tow DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 26 of 1285

(6) Remove the two bolts attaching the strut to the

steering knuckle (Fig. 1).

(7) Lower the vehicle just enough to open the

hood, but without letting the tires touch the floor.

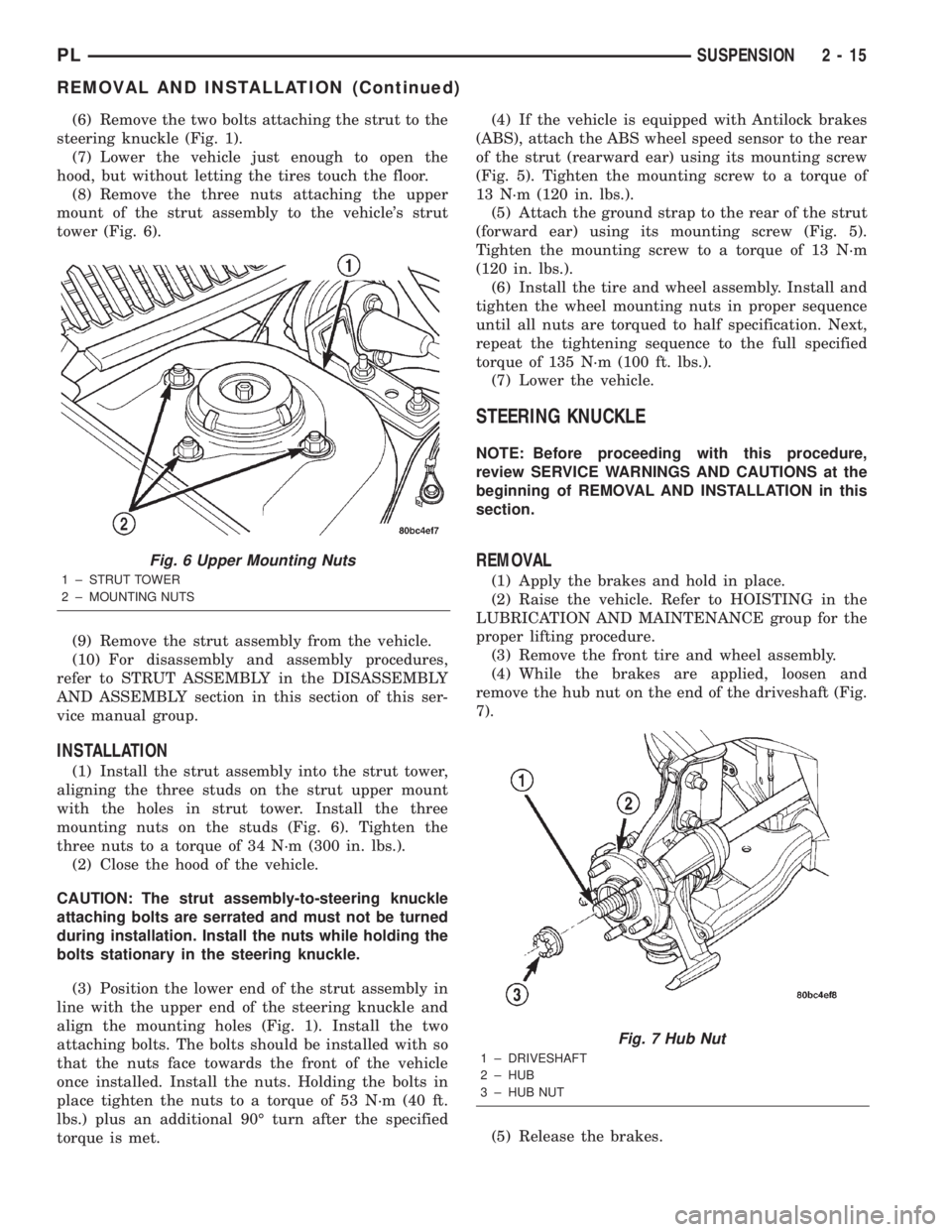

(8) Remove the three nuts attaching the upper

mount of the strut assembly to the vehicle's strut

tower (Fig. 6).

(9) Remove the strut assembly from the vehicle.

(10) For disassembly and assembly procedures,

refer to STRUT ASSEMBLY in the DISASSEMBLY

AND ASSEMBLY section in this section of this ser-

vice manual group.

INSTALLATION

(1) Install the strut assembly into the strut tower,

aligning the three studs on the strut upper mount

with the holes in strut tower. Install the three

mounting nuts on the studs (Fig. 6). Tighten the

three nuts to a torque of 34 N´m (300 in. lbs.).

(2) Close the hood of the vehicle.

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during installation. Install the nuts while holding the

bolts stationary in the steering knuckle.

(3) Position the lower end of the strut assembly in

line with the upper end of the steering knuckle and

align the mounting holes (Fig. 1). Install the two

attaching bolts. The bolts should be installed with so

that the nuts face towards the front of the vehicle

once installed. Install the nuts. Holding the bolts in

place tighten the nuts to a torque of 53 N´m (40 ft.

lbs.) plus an additional 90É turn after the specified

torque is met.(4) If the vehicle is equipped with Antilock brakes

(ABS), attach the ABS wheel speed sensor to the rear

of the strut (rearward ear) using its mounting screw

(Fig. 5). Tighten the mounting screw to a torque of

13 N´m (120 in. lbs.).

(5) Attach the ground strap to the rear of the strut

(forward ear) using its mounting screw (Fig. 5).

Tighten the mounting screw to a torque of 13 N´m

(120 in. lbs.).

(6) Install the tire and wheel assembly. Install and

tighten the wheel mounting nuts in proper sequence

until all nuts are torqued to half specification. Next,

repeat the tightening sequence to the full specified

torque of 135 N´m (100 ft. lbs.).

(7) Lower the vehicle.

STEERING KNUCKLE

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Apply the brakes and hold in place.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(3) Remove the front tire and wheel assembly.

(4) While the brakes are applied, loosen and

remove the hub nut on the end of the driveshaft (Fig.

7).

(5) Release the brakes.

Fig. 6 Upper Mounting Nuts

1 ± STRUT TOWER

2 ± MOUNTING NUTS

Fig. 7 Hub Nut

1 ± DRIVESHAFT

2 ± HUB

3 ± HUB NUT

PLSUSPENSION 2 - 15

REMOVAL AND INSTALLATION (Continued)

Page 28 of 1285

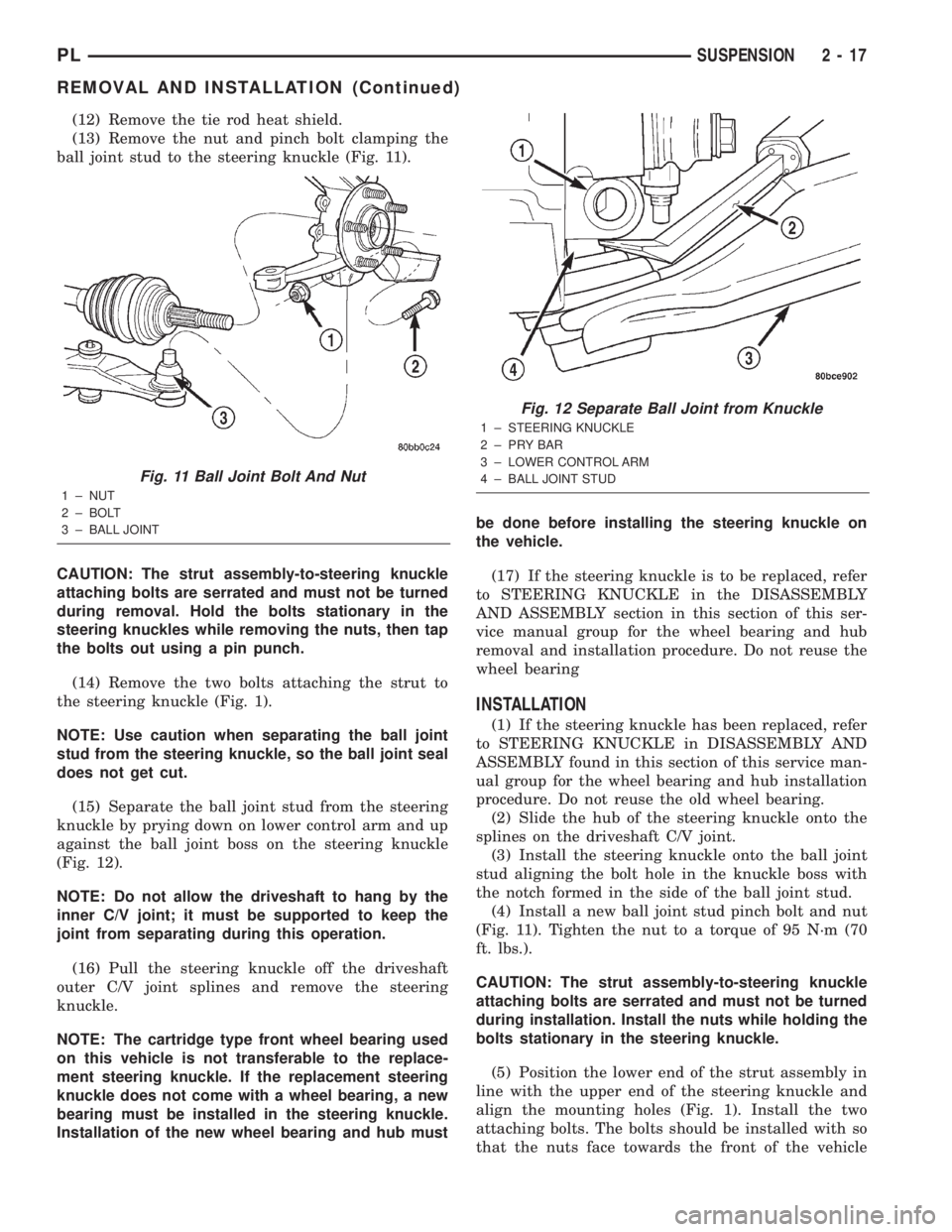

(12) Remove the tie rod heat shield.

(13) Remove the nut and pinch bolt clamping the

ball joint stud to the steering knuckle (Fig. 11).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during removal. Hold the bolts stationary in the

steering knuckles while removing the nuts, then tap

the bolts out using a pin punch.

(14) Remove the two bolts attaching the strut to

the steering knuckle (Fig. 1).

NOTE: Use caution when separating the ball joint

stud from the steering knuckle, so the ball joint seal

does not get cut.

(15) Separate the ball joint stud from the steering

knuckle by prying down on lower control arm and up

against the ball joint boss on the steering knuckle

(Fig. 12).

NOTE: Do not allow the driveshaft to hang by the

inner C/V joint; it must be supported to keep the

joint from separating during this operation.

(16) Pull the steering knuckle off the driveshaft

outer C/V joint splines and remove the steering

knuckle.

NOTE: The cartridge type front wheel bearing used

on this vehicle is not transferable to the replace-

ment steering knuckle. If the replacement steering

knuckle does not come with a wheel bearing, a new

bearing must be installed in the steering knuckle.

Installation of the new wheel bearing and hub mustbe done before installing the steering knuckle on

the vehicle.

(17) If the steering knuckle is to be replaced, refer

to STEERING KNUCKLE in the DISASSEMBLY

AND ASSEMBLY section in this section of this ser-

vice manual group for the wheel bearing and hub

removal and installation procedure. Do not reuse the

wheel bearing

INSTALLATION

(1) If the steering knuckle has been replaced, refer

to STEERING KNUCKLE in DISASSEMBLY AND

ASSEMBLY found in this section of this service man-

ual group for the wheel bearing and hub installation

procedure. Do not reuse the old wheel bearing.

(2) Slide the hub of the steering knuckle onto the

splines on the driveshaft C/V joint.

(3) Install the steering knuckle onto the ball joint

stud aligning the bolt hole in the knuckle boss with

the notch formed in the side of the ball joint stud.

(4) Install a new ball joint stud pinch bolt and nut

(Fig. 11). Tighten the nut to a torque of 95 N´m (70

ft. lbs.).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during installation. Install the nuts while holding the

bolts stationary in the steering knuckle.

(5) Position the lower end of the strut assembly in

line with the upper end of the steering knuckle and

align the mounting holes (Fig. 1). Install the two

attaching bolts. The bolts should be installed with so

that the nuts face towards the front of the vehicle

Fig. 11 Ball Joint Bolt And Nut

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

Fig. 12 Separate Ball Joint from Knuckle

1 ± STEERING KNUCKLE

2±PRYBAR

3 ± LOWER CONTROL ARM

4 ± BALL JOINT STUD

PLSUSPENSION 2 - 17

REMOVAL AND INSTALLATION (Continued)

Page 31 of 1285

with the notch formed in the side of the ball joint

stud.

(4) If the right lower control arm has been ser-

viced, install the engine torque strut (Fig. 16). Follow

the procedure described in the ENGINE service man-

ual group to properly align and tighten the torque

strut.

(5) Install a new ball joint stud pinch bolt and nut

(Fig. 15). Tighten the nut to a torque of 95 N´m (70

ft. lbs.).

(6) Rotate the forward ends of the stabilizer bar

into mounting position.

(7) Install both stabilizer bar links back on vehicle

(Fig. 14). Start each stabilizer bar link bolt with

bushing from the bottom, through the stabilizer bar,

inner link bushings, lower control arm, and into the

upper retainer/nut and bushing (Fig. 1). Do not fully

tighten the link assemblies at this time.

(8) Lower the vehicle to ground level.

NOTE: It may be necessary to put the vehicle on a

platform hoist or alignment rack to gain access to

the stabilizer bar mounting bolts with the vehicle at

curb height.

(9) Tighten each stabilizer bar link by holding the

upper retainer/nut with a wrench and turning the

link bolt. Tighten each link bolt to a torque of 23

N´m (200 in. lbs.).

(10) If previously loosened, tighten the stabilizer

bar cushion retainer bolts to a torque of 28 N´m (250

in. lbs.).

STABILIZER BAR (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

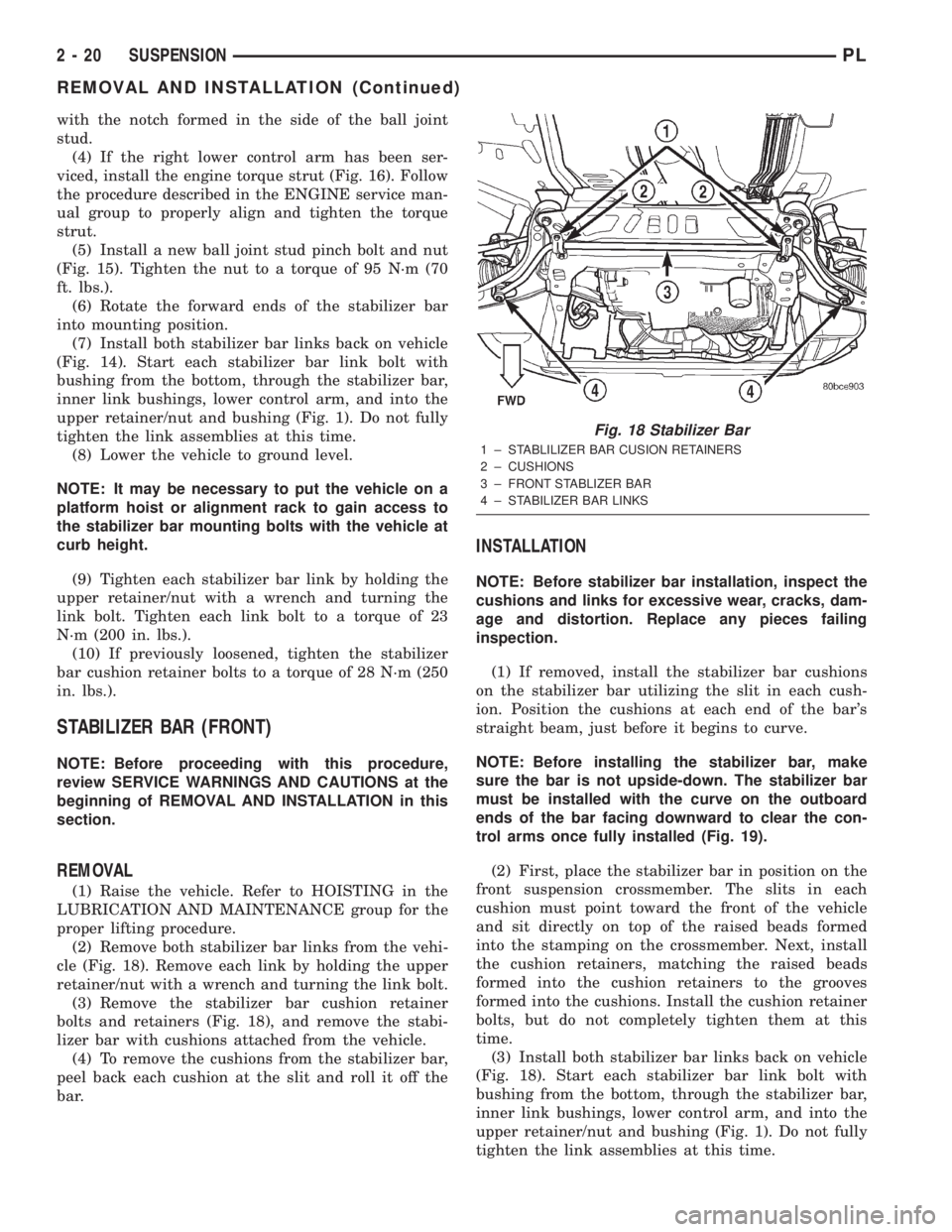

(2) Remove both stabilizer bar links from the vehi-

cle (Fig. 18). Remove each link by holding the upper

retainer/nut with a wrench and turning the link bolt.

(3) Remove the stabilizer bar cushion retainer

bolts and retainers (Fig. 18), and remove the stabi-

lizer bar with cushions attached from the vehicle.

(4) To remove the cushions from the stabilizer bar,

peel back each cushion at the slit and roll it off the

bar.

INSTALLATION

NOTE: Before stabilizer bar installation, inspect the

cushions and links for excessive wear, cracks, dam-

age and distortion. Replace any pieces failing

inspection.

(1) If removed, install the stabilizer bar cushions

on the stabilizer bar utilizing the slit in each cush-

ion. Position the cushions at each end of the bar's

straight beam, just before it begins to curve.

NOTE: Before installing the stabilizer bar, make

sure the bar is not upside-down. The stabilizer bar

must be installed with the curve on the outboard

ends of the bar facing downward to clear the con-

trol arms once fully installed (Fig. 19).

(2) First, place the stabilizer bar in position on the

front suspension crossmember. The slits in each

cushion must point toward the front of the vehicle

and sit directly on top of the raised beads formed

into the stamping on the crossmember. Next, install

the cushion retainers, matching the raised beads

formed into the cushion retainers to the grooves

formed into the cushions. Install the cushion retainer

bolts, but do not completely tighten them at this

time.

(3) Install both stabilizer bar links back on vehicle

(Fig. 18). Start each stabilizer bar link bolt with

bushing from the bottom, through the stabilizer bar,

inner link bushings, lower control arm, and into the

upper retainer/nut and bushing (Fig. 1). Do not fully

tighten the link assemblies at this time.

Fig. 18 Stabilizer Bar

1 ± STABLILIZER BAR CUSION RETAINERS

2 ± CUSHIONS

3 ± FRONT STABLIZER BAR

4 ± STABILIZER BAR LINKS

2 - 20 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 35 of 1285

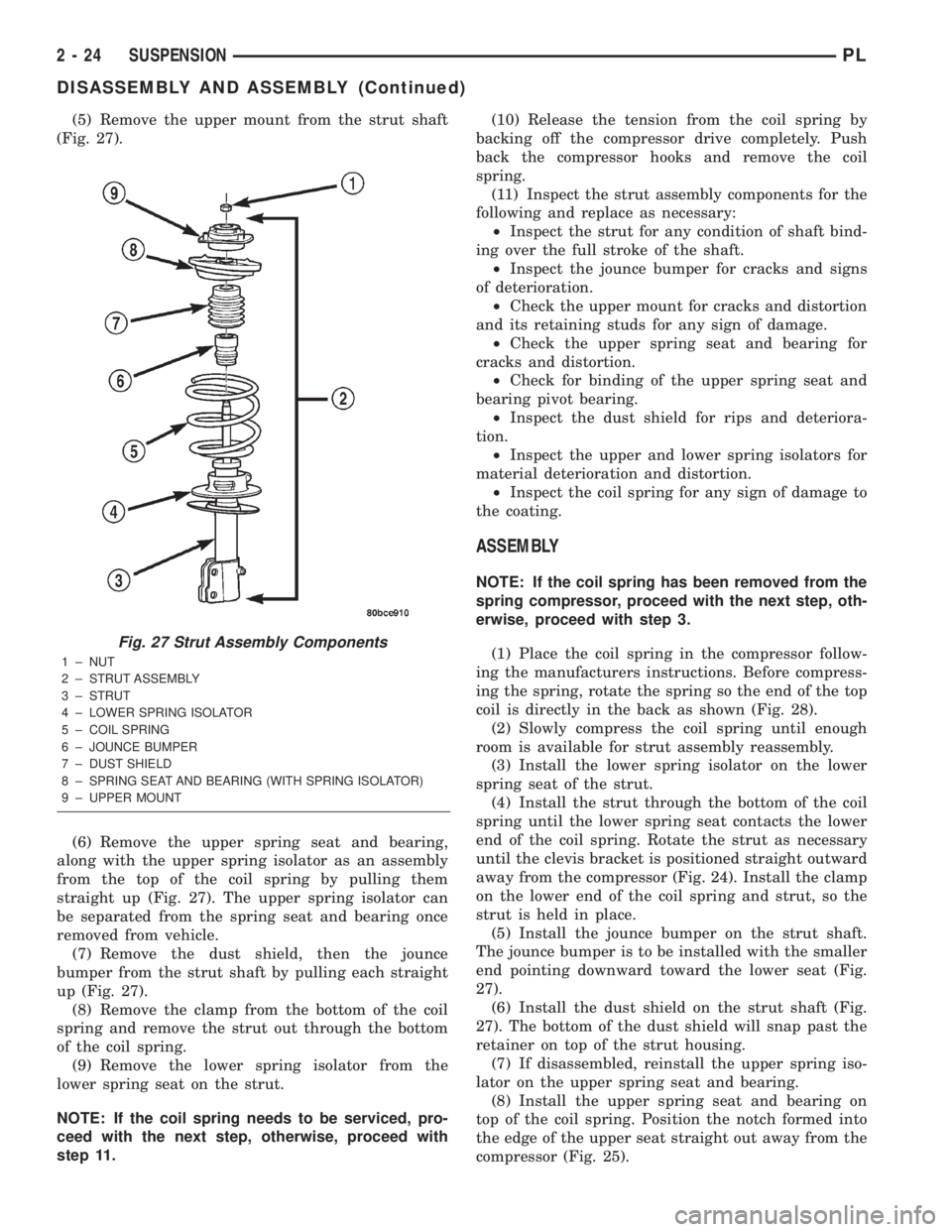

(5) Remove the upper mount from the strut shaft

(Fig. 27).

(6) Remove the upper spring seat and bearing,

along with the upper spring isolator as an assembly

from the top of the coil spring by pulling them

straight up (Fig. 27). The upper spring isolator can

be separated from the spring seat and bearing once

removed from vehicle.

(7) Remove the dust shield, then the jounce

bumper from the strut shaft by pulling each straight

up (Fig. 27).

(8) Remove the clamp from the bottom of the coil

spring and remove the strut out through the bottom

of the coil spring.

(9) Remove the lower spring isolator from the

lower spring seat on the strut.

NOTE: If the coil spring needs to be serviced, pro-

ceed with the next step, otherwise, proceed with

step 11.(10) Release the tension from the coil spring by

backing off the compressor drive completely. Push

back the compressor hooks and remove the coil

spring.

(11) Inspect the strut assembly components for the

following and replace as necessary:

²Inspect the strut for any condition of shaft bind-

ing over the full stroke of the shaft.

²Inspect the jounce bumper for cracks and signs

of deterioration.

²Check the upper mount for cracks and distortion

and its retaining studs for any sign of damage.

²Check the upper spring seat and bearing for

cracks and distortion.

²Check for binding of the upper spring seat and

bearing pivot bearing.

²Inspect the dust shield for rips and deteriora-

tion.

²Inspect the upper and lower spring isolators for

material deterioration and distortion.

²Inspect the coil spring for any sign of damage to

the coating.

ASSEMBLY

NOTE: If the coil spring has been removed from the

spring compressor, proceed with the next step, oth-

erwise, proceed with step 3.

(1) Place the coil spring in the compressor follow-

ing the manufacturers instructions. Before compress-

ing the spring, rotate the spring so the end of the top

coil is directly in the back as shown (Fig. 28).

(2) Slowly compress the coil spring until enough

room is available for strut assembly reassembly.

(3) Install the lower spring isolator on the lower

spring seat of the strut.

(4) Install the strut through the bottom of the coil

spring until the lower spring seat contacts the lower

end of the coil spring. Rotate the strut as necessary

until the clevis bracket is positioned straight outward

away from the compressor (Fig. 24). Install the clamp

on the lower end of the coil spring and strut, so the

strut is held in place.

(5) Install the jounce bumper on the strut shaft.

The jounce bumper is to be installed with the smaller

end pointing downward toward the lower seat (Fig.

27).

(6) Install the dust shield on the strut shaft (Fig.

27). The bottom of the dust shield will snap past the

retainer on top of the strut housing.

(7) If disassembled, reinstall the upper spring iso-

lator on the upper spring seat and bearing.

(8) Install the upper spring seat and bearing on

top of the coil spring. Position the notch formed into

the edge of the upper seat straight out away from the

compressor (Fig. 25).

Fig. 27 Strut Assembly Components

1 ± NUT

2 ± STRUT ASSEMBLY

3 ± STRUT

4 ± LOWER SPRING ISOLATOR

5 ± COIL SPRING

6 ± JOUNCE BUMPER

7 ± DUST SHIELD

8 ± SPRING SEAT AND BEARING (WITH SPRING ISOLATOR)

9 ± UPPER MOUNT

2 - 24 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 39 of 1285

ASSEMBLY

(1) Wipe the bore of the steering knuckle clean of

any grease or dirt with a clean, dry shop towel.

(2) Place the new wheel bearing into the bore of

the steering knuckle. Be sure the wheel bearing is

placed squarely into the bore. Place the steering

knuckle in an arbor press with Receiver, Special Tool

C-4698-2, supporting the steering knuckle (Fig. 39).

Place Driver, Special Tool 5052, on the outer race of

the wheel bearing. Press the wheel bearing into the

steering knuckle until it is fully bottomed in the bore

of the steering knuckle. Remove the knuckle from the

press.

NOTE: Only the original or identical replacement

bolts are to be used to mount the bearing retainer

plate to the steering knuckle.

(3) Install the bearing retainer plate on the steer-

ing knuckle (Fig. 40). Install the three bearing

retainer mounting bolts. Tighten the bearing retainer

plate mounting bolts to a torque of 28 N´m (250 in.

lbs.).

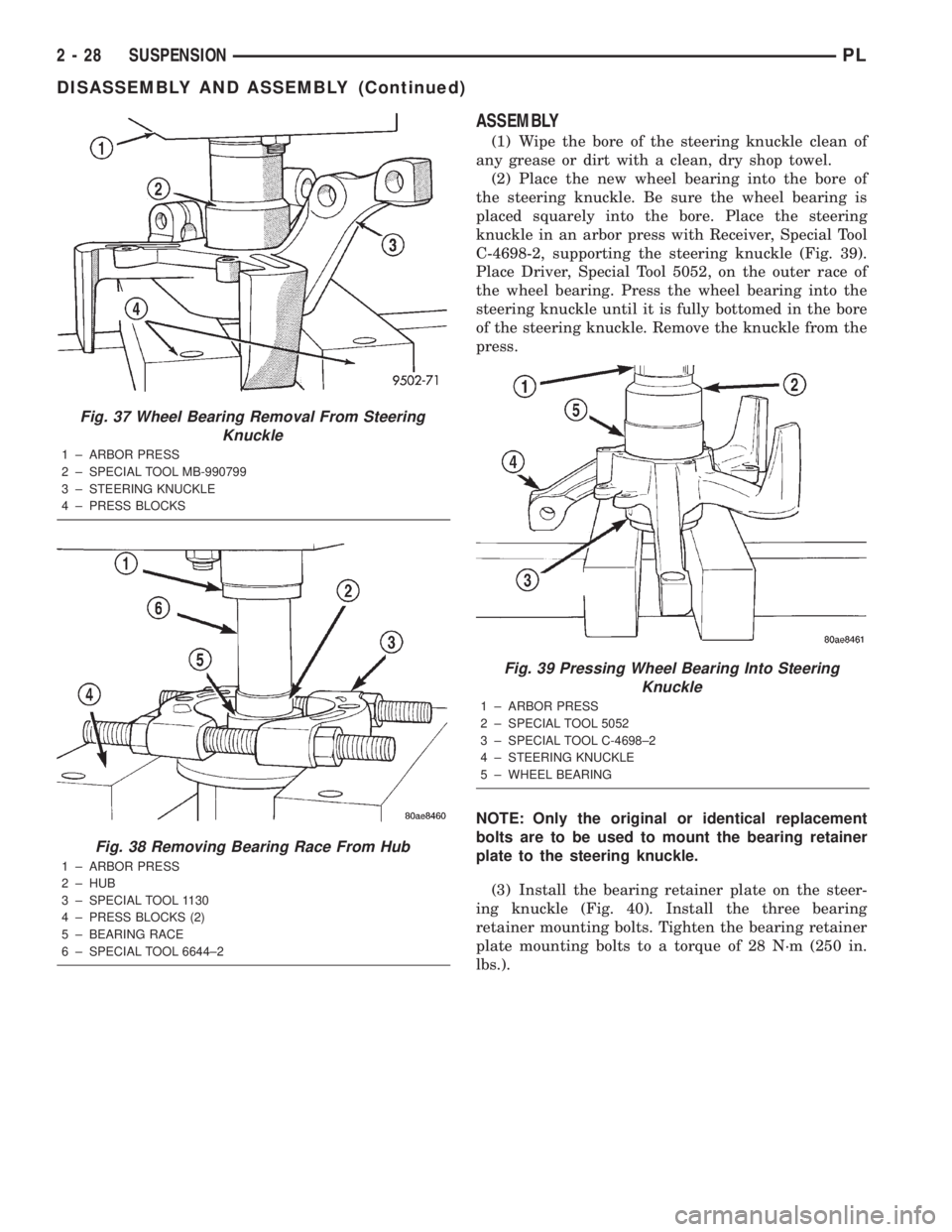

Fig. 37 Wheel Bearing Removal From Steering

Knuckle

1 ± ARBOR PRESS

2 ± SPECIAL TOOL MB-990799

3 ± STEERING KNUCKLE

4 ± PRESS BLOCKS

Fig. 38 Removing Bearing Race From Hub

1 ± ARBOR PRESS

2 ± HUB

3 ± SPECIAL TOOL 1130

4 ± PRESS BLOCKS (2)

5 ± BEARING RACE

6 ± SPECIAL TOOL 6644±2

Fig. 39 Pressing Wheel Bearing Into Steering

Knuckle

1 ± ARBOR PRESS

2 ± SPECIAL TOOL 5052

3 ± SPECIAL TOOL C-4698±2

4 ± STEERING KNUCKLE

5 ± WHEEL BEARING

2 - 28 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 44 of 1285

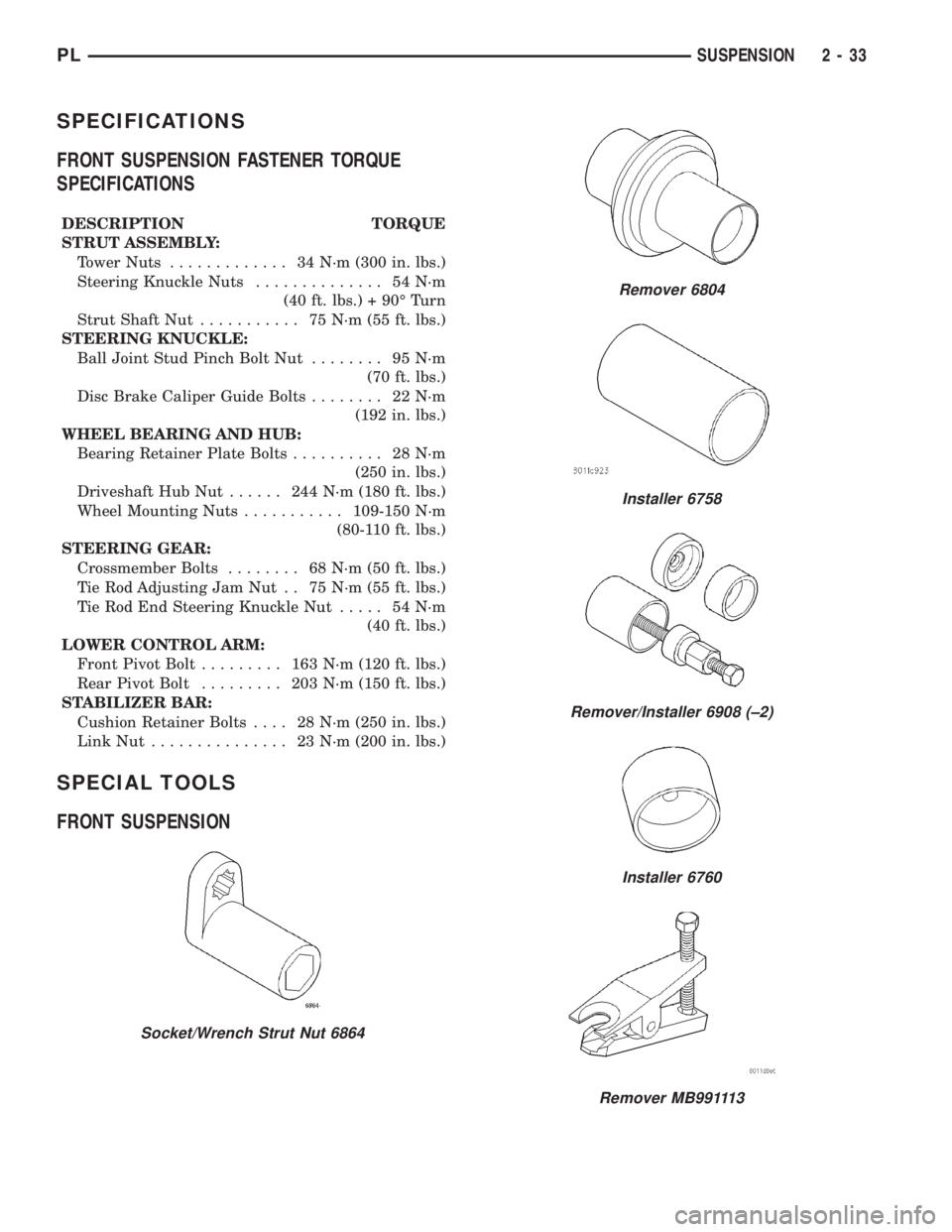

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

STRUT ASSEMBLY:

Tower Nuts............. 34N´m(300 in. lbs.)

Steering Knuckle Nuts.............. 54N´m

(40 ft. lbs.) + 90É Turn

Strut Shaft Nut........... 75N´m(55ft.lbs.)

STEERING KNUCKLE:

Ball Joint Stud Pinch Bolt Nut........ 95N´m

(70 ft. lbs.)

Disc Brake Caliper Guide Bolts........ 22N´m

(192 in. lbs.)

WHEEL BEARING AND HUB:

Bearing Retainer Plate Bolts.......... 28N´m

(250 in. lbs.)

Driveshaft Hub Nut...... 244N´m(180 ft. lbs.)

Wheel Mounting Nuts...........109-150 N´m

(80-110 ft. lbs.)

STEERING GEAR:

Crossmember Bolts........ 68N´m(50ft.lbs.)

Tie Rod Adjusting Jam Nut . . 75 N´m (55 ft. lbs.)

Tie Rod End Steering Knuckle Nut..... 54N´m

(40 ft. lbs.)

LOWER CONTROL ARM:

Front Pivot Bolt......... 163N´m(120 ft. lbs.)

Rear Pivot Bolt......... 203N´m(150 ft. lbs.)

STABILIZER BAR:

Cushion Retainer Bolts.... 28N´m(250 in. lbs.)

Link Nut............... 23N´m(200 in. lbs.)

SPECIAL TOOLS

FRONT SUSPENSION

Socket/Wrench Strut Nut 6864

Remover 6804

Installer 6758

Remover/Installer 6908 (±2)

Installer 6760

Remover MB991113

PLSUSPENSION 2 - 33

Page 48 of 1285

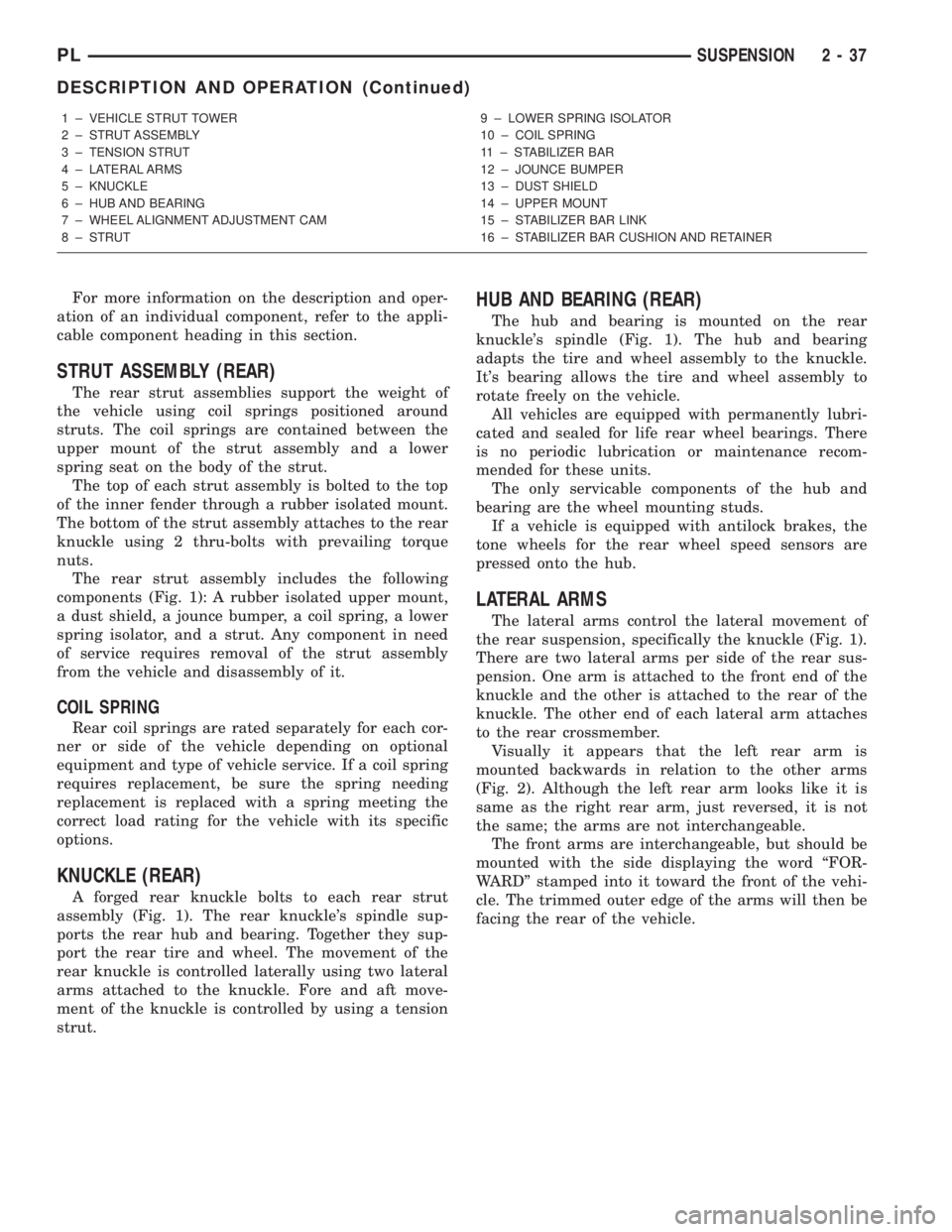

For more information on the description and oper-

ation of an individual component, refer to the appli-

cable component heading in this section.

STRUT ASSEMBLY (REAR)

The rear strut assemblies support the weight of

the vehicle using coil springs positioned around

struts. The coil springs are contained between the

upper mount of the strut assembly and a lower

spring seat on the body of the strut.

The top of each strut assembly is bolted to the top

of the inner fender through a rubber isolated mount.

The bottom of the strut assembly attaches to the rear

knuckle using 2 thru-bolts with prevailing torque

nuts.

The rear strut assembly includes the following

components (Fig. 1): A rubber isolated upper mount,

a dust shield, a jounce bumper, a coil spring, a lower

spring isolator, and a strut. Any component in need

of service requires removal of the strut assembly

from the vehicle and disassembly of it.

COIL SPRING

Rear coil springs are rated separately for each cor-

ner or side of the vehicle depending on optional

equipment and type of vehicle service. If a coil spring

requires replacement, be sure the spring needing

replacement is replaced with a spring meeting the

correct load rating for the vehicle with its specific

options.

KNUCKLE (REAR)

A forged rear knuckle bolts to each rear strut

assembly (Fig. 1). The rear knuckle's spindle sup-

ports the rear hub and bearing. Together they sup-

port the rear tire and wheel. The movement of the

rear knuckle is controlled laterally using two lateral

arms attached to the knuckle. Fore and aft move-

ment of the knuckle is controlled by using a tension

strut.

HUB AND BEARING (REAR)

The hub and bearing is mounted on the rear

knuckle's spindle (Fig. 1). The hub and bearing

adapts the tire and wheel assembly to the knuckle.

It's bearing allows the tire and wheel assembly to

rotate freely on the vehicle.

All vehicles are equipped with permanently lubri-

cated and sealed for life rear wheel bearings. There

is no periodic lubrication or maintenance recom-

mended for these units.

The only servicable components of the hub and

bearing are the wheel mounting studs.

If a vehicle is equipped with antilock brakes, the

tone wheels for the rear wheel speed sensors are

pressed onto the hub.

LATERAL ARMS

The lateral arms control the lateral movement of

the rear suspension, specifically the knuckle (Fig. 1).

There are two lateral arms per side of the rear sus-

pension. One arm is attached to the front end of the

knuckle and the other is attached to the rear of the

knuckle. The other end of each lateral arm attaches

to the rear crossmember.

Visually it appears that the left rear arm is

mounted backwards in relation to the other arms

(Fig. 2). Although the left rear arm looks like it is

same as the right rear arm, just reversed, it is not

the same; the arms are not interchangeable.

The front arms are interchangeable, but should be

mounted with the side displaying the word ªFOR-

WARDº stamped into it toward the front of the vehi-

cle. The trimmed outer edge of the arms will then be

facing the rear of the vehicle.

1 ± VEHICLE STRUT TOWER

2 ± STRUT ASSEMBLY

3 ± TENSION STRUT

4 ± LATERAL ARMS

5 ± KNUCKLE

6 ± HUB AND BEARING

7 ± WHEEL ALIGNMENT ADJUSTMENT CAM

8 ± STRUT9 ± LOWER SPRING ISOLATOR

10 ± COIL SPRING

11 ± STABILIZER BAR

12 ± JOUNCE BUMPER

13 ± DUST SHIELD

14 ± UPPER MOUNT

15 ± STABILIZER BAR LINK

16 ± STABILIZER BAR CUSHION AND RETAINER

PLSUSPENSION 2 - 37

DESCRIPTION AND OPERATION (Continued)

Page 52 of 1285

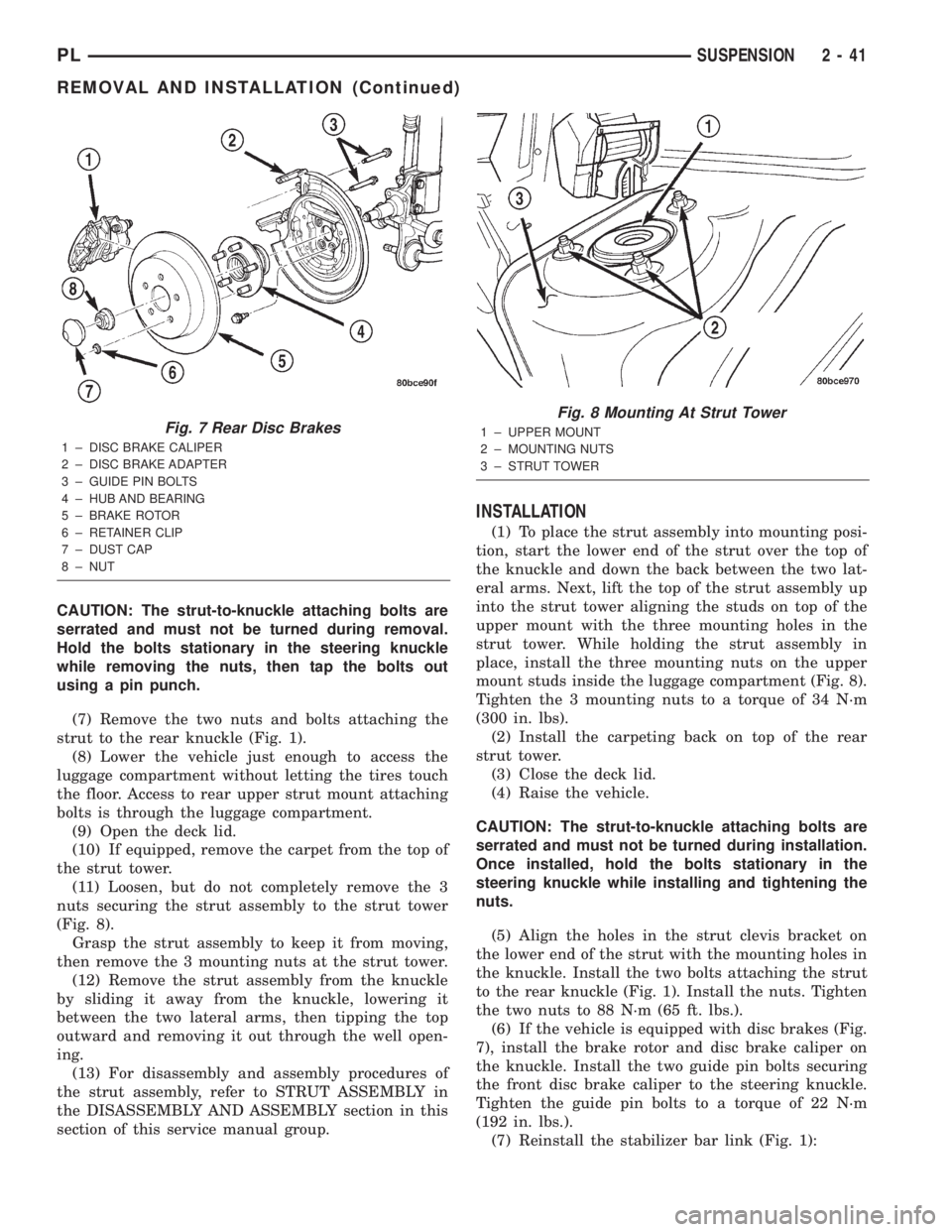

CAUTION: The strut-to-knuckle attaching bolts are

serrated and must not be turned during removal.

Hold the bolts stationary in the steering knuckle

while removing the nuts, then tap the bolts out

using a pin punch.

(7) Remove the two nuts and bolts attaching the

strut to the rear knuckle (Fig. 1).

(8) Lower the vehicle just enough to access the

luggage compartment without letting the tires touch

the floor. Access to rear upper strut mount attaching

bolts is through the luggage compartment.

(9) Open the deck lid.

(10) If equipped, remove the carpet from the top of

the strut tower.

(11) Loosen, but do not completely remove the 3

nuts securing the strut assembly to the strut tower

(Fig. 8).

Grasp the strut assembly to keep it from moving,

then remove the 3 mounting nuts at the strut tower.

(12) Remove the strut assembly from the knuckle

by sliding it away from the knuckle, lowering it

between the two lateral arms, then tipping the top

outward and removing it out through the well open-

ing.

(13) For disassembly and assembly procedures of

the strut assembly, refer to STRUT ASSEMBLY in

the DISASSEMBLY AND ASSEMBLY section in this

section of this service manual group.

INSTALLATION

(1) To place the strut assembly into mounting posi-

tion, start the lower end of the strut over the top of

the knuckle and down the back between the two lat-

eral arms. Next, lift the top of the strut assembly up

into the strut tower aligning the studs on top of the

upper mount with the three mounting holes in the

strut tower. While holding the strut assembly in

place, install the three mounting nuts on the upper

mount studs inside the luggage compartment (Fig. 8).

Tighten the 3 mounting nuts to a torque of 34 N´m

(300 in. lbs).

(2) Install the carpeting back on top of the rear

strut tower.

(3) Close the deck lid.

(4) Raise the vehicle.

CAUTION: The strut-to-knuckle attaching bolts are

serrated and must not be turned during installation.

Once installed, hold the bolts stationary in the

steering knuckle while installing and tightening the

nuts.

(5) Align the holes in the strut clevis bracket on

the lower end of the strut with the mounting holes in

the knuckle. Install the two bolts attaching the strut

to the rear knuckle (Fig. 1). Install the nuts. Tighten

the two nuts to 88 N´m (65 ft. lbs.).

(6) If the vehicle is equipped with disc brakes (Fig.

7), install the brake rotor and disc brake caliper on

the knuckle. Install the two guide pin bolts securing

the front disc brake caliper to the steering knuckle.

Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).

(7) Reinstall the stabilizer bar link (Fig. 1):

Fig. 7 Rear Disc Brakes

1 ± DISC BRAKE CALIPER

2 ± DISC BRAKE ADAPTER

3 ± GUIDE PIN BOLTS

4 ± HUB AND BEARING

5 ± BRAKE ROTOR

6 ± RETAINER CLIP

7 ± DUST CAP

8 ± NUT

Fig. 8 Mounting At Strut Tower

1 ± UPPER MOUNT

2 ± MOUNTING NUTS

3 ± STRUT TOWER

PLSUSPENSION 2 - 41

REMOVAL AND INSTALLATION (Continued)

Page 56 of 1285

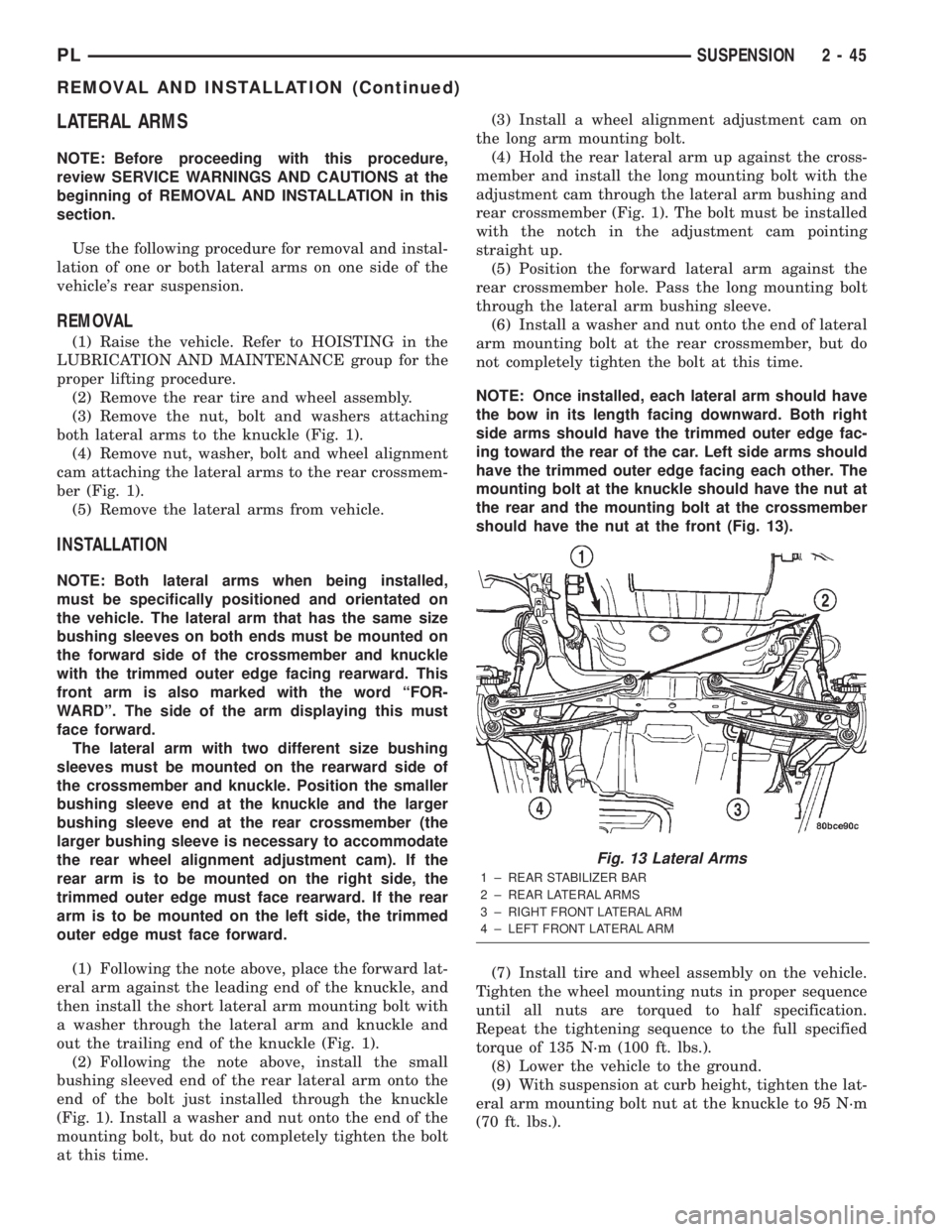

LATERAL ARMS

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

Use the following procedure for removal and instal-

lation of one or both lateral arms on one side of the

vehicle's rear suspension.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the rear tire and wheel assembly.

(3) Remove the nut, bolt and washers attaching

both lateral arms to the knuckle (Fig. 1).

(4) Remove nut, washer, bolt and wheel alignment

cam attaching the lateral arms to the rear crossmem-

ber (Fig. 1).

(5) Remove the lateral arms from vehicle.

INSTALLATION

NOTE: Both lateral arms when being installed,

must be specifically positioned and orientated on

the vehicle. The lateral arm that has the same size

bushing sleeves on both ends must be mounted on

the forward side of the crossmember and knuckle

with the trimmed outer edge facing rearward. This

front arm is also marked with the word ªFOR-

WARDº. The side of the arm displaying this must

face forward.

The lateral arm with two different size bushing

sleeves must be mounted on the rearward side of

the crossmember and knuckle. Position the smaller

bushing sleeve end at the knuckle and the larger

bushing sleeve end at the rear crossmember (the

larger bushing sleeve is necessary to accommodate

the rear wheel alignment adjustment cam). If the

rear arm is to be mounted on the right side, the

trimmed outer edge must face rearward. If the rear

arm is to be mounted on the left side, the trimmed

outer edge must face forward.

(1) Following the note above, place the forward lat-

eral arm against the leading end of the knuckle, and

then install the short lateral arm mounting bolt with

a washer through the lateral arm and knuckle and

out the trailing end of the knuckle (Fig. 1).

(2) Following the note above, install the small

bushing sleeved end of the rear lateral arm onto the

end of the bolt just installed through the knuckle

(Fig. 1). Install a washer and nut onto the end of the

mounting bolt, but do not completely tighten the bolt

at this time.(3) Install a wheel alignment adjustment cam on

the long arm mounting bolt.

(4) Hold the rear lateral arm up against the cross-

member and install the long mounting bolt with the

adjustment cam through the lateral arm bushing and

rear crossmember (Fig. 1). The bolt must be installed

with the notch in the adjustment cam pointing

straight up.

(5) Position the forward lateral arm against the

rear crossmember hole. Pass the long mounting bolt

through the lateral arm bushing sleeve.

(6) Install a washer and nut onto the end of lateral

arm mounting bolt at the rear crossmember, but do

not completely tighten the bolt at this time.

NOTE: Once installed, each lateral arm should have

the bow in its length facing downward. Both right

side arms should have the trimmed outer edge fac-

ing toward the rear of the car. Left side arms should

have the trimmed outer edge facing each other. The

mounting bolt at the knuckle should have the nut at

the rear and the mounting bolt at the crossmember

should have the nut at the front (Fig. 13).

(7) Install tire and wheel assembly on the vehicle.

Tighten the wheel mounting nuts in proper sequence

until all nuts are torqued to half specification.

Repeat the tightening sequence to the full specified

torque of 135 N´m (100 ft. lbs.).

(8) Lower the vehicle to the ground.

(9) With suspension at curb height, tighten the lat-

eral arm mounting bolt nut at the knuckle to 95 N´m

(70 ft. lbs.).

Fig. 13 Lateral Arms

1 ± REAR STABILIZER BAR

2 ± REAR LATERAL ARMS

3 ± RIGHT FRONT LATERAL ARM

4 ± LEFT FRONT LATERAL ARM

PLSUSPENSION 2 - 45

REMOVAL AND INSTALLATION (Continued)

Page 58 of 1285

nuts are torqued to half specification. Repeat the

tightening sequence, this time, to full specified

torque of 135 N´m (100 ft. lbs.).

(8) Lower the vehicle to ground level.

(9) Set the rear toe on the vehicle to the required

specification if necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.

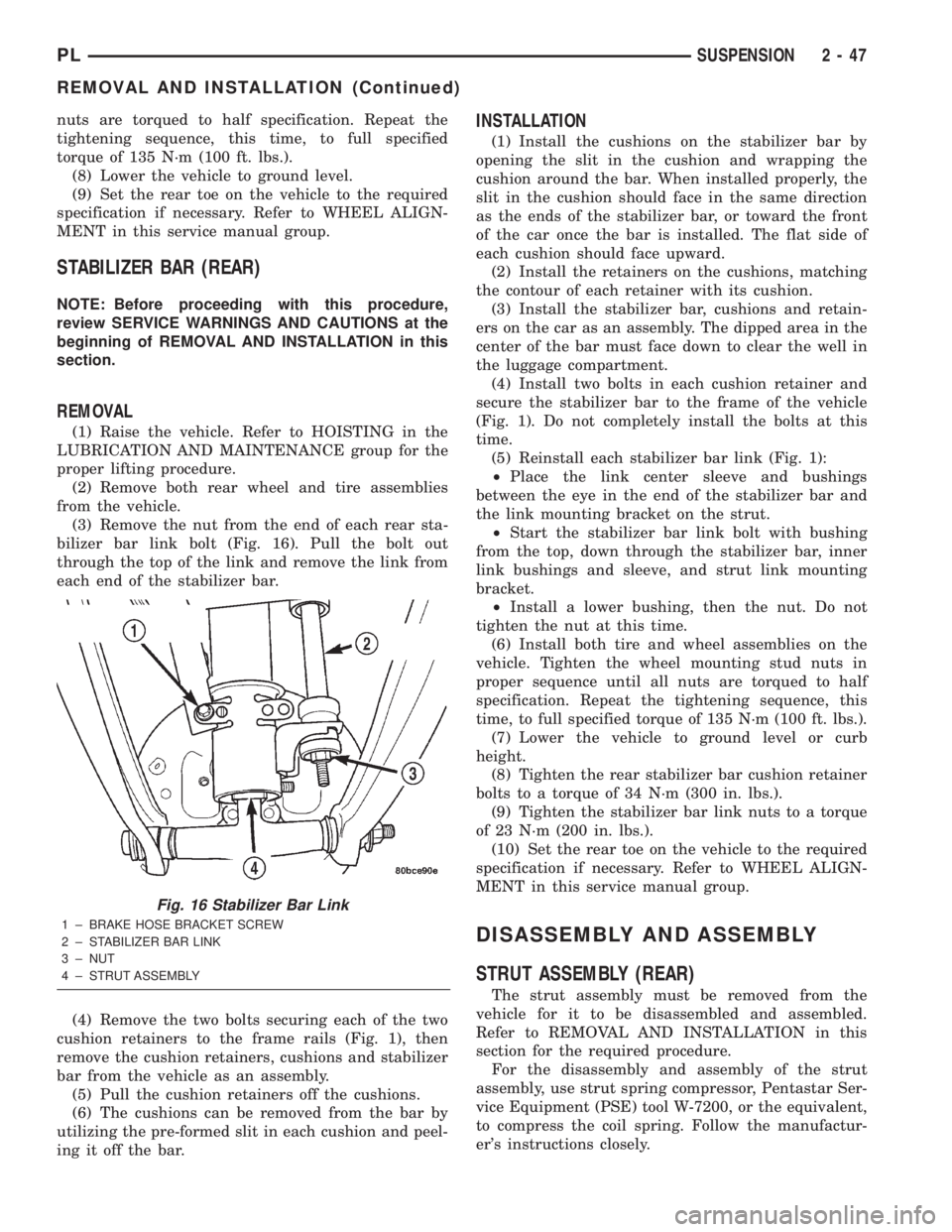

STABILIZER BAR (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove both rear wheel and tire assemblies

from the vehicle.

(3) Remove the nut from the end of each rear sta-

bilizer bar link bolt (Fig. 16). Pull the bolt out

through the top of the link and remove the link from

each end of the stabilizer bar.

(4) Remove the two bolts securing each of the two

cushion retainers to the frame rails (Fig. 1), then

remove the cushion retainers, cushions and stabilizer

bar from the vehicle as an assembly.

(5) Pull the cushion retainers off the cushions.

(6) The cushions can be removed from the bar by

utilizing the pre-formed slit in each cushion and peel-

ing it off the bar.

INSTALLATION

(1) Install the cushions on the stabilizer bar by

opening the slit in the cushion and wrapping the

cushion around the bar. When installed properly, the

slit in the cushion should face in the same direction

as the ends of the stabilizer bar, or toward the front

of the car once the bar is installed. The flat side of

each cushion should face upward.

(2) Install the retainers on the cushions, matching

the contour of each retainer with its cushion.

(3) Install the stabilizer bar, cushions and retain-

ers on the car as an assembly. The dipped area in the

center of the bar must face down to clear the well in

the luggage compartment.

(4) Install two bolts in each cushion retainer and

secure the stabilizer bar to the frame of the vehicle

(Fig. 1). Do not completely install the bolts at this

time.

(5) Reinstall each stabilizer bar link (Fig. 1):

²Place the link center sleeve and bushings

between the eye in the end of the stabilizer bar and

the link mounting bracket on the strut.

²Start the stabilizer bar link bolt with bushing

from the top, down through the stabilizer bar, inner

link bushings and sleeve, and strut link mounting

bracket.

²Install a lower bushing, then the nut. Do not

tighten the nut at this time.

(6) Install both tire and wheel assemblies on the

vehicle. Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Repeat the tightening sequence, this

time, to full specified torque of 135 N´m (100 ft. lbs.).

(7) Lower the vehicle to ground level or curb

height.

(8) Tighten the rear stabilizer bar cushion retainer

bolts to a torque of 34 N´m (300 in. lbs.).

(9) Tighten the stabilizer bar link nuts to a torque

of 23 N´m (200 in. lbs.).

(10) Set the rear toe on the vehicle to the required

specification if necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY (REAR)

The strut assembly must be removed from the

vehicle for it to be disassembled and assembled.

Refer to REMOVAL AND INSTALLATION in this

section for the required procedure.

For the disassembly and assembly of the strut

assembly, use strut spring compressor, Pentastar Ser-

vice Equipment (PSE) tool W-7200, or the equivalent,

to compress the coil spring. Follow the manufactur-

er's instructions closely.

Fig. 16 Stabilizer Bar Link

1 ± BRAKE HOSE BRACKET SCREW

2 ± STABILIZER BAR LINK

3 ± NUT

4 ± STRUT ASSEMBLY

PLSUSPENSION 2 - 47

REMOVAL AND INSTALLATION (Continued)