tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 733 of 1285

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (makeup air) at

the cylinder head cover and plug or cap the nipple on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and CCV hose. Proceed to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of theengine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil galley cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurized the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, refer to Crank-

shaft Oil SealÐRear for proper replacement proce-

dures.

9 - 10 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 739 of 1285

CRANKSHAFT

A nodular cast iron crankshaft is used. The engine

has five main bearings. The number three main is

flanged to control thrust. The mains and connecting

rod journals have undercut fillet radiuses that are

deep rolled for added strength. To optimize bearing

loading, eight counterweights are used. Hydrody-

namic seals provide end sealing, where the crank-

shaft exits the block. Anaerobic gasket material is

used for parting line sealing. A sintered iron timing

belt sprocket is mounted on the crankshaft nose. This

sprocket transmits crankshaft movement, via timing

belt to the camshaft sprocket providing timed valve

actuation.

PISTONS

The engineDOES NOThave provision for a free

wheeling valve train. Non free wheeling valve train

means, in the event of a broken timing belt pistons

will contact the valves. The engine uses pressed-in

piston pins to attach forged powdered metal connect-

ing rods. The connecting rods are a cracked cap

design and are not repairable. Hex head cap screw

are used to provide alignment and durability in the

assembly. Pistons and connecting rods are serviced as

an assembly.

PISTON RINGS

The piston rings include a molybdenum faced top

ring for reliable compression sealing and a taper

faced intermediate ring for additional cylinder pres-

sure control. Oil Control Ring Package consist of two

steel rails and an expander spacer.

CYLINDER HEAD

The aluminum cylinder head features a Single

Over Head Camshaft (SOHC), four-valves per cylin-

der, cross flow design. The valves are arranged in

two inline banks, with the two intake per cylinder

facing toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFT

The nodular iron camshaft has five bearing jour-

nals and three cam lobes per cylinder. Provision for a

cam position sensor is provided on the camshaft at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVES

Four valves per cylinder are actuated by roller

rocker arms/hydraulic lash adjusters assemblies

which pivot on rocker arm shafts. All valves have

chrome plated valve stems. Viton rubber valve stem

seals are integral with spring seats. Valve springs,

spring retainers, and locks are conventional design.

INTAKE MANIFOLD

The intake manifold is a molded plastic composi-

tion, attached to the cylinder head with five fasten-

ers. This long branch design enhances low and mid-

range torque.

EXHAUST MANIFOLD

The exhaust manifold is made of nodular cast iron

for strength and high temperatures. Exhaust gasses

exit the manifold into an articulated joint connection

and exhaust pipe.

COMPONENT REPLACEMENT

If any of the following parts have been changed or

replaced:

²Camshaft

²Camshaft Position Sensor

²Camshaft Position Sensor Target Magnet

²Cylinder Block

²Cylinder Head

²Water Pump

²Powertrain Control Module (PCM)

²Timing Belt and Timing Belt Tensioner

The camshaft and crankshaft timing relearn proce-

dure must be performed. Refer to the component

Removal and Installation procedure in this section.

9 - 16 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 740 of 1285

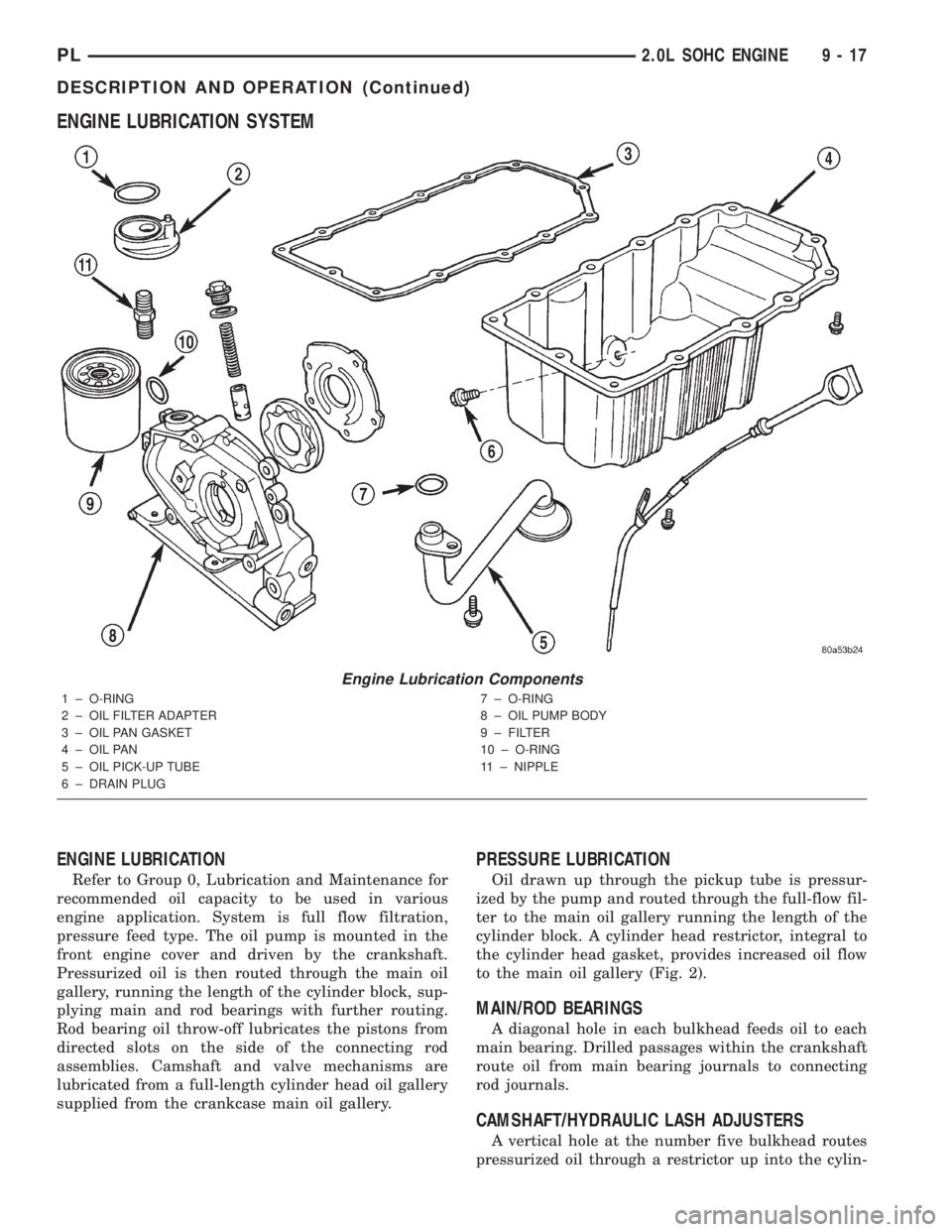

ENGINE LUBRICATION SYSTEM

ENGINE LUBRICATION

Refer to Group 0, Lubrication and Maintenance for

recommended oil capacity to be used in various

engine application. System is full flow filtration,

pressure feed type. The oil pump is mounted in the

front engine cover and driven by the crankshaft.

Pressurized oil is then routed through the main oil

gallery, running the length of the cylinder block, sup-

plying main and rod bearings with further routing.

Rod bearing oil throw-off lubricates the pistons from

directed slots on the side of the connecting rod

assemblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full-flow fil-

ter to the main oil gallery running the length of the

cylinder block. A cylinder head restrictor, integral to

the cylinder head gasket, provides increased oil flow

to the main oil gallery (Fig. 2).

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up into the cylin-

Engine Lubrication Components

1 ± O-RING

2 ± OIL FILTER ADAPTER

3 ± OIL PAN GASKET

4 ± OIL PAN

5 ± OIL PICK-UP TUBE

6 ± DRAIN PLUG7 ± O-RING

8 ± OIL PUMP BODY

9 ± FILTER

10 ± O-RING

11 ± NIPPLE

PL2.0L SOHC ENGINE 9 - 17

DESCRIPTION AND OPERATION (Continued)

Page 741 of 1285

der head. The rocker shafts route oil to the rocker

arms/hydraulic lash adjuster assemblies.

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

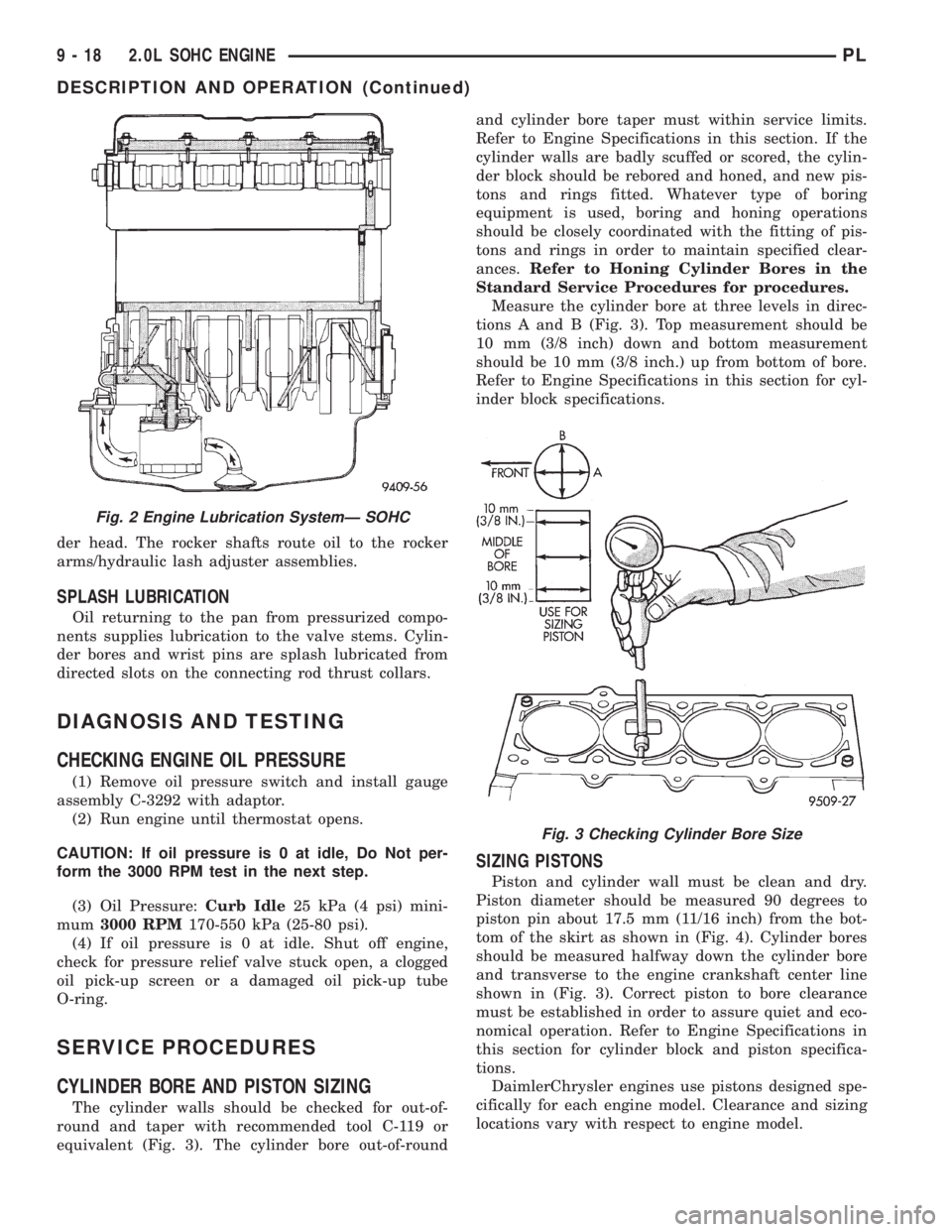

CYLINDER BORE AND PISTON SIZING

The cylinder walls should be checked for out-of-

round and taper with recommended tool C-119 or

equivalent (Fig. 3). The cylinder bore out-of-roundand cylinder bore taper must within service limits.

Refer to Engine Specifications in this section. If the

cylinder walls are badly scuffed or scored, the cylin-

der block should be rebored and honed, and new pis-

tons and rings fitted. Whatever type of boring

equipment is used, boring and honing operations

should be closely coordinated with the fitting of pis-

tons and rings in order to maintain specified clear-

ances.Refer to Honing Cylinder Bores in the

Standard Service Procedures for procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 3). Top measurement should be

10 mm (3/8 inch) down and bottom measurement

should be 10 mm (3/8 inch.) up from bottom of bore.

Refer to Engine Specifications in this section for cyl-

inder block specifications.

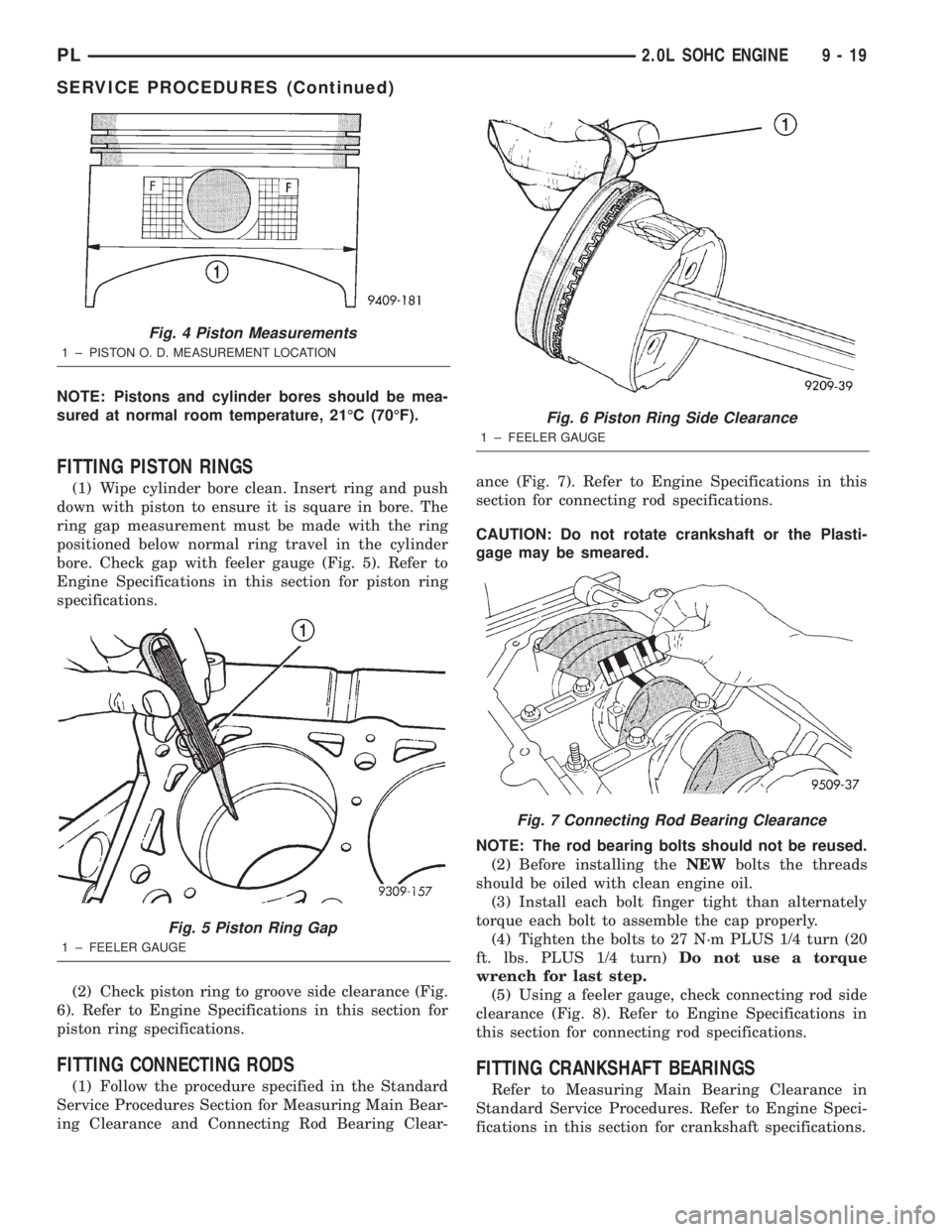

SIZING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 17.5 mm (11/16 inch) from the bot-

tom of the skirt as shown in (Fig. 4). Cylinder bores

should be measured halfway down the cylinder bore

and transverse to the engine crankshaft center line

shown in (Fig. 3). Correct piston to bore clearance

must be established in order to assure quiet and eco-

nomical operation. Refer to Engine Specifications in

this section for cylinder block and piston specifica-

tions.

DaimlerChrysler engines use pistons designed spe-

cifically for each engine model. Clearance and sizing

locations vary with respect to engine model.

Fig. 2 Engine Lubrication SystemÐ SOHC

Fig. 3 Checking Cylinder Bore Size

9 - 18 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 742 of 1285

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 21ÉC (70ÉF).

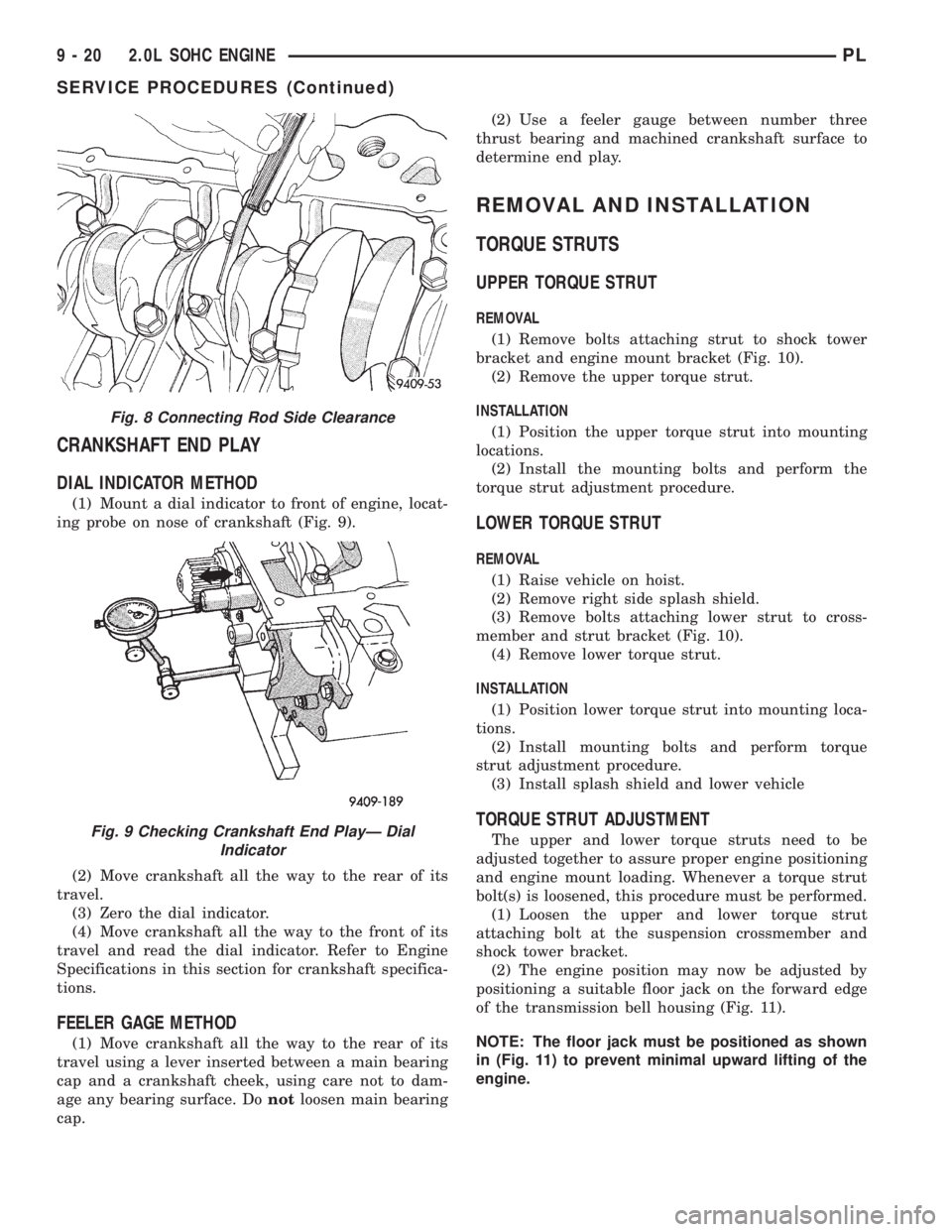

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioned below normal ring travel in the cylinder

bore. Check gap with feeler gauge (Fig. 5). Refer to

Engine Specifications in this section for piston ring

specifications.

(2) Check piston ring to groove side clearance (Fig.

6). Refer to Engine Specifications in this section for

piston ring specifications.

FITTING CONNECTING RODS

(1) Follow the procedure specified in the Standard

Service Procedures Section for Measuring Main Bear-

ing Clearance and Connecting Rod Bearing Clear-ance (Fig. 7). Refer to Engine Specifications in this

section for connecting rod specifications.

CAUTION: Do not rotate crankshaft or the Plasti-

gage may be smeared.

NOTE: The rod bearing bolts should not be reused.

(2) Before installing theNEWbolts the threads

should be oiled with clean engine oil.

(3) Install each bolt finger tight than alternately

torque each bolt to assemble the cap properly.

(4) Tighten the bolts to 27 N´m PLUS 1/4 turn (20

ft. lbs. PLUS 1/4 turn)Do not use a torque

wrench for last step.

(5) Using a feeler gauge, check connecting rod side

clearance (Fig. 8). Refer to Engine Specifications in

this section for connecting rod specifications.

FITTING CRANKSHAFT BEARINGS

Refer to Measuring Main Bearing Clearance in

Standard Service Procedures. Refer to Engine Speci-

fications in this section for crankshaft specifications.

Fig. 4 Piston Measurements

1 ± PISTON O. D. MEASUREMENT LOCATION

Fig. 5 Piston Ring Gap

1 ± FEELER GAUGE

Fig. 6 Piston Ring Side Clearance

1 ± FEELER GAUGE

Fig. 7 Connecting Rod Bearing Clearance

PL2.0L SOHC ENGINE 9 - 19

SERVICE PROCEDURES (Continued)

Page 743 of 1285

CRANKSHAFT END PLAY

DIAL INDICATOR METHOD

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 9).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front of its

travel and read the dial indicator. Refer to Engine

Specifications in this section for crankshaft specifica-

tions.

FEELER GAGE METHOD

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearing

cap and a crankshaft cheek, using care not to dam-

age any bearing surface. Donotloosen main bearing

cap.(2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

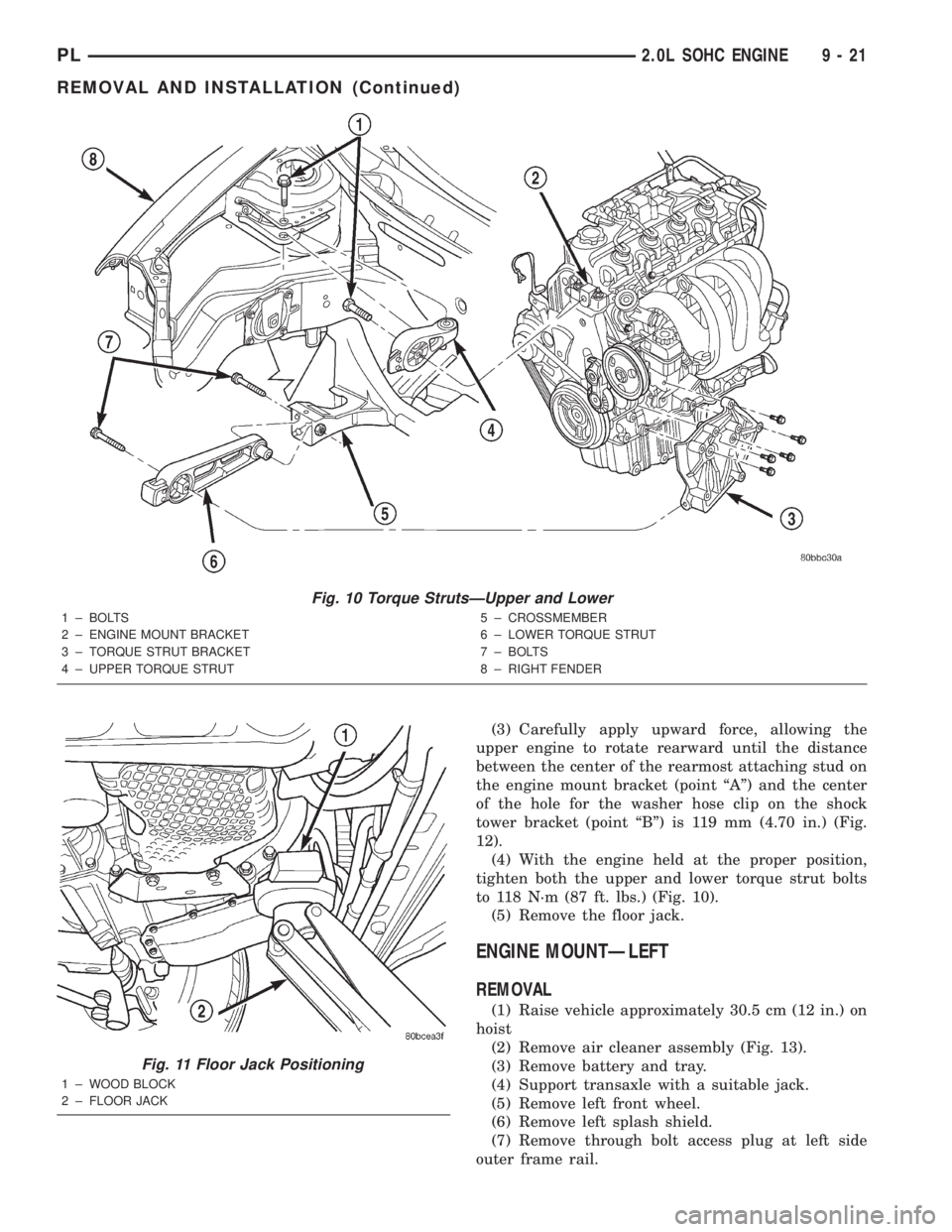

REMOVAL AND INSTALLATION

TORQUE STRUTS

UPPER TORQUE STRUT

REMOVAL

(1) Remove bolts attaching strut to shock tower

bracket and engine mount bracket (Fig. 10).

(2) Remove the upper torque strut.

INSTALLATION

(1) Position the upper torque strut into mounting

locations.

(2) Install the mounting bolts and perform the

torque strut adjustment procedure.

LOWER TORQUE STRUT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove right side splash shield.

(3) Remove bolts attaching lower strut to cross-

member and strut bracket (Fig. 10).

(4) Remove lower torque strut.

INSTALLATION

(1) Position lower torque strut into mounting loca-

tions.

(2) Install mounting bolts and perform torque

strut adjustment procedure.

(3) Install splash shield and lower vehicle

TORQUE STRUT ADJUSTMENT

The upper and lower torque struts need to be

adjusted together to assure proper engine positioning

and engine mount loading. Whenever a torque strut

bolt(s) is loosened, this procedure must be performed.

(1) Loosen the upper and lower torque strut

attaching bolt at the suspension crossmember and

shock tower bracket.

(2) The engine position may now be adjusted by

positioning a suitable floor jack on the forward edge

of the transmission bell housing (Fig. 11).

NOTE: The floor jack must be positioned as shown

in (Fig. 11) to prevent minimal upward lifting of the

engine.

Fig. 8 Connecting Rod Side Clearance

Fig. 9 Checking Crankshaft End PlayÐ Dial

Indicator

9 - 20 2.0L SOHC ENGINEPL

SERVICE PROCEDURES (Continued)

Page 744 of 1285

(3) Carefully apply upward force, allowing the

upper engine to rotate rearward until the distance

between the center of the rearmost attaching stud on

the engine mount bracket (point ªAº) and the center

of the hole for the washer hose clip on the shock

tower bracket (point ªBº) is 119 mm (4.70 in.) (Fig.

12).

(4) With the engine held at the proper position,

tighten both the upper and lower torque strut bolts

to 118 N´m (87 ft. lbs.) (Fig. 10).

(5) Remove the floor jack.

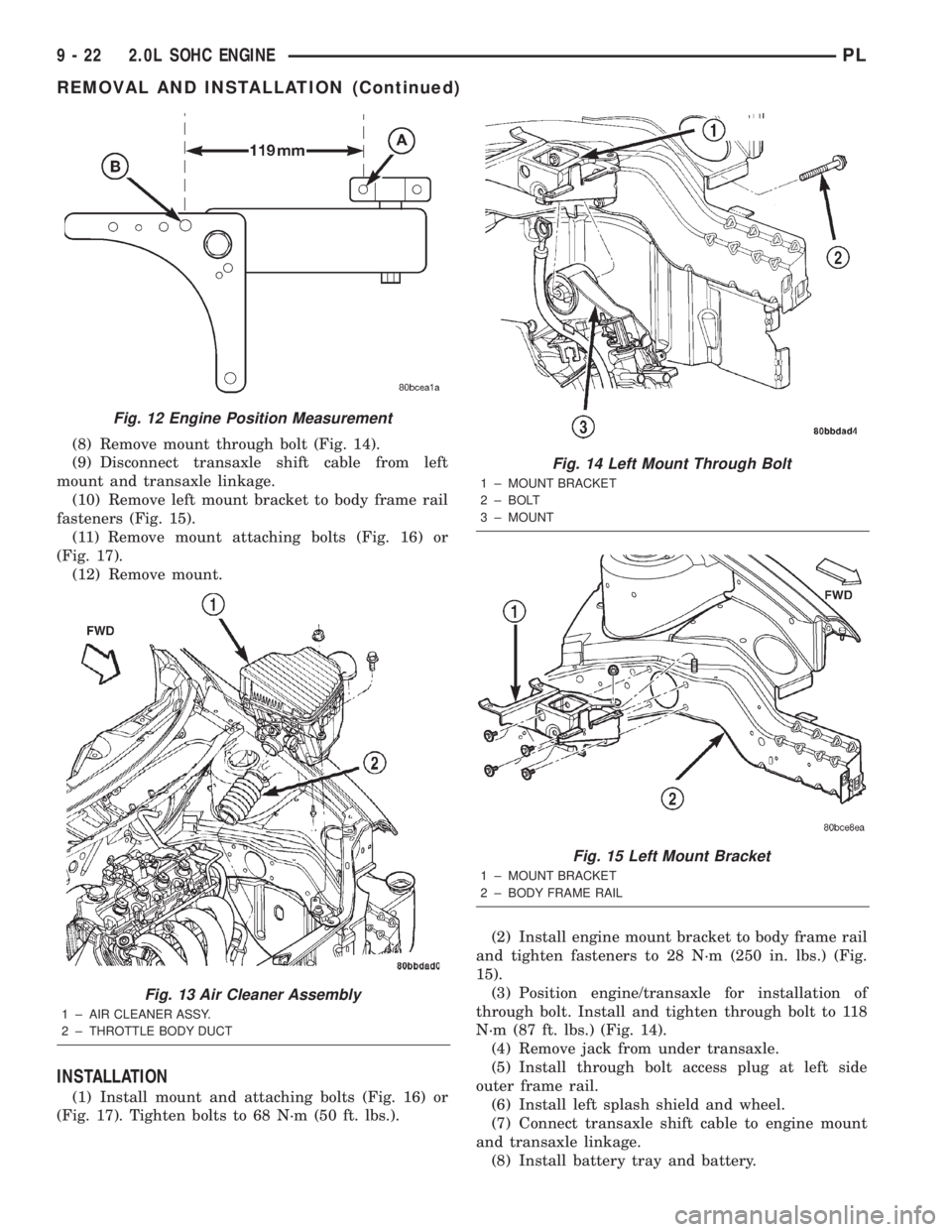

ENGINE MOUNTÐLEFT

REMOVAL

(1) Raise vehicle approximately 30.5 cm (12 in.) on

hoist

(2) Remove air cleaner assembly (Fig. 13).

(3) Remove battery and tray.

(4) Support transaxle with a suitable jack.

(5) Remove left front wheel.

(6) Remove left splash shield.

(7) Remove through bolt access plug at left side

outer frame rail.

Fig. 10 Torque StrutsÐUpper and Lower

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET

3 ± TORQUE STRUT BRACKET

4 ± UPPER TORQUE STRUT5 ± CROSSMEMBER

6 ± LOWER TORQUE STRUT

7 ± BOLTS

8 ± RIGHT FENDER

Fig. 11 Floor Jack Positioning

1 ± WOOD BLOCK

2 ± FLOOR JACK

PL2.0L SOHC ENGINE 9 - 21

REMOVAL AND INSTALLATION (Continued)

Page 745 of 1285

(8) Remove mount through bolt (Fig. 14).

(9) Disconnect transaxle shift cable from left

mount and transaxle linkage.

(10) Remove left mount bracket to body frame rail

fasteners (Fig. 15).

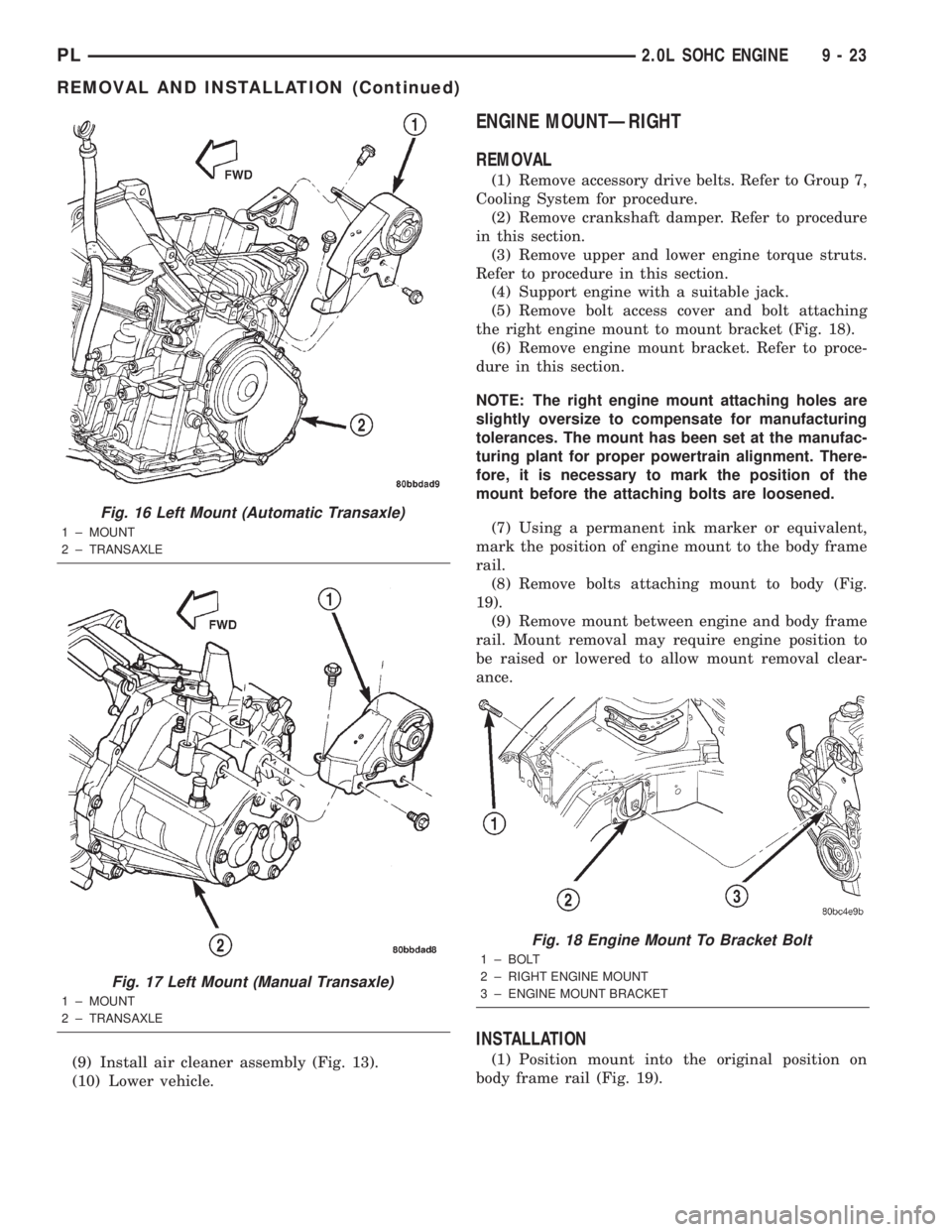

(11) Remove mount attaching bolts (Fig. 16) or

(Fig. 17).

(12) Remove mount.

INSTALLATION

(1) Install mount and attaching bolts (Fig. 16) or

(Fig. 17). Tighten bolts to 68 N´m (50 ft. lbs.).(2) Install engine mount bracket to body frame rail

and tighten fasteners to 28 N´m (250 in. lbs.) (Fig.

15).

(3) Position engine/transaxle for installation of

through bolt. Install and tighten through bolt to 118

N´m (87 ft. lbs.) (Fig. 14).

(4) Remove jack from under transaxle.

(5) Install through bolt access plug at left side

outer frame rail.

(6) Install left splash shield and wheel.

(7) Connect transaxle shift cable to engine mount

and transaxle linkage.

(8) Install battery tray and battery.

Fig. 12 Engine Position Measurement

Fig. 13 Air Cleaner Assembly

1 ± AIR CLEANER ASSY.

2 ± THROTTLE BODY DUCT

Fig. 14 Left Mount Through Bolt

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

Fig. 15 Left Mount Bracket

1 ± MOUNT BRACKET

2 ± BODY FRAME RAIL

9 - 22 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 746 of 1285

(9) Install air cleaner assembly (Fig. 13).

(10) Lower vehicle.

ENGINE MOUNTÐRIGHT

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(2) Remove crankshaft damper. Refer to procedure

in this section.

(3) Remove upper and lower engine torque struts.

Refer to procedure in this section.

(4) Support engine with a suitable jack.

(5) Remove bolt access cover and bolt attaching

the right engine mount to mount bracket (Fig. 18).

(6) Remove engine mount bracket. Refer to proce-

dure in this section.

NOTE: The right engine mount attaching holes are

slightly oversize to compensate for manufacturing

tolerances. The mount has been set at the manufac-

turing plant for proper powertrain alignment. There-

fore, it is necessary to mark the position of the

mount before the attaching bolts are loosened.

(7) Using a permanent ink marker or equivalent,

mark the position of engine mount to the body frame

rail.

(8) Remove bolts attaching mount to body (Fig.

19).

(9) Remove mount between engine and body frame

rail. Mount removal may require engine position to

be raised or lowered to allow mount removal clear-

ance.

INSTALLATION

(1) Position mount into the original position on

body frame rail (Fig. 19).

Fig. 16 Left Mount (Automatic Transaxle)

1 ± MOUNT

2 ± TRANSAXLE

Fig. 17 Left Mount (Manual Transaxle)

1 ± MOUNT

2 ± TRANSAXLE

Fig. 18 Engine Mount To Bracket Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

PL2.0L SOHC ENGINE 9 - 23

REMOVAL AND INSTALLATION (Continued)

Page 748 of 1285

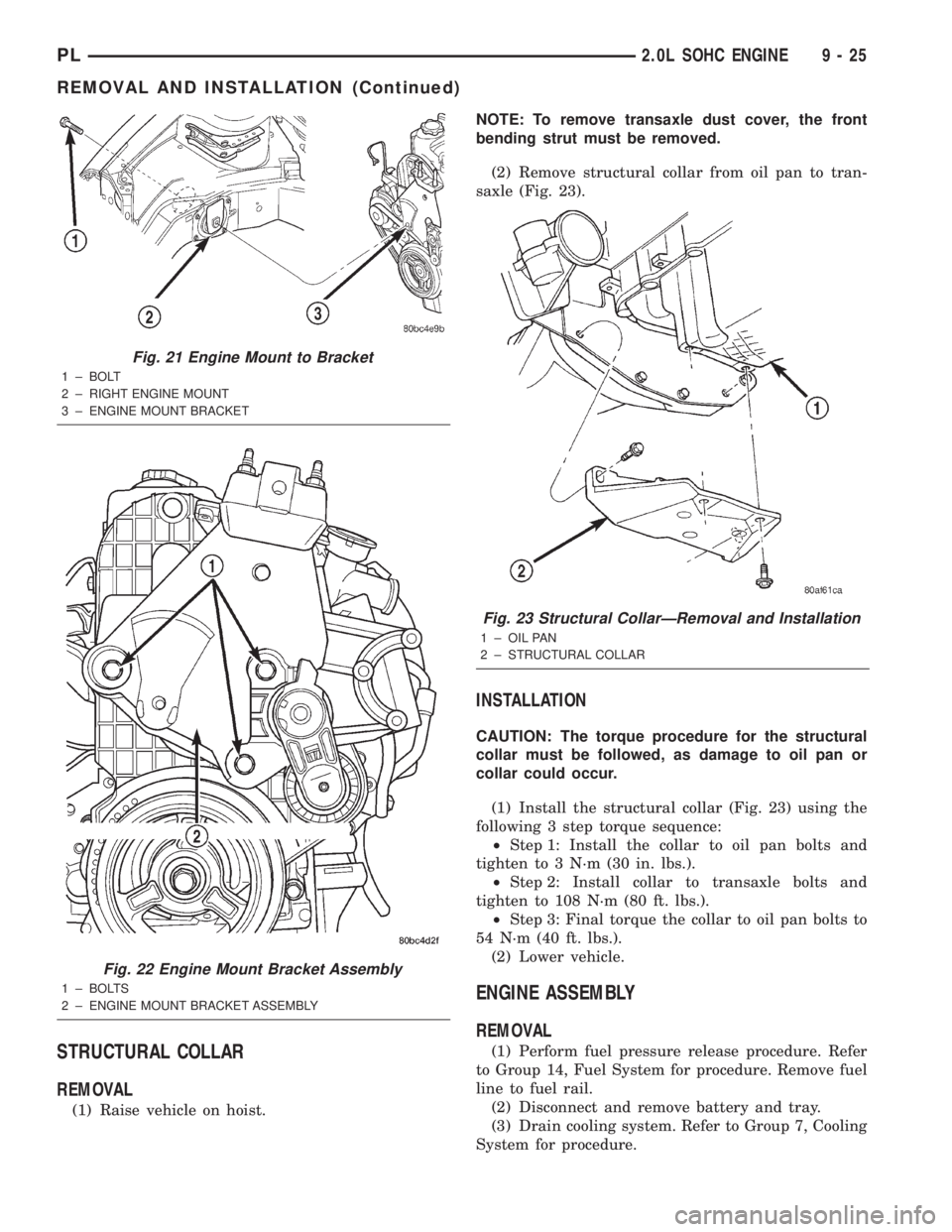

STRUCTURAL COLLAR

REMOVAL

(1) Raise vehicle on hoist.NOTE: To remove transaxle dust cover, the front

bending strut must be removed.

(2) Remove structural collar from oil pan to tran-

saxle (Fig. 23).

INSTALLATION

CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(1) Install the structural collar (Fig. 23) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(2) Lower vehicle.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect and remove battery and tray.

(3) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

Fig. 21 Engine Mount to Bracket

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

Fig. 22 Engine Mount Bracket Assembly

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET ASSEMBLY

Fig. 23 Structural CollarÐRemoval and Installation

1 ± OIL PAN

2 ± STRUCTURAL COLLAR

PL2.0L SOHC ENGINE 9 - 25

REMOVAL AND INSTALLATION (Continued)