tow DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 59 of 1285

DISASSEMBLY

(1) If both struts are being serviced at the same

time, mark the coil spring and strut assembly accord-

ing to which side of the vehicle the strut was

removed from, and which strut the coil spring was

removed from.

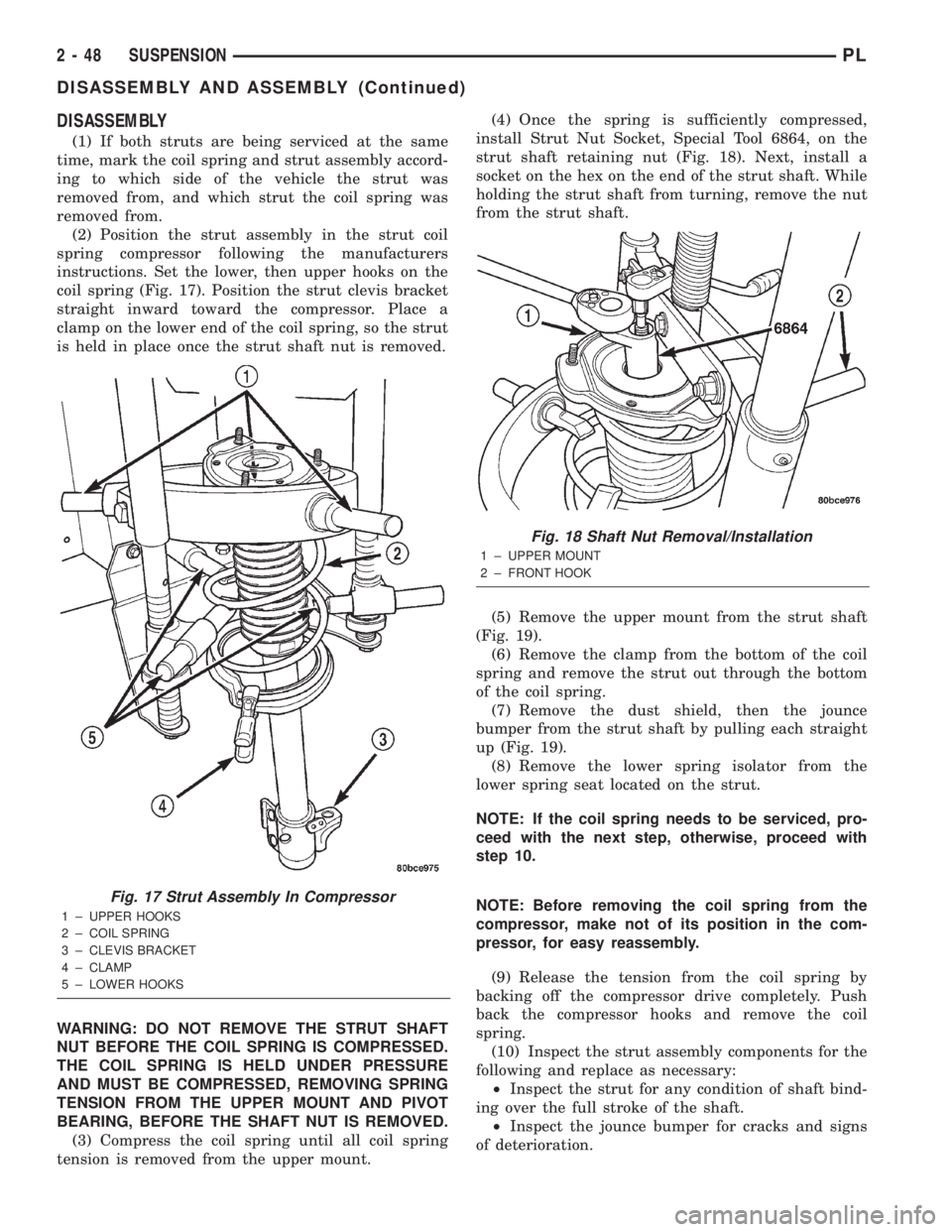

(2) Position the strut assembly in the strut coil

spring compressor following the manufacturers

instructions. Set the lower, then upper hooks on the

coil spring (Fig. 17). Position the strut clevis bracket

straight inward toward the compressor. Place a

clamp on the lower end of the coil spring, so the strut

is held in place once the strut shaft nut is removed.

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT BEFORE THE COIL SPRING IS COMPRESSED.

THE COIL SPRING IS HELD UNDER PRESSURE

AND MUST BE COMPRESSED, REMOVING SPRING

TENSION FROM THE UPPER MOUNT AND PIVOT

BEARING, BEFORE THE SHAFT NUT IS REMOVED.

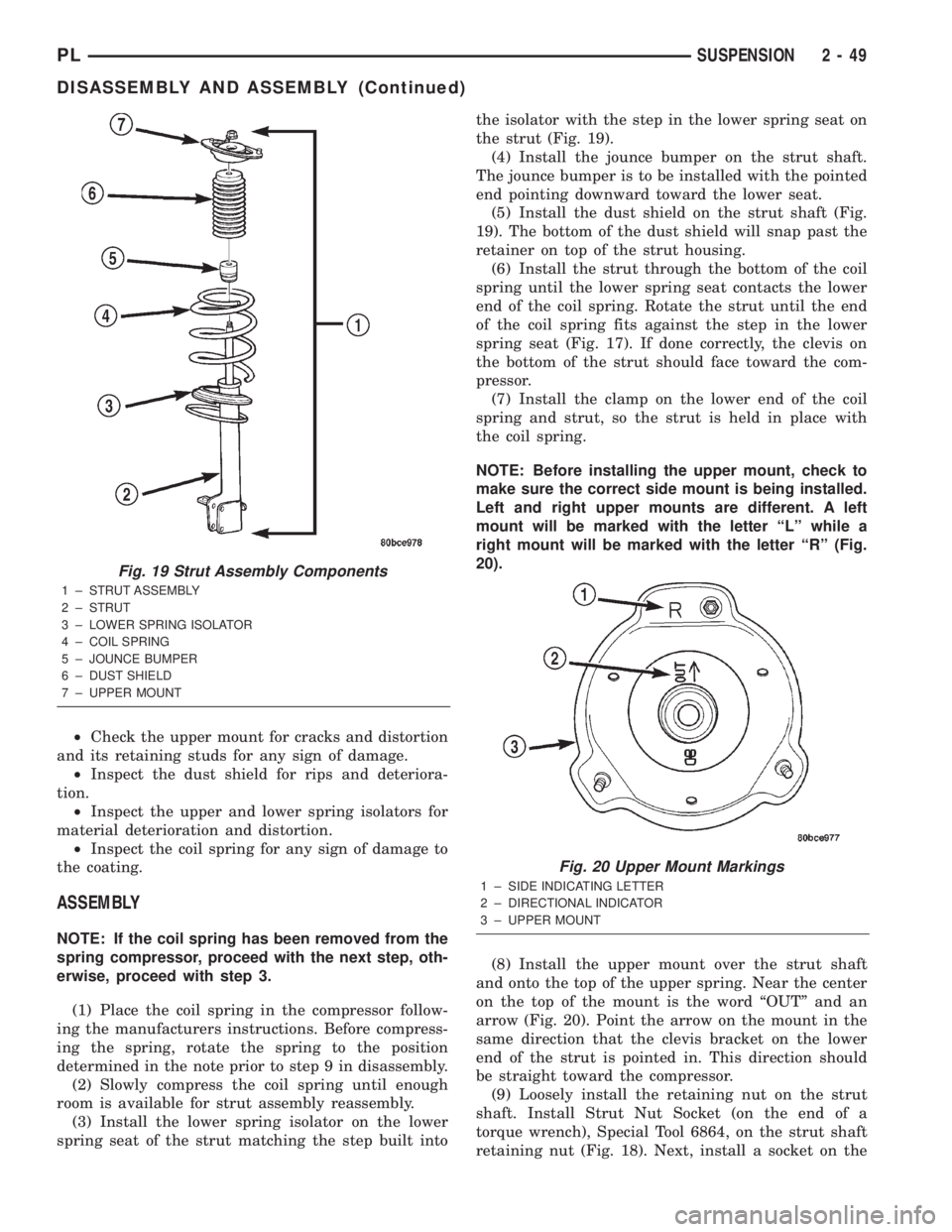

(3) Compress the coil spring until all coil spring

tension is removed from the upper mount.(4) Once the spring is sufficiently compressed,

install Strut Nut Socket, Special Tool 6864, on the

strut shaft retaining nut (Fig. 18). Next, install a

socket on the hex on the end of the strut shaft. While

holding the strut shaft from turning, remove the nut

from the strut shaft.

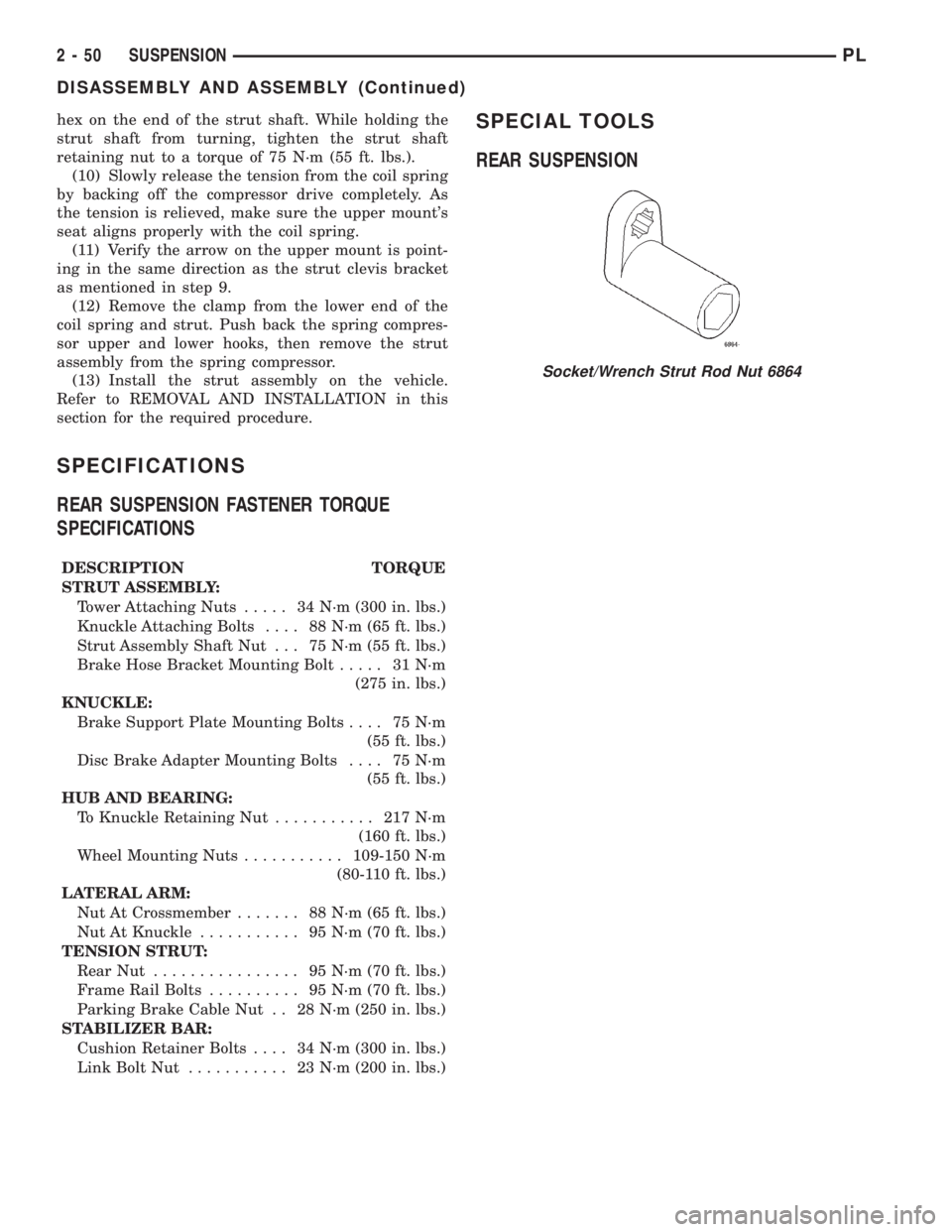

(5) Remove the upper mount from the strut shaft

(Fig. 19).

(6) Remove the clamp from the bottom of the coil

spring and remove the strut out through the bottom

of the coil spring.

(7) Remove the dust shield, then the jounce

bumper from the strut shaft by pulling each straight

up (Fig. 19).

(8) Remove the lower spring isolator from the

lower spring seat located on the strut.

NOTE: If the coil spring needs to be serviced, pro-

ceed with the next step, otherwise, proceed with

step 10.

NOTE: Before removing the coil spring from the

compressor, make not of its position in the com-

pressor, for easy reassembly.

(9) Release the tension from the coil spring by

backing off the compressor drive completely. Push

back the compressor hooks and remove the coil

spring.

(10) Inspect the strut assembly components for the

following and replace as necessary:

²Inspect the strut for any condition of shaft bind-

ing over the full stroke of the shaft.

²Inspect the jounce bumper for cracks and signs

of deterioration.

Fig. 17 Strut Assembly In Compressor

1 ± UPPER HOOKS

2 ± COIL SPRING

3 ± CLEVIS BRACKET

4 ± CLAMP

5 ± LOWER HOOKS

Fig. 18 Shaft Nut Removal/Installation

1 ± UPPER MOUNT

2 ± FRONT HOOK

2 - 48 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 60 of 1285

²Check the upper mount for cracks and distortion

and its retaining studs for any sign of damage.

²Inspect the dust shield for rips and deteriora-

tion.

²Inspect the upper and lower spring isolators for

material deterioration and distortion.

²Inspect the coil spring for any sign of damage to

the coating.

ASSEMBLY

NOTE: If the coil spring has been removed from the

spring compressor, proceed with the next step, oth-

erwise, proceed with step 3.

(1) Place the coil spring in the compressor follow-

ing the manufacturers instructions. Before compress-

ing the spring, rotate the spring to the position

determined in the note prior to step 9 in disassembly.

(2) Slowly compress the coil spring until enough

room is available for strut assembly reassembly.

(3) Install the lower spring isolator on the lower

spring seat of the strut matching the step built intothe isolator with the step in the lower spring seat on

the strut (Fig. 19).

(4) Install the jounce bumper on the strut shaft.

The jounce bumper is to be installed with the pointed

end pointing downward toward the lower seat.

(5) Install the dust shield on the strut shaft (Fig.

19). The bottom of the dust shield will snap past the

retainer on top of the strut housing.

(6) Install the strut through the bottom of the coil

spring until the lower spring seat contacts the lower

end of the coil spring. Rotate the strut until the end

of the coil spring fits against the step in the lower

spring seat (Fig. 17). If done correctly, the clevis on

the bottom of the strut should face toward the com-

pressor.

(7) Install the clamp on the lower end of the coil

spring and strut, so the strut is held in place with

the coil spring.

NOTE: Before installing the upper mount, check to

make sure the correct side mount is being installed.

Left and right upper mounts are different. A left

mount will be marked with the letter ªLº while a

right mount will be marked with the letter ªRº (Fig.

20).

(8) Install the upper mount over the strut shaft

and onto the top of the upper spring. Near the center

on the top of the mount is the word ªOUTº and an

arrow (Fig. 20). Point the arrow on the mount in the

same direction that the clevis bracket on the lower

end of the strut is pointed in. This direction should

be straight toward the compressor.

(9) Loosely install the retaining nut on the strut

shaft. Install Strut Nut Socket (on the end of a

torque wrench), Special Tool 6864, on the strut shaft

retaining nut (Fig. 18). Next, install a socket on the

Fig. 19 Strut Assembly Components

1 ± STRUT ASSEMBLY

2 ± STRUT

3 ± LOWER SPRING ISOLATOR

4 ± COIL SPRING

5 ± JOUNCE BUMPER

6 ± DUST SHIELD

7 ± UPPER MOUNT

Fig. 20 Upper Mount Markings

1 ± SIDE INDICATING LETTER

2 ± DIRECTIONAL INDICATOR

3 ± UPPER MOUNT

PLSUSPENSION 2 - 49

DISASSEMBLY AND ASSEMBLY (Continued)

Page 61 of 1285

hex on the end of the strut shaft. While holding the

strut shaft from turning, tighten the strut shaft

retaining nut to a torque of 75 N´m (55 ft. lbs.).

(10) Slowly release the tension from the coil spring

by backing off the compressor drive completely. As

the tension is relieved, make sure the upper mount's

seat aligns properly with the coil spring.

(11) Verify the arrow on the upper mount is point-

ing in the same direction as the strut clevis bracket

as mentioned in step 9.

(12) Remove the clamp from the lower end of the

coil spring and strut. Push back the spring compres-

sor upper and lower hooks, then remove the strut

assembly from the spring compressor.

(13) Install the strut assembly on the vehicle.

Refer to REMOVAL AND INSTALLATION in this

section for the required procedure.

SPECIFICATIONS

REAR SUSPENSION FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

STRUT ASSEMBLY:

Tower Attaching Nuts..... 34N´m(300 in. lbs.)

Knuckle Attaching Bolts.... 88N´m(65ft.lbs.)

Strut Assembly Shaft Nut . . . 75 N´m (55 ft. lbs.)

Brake Hose Bracket Mounting Bolt..... 31N´m

(275 in. lbs.)

KNUCKLE:

Brake Support Plate Mounting Bolts.... 75N´m

(55 ft. lbs.)

Disc Brake Adapter Mounting Bolts.... 75N´m

(55 ft. lbs.)

HUB AND BEARING:

To Knuckle Retaining Nut........... 217N´m

(160 ft. lbs.)

Wheel Mounting Nuts...........109-150 N´m

(80-110 ft. lbs.)

LATERAL ARM:

Nut At Crossmember....... 88N´m(65ft.lbs.)

Nut At Knuckle........... 95N´m(70ft.lbs.)

TENSION STRUT:

Rear Nut................ 95N´m(70ft.lbs.)

Frame Rail Bolts.......... 95N´m(70ft.lbs.)

Parking Brake Cable Nut . . 28 N´m (250 in. lbs.)

STABILIZER BAR:

Cushion Retainer Bolts.... 34N´m(300 in. lbs.)

Link Bolt Nut........... 23N´m(200 in. lbs.)

SPECIAL TOOLS

REAR SUSPENSION

Socket/Wrench Strut Rod Nut 6864

2 - 50 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 71 of 1285

INSTALLATION

NOTE: The inner tripod joint sealing boots are

made from two different types of material. High±

temperature applications use silicone rubber

whereas standard temperature applications use

Hytrel plastic. The silicone sealing boots are soft

and pliable. The Hytrel sealing boots are stiff and

rigid. The replacement sealing boot MUST BE the

same type of material as the sealing boot that was

removed.

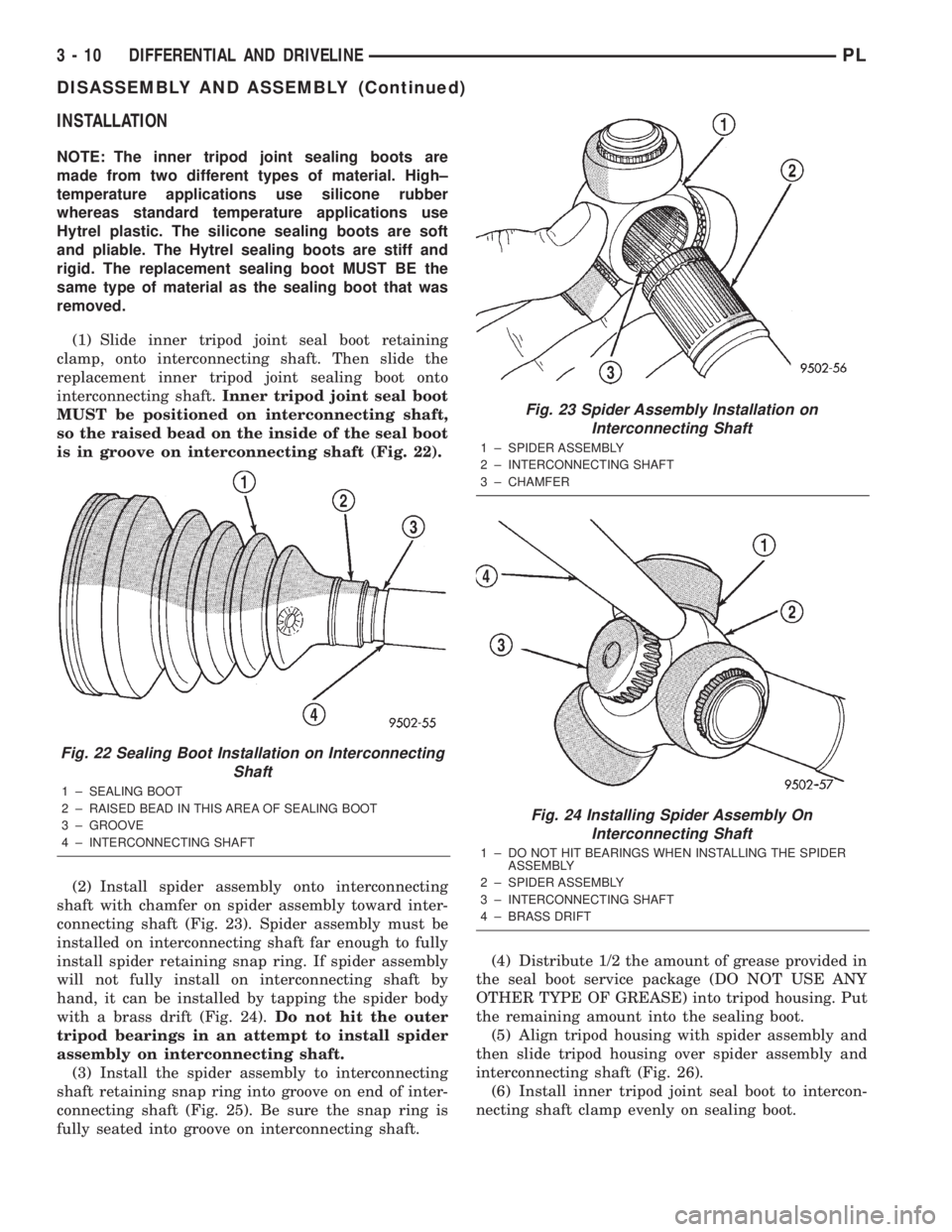

(1) Slide inner tripod joint seal boot retaining

clamp, onto interconnecting shaft. Then slide the

replacement inner tripod joint sealing boot onto

interconnecting shaft.Inner tripod joint seal boot

MUST be positioned on interconnecting shaft,

so the raised bead on the inside of the seal boot

is in groove on interconnecting shaft (Fig. 22).

(2) Install spider assembly onto interconnecting

shaft with chamfer on spider assembly toward inter-

connecting shaft (Fig. 23). Spider assembly must be

installed on interconnecting shaft far enough to fully

install spider retaining snap ring. If spider assembly

will not fully install on interconnecting shaft by

hand, it can be installed by tapping the spider body

with a brass drift (Fig. 24).Do not hit the outer

tripod bearings in an attempt to install spider

assembly on interconnecting shaft.

(3) Install the spider assembly to interconnecting

shaft retaining snap ring into groove on end of inter-

connecting shaft (Fig. 25). Be sure the snap ring is

fully seated into groove on interconnecting shaft.(4) Distribute 1/2 the amount of grease provided in

the seal boot service package (DO NOT USE ANY

OTHER TYPE OF GREASE) into tripod housing. Put

the remaining amount into the sealing boot.

(5) Align tripod housing with spider assembly and

then slide tripod housing over spider assembly and

interconnecting shaft (Fig. 26).

(6) Install inner tripod joint seal boot to intercon-

necting shaft clamp evenly on sealing boot.

Fig. 22 Sealing Boot Installation on Interconnecting

Shaft

1 ± SEALING BOOT

2 ± RAISED BEAD IN THIS AREA OF SEALING BOOT

3 ± GROOVE

4 ± INTERCONNECTING SHAFT

Fig. 23 Spider Assembly Installation on

Interconnecting Shaft

1 ± SPIDER ASSEMBLY

2 ± INTERCONNECTING SHAFT

3 ± CHAMFER

Fig. 24 Installing Spider Assembly On

Interconnecting Shaft

1 ± DO NOT HIT BEARINGS WHEN INSTALLING THE SPIDER

ASSEMBLY

2 ± SPIDER ASSEMBLY

3 ± INTERCONNECTING SHAFT

4 ± BRASS DRIFT

3 - 10 DIFFERENTIAL AND DRIVELINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 102 of 1285

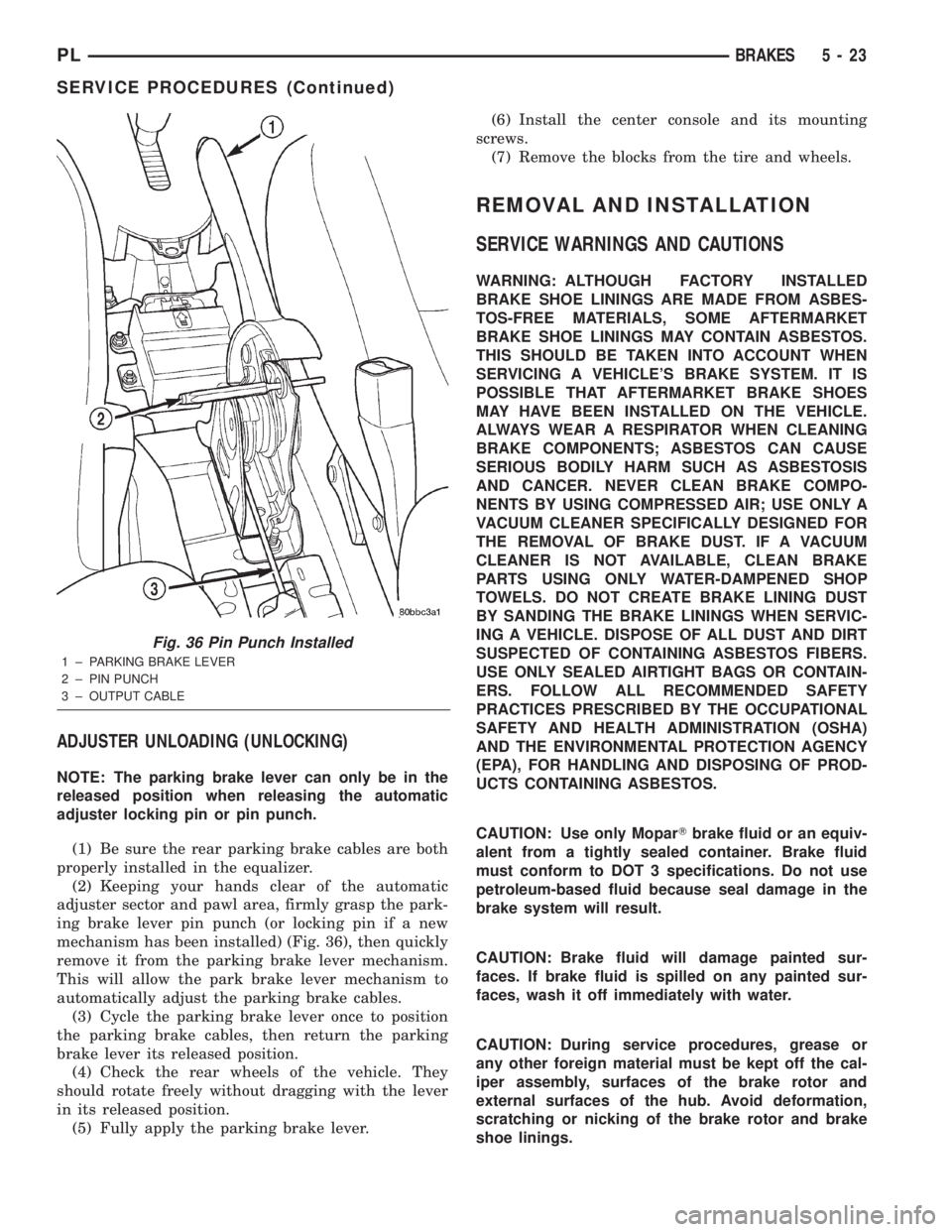

ADJUSTER UNLOADING (UNLOCKING)

NOTE: The parking brake lever can only be in the

released position when releasing the automatic

adjuster locking pin or pin punch.

(1) Be sure the rear parking brake cables are both

properly installed in the equalizer.

(2) Keeping your hands clear of the automatic

adjuster sector and pawl area, firmly grasp the park-

ing brake lever pin punch (or locking pin if a new

mechanism has been installed) (Fig. 36), then quickly

remove it from the parking brake lever mechanism.

This will allow the park brake lever mechanism to

automatically adjust the parking brake cables.

(3) Cycle the parking brake lever once to position

the parking brake cables, then return the parking

brake lever its released position.

(4) Check the rear wheels of the vehicle. They

should rotate freely without dragging with the lever

in its released position.

(5) Fully apply the parking brake lever.(6) Install the center console and its mounting

screws.

(7) Remove the blocks from the tire and wheels.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKE SHOE LININGS ARE MADE FROM ASBES-

TOS-FREE MATERIALS, SOME AFTERMARKET

BRAKE SHOE LININGS MAY CONTAIN ASBESTOS.

THIS SHOULD BE TAKEN INTO ACCOUNT WHEN

SERVICING A VEHICLE'S BRAKE SYSTEM. IT IS

POSSIBLE THAT AFTERMARKET BRAKE SHOES

MAY HAVE BEEN INSTALLED ON THE VEHICLE.

ALWAYS WEAR A RESPIRATOR WHEN CLEANING

BRAKE COMPONENTS; ASBESTOS CAN CAUSE

SERIOUS BODILY HARM SUCH AS ASBESTOSIS

AND CANCER. NEVER CLEAN BRAKE COMPO-

NENTS BY USING COMPRESSED AIR; USE ONLY A

VACUUM CLEANER SPECIFICALLY DESIGNED FOR

THE REMOVAL OF BRAKE DUST. IF A VACUUM

CLEANER IS NOT AVAILABLE, CLEAN BRAKE

PARTS USING ONLY WATER-DAMPENED SHOP

TOWELS. DO NOT CREATE BRAKE LINING DUST

BY SANDING THE BRAKE LININGS WHEN SERVIC-

ING A VEHICLE. DISPOSE OF ALL DUST AND DIRT

SUSPECTED OF CONTAINING ASBESTOS FIBERS.

USE ONLY SEALED AIRTIGHT BAGS OR CONTAIN-

ERS. FOLLOW ALL RECOMMENDED SAFETY

PRACTICES PRESCRIBED BY THE OCCUPATIONAL

SAFETY AND HEALTH ADMINISTRATION (OSHA)

AND THE ENVIRONMENTAL PROTECTION AGENCY

(EPA), FOR HANDLING AND DISPOSING OF PROD-

UCTS CONTAINING ASBESTOS.

CAUTION: Use only MoparTbrake fluid or an equiv-

alent from a tightly sealed container. Brake fluid

must conform to DOT 3 specifications. Do not use

petroleum-based fluid because seal damage in the

brake system will result.

CAUTION: Brake fluid will damage painted sur-

faces. If brake fluid is spilled on any painted sur-

faces, wash it off immediately with water.

CAUTION: During service procedures, grease or

any other foreign material must be kept off the cal-

iper assembly, surfaces of the brake rotor and

external surfaces of the hub. Avoid deformation,

scratching or nicking of the brake rotor and brake

shoe linings.

Fig. 36 Pin Punch Installed

1 ± PARKING BRAKE LEVER

2 ± PIN PUNCH

3 ± OUTPUT CABLE

PLBRAKES 5 - 23

SERVICE PROCEDURES (Continued)

Page 104 of 1285

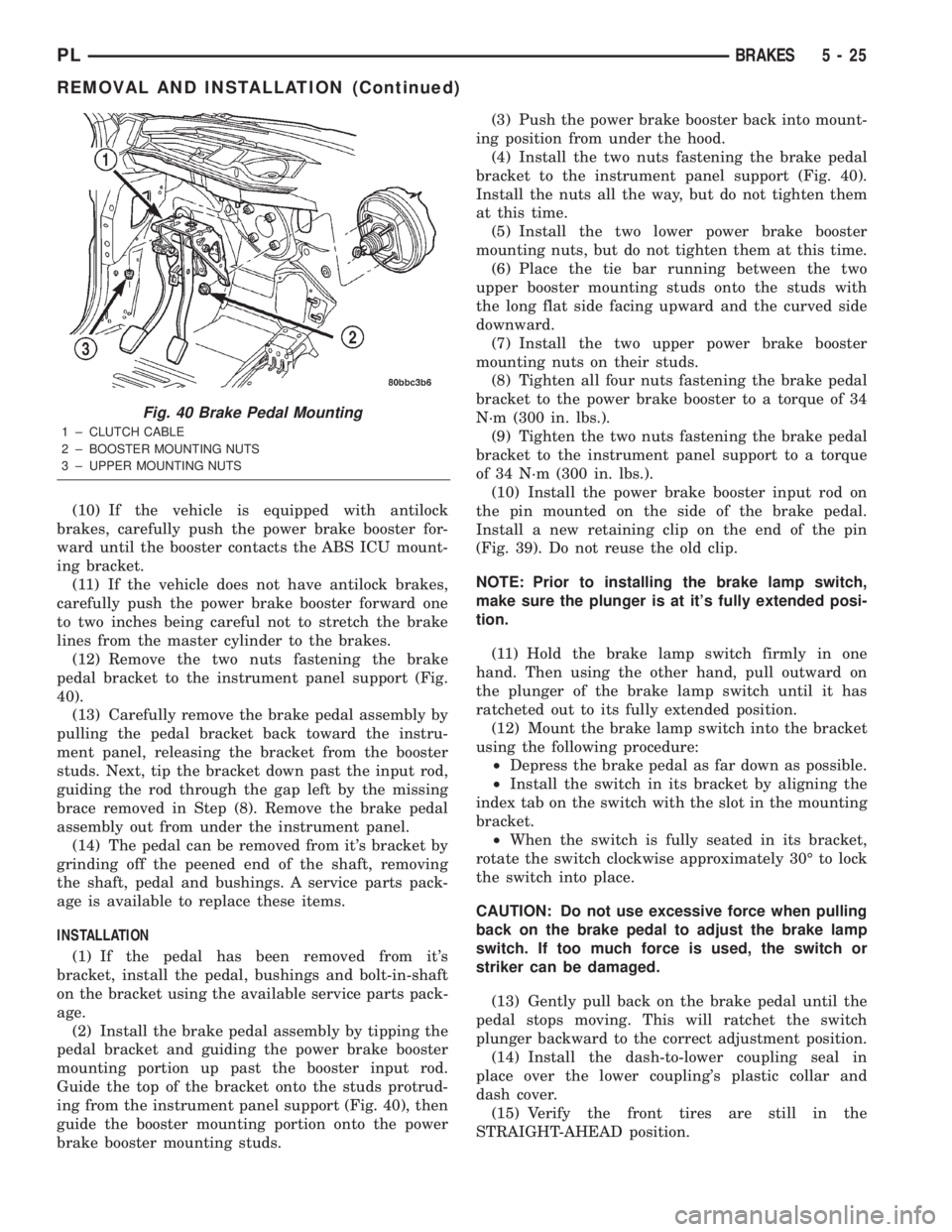

(10) If the vehicle is equipped with antilock

brakes, carefully push the power brake booster for-

ward until the booster contacts the ABS ICU mount-

ing bracket.

(11) If the vehicle does not have antilock brakes,

carefully push the power brake booster forward one

to two inches being careful not to stretch the brake

lines from the master cylinder to the brakes.

(12) Remove the two nuts fastening the brake

pedal bracket to the instrument panel support (Fig.

40).

(13) Carefully remove the brake pedal assembly by

pulling the pedal bracket back toward the instru-

ment panel, releasing the bracket from the booster

studs. Next, tip the bracket down past the input rod,

guiding the rod through the gap left by the missing

brace removed in Step (8). Remove the brake pedal

assembly out from under the instrument panel.

(14) The pedal can be removed from it's bracket by

grinding off the peened end of the shaft, removing

the shaft, pedal and bushings. A service parts pack-

age is available to replace these items.

INSTALLATION

(1) If the pedal has been removed from it's

bracket, install the pedal, bushings and bolt-in-shaft

on the bracket using the available service parts pack-

age.

(2) Install the brake pedal assembly by tipping the

pedal bracket and guiding the power brake booster

mounting portion up past the booster input rod.

Guide the top of the bracket onto the studs protrud-

ing from the instrument panel support (Fig. 40), then

guide the booster mounting portion onto the power

brake booster mounting studs.(3) Push the power brake booster back into mount-

ing position from under the hood.

(4) Install the two nuts fastening the brake pedal

bracket to the instrument panel support (Fig. 40).

Install the nuts all the way, but do not tighten them

at this time.

(5) Install the two lower power brake booster

mounting nuts, but do not tighten them at this time.

(6) Place the tie bar running between the two

upper booster mounting studs onto the studs with

the long flat side facing upward and the curved side

downward.

(7) Install the two upper power brake booster

mounting nuts on their studs.

(8) Tighten all four nuts fastening the brake pedal

bracket to the power brake booster to a torque of 34

N´m (300 in. lbs.).

(9) Tighten the two nuts fastening the brake pedal

bracket to the instrument panel support to a torque

of 34 N´m (300 in. lbs.).

(10) Install the power brake booster input rod on

the pin mounted on the side of the brake pedal.

Install a new retaining clip on the end of the pin

(Fig. 39). Do not reuse the old clip.

NOTE: Prior to installing the brake lamp switch,

make sure the plunger is at it's fully extended posi-

tion.

(11) Hold the brake lamp switch firmly in one

hand. Then using the other hand, pull outward on

the plunger of the brake lamp switch until it has

ratcheted out to its fully extended position.

(12) Mount the brake lamp switch into the bracket

using the following procedure:

²Depress the brake pedal as far down as possible.

²Install the switch in its bracket by aligning the

index tab on the switch with the slot in the mounting

bracket.

²When the switch is fully seated in its bracket,

rotate the switch clockwise approximately 30É to lock

the switch into place.

CAUTION: Do not use excessive force when pulling

back on the brake pedal to adjust the brake lamp

switch. If too much force is used, the switch or

striker can be damaged.

(13) Gently pull back on the brake pedal until the

pedal stops moving. This will ratchet the switch

plunger backward to the correct adjustment position.

(14) Install the dash-to-lower coupling seal in

place over the lower coupling's plastic collar and

dash cover.

(15) Verify the front tires are still in the

STRAIGHT-AHEAD position.

Fig. 40 Brake Pedal Mounting

1 ± CLUTCH CABLE

2 ± BOOSTER MOUNTING NUTS

3 ± UPPER MOUNTING NUTS

PLBRAKES 5 - 25

REMOVAL AND INSTALLATION (Continued)

Page 108 of 1285

(4) Position the master cylinder on the studs of the

power brake booster, aligning the push rod of the

power brake booster with master cylinder piston

push rod. Carefully push the master cylinder onto

the studs until it contacts the face of the booster.

(5) Install the two master cylinder mounting nuts

and tighten each to a torque of 28 N´m (250 in. lbs.).

(6) Connect the four brake tubes to the master cyl-

inder and proportioning valve ports (Fig. 45). Tighten

all tube nuts to a torque of 17 N´m (145 in. lbs.).

(7) Connect the brake fluid level switch wiring

connector.

(8) Install the battery and clamp it in place.

(9) Connect the positive, then the negative

(ground) cable on the battery.

(10) Fill the master cylinder to the proper level.

(11) Road test the vehicle to ensure proper opera-

tion of the brakes.

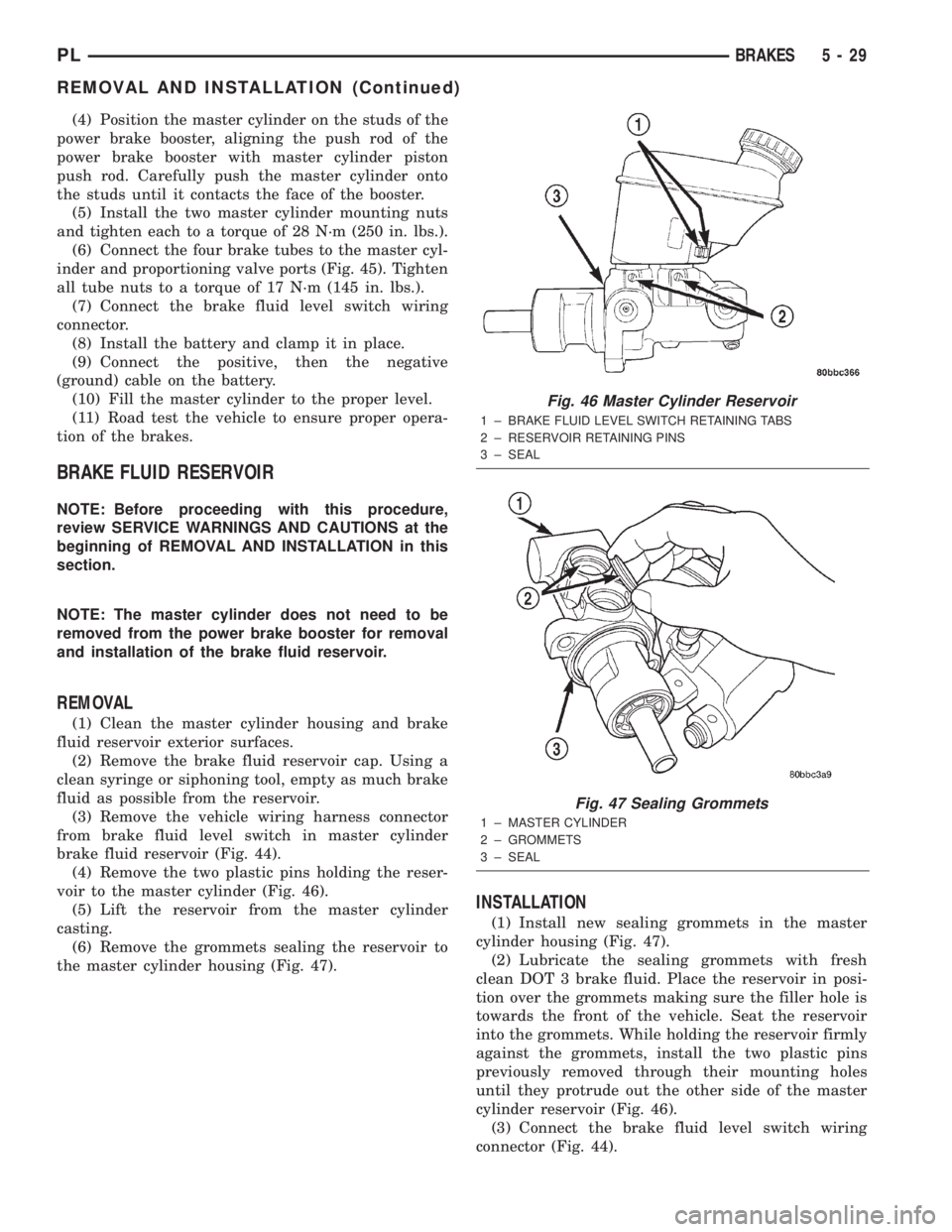

BRAKE FLUID RESERVOIR

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

NOTE: The master cylinder does not need to be

removed from the power brake booster for removal

and installation of the brake fluid reservoir.

REMOVAL

(1) Clean the master cylinder housing and brake

fluid reservoir exterior surfaces.

(2) Remove the brake fluid reservoir cap. Using a

clean syringe or siphoning tool, empty as much brake

fluid as possible from the reservoir.

(3) Remove the vehicle wiring harness connector

from brake fluid level switch in master cylinder

brake fluid reservoir (Fig. 44).

(4) Remove the two plastic pins holding the reser-

voir to the master cylinder (Fig. 46).

(5) Lift the reservoir from the master cylinder

casting.

(6) Remove the grommets sealing the reservoir to

the master cylinder housing (Fig. 47).

INSTALLATION

(1) Install new sealing grommets in the master

cylinder housing (Fig. 47).

(2) Lubricate the sealing grommets with fresh

clean DOT 3 brake fluid. Place the reservoir in posi-

tion over the grommets making sure the filler hole is

towards the front of the vehicle. Seat the reservoir

into the grommets. While holding the reservoir firmly

against the grommets, install the two plastic pins

previously removed through their mounting holes

until they protrude out the other side of the master

cylinder reservoir (Fig. 46).

(3) Connect the brake fluid level switch wiring

connector (Fig. 44).

Fig. 46 Master Cylinder Reservoir

1 ± BRAKE FLUID LEVEL SWITCH RETAINING TABS

2 ± RESERVOIR RETAINING PINS

3 ± SEAL

Fig. 47 Sealing Grommets

1 ± MASTER CYLINDER

2 ± GROMMETS

3 ± SEAL

PLBRAKES 5 - 29

REMOVAL AND INSTALLATION (Continued)

Page 110 of 1285

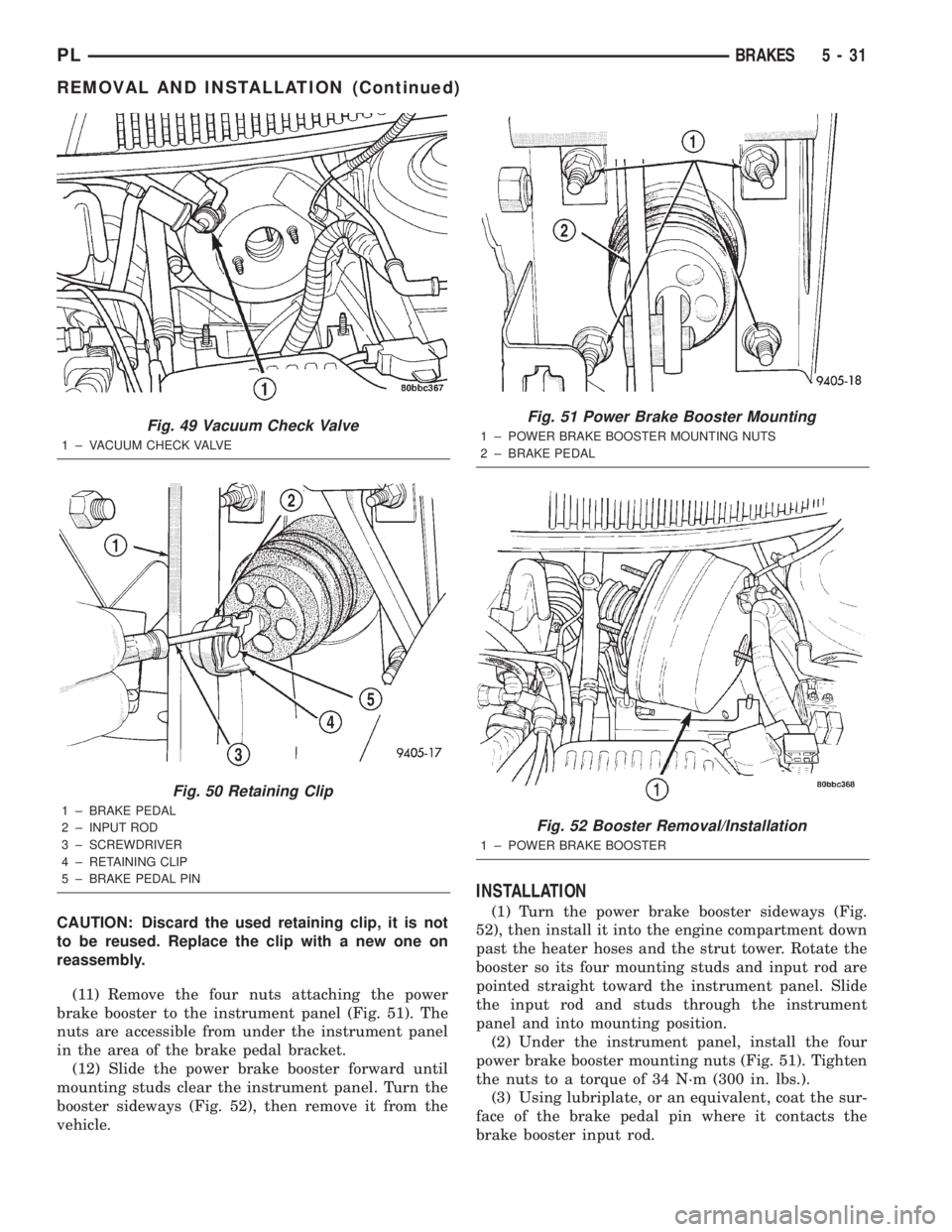

CAUTION: Discard the used retaining clip, it is not

to be reused. Replace the clip with a new one on

reassembly.

(11) Remove the four nuts attaching the power

brake booster to the instrument panel (Fig. 51). The

nuts are accessible from under the instrument panel

in the area of the brake pedal bracket.

(12) Slide the power brake booster forward until

mounting studs clear the instrument panel. Turn the

booster sideways (Fig. 52), then remove it from the

vehicle.

INSTALLATION

(1) Turn the power brake booster sideways (Fig.

52), then install it into the engine compartment down

past the heater hoses and the strut tower. Rotate the

booster so its four mounting studs and input rod are

pointed straight toward the instrument panel. Slide

the input rod and studs through the instrument

panel and into mounting position.

(2) Under the instrument panel, install the four

power brake booster mounting nuts (Fig. 51). Tighten

the nuts to a torque of 34 N´m (300 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the

brake booster input rod.

Fig. 49 Vacuum Check Valve

1 ± VACUUM CHECK VALVE

Fig. 50 Retaining Clip

1 ± BRAKE PEDAL

2 ± INPUT ROD

3 ± SCREWDRIVER

4 ± RETAINING CLIP

5 ± BRAKE PEDAL PIN

Fig. 51 Power Brake Booster Mounting

1 ± POWER BRAKE BOOSTER MOUNTING NUTS

2 ± BRAKE PEDAL

Fig. 52 Booster Removal/Installation

1 ± POWER BRAKE BOOSTER

PLBRAKES 5 - 31

REMOVAL AND INSTALLATION (Continued)

Page 133 of 1285

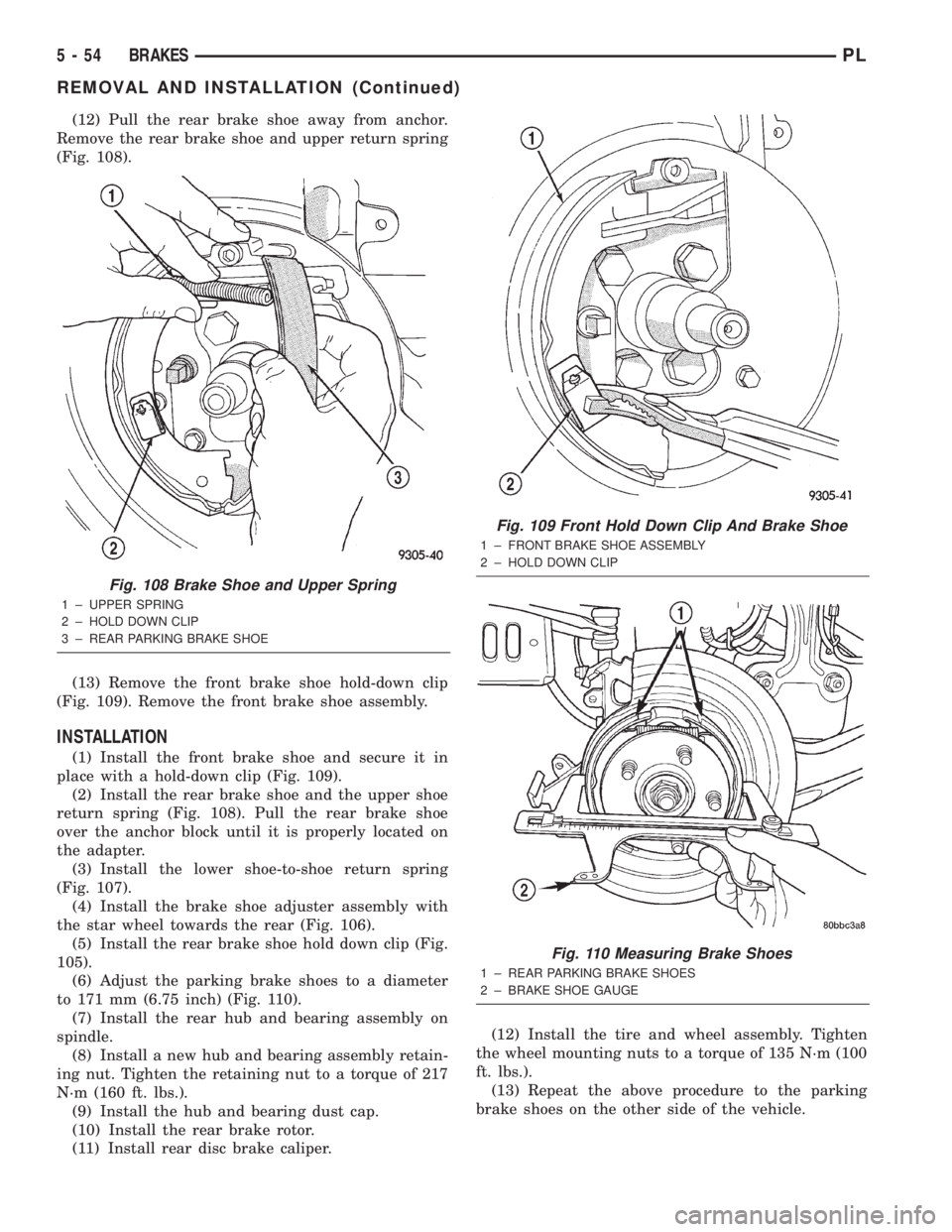

(12) Pull the rear brake shoe away from anchor.

Remove the rear brake shoe and upper return spring

(Fig. 108).

(13) Remove the front brake shoe hold-down clip

(Fig. 109). Remove the front brake shoe assembly.

INSTALLATION

(1) Install the front brake shoe and secure it in

place with a hold-down clip (Fig. 109).

(2) Install the rear brake shoe and the upper shoe

return spring (Fig. 108). Pull the rear brake shoe

over the anchor block until it is properly located on

the adapter.

(3) Install the lower shoe-to-shoe return spring

(Fig. 107).

(4) Install the brake shoe adjuster assembly with

the star wheel towards the rear (Fig. 106).

(5) Install the rear brake shoe hold down clip (Fig.

105).

(6) Adjust the parking brake shoes to a diameter

to 171 mm (6.75 inch) (Fig. 110).

(7) Install the rear hub and bearing assembly on

spindle.

(8) Install a new hub and bearing assembly retain-

ing nut. Tighten the retaining nut to a torque of 217

N´m (160 ft. lbs.).

(9) Install the hub and bearing dust cap.

(10) Install the rear brake rotor.

(11) Install rear disc brake caliper.(12) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(13) Repeat the above procedure to the parking

brake shoes on the other side of the vehicle.

Fig. 108 Brake Shoe and Upper Spring

1 ± UPPER SPRING

2 ± HOLD DOWN CLIP

3 ± REAR PARKING BRAKE SHOE

Fig. 109 Front Hold Down Clip And Brake Shoe

1 ± FRONT BRAKE SHOE ASSEMBLY

2 ± HOLD DOWN CLIP

Fig. 110 Measuring Brake Shoes

1 ± REAR PARKING BRAKE SHOES

2 ± BRAKE SHOE GAUGE

5 - 54 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 134 of 1285

(14) Adjust the parking brake shoes as necessary.

Refer to ADJUSTMENTS in this section of this ser-

vice manual group.

(15) Lower the vehicle.

DISASSEMBLY AND ASSEMBLY

DISC BRAKE CALIPER (FRONT AND REAR)

Before disassembling the brake caliper, clean and

inspect it. Refer to CLEANING AND INSPECTION

in this section of this service manual group.

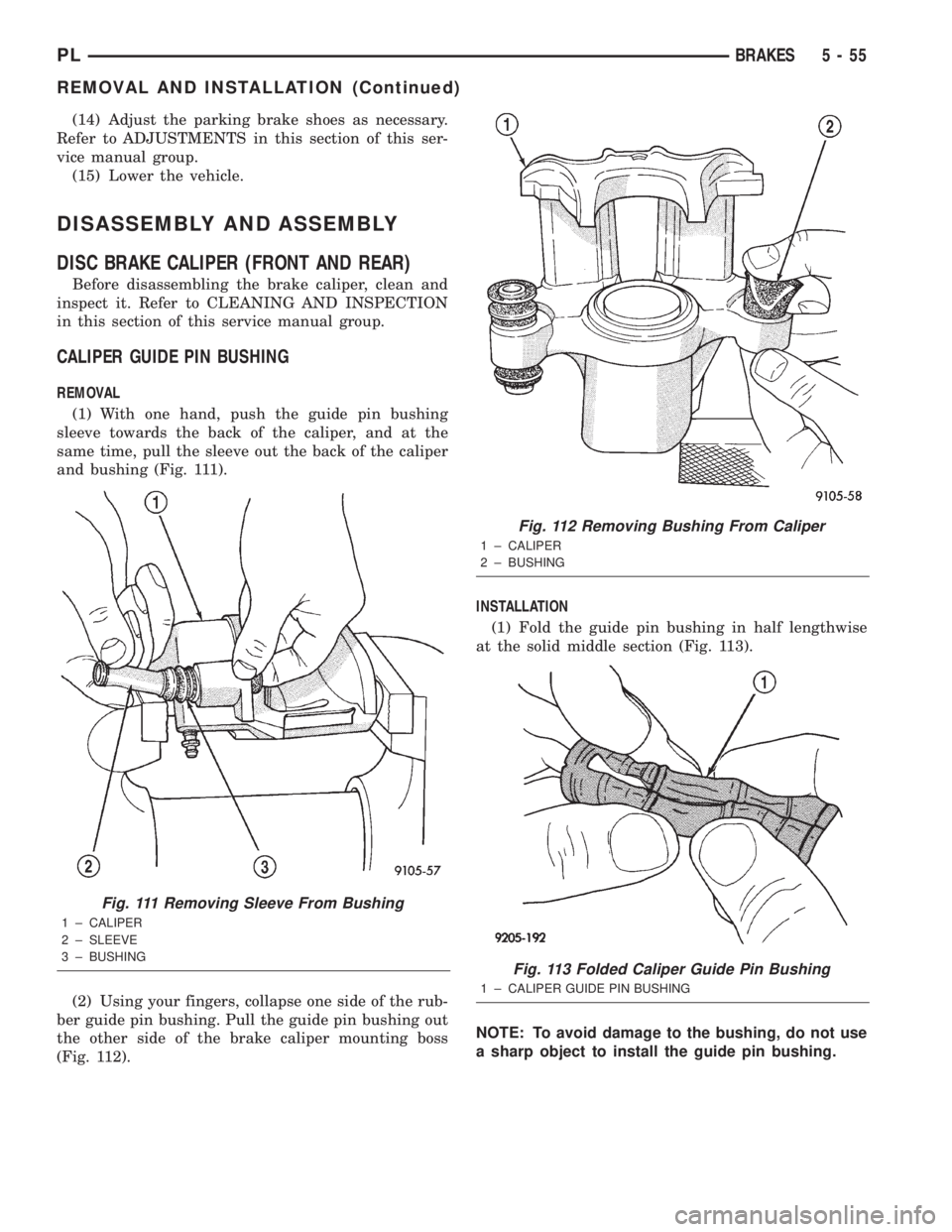

CALIPER GUIDE PIN BUSHING

REMOVAL

(1) With one hand, push the guide pin bushing

sleeve towards the back of the caliper, and at the

same time, pull the sleeve out the back of the caliper

and bushing (Fig. 111).

(2) Using your fingers, collapse one side of the rub-

ber guide pin bushing. Pull the guide pin bushing out

the other side of the brake caliper mounting boss

(Fig. 112).INSTALLATION

(1) Fold the guide pin bushing in half lengthwise

at the solid middle section (Fig. 113).

NOTE: To avoid damage to the bushing, do not use

a sharp object to install the guide pin bushing.

Fig. 111 Removing Sleeve From Bushing

1 ± CALIPER

2 ± SLEEVE

3 ± BUSHING

Fig. 112 Removing Bushing From Caliper

1 ± CALIPER

2 ± BUSHING

Fig. 113 Folded Caliper Guide Pin Bushing

1 ± CALIPER GUIDE PIN BUSHING

PLBRAKES 5 - 55

REMOVAL AND INSTALLATION (Continued)