light DODGE NEON 1999 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 371 of 1200

(3) Connect one lead of test light to a ground ter-

minal. Touch other test light lead to Red Wire termi-

nal.

(a) If test light comes on, the wiring circuit

between the battery and switch is functional.

(b) If test light does not come on, check fuse 3 in

the fuse block or for a open circuit.

(4) If test light comes on, the wiring circuit

between the battery and switch is functional.

REMOVAL AND INSTALLATION

DOOR LOCK MOTOR

REMOVAL

(1) Remove door trim panel, refer to Group 23,

Body for removal procedures.

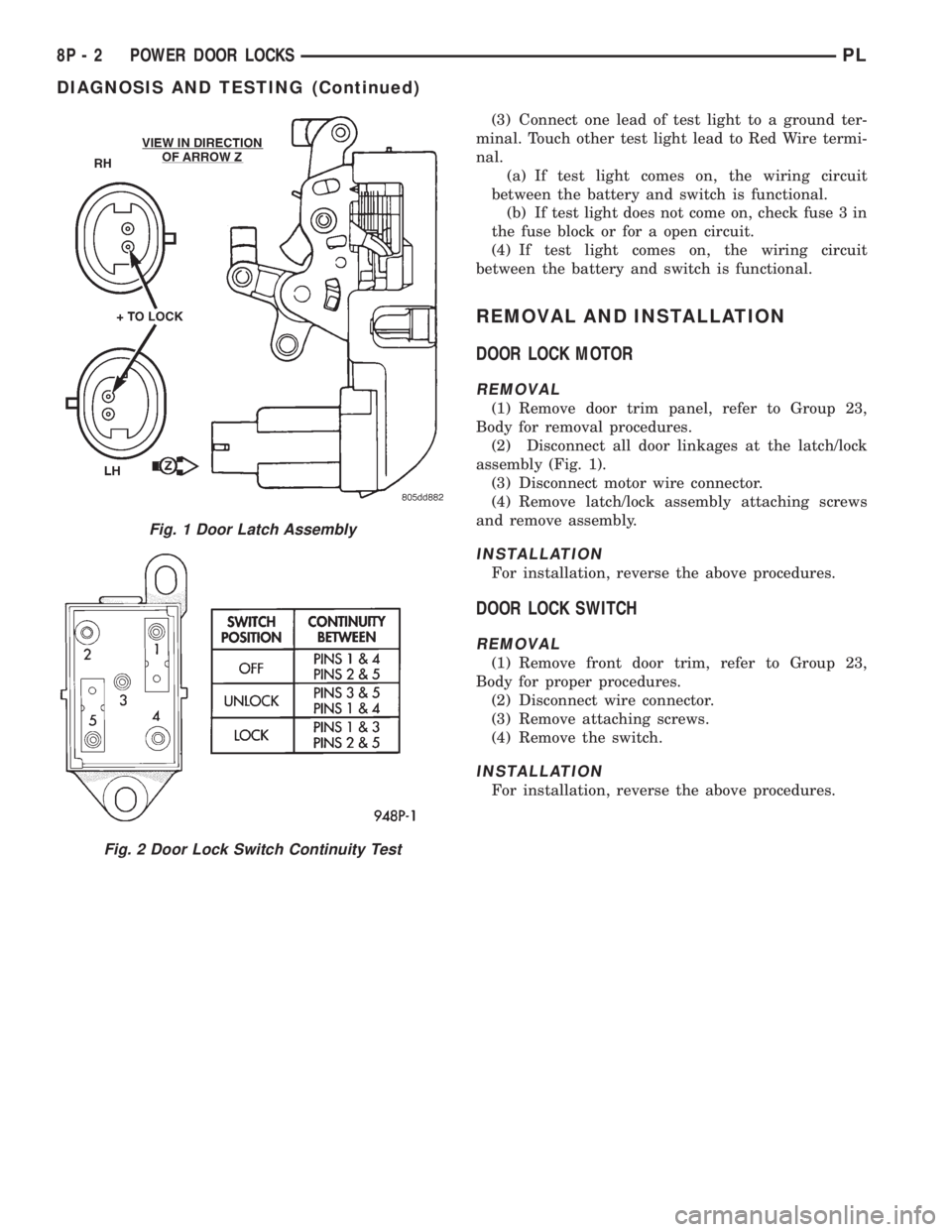

(2) Disconnect all door linkages at the latch/lock

assembly (Fig. 1).

(3) Disconnect motor wire connector.

(4) Remove latch/lock assembly attaching screws

and remove assembly.

INSTALLATION

For installation, reverse the above procedures.

DOOR LOCK SWITCH

REMOVAL

(1) Remove front door trim, refer to Group 23,

Body for proper procedures.

(2) Disconnect wire connector.

(3) Remove attaching screws.

(4) Remove the switch.

INSTALLATION

For installation, reverse the above procedures.

Fig. 1 Door Latch Assembly

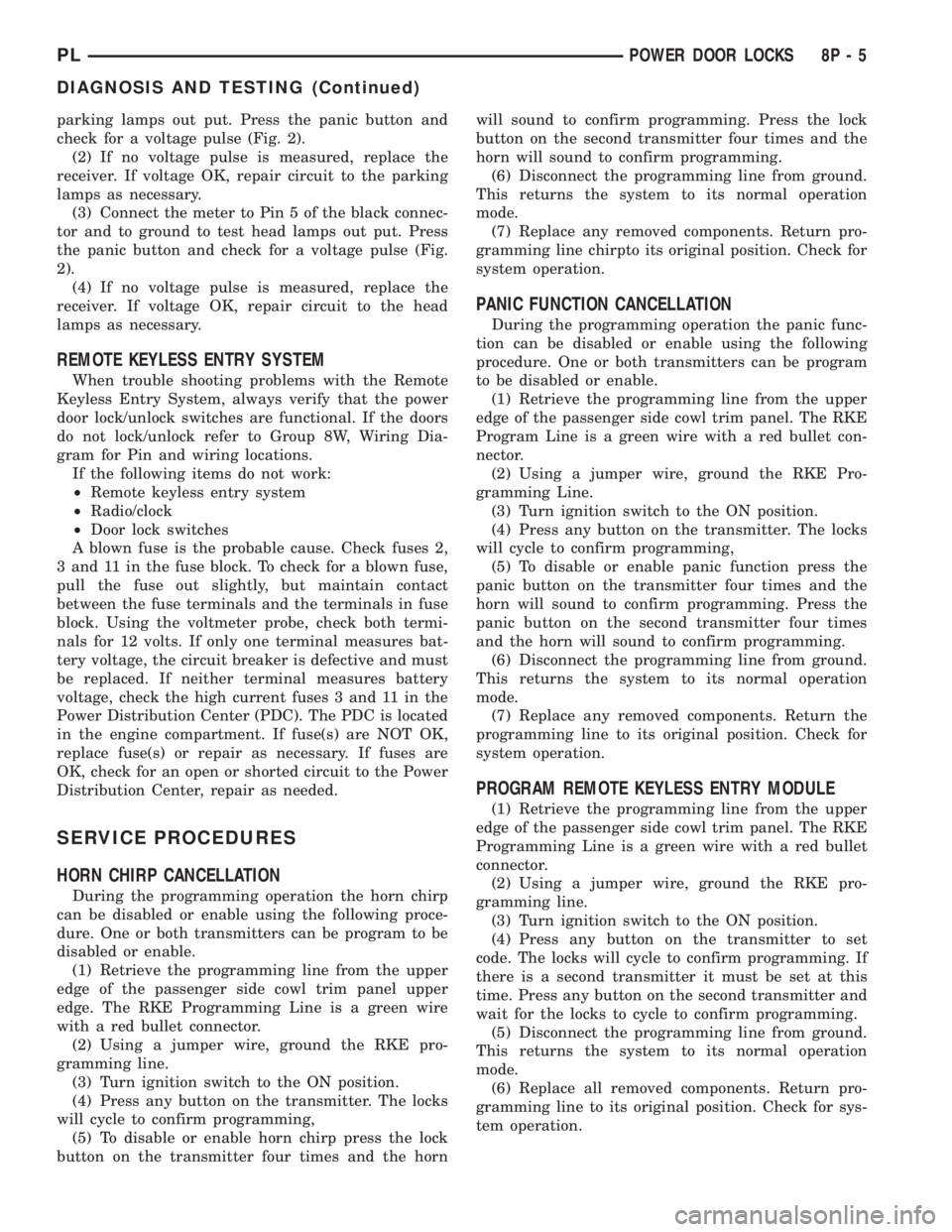

Fig. 2 Door Lock Switch Continuity Test

8P - 2 POWER DOOR LOCKSPL

DIAGNOSIS AND TESTING (Continued)

Page 374 of 1200

parking lamps out put. Press the panic button and

check for a voltage pulse (Fig. 2).

(2) If no voltage pulse is measured, replace the

receiver. If voltage OK, repair circuit to the parking

lamps as necessary.

(3) Connect the meter to Pin 5 of the black connec-

tor and to ground to test head lamps out put. Press

the panic button and check for a voltage pulse (Fig.

2).

(4) If no voltage pulse is measured, replace the

receiver. If voltage OK, repair circuit to the head

lamps as necessary.

REMOTE KEYLESS ENTRY SYSTEM

When trouble shooting problems with the Remote

Keyless Entry System, always verify that the power

door lock/unlock switches are functional. If the doors

do not lock/unlock refer to Group 8W, Wiring Dia-

gram for Pin and wiring locations.

If the following items do not work:

²Remote keyless entry system

²Radio/clock

²Door lock switches

A blown fuse is the probable cause. Check fuses 2,

3 and 11 in the fuse block. To check for a blown fuse,

pull the fuse out slightly, but maintain contact

between the fuse terminals and the terminals in fuse

block. Using the voltmeter probe, check both termi-

nals for 12 volts. If only one terminal measures bat-

tery voltage, the circuit breaker is defective and must

be replaced. If neither terminal measures battery

voltage, check the high current fuses 3 and 11 in the

Power Distribution Center (PDC). The PDC is located

in the engine compartment. If fuse(s) are NOT OK,

replace fuse(s) or repair as necessary. If fuses are

OK, check for an open or shorted circuit to the Power

Distribution Center, repair as needed.

SERVICE PROCEDURES

HORN CHIRP CANCELLATION

During the programming operation the horn chirp

can be disabled or enable using the following proce-

dure. One or both transmitters can be program to be

disabled or enable.

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel upper

edge. The RKE Programming Line is a green wire

with a red bullet connector.

(2) Using a jumper wire, ground the RKE pro-

gramming line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter. The locks

will cycle to confirm programming,

(5) To disable or enable horn chirp press the lock

button on the transmitter four times and the hornwill sound to confirm programming. Press the lock

button on the second transmitter four times and the

horn will sound to confirm programming.

(6) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(7) Replace any removed components. Return pro-

gramming line chirpto its original position. Check for

system operation.

PANIC FUNCTION CANCELLATION

During the programming operation the panic func-

tion can be disabled or enable using the following

procedure. One or both transmitters can be program

to be disabled or enable.

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel. The RKE

Program Line is a green wire with a red bullet con-

nector.

(2) Using a jumper wire, ground the RKE Pro-

gramming Line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter. The locks

will cycle to confirm programming,

(5) To disable or enable panic function press the

panic button on the transmitter four times and the

horn will sound to confirm programming. Press the

panic button on the second transmitter four times

and the horn will sound to confirm programming.

(6) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(7) Replace any removed components. Return the

programming line to its original position. Check for

system operation.

PROGRAM REMOTE KEYLESS ENTRY MODULE

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel. The RKE

Programming Line is a green wire with a red bullet

connector.

(2) Using a jumper wire, ground the RKE pro-

gramming line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter to set

code. The locks will cycle to confirm programming. If

there is a second transmitter it must be set at this

time. Press any button on the second transmitter and

wait for the locks to cycle to confirm programming.

(5) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(6) Replace all removed components. Return pro-

gramming line to its original position. Check for sys-

tem operation.

PLPOWER DOOR LOCKS 8P - 5

DIAGNOSIS AND TESTING (Continued)

Page 376 of 1200

IMMOBILIZER SYSTEM

CONTENTS

page page

DESCRIPTION AND OPERATION

IMMOBILIZER RECEIVER................ 1

IMMOBILIZER SYSTEM.................. 1

IMMOBILIZER TRANSMITTER............. 2

POWER-UP MODE...................... 2

DIAGNOSIS AND TESTING

IMMOBILIZER DIAGNOSIS............... 2SERVICE PROCEDURES

VEHICLE IMMOBILIZER SYSTEM.......... 3

REMOVAL AND INSTALLATION

IMMOBILIZER RECEIVER................ 3

DESCRIPTION AND OPERATION

IMMOBILIZER SYSTEM

The Immobilizer system includes the following

unique items:

²An immobilizer module receiver that controls

system operation and also controls the RKE and Illu-

minated entry systems, if equipped.

²An encoded Crankshaft Position Sensor for the

ignition system. The Immobilizer module decodes the

signal from the crankshaft so the PCM can recognize

it as a valid Crankshaft Position Sensor signal, and

allow the engine to run.

²A wiring harness that interconnects the crank-

shaft sensor, the immobilizer receiver, and the PCM.

²Two key fob transmitters.

The Immobilizer System prevents unauthorized

operation of the vehicle by disabling the engine and

starter. The system will NOT allow the vehicle to

start unless the UNLOCK button on the RKE trans-

mitter is pressed. The system will be activated after

turning the ignition switch to the OFF position and

using one of the following methods.

(1) Press the LOCK button on the RKE transmit-

ter.

(2) LOCK the doors by pressing a power lock but-

ton switch.

(3) LOCK the driver or passenger door using the

key.

²The Security light will flash, for about 16 sec-

onds, indicating that the engine and starter will be

disabled.

²The Security light remaining on, indicates the

system is not operational.

²The Immobilizer will activate automatically

within 10 minutes of the ignition switch being in the

OFF position, whether the vehicle has been locked or

unlocked.²An attempt to start the vehicle without pressing

the UNLOCK button on the RKE transmitter will

result in a warning chime and the Security light

flashing.

NOTE: The ignition switch must be in the OFF posi-

tion in order for the system to be activated, whether

the doors are closed or not.

IMMOBILIZER RECEIVER

The immobilizer receiver is programmed to

respond to the Lock and Unlock radio signals issued

by the immobilizer transmitters. The receiver will

only respond to the radio signals of transmitters (up

to four) whose vehicle access codes have been stored

in the receiver's electronic memory. The receiver is

programmed at the assembly plant with the vehicle

access codes of the two transmitters that are shipped

with the vehicle.

The immobilizer receiver also has a central pro-

cessing unit, which contains the immobilizer system

logic. The programming in the immobilizer receiver

allows the system to learn and retain transmitter

vehicle access codes, as well as to communicate with

the Powertrain Control Module (PCM) and/or the

DRB scan tool on the Chrysler Collision Detection

(CCD) data bus network.

The CCD data bus network allows the sharing of

sensor information. This helps to reduce wiring har-

ness complexity, reduce internal controller hardware,

and reduce component sensor current loads. At the

same time, the CCD data bus network provides

increased reliability and enhanced diagnostic capabil-

ities.

Each immobilizer transmitter has a different vehi-

cle access code, which must be programmed into the

memory of the immobilizer receiver in the vehicle in

order to operate the immobilizer system. A DRB scan

tool must be used to program new or additional

PLIMMOBILIZER SYSTEM 8Q - 1

Page 382 of 1200

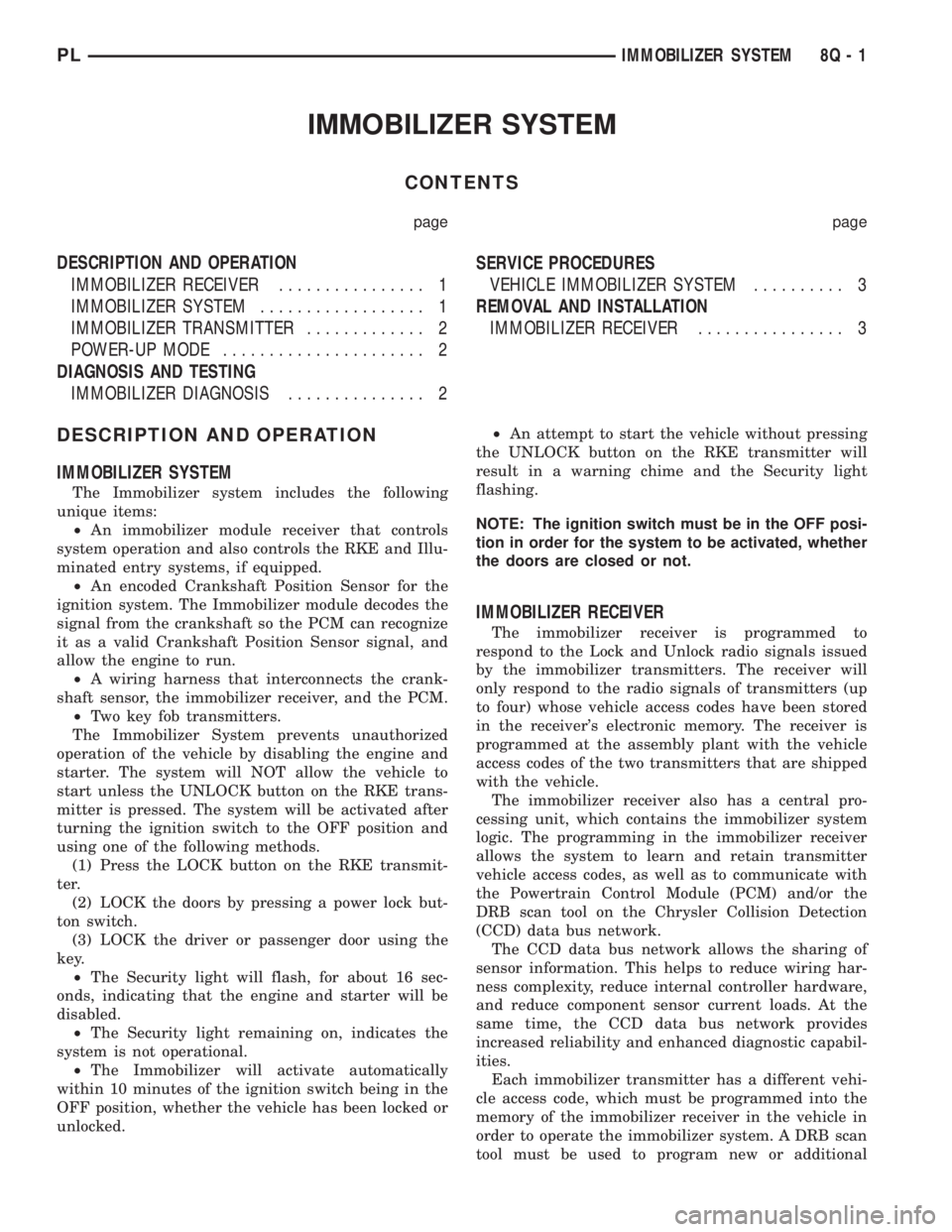

INSTALLATION

(1) Install new motor on regulator by positioning

motor gearbox so that it engages regulator sector

teeth.

(2) A slight rotational or rocking movement may

be necessary to bring three motor gearbox screw

holes into proper position.

(3) Install three gearbox screws and one tie down

bracket screw, if applicable. Tighten to 5.6 to 8 N´m

(50 to 70 in. lbs.) torque.

(4) Install regulator, using the switch, test opera-

tion of motor.

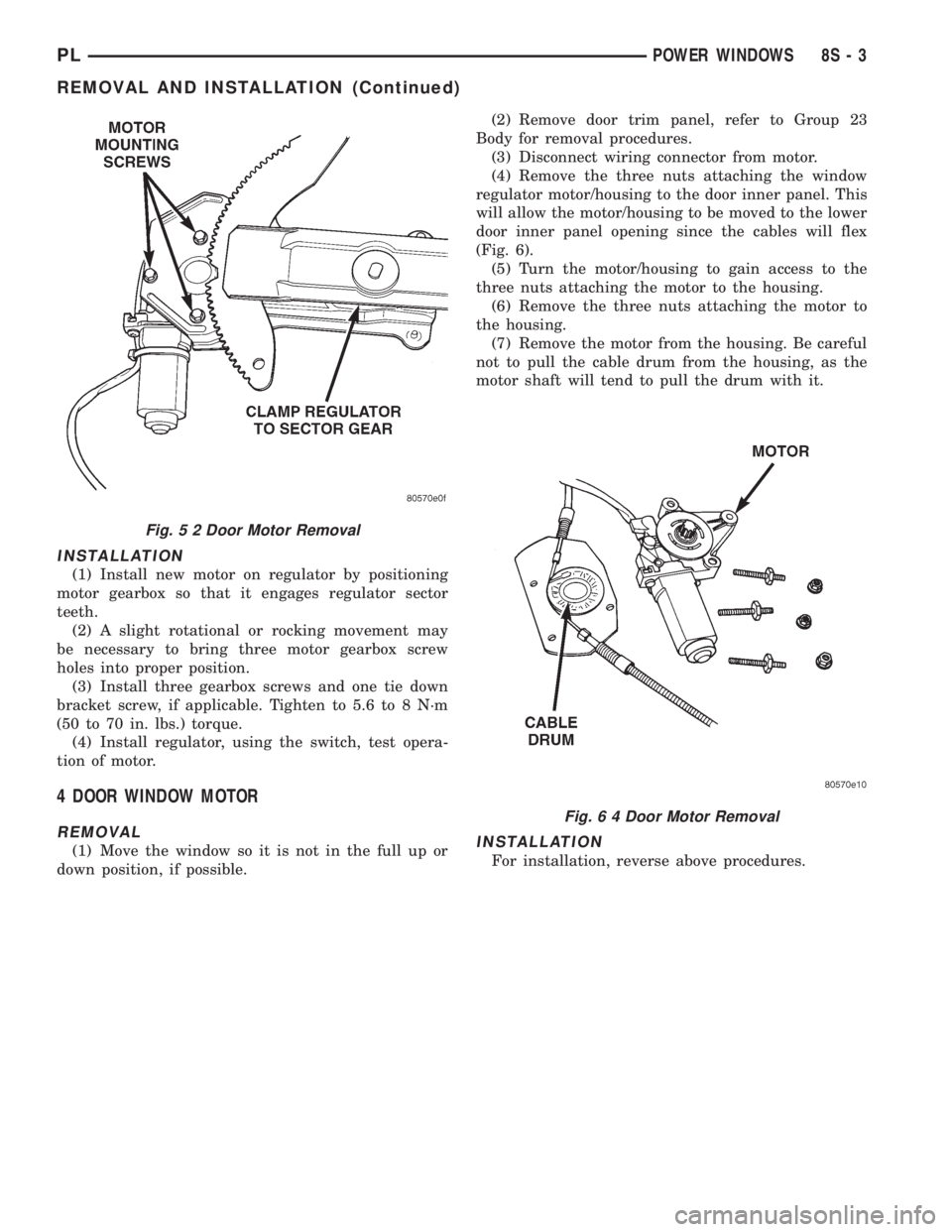

4 DOOR WINDOW MOTOR

REMOVAL

(1) Move the window so it is not in the full up or

down position, if possible.(2) Remove door trim panel, refer to Group 23

Body for removal procedures.

(3) Disconnect wiring connector from motor.

(4) Remove the three nuts attaching the window

regulator motor/housing to the door inner panel. This

will allow the motor/housing to be moved to the lower

door inner panel opening since the cables will flex

(Fig. 6).

(5) Turn the motor/housing to gain access to the

three nuts attaching the motor to the housing.

(6) Remove the three nuts attaching the motor to

the housing.

(7) Remove the motor from the housing. Be careful

not to pull the cable drum from the housing, as the

motor shaft will tend to pull the drum with it.INSTALLATION

For installation, reverse above procedures.

Fig. 5 2 Door Motor Removal

Fig. 6 4 Door Motor Removal

PLPOWER WINDOWS 8S - 3

REMOVAL AND INSTALLATION (Continued)

Page 390 of 1200

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

CHIME SYSTEM CONDITIONS.............. 1

FASTEN SEAT BELTS..................... 1

HEADLAMPS LEFT ON.................... 1KEY LEFT IN IGNITION SWITCH............ 1

REMOVAL AND INSTALLATION

CHIME................................. 2

HEADLAMP SWITCH..................... 2

KEY-IN SWITCH......................... 2

SEAT BELT BUCKLE...................... 2

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AN

AIRBAG, REFER TO THE AIRBAG PORTION OF

THIS SECTION FOR STEERING WHEEL OR SWITCH

REMOVAL AND INSTALLATION PROCEDURES.

The seat belt reminder system uses both visual

and audible signals. A combined seat belt and key

reminder chime with a red light on the instrument

panel.

The system will always illuminate the seat belt

reminder lamp for four to eight seconds when the

ignition switch is turned to the ON position. The

CHIME will sound during the same time interval if

the driver's seat belt is not fastened. Passenger belts

are not connected to the system. The chime will acti-

vate if the drivers door is opened and:

²The key is in the ignition switch, with the igni-

tion switch in either the OFF or accessory (ACC)

position

²The head lamps are ON.

The chime is part of the instrument cluster.

NOTE: This group covers both Left-Hand Drive

(LHD) and Right-Hand Drive (RHD) versions of this

model. Whenever required and feasible, the RHD

versions of affected vehicle components have been

constructed as mirror-image of the LHD versions.

While most of the illustrations used in this group

represent only the LHD version, the diagnostic and

service procedures outlined can generally be

applied to either version. Exceptions to this rule

have been clearly identified as LHD, RHD, or Export

if a special illustration or procedure is required.

DIAGNOSIS AND TESTING

FASTEN SEAT BELTS

To test the fasten seat belts function, turn the igni-

tion switch to the ON position with the driver's seat

belt unbuckled and fully retracted. The seat belt

warning lamp should light for four to eight seconds

and the tone should sound three to five times.

HEADLAMPS LEFT ON

To test the headlamps left on function:

²Turn headlamps

²Driver's door open

²Key removed from the ignition switch

Chime should sound until headlamps are turned

off or driver's door is closed.

KEY LEFT IN IGNITION SWITCH

To test the key left in ignition function, insert key

into the ignition and open driver's door. Chime

should sound until key is removed from ignition or

driver's door is closed.

CHIME SYSTEM CONDITIONS

The cluster harness connector, J1 is car right and

the J2 is car left.

NO TONE WHEN IGNITION SWITCH IS

TURNED ON AND DRIVERS SEAT BELT IS

UNBUCKLED

(1) Using an ohmmeter, with the seat belt fully

retracted, check for continuity to ground at Pin 4 of

the J1 wire harness connector (Fig. 1). If OK, go to

step 2. If not OK, repair as necessary .

(2) Check for continuity to ground at Pin 8 of the

J1 wire harness connector. If OK, go to Step 3. If not

OK, repair as necessary.

(3) Using voltmeter, check for battery feed at Pin 6

of the J1 wire harness connector. Check for ignition

feed at Pin 5 of the J1 wire harness connector. If not

OK, repair as necessary.

PLCHIME WARNING/REMINDER SYSTEM 8U - 1

Page 392 of 1200

WIRING DIAGRAMS

CONTENTS

page page

AIR CONDITIONING-HEATER.......... 8W-42-1

AIRBAG SYSTEM................... 8W-43-1

ANTI-LOCK BRAKES................. 8W-35-1

AUDIO SYSTEMS................... 8W-47-1

CHARGING SYSTEM................. 8W-20-1

COMPONENT INDEX................. 8W-02-1

CONNECTOR/GROUND LOCATIONS..... 8W-90-1

CONNECTOR PIN-OUTS.............. 8W-80-1

FRONT LIGHTING................... 8W-50-1

FUEL/IGNITION SYSTEMS............ 8W-30-1

FUSE BLOCK....................... 8W-11-1

GENERAL INFORMATION............. 8W-01-1

GROUND DISTRIBUTION............. 8W-15-1

HORN/CIGAR LIGHTER............... 8W-41-1INSTRUMENT CLUSTER.............. 8W-40-1

INTERIOR LIGHTING................. 8W-44-1

POWER DISTRIBUTION.............. 8W-10-1

POWER DOOR LOCKS............... 8W-61-1

POWER MIRRORS.................. 8W-62-1

POWER SUNROOF.................. 8W-64-1

POWER WINDOWS.................. 8W-60-1

REAR LIGHTING.................... 8W-51-1

REAR WINDOW DEFOGGER........... 8W-48-1

SPLICE INFORMATION............... 8W-70-1

SPLICE LOCATIONS................. 8W-95-1

STARTING SYSTEM................. 8W-21-1

TURN SIGNALS..................... 8W-52-1

WIPERS........................... 8W-53-1

PLWIRING DIAGRAMS 8W - 1

Page 397 of 1200

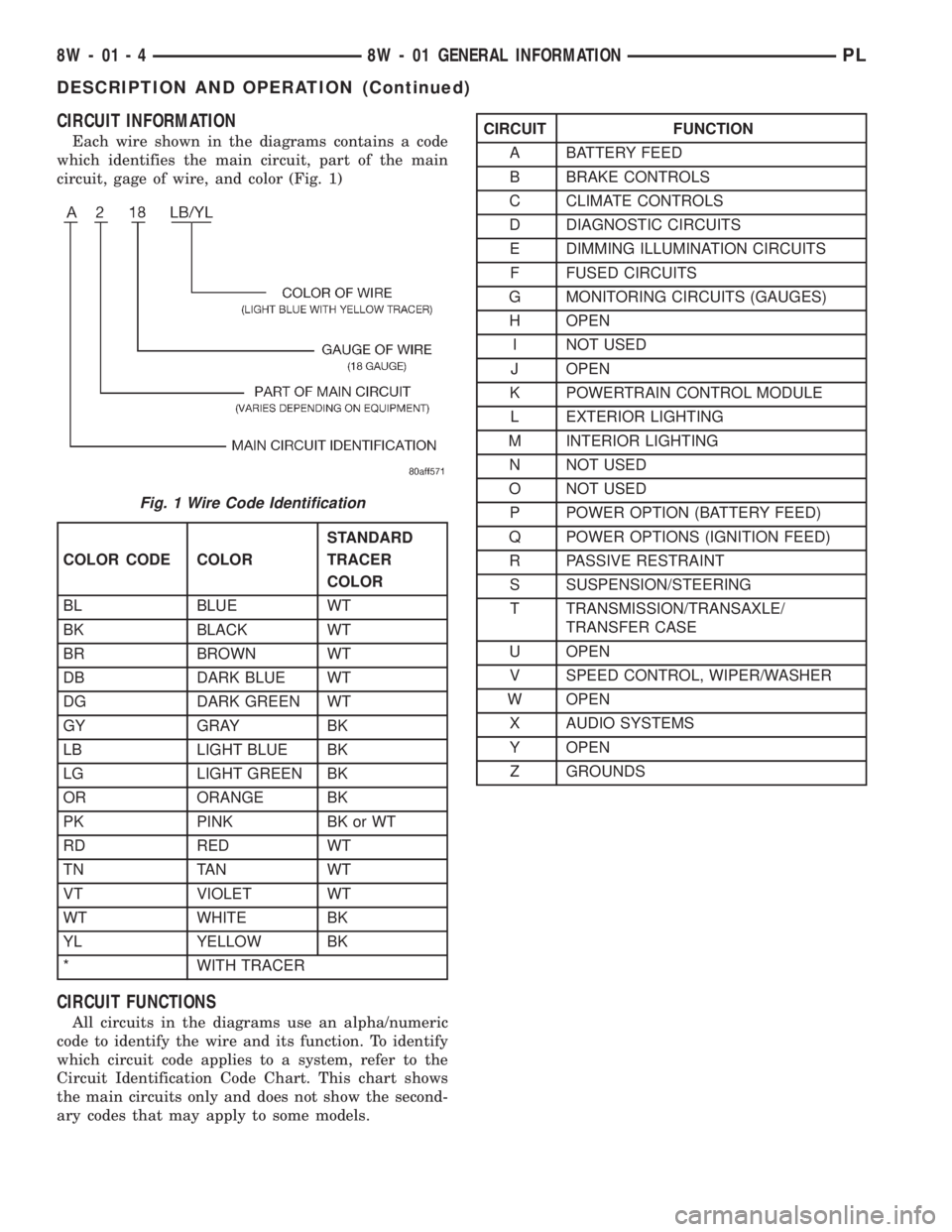

CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 1)

CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

Fig. 1 Wire Code Identification

COLOR CODE COLORSTANDARD

TRACER

COLOR

BL BLUE WT

BK BLACK WT

BR BROWN WT

DB DARK BLUE WT

DG DARK GREEN WT

GY GRAY BK

LB LIGHT BLUE BK

LG LIGHT GREEN BK

OR ORANGE BK

PK PINK BK or WT

RD RED WT

TN TAN WT

VT VIOLET WT

WT WHITE BK

YL YELLOW BK

* WITH TRACER

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS (GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY FEED)

Q POWER OPTIONS (IGNITION FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

8W - 01 - 4 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 398 of 1200

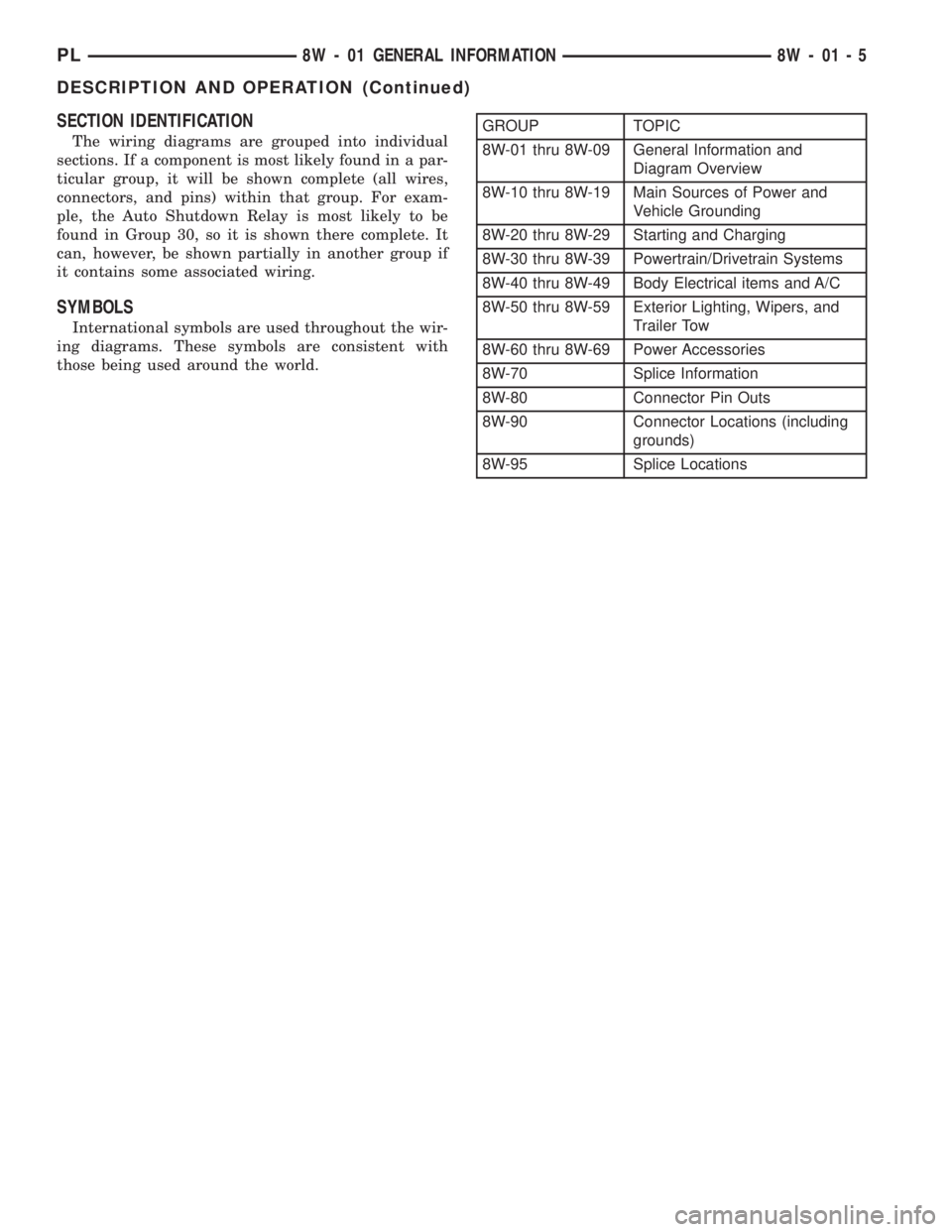

SECTION IDENTIFICATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world.

GROUP TOPIC

8W-01 thru 8W-09 General Information and

Diagram Overview

8W-10 thru 8W-19 Main Sources of Power and

Vehicle Grounding

8W-20 thru 8W-29 Starting and Charging

8W-30 thru 8W-39 Powertrain/Drivetrain Systems

8W-40 thru 8W-49 Body Electrical items and A/C

8W-50 thru 8W-59 Exterior Lighting, Wipers, and

Trailer Tow

8W-60 thru 8W-69 Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-90 Connector Locations (including

grounds)

8W-95 Splice Locations

PL8W - 01 GENERAL INFORMATION 8W - 01 - 5

DESCRIPTION AND OPERATION (Continued)

Page 403 of 1200

TESTING FOR A SHORT TO GROUND

(1) Remove the fuse and disconnect all items

involved with the fuse.

(2) Connect a test light or a voltmeter across the

terminals of the fuse.

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

TESTING FOR A SHORT TO GROUND ON

FUSES POWERING SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting the items in the fuse circuit

one at a time. When the fuse blows the circuit with

the short to ground has been isolated.

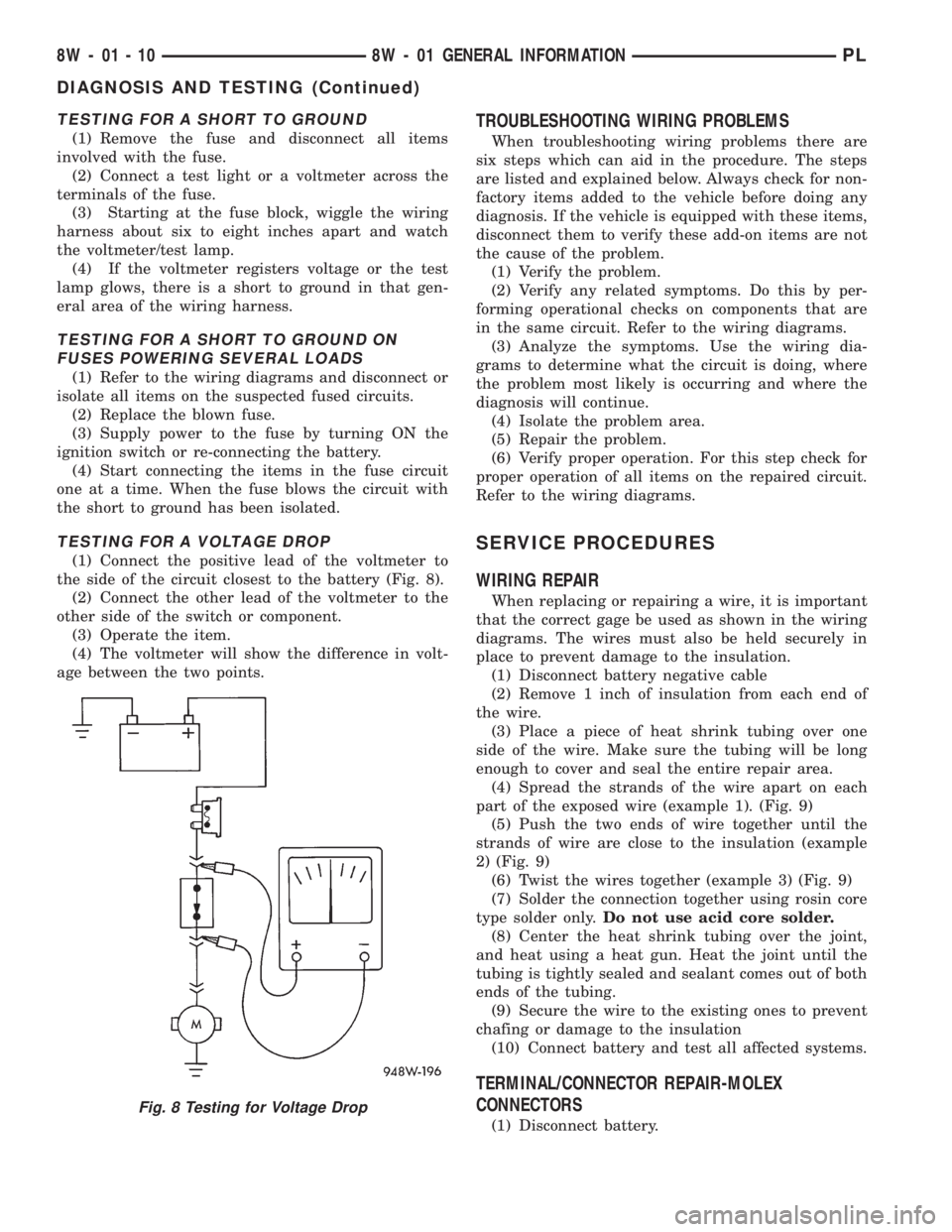

TESTING FOR A VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 8).

(2) Connect the other lead of the voltmeter to the

other side of the switch or component.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-

factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,

disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem.

(6) Verify proper operation. For this step check for

proper operation of all items on the repaired circuit.

Refer to the wiring diagrams.

SERVICE PROCEDURES

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gage be used as shown in the wiring

diagrams. The wires must also be held securely in

place to prevent damage to the insulation.

(1) Disconnect battery negative cable

(2) Remove 1 inch of insulation from each end of

the wire.

(3) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(4) Spread the strands of the wire apart on each

part of the exposed wire (example 1). (Fig. 9)

(5) Push the two ends of wire together until the

strands of wire are close to the insulation (example

2) (Fig. 9)

(6) Twist the wires together (example 3) (Fig. 9)

(7) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(8) Center the heat shrink tubing over the joint,

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(9) Secure the wire to the existing ones to prevent

chafing or damage to the insulation

(10) Connect battery and test all affected systems.

TERMINAL/CONNECTOR REPAIR-MOLEX

CONNECTORS

(1) Disconnect battery.

Fig. 8 Testing for Voltage Drop

8W - 01 - 10 8W - 01 GENERAL INFORMATIONPL

DIAGNOSIS AND TESTING (Continued)

Page 410 of 1200

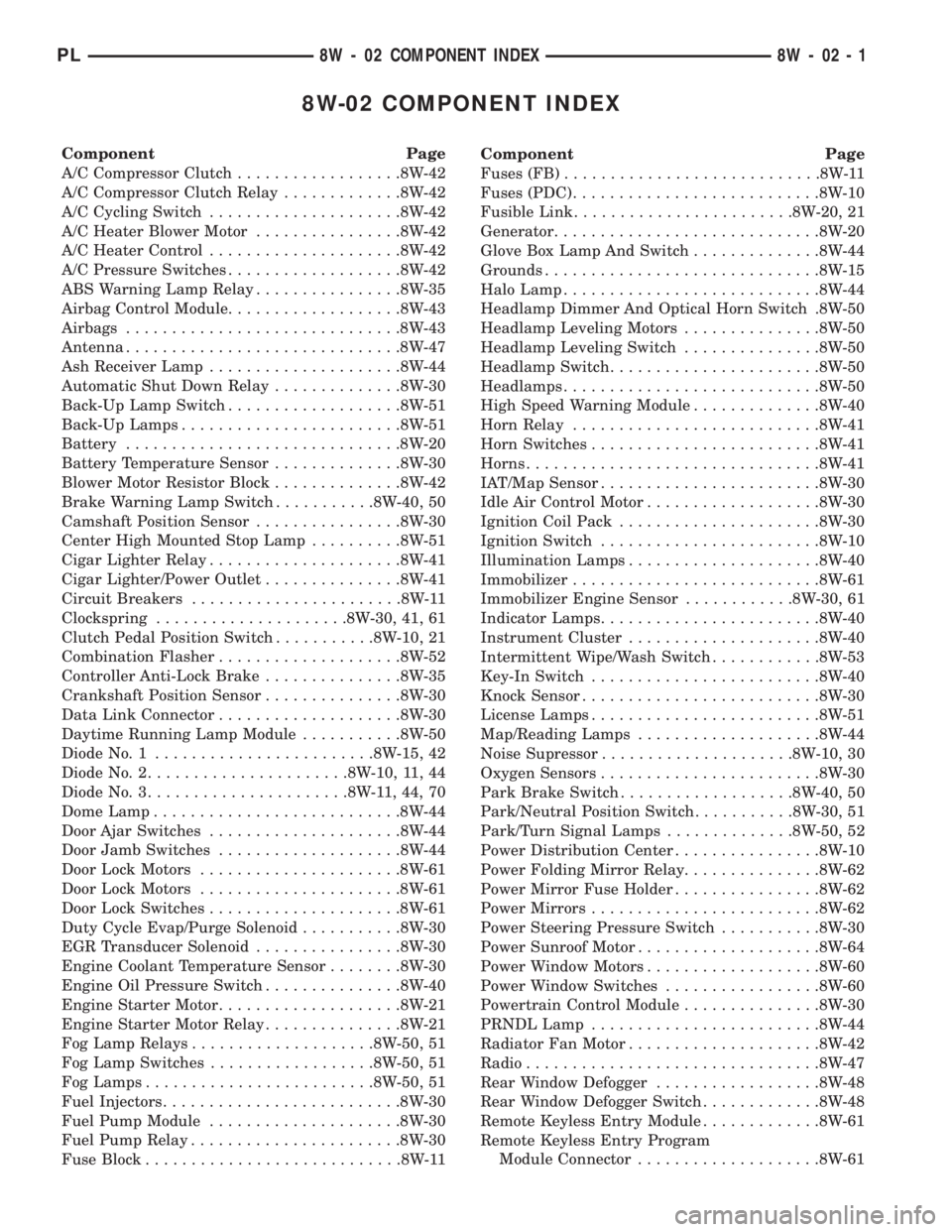

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch..................8W-42

A/C Compressor Clutch Relay.............8W-42

A/C Cycling Switch.....................8W-42

A/C Heater Blower Motor................8W-42

A/C Heater Control.....................8W-42

A/C Pressure Switches...................8W-42

ABS Warning Lamp Relay................8W-35

Airbag Control Module...................8W-43

Airbags..............................8W-43

Antenna..............................8W-47

Ash Receiver Lamp.....................8W-44

Automatic Shut Down Relay..............8W-30

Back-Up Lamp Switch...................8W-51

Back-Up Lamps........................8W-51

Battery..............................8W-20

Battery Temperature Sensor..............8W-30

Blower Motor Resistor Block..............8W-42

Brake Warning Lamp Switch...........8W-40, 50

Camshaft Position Sensor................8W-30

Center High Mounted Stop Lamp..........8W-51

Cigar Lighter Relay.....................8W-41

Cigar Lighter/Power Outlet...............8W-41

Circuit Breakers.......................8W-11

Clockspring.....................8W-30, 41, 61

Clutch Pedal Position Switch...........8W-10, 21

Combination Flasher....................8W-52

Controller Anti-Lock Brake...............8W-35

Crankshaft Position Sensor...............8W-30

Data Link Connector....................8W-30

Daytime Running Lamp Module...........8W-50

Diode No. 1........................8W-15, 42

Diode No. 2......................8W-10, 11, 44

Diode No. 3......................8W-11,44,70

Dome Lamp...........................8W-44

Door Ajar Switches.....................8W-44

Door Jamb Switches....................8W-44

Door Lock Motors......................8W-61

Door Lock Motors......................8W-61

Door Lock Switches.....................8W-61

Duty Cycle Evap/Purge Solenoid...........8W-30

EGR Transducer Solenoid................8W-30

Engine Coolant Temperature Sensor........8W-30

Engine Oil Pressure Switch...............8W-40

Engine Starter Motor....................8W-21

Engine Starter Motor Relay...............8W-21

Fog Lamp Relays....................8W-50, 51

Fog Lamp Switches..................8W-50, 51

Fog Lamps.........................8W-50, 51

Fuel Injectors..........................8W-30

Fuel Pump Module.....................8W-30

Fuel Pump Relay.......................8W-30

Fuse Block............................8W-11Component Page

Fuses (FB)............................8W-11

Fuses (PDC)...........................8W-10

Fusible Link........................8W-20, 21

Generator.............................8W-20

Glove Box Lamp And Switch..............8W-44

Grounds..............................8W-15

Halo Lamp............................8W-44

Headlamp Dimmer And Optical Horn Switch .8W-50

Headlamp Leveling Motors...............8W-50

Headlamp Leveling Switch...............8W-50

Headlamp Switch.......................8W-50

Headlamps............................8W-50

High Speed Warning Module..............8W-40

Horn Relay...........................8W-41

Horn Switches.........................8W-41

Horns................................8W-41

IAT/Map Sensor........................8W-30

Idle Air Control Motor...................8W-30

Ignition Coil Pack......................8W-30

Ignition Switch........................8W-10

Illumination Lamps.....................8W-40

Immobilizer...........................8W-61

Immobilizer Engine Sensor............8W-30, 61

Indicator Lamps........................8W-40

Instrument Cluster.....................8W-40

Intermittent Wipe/Wash Switch............8W-53

Key-In Switch.........................8W-40

Knock Sensor..........................8W-30

License Lamps.........................8W-51

Map/Reading Lamps....................8W-44

Noise Supressor.....................8W-10, 30

Oxygen Sensors........................8W-30

Park Brake Switch...................8W-40, 50

Park/Neutral Position Switch...........8W-30, 51

Park/Turn Signal Lamps..............8W-50, 52

Power Distribution Center................8W-10

Power Folding Mirror Relay...............8W-62

Power Mirror Fuse Holder................8W-62

Power Mirrors.........................8W-62

Power Steering Pressure Switch...........8W-30

Power Sunroof Motor....................8W-64

Power Window Motors...................8W-60

Power Window Switches.................8W-60

Powertrain Control Module...............8W-30

PRNDL Lamp.........................8W-44

Radiator Fan Motor.....................8W-42

Radio................................8W-47

Rear Window Defogger..................8W-48

Rear Window Defogger Switch.............8W-48

Remote Keyless Entry Module.............8W-61

Remote Keyless Entry Program

Module Connector....................8W-61

PL8W - 02 COMPONENT INDEX 8W - 02 - 1