lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 809 of 1285

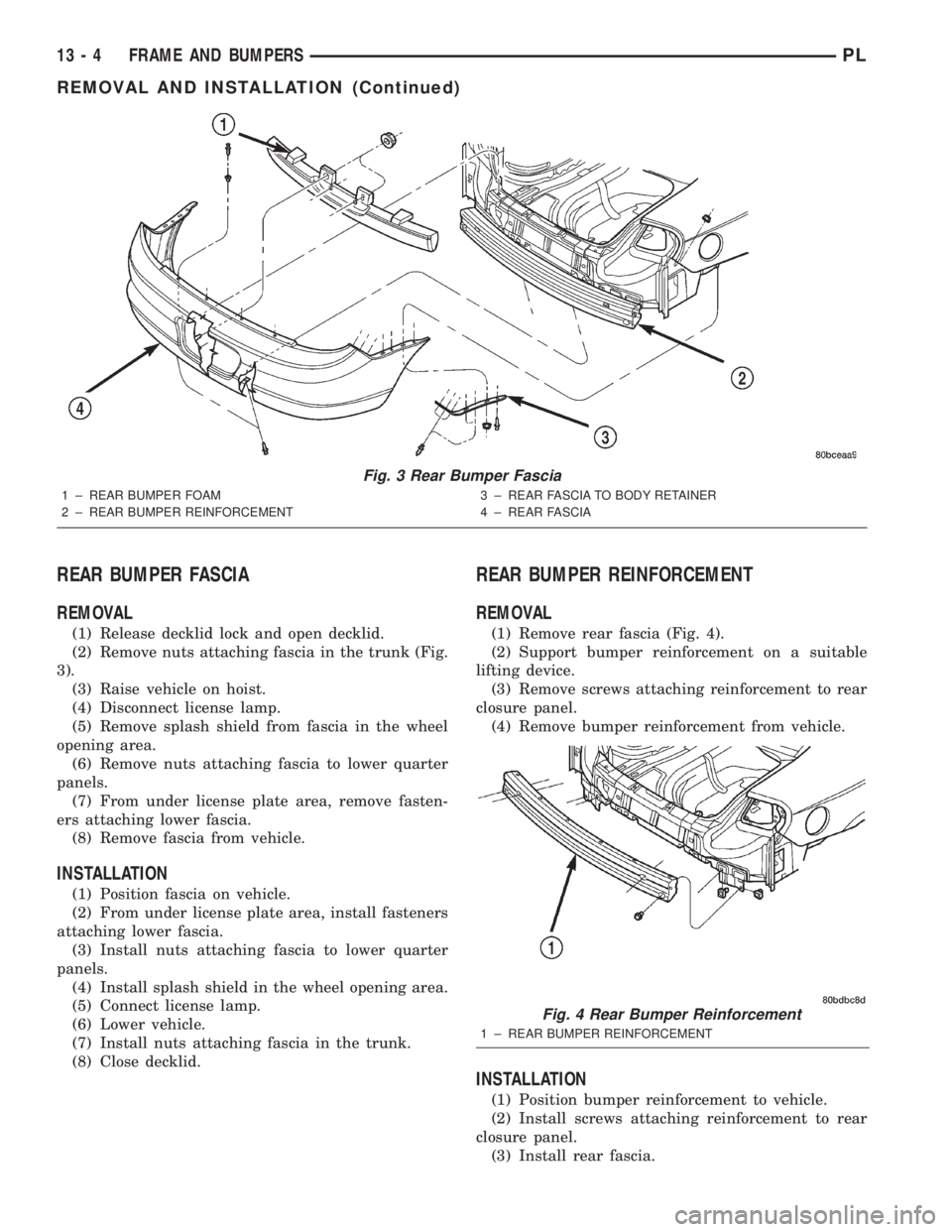

REAR BUMPER FASCIA

REMOVAL

(1) Release decklid lock and open decklid.

(2) Remove nuts attaching fascia in the trunk (Fig.

3).

(3) Raise vehicle on hoist.

(4) Disconnect license lamp.

(5) Remove splash shield from fascia in the wheel

opening area.

(6) Remove nuts attaching fascia to lower quarter

panels.

(7) From under license plate area, remove fasten-

ers attaching lower fascia.

(8) Remove fascia from vehicle.

INSTALLATION

(1) Position fascia on vehicle.

(2) From under license plate area, install fasteners

attaching lower fascia.

(3) Install nuts attaching fascia to lower quarter

panels.

(4) Install splash shield in the wheel opening area.

(5) Connect license lamp.

(6) Lower vehicle.

(7) Install nuts attaching fascia in the trunk.

(8) Close decklid.

REAR BUMPER REINFORCEMENT

REMOVAL

(1) Remove rear fascia (Fig. 4).

(2) Support bumper reinforcement on a suitable

lifting device.

(3) Remove screws attaching reinforcement to rear

closure panel.

(4) Remove bumper reinforcement from vehicle.

INSTALLATION

(1) Position bumper reinforcement to vehicle.

(2) Install screws attaching reinforcement to rear

closure panel.

(3) Install rear fascia.

Fig. 3 Rear Bumper Fascia

1 ± REAR BUMPER FOAM

2 ± REAR BUMPER REINFORCEMENT3 ± REAR FASCIA TO BODY RETAINER

4 ± REAR FASCIA

Fig. 4 Rear Bumper Reinforcement

1 ± REAR BUMPER REINFORCEMENT

13 - 4 FRAME AND BUMPERSPL

REMOVAL AND INSTALLATION (Continued)

Page 826 of 1285

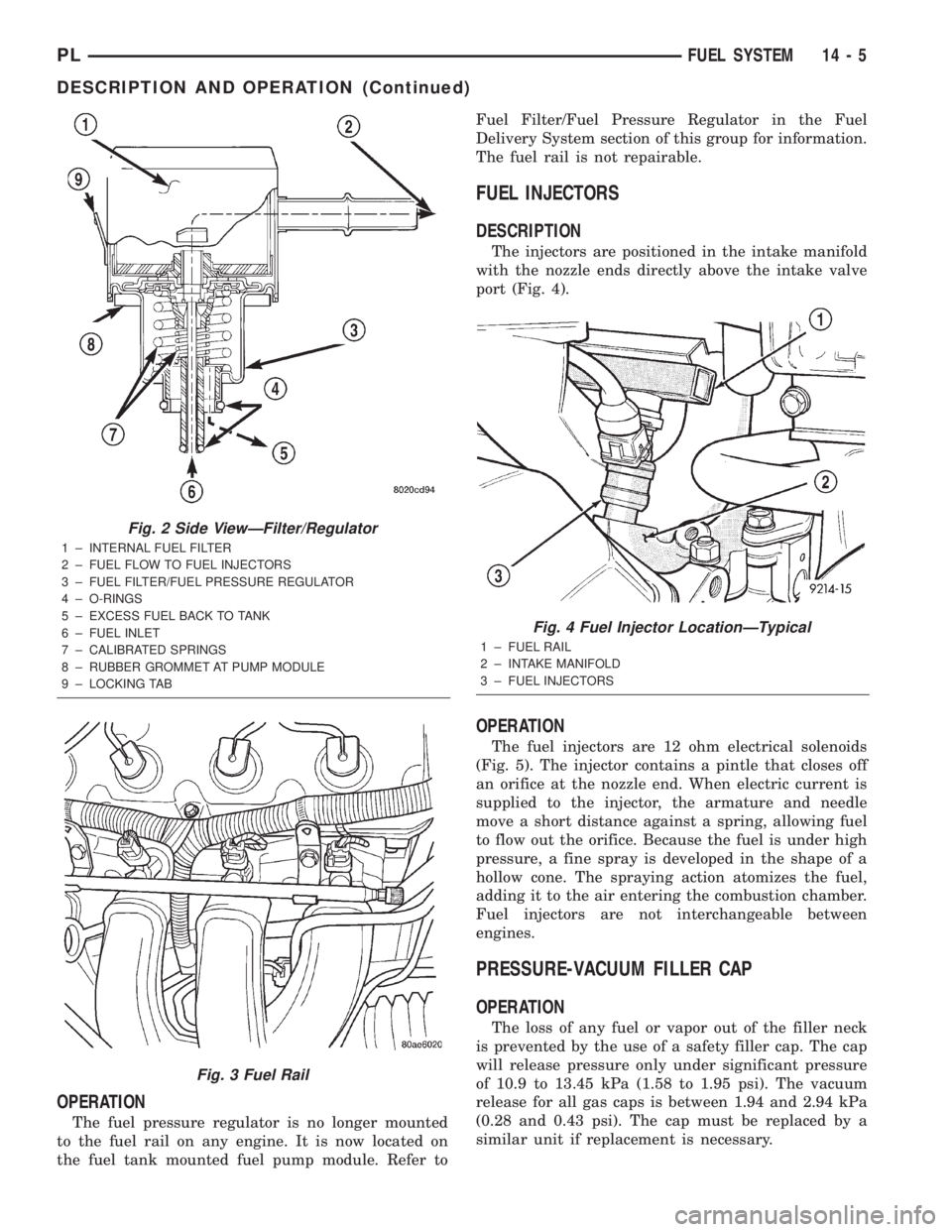

OPERATION

The fuel pressure regulator is no longer mounted

to the fuel rail on any engine. It is now located on

the fuel tank mounted fuel pump module. Refer toFuel Filter/Fuel Pressure Regulator in the Fuel

Delivery System section of this group for information.

The fuel rail is not repairable.

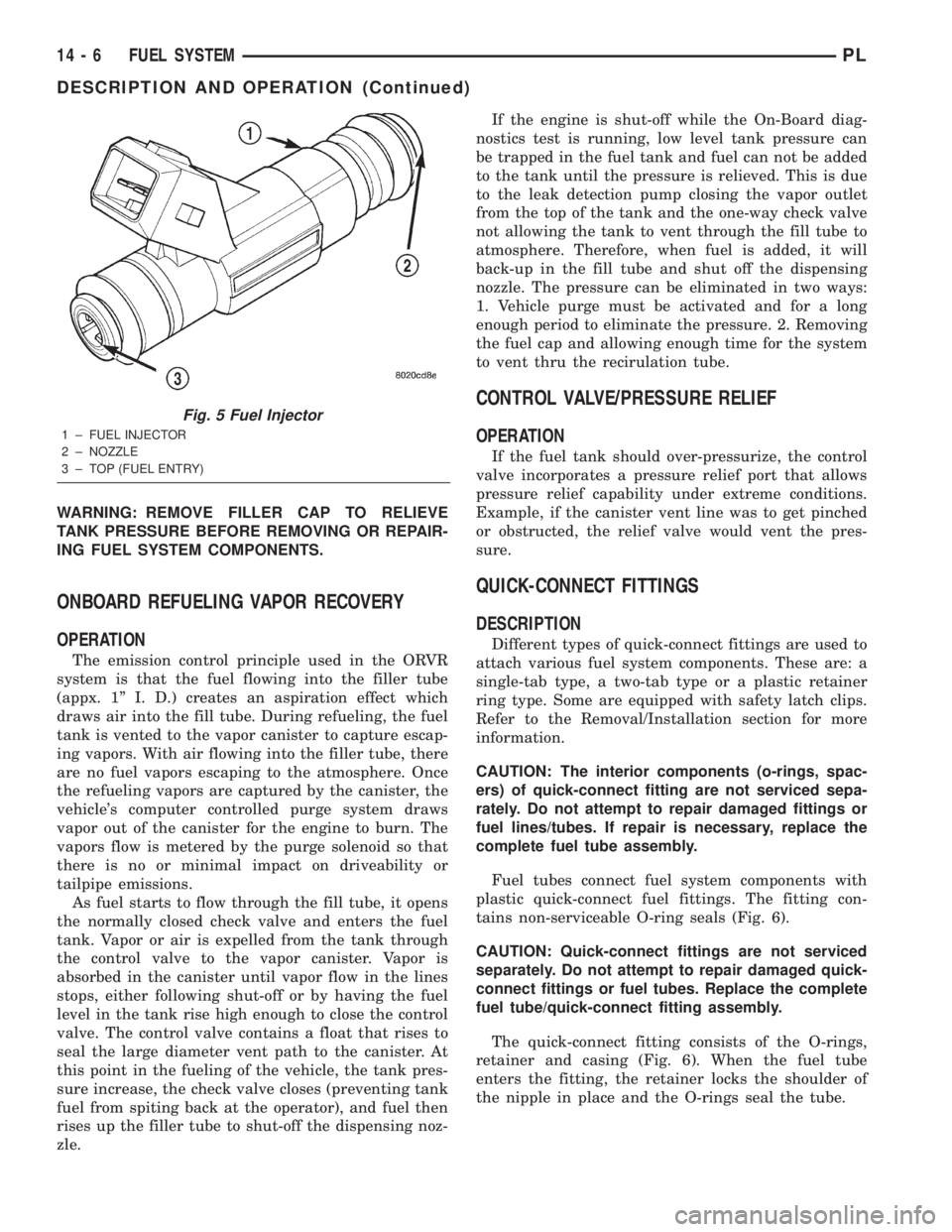

FUEL INJECTORS

DESCRIPTION

The injectors are positioned in the intake manifold

with the nozzle ends directly above the intake valve

port (Fig. 4).

OPERATION

The fuel injectors are 12 ohm electrical solenoids

(Fig. 5). The injector contains a pintle that closes off

an orifice at the nozzle end. When electric current is

supplied to the injector, the armature and needle

move a short distance against a spring, allowing fuel

to flow out the orifice. Because the fuel is under high

pressure, a fine spray is developed in the shape of a

hollow cone. The spraying action atomizes the fuel,

adding it to the air entering the combustion chamber.

Fuel injectors are not interchangeable between

engines.

PRESSURE-VACUUM FILLER CAP

OPERATION

The loss of any fuel or vapor out of the filler neck

is prevented by the use of a safety filler cap. The cap

will release pressure only under significant pressure

of 10.9 to 13.45 kPa (1.58 to 1.95 psi). The vacuum

release for all gas caps is between 1.94 and 2.94 kPa

(0.28 and 0.43 psi). The cap must be replaced by a

similar unit if replacement is necessary.

Fig. 2 Side ViewÐFilter/Regulator

1 ± INTERNAL FUEL FILTER

2 ± FUEL FLOW TO FUEL INJECTORS

3 ± FUEL FILTER/FUEL PRESSURE REGULATOR

4 ± O-RINGS

5 ± EXCESS FUEL BACK TO TANK

6 ± FUEL INLET

7 ± CALIBRATED SPRINGS

8 ± RUBBER GROMMET AT PUMP MODULE

9 ± LOCKING TAB

Fig. 3 Fuel Rail

Fig. 4 Fuel Injector LocationÐTypical

1 ± FUEL RAIL

2 ± INTAKE MANIFOLD

3 ± FUEL INJECTORS

PLFUEL SYSTEM 14 - 5

DESCRIPTION AND OPERATION (Continued)

Page 827 of 1285

WARNING: REMOVE FILLER CAP TO RELIEVE

TANK PRESSURE BEFORE REMOVING OR REPAIR-

ING FUEL SYSTEM COMPONENTS.

ONBOARD REFUELING VAPOR RECOVERY

OPERATION

The emission control principle used in the ORVR

system is that the fuel flowing into the filler tube

(appx. 1º I. D.) creates an aspiration effect which

draws air into the fill tube. During refueling, the fuel

tank is vented to the vapor canister to capture escap-

ing vapors. With air flowing into the filler tube, there

are no fuel vapors escaping to the atmosphere. Once

the refueling vapors are captured by the canister, the

vehicle's computer controlled purge system draws

vapor out of the canister for the engine to burn. The

vapors flow is metered by the purge solenoid so that

there is no or minimal impact on driveability or

tailpipe emissions.

As fuel starts to flow through the fill tube, it opens

the normally closed check valve and enters the fuel

tank. Vapor or air is expelled from the tank through

the control valve to the vapor canister. Vapor is

absorbed in the canister until vapor flow in the lines

stops, either following shut-off or by having the fuel

level in the tank rise high enough to close the control

valve. The control valve contains a float that rises to

seal the large diameter vent path to the canister. At

this point in the fueling of the vehicle, the tank pres-

sure increase, the check valve closes (preventing tank

fuel from spiting back at the operator), and fuel then

rises up the filler tube to shut-off the dispensing noz-

zle.If the engine is shut-off while the On-Board diag-

nostics test is running, low level tank pressure can

be trapped in the fuel tank and fuel can not be added

to the tank until the pressure is relieved. This is due

to the leak detection pump closing the vapor outlet

from the top of the tank and the one-way check valve

not allowing the tank to vent through the fill tube to

atmosphere. Therefore, when fuel is added, it will

back-up in the fill tube and shut off the dispensing

nozzle. The pressure can be eliminated in two ways:

1. Vehicle purge must be activated and for a long

enough period to eliminate the pressure. 2. Removing

the fuel cap and allowing enough time for the system

to vent thru the recirulation tube.

CONTROL VALVE/PRESSURE RELIEF

OPERATION

If the fuel tank should over-pressurize, the control

valve incorporates a pressure relief port that allows

pressure relief capability under extreme conditions.

Example, if the canister vent line was to get pinched

or obstructed, the relief valve would vent the pres-

sure.

QUICK-CONNECT FITTINGS

DESCRIPTION

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type. Some are equipped with safety latch clips.

Refer to the Removal/Installation section for more

information.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

Fuel tubes connect fuel system components with

plastic quick-connect fuel fittings. The fitting con-

tains non-serviceable O-ring seals (Fig. 6).

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

The quick-connect fitting consists of the O-rings,

retainer and casing (Fig. 6). When the fuel tube

enters the fitting, the retainer locks the shoulder of

the nipple in place and the O-rings seal the tube.

Fig. 5 Fuel Injector

1 ± FUEL INJECTOR

2 ± NOZZLE

3 ± TOP (FUEL ENTRY)

14 - 6 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 830 of 1285

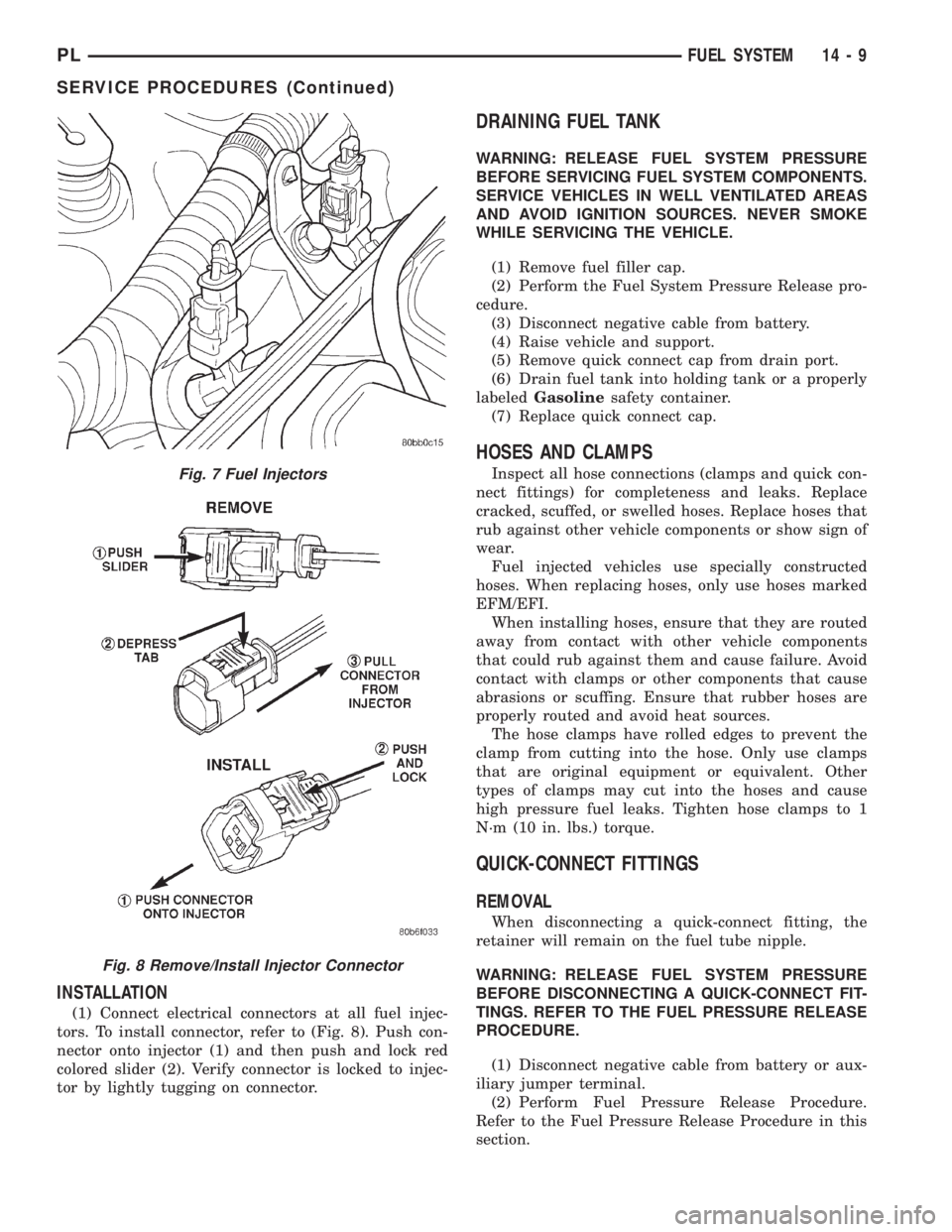

INSTALLATION

(1) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 8). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

DRAINING FUEL TANK

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap.

(2) Perform the Fuel System Pressure Release pro-

cedure.

(3) Disconnect negative cable from battery.

(4) Raise vehicle and support.

(5) Remove quick connect cap from drain port.

(6) Drain fuel tank into holding tank or a properly

labeledGasolinesafety container.

(7) Replace quick connect cap.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

Fig. 7 Fuel Injectors

Fig. 8 Remove/Install Injector Connector

PLFUEL SYSTEM 14 - 9

SERVICE PROCEDURES (Continued)

Page 831 of 1285

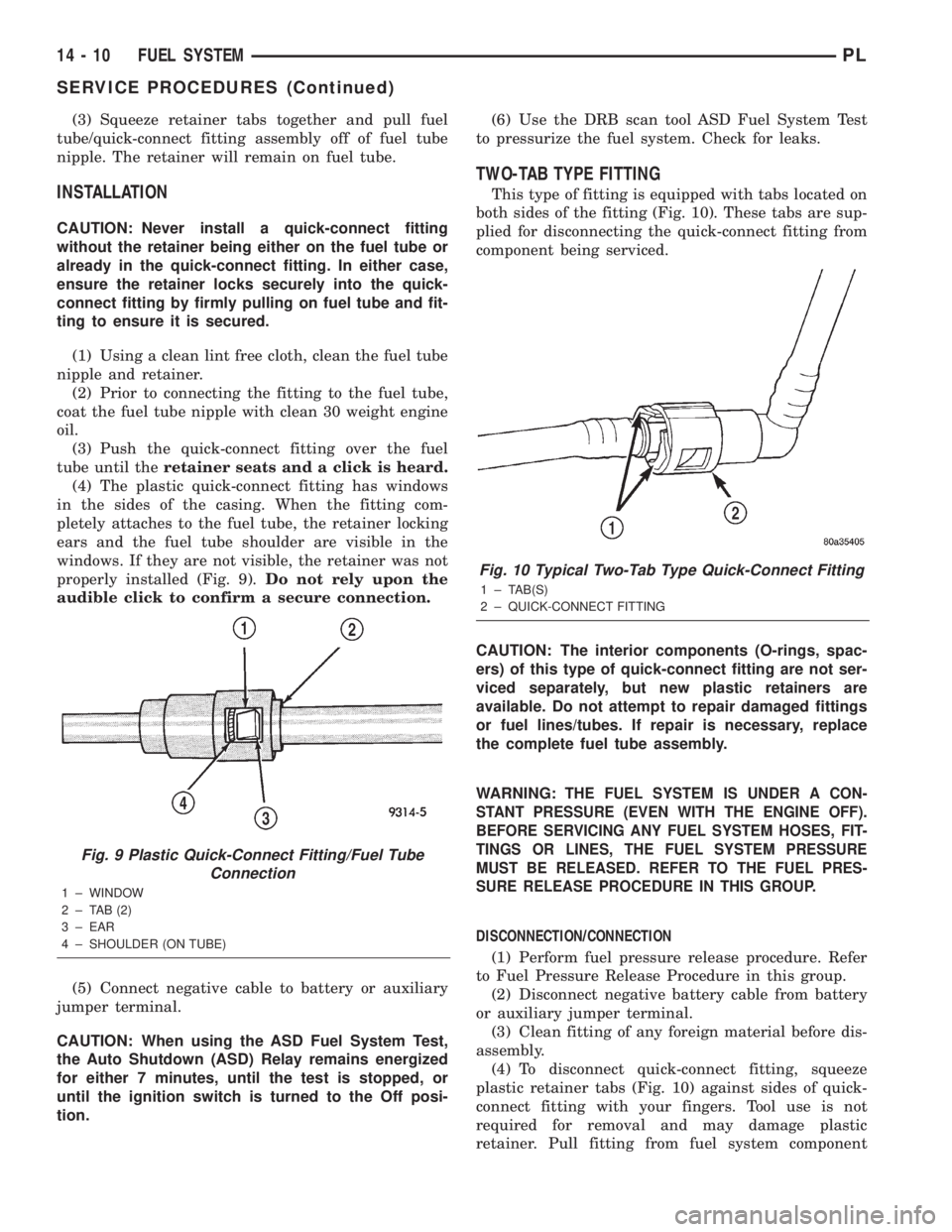

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 9).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

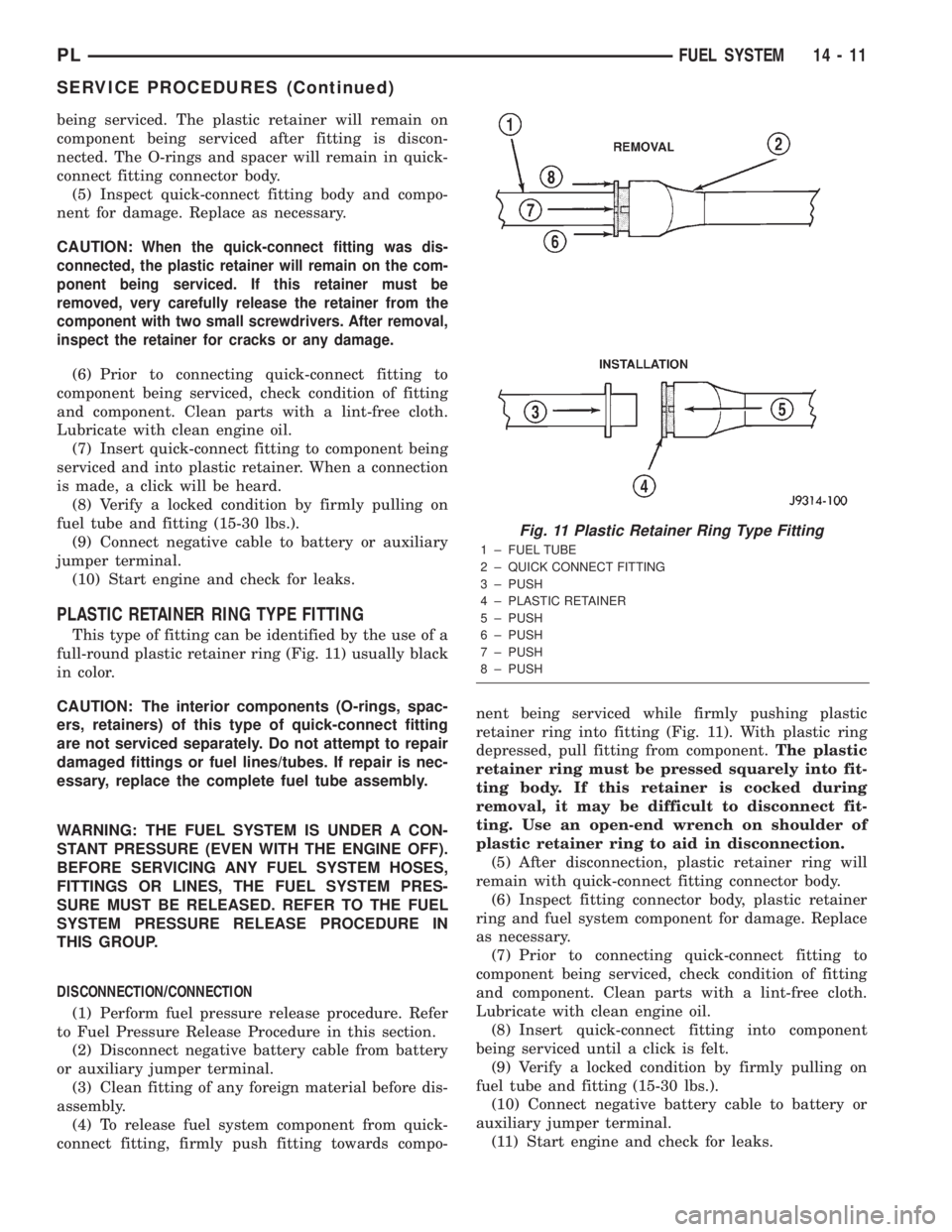

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 10). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

WARNING:

THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES, FIT-

TINGS OR LINES, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL PRES-

SURE RELEASE PROCEDURE IN THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this group.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 10) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer. Pull fitting from fuel system component

Fig. 9 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 ± WINDOW

2 ± TAB (2)

3 ± EAR

4 ± SHOULDER (ON TUBE)

Fig. 10 Typical Two-Tab Type Quick-Connect Fitting

1 ± TAB(S)

2 ± QUICK-CONNECT FITTING

14 - 10 FUEL SYSTEMPL

SERVICE PROCEDURES (Continued)

Page 832 of 1285

being serviced. The plastic retainer will remain on

component being serviced after fitting is discon-

nected. The O-rings and spacer will remain in quick-

connect fitting connector body.

(5) Inspect quick-connect fitting body and compo-

nent for damage. Replace as necessary.

CAUTION:

When the quick-connect fitting was dis-

connected, the plastic retainer will remain on the com-

ponent being serviced. If this retainer must be

removed, very carefully release the retainer from the

component with two small screwdrivers. After removal,

inspect the retainer for cracks or any damage.

(6) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(7) Insert quick-connect fitting to component being

serviced and into plastic retainer. When a connection

is made, a click will be heard.

(8) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(9) Connect negative cable to battery or auxiliary

jumper terminal.

(10) Start engine and check for leaks.

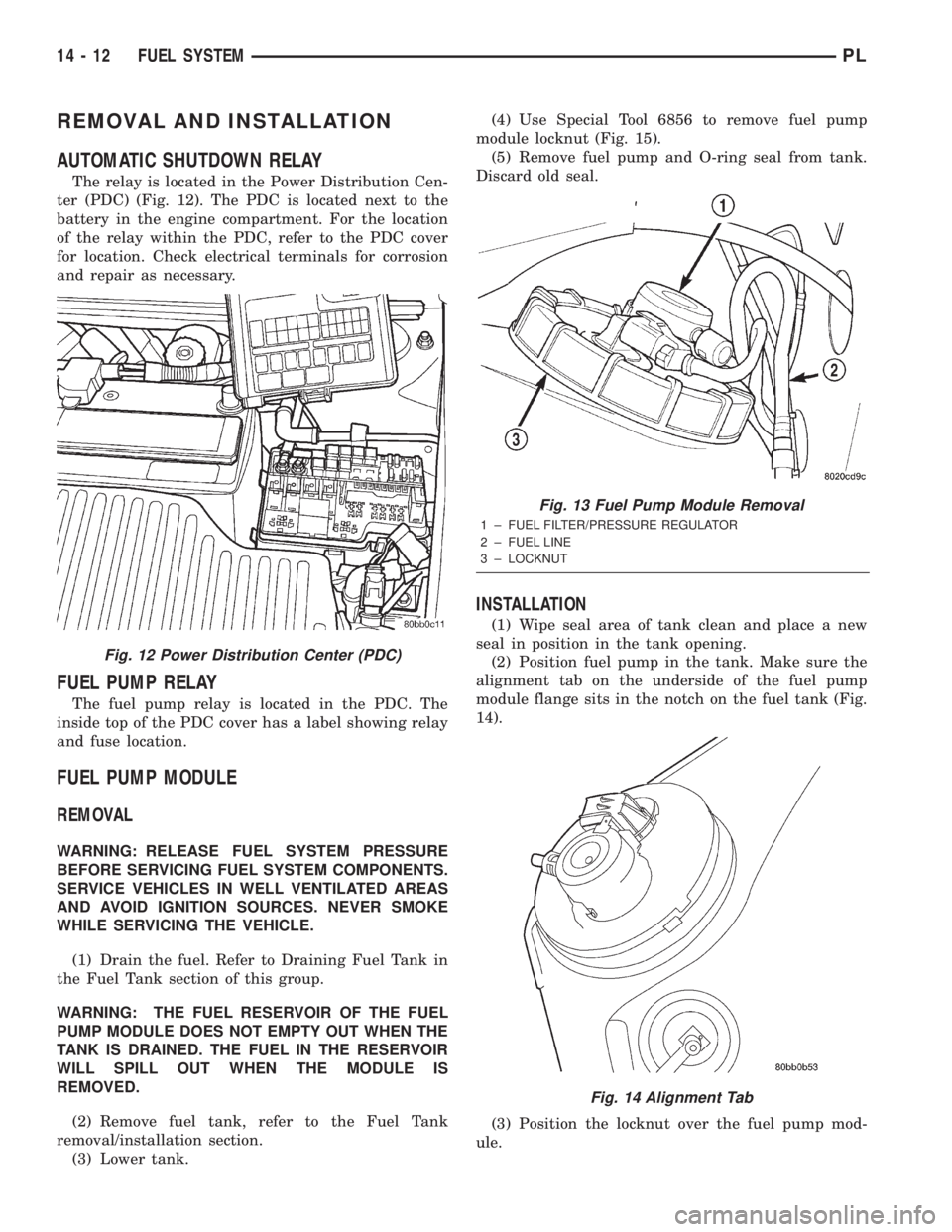

PLASTIC RETAINER RING TYPE FITTING

This type of fitting can be identified by the use of a

full-round plastic retainer ring (Fig. 11) usually black

in color.

CAUTION: The interior components (O-rings, spac-

ers, retainers) of this type of quick-connect fitting

are not serviced separately. Do not attempt to repair

damaged fittings or fuel lines/tubes. If repair is nec-

essary, replace the complete fuel tube assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this section.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To release fuel system component from quick-

connect fitting, firmly push fitting towards compo-nent being serviced while firmly pushing plastic

retainer ring into fitting (Fig. 11). With plastic ring

depressed, pull fitting from component.The plastic

retainer ring must be pressed squarely into fit-

ting body. If this retainer is cocked during

removal, it may be difficult to disconnect fit-

ting. Use an open-end wrench on shoulder of

plastic retainer ring to aid in disconnection.

(5) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(6) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage. Replace

as necessary.

(7) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(8) Insert quick-connect fitting into component

being serviced until a click is felt.

(9) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(10) Connect negative battery cable to battery or

auxiliary jumper terminal.

(11) Start engine and check for leaks.

Fig. 11 Plastic Retainer Ring Type Fitting

1 ± FUEL TUBE

2 ± QUICK CONNECT FITTING

3 ± PUSH

4 ± PLASTIC RETAINER

5 ± PUSH

6 ± PUSH

7 ± PUSH

8 ± PUSH

PLFUEL SYSTEM 14 - 11

SERVICE PROCEDURES (Continued)

Page 833 of 1285

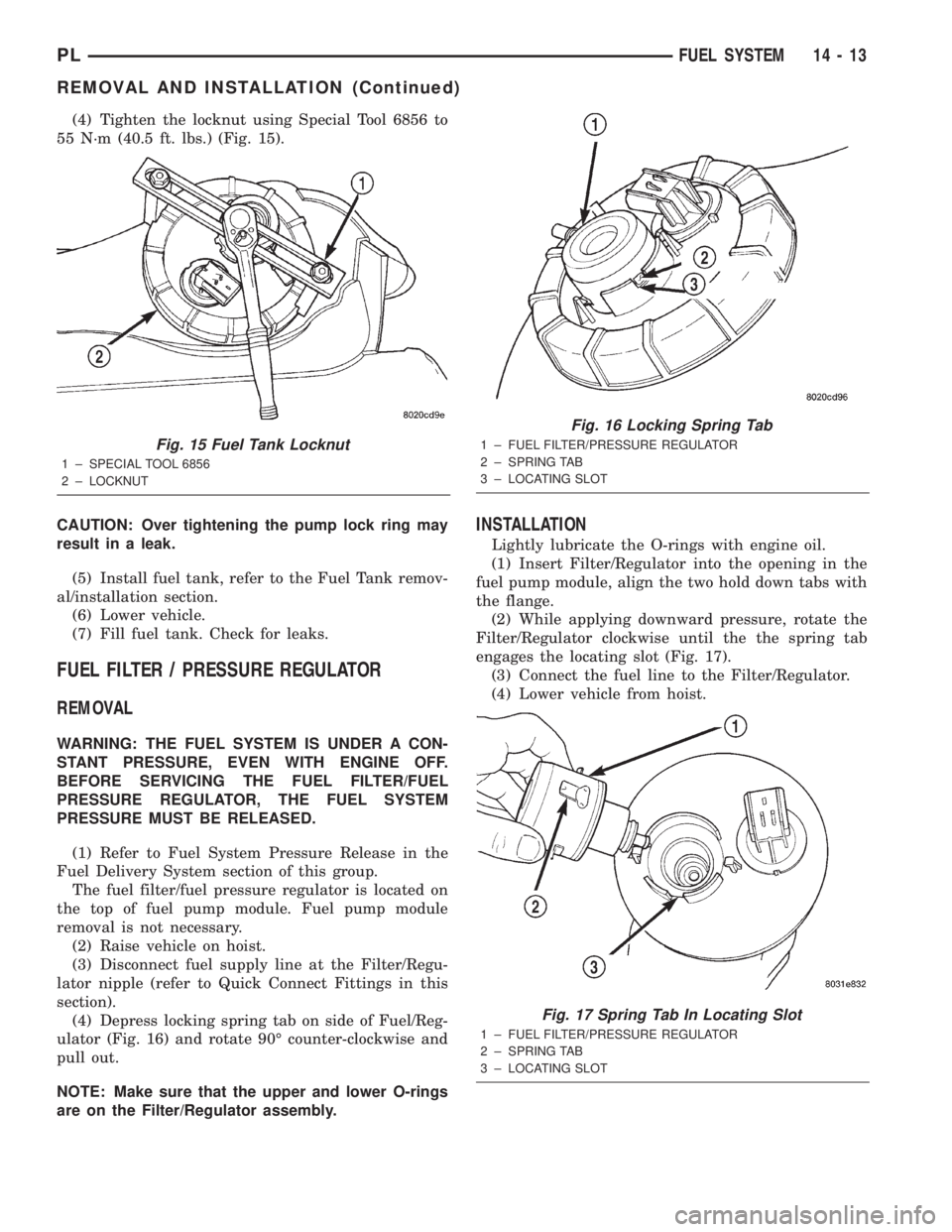

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 12). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

FUEL PUMP MODULE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Drain the fuel. Refer to Draining Fuel Tank in

the Fuel Tank section of this group.

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

WILL SPILL OUT WHEN THE MODULE IS

REMOVED.

(2) Remove fuel tank, refer to the Fuel Tank

removal/installation section.

(3) Lower tank.(4) Use Special Tool 6856 to remove fuel pump

module locknut (Fig. 15).

(5) Remove fuel pump and O-ring seal from tank.

Discard old seal.

INSTALLATION

(1) Wipe seal area of tank clean and place a new

seal in position in the tank opening.

(2) Position fuel pump in the tank. Make sure the

alignment tab on the underside of the fuel pump

module flange sits in the notch on the fuel tank (Fig.

14).

(3) Position the locknut over the fuel pump mod-

ule.

Fig. 12 Power Distribution Center (PDC)

Fig. 13 Fuel Pump Module Removal

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± FUEL LINE

3 ± LOCKNUT

Fig. 14 Alignment Tab

14 - 12 FUEL SYSTEMPL

Page 834 of 1285

(4) Tighten the locknut using Special Tool 6856 to

55 N´m (40.5 ft. lbs.) (Fig. 15).

CAUTION: Over tightening the pump lock ring may

result in a leak.

(5) Install fuel tank, refer to the Fuel Tank remov-

al/installation section.

(6) Lower vehicle.

(7) Fill fuel tank. Check for leaks.

FUEL FILTER / PRESSURE REGULATOR

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE, EVEN WITH ENGINE OFF.

BEFORE SERVICING THE FUEL FILTER/FUEL

PRESSURE REGULATOR, THE FUEL SYSTEM

PRESSURE MUST BE RELEASED.

(1) Refer to Fuel System Pressure Release in the

Fuel Delivery System section of this group.

The fuel filter/fuel pressure regulator is located on

the top of fuel pump module. Fuel pump module

removal is not necessary.

(2) Raise vehicle on hoist.

(3) Disconnect fuel supply line at the Filter/Regu-

lator nipple (refer to Quick Connect Fittings in this

section).

(4) Depress locking spring tab on side of Fuel/Reg-

ulator (Fig. 16) and rotate 90É counter-clockwise and

pull out.

NOTE: Make sure that the upper and lower O-rings

are on the Filter/Regulator assembly.

INSTALLATION

Lightly lubricate the O-rings with engine oil.

(1) Insert Filter/Regulator into the opening in the

fuel pump module, align the two hold down tabs with

the flange.

(2) While applying downward pressure, rotate the

Filter/Regulator clockwise until the the spring tab

engages the locating slot (Fig. 17).

(3) Connect the fuel line to the Filter/Regulator.

(4) Lower vehicle from hoist.

Fig. 15 Fuel Tank Locknut

1 ± SPECIAL TOOL 6856

2 ± LOCKNUT

Fig. 16 Locking Spring Tab

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± SPRING TAB

3 ± LOCATING SLOT

Fig. 17 Spring Tab In Locating Slot

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± SPRING TAB

3 ± LOCATING SLOT

PLFUEL SYSTEM 14 - 13

REMOVAL AND INSTALLATION (Continued)

Page 835 of 1285

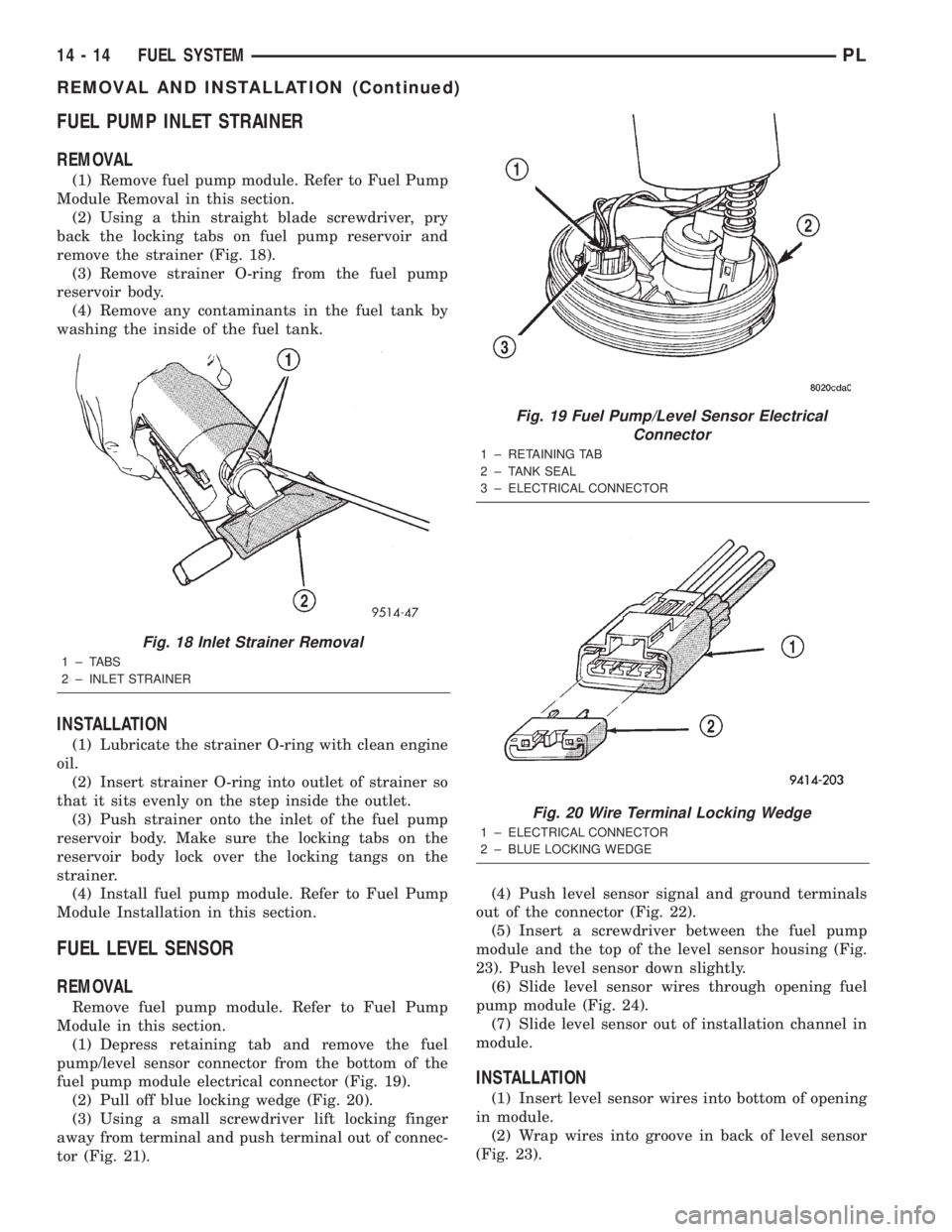

FUEL PUMP INLET STRAINER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 18).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

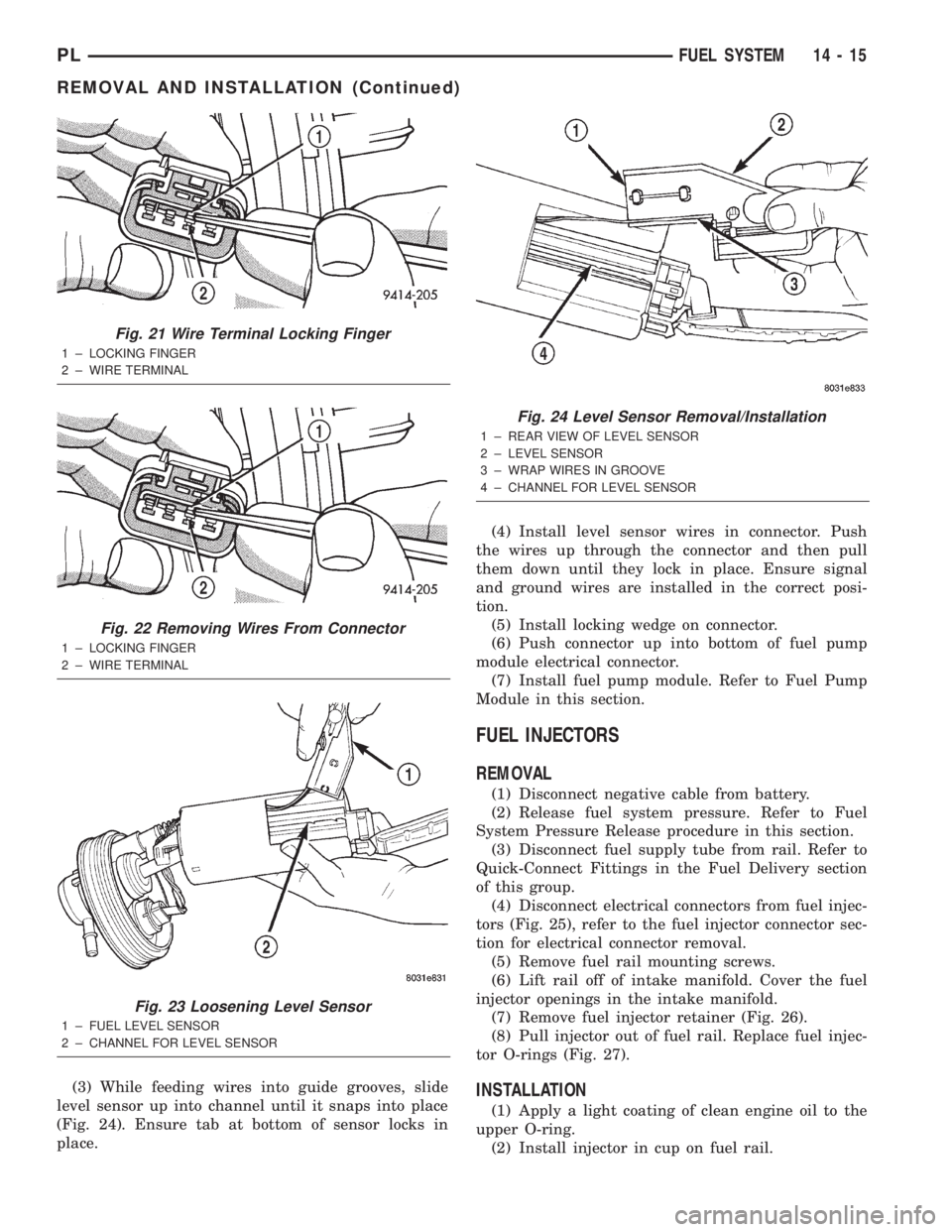

FUEL LEVEL SENSOR

REMOVAL

Remove fuel pump module. Refer to Fuel Pump

Module in this section.

(1) Depress retaining tab and remove the fuel

pump/level sensor connector from the bottom of the

fuel pump module electrical connector (Fig. 19).

(2) Pull off blue locking wedge (Fig. 20).

(3) Using a small screwdriver lift locking finger

away from terminal and push terminal out of connec-

tor (Fig. 21).(4) Push level sensor signal and ground terminals

out of the connector (Fig. 22).

(5) Insert a screwdriver between the fuel pump

module and the top of the level sensor housing (Fig.

23). Push level sensor down slightly.

(6) Slide level sensor wires through opening fuel

pump module (Fig. 24).

(7) Slide level sensor out of installation channel in

module.

INSTALLATION

(1) Insert level sensor wires into bottom of opening

in module.

(2) Wrap wires into groove in back of level sensor

(Fig. 23).

Fig. 18 Inlet Strainer Removal

1±TABS

2 ± INLET STRAINER

Fig. 19 Fuel Pump/Level Sensor Electrical

Connector

1 ± RETAINING TAB

2 ± TANK SEAL

3 ± ELECTRICAL CONNECTOR

Fig. 20 Wire Terminal Locking Wedge

1 ± ELECTRICAL CONNECTOR

2 ± BLUE LOCKING WEDGE

14 - 14 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 836 of 1285

(3) While feeding wires into guide grooves, slide

level sensor up into channel until it snaps into place

(Fig. 24). Ensure tab at bottom of sensor locks in

place.(4) Install level sensor wires in connector. Push

the wires up through the connector and then pull

them down until they lock in place. Ensure signal

and ground wires are installed in the correct posi-

tion.

(5) Install locking wedge on connector.

(6) Push connector up into bottom of fuel pump

module electrical connector.

(7) Install fuel pump module. Refer to Fuel Pump

Module in this section.

FUEL INJECTORS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Release fuel system pressure. Refer to Fuel

System Pressure Release procedure in this section.

(3) Disconnect fuel supply tube from rail. Refer to

Quick-Connect Fittings in the Fuel Delivery section

of this group.

(4) Disconnect electrical connectors from fuel injec-

tors (Fig. 25), refer to the fuel injector connector sec-

tion for electrical connector removal.

(5) Remove fuel rail mounting screws.

(6) Lift rail off of intake manifold. Cover the fuel

injector openings in the intake manifold.

(7) Remove fuel injector retainer (Fig. 26).

(8) Pull injector out of fuel rail. Replace fuel injec-

tor O-rings (Fig. 27).

INSTALLATION

(1) Apply a light coating of clean engine oil to the

upper O-ring.

(2) Install injector in cup on fuel rail.

Fig. 21 Wire Terminal Locking Finger

1 ± LOCKING FINGER

2 ± WIRE TERMINAL

Fig. 22 Removing Wires From Connector

1 ± LOCKING FINGER

2 ± WIRE TERMINAL

Fig. 23 Loosening Level Sensor

1 ± FUEL LEVEL SENSOR

2 ± CHANNEL FOR LEVEL SENSOR

Fig. 24 Level Sensor Removal/Installation

1 ± REAR VIEW OF LEVEL SENSOR

2 ± LEVEL SENSOR

3 ± WRAP WIRES IN GROOVE

4 ± CHANNEL FOR LEVEL SENSOR

PLFUEL SYSTEM 14 - 15

REMOVAL AND INSTALLATION (Continued)