when the headlamp switch is placed in courtesy posi-

tion.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position.

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 271 of 1200

When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained.

The procedure for setting the clock varies slightly

with each radio. The correct procedure is described in

the individual radio operating instructions. Refer to

the Owner's Manual supplied with the vehicle.

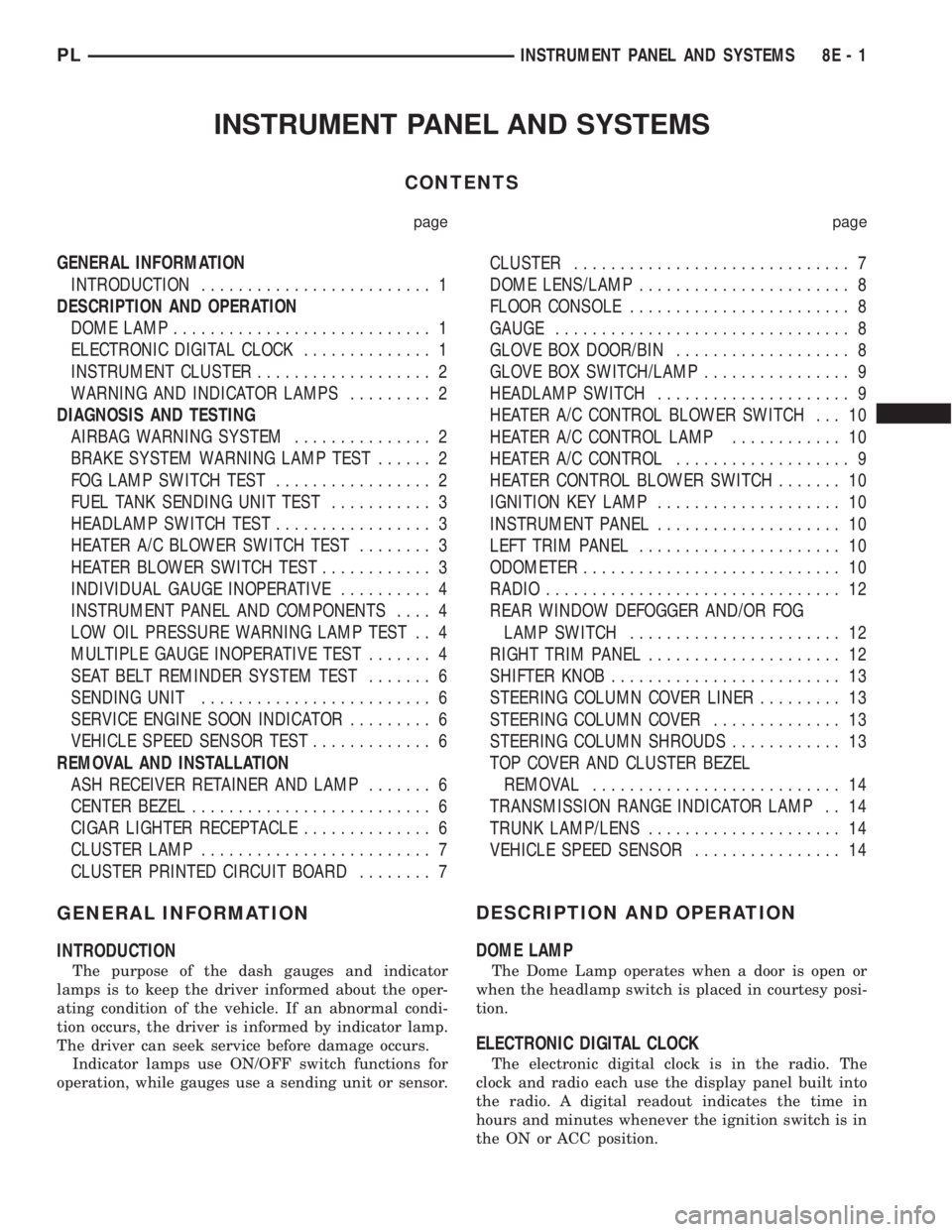

INSTRUMENT CLUSTER

There are two conventional instrument cluster

assemblies available. The clusters electronically drive

the speedometer, odometer, and gauges (Fig. 1) and

(Fig. 2).

GAUGES

All gauges in the electronic clusters are the analog

type gauges. When the ignition switch is moved to

the OFF position, the cluster drives each gauge to its

lowest position.

WARNING AND INDICATOR LAMPS

The instrument cluster has warning lamps and

indicators for the following systems:

²Airbag

²Anti-lock Brakes (ABS) if equipped

²Brake warning

²Charging System

²Door Ajar

²High beam indicator

²Low oil pressure

²Malfunction indicator (service engine soon) lamp

²Right and left turn signals.

²Seat belt warning

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM

For testing of this system refer to Group 8M,

Restraint Systems.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when the

parking brake is applied with ignition switch turned

to the ON position. The same lamp will also illumi-

nate if one of the two service brake systems fail the

when brake pedal is applied.

To test the system:

²As the ignition switch is turned to the start posi-

tion the lamp should light.

²Turn ignition switch to the ON position and

apply the parking brake. The lamp should light.

If lamp fails to light inspect for:

²A burned out lamp

²Loose, corroded or damaged socket

²A damaged circuit board

²A broken or disconnected wire at the switch

²Defective switch

To test the service brake warning system, refer to

Group 5, Brakes, Hydraulic System Control Valves.

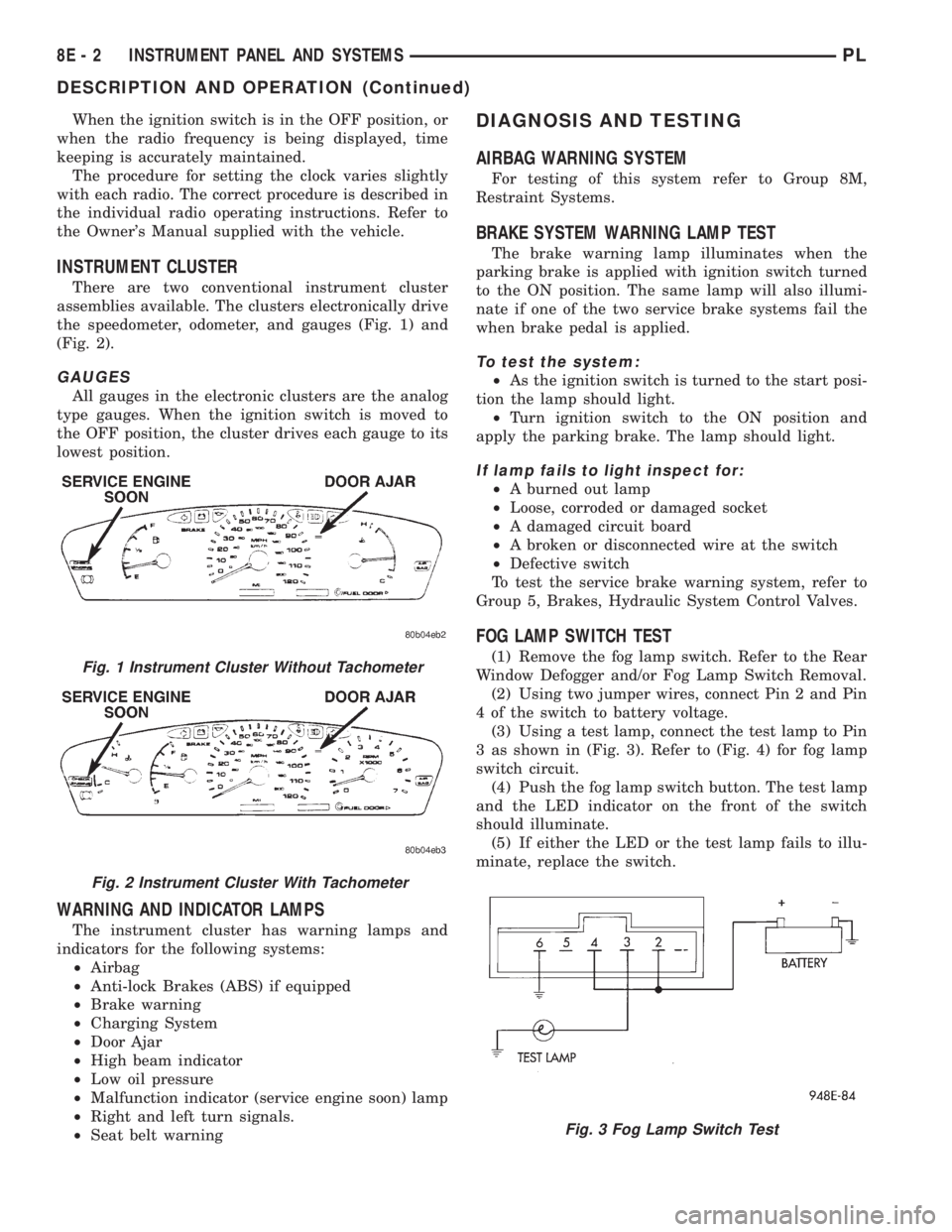

FOG LAMP SWITCH TEST

(1) Remove the fog lamp switch. Refer to the Rear

Window Defogger and/or Fog Lamp Switch Removal.

(2) Using two jumper wires, connect Pin 2 and Pin

4 of the switch to battery voltage.

(3) Using a test lamp, connect the test lamp to Pin

3 as shown in (Fig. 3). Refer to (Fig. 4) for fog lamp

switch circuit.

(4) Push the fog lamp switch button. The test lamp

and the LED indicator on the front of the switch

should illuminate.

(5) If either the LED or the test lamp fails to illu-

minate, replace the switch.Fig. 1 Instrument Cluster Without Tachometer

Fig. 2 Instrument Cluster With Tachometer

Fig. 3 Fog Lamp Switch Test

8E - 2 INSTRUMENT PANEL AND SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 273 of 1200

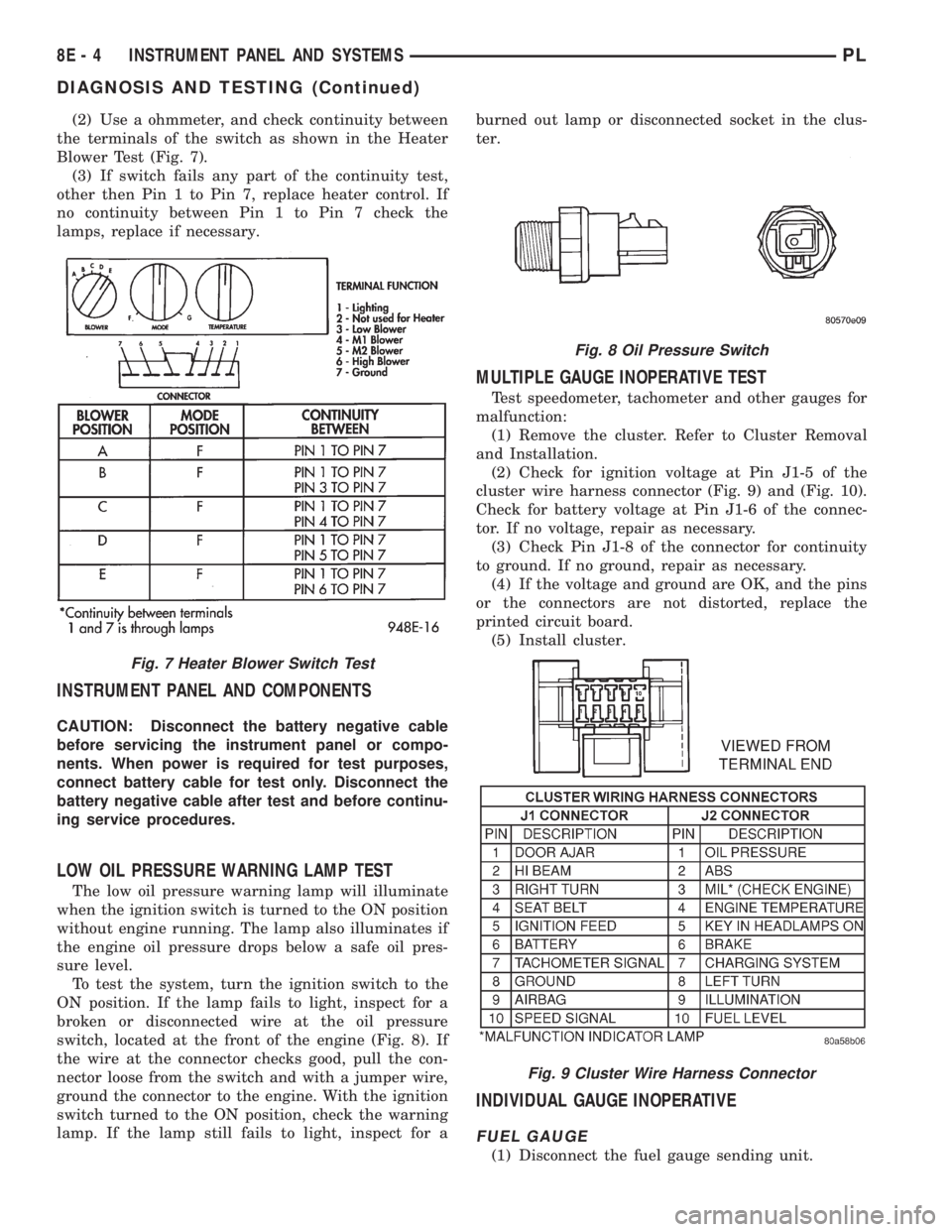

(2) Use a ohmmeter, and check continuity between

the terminals of the switch as shown in the Heater

Blower Test (Fig. 7).

(3) If switch fails any part of the continuity test,

other then Pin 1 to Pin 7, replace heater control. If

no continuity between Pin 1 to Pin 7 check the

lamps, replace if necessary.

INSTRUMENT PANEL AND COMPONENTS

CAUTION: Disconnect the battery negative cable

before servicing the instrument panel or compo-

nents. When power is required for test purposes,

connect battery cable for test only. Disconnect the

battery negative cable after test and before continu-

ing service procedures.

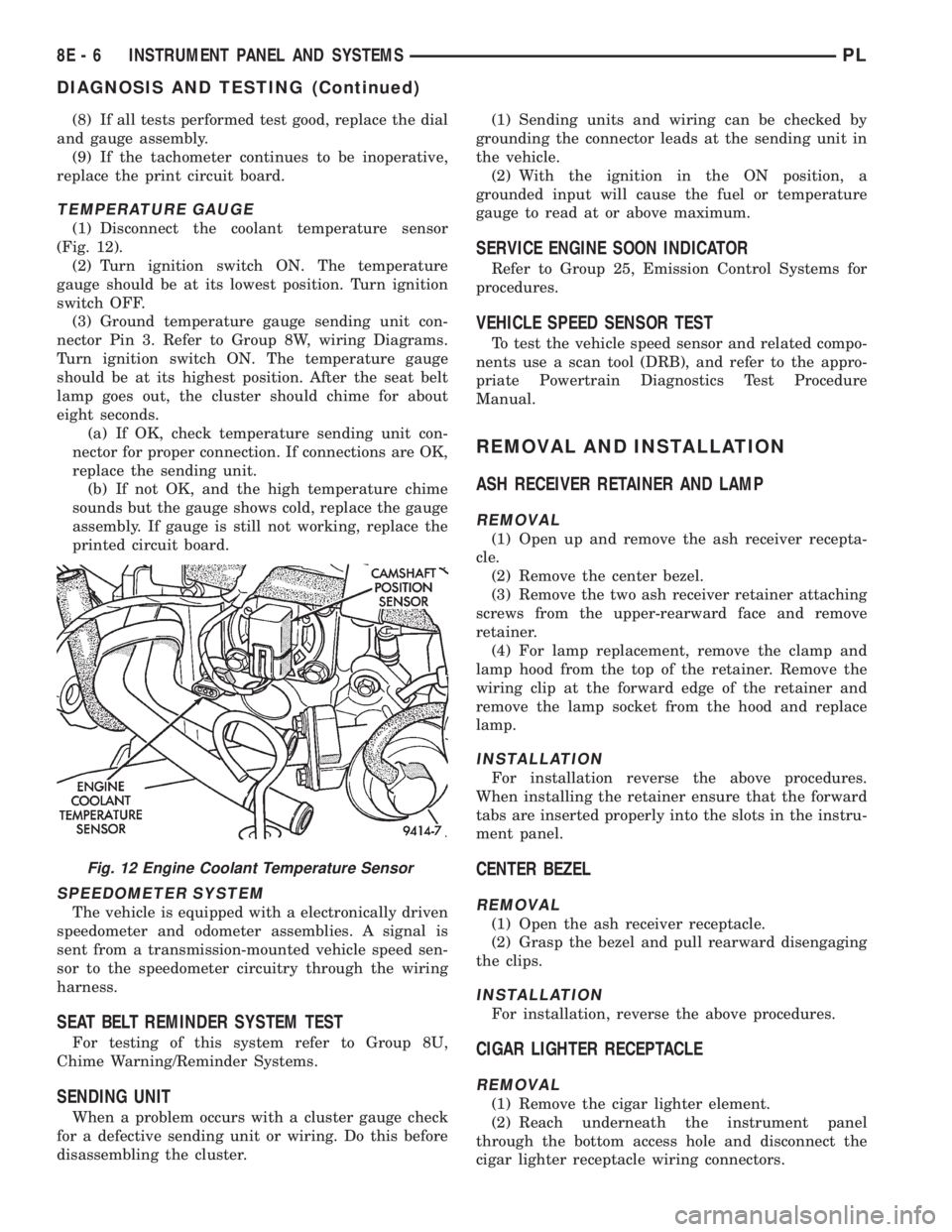

LOW OIL PRESSURE WARNING LAMP TEST

The low oil pressure warning lamp will illuminate

when the ignition switch is turned to the ON position

without engine running. The lamp also illuminates if

the engine oil pressure drops below a safe oil pres-

sure level.

To test the system, turn the ignition switch to the

ON position. If the lamp fails to light, inspect for a

broken or disconnected wire at the oil pressure

switch, located at the front of the engine (Fig. 8). If

the wire at the connector checks good, pull the con-

nector loose from the switch and with a jumper wire,

ground the connector to the engine. With the ignition

switch turned to the ON position, check the warning

lamp. If the lamp still fails to light, inspect for aburned out lamp or disconnected socket in the clus-

ter.

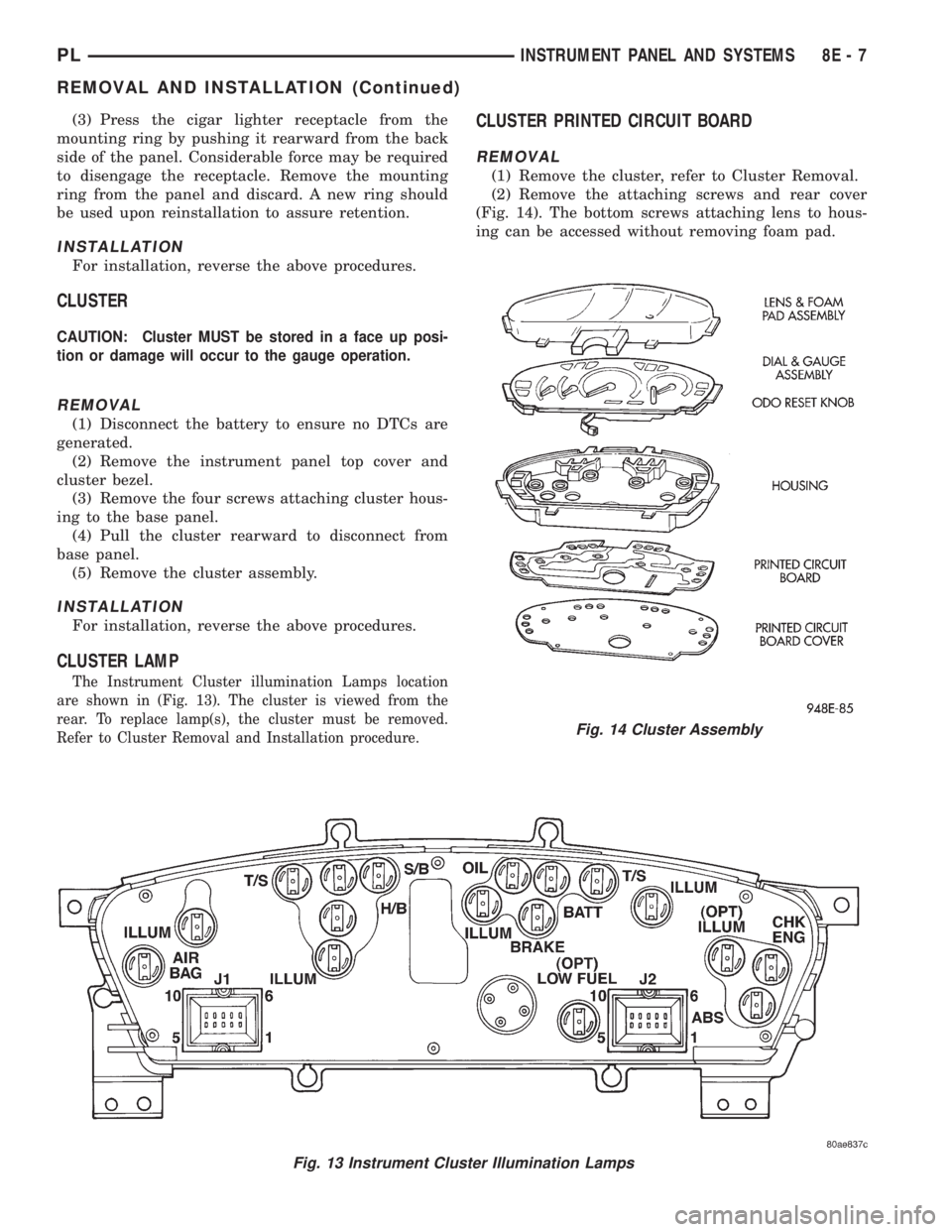

MULTIPLE GAUGE INOPERATIVE TEST

Test speedometer, tachometer and other gauges for

malfunction:

(1) Remove the cluster. Refer to Cluster Removal

and Installation.

(2) Check for ignition voltage at Pin J1-5 of the

cluster wire harness connector (Fig. 9) and (Fig. 10).

Check for battery voltage at Pin J1-6 of the connec-

tor. If no voltage, repair as necessary.

(3) Check Pin J1-8 of the connector for continuity

to ground. If no ground, repair as necessary.

(4) If the voltage and ground are OK, and the pins

or the connectors are not distorted, replace the

printed circuit board.

(5) Install cluster.

INDIVIDUAL GAUGE INOPERATIVE

FUEL GAUGE

(1) Disconnect the fuel gauge sending unit.

Fig. 7 Heater Blower Switch Test

Fig. 8 Oil Pressure Switch

Fig. 9 Cluster Wire Harness Connector

8E - 4 INSTRUMENT PANEL AND SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 275 of 1200

(8) If all tests performed test good, replace the dial

and gauge assembly.

(9) If the tachometer continues to be inoperative,

replace the print circuit board.

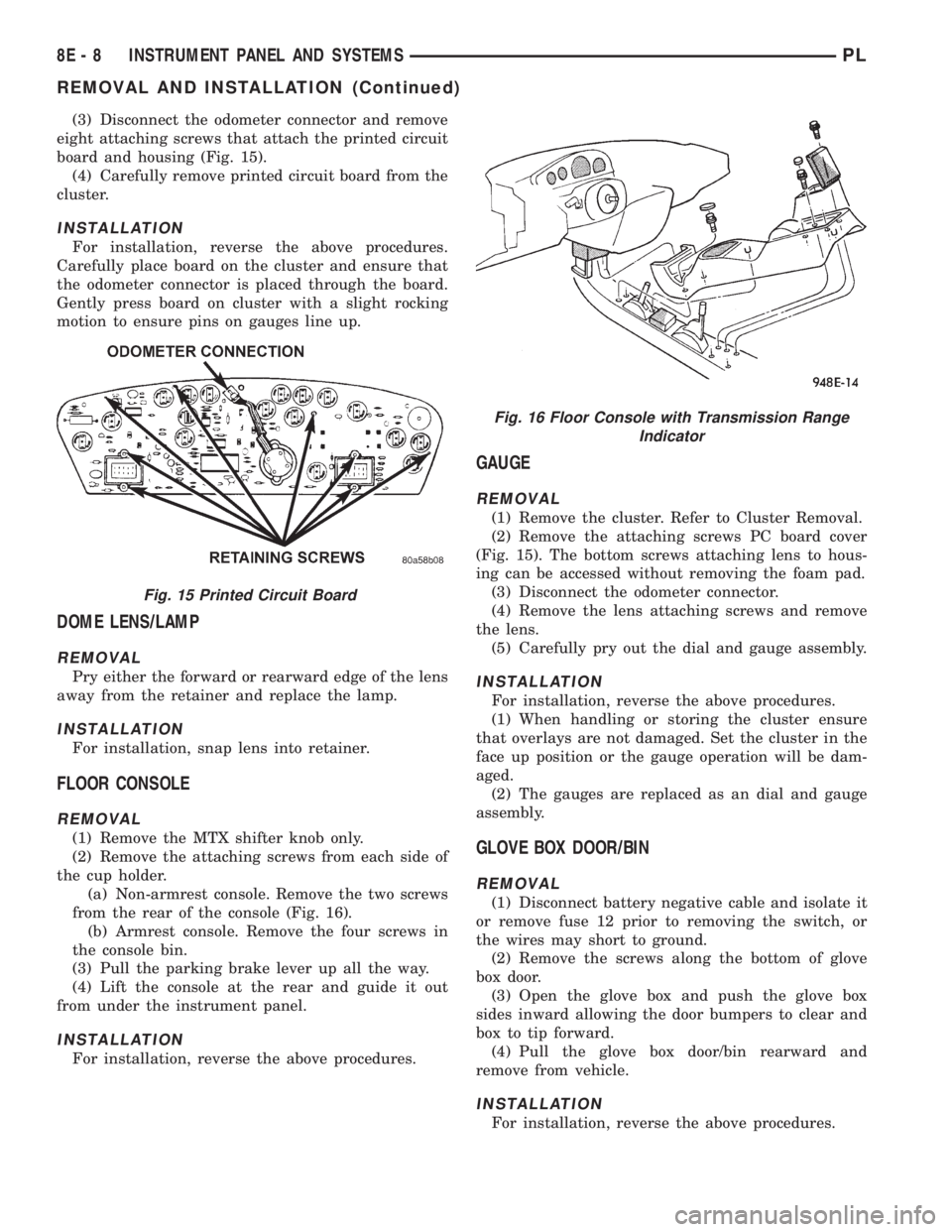

TEMPERATURE GAUGE

(1) Disconnect the coolant temperature sensor

(Fig. 12).

(2) Turn ignition switch ON. The temperature

gauge should be at its lowest position. Turn ignition

switch OFF.

(3) Ground temperature gauge sending unit con-

nector Pin 3. Refer to Group 8W, wiring Diagrams.

Turn ignition switch ON. The temperature gauge

should be at its highest position. After the seat belt

lamp goes out, the cluster should chime for about

eight seconds.

(a) If OK, check temperature sending unit con-

nector for proper connection. If connections are OK,

replace the sending unit.

(b) If not OK, and the high temperature chime

sounds but the gauge shows cold, replace the gauge

assembly. If gauge is still not working, replace the

printed circuit board.

SPEEDOMETER SYSTEM

The vehicle is equipped with a electronically driven

speedometer and odometer assemblies. A signal is

sent from a transmission-mounted vehicle speed sen-

sor to the speedometer circuitry through the wiring

harness.

SEAT BELT REMINDER SYSTEM TEST

For testing of this system refer to Group 8U,

Chime Warning/Reminder Systems.

SENDING UNIT

When a problem occurs with a cluster gauge check

for a defective sending unit or wiring. Do this before

disassembling the cluster.(1) Sending units and wiring can be checked by

grounding the connector leads at the sending unit in

the vehicle.

(2) With the ignition in the ON position, a

grounded input will cause the fuel or temperature

gauge to read at or above maximum.

SERVICE ENGINE SOON INDICATOR

Refer to Group 25, Emission Control Systems for

procedures.

VEHICLE SPEED SENSOR TEST

To test the vehicle speed sensor and related compo-

nents use a scan tool (DRB), and refer to the appro-

priate Powertrain Diagnostics Test Procedure

Manual.

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP

REMOVAL

(1) Open up and remove the ash receiver recepta-

cle.

(2) Remove the center bezel.

(3) Remove the two ash receiver retainer attaching

screws from the upper-rearward face and remove

retainer.

(4) For lamp replacement, remove the clamp and

lamp hood from the top of the retainer. Remove the

wiring clip at the forward edge of the retainer and

remove the lamp socket from the hood and replace

lamp.

INSTALLATION

For installation reverse the above procedures.

When installing the retainer ensure that the forward

tabs are inserted properly into the slots in the instru-

ment panel.

CENTER BEZEL

REMOVAL

(1) Open the ash receiver receptacle.

(2) Grasp the bezel and pull rearward disengaging

the clips.

INSTALLATION

For installation, reverse the above procedures.

CIGAR LIGHTER RECEPTACLE

REMOVAL

(1) Remove the cigar lighter element.

(2) Reach underneath the instrument panel

through the bottom access hole and disconnect the

cigar lighter receptacle wiring connectors.

Fig. 12 Engine Coolant Temperature Sensor

8E - 6 INSTRUMENT PANEL AND SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 276 of 1200

(3) Press the cigar lighter receptacle from the

mounting ring by pushing it rearward from the back

side of the panel. Considerable force may be required

to disengage the receptacle. Remove the mounting

ring from the panel and discard. A new ring should

be used upon reinstallation to assure retention.

INSTALLATION

For installation, reverse the above procedures.

CLUSTER

CAUTION: Cluster MUST be stored in a face up posi-

tion or damage will occur to the gauge operation.

REMOVAL

(1) Disconnect the battery to ensure no DTCs are

generated.

(2) Remove the instrument panel top cover and

cluster bezel.

(3) Remove the four screws attaching cluster hous-

ing to the base panel.

(4) Pull the cluster rearward to disconnect from

base panel.

(5) Remove the cluster assembly.

INSTALLATION

For installation, reverse the above procedures.

CLUSTER LAMP

The Instrument Cluster illumination Lamps location

are shown in (Fig. 13). The cluster is viewed from the

rear. To replace lamp(s), the cluster must be removed.

Refer to Cluster Removal and Installation procedure.

CLUSTER PRINTED CIRCUIT BOARD

REMOVAL

(1) Remove the cluster, refer to Cluster Removal.

(2) Remove the attaching screws and rear cover

(Fig. 14). The bottom screws attaching lens to hous-

ing can be accessed without removing foam pad.

Fig. 13 Instrument Cluster Illumination Lamps

Fig. 14 Cluster Assembly

PLINSTRUMENT PANEL AND SYSTEMS 8E - 7

REMOVAL AND INSTALLATION (Continued)

Page 277 of 1200

(3) Disconnect the odometer connector and remove

eight attaching screws that attach the printed circuit

board and housing (Fig. 15).

(4) Carefully remove printed circuit board from the

cluster.

INSTALLATION

For installation, reverse the above procedures.

Carefully place board on the cluster and ensure that

the odometer connector is placed through the board.

Gently press board on cluster with a slight rocking

motion to ensure pins on gauges line up.

DOME LENS/LAMP

REMOVAL

Pry either the forward or rearward edge of the lens

away from the retainer and replace the lamp.

INSTALLATION

For installation, snap lens into retainer.

FLOOR CONSOLE

REMOVAL

(1) Remove the MTX shifter knob only.

(2) Remove the attaching screws from each side of

the cup holder.

(a) Non-armrest console. Remove the two screws

from the rear of the console (Fig. 16).

(b) Armrest console. Remove the four screws in

the console bin.

(3) Pull the parking brake lever up all the way.

(4) Lift the console at the rear and guide it out

from under the instrument panel.

INSTALLATION

For installation, reverse the above procedures.

GAUGE

REMOVAL

(1) Remove the cluster. Refer to Cluster Removal.

(2) Remove the attaching screws PC board cover

(Fig. 15). The bottom screws attaching lens to hous-

ing can be accessed without removing the foam pad.

(3) Disconnect the odometer connector.

(4) Remove the lens attaching screws and remove

the lens.

(5) Carefully pry out the dial and gauge assembly.

INSTALLATION

For installation, reverse the above procedures.

(1) When handling or storing the cluster ensure

that overlays are not damaged. Set the cluster in the

face up position or the gauge operation will be dam-

aged.

(2) The gauges are replaced as an dial and gauge

assembly.

GLOVE BOX DOOR/BIN

REMOVAL

(1) Disconnect battery negative cable and isolate it

or remove fuse 12 prior to removing the switch, or

the wires may short to ground.

(2) Remove the screws along the bottom of glove

box door.

(3) Open the glove box and push the glove box

sides inward allowing the door bumpers to clear and

box to tip forward.

(4) Pull the glove box door/bin rearward and

remove from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Fig. 15 Printed Circuit Board

Fig. 16 Floor Console with Transmission Range

Indicator

8E - 8 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 281 of 1200

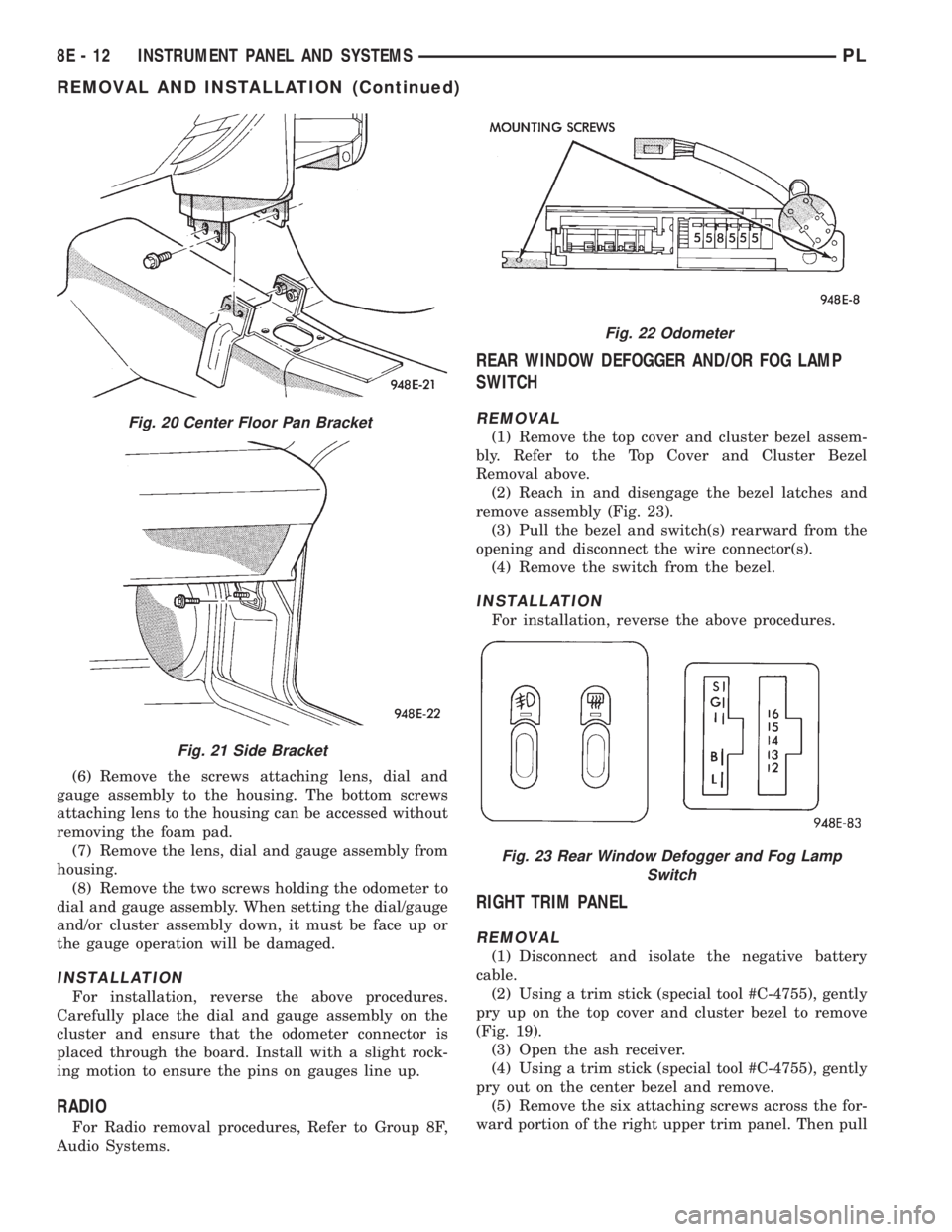

(6) Remove the screws attaching lens, dial and

gauge assembly to the housing. The bottom screws

attaching lens to the housing can be accessed without

removing the foam pad.

(7) Remove the lens, dial and gauge assembly from

housing.

(8) Remove the two screws holding the odometer to

dial and gauge assembly. When setting the dial/gauge

and/or cluster assembly down, it must be face up or

the gauge operation will be damaged.

INSTALLATION

For installation, reverse the above procedures.

Carefully place the dial and gauge assembly on the

cluster and ensure that the odometer connector is

placed through the board. Install with a slight rock-

ing motion to ensure the pins on gauges line up.

RADIO

For Radio removal procedures, Refer to Group 8F,

Audio Systems.

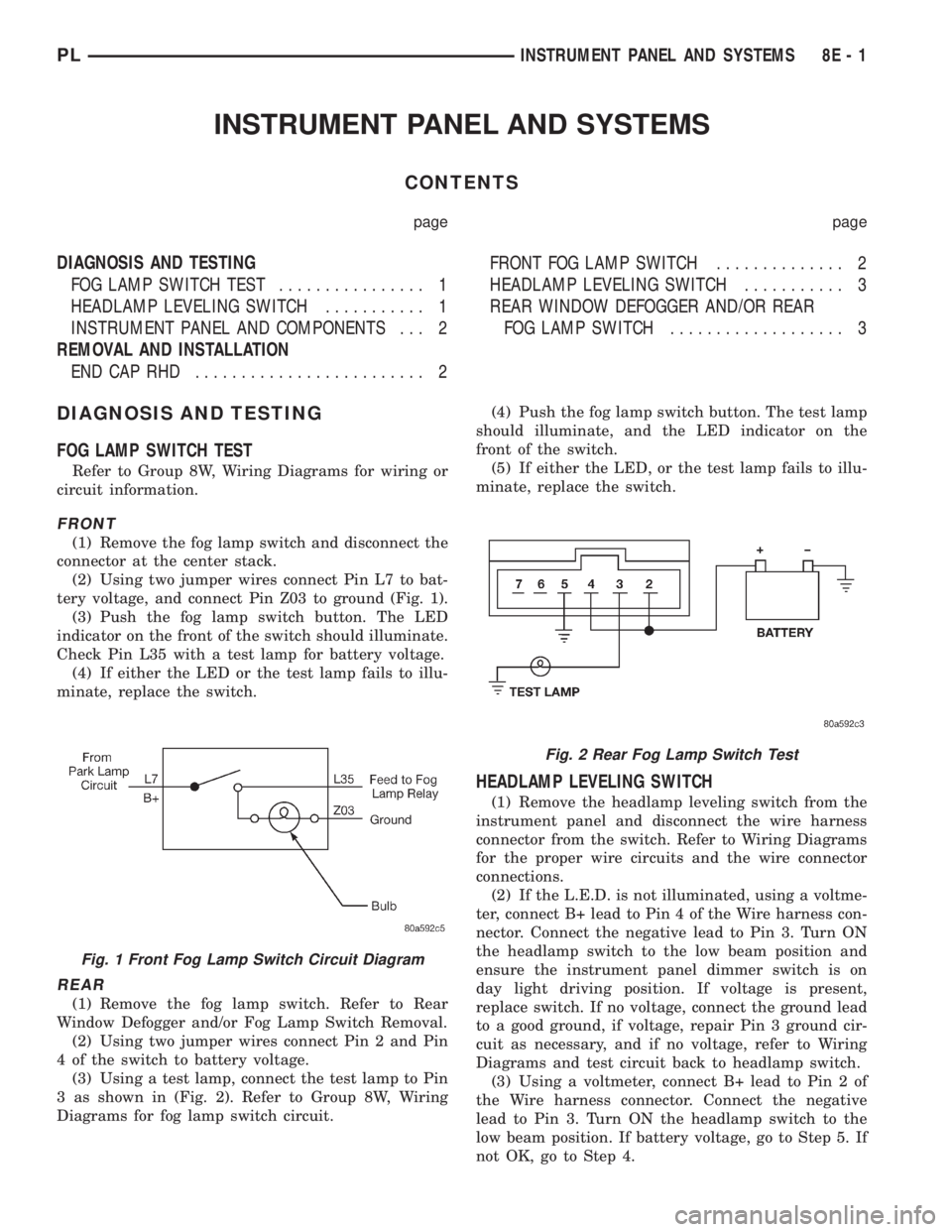

REAR WINDOW DEFOGGER AND/OR FOG LAMP

SWITCH

REMOVAL

(1) Remove the top cover and cluster bezel assem-

bly. Refer to the Top Cover and Cluster Bezel

Removal above.

(2) Reach in and disengage the bezel latches and

remove assembly (Fig. 23).

(3) Pull the bezel and switch(s) rearward from the

opening and disconnect the wire connector(s).

(4) Remove the switch from the bezel.

INSTALLATION

For installation, reverse the above procedures.

RIGHT TRIM PANEL

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Using a trim stick (special tool #C-4755), gently

pry up on the top cover and cluster bezel to remove

(Fig. 19).

(3) Open the ash receiver.

(4) Using a trim stick (special tool #C-4755), gently

pry out on the center bezel and remove.

(5) Remove the six attaching screws across the for-

ward portion of the right upper trim panel. Then pull

Fig. 20 Center Floor Pan Bracket

Fig. 21 Side Bracket

Fig. 22 Odometer

Fig. 23 Rear Window Defogger and Fog Lamp

Switch

8E - 12 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 284 of 1200

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

DIAGNOSIS AND TESTING

FOG LAMP SWITCH TEST................ 1

HEADLAMP LEVELING SWITCH........... 1

INSTRUMENT PANEL AND COMPONENTS . . . 2

REMOVAL AND INSTALLATION

END CAP RHD ......................... 2FRONT FOG LAMP SWITCH.............. 2

HEADLAMP LEVELING SWITCH........... 3

REAR WINDOW DEFOGGER AND/OR REAR

FOG LAMP SWITCH................... 3

DIAGNOSIS AND TESTING

FOG LAMP SWITCH TEST

Refer to Group 8W, Wiring Diagrams for wiring or

circuit information.

FRONT

(1) Remove the fog lamp switch and disconnect the

connector at the center stack.

(2) Using two jumper wires connect Pin L7 to bat-

tery voltage, and connect Pin Z03 to ground (Fig. 1).

(3) Push the fog lamp switch button. The LED

indicator on the front of the switch should illuminate.

Check Pin L35 with a test lamp for battery voltage.

(4) If either the LED or the test lamp fails to illu-

minate, replace the switch.

REAR

(1) Remove the fog lamp switch. Refer to Rear

Window Defogger and/or Fog Lamp Switch Removal.

(2) Using two jumper wires connect Pin 2 and Pin

4 of the switch to battery voltage.

(3) Using a test lamp, connect the test lamp to Pin

3 as shown in (Fig. 2). Refer to Group 8W, Wiring

Diagrams for fog lamp switch circuit.(4) Push the fog lamp switch button. The test lamp

should illuminate, and the LED indicator on the

front of the switch.

(5) If either the LED, or the test lamp fails to illu-

minate, replace the switch.

HEADLAMP LEVELING SWITCH

(1) Remove the headlamp leveling switch from the

instrument panel and disconnect the wire harness

connector from the switch. Refer to Wiring Diagrams

for the proper wire circuits and the wire connector

connections.

(2) If the L.E.D. is not illuminated, using a voltme-

ter, connect B+ lead to Pin 4 of the Wire harness con-

nector. Connect the negative lead to Pin 3. Turn ON

the headlamp switch to the low beam position and

ensure the instrument panel dimmer switch is on

day light driving position. If voltage is present,

replace switch. If no voltage, connect the ground lead

to a good ground, if voltage, repair Pin 3 ground cir-

cuit as necessary, and if no voltage, refer to Wiring

Diagrams and test circuit back to headlamp switch.

(3) Using a voltmeter, connect B+ lead to Pin 2 of

the Wire harness connector. Connect the negative

lead to Pin 3. Turn ON the headlamp switch to the

low beam position. If battery voltage, go to Step 5. If

not OK, go to Step 4.

Fig. 1 Front Fog Lamp Switch Circuit Diagram

Fig. 2 Rear Fog Lamp Switch Test

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1