key DODGE NEON 1999 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 985 of 1200

the use of special dyes to aid in detecting fluid leaks.

The use of transmission sealers should be avoided,

since they may adversely affect seals.

DESCRIPTION AND OPERATION

TORQUE CONVERTER CLUTCH

A torque converter clutch is standard on all vehi-

cles. The torque converter clutch is activated only in

direct drive and is controlled by the engine electron-

ics. A solenoid on the valve body, is powered by the

powertrain control module to activate the torque con-

verter clutch.

HYDRAULIC CONTROL SYSTEM

The hydraulic control system makes the transaxle

fully automatic, and has four important functions to

perform. The components of any automatic control

system may be grouped into the following basic

groups:

²Pressure supply system

²Pressure regulating valves

²Flow control valves

²Clutches

²Band servos

Taking each of these basic groups or systems in

turn, the control system may be described as follows:

PRESSURE SUPPLY SYSTEM

The pressure supply system consists of an oil pump

driven by the engine through the torque converter.

The single pump furnishes pressure for all hydraulic

and lubrication requirements.Oil pump housing

assemblies are available with preselected pump

gears.

PRESSURE REGULATING VALVES

The pressure regulating valve controls line pres-

sure dependent on throttle opening. The governor

valve transmits regulated pressure to the valve body

(in conjunction with vehicle speed) to control upshift

and downshift.

The throttle valve transmits regulated pressure to

the transaxle (dependent on throttle position) to con-

trol upshift and downshift.

FLOW CONTROL VALVES

The manual valve provides the different transaxle

drive ranges selected by the vehicle operator.

The 1-2 shift valve automatically shifts the tran-

saxle from first to second or from second to first,

depending on the vehicle operation.

The 2-3 shift valve automatically shifts the tran-

saxle from second to third or from third to second

depending on the vehicle operation.The kickdown valve makes possible a forced down-

shift from third to second, second to first, or third to

first (depending on vehicle speed). This can be done

by depressing the accelerator pedal past the detent

feel near wide open throttle.

The shuttle valve has two separate functions and

performs each independently of the other. The first is

providing fast release of the kickdown band, and

smooth front clutch engagement when a lift-foot

upshift from second to third is made. The second

function is to regulate the application of the kick-

down servo and band when making third±to±second

kickdown.

The bypass valve provides for smooth application

of the kickdown band on 1-2 upshifts.

The torque converter clutch solenoid allows for the

electronic control of the torque converter clutch. It

also disengages the torque converter at closed throt-

tle. This is done during engine warm-up and part-

throttle acceleration.

The switch valve directs oil to apply the torque

converter clutch in one position. The switch valve

releases the torque converter clutch in the other posi-

tion.

CLUTCHES, BAND SERVOS, AND ACCUMULATOR

The front and rear clutch pistons, and both servo

pistons, are moved hydraulically to engage the

clutches and apply the bands. The pistons are

released by spring tension when hydraulic pressure

is released. On the 2-3 upshift, the kickdown servo

piston is released by spring tension and hydraulic

pressure.

The accumulator controls the hydraulic pressure

on the apply±side of the kickdown servo during the

1-2 upshift; thereby cushioning the kickdown band

application at any throttle position.

AUTOMATIC TRANSMISSION SHIFTER/IGNITION

INTERLOCK

The Shifter/Ignition Interlock, is a mechanical

cable operated system (Fig. 1). It interconnects the

automatic transmission floor±mounted shifter to the

steering column ignition switch. The interlock system

locks the floor±mounted shift lever into the PARK

position whenever the ignition switch is in the LOCK

or ACCESSORY position. When the key is in the

OFF or RUN position, the shifter is unlocked and

will move into any position. Also the interlock system

prevents the ignition switch from being turned to

LOCK or ACCESSORY position, unless shifter is in

the PARK position.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by alever typegear-

shift incorporated within the console. The control has

21 - 42 TRANSAXLEPL

GENERAL INFORMATION (Continued)

Page 1005 of 1200

(7) Pull cable up and out of the gearshift mecha-

nism.

(8) Remove the three screws along the bottom of

the lower steering column cover and screw on the left

outward face of cover.

(9) Grasp the cover and pull rearward until the

clips disengage.

(10) Remove two screws at the upper area of the

column liner and lower left corner.

(11) Remove steering column cover and steering

column cover liner.

(12) Lift up the top cover and cluster bezel until

the clips disengage and separate to provide clear-

ance.

(13) Insert a screwdriver into access hole in the

lower shroud. Depress the cylinder button while

rotating the cylinder with the key inserted between

the ON and START positions. This will disengage the

cylinder from the column.

(14) Pull out the key cylinder.

(15) Remove the three lower±to±upper shroud

attaching screws through the bottom of the lower

shroud.

(16) Separate the upper and lower shrouds.

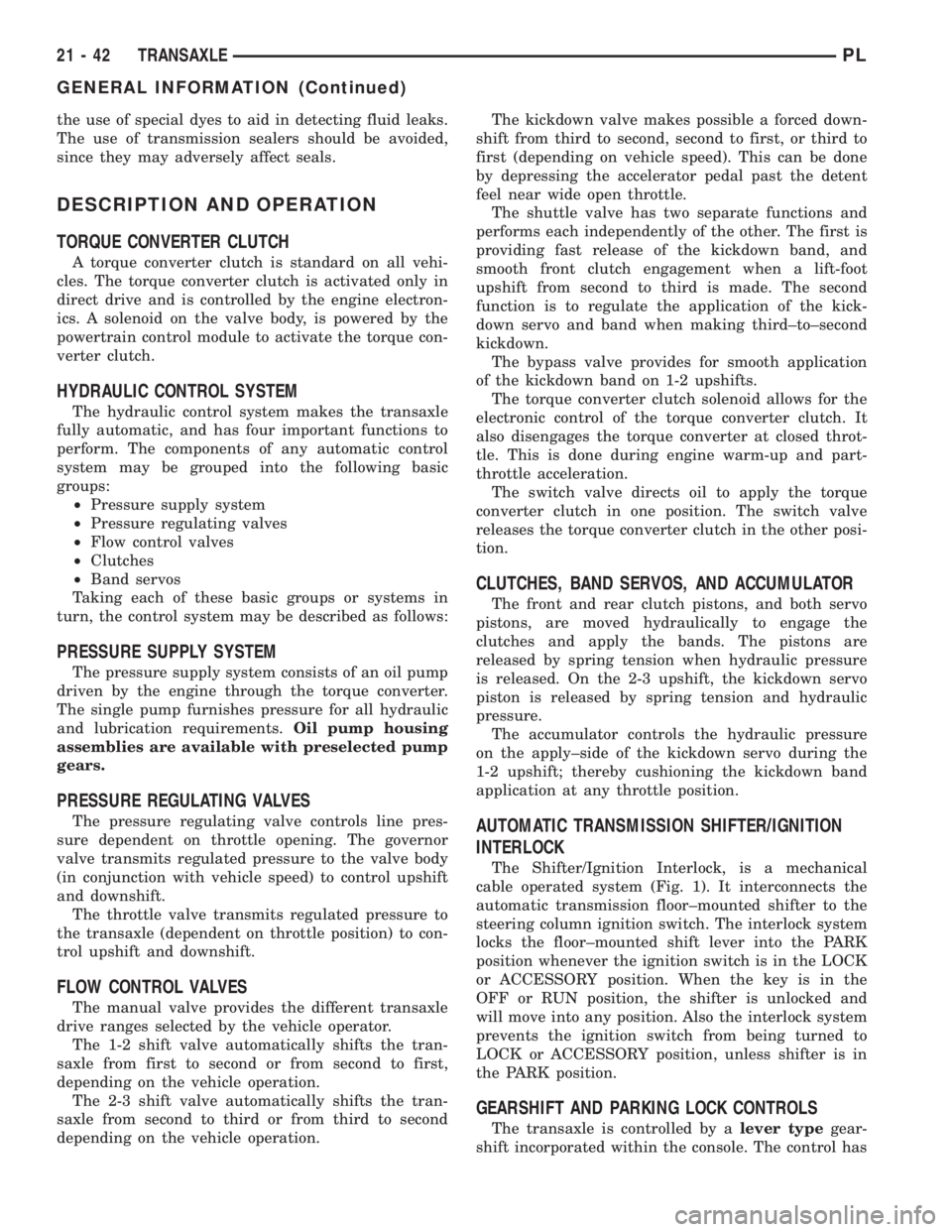

(17) Grasp the interlock cable clip and connector.

Remove the cable from the interlock housing (Fig.

17).

(18) Unclip the cable from the retaining clip

located within the wiring harness.

(19) Remove interlock cable from under center con-

sole mounting bracket and out front of dash panel.

INSTALLATION

CAUTION: When installing interlock cable assem-

bly, care must be taken not to bend exposed cable

wire and slug at shifter end of cable.

(1) Route interlock cable into lower dash panel.(2) Install the ignition switch into housing. Turn

the ignition switch to the RUN position.

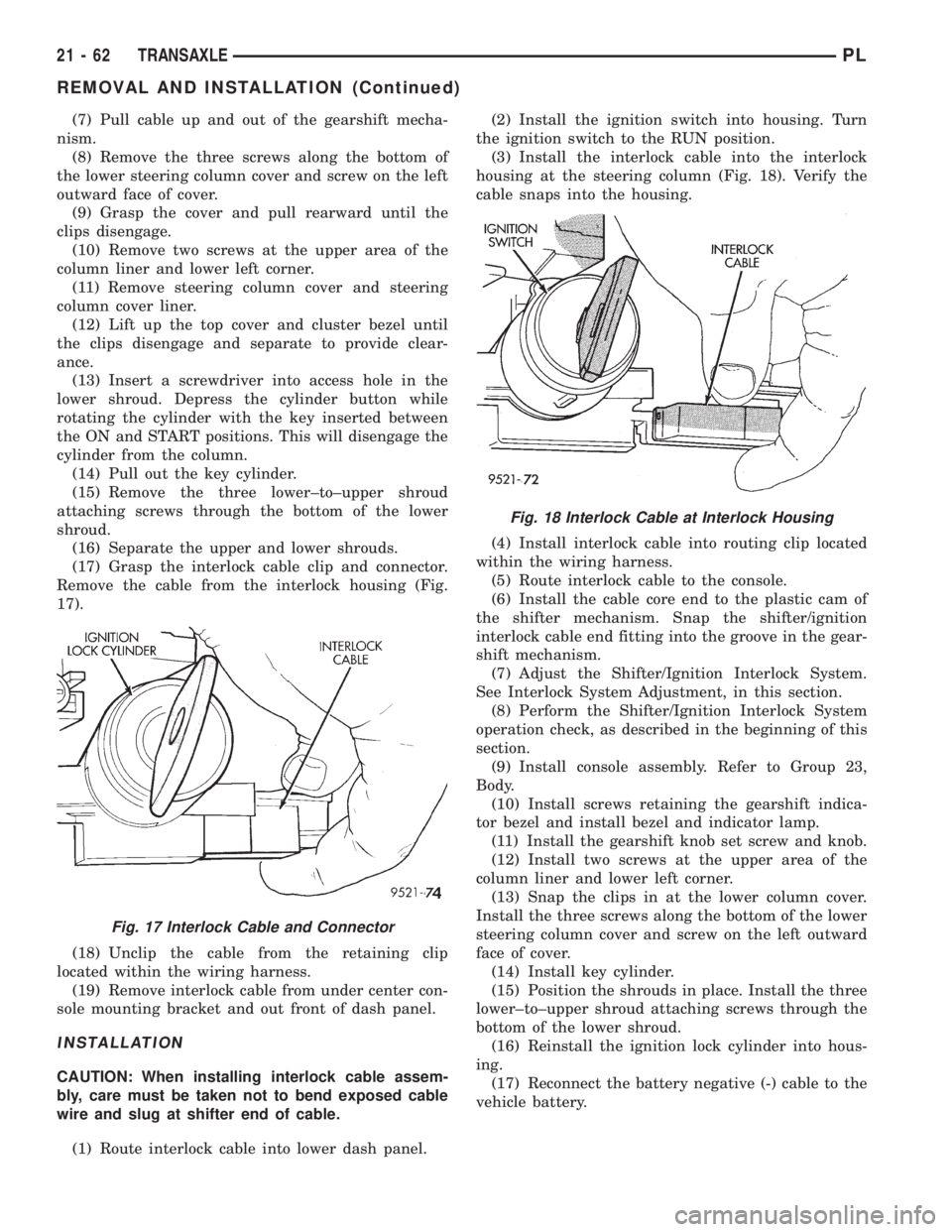

(3) Install the interlock cable into the interlock

housing at the steering column (Fig. 18). Verify the

cable snaps into the housing.

(4) Install interlock cable into routing clip located

within the wiring harness.

(5) Route interlock cable to the console.

(6) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the shifter/ignition

interlock cable end fitting into the groove in the gear-

shift mechanism.

(7) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section.

(8) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section.

(9) Install console assembly. Refer to Group 23,

Body.

(10) Install screws retaining the gearshift indica-

tor bezel and install bezel and indicator lamp.

(11) Install the gearshift knob set screw and knob.

(12) Install two screws at the upper area of the

column liner and lower left corner.

(13) Snap the clips in at the lower column cover.

Install the three screws along the bottom of the lower

steering column cover and screw on the left outward

face of cover.

(14) Install key cylinder.

(15) Position the shrouds in place. Install the three

lower±to±upper shroud attaching screws through the

bottom of the lower shroud.

(16) Reinstall the ignition lock cylinder into hous-

ing.

(17) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 17 Interlock Cable and Connector

Fig. 18 Interlock Cable at Interlock Housing

21 - 62 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1006 of 1200

INTERLOCK SYSTEM ADJUSTMENT

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

with needle nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

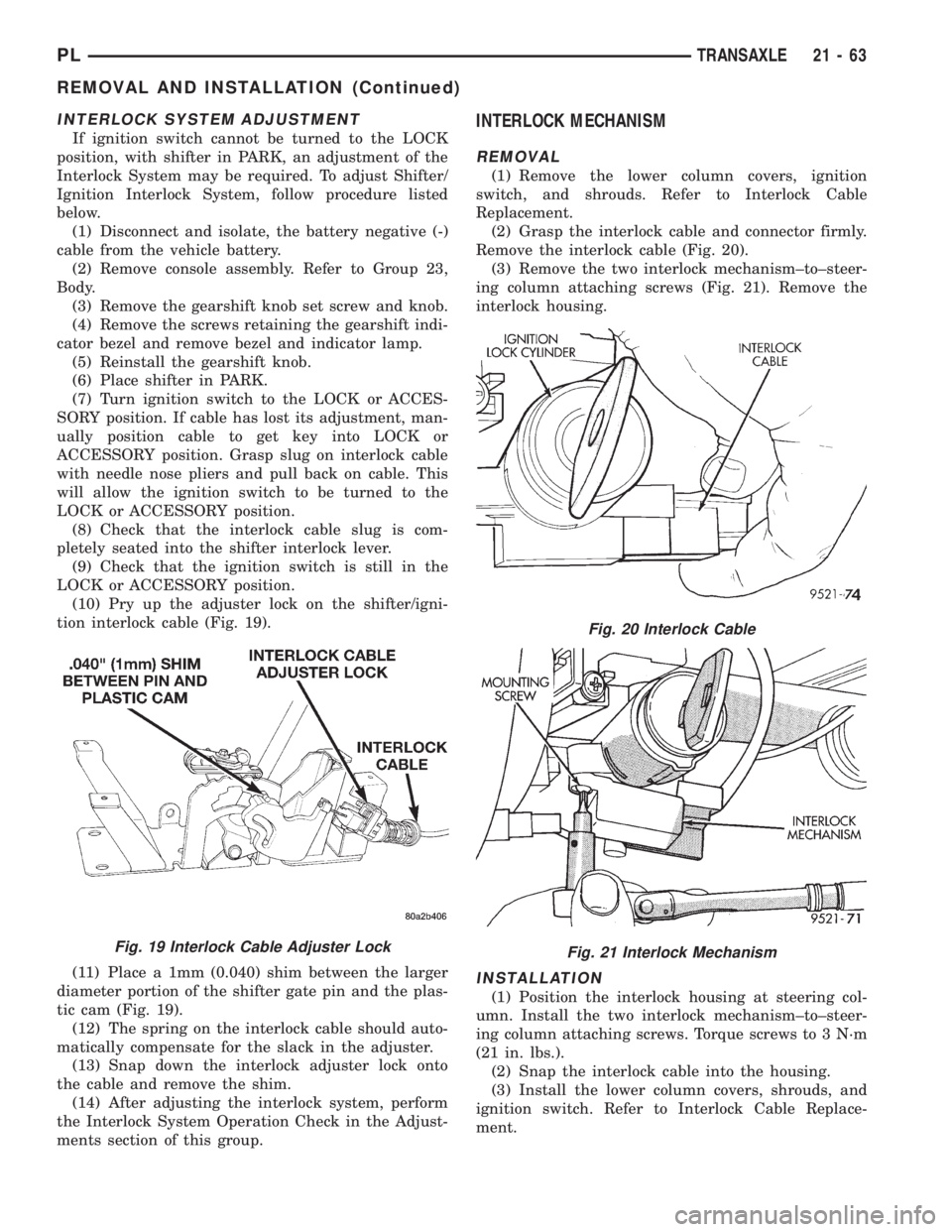

(10) Pry up the adjuster lock on the shifter/igni-

tion interlock cable (Fig. 19).

(11) Place a 1mm (0.040) shim between the larger

diameter portion of the shifter gate pin and the plas-

tic cam (Fig. 19).

(12) The spring on the interlock cable should auto-

matically compensate for the slack in the adjuster.

(13) Snap down the interlock adjuster lock onto

the cable and remove the shim.

(14) After adjusting the interlock system, perform

the Interlock System Operation Check in the Adjust-

ments section of this group.

INTERLOCK MECHANISM

REMOVAL

(1) Remove the lower column covers, ignition

switch, and shrouds. Refer to Interlock Cable

Replacement.

(2) Grasp the interlock cable and connector firmly.

Remove the interlock cable (Fig. 20).

(3) Remove the two interlock mechanism±to±steer-

ing column attaching screws (Fig. 21). Remove the

interlock housing.

INSTALLATION

(1) Position the interlock housing at steering col-

umn. Install the two interlock mechanism±to±steer-

ing column attaching screws. Torque screws to 3 N´m

(21 in. lbs.).

(2) Snap the interlock cable into the housing.

(3) Install the lower column covers, shrouds, and

ignition switch. Refer to Interlock Cable Replace-

ment.

Fig. 19 Interlock Cable Adjuster Lock

Fig. 20 Interlock Cable

Fig. 21 Interlock Mechanism

PLTRANSAXLE 21 - 63

REMOVAL AND INSTALLATION (Continued)

Page 1043 of 1200

ADJUSTMENT

(1) Set parking brake.

(2) Remove floor console. Refer to Group 23, Body.

(3) Place gearshift lever in the (PARK) (P) posi-

tion.

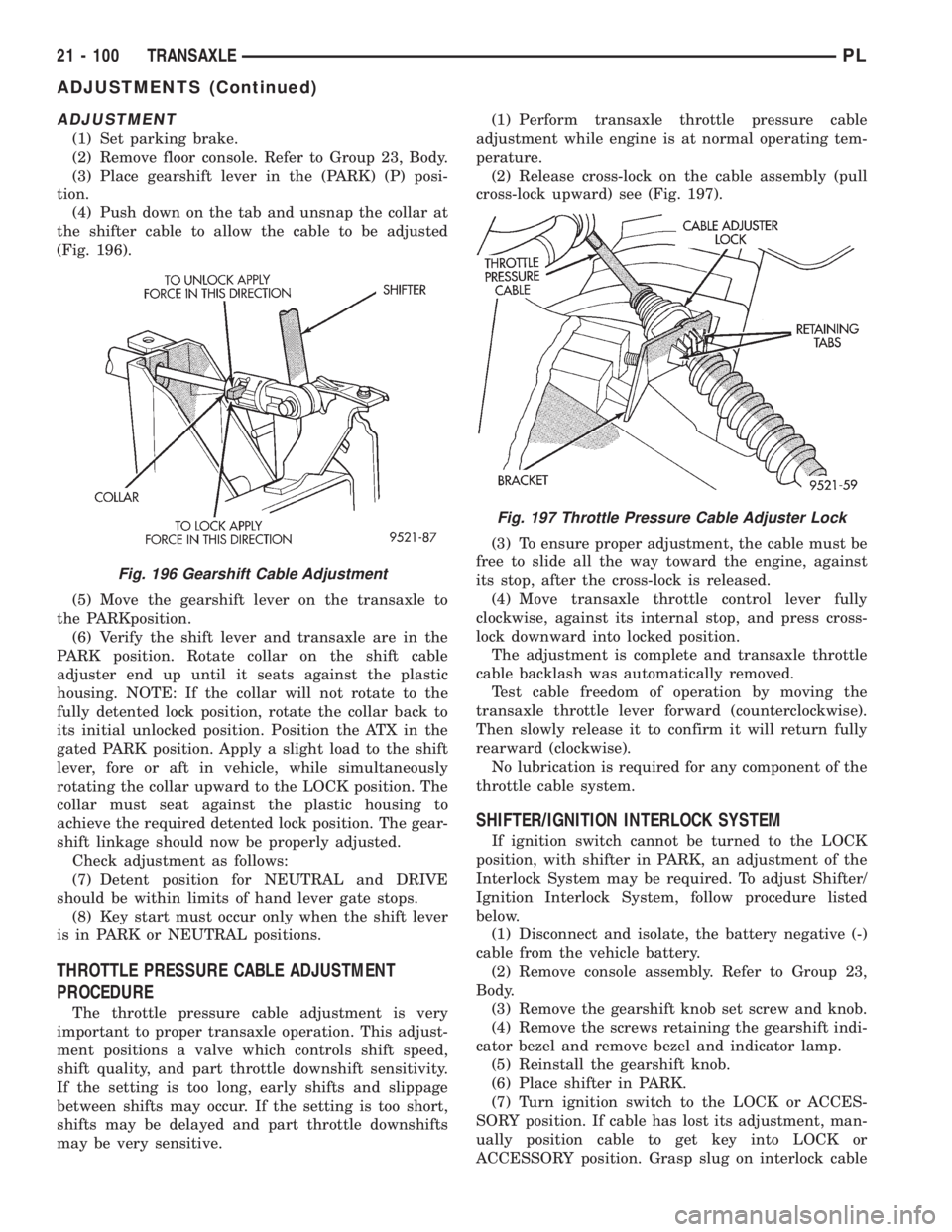

(4) Push down on the tab and unsnap the collar at

the shifter cable to allow the cable to be adjusted

(Fig. 196).

(5) Move the gearshift lever on the transaxle to

the PARKposition.

(6) Verify the shift lever and transaxle are in the

PARK position. Rotate collar on the shift cable

adjuster end up until it seats against the plastic

housing. NOTE: If the collar will not rotate to the

fully detented lock position, rotate the collar back to

its initial unlocked position. Position the ATX in the

gated PARK position. Apply a slight load to the shift

lever, fore or aft in vehicle, while simultaneously

rotating the collar upward to the LOCK position. The

collar must seat against the plastic housing to

achieve the required detented lock position. The gear-

shift linkage should now be properly adjusted.

Check adjustment as follows:

(7) Detent position for NEUTRAL and DRIVE

should be within limits of hand lever gate stops.

(8) Key start must occur only when the shift lever

is in PARK or NEUTRAL positions.

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE

The throttle pressure cable adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too long, early shifts and slippage

between shifts may occur. If the setting is too short,

shifts may be delayed and part throttle downshifts

may be very sensitive.(1) Perform transaxle throttle pressure cable

adjustment while engine is at normal operating tem-

perature.

(2) Release cross-lock on the cable assembly (pull

cross-lock upward) see (Fig. 197).

(3) To ensure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released.

(4) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position.

The adjustment is complete and transaxle throttle

cable backlash was automatically removed.

Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise).

No lubrication is required for any component of the

throttle cable system.

SHIFTER/IGNITION INTERLOCK SYSTEM

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

Fig. 196 Gearshift Cable Adjustment

Fig. 197 Throttle Pressure Cable Adjuster Lock

21 - 100 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1064 of 1200

TRANSAXLE

CONTENTS

page page

DESCRIPTION AND OPERATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM........................ 1

DIAGNOSIS AND TESTING

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM........................ 1REMOVAL AND INSTALLATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) CABLE ASSEMBLY................ 2

ADJUSTMENTS

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM ADJUSTMENT............ 4

DESCRIPTION AND OPERATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM

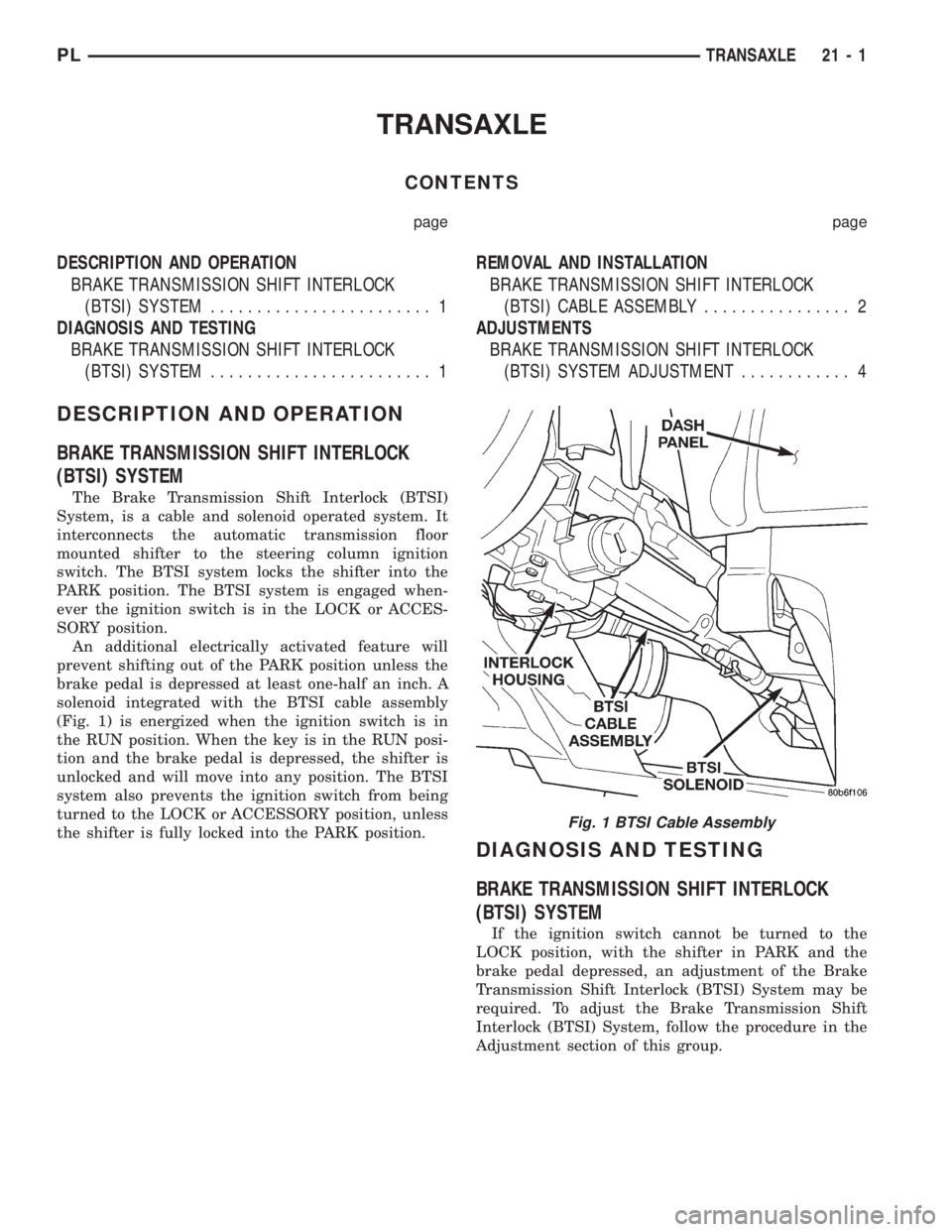

The Brake Transmission Shift Interlock (BTSI)

System, is a cable and solenoid operated system. It

interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch. The BTSI system locks the shifter into the

PARK position. The BTSI system is engaged when-

ever the ignition switch is in the LOCK or ACCES-

SORY position.

An additional electrically activated feature will

prevent shifting out of the PARK position unless the

brake pedal is depressed at least one-half an inch. A

solenoid integrated with the BTSI cable assembly

(Fig. 1) is energized when the ignition switch is in

the RUN position. When the key is in the RUN posi-

tion and the brake pedal is depressed, the shifter is

unlocked and will move into any position. The BTSI

system also prevents the ignition switch from being

turned to the LOCK or ACCESSORY position, unless

the shifter is fully locked into the PARK position.

DIAGNOSIS AND TESTING

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM

If the ignition switch cannot be turned to the

LOCK position, with the shifter in PARK and the

brake pedal depressed, an adjustment of the Brake

Transmission Shift Interlock (BTSI) System may be

required. To adjust the Brake Transmission Shift

Interlock (BTSI) System, follow the procedure in the

Adjustment section of this group.

Fig. 1 BTSI Cable Assembly

PLTRANSAXLE 21 - 1

Page 1067 of 1200

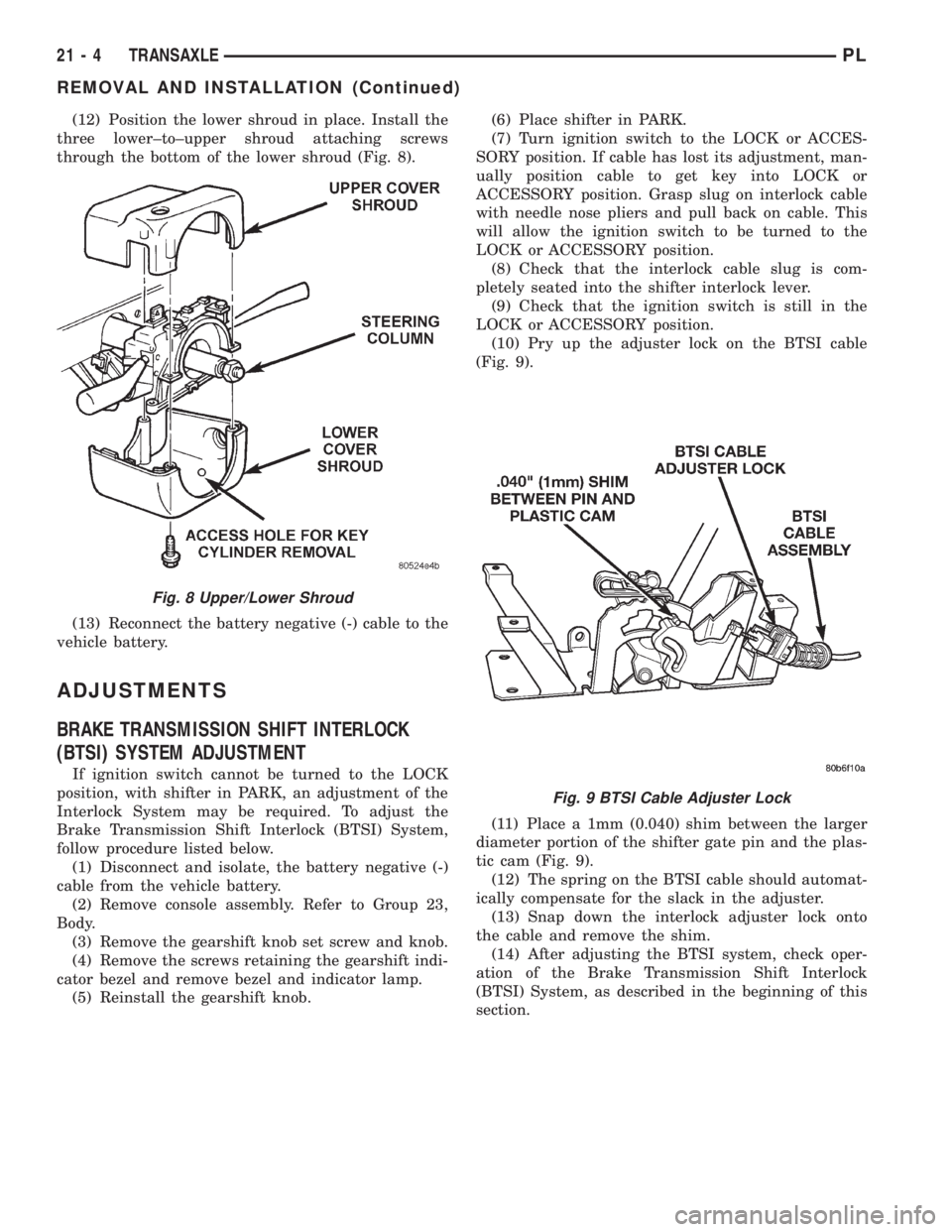

(12) Position the lower shroud in place. Install the

three lower±to±upper shroud attaching screws

through the bottom of the lower shroud (Fig. 8).

(13) Reconnect the battery negative (-) cable to the

vehicle battery.

ADJUSTMENTS

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM ADJUSTMENT

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust the

Brake Transmission Shift Interlock (BTSI) System,

follow procedure listed below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

with needle nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

(10) Pry up the adjuster lock on the BTSI cable

(Fig. 9).

(11) Place a 1mm (0.040) shim between the larger

diameter portion of the shifter gate pin and the plas-

tic cam (Fig. 9).

(12) The spring on the BTSI cable should automat-

ically compensate for the slack in the adjuster.

(13) Snap down the interlock adjuster lock onto

the cable and remove the shim.

(14) After adjusting the BTSI system, check oper-

ation of the Brake Transmission Shift Interlock

(BTSI) System, as described in the beginning of this

section.

Fig. 8 Upper/Lower Shroud

Fig. 9 BTSI Cable Adjuster Lock

21 - 4 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1106 of 1200

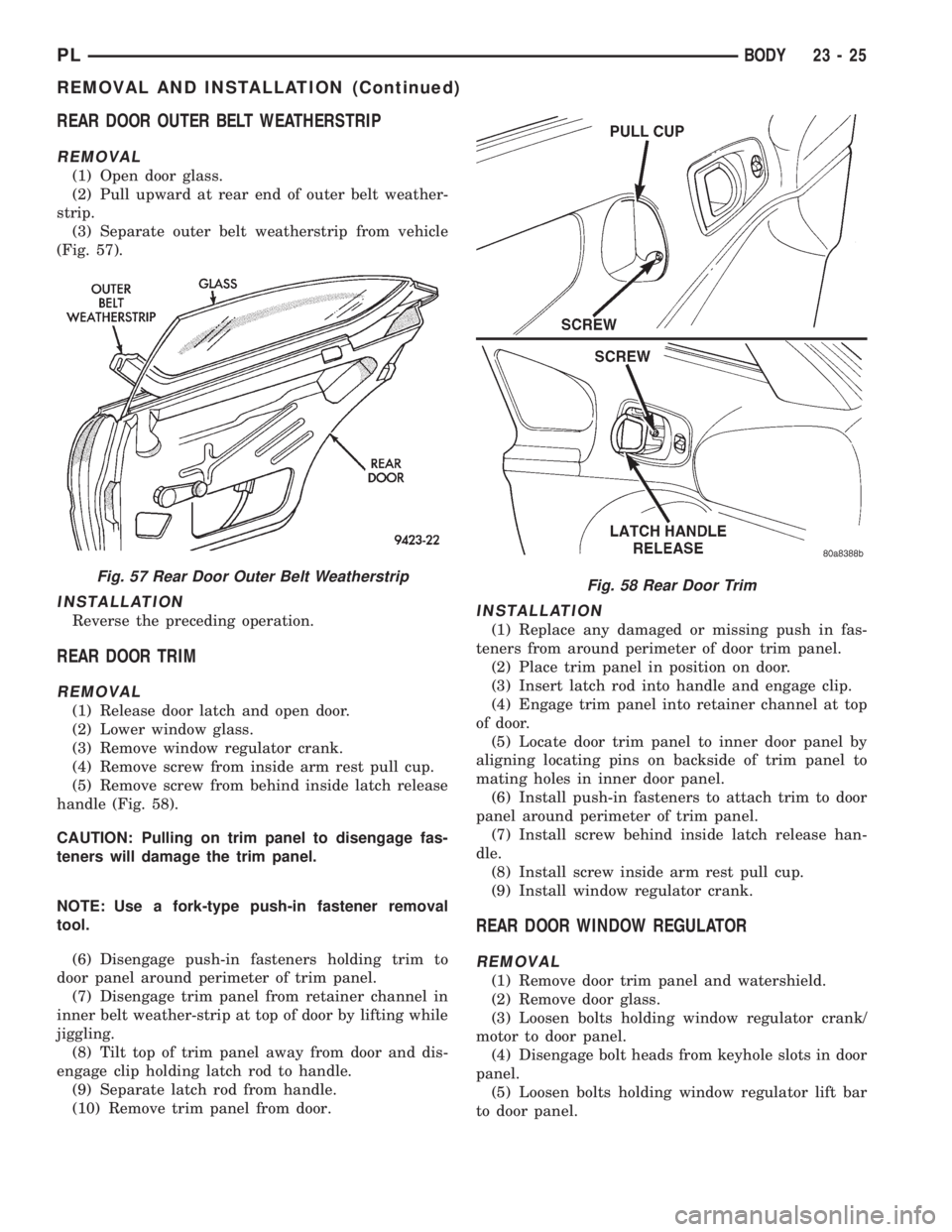

REAR DOOR OUTER BELT WEATHERSTRIP

REMOVAL

(1) Open door glass.

(2) Pull upward at rear end of outer belt weather-

strip.

(3) Separate outer belt weatherstrip from vehicle

(Fig. 57).

INSTALLATION

Reverse the preceding operation.

REAR DOOR TRIM

REMOVAL

(1) Release door latch and open door.

(2) Lower window glass.

(3) Remove window regulator crank.

(4) Remove screw from inside arm rest pull cup.

(5) Remove screw from behind inside latch release

handle (Fig. 58).

CAUTION: Pulling on trim panel to disengage fas-

teners will damage the trim panel.

NOTE: Use a fork-type push-in fastener removal

tool.

(6) Disengage push-in fasteners holding trim to

door panel around perimeter of trim panel.

(7) Disengage trim panel from retainer channel in

inner belt weather-strip at top of door by lifting while

jiggling.

(8) Tilt top of trim panel away from door and dis-

engage clip holding latch rod to handle.

(9) Separate latch rod from handle.

(10) Remove trim panel from door.

INSTALLATION

(1) Replace any damaged or missing push in fas-

teners from around perimeter of door trim panel.

(2) Place trim panel in position on door.

(3) Insert latch rod into handle and engage clip.

(4) Engage trim panel into retainer channel at top

of door.

(5) Locate door trim panel to inner door panel by

aligning locating pins on backside of trim panel to

mating holes in inner door panel.

(6) Install push-in fasteners to attach trim to door

panel around perimeter of trim panel.

(7) Install screw behind inside latch release han-

dle.

(8) Install screw inside arm rest pull cup.

(9) Install window regulator crank.

REAR DOOR WINDOW REGULATOR

REMOVAL

(1) Remove door trim panel and watershield.

(2) Remove door glass.

(3) Loosen bolts holding window regulator crank/

motor to door panel.

(4) Disengage bolt heads from keyhole slots in door

panel.

(5) Loosen bolts holding window regulator lift bar

to door panel.

Fig. 57 Rear Door Outer Belt WeatherstripFig. 58 Rear Door Trim

PLBODY 23 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1107 of 1200

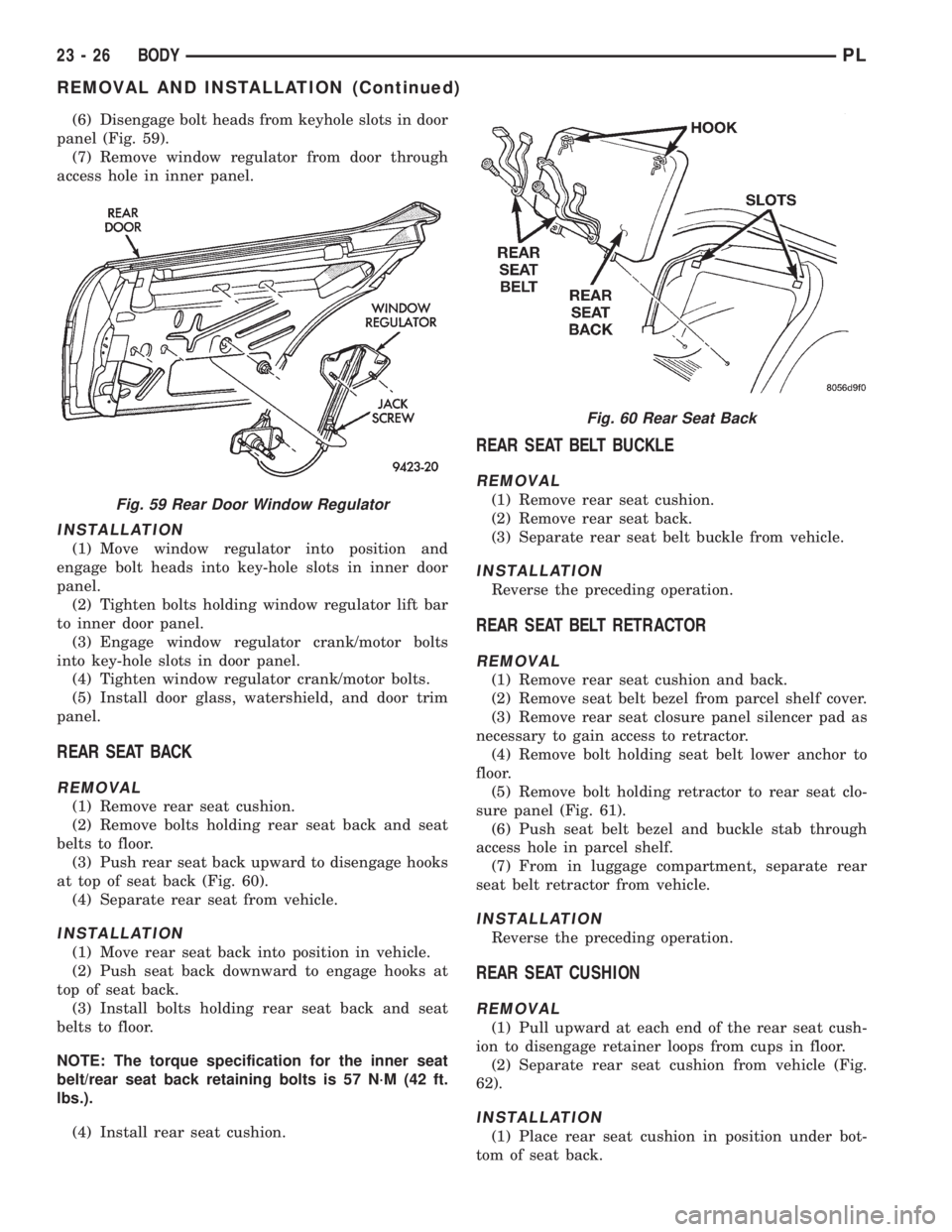

(6) Disengage bolt heads from keyhole slots in door

panel (Fig. 59).

(7) Remove window regulator from door through

access hole in inner panel.

INSTALLATION

(1) Move window regulator into position and

engage bolt heads into key-hole slots in inner door

panel.

(2) Tighten bolts holding window regulator lift bar

to inner door panel.

(3) Engage window regulator crank/motor bolts

into key-hole slots in door panel.

(4) Tighten window regulator crank/motor bolts.

(5) Install door glass, watershield, and door trim

panel.

REAR SEAT BACK

REMOVAL

(1) Remove rear seat cushion.

(2) Remove bolts holding rear seat back and seat

belts to floor.

(3) Push rear seat back upward to disengage hooks

at top of seat back (Fig. 60).

(4) Separate rear seat from vehicle.

INSTALLATION

(1) Move rear seat back into position in vehicle.

(2) Push seat back downward to engage hooks at

top of seat back.

(3) Install bolts holding rear seat back and seat

belts to floor.

NOTE: The torque specification for the inner seat

belt/rear seat back retaining bolts is 57 N´M (42 ft.

lbs.).

(4) Install rear seat cushion.

REAR SEAT BELT BUCKLE

REMOVAL

(1) Remove rear seat cushion.

(2) Remove rear seat back.

(3) Separate rear seat belt buckle from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR SEAT BELT RETRACTOR

REMOVAL

(1) Remove rear seat cushion and back.

(2) Remove seat belt bezel from parcel shelf cover.

(3) Remove rear seat closure panel silencer pad as

necessary to gain access to retractor.

(4) Remove bolt holding seat belt lower anchor to

floor.

(5) Remove bolt holding retractor to rear seat clo-

sure panel (Fig. 61).

(6) Push seat belt bezel and buckle stab through

access hole in parcel shelf.

(7) From in luggage compartment, separate rear

seat belt retractor from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR SEAT CUSHION

REMOVAL

(1) Pull upward at each end of the rear seat cush-

ion to disengage retainer loops from cups in floor.

(2) Separate rear seat cushion from vehicle (Fig.

62).

INSTALLATION

(1) Place rear seat cushion in position under bot-

tom of seat back.

Fig. 59 Rear Door Window Regulator

Fig. 60 Rear Seat Back

23 - 26 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1116 of 1200

INSTALLATION

Reverse the preceding operation. Adjust inner belt

stabilizer against glass with enough tension to allow

free up and down movement.

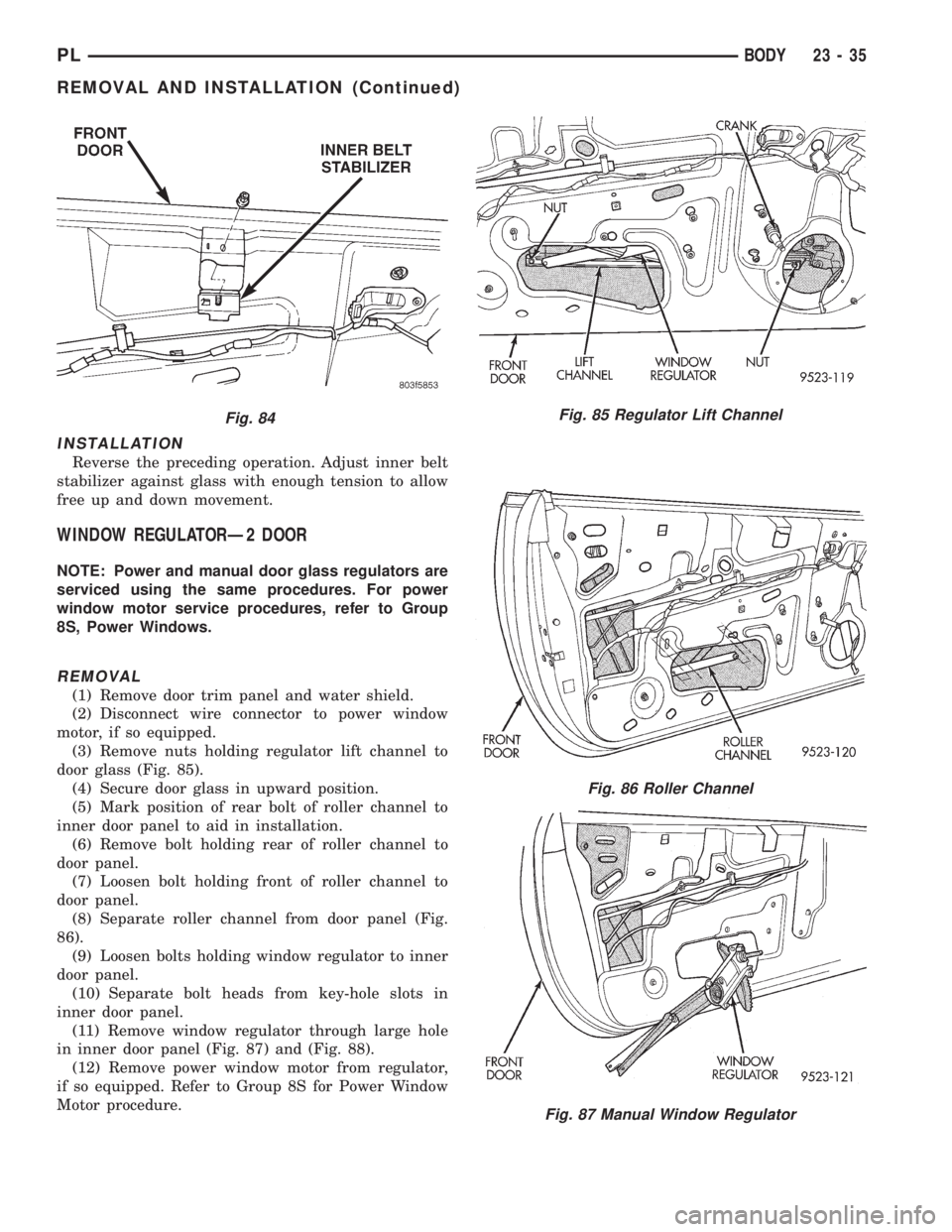

WINDOW REGULATORÐ2 DOOR

NOTE: Power and manual door glass regulators are

serviced using the same procedures. For power

window motor service procedures, refer to Group

8S, Power Windows.

REMOVAL

(1) Remove door trim panel and water shield.

(2) Disconnect wire connector to power window

motor, if so equipped.

(3) Remove nuts holding regulator lift channel to

door glass (Fig. 85).

(4) Secure door glass in upward position.

(5) Mark position of rear bolt of roller channel to

inner door panel to aid in installation.

(6) Remove bolt holding rear of roller channel to

door panel.

(7) Loosen bolt holding front of roller channel to

door panel.

(8) Separate roller channel from door panel (Fig.

86).

(9) Loosen bolts holding window regulator to inner

door panel.

(10) Separate bolt heads from key-hole slots in

inner door panel.

(11) Remove window regulator through large hole

in inner door panel (Fig. 87) and (Fig. 88).

(12) Remove power window motor from regulator,

if so equipped. Refer to Group 8S for Power Window

Motor procedure.

Fig. 84Fig. 85 Regulator Lift Channel

Fig. 86 Roller Channel

Fig. 87 Manual Window Regulator

PLBODY 23 - 35

REMOVAL AND INSTALLATION (Continued)

Page 1117 of 1200

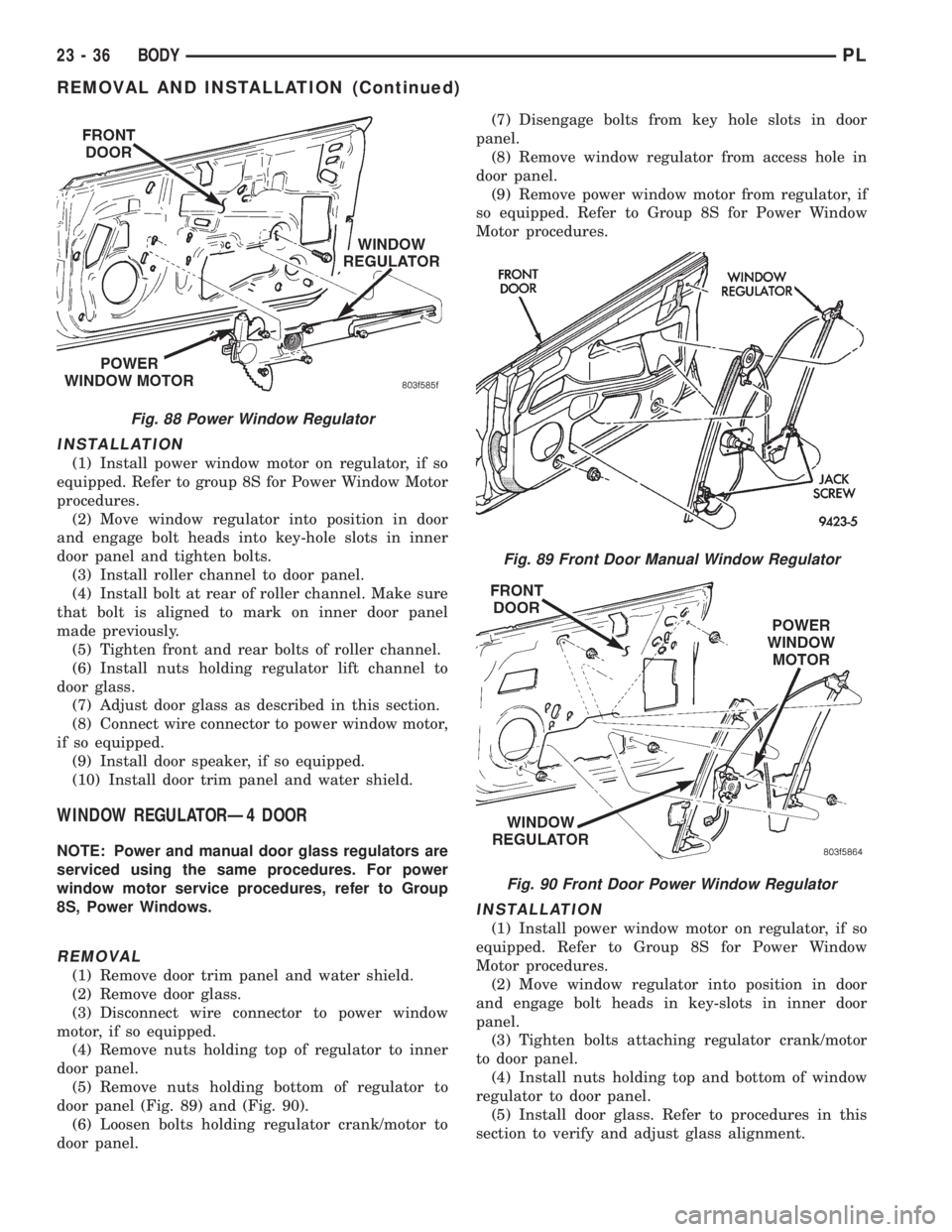

INSTALLATION

(1) Install power window motor on regulator, if so

equipped. Refer to group 8S for Power Window Motor

procedures.

(2) Move window regulator into position in door

and engage bolt heads into key-hole slots in inner

door panel and tighten bolts.

(3) Install roller channel to door panel.

(4) Install bolt at rear of roller channel. Make sure

that bolt is aligned to mark on inner door panel

made previously.

(5) Tighten front and rear bolts of roller channel.

(6) Install nuts holding regulator lift channel to

door glass.

(7) Adjust door glass as described in this section.

(8) Connect wire connector to power window motor,

if so equipped.

(9) Install door speaker, if so equipped.

(10) Install door trim panel and water shield.

WINDOW REGULATORÐ4 DOOR

NOTE: Power and manual door glass regulators are

serviced using the same procedures. For power

window motor service procedures, refer to Group

8S, Power Windows.

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove door glass.

(3) Disconnect wire connector to power window

motor, if so equipped.

(4) Remove nuts holding top of regulator to inner

door panel.

(5) Remove nuts holding bottom of regulator to

door panel (Fig. 89) and (Fig. 90).

(6) Loosen bolts holding regulator crank/motor to

door panel.(7) Disengage bolts from key hole slots in door

panel.

(8) Remove window regulator from access hole in

door panel.

(9) Remove power window motor from regulator, if

so equipped. Refer to Group 8S for Power Window

Motor procedures.

INSTALLATION

(1) Install power window motor on regulator, if so

equipped. Refer to Group 8S for Power Window

Motor procedures.

(2) Move window regulator into position in door

and engage bolt heads in key-slots in inner door

panel.

(3) Tighten bolts attaching regulator crank/motor

to door panel.

(4) Install nuts holding top and bottom of window

regulator to door panel.

(5) Install door glass. Refer to procedures in this

section to verify and adjust glass alignment.

Fig. 88 Power Window Regulator

Fig. 89 Front Door Manual Window Regulator

Fig. 90 Front Door Power Window Regulator

23 - 36 BODYPL

REMOVAL AND INSTALLATION (Continued)