tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 789 of 1285

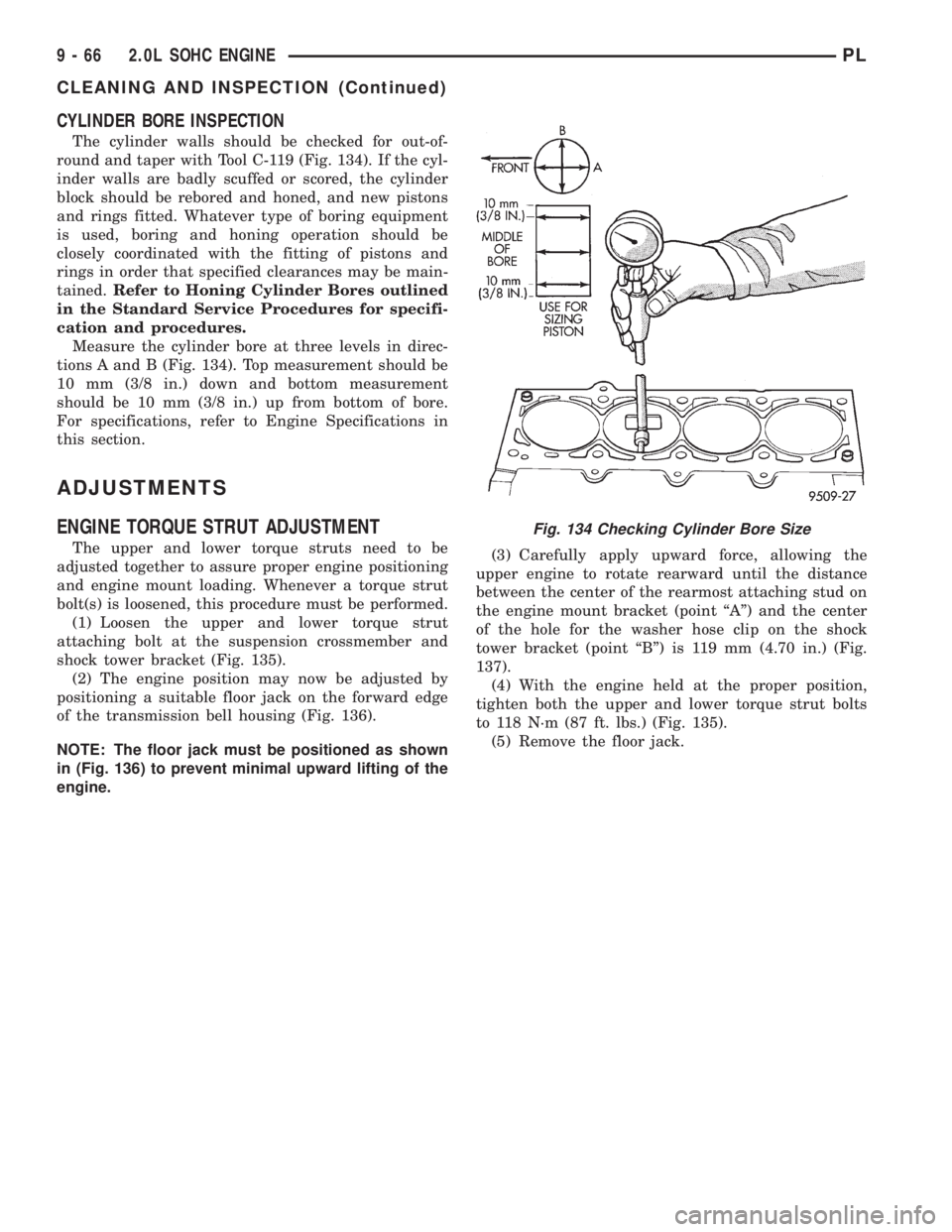

CYLINDER BORE INSPECTION

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 134). If the cyl-

inder walls are badly scuffed or scored, the cylinder

block should be rebored and honed, and new pistons

and rings fitted. Whatever type of boring equipment

is used, boring and honing operation should be

closely coordinated with the fitting of pistons and

rings in order that specified clearances may be main-

tained.Refer to Honing Cylinder Bores outlined

in the Standard Service Procedures for specifi-

cation and procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 134). Top measurement should be

10 mm (3/8 in.) down and bottom measurement

should be 10 mm (3/8 in.) up from bottom of bore.

For specifications, refer to Engine Specifications in

this section.

ADJUSTMENTS

ENGINE TORQUE STRUT ADJUSTMENT

The upper and lower torque struts need to be

adjusted together to assure proper engine positioning

and engine mount loading. Whenever a torque strut

bolt(s) is loosened, this procedure must be performed.

(1) Loosen the upper and lower torque strut

attaching bolt at the suspension crossmember and

shock tower bracket (Fig. 135).

(2) The engine position may now be adjusted by

positioning a suitable floor jack on the forward edge

of the transmission bell housing (Fig. 136).

NOTE: The floor jack must be positioned as shown

in (Fig. 136) to prevent minimal upward lifting of the

engine.(3) Carefully apply upward force, allowing the

upper engine to rotate rearward until the distance

between the center of the rearmost attaching stud on

the engine mount bracket (point ªAº) and the center

of the hole for the washer hose clip on the shock

tower bracket (point ªBº) is 119 mm (4.70 in.) (Fig.

137).

(4) With the engine held at the proper position,

tighten both the upper and lower torque strut bolts

to 118 N´m (87 ft. lbs.) (Fig. 135).

(5) Remove the floor jack.

Fig. 134 Checking Cylinder Bore Size

9 - 66 2.0L SOHC ENGINEPL

CLEANING AND INSPECTION (Continued)

Page 792 of 1285

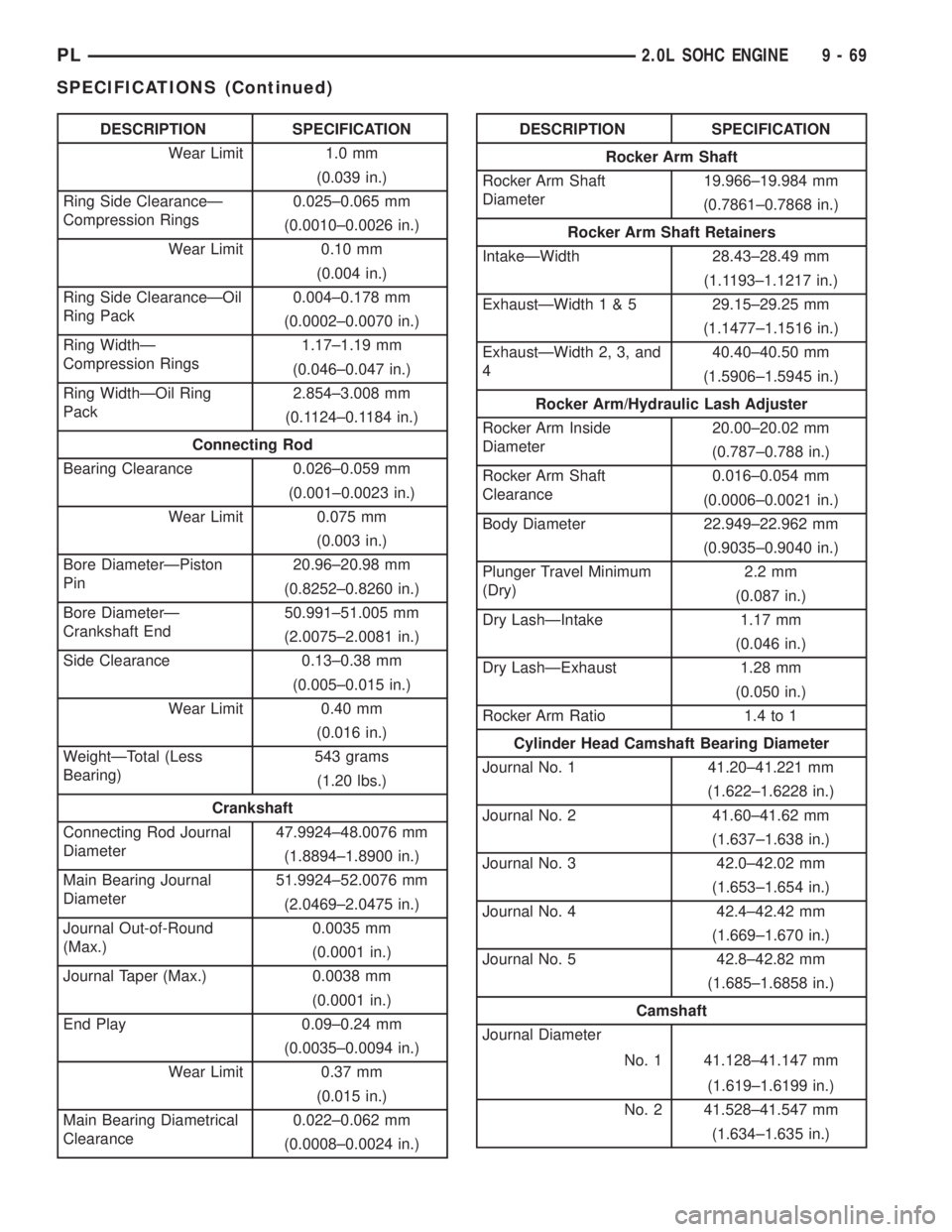

DESCRIPTION SPECIFICATION

Wear Limit 1.0 mm

(0.039 in.)

Ring Side ClearanceÐ

Compression Rings0.025±0.065 mm

(0.0010±0.0026 in.)

Wear Limit 0.10 mm

(0.004 in.)

Ring Side ClearanceÐOil

Ring Pack0.004±0.178 mm

(0.0002±0.0070 in.)

Ring WidthÐ

Compression Rings1.17±1.19 mm

(0.046±0.047 in.)

Ring WidthÐOil Ring

Pack2.854±3.008 mm

(0.1124±0.1184 in.)

Connecting Rod

Bearing Clearance 0.026±0.059 mm

(0.001±0.0023 in.)

Wear Limit 0.075 mm

(0.003 in.)

Bore DiameterÐPiston

Pin20.96±20.98 mm

(0.8252±0.8260 in.)

Bore DiameterÐ

Crankshaft End50.991±51.005 mm

(2.0075±2.0081 in.)

Side Clearance 0.13±0.38 mm

(0.005±0.015 in.)

Wear Limit 0.40 mm

(0.016 in.)

WeightÐTotal (Less

Bearing)543 grams

(1.20 lbs.)

Crankshaft

Connecting Rod Journal

Diameter47.9924±48.0076 mm

(1.8894±1.8900 in.)

Main Bearing Journal

Diameter51.9924±52.0076 mm

(2.0469±2.0475 in.)

Journal Out-of-Round

(Max.)0.0035 mm

(0.0001 in.)

Journal Taper (Max.) 0.0038 mm

(0.0001 in.)

End Play 0.09±0.24 mm

(0.0035±0.0094 in.)

Wear Limit 0.37 mm

(0.015 in.)

Main Bearing Diametrical

Clearance0.022±0.062 mm

(0.0008±0.0024 in.)DESCRIPTION SPECIFICATION

Rocker Arm Shaft

Rocker Arm Shaft

Diameter19.966±19.984 mm

(0.7861±0.7868 in.)

Rocker Arm Shaft Retainers

IntakeÐWidth 28.43±28.49 mm

(1.1193±1.1217 in.)

ExhaustÐWidth1&529.15±29.25 mm

(1.1477±1.1516 in.)

ExhaustÐWidth 2, 3, and

440.40±40.50 mm

(1.5906±1.5945 in.)

Rocker Arm/Hydraulic Lash Adjuster

Rocker Arm Inside

Diameter20.00±20.02 mm

(0.787±0.788 in.)

Rocker Arm Shaft

Clearance0.016±0.054 mm

(0.0006±0.0021 in.)

Body Diameter 22.949±22.962 mm

(0.9035±0.9040 in.)

Plunger Travel Minimum

(Dry)2.2 mm

(0.087 in.)

Dry LashÐIntake 1.17 mm

(0.046 in.)

Dry LashÐExhaust 1.28 mm

(0.050 in.)

Rocker Arm Ratio 1.4 to 1

Cylinder Head Camshaft Bearing Diameter

Journal No. 1 41.20±41.221 mm

(1.622±1.6228 in.)

Journal No. 2 41.60±41.62 mm

(1.637±1.638 in.)

Journal No. 3 42.0±42.02 mm

(1.653±1.654 in.)

Journal No. 4 42.4±42.42 mm

(1.669±1.670 in.)

Journal No. 5 42.8±42.82 mm

(1.685±1.6858 in.)

Camshaft

Journal Diameter

No. 1 41.128±41.147 mm

(1.619±1.6199 in.)

No. 2 41.528±41.547 mm

(1.634±1.635 in.)

PL2.0L SOHC ENGINE 9 - 69

SPECIFICATIONS (Continued)

Page 794 of 1285

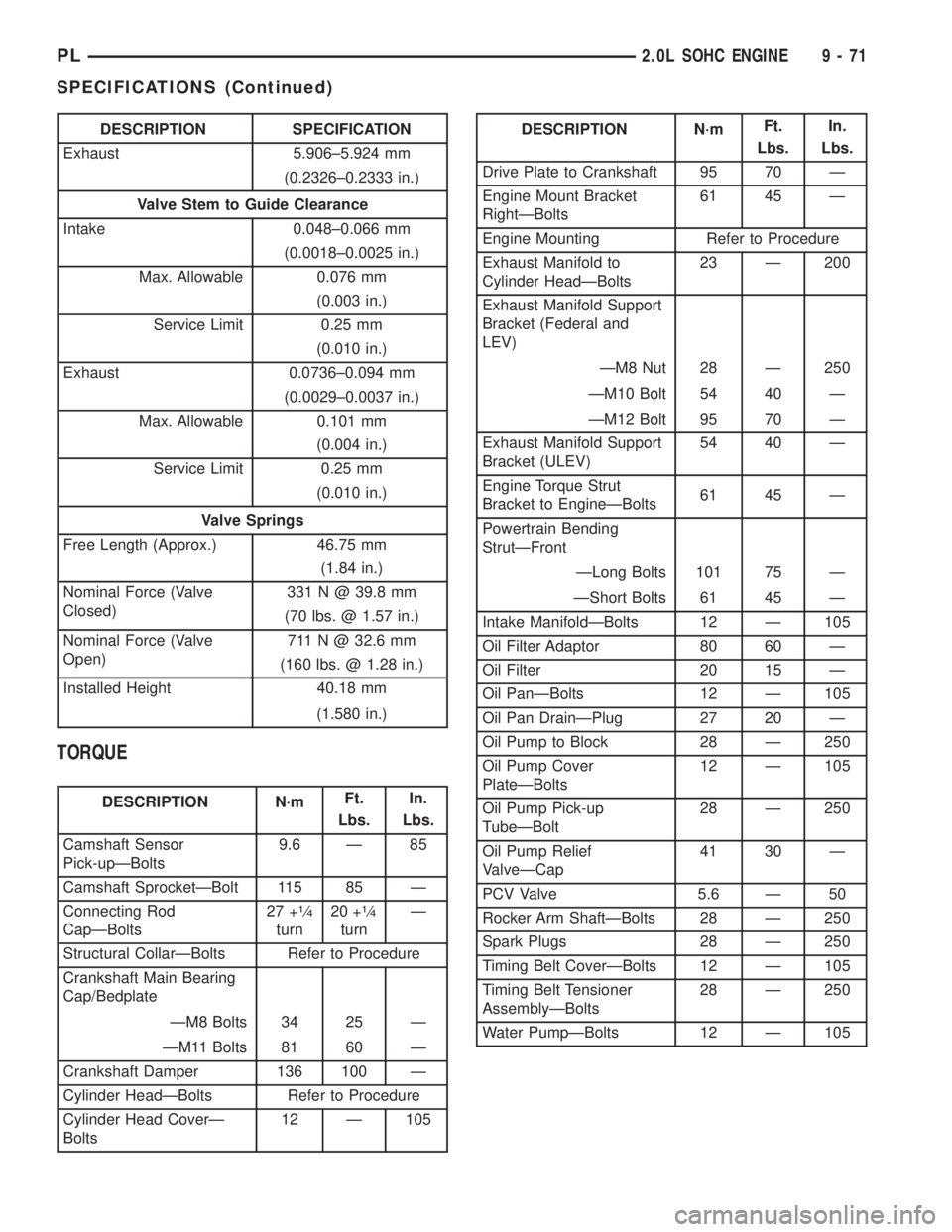

DESCRIPTION SPECIFICATION

Exhaust 5.906±5.924 mm

(0.2326±0.2333 in.)

Valve Stem to Guide Clearance

Intake 0.048±0.066 mm

(0.0018±0.0025 in.)

Max. Allowable 0.076 mm

(0.003 in.)

Service Limit 0.25 mm

(0.010 in.)

Exhaust 0.0736±0.094 mm

(0.0029±0.0037 in.)

Max. Allowable 0.101 mm

(0.004 in.)

Service Limit 0.25 mm

(0.010 in.)

Valve Springs

Free Length (Approx.) 46.75 mm

(1.84 in.)

Nominal Force (Valve

Closed)331 N @ 39.8 mm

(70 lbs. @ 1.57 in.)

Nominal Force (Valve

Open)711 N @ 32.6 mm

(160 lbs. @ 1.28 in.)

Installed Height 40.18 mm

(1.580 in.)

TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Camshaft Sensor

Pick-upÐBolts9.6 Ð 85

Camshaft SprocketÐBolt 115 85 Ð

Connecting Rod

CapÐBolts27 +

1¤4

turn20 +

1¤4

turnÐ

Structural CollarÐBolts Refer to Procedure

Crankshaft Main Bearing

Cap/Bedplate

ÐM8 Bolts 34 25 Ð

ÐM11 Bolts 81 60 Ð

Crankshaft Damper 136 100 Ð

Cylinder HeadÐBolts Refer to Procedure

Cylinder Head CoverÐ

Bolts12 Ð 105

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Drive Plate to Crankshaft 95 70 Ð

Engine Mount Bracket

RightÐBolts61 45 Ð

Engine Mounting Refer to Procedure

Exhaust Manifold to

Cylinder HeadÐBolts23 Ð 200

Exhaust Manifold Support

Bracket (Federal and

LEV)

ÐM8 Nut 28 Ð 250

ÐM10 Bolt 54 40 Ð

ÐM12 Bolt 95 70 Ð

Exhaust Manifold Support

Bracket (ULEV)54 40 Ð

Engine Torque Strut

Bracket to EngineÐBolts61 45 Ð

Powertrain Bending

StrutÐFront

ÐLong Bolts 101 75 Ð

ÐShort Bolts 61 45 Ð

Intake ManifoldÐBolts 12 Ð 105

Oil Filter Adaptor 80 60 Ð

Oil Filter 20 15 Ð

Oil PanÐBolts 12 Ð 105

Oil Pan DrainÐPlug 27 20 Ð

Oil Pump to Block 28 Ð 250

Oil Pump Cover

PlateÐBolts12 Ð 105

Oil Pump Pick-up

TubeÐBolt28 Ð 250

Oil Pump Relief

ValveÐCap41 30 Ð

PCV Valve 5.6 Ð 50

Rocker Arm ShaftÐBolts 28 Ð 250

Spark Plugs 28 Ð 250

Timing Belt CoverÐBolts 12 Ð 105

Timing Belt Tensioner

AssemblyÐBolts28 Ð 250

Water PumpÐBolts 12 Ð 105

PL2.0L SOHC ENGINE 9 - 71

SPECIFICATIONS (Continued)

Page 798 of 1285

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

EXHAUST SYSTEM........................1

EXHAUST FLEX-JOINT COUPLING............1

CATALYTIC CONVERTER....................1

EXHAUST HEAT SHIELDS..................3

DIAGNOSIS AND TESTING

EXHAUST SYSTEM DIAGNOSIS CHART.......4

REMOVAL AND INSTALLATION

EXHAUST PIPE AND MUFFLER..............4CATALYTIC CONVERTER....................7

CLEANING AND INSPECTION

EXHAUST SYSTEM........................8

ADJUSTMENTS

EXHAUST SYSTEM ALIGNMENT.............8

SPECIFICATIONS

TORQUE SPECIFICATION CHART.............8

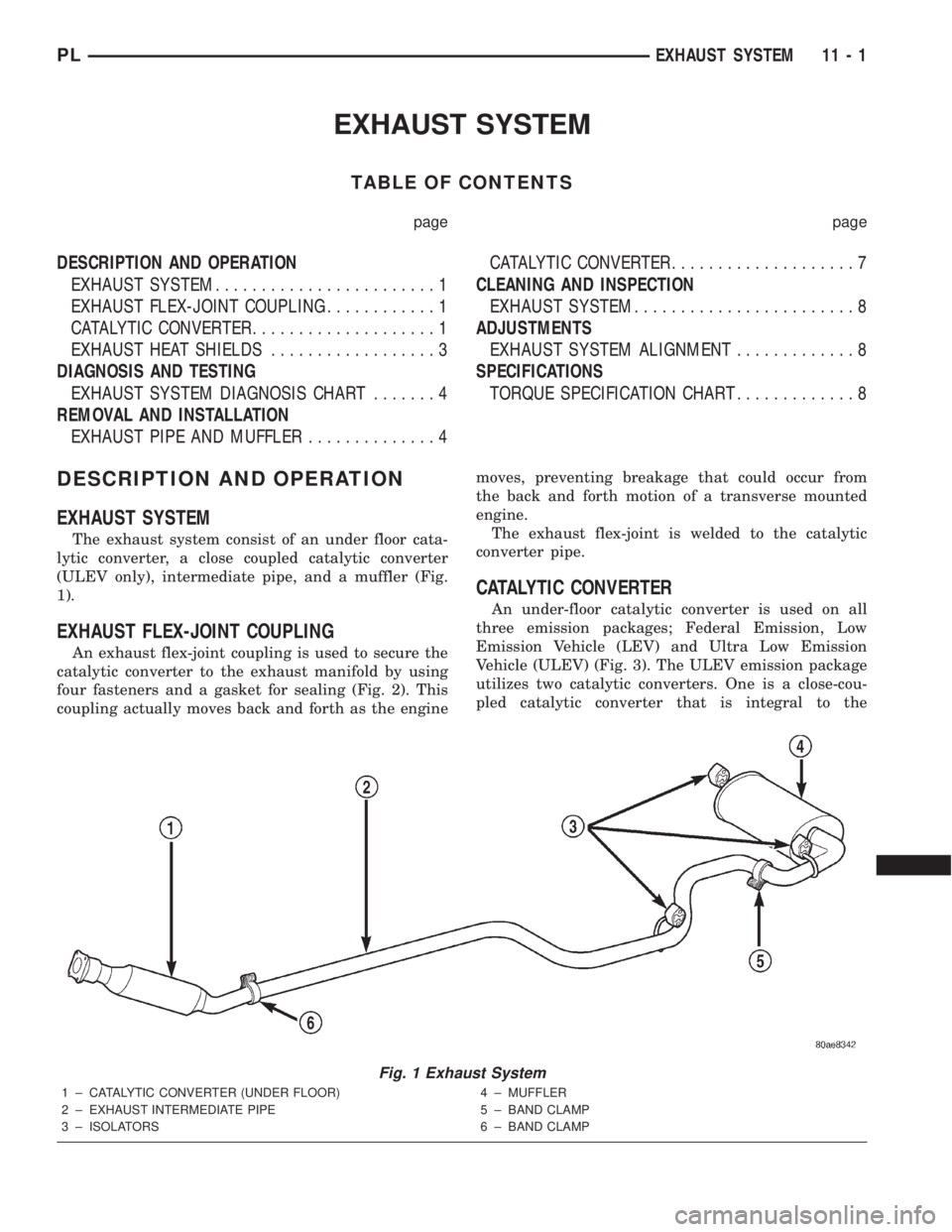

DESCRIPTION AND OPERATION

EXHAUST SYSTEM

The exhaust system consist of an under floor cata-

lytic converter, a close coupled catalytic converter

(ULEV only), intermediate pipe, and a muffler (Fig.

1).

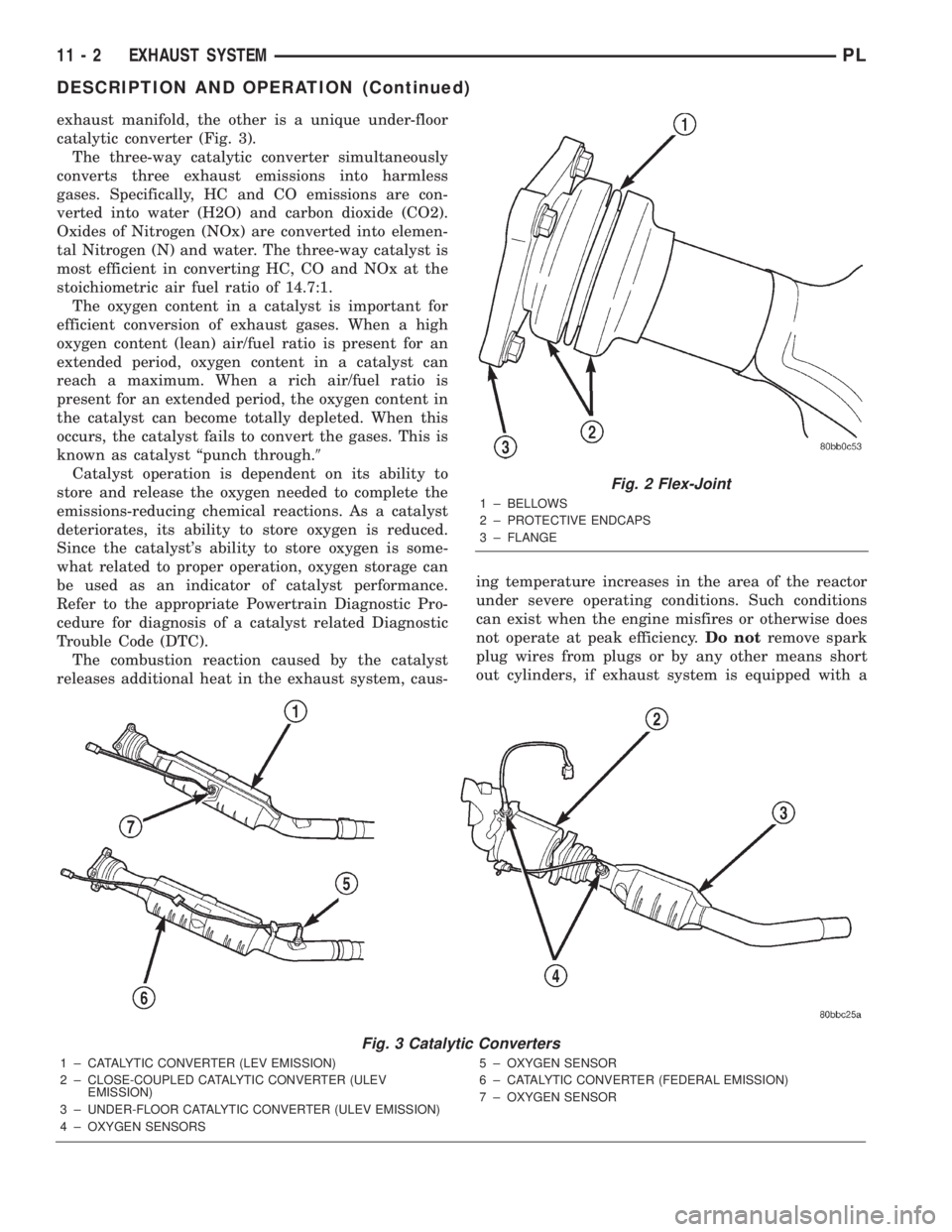

EXHAUST FLEX-JOINT COUPLING

An exhaust flex-joint coupling is used to secure the

catalytic converter to the exhaust manifold by using

four fasteners and a gasket for sealing (Fig. 2). This

coupling actually moves back and forth as the enginemoves, preventing breakage that could occur from

the back and forth motion of a transverse mounted

engine.

The exhaust flex-joint is welded to the catalytic

converter pipe.

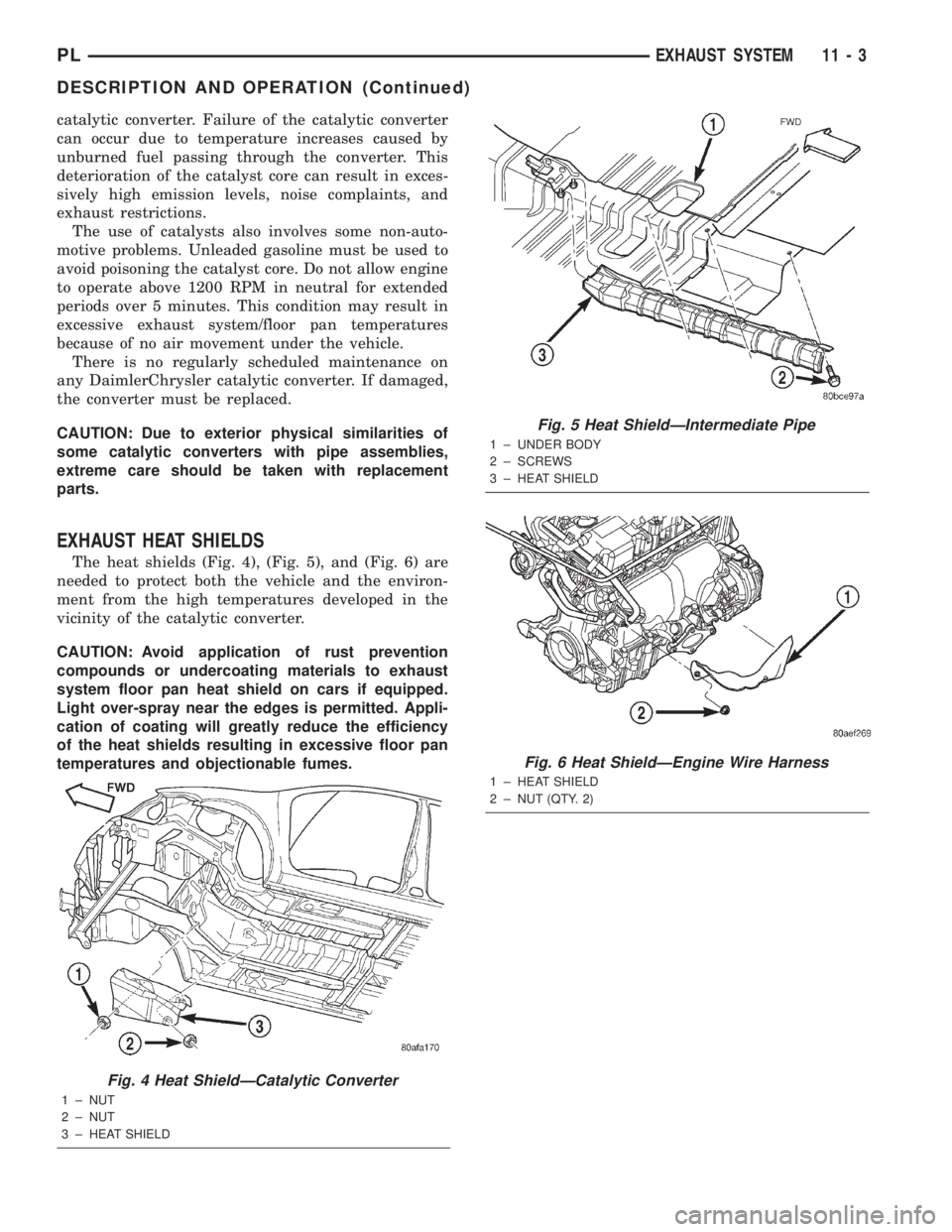

CATALYTIC CONVERTER

An under-floor catalytic converter is used on all

three emission packages; Federal Emission, Low

Emission Vehicle (LEV) and Ultra Low Emission

Vehicle (ULEV) (Fig. 3). The ULEV emission package

utilizes two catalytic converters. One is a close-cou-

pled catalytic converter that is integral to the

Fig. 1 Exhaust System

1 ± CATALYTIC CONVERTER (UNDER FLOOR)

2 ± EXHAUST INTERMEDIATE PIPE

3 ± ISOLATORS4 ± MUFFLER

5 ± BAND CLAMP

6 ± BAND CLAMP

PLEXHAUST SYSTEM 11 - 1

Page 799 of 1285

exhaust manifold, the other is a unique under-floor

catalytic converter (Fig. 3).

The three-way catalytic converter simultaneously

converts three exhaust emissions into harmless

gases. Specifically, HC and CO emissions are con-

verted into water (H2O) and carbon dioxide (CO2).

Oxides of Nitrogen (NOx) are converted into elemen-

tal Nitrogen (N) and water. The three-way catalyst is

most efficient in converting HC, CO and NOx at the

stoichiometric air fuel ratio of 14.7:1.

The oxygen content in a catalyst is important for

efficient conversion of exhaust gases. When a high

oxygen content (lean) air/fuel ratio is present for an

extended period, oxygen content in a catalyst can

reach a maximum. When a rich air/fuel ratio is

present for an extended period, the oxygen content in

the catalyst can become totally depleted. When this

occurs, the catalyst fails to convert the gases. This is

known as catalyst ªpunch through.9

Catalyst operation is dependent on its ability to

store and release the oxygen needed to complete the

emissions-reducing chemical reactions. As a catalyst

deteriorates, its ability to store oxygen is reduced.

Since the catalyst's ability to store oxygen is some-

what related to proper operation, oxygen storage can

be used as an indicator of catalyst performance.

Refer to the appropriate Powertrain Diagnostic Pro-

cedure for diagnosis of a catalyst related Diagnostic

Trouble Code (DTC).

The combustion reaction caused by the catalyst

releases additional heat in the exhaust system, caus-ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency.Do notremove spark

plug wires from plugs or by any other means short

out cylinders, if exhaust system is equipped with a

Fig. 2 Flex-Joint

1 ± BELLOWS

2 ± PROTECTIVE ENDCAPS

3 ± FLANGE

Fig. 3 Catalytic Converters

1 ± CATALYTIC CONVERTER (LEV EMISSION)

2 ± CLOSE-COUPLED CATALYTIC CONVERTER (ULEV

EMISSION)

3 ± UNDER-FLOOR CATALYTIC CONVERTER (ULEV EMISSION)

4 ± OXYGEN SENSORS5 ± OXYGEN SENSOR

6 ± CATALYTIC CONVERTER (FEDERAL EMISSION)

7 ± OXYGEN SENSOR

11 - 2 EXHAUST SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 800 of 1285

catalytic converter. Failure of the catalytic converter

can occur due to temperature increases caused by

unburned fuel passing through the converter. This

deterioration of the catalyst core can result in exces-

sively high emission levels, noise complaints, and

exhaust restrictions.

The use of catalysts also involves some non-auto-

motive problems. Unleaded gasoline must be used to

avoid poisoning the catalyst core. Do not allow engine

to operate above 1200 RPM in neutral for extended

periods over 5 minutes. This condition may result in

excessive exhaust system/floor pan temperatures

because of no air movement under the vehicle.

There is no regularly scheduled maintenance on

any DaimlerChrysler catalytic converter. If damaged,

the converter must be replaced.

CAUTION: Due to exterior physical similarities of

some catalytic converters with pipe assemblies,

extreme care should be taken with replacement

parts.

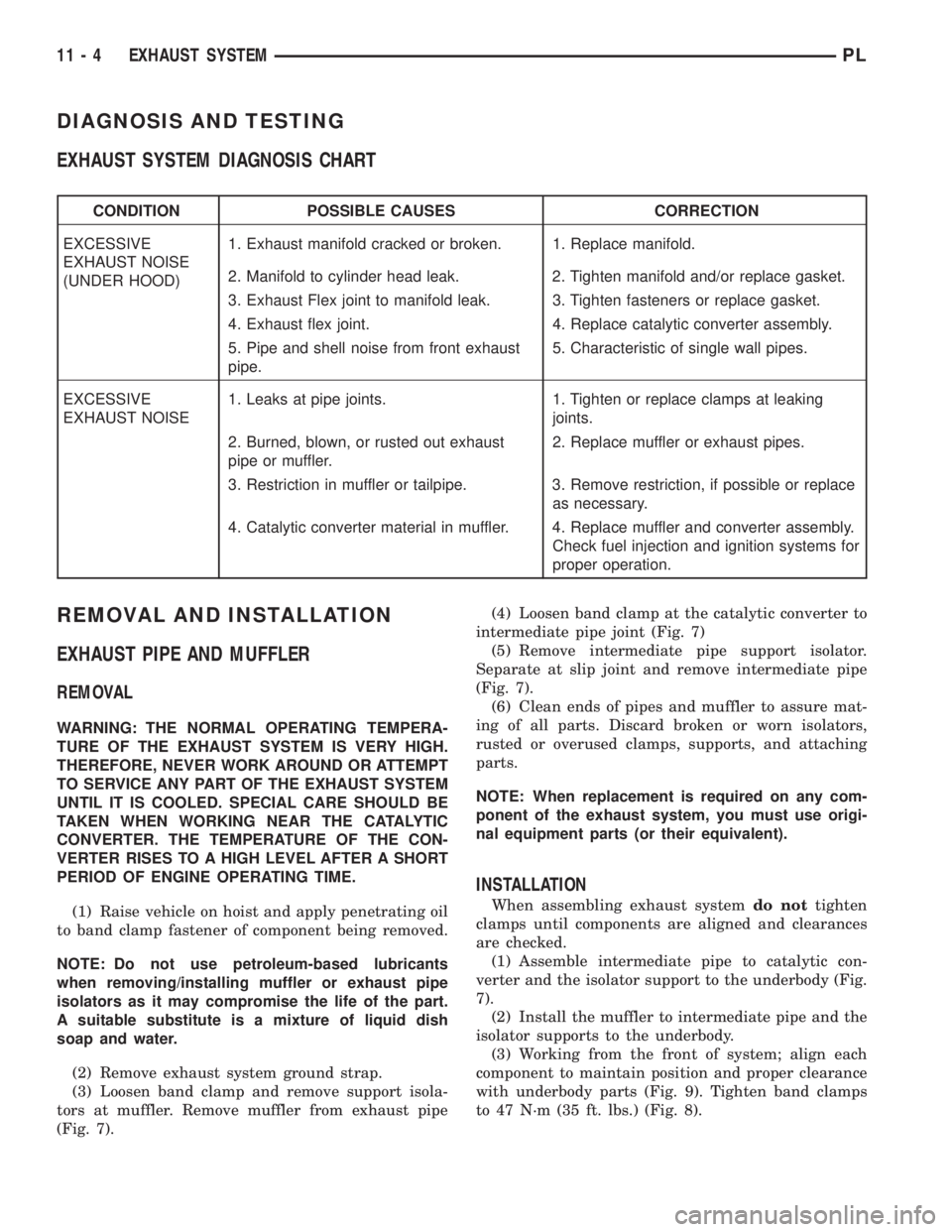

EXHAUST HEAT SHIELDS

The heat shields (Fig. 4), (Fig. 5), and (Fig. 6) are

needed to protect both the vehicle and the environ-

ment from the high temperatures developed in the

vicinity of the catalytic converter.

CAUTION: Avoid application of rust prevention

compounds or undercoating materials to exhaust

system floor pan heat shield on cars if equipped.

Light over-spray near the edges is permitted. Appli-

cation of coating will greatly reduce the efficiency

of the heat shields resulting in excessive floor pan

temperatures and objectionable fumes.

Fig. 4 Heat ShieldÐCatalytic Converter

1 ± NUT

2 ± NUT

3 ± HEAT SHIELD

Fig. 5 Heat ShieldÐIntermediate Pipe

1 ± UNDER BODY

2 ± SCREWS

3 ± HEAT SHIELD

Fig. 6 Heat ShieldÐEngine Wire Harness

1 ± HEAT SHIELD

2 ± NUT (QTY. 2)

PLEXHAUST SYSTEM 11 - 3

DESCRIPTION AND OPERATION (Continued)

Page 801 of 1285

DIAGNOSIS AND TESTING

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE

EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or broken. 1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace gasket.

3. Exhaust Flex joint to manifold leak. 3. Tighten fasteners or replace gasket.

4. Exhaust flex joint. 4. Replace catalytic converter assembly.

5. Pipe and shell noise from front exhaust

pipe.5. Characteristic of single wall pipes.

EXCESSIVE

EXHAUST NOISE1. Leaks at pipe joints. 1. Tighten or replace clamps at leaking

joints.

2. Burned, blown, or rusted out exhaust

pipe or muffler.2. Replace muffler or exhaust pipes.

3. Restriction in muffler or tailpipe. 3. Remove restriction, if possible or replace

as necessary.

4. Catalytic converter material in muffler. 4. Replace muffler and converter assembly.

Check fuel injection and ignition systems for

proper operation.

REMOVAL AND INSTALLATION

EXHAUST PIPE AND MUFFLER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATING TIME.

(1) Raise vehicle on hoist and apply penetrating oil

to band clamp fastener of component being removed.

NOTE: Do not use petroleum-based lubricants

when removing/installing muffler or exhaust pipe

isolators as it may compromise the life of the part.

A suitable substitute is a mixture of liquid dish

soap and water.

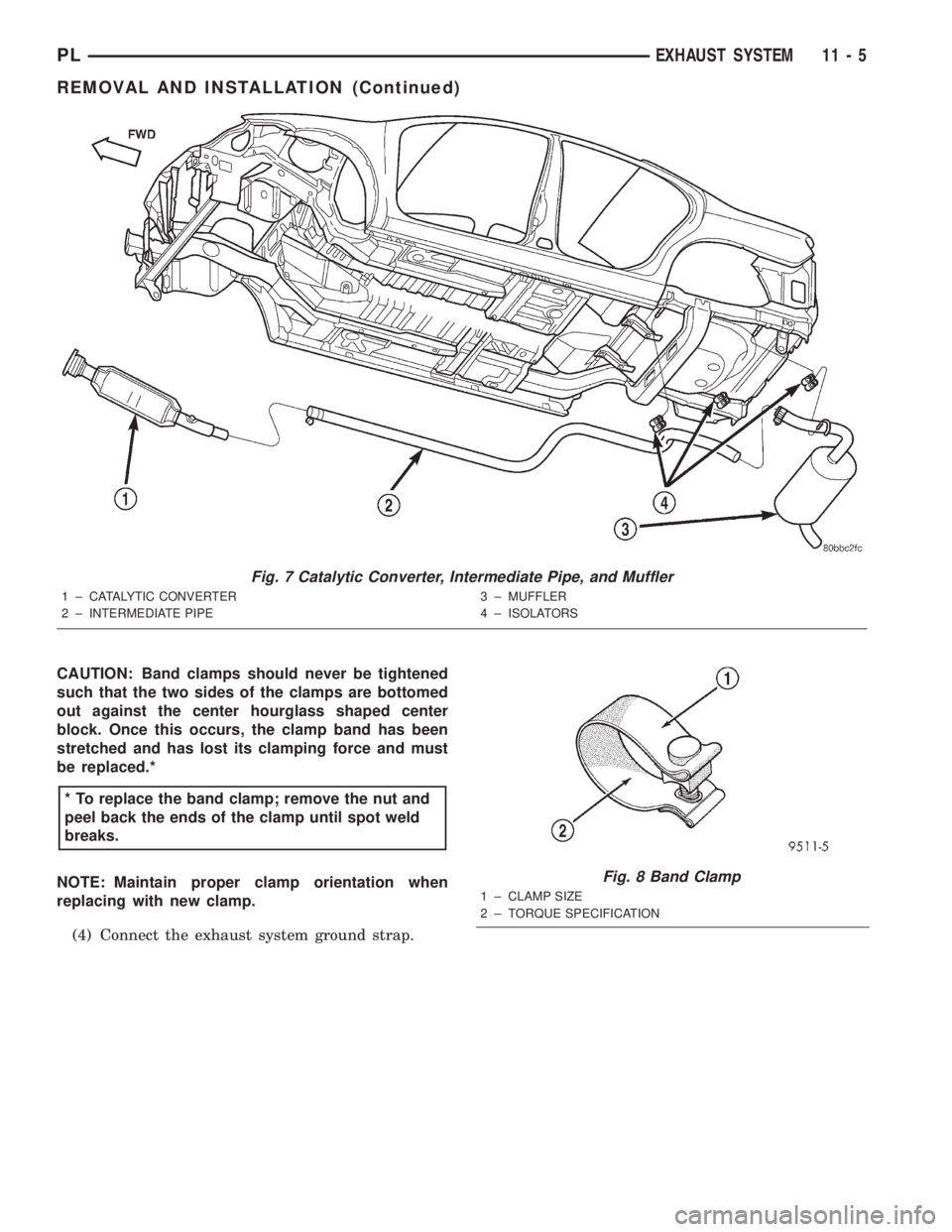

(2) Remove exhaust system ground strap.

(3) Loosen band clamp and remove support isola-

tors at muffler. Remove muffler from exhaust pipe

(Fig. 7).(4) Loosen band clamp at the catalytic converter to

intermediate pipe joint (Fig. 7)

(5) Remove intermediate pipe support isolator.

Separate at slip joint and remove intermediate pipe

(Fig. 7).

(6) Clean ends of pipes and muffler to assure mat-

ing of all parts. Discard broken or worn isolators,

rusted or overused clamps, supports, and attaching

parts.

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble intermediate pipe to catalytic con-

verter and the isolator support to the underbody (Fig.

7).

(2) Install the muffler to intermediate pipe and the

isolator supports to the underbody.

(3) Working from the front of system; align each

component to maintain position and proper clearance

with underbody parts (Fig. 9). Tighten band clamps

to 47 N´m (35 ft. lbs.) (Fig. 8).

11 - 4 EXHAUST SYSTEMPL

Page 802 of 1285

CAUTION: Band clamps should never be tightened

such that the two sides of the clamps are bottomed

out against the center hourglass shaped center

block. Once this occurs, the clamp band has been

stretched and has lost its clamping force and must

be replaced.*

NOTE: Maintain proper clamp orientation when

replacing with new clamp.

(4) Connect the exhaust system ground strap.

Fig. 7 Catalytic Converter, Intermediate Pipe, and Muffler

1 ± CATALYTIC CONVERTER

2 ± INTERMEDIATE PIPE3 ± MUFFLER

4 ± ISOLATORS

* To replace the band clamp; remove the nut and

peel back the ends of the clamp until spot weld

breaks.

Fig. 8 Band Clamp

1 ± CLAMP SIZE

2 ± TORQUE SPECIFICATION

PLEXHAUST SYSTEM 11 - 5

REMOVAL AND INSTALLATION (Continued)

Page 804 of 1285

CATALYTIC CONVERTER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER ATTEMPT TO SERVICE ANY

PART OF THE EXHAUST SYSTEM UNTIL IT IS

COOLED. SPECIAL CARE SHOULD BE TAKEN

WHEN WORKING NEAR THE CATALYTIC CON-

VERTER. THE TEMPERATURE OF THE CONVERTER

RISES TO A HIGH LEVEL AFTER A SHORT PERIOD

OF ENGINE OPERATION TIME.

NOTE: Vehicles equipped with the ULEV emission

package are equipped with an additional catalytic

converter that is integral to the exhaust manifold.

Refer to Exhaust Manifold in Group 9, Engine for

procedure.

(1) Remove muffler and exhaust pipe. Refer to pro-

cedure in this section.

(2) Disconnect downstream oxygen sensor electri-

cal connector.

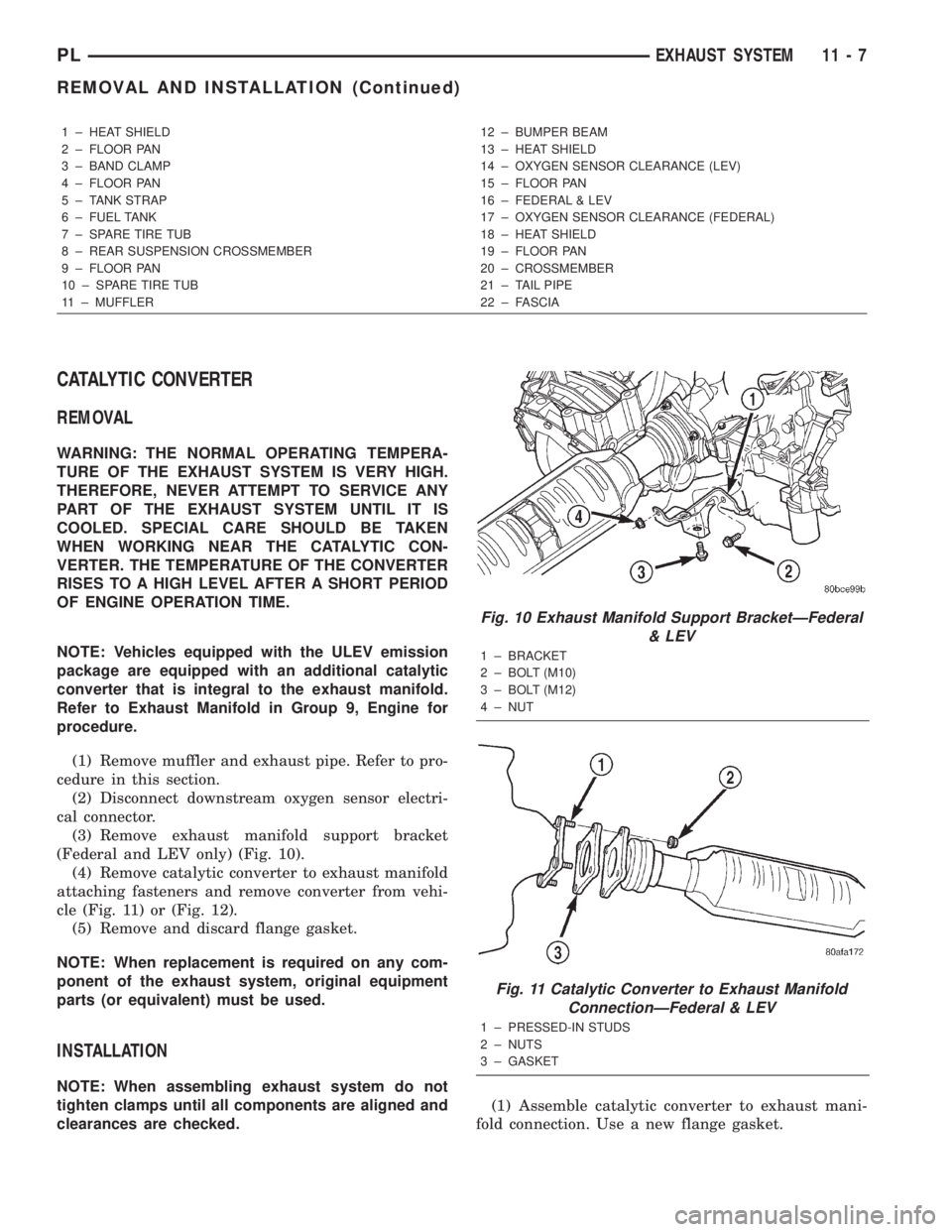

(3) Remove exhaust manifold support bracket

(Federal and LEV only) (Fig. 10).

(4) Remove catalytic converter to exhaust manifold

attaching fasteners and remove converter from vehi-

cle (Fig. 11) or (Fig. 12).

(5) Remove and discard flange gasket.

NOTE: When replacement is required on any com-

ponent of the exhaust system, original equipment

parts (or equivalent) must be used.

INSTALLATION

NOTE: When assembling exhaust system do not

tighten clamps until all components are aligned and

clearances are checked.(1) Assemble catalytic converter to exhaust mani-

fold connection. Use a new flange gasket.

1 ± HEAT SHIELD

2 ± FLOOR PAN

3 ± BAND CLAMP

4 ± FLOOR PAN

5 ± TANK STRAP

6 ± FUEL TANK

7 ± SPARE TIRE TUB

8 ± REAR SUSPENSION CROSSMEMBER

9 ± FLOOR PAN

10 ± SPARE TIRE TUB

11 ± MUFFLER12 ± BUMPER BEAM

13 ± HEAT SHIELD

14 ± OXYGEN SENSOR CLEARANCE (LEV)

15 ± FLOOR PAN

16 ± FEDERAL & LEV

17 ± OXYGEN SENSOR CLEARANCE (FEDERAL)

18 ± HEAT SHIELD

19 ± FLOOR PAN

20 ± CROSSMEMBER

21 ± TAIL PIPE

22 ± FASCIA

Fig. 10 Exhaust Manifold Support BracketÐFederal

& LEV

1 ± BRACKET

2 ± BOLT (M10)

3 ± BOLT (M12)

4 ± NUT

Fig. 11 Catalytic Converter to Exhaust Manifold

ConnectionÐFederal & LEV

1 ± PRESSED-IN STUDS

2 ± NUTS

3 ± GASKET

PLEXHAUST SYSTEM 11 - 7

REMOVAL AND INSTALLATION (Continued)

Page 811 of 1285

CAUTION: After removing the steering knuckle from

the ball joint stud, do not pull outward on the knuckle.

Pulling the steering knuckle outward at this point can

separate the inner C/V joint on the driveshaft. Refer to

FRONT DRIVESHAFTS in the DIFFERENTIAL AND

DRIVELINE group for further information.

NOTE: Use caution when separating the ball joint

stud from the steering knuckle, so the ball joint seal

does not get cut.

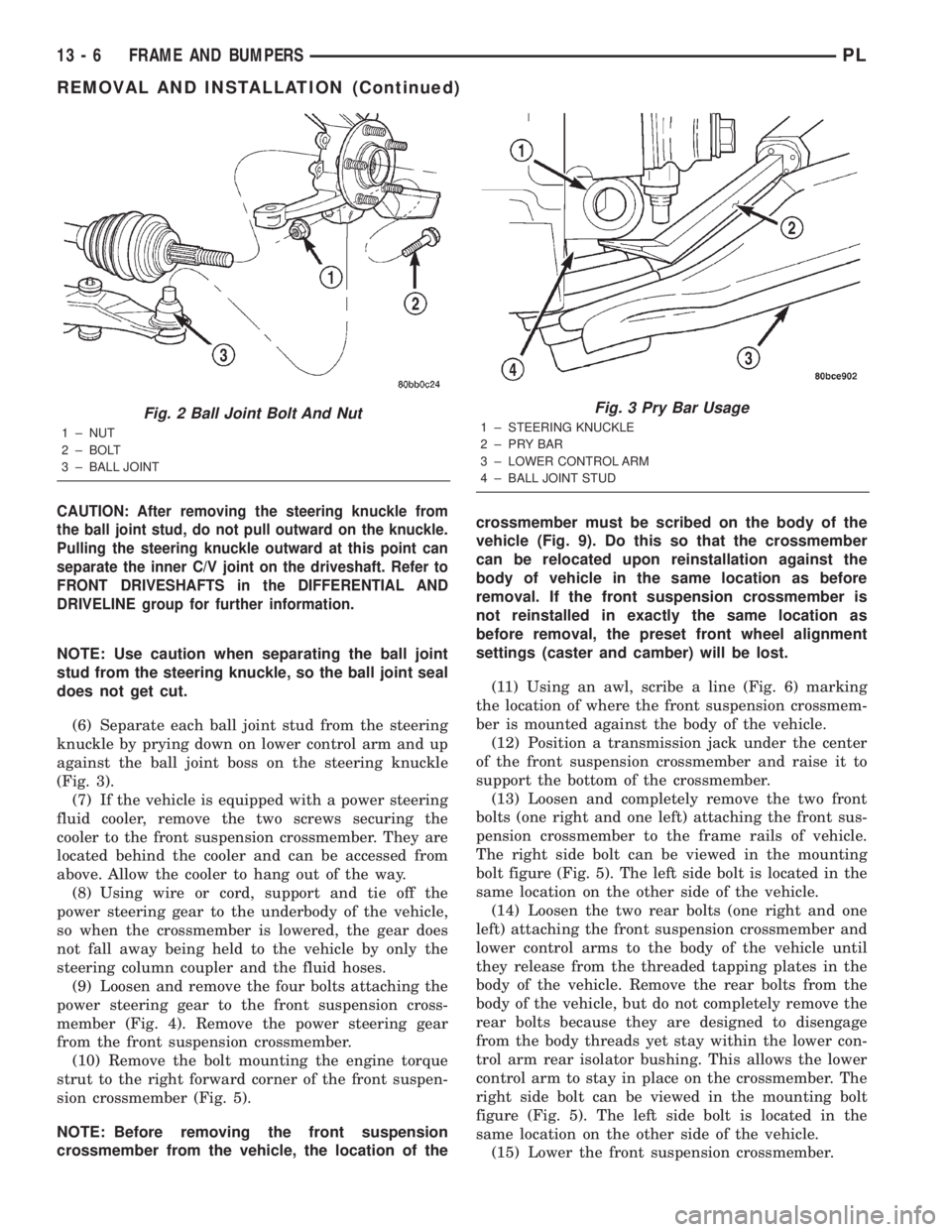

(6) Separate each ball joint stud from the steering

knuckle by prying down on lower control arm and up

against the ball joint boss on the steering knuckle

(Fig. 3).

(7) If the vehicle is equipped with a power steering

fluid cooler, remove the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler and can be accessed from

above. Allow the cooler to hang out of the way.

(8) Using wire or cord, support and tie off the

power steering gear to the underbody of the vehicle,

so when the crossmember is lowered, the gear does

not fall away being held to the vehicle by only the

steering column coupler and the fluid hoses.

(9) Loosen and remove the four bolts attaching the

power steering gear to the front suspension cross-

member (Fig. 4). Remove the power steering gear

from the front suspension crossmember.

(10) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 5).

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of thecrossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

(11) Using an awl, scribe a line (Fig. 6) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.

(12) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(13) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle.

(14) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Remove the rear bolts from the

body of the vehicle, but do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle.

(15) Lower the front suspension crossmember.

Fig. 2 Ball Joint Bolt And Nut

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

Fig. 3 Pry Bar Usage

1 ± STEERING KNUCKLE

2±PRYBAR

3 ± LOWER CONTROL ARM

4 ± BALL JOINT STUD

13 - 6 FRAME AND BUMPERSPL

REMOVAL AND INSTALLATION (Continued)