lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 750 of 1285

(8) Install lower engine torque strut. Refer to pro-

cedure in this section.

(9) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System for procedure and torque

specifications.

(10) Connect the downstream oxygen sensor.

(11) Install A/C compressor and hoses. Refer to

Group 24, Heater and Air Conditioning for procedure.

(12) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(13) Install inner splash shield.

(14) Install wheels and lower vehicle.

(15) Install power steering pump and reservoir.

Refer to Group 7, Cooling System Accessory Drive

Section for belt tension adjustment.

(16)Manual Transmission:Connect clutch cable,

reverse light electrical connector and shift linkages.

Refer to Group 6, Clutch.

(17)Automatic Transmission:Connect shifter,

kickdown linkage and cooler lines. Refer to Group 21,

Transaxle for procedures.

(18) Connect fuel line and heater hoses.

(19)

Install all ground straps. Connect engine wiring

harness. Refer to Group 8, Electrical for procedure.

(20) Install lower radiator hose, fan module, and

upper radiator hose. Refer to Group 7, Cooling Sys-

tem for procedures

(21) Fill cooling system. Refer to Group 7, Cooling

System for filling procedure.

(22) Install battery tray and battery.

(23) Install air cleaner housing assembly and con-

nect intake duct to intake manifold.(24) Connect all throttle body electrical connectors

and linkage.

(25) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

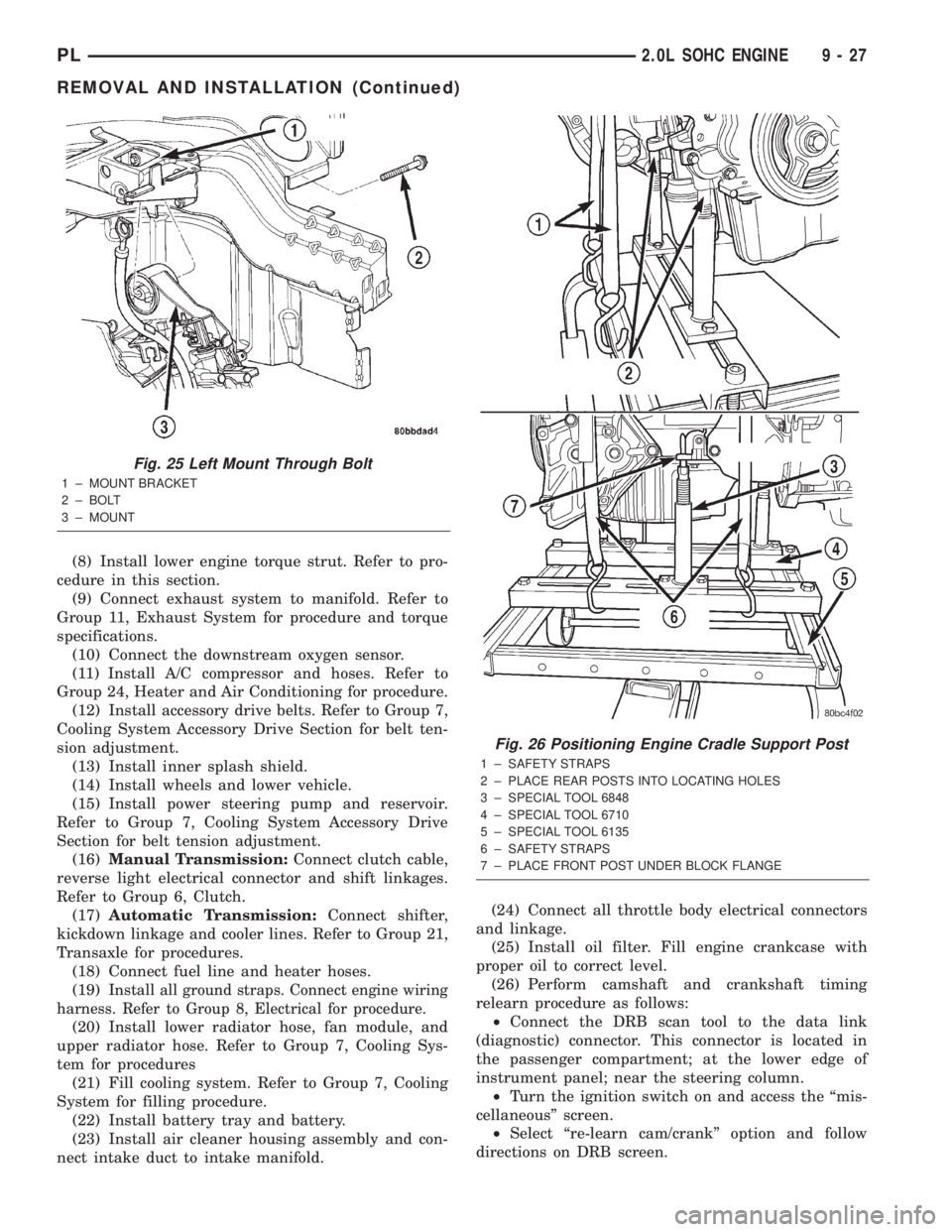

Fig. 25 Left Mount Through Bolt

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

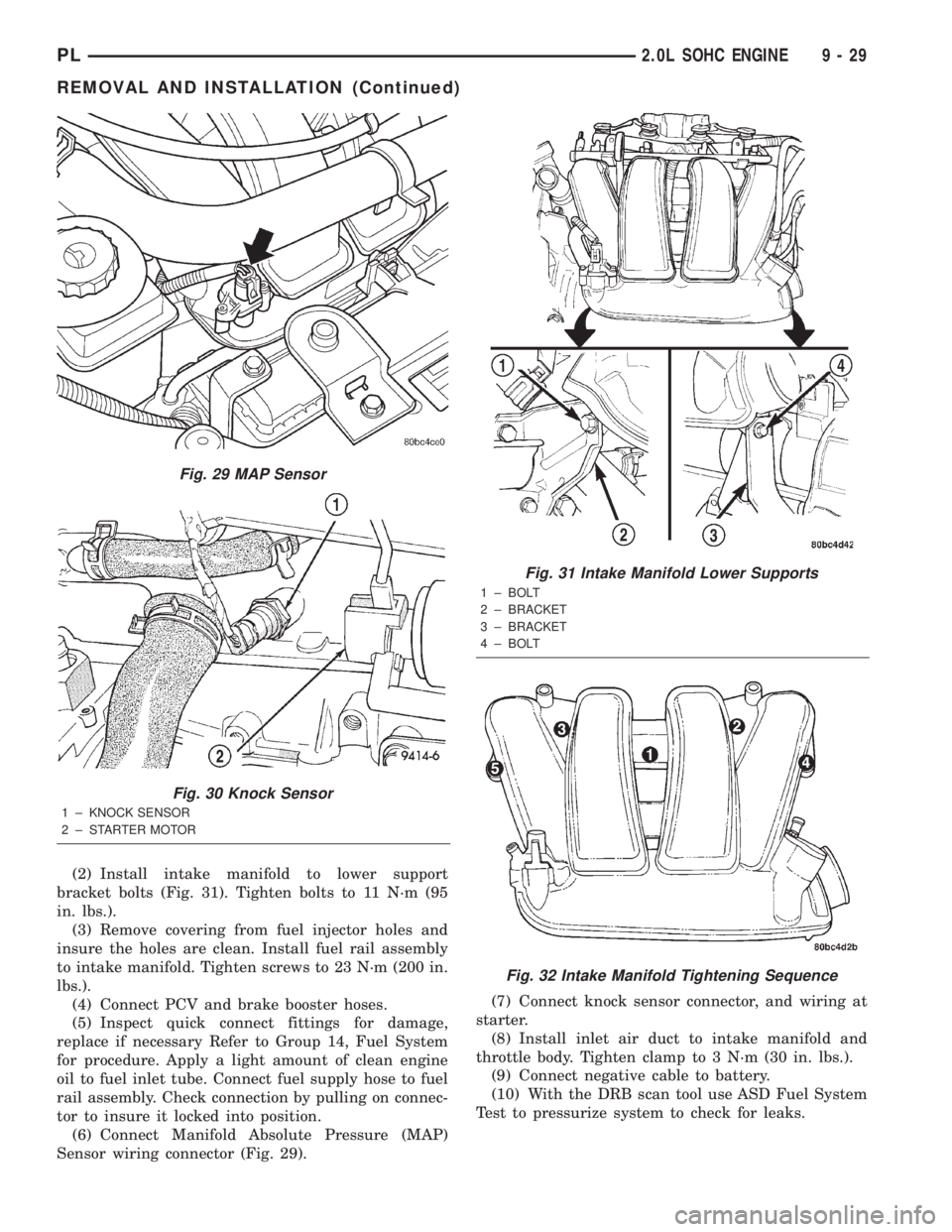

Fig. 26 Positioning Engine Cradle Support Post

1 ± SAFETY STRAPS

2 ± PLACE REAR POSTS INTO LOCATING HOLES

3 ± SPECIAL TOOL 6848

4 ± SPECIAL TOOL 6710

5 ± SPECIAL TOOL 6135

6 ± SAFETY STRAPS

7 ± PLACE FRONT POST UNDER BLOCK FLANGE

PL2.0L SOHC ENGINE 9 - 27

REMOVAL AND INSTALLATION (Continued)

Page 752 of 1285

(2) Install intake manifold to lower support

bracket bolts (Fig. 31). Tighten bolts to 11 N´m (95

in. lbs.).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

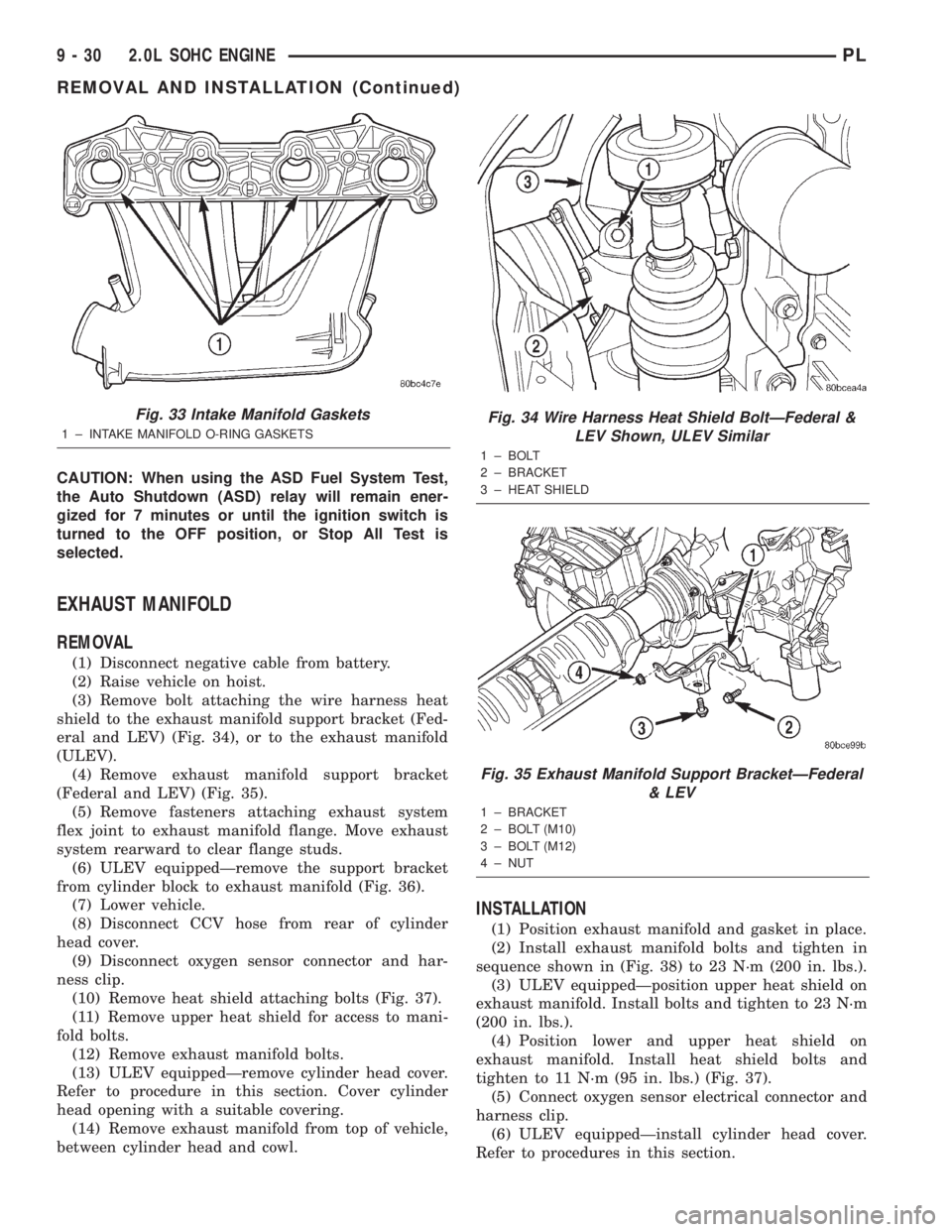

(6) Connect Manifold Absolute Pressure (MAP)

Sensor wiring connector (Fig. 29).(7) Connect knock sensor connector, and wiring at

starter.

(8) Install inlet air duct to intake manifold and

throttle body. Tighten clamp to 3 N´m (30 in. lbs.).

(9) Connect negative cable to battery.

(10) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

Fig. 29 MAP Sensor

Fig. 30 Knock Sensor

1 ± KNOCK SENSOR

2 ± STARTER MOTOR

Fig. 31 Intake Manifold Lower Supports

1 ± BOLT

2 ± BRACKET

3 ± BRACKET

4 ± BOLT

Fig. 32 Intake Manifold Tightening Sequence

PL2.0L SOHC ENGINE 9 - 29

REMOVAL AND INSTALLATION (Continued)

Page 753 of 1285

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

EXHAUST MANIFOLD

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

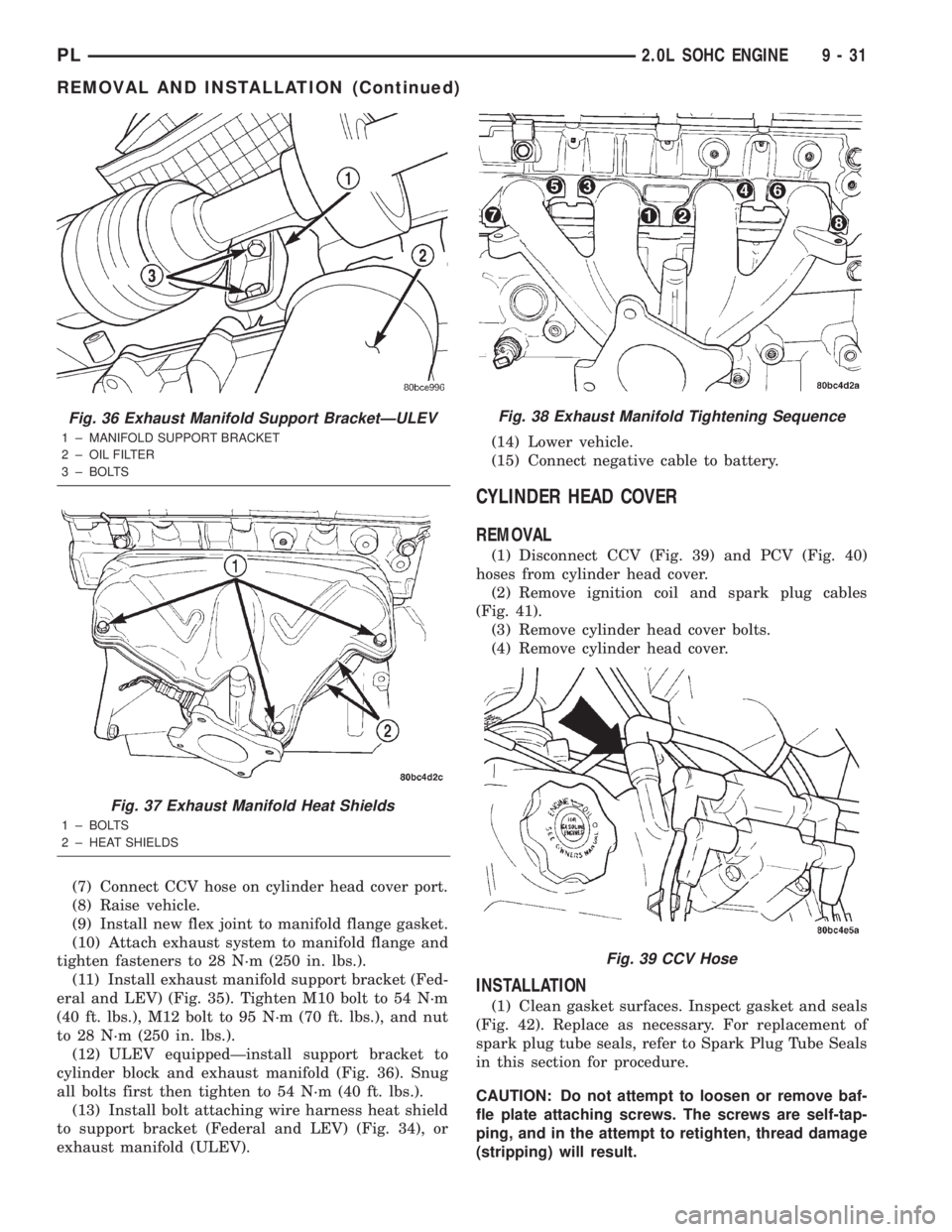

(3) Remove bolt attaching the wire harness heat

shield to the exhaust manifold support bracket (Fed-

eral and LEV) (Fig. 34), or to the exhaust manifold

(ULEV).

(4) Remove exhaust manifold support bracket

(Federal and LEV) (Fig. 35).

(5) Remove fasteners attaching exhaust system

flex joint to exhaust manifold flange. Move exhaust

system rearward to clear flange studs.

(6) ULEV equippedÐremove the support bracket

from cylinder block to exhaust manifold (Fig. 36).

(7) Lower vehicle.

(8) Disconnect CCV hose from rear of cylinder

head cover.

(9) Disconnect oxygen sensor connector and har-

ness clip.

(10) Remove heat shield attaching bolts (Fig. 37).

(11) Remove upper heat shield for access to mani-

fold bolts.

(12) Remove exhaust manifold bolts.

(13) ULEV equippedÐremove cylinder head cover.

Refer to procedure in this section. Cover cylinder

head opening with a suitable covering.

(14) Remove exhaust manifold from top of vehicle,

between cylinder head and cowl.

INSTALLATION

(1) Position exhaust manifold and gasket in place.

(2) Install exhaust manifold bolts and tighten in

sequence shown in (Fig. 38) to 23 N´m (200 in. lbs.).

(3) ULEV equippedÐposition upper heat shield on

exhaust manifold. Install bolts and tighten to 23 N´m

(200 in. lbs.).

(4) Position lower and upper heat shield on

exhaust manifold. Install heat shield bolts and

tighten to 11 N´m (95 in. lbs.) (Fig. 37).

(5) Connect oxygen sensor electrical connector and

harness clip.

(6) ULEV equippedÐinstall cylinder head cover.

Refer to procedures in this section.

Fig. 33 Intake Manifold Gaskets

1 ± INTAKE MANIFOLD O-RING GASKETS

Fig. 34 Wire Harness Heat Shield BoltÐFederal &

LEV Shown, ULEV Similar

1 ± BOLT

2 ± BRACKET

3 ± HEAT SHIELD

Fig. 35 Exhaust Manifold Support BracketÐFederal

& LEV

1 ± BRACKET

2 ± BOLT (M10)

3 ± BOLT (M12)

4 ± NUT

9 - 30 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 754 of 1285

(7) Connect CCV hose on cylinder head cover port.

(8) Raise vehicle.

(9) Install new flex joint to manifold flange gasket.

(10) Attach exhaust system to manifold flange and

tighten fasteners to 28 N´m (250 in. lbs.).

(11) Install exhaust manifold support bracket (Fed-

eral and LEV) (Fig. 35). Tighten M10 bolt to 54 N´m

(40 ft. lbs.), M12 bolt to 95 N´m (70 ft. lbs.), and nut

to 28 N´m (250 in. lbs.).

(12) ULEV equippedÐinstall support bracket to

cylinder block and exhaust manifold (Fig. 36). Snug

all bolts first then tighten to 54 N´m (40 ft. lbs.).

(13) Install bolt attaching wire harness heat shield

to support bracket (Federal and LEV) (Fig. 34), or

exhaust manifold (ULEV).(14) Lower vehicle.

(15) Connect negative cable to battery.

CYLINDER HEAD COVER

REMOVAL

(1) Disconnect CCV (Fig. 39) and PCV (Fig. 40)

hoses from cylinder head cover.

(2) Remove ignition coil and spark plug cables

(Fig. 41).

(3) Remove cylinder head cover bolts.

(4) Remove cylinder head cover.

INSTALLATION

(1) Clean gasket surfaces. Inspect gasket and seals

(Fig. 42). Replace as necessary. For replacement of

spark plug tube seals, refer to Spark Plug Tube Seals

in this section for procedure.

CAUTION: Do not attempt to loosen or remove baf-

fle plate attaching screws. The screws are self-tap-

ping, and in the attempt to retighten, thread damage

(stripping) will result.

Fig. 36 Exhaust Manifold Support BracketÐULEV

1 ± MANIFOLD SUPPORT BRACKET

2 ± OIL FILTER

3 ± BOLTS

Fig. 37 Exhaust Manifold Heat Shields

1 ± BOLTS

2 ± HEAT SHIELDS

Fig. 38 Exhaust Manifold Tightening Sequence

Fig. 39 CCV Hose

PL2.0L SOHC ENGINE 9 - 31

REMOVAL AND INSTALLATION (Continued)

Page 756 of 1285

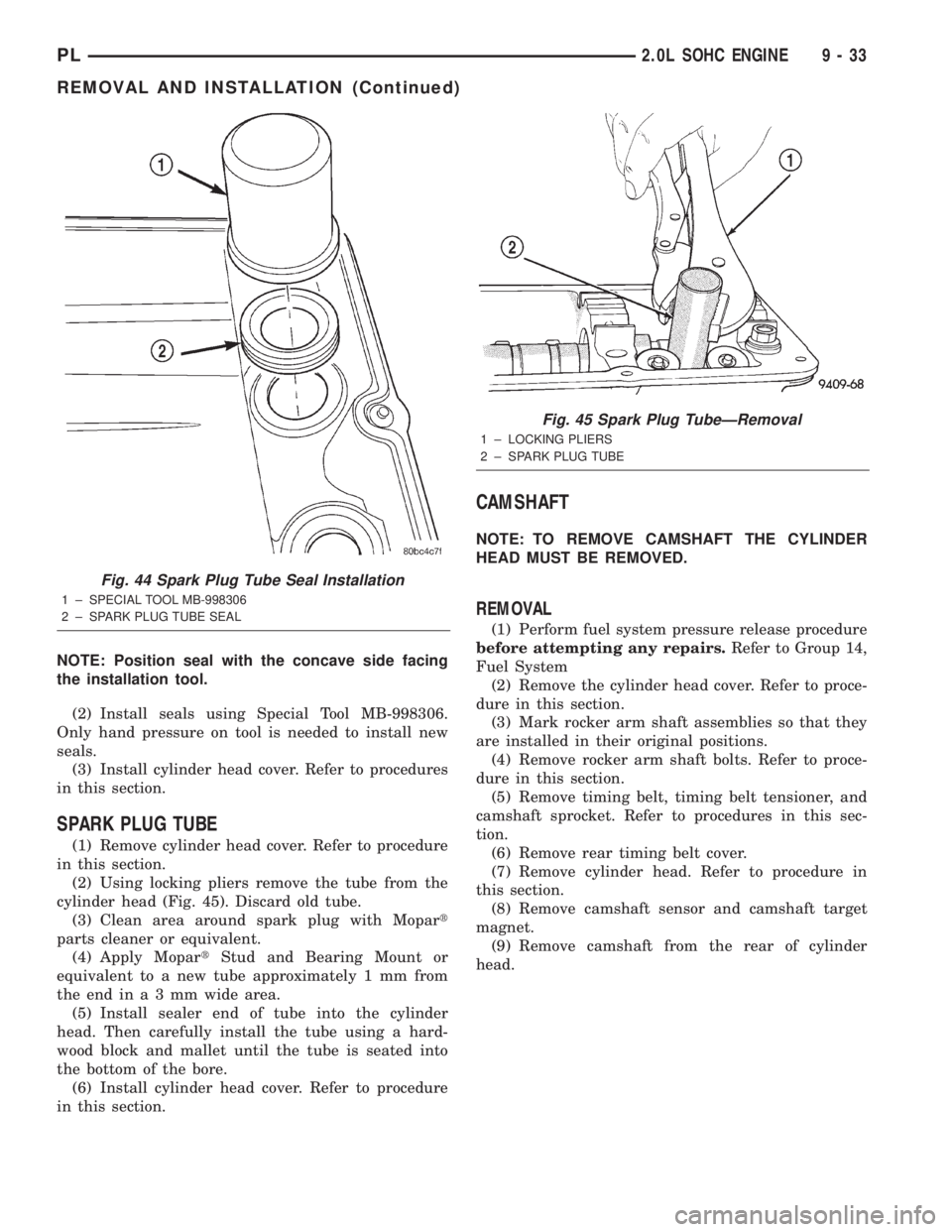

NOTE: Position seal with the concave side facing

the installation tool.

(2) Install seals using Special Tool MB-998306.

Only hand pressure on tool is needed to install new

seals.

(3) Install cylinder head cover. Refer to procedures

in this section.

SPARK PLUG TUBE

(1) Remove cylinder head cover. Refer to procedure

in this section.

(2) Using locking pliers remove the tube from the

cylinder head (Fig. 45). Discard old tube.

(3) Clean area around spark plug with Mopart

parts cleaner or equivalent.

(4) Apply MopartStud and Bearing Mount or

equivalent to a new tube approximately 1 mm from

theendina3mmwide area.

(5) Install sealer end of tube into the cylinder

head. Then carefully install the tube using a hard-

wood block and mallet until the tube is seated into

the bottom of the bore.

(6) Install cylinder head cover. Refer to procedure

in this section.

CAMSHAFT

NOTE: TO REMOVE CAMSHAFT THE CYLINDER

HEAD MUST BE REMOVED.

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Remove the cylinder head cover. Refer to proce-

dure in this section.

(3) Mark rocker arm shaft assemblies so that they

are installed in their original positions.

(4) Remove rocker arm shaft bolts. Refer to proce-

dure in this section.

(5) Remove timing belt, timing belt tensioner, and

camshaft sprocket. Refer to procedures in this sec-

tion.

(6) Remove rear timing belt cover.

(7) Remove cylinder head. Refer to procedure in

this section.

(8) Remove camshaft sensor and camshaft target

magnet.

(9) Remove camshaft from the rear of cylinder

head.

Fig. 44 Spark Plug Tube Seal Installation

1 ± SPECIAL TOOL MB-998306

2 ± SPARK PLUG TUBE SEAL

Fig. 45 Spark Plug TubeÐRemoval

1 ± LOCKING PLIERS

2 ± SPARK PLUG TUBE

PL2.0L SOHC ENGINE 9 - 33

REMOVAL AND INSTALLATION (Continued)

Page 757 of 1285

INSPECT CYLINDER HEAD FOR THE FOLLOWING:

NOTE:

²Check oil feed holes for blockage.

²Inspect cylinder head camshaft bearings for

wear, Refer to Cylinder Head, Inspection and Clean-

ing.

²Check camshaft bearing journals for scratches

and worn areas. If light scratches are present, they

may be removed with 400 grit sand paper. If deep

scratches are present, replace the camshaft and

check the cylinder head for damage. Replace the

cylinder head if worn or damaged. Check the lobes

for pitting and wear. If the lobes show signs of

wear, check the corresponding rocker arm roller for

wear or damage. Replace rocker arm/hydraulic lash

adjuster if worn or damaged. If lobes show signs of

pitting on the nose, flank or base circle; replace the

camshaft.

INSTALLATION

(1) Lubricate the camshaft journals with oil and

install camshaftwithoutrocker arm assemblies

installed.

(2) Install camshaft target magnet into the end of

the camshaft. Tighten mounting screw to 3.4 N´m (30

in. lbs.).

(3) Install camshaft position sensor and tighten

mounting screws to 9 N´m (80 in. lbs.).

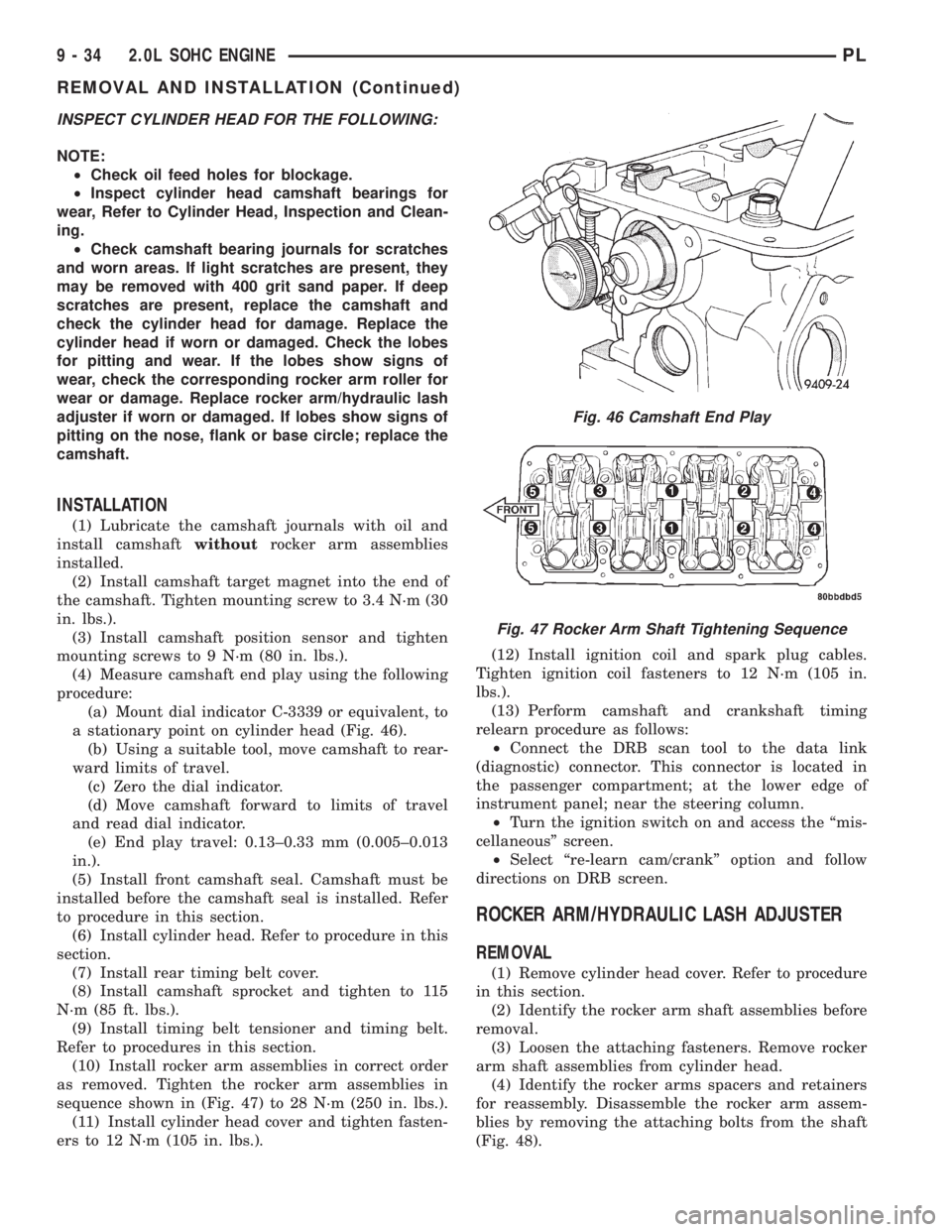

(4) Measure camshaft end play using the following

procedure:

(a) Mount dial indicator C-3339 or equivalent, to

a stationary point on cylinder head (Fig. 46).

(b) Using a suitable tool, move camshaft to rear-

ward limits of travel.

(c) Zero the dial indicator.

(d) Move camshaft forward to limits of travel

and read dial indicator.

(e) End play travel: 0.13±0.33 mm (0.005±0.013

in.).

(5) Install front camshaft seal. Camshaft must be

installed before the camshaft seal is installed. Refer

to procedure in this section.

(6) Install cylinder head. Refer to procedure in this

section.

(7) Install rear timing belt cover.

(8) Install camshaft sprocket and tighten to 115

N´m (85 ft. lbs.).

(9) Install timing belt tensioner and timing belt.

Refer to procedures in this section.

(10) Install rocker arm assemblies in correct order

as removed. Tighten the rocker arm assemblies in

sequence shown in (Fig. 47) to 28 N´m (250 in. lbs.).

(11) Install cylinder head cover and tighten fasten-

ers to 12 N´m (105 in. lbs.).(12) Install ignition coil and spark plug cables.

Tighten ignition coil fasteners to 12 N´m (105 in.

lbs.).

(13) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

ROCKER ARM/HYDRAULIC LASH ADJUSTER

REMOVAL

(1) Remove cylinder head cover. Refer to procedure

in this section.

(2) Identify the rocker arm shaft assemblies before

removal.

(3) Loosen the attaching fasteners. Remove rocker

arm shaft assemblies from cylinder head.

(4) Identify the rocker arms spacers and retainers

for reassembly. Disassemble the rocker arm assem-

blies by removing the attaching bolts from the shaft

(Fig. 48).

Fig. 46 Camshaft End Play

Fig. 47 Rocker Arm Shaft Tightening Sequence

9 - 34 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 759 of 1285

HYDRAULIC LASH ADJUSTER NOISE

A tappet-like noise may be produced from several

items. Refer to Lash Adjuster Noise - Diagnosis in

Standard Service Procedures, in this Group.Lash

adjusters are replaced with the rocker arm as

an assembly.

VALVE SEALS AND SPRINGSÐIN VEHICLE

REMOVAL

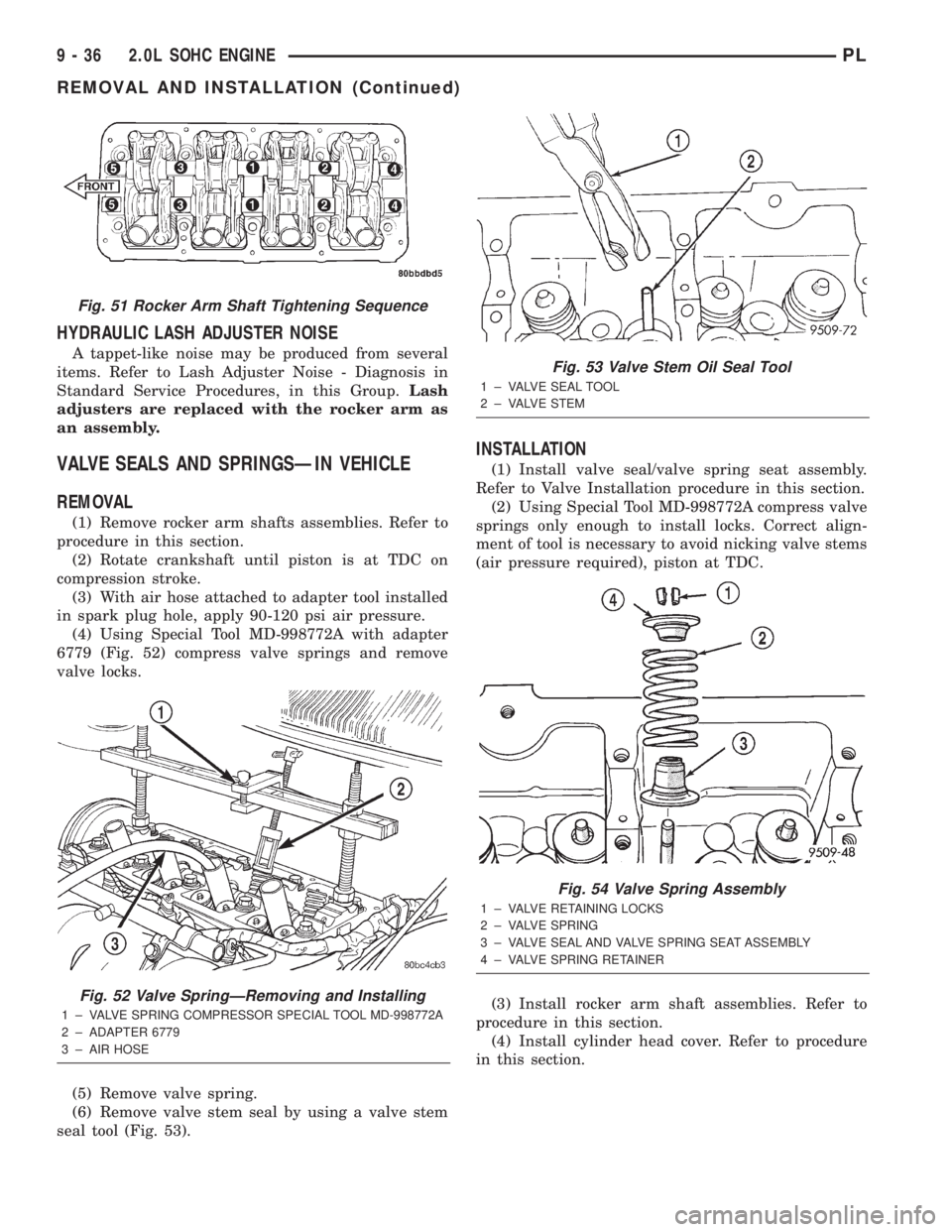

(1) Remove rocker arm shafts assemblies. Refer to

procedure in this section.

(2) Rotate crankshaft until piston is at TDC on

compression stroke.

(3) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure.

(4) Using Special Tool MD-998772A with adapter

6779 (Fig. 52) compress valve springs and remove

valve locks.

(5) Remove valve spring.

(6) Remove valve stem seal by using a valve stem

seal tool (Fig. 53).

INSTALLATION

(1) Install valve seal/valve spring seat assembly.

Refer to Valve Installation procedure in this section.

(2) Using Special Tool MD-998772A compress valve

springs only enough to install locks. Correct align-

ment of tool is necessary to avoid nicking valve stems

(air pressure required), piston at TDC.

(3) Install rocker arm shaft assemblies. Refer to

procedure in this section.

(4) Install cylinder head cover. Refer to procedure

in this section.

Fig. 51 Rocker Arm Shaft Tightening Sequence

Fig. 52 Valve SpringÐRemoving and Installing

1 ± VALVE SPRING COMPRESSOR SPECIAL TOOL MD-998772A

2 ± ADAPTER 6779

3 ± AIR HOSE

Fig. 53 Valve Stem Oil Seal Tool

1 ± VALVE SEAL TOOL

2 ± VALVE STEM

Fig. 54 Valve Spring Assembly

1 ± VALVE RETAINING LOCKS

2 ± VALVE SPRING

3 ± VALVE SEAL AND VALVE SPRING SEAT ASSEMBLY

4 ± VALVE SPRING RETAINER

9 - 36 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 761 of 1285

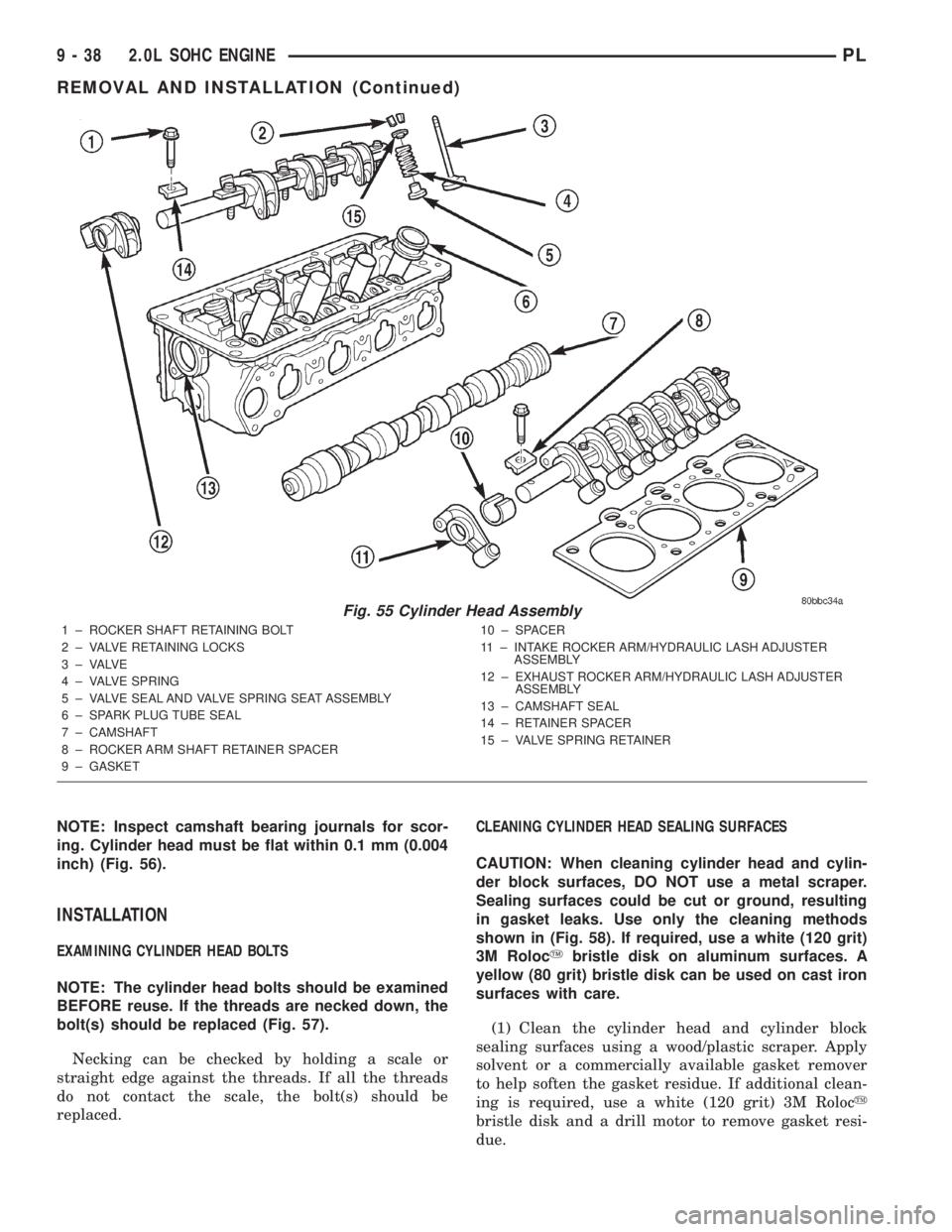

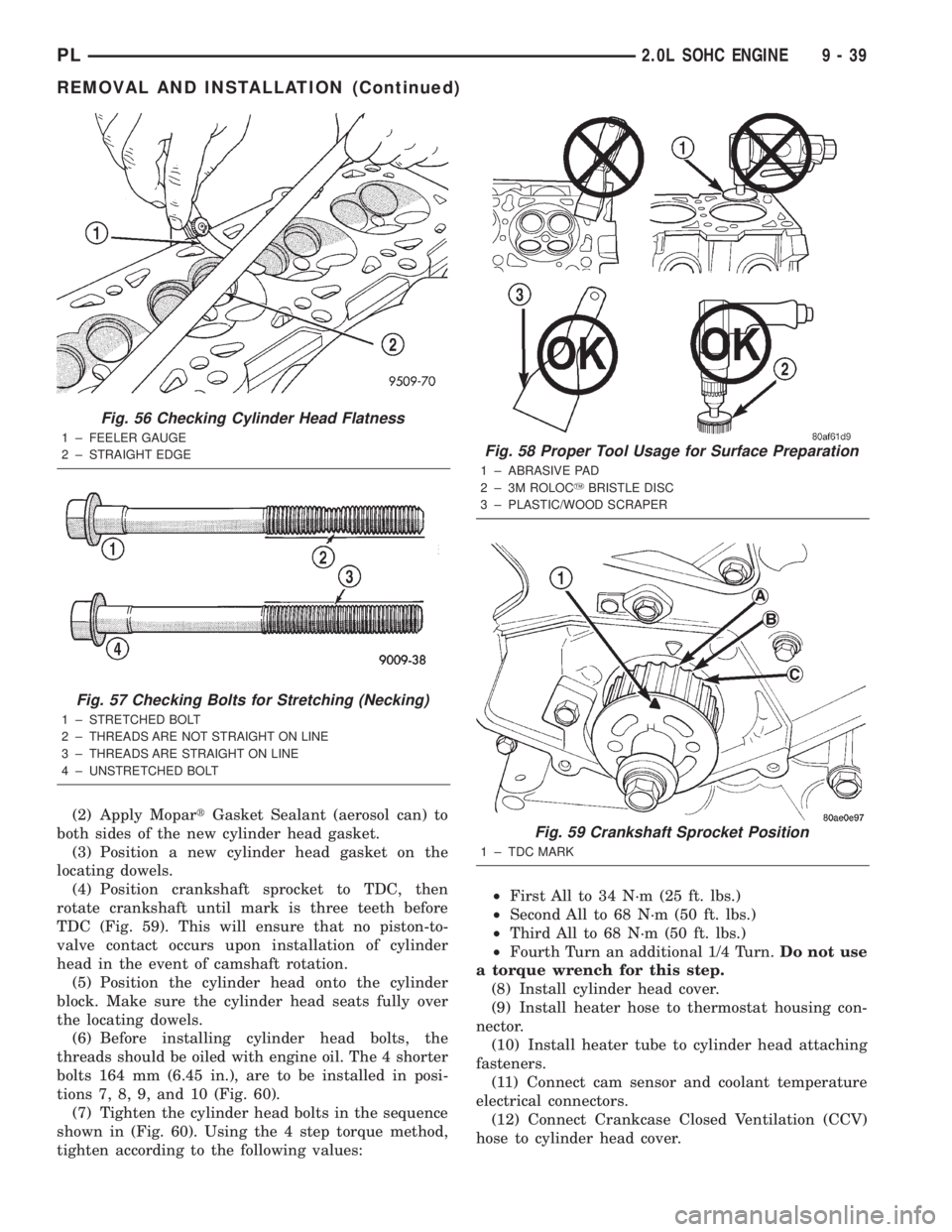

NOTE: Inspect camshaft bearing journals for scor-

ing. Cylinder head must be flat within 0.1 mm (0.004

inch) (Fig. 56).

INSTALLATION

EXAMINING CYLINDER HEAD BOLTS

NOTE: The cylinder head bolts should be examined

BEFORE reuse. If the threads are necked down, the

bolt(s) should be replaced (Fig. 57).

Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale, the bolt(s) should be

replaced.CLEANING CYLINDER HEAD SEALING SURFACES

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper.

Sealing surfaces could be cut or ground, resulting

in gasket leaks. Use only the cleaning methods

shown in (Fig. 58). If required, use a white (120 grit)

3M RolocYbristle disk on aluminum surfaces. A

yellow (80 grit) bristle disk can be used on cast iron

surfaces with care.

(1) Clean the cylinder head and cylinder block

sealing surfaces using a wood/plastic scraper. Apply

solvent or a commercially available gasket remover

to help soften the gasket residue. If additional clean-

ing is required, use a white (120 grit) 3M Rolocy

bristle disk and a drill motor to remove gasket resi-

due.

Fig. 55 Cylinder Head Assembly

1 ± ROCKER SHAFT RETAINING BOLT

2 ± VALVE RETAINING LOCKS

3 ± VALVE

4 ± VALVE SPRING

5 ± VALVE SEAL AND VALVE SPRING SEAT ASSEMBLY

6 ± SPARK PLUG TUBE SEAL

7 ± CAMSHAFT

8 ± ROCKER ARM SHAFT RETAINER SPACER

9 ± GASKET10 ± SPACER

11 ± INTAKE ROCKER ARM/HYDRAULIC LASH ADJUSTER

ASSEMBLY

12 ± EXHAUST ROCKER ARM/HYDRAULIC LASH ADJUSTER

ASSEMBLY

13 ± CAMSHAFT SEAL

14 ± RETAINER SPACER

15 ± VALVE SPRING RETAINER

9 - 38 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 762 of 1285

(2) Apply MopartGasket Sealant (aerosol can) to

both sides of the new cylinder head gasket.

(3) Position a new cylinder head gasket on the

locating dowels.

(4) Position crankshaft sprocket to TDC, then

rotate crankshaft until mark is three teeth before

TDC (Fig. 59). This will ensure that no piston-to-

valve contact occurs upon installation of cylinder

head in the event of camshaft rotation.

(5) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

(6) Before installing cylinder head bolts, the

threads should be oiled with engine oil. The 4 shorter

bolts 164 mm (6.45 in.), are to be installed in posi-

tions 7, 8, 9, and 10 (Fig. 60).

(7) Tighten the cylinder head bolts in the sequence

shown in (Fig. 60). Using the 4 step torque method,

tighten according to the following values:²First All to 34 N´m (25 ft. lbs.)

²Second All to 68 N´m (50 ft. lbs.)

²Third All to 68 N´m (50 ft. lbs.)

²Fourth Turn an additional 1/4 Turn.Do not use

a torque wrench for this step.

(8) Install cylinder head cover.

(9) Install heater hose to thermostat housing con-

nector.

(10) Install heater tube to cylinder head attaching

fasteners.

(11) Connect cam sensor and coolant temperature

electrical connectors.

(12) Connect Crankcase Closed Ventilation (CCV)

hose to cylinder head cover.

Fig. 56 Checking Cylinder Head Flatness

1 ± FEELER GAUGE

2 ± STRAIGHT EDGE

Fig. 57 Checking Bolts for Stretching (Necking)

1 ± STRETCHED BOLT

2 ± THREADS ARE NOT STRAIGHT ON LINE

3 ± THREADS ARE STRAIGHT ON LINE

4 ± UNSTRETCHED BOLT

Fig. 58 Proper Tool Usage for Surface Preparation

1 ± ABRASIVE PAD

2 ± 3M ROLOCYBRISTLE DISC

3 ± PLASTIC/WOOD SCRAPER

Fig. 59 Crankshaft Sprocket Position

1 ± TDC MARK

PL2.0L SOHC ENGINE 9 - 39

REMOVAL AND INSTALLATION (Continued)

Page 767 of 1285

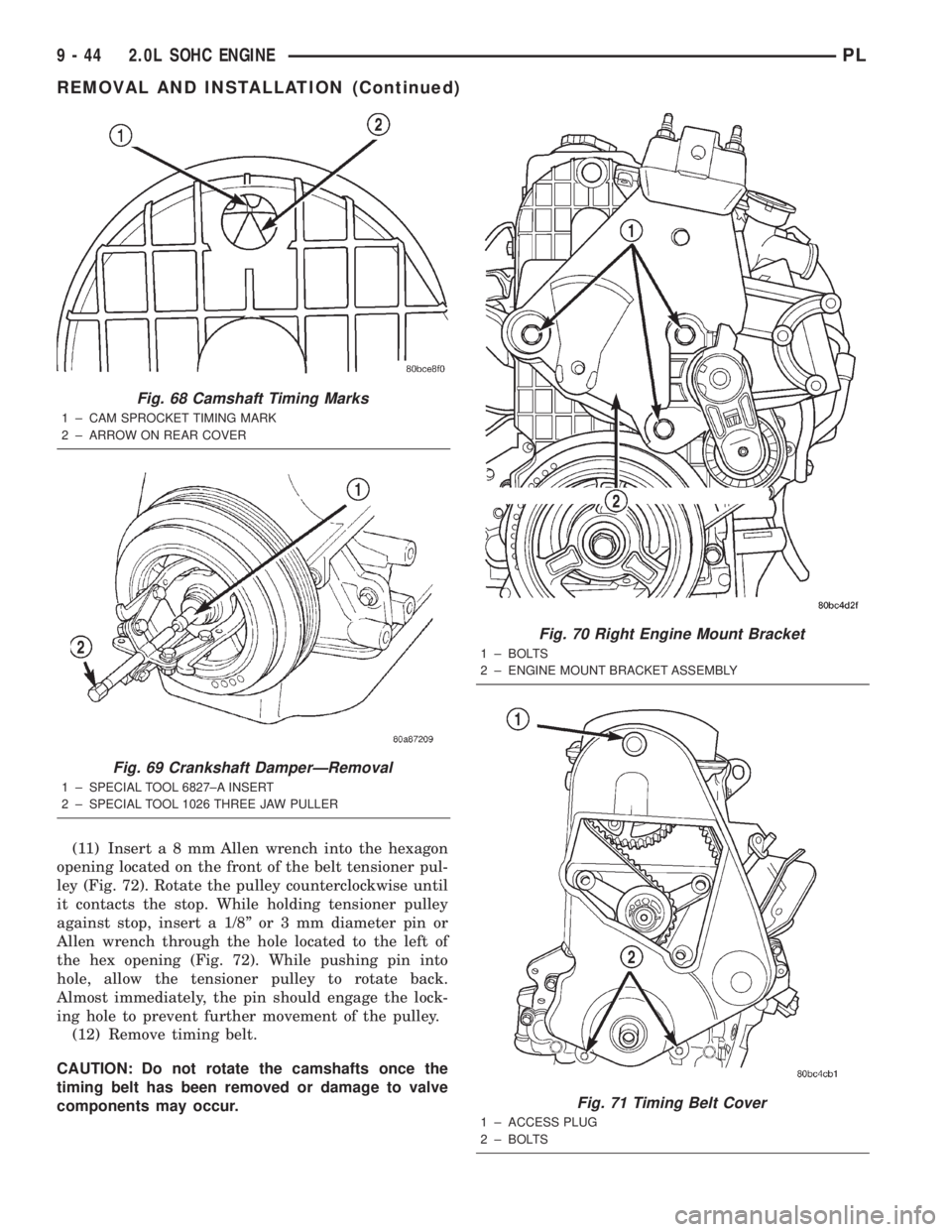

(11) Inserta8mmAllen wrench into the hexagon

opening located on the front of the belt tensioner pul-

ley (Fig. 72). Rotate the pulley counterclockwise until

it contacts the stop. While holding tensioner pulley

against stop, insert a 1/8º or 3 mm diameter pin or

Allen wrench through the hole located to the left of

the hex opening (Fig. 72). While pushing pin into

hole, allow the tensioner pulley to rotate back.

Almost immediately, the pin should engage the lock-

ing hole to prevent further movement of the pulley.

(12) Remove timing belt.

CAUTION: Do not rotate the camshafts once the

timing belt has been removed or damage to valve

components may occur.

Fig. 68 Camshaft Timing Marks

1 ± CAM SPROCKET TIMING MARK

2 ± ARROW ON REAR COVER

Fig. 69 Crankshaft DamperÐRemoval

1 ± SPECIAL TOOL 6827±A INSERT

2 ± SPECIAL TOOL 1026 THREE JAW PULLER

Fig. 70 Right Engine Mount Bracket

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET ASSEMBLY

Fig. 71 Timing Belt Cover

1 ± ACCESS PLUG

2 ± BOLTS

9 - 44 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)