headlamp DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 311 of 1285

HEADLAMP ALIGNMENT

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

HEADLAMP ALIGNMENT....................4

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION........4ADJUSTMENTS

HEADLAMP ADJUSTMENT USING

ALIGNMENT SCREEN....................4

FOG LAMP ALIGNMENT....................6

DESCRIPTION AND OPERATION

HEADLAMP ALIGNMENT

Headlamps and Fog Lamps should be aligned

using the screen method which is provided in this

section.The preferred headlamp alignment set-

ting is 0 for the left/right adjustment and 0 for

the up/down adjustment.

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP ADJUSTMENT USING ALIGNMENT

SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft.) away from front

of headlamp lens.

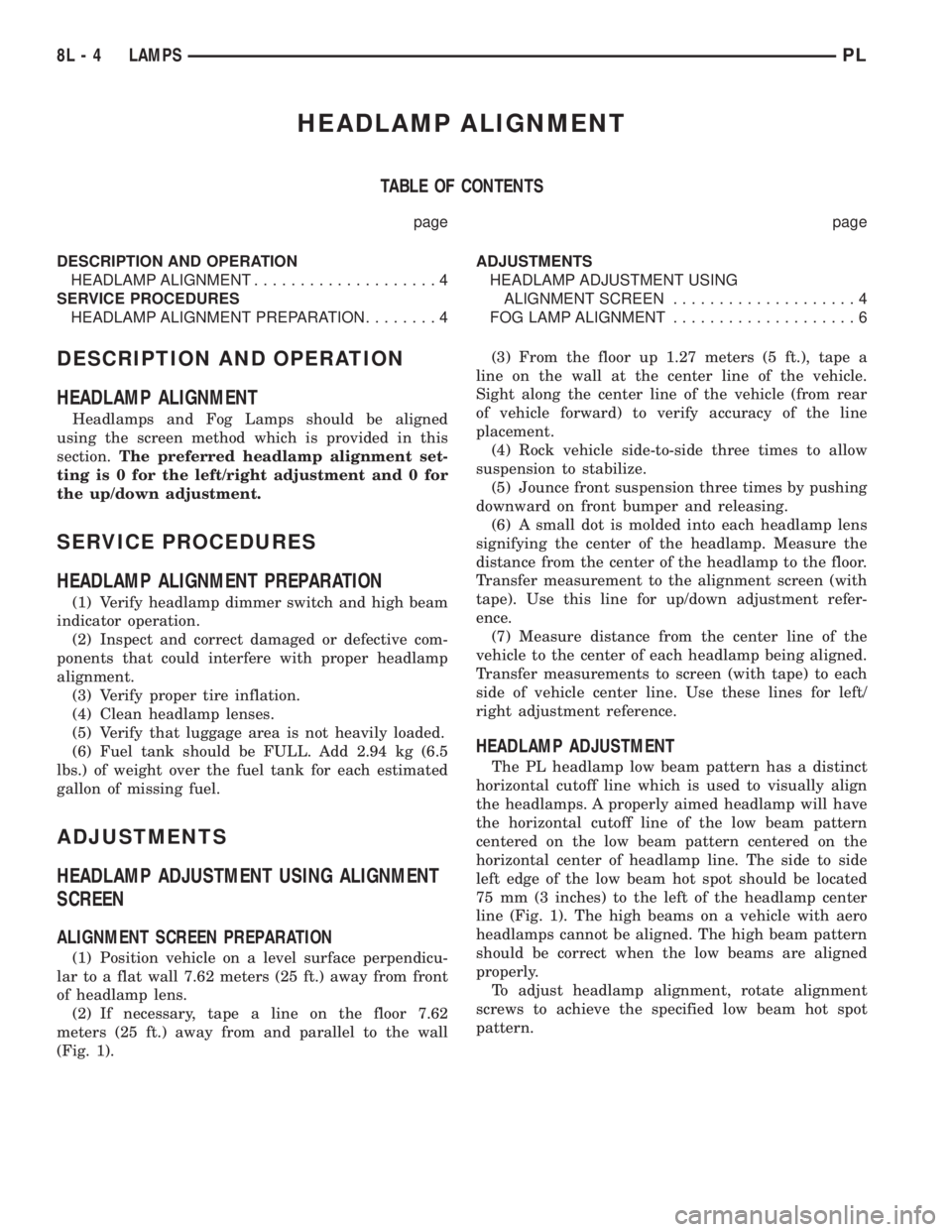

(2) If necessary, tape a line on the floor 7.62

meters (25 ft.) away from and parallel to the wall

(Fig. 1).(3) From the floor up 1.27 meters (5 ft.), tape a

line on the wall at the center line of the vehicle.

Sight along the center line of the vehicle (from rear

of vehicle forward) to verify accuracy of the line

placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize.

(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) A small dot is molded into each headlamp lens

signifying the center of the headlamp. Measure the

distance from the center of the headlamp to the floor.

Transfer measurement to the alignment screen (with

tape). Use this line for up/down adjustment refer-

ence.

(7) Measure distance from the center line of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle center line. Use these lines for left/

right adjustment reference.

HEADLAMP ADJUSTMENT

The PL headlamp low beam pattern has a distinct

horizontal cutoff line which is used to visually align

the headlamps. A properly aimed headlamp will have

the horizontal cutoff line of the low beam pattern

centered on the low beam pattern centered on the

horizontal center of headlamp line. The side to side

left edge of the low beam hot spot should be located

75 mm (3 inches) to the left of the headlamp center

line (Fig. 1). The high beams on a vehicle with aero

headlamps cannot be aligned. The high beam pattern

should be correct when the low beams are aligned

properly.

To adjust headlamp alignment, rotate alignment

screws to achieve the specified low beam hot spot

pattern.

8L - 4 LAMPSPL

Page 312 of 1285

Fig. 1 Headlamp Alignment Screen

1 ± FLOOR TO CENTER OF HEADLAMP

2 ± 75mm (3 inches)

3 ± VEHICLE CENTER LINE

4 ± HEADLAMP CENTER LINE5 ± LOW BEAM HORIZONTAL CUTOFF LINE

6 ± FRONT OF HEADLAMP

7 ± 7.62 meters (25 feet)

8 ± 75mm (3 inches)

PLLAMPS 8L - 5

ADJUSTMENTS (Continued)

Page 313 of 1285

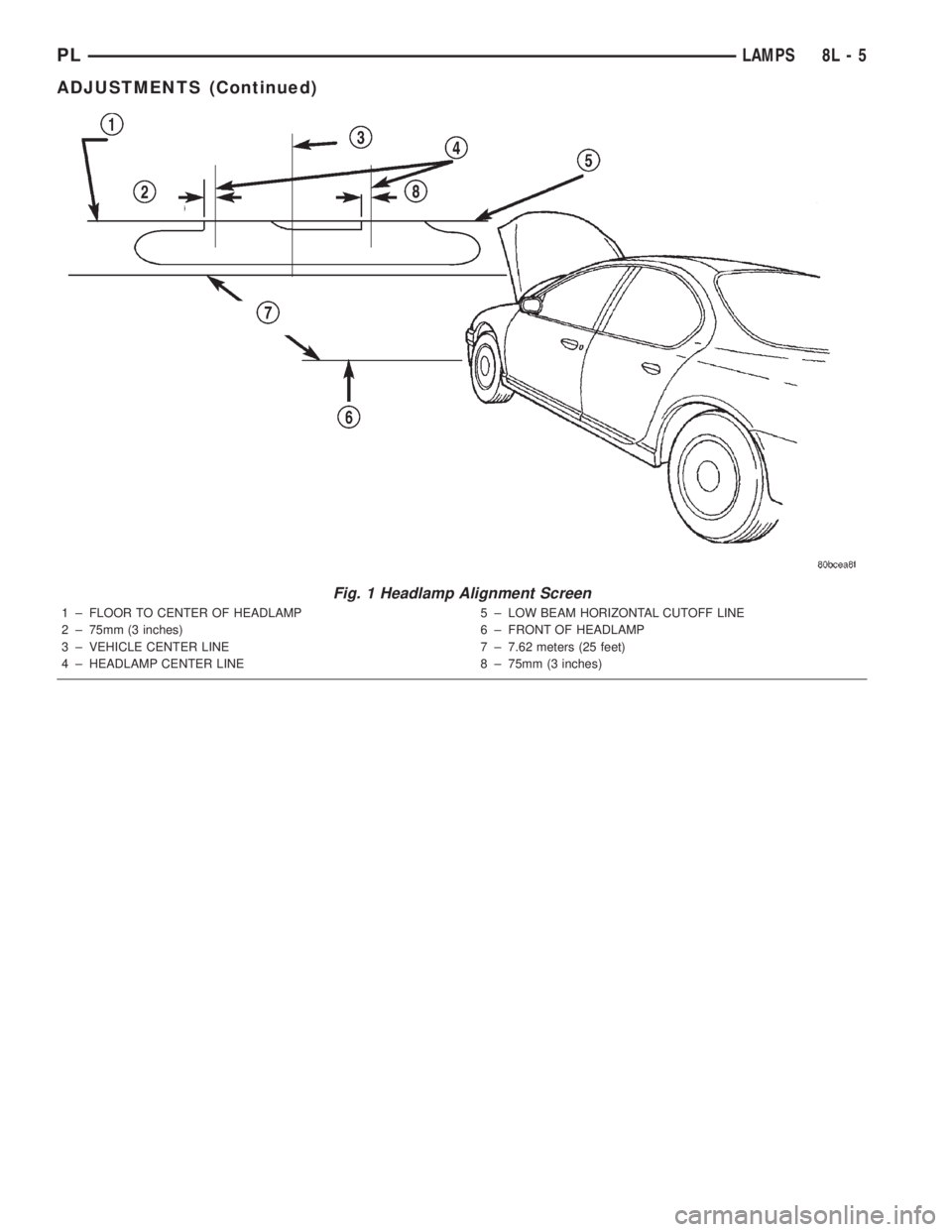

FOG LAMP ALIGNMENT

Prepare an alignment screen. Refer to Alignment

Screen Preparation paragraph in this section. Disen-

gage the wire connectors from the back of the head-

lamp bulbs to disable the headlamps. This will allow

a more accurate projection reading of the fog lamps.

Turn on the headlamp switch and actuate the foglamp switch. A properly aligned fog lamp will project

a pattern on the alignment screen 100 mm (4 in.)

below the fog lamp center line and straight ahead.

To adjust fog lamp alignment, rotate the alignment

screen located on the bottom of the fog lamp from

under the fascia to achieve the specified pattern posi-

tion. (Fig. 2).

Fig. 2 Lamp Alignment Screen

1 ± CENTER LINE OF FOG LAMPS

2 ± CENTER LINE VEHICLE

3 ± FLOOR TO CENTER OF FOG LAMP

4 ± 4 inches5 ± FOG LAMP HOT SPOT

6 ± FRONT OF FOG LAMP

7 ± 7.62 meters

(25 feet)

8L - 6 LAMPSPL

ADJUSTMENTS (Continued)

Page 314 of 1285

LAMP BULB SERVICE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

BULB...................................7

REMOVAL AND INSTALLATION

HEADLAMP BULB.........................7

FOG LAMP BULB..........................8

PARK AND TURN SIGNAL LAMP BULB.........8

FRONT SIDE MARKER LAMP BULB...........9

CENTER HIGH MOUNTED STOP LAMP BULB....9

TAIL, STOP, BACK-UP AND TURN SIGNAL

LAMP BULB............................9LICENSE PLATE LAMP BULB...............10

UNDERHOOD LAMP BULB.................10

REAR CARGO LAMP BULB.................10

DOME LAMP BULB.......................10

TRANSAXLE RANGE INDICATOR LAMP BULB . . 10

GLOVE BOX LAMP BULB...................11

FLOOR CONSOLE LAMP BULB..............11

VISOR VANITY LAMP BULB.................11

DESCRIPTION AND OPERATION

BULB

The electric light bulb is a source of electromag-

netic radiation which generates light. Vehicles use

many different types of bulbs:

²Headlamp bulb

²Fog Lamp bulb

²Tail Lamp bulb

²Stop Lamp bulb

²Turn Signal bulb

²Back up Lamp bulb

²Dome Lamp bulb

²Transaxle Range Indicator Lamp bulb (PRNDL)

²Glove Box Lamp bulb

²Floor Console Lamp bulb

²Rear Cargo Lamp bulb

²Visor Vanity Lamp bulb

²Underhood Lamp bulb

²etc.

REMOVAL AND INSTALLATION

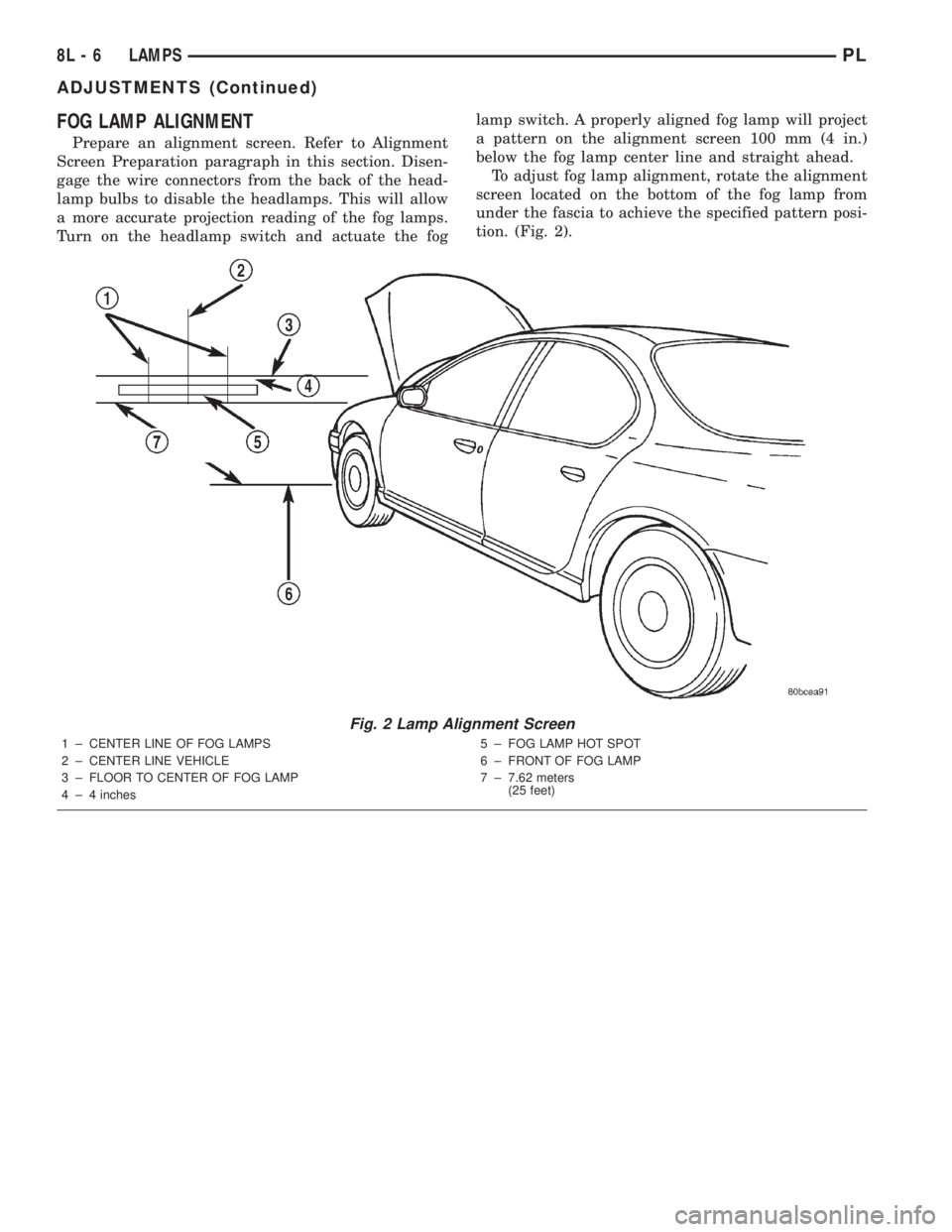

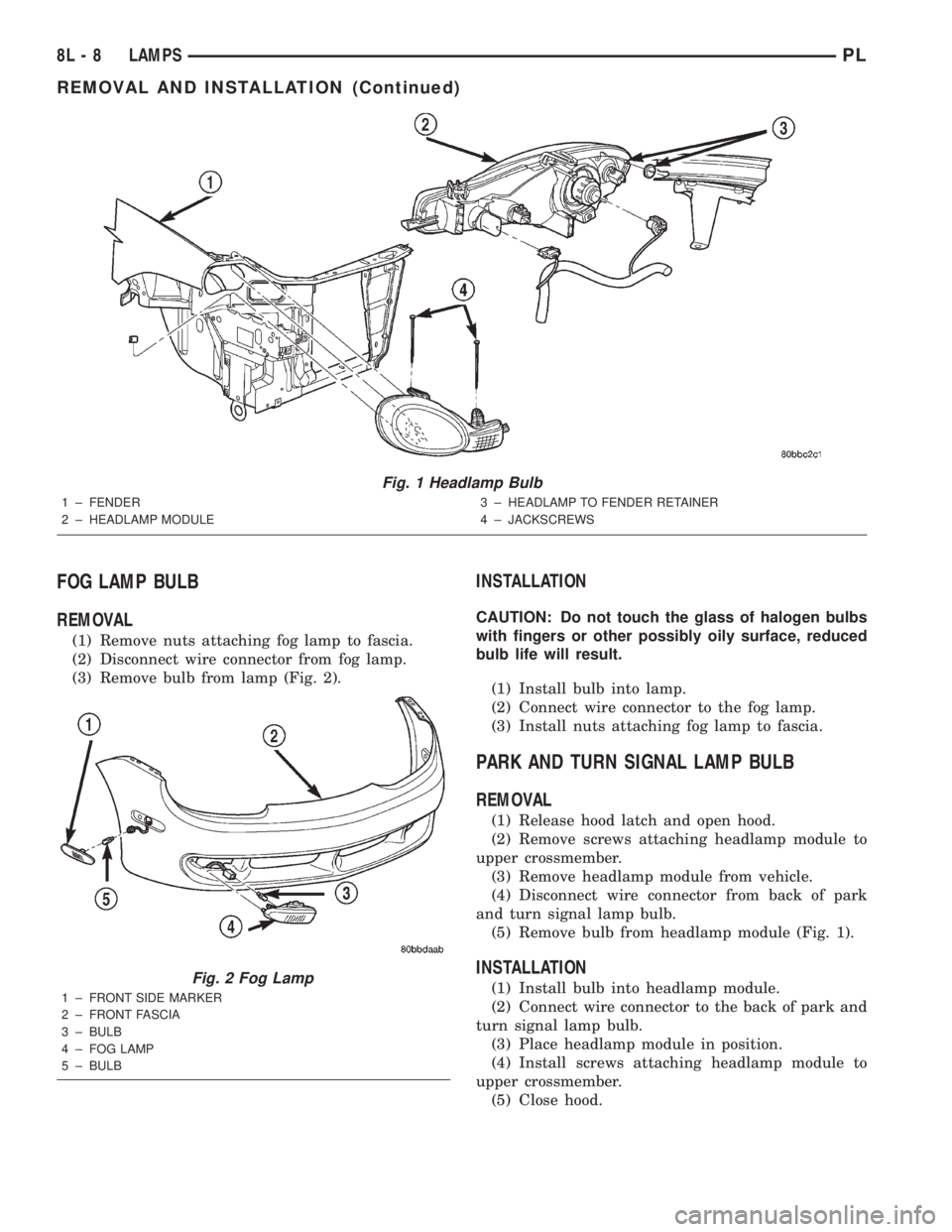

HEADLAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws attaching headlamp module to

upper crossmember.

(3) Remove headlamp module from vehicle.

(4) Disconnect wire connector from back of head-

lamp bulb.

(5) Rotate retaining ring counterclockwise one

quarter turn.

(6) Remove retaining ring from headlamp module.

(7) Remove bulb from headlamp module (Fig. 1).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

(1) Install bulb into headlamp module.

(2) Install retaining ring to headlamp module.

(3) Rotate retaining ring clockwise one quarter

turn.

(4) Connect wire connector to the back of head-

lamp bulb.

(5) Place headlamp module in position.

(6) Install screws attaching headlamp module to

upper crossmember.

(7) Close hood.

PLLAMPS 8L - 7

Page 315 of 1285

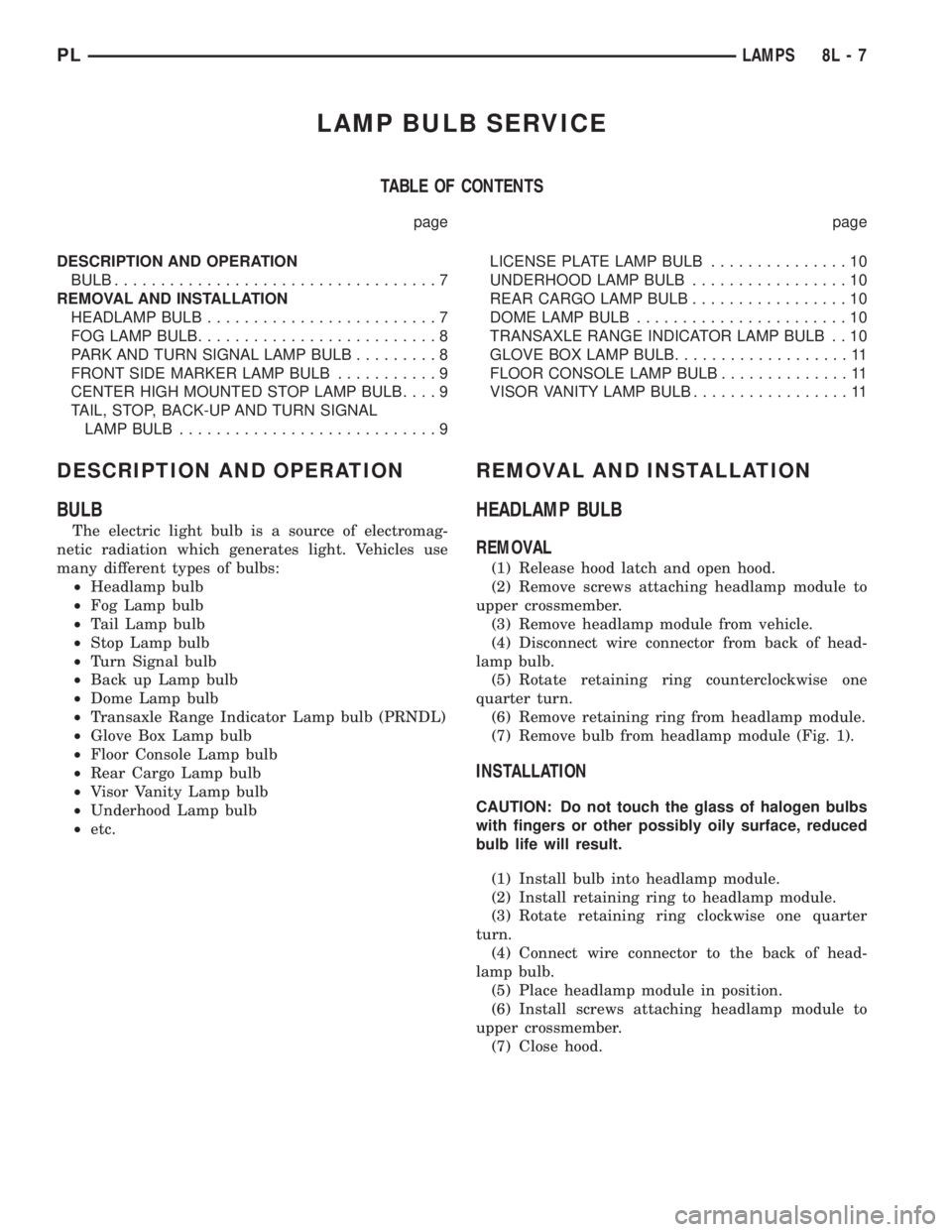

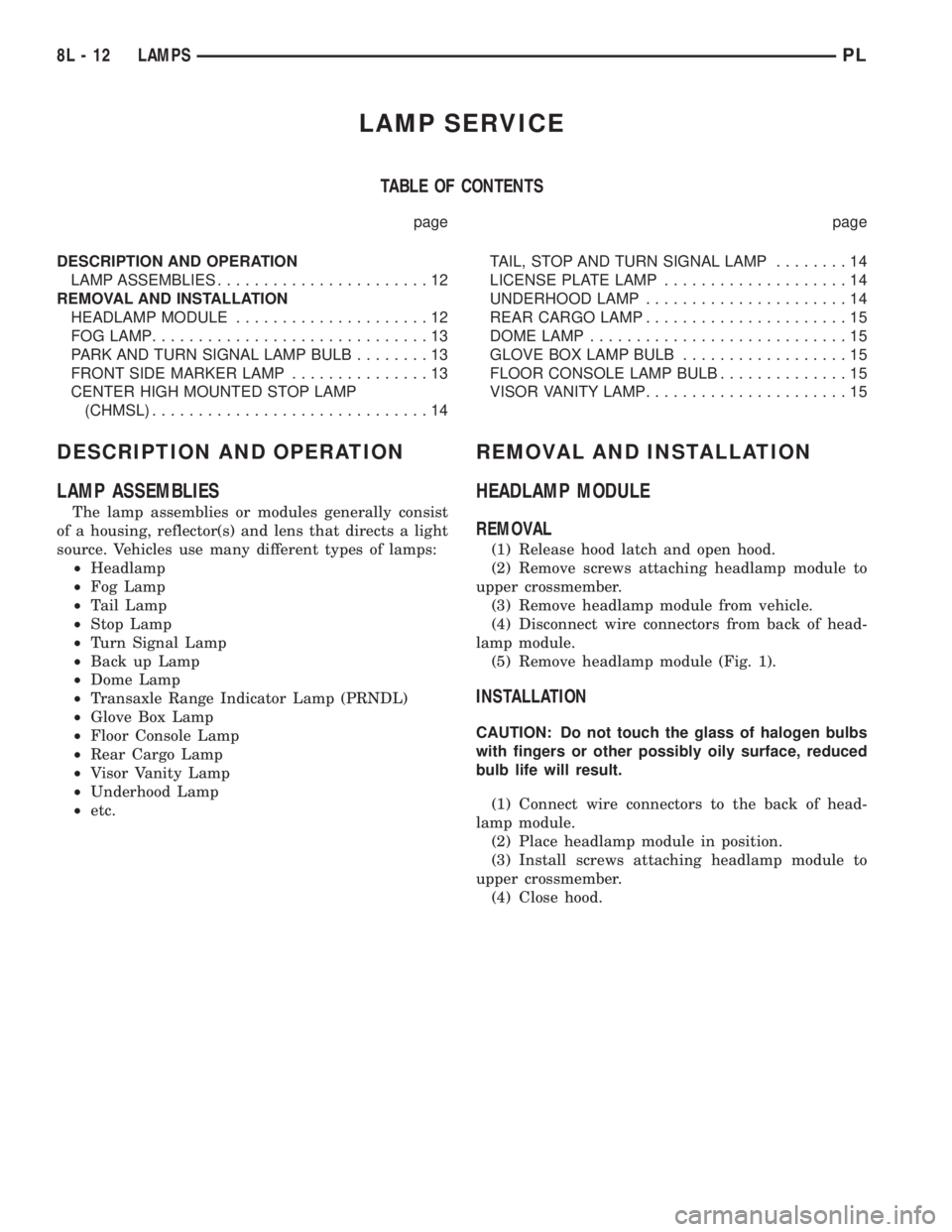

FOG LAMP BULB

REMOVAL

(1) Remove nuts attaching fog lamp to fascia.

(2) Disconnect wire connector from fog lamp.

(3) Remove bulb from lamp (Fig. 2).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

(1) Install bulb into lamp.

(2) Connect wire connector to the fog lamp.

(3) Install nuts attaching fog lamp to fascia.

PARK AND TURN SIGNAL LAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws attaching headlamp module to

upper crossmember.

(3) Remove headlamp module from vehicle.

(4) Disconnect wire connector from back of park

and turn signal lamp bulb.

(5) Remove bulb from headlamp module (Fig. 1).

INSTALLATION

(1) Install bulb into headlamp module.

(2) Connect wire connector to the back of park and

turn signal lamp bulb.

(3) Place headlamp module in position.

(4) Install screws attaching headlamp module to

upper crossmember.

(5) Close hood.

Fig. 1 Headlamp Bulb

1 ± FENDER

2 ± HEADLAMP MODULE3 ± HEADLAMP TO FENDER RETAINER

4 ± JACKSCREWS

Fig. 2 Fog Lamp

1 ± FRONT SIDE MARKER

2 ± FRONT FASCIA

3 ± BULB

4 ± FOG LAMP

5 ± BULB

8L - 8 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 319 of 1285

LAMP SERVICE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

LAMP ASSEMBLIES.......................12

REMOVAL AND INSTALLATION

HEADLAMP MODULE.....................12

FOG LAMP..............................13

PARK AND TURN SIGNAL LAMP BULB........13

FRONT SIDE MARKER LAMP...............13

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)..............................14TAIL, STOP AND TURN SIGNAL LAMP........14

LICENSE PLATE LAMP....................14

UNDERHOOD LAMP......................14

REAR CARGO LAMP......................15

DOME LAMP............................15

GLOVE BOX LAMP BULB..................15

FLOOR CONSOLE LAMP BULB..............15

VISOR VANITY LAMP......................15

DESCRIPTION AND OPERATION

LAMP ASSEMBLIES

The lamp assemblies or modules generally consist

of a housing, reflector(s) and lens that directs a light

source. Vehicles use many different types of lamps:

²Headlamp

²Fog Lamp

²Tail Lamp

²Stop Lamp

²Turn Signal Lamp

²Back up Lamp

²Dome Lamp

²Transaxle Range Indicator Lamp (PRNDL)

²Glove Box Lamp

²Floor Console Lamp

²Rear Cargo Lamp

²Visor Vanity Lamp

²Underhood Lamp

²etc.

REMOVAL AND INSTALLATION

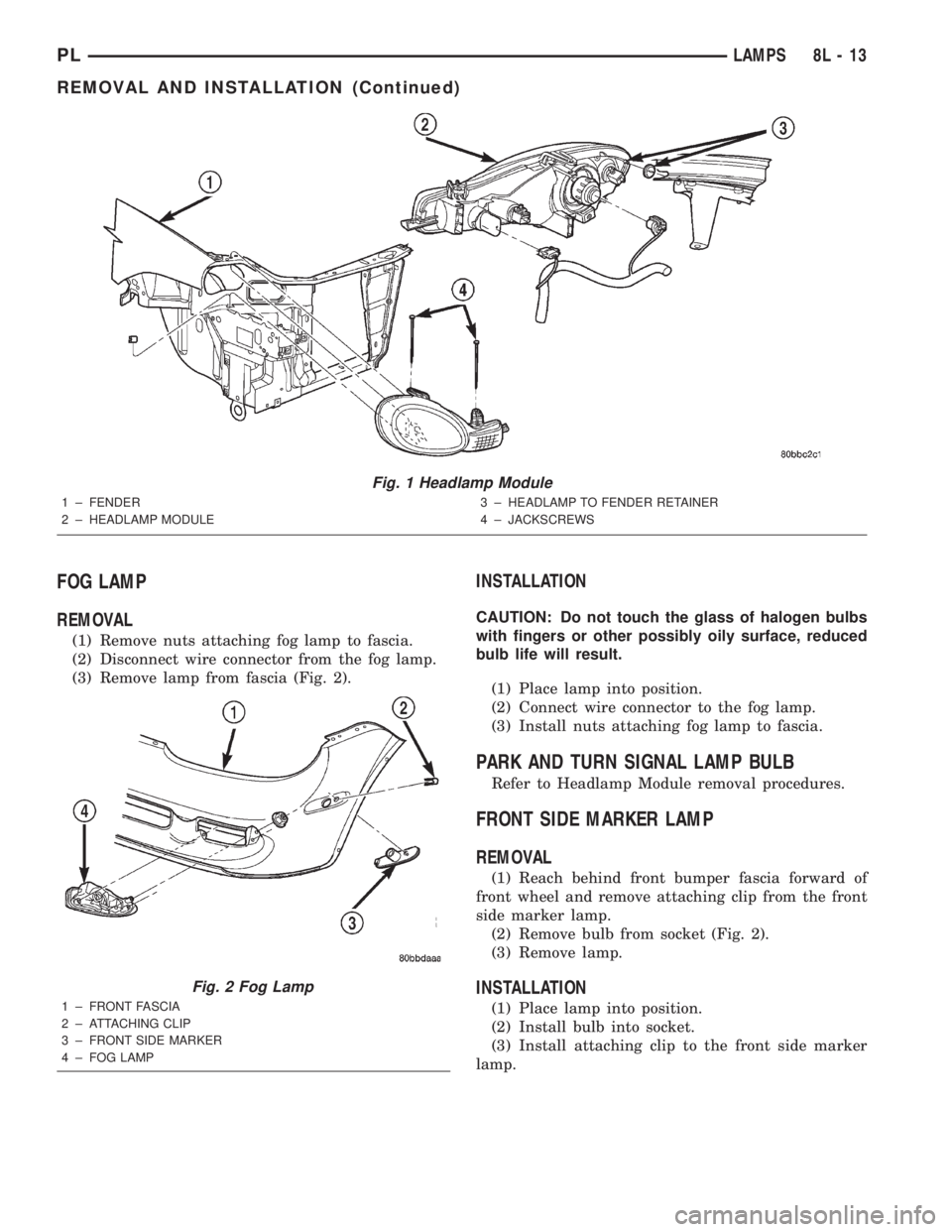

HEADLAMP MODULE

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws attaching headlamp module to

upper crossmember.

(3) Remove headlamp module from vehicle.

(4) Disconnect wire connectors from back of head-

lamp module.

(5) Remove headlamp module (Fig. 1).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

(1) Connect wire connectors to the back of head-

lamp module.

(2) Place headlamp module in position.

(3) Install screws attaching headlamp module to

upper crossmember.

(4) Close hood.

8L - 12 LAMPSPL

Page 320 of 1285

FOG LAMP

REMOVAL

(1) Remove nuts attaching fog lamp to fascia.

(2) Disconnect wire connector from the fog lamp.

(3) Remove lamp from fascia (Fig. 2).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

(1) Place lamp into position.

(2) Connect wire connector to the fog lamp.

(3) Install nuts attaching fog lamp to fascia.

PARK AND TURN SIGNAL LAMP BULB

Refer to Headlamp Module removal procedures.

FRONT SIDE MARKER LAMP

REMOVAL

(1) Reach behind front bumper fascia forward of

front wheel and remove attaching clip from the front

side marker lamp.

(2) Remove bulb from socket (Fig. 2).

(3) Remove lamp.

INSTALLATION

(1) Place lamp into position.

(2) Install bulb into socket.

(3) Install attaching clip to the front side marker

lamp.

Fig. 1 Headlamp Module

1 ± FENDER

2 ± HEADLAMP MODULE3 ± HEADLAMP TO FENDER RETAINER

4 ± JACKSCREWS

Fig. 2 Fog Lamp

1 ± FRONT FASCIA

2 ± ATTACHING CLIP

3 ± FRONT SIDE MARKER

4 ± FOG LAMP

PLLAMPS 8L - 13

REMOVAL AND INSTALLATION (Continued)

Page 324 of 1285

BULB APPLICATION

TABLE OF CONTENTS

page page

SPECIFICATIONS

EXTERIOR LAMPS........................17INTERIOR LAMPS........................17

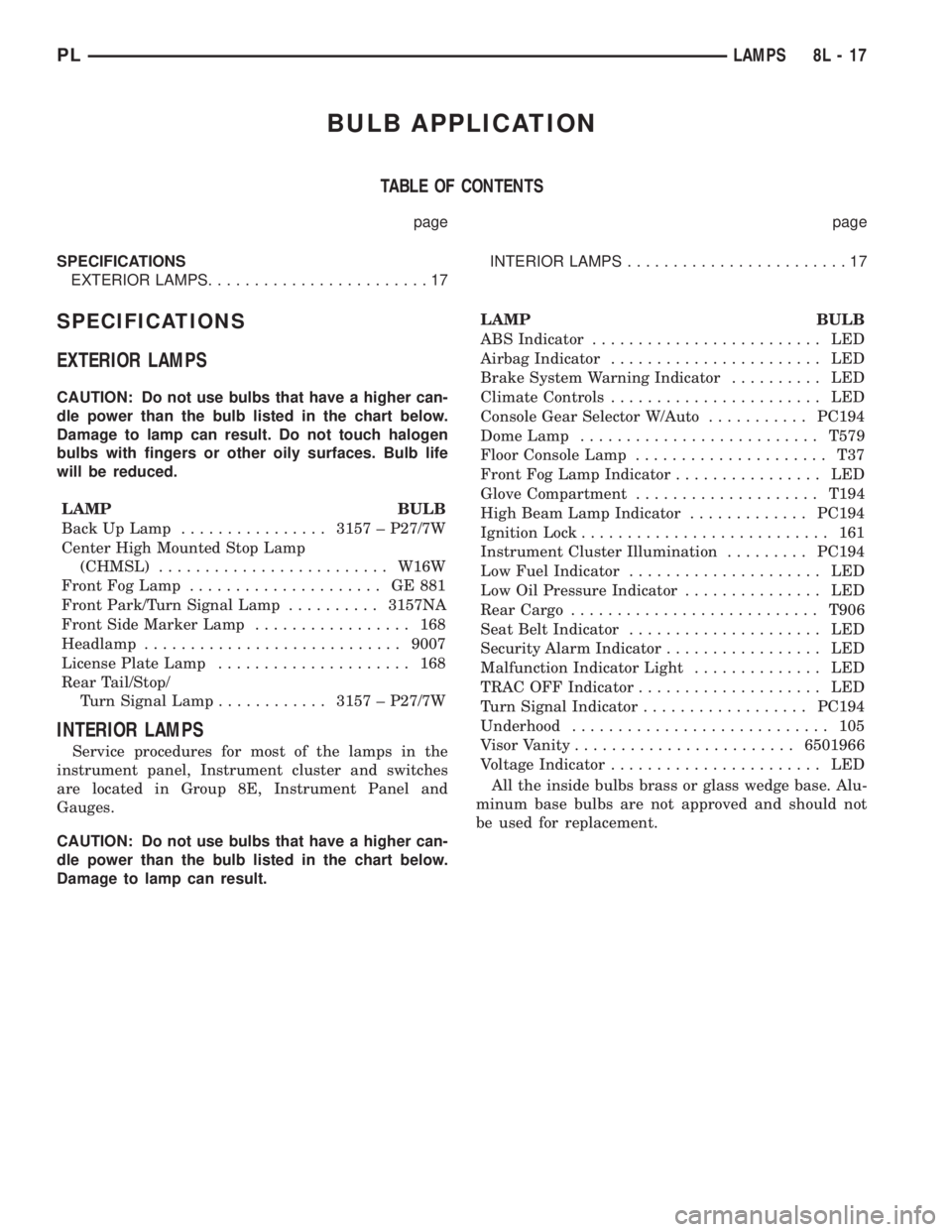

SPECIFICATIONS

EXTERIOR LAMPS

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the chart below.

Damage to lamp can result. Do not touch halogen

bulbs with fingers or other oily surfaces. Bulb life

will be reduced.

LAMP BULB

Back Up Lamp................3157 ± P27/7W

Center High Mounted Stop Lamp

(CHMSL).........................W16W

Front Fog Lamp..................... GE881

Front Park/Turn Signal Lamp..........3157NA

Front Side Marker Lamp................. 168

Headlamp............................9007

License Plate Lamp..................... 168

Rear Tail/Stop/

Turn Signal Lamp............3157 ± P27/7W

INTERIOR LAMPS

Service procedures for most of the lamps in the

instrument panel, Instrument cluster and switches

are located in Group 8E, Instrument Panel and

Gauges.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the chart below.

Damage to lamp can result.LAMP BULB

ABS Indicator......................... LED

Airbag Indicator....................... LED

Brake System Warning Indicator.......... LED

Climate Controls....................... LED

Console Gear Selector W/Auto...........PC194

Dome Lamp..........................T579

Floor Console Lamp..................... T37

Front Fog Lamp Indicator................ LED

Glove Compartment....................T194

High Beam Lamp Indicator.............PC194

Ignition Lock........................... 161

Instrument Cluster Illumination.........PC194

Low Fuel Indicator..................... LED

Low Oil Pressure Indicator............... LED

Rear Cargo...........................T906

Seat Belt Indicator..................... LED

Security Alarm Indicator................. LED

Malfunction Indicator Light.............. LED

TRAC OFF Indicator.................... LED

Turn Signal Indicator..................PC194

Underhood............................ 105

Visor Vanity........................6501966

Voltage Indicator....................... LED

All the inside bulbs brass or glass wedge base. Alu-

minum base bulbs are not approved and should not

be used for replacement.

PLLAMPS 8L - 17

Page 326 of 1285

LAMPS

TABLE OF CONTENTS

page page

LAMP DIAGNOSIS......................... 1

HEADLAMP ALIGNMENT.................... 2

LAMP BULB SERVICE...................... 4LAMP SERVICE........................... 12

BULB APPLICATION....................... 19

LAMP DIAGNOSIS

TABLE OF CONTENTS

page

GENERAL INFORMATION

HEADLAMP LEVELING MOTOR...............1

GENERAL INFORMATION

HEADLAMP LEVELING MOTOR

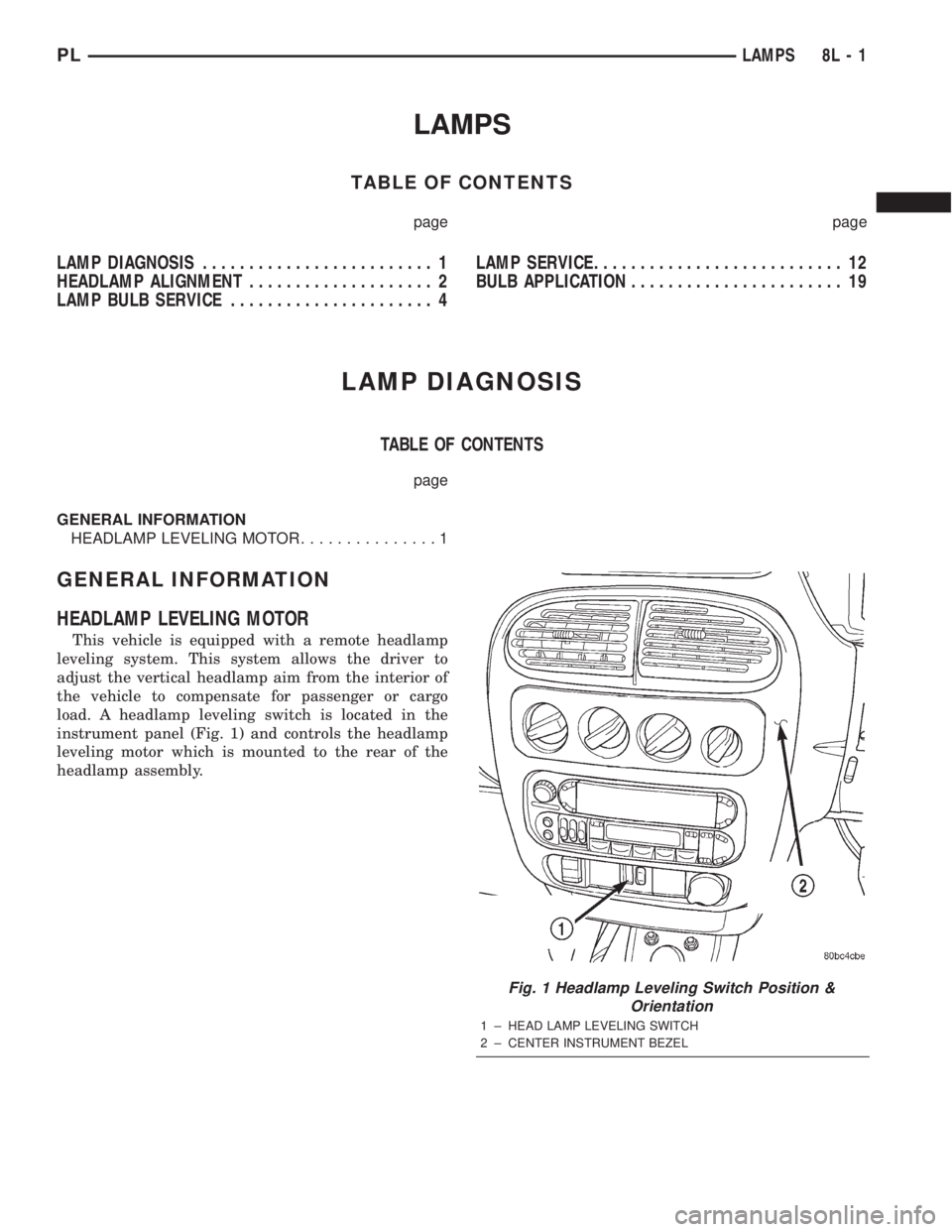

This vehicle is equipped with a remote headlamp

leveling system. This system allows the driver to

adjust the vertical headlamp aim from the interior of

the vehicle to compensate for passenger or cargo

load. A headlamp leveling switch is located in the

instrument panel (Fig. 1) and controls the headlamp

leveling motor which is mounted to the rear of the

headlamp assembly.

Fig. 1 Headlamp Leveling Switch Position &

Orientation

1 ± HEAD LAMP LEVELING SWITCH

2 ± CENTER INSTRUMENT BEZEL

PLLAMPS 8L - 1

Page 327 of 1285

HEADLAMP ALIGNMENT

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

HEADLAMP ALIGNMENT....................2

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION........2ADJUSTMENTS

HEADLAMP ADJUSTMENT USING

ALIGNMENT SCREEN....................2

DESCRIPTION AND OPERATION

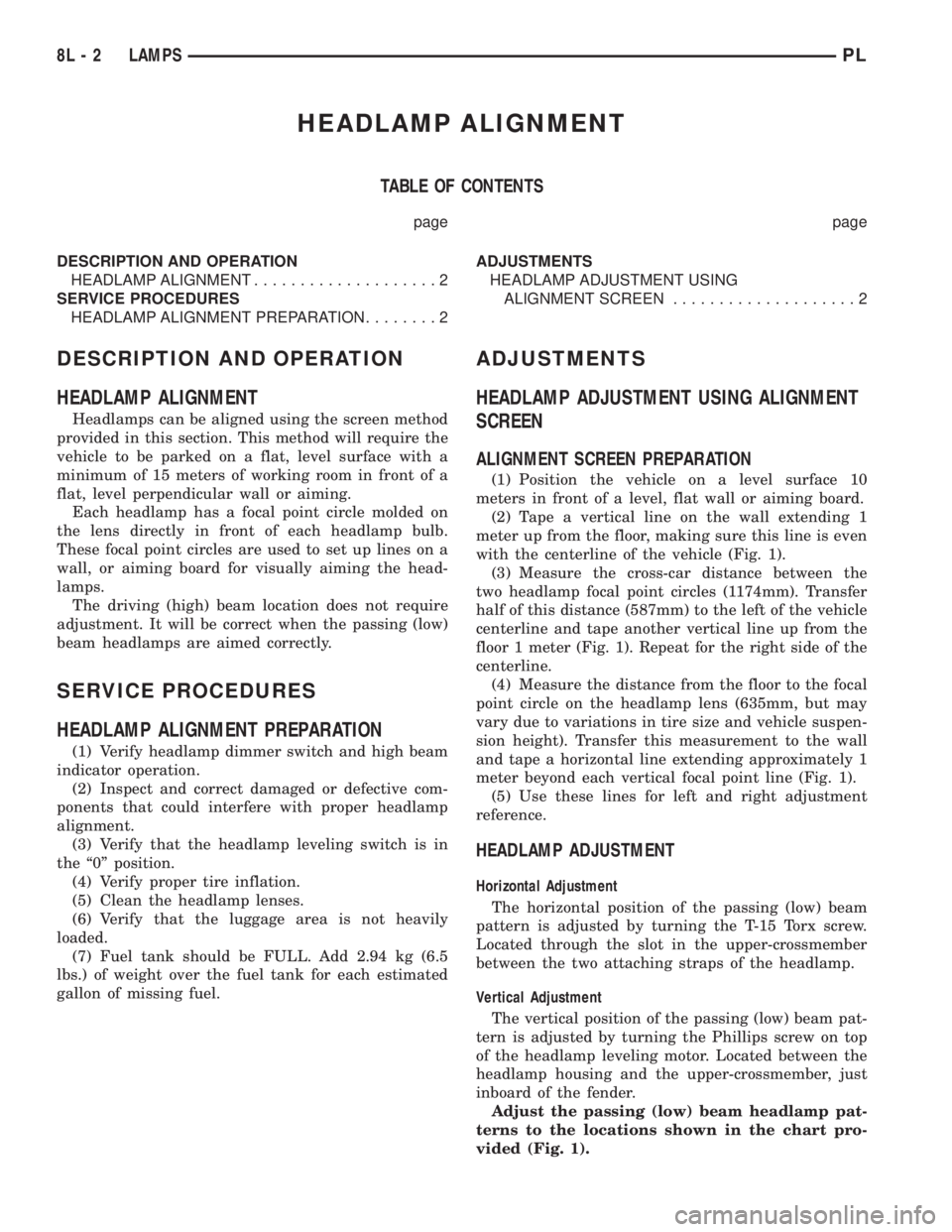

HEADLAMP ALIGNMENT

Headlamps can be aligned using the screen method

provided in this section. This method will require the

vehicle to be parked on a flat, level surface with a

minimum of 15 meters of working room in front of a

flat, level perpendicular wall or aiming.

Each headlamp has a focal point circle molded on

the lens directly in front of each headlamp bulb.

These focal point circles are used to set up lines on a

wall, or aiming board for visually aiming the head-

lamps.

The driving (high) beam location does not require

adjustment. It will be correct when the passing (low)

beam headlamps are aimed correctly.

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify that the headlamp leveling switch is in

the ª0º position.

(4) Verify proper tire inflation.

(5) Clean the headlamp lenses.

(6) Verify that the luggage area is not heavily

loaded.

(7) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP ADJUSTMENT USING ALIGNMENT

SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position the vehicle on a level surface 10

meters in front of a level, flat wall or aiming board.

(2) Tape a vertical line on the wall extending 1

meter up from the floor, making sure this line is even

with the centerline of the vehicle (Fig. 1).

(3) Measure the cross-car distance between the

two headlamp focal point circles (1174mm). Transfer

half of this distance (587mm) to the left of the vehicle

centerline and tape another vertical line up from the

floor 1 meter (Fig. 1). Repeat for the right side of the

centerline.

(4) Measure the distance from the floor to the focal

point circle on the headlamp lens (635mm, but may

vary due to variations in tire size and vehicle suspen-

sion height). Transfer this measurement to the wall

and tape a horizontal line extending approximately 1

meter beyond each vertical focal point line (Fig. 1).

(5) Use these lines for left and right adjustment

reference.

HEADLAMP ADJUSTMENT

Horizontal Adjustment

The horizontal position of the passing (low) beam

pattern is adjusted by turning the T-15 Torx screw.

Located through the slot in the upper-crossmember

between the two attaching straps of the headlamp.

Vertical Adjustment

The vertical position of the passing (low) beam pat-

tern is adjusted by turning the Phillips screw on top

of the headlamp leveling motor. Located between the

headlamp housing and the upper-crossmember, just

inboard of the fender.

Adjust the passing (low) beam headlamp pat-

terns to the locations shown in the chart pro-

vided (Fig. 1).

8L - 2 LAMPSPL