lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 770 of 1285

(5) Remove camshaft seal by carefully using a suit-

able pry tool. Be careful not to nick or damage thecamshaft seal surface or cylinder head seal retaining

bore.

CAUTION: Do not nick shaft seal surface or seal

bore.

(6) Shaft seal lip surface must be free of varnish,

dirt or nicks. Polish with 400 grit paper, if necessary.

INSTALLATION

(1) Install camshaft seal flush with cylinder head

using Special Tool MD998306 (Fig. 80).

(2) Install rear timing belt cover.

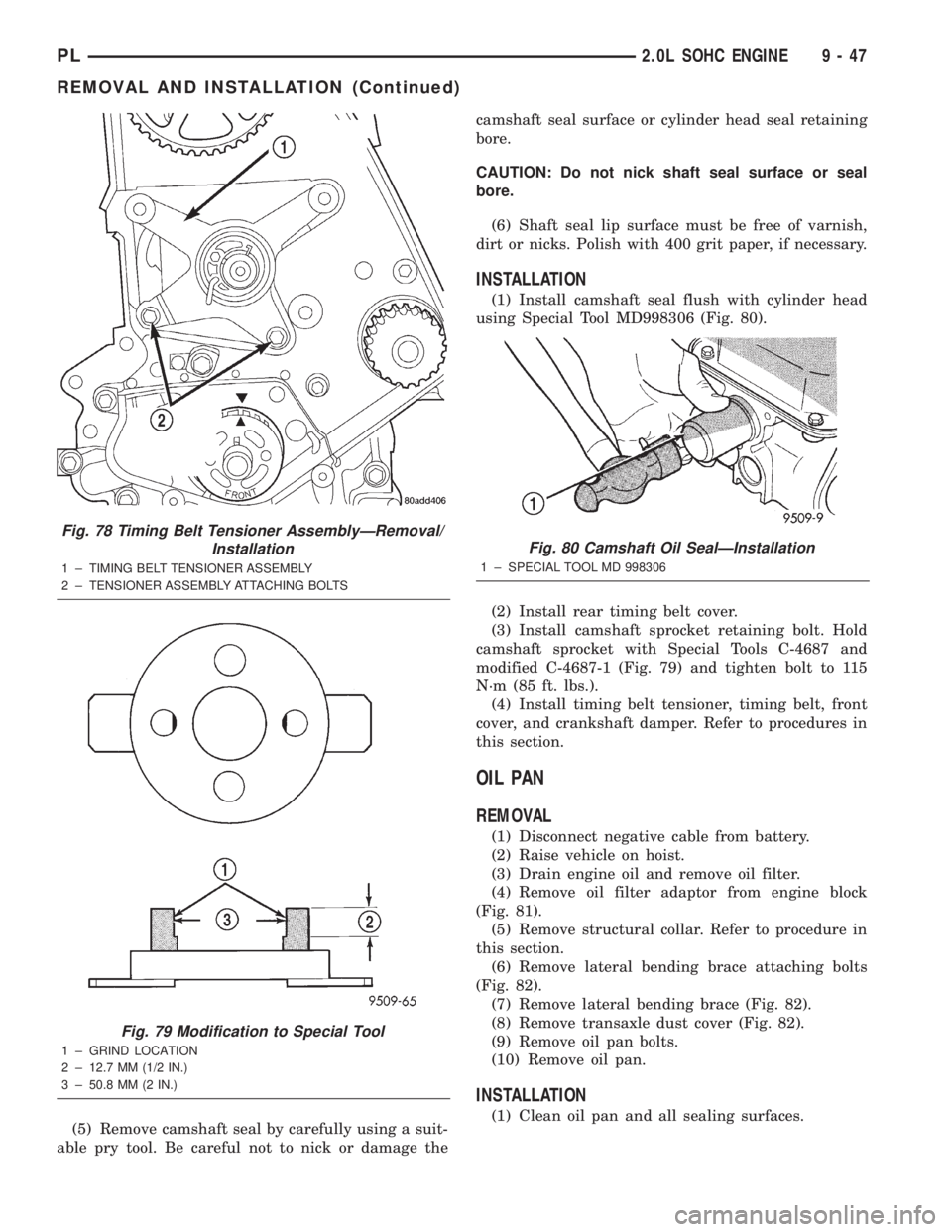

(3) Install camshaft sprocket retaining bolt. Hold

camshaft sprocket with Special Tools C-4687 and

modified C-4687-1 (Fig. 79) and tighten bolt to 115

N´m (85 ft. lbs.).

(4) Install timing belt tensioner, timing belt, front

cover, and crankshaft damper. Refer to procedures in

this section.

OIL PAN

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Drain engine oil and remove oil filter.

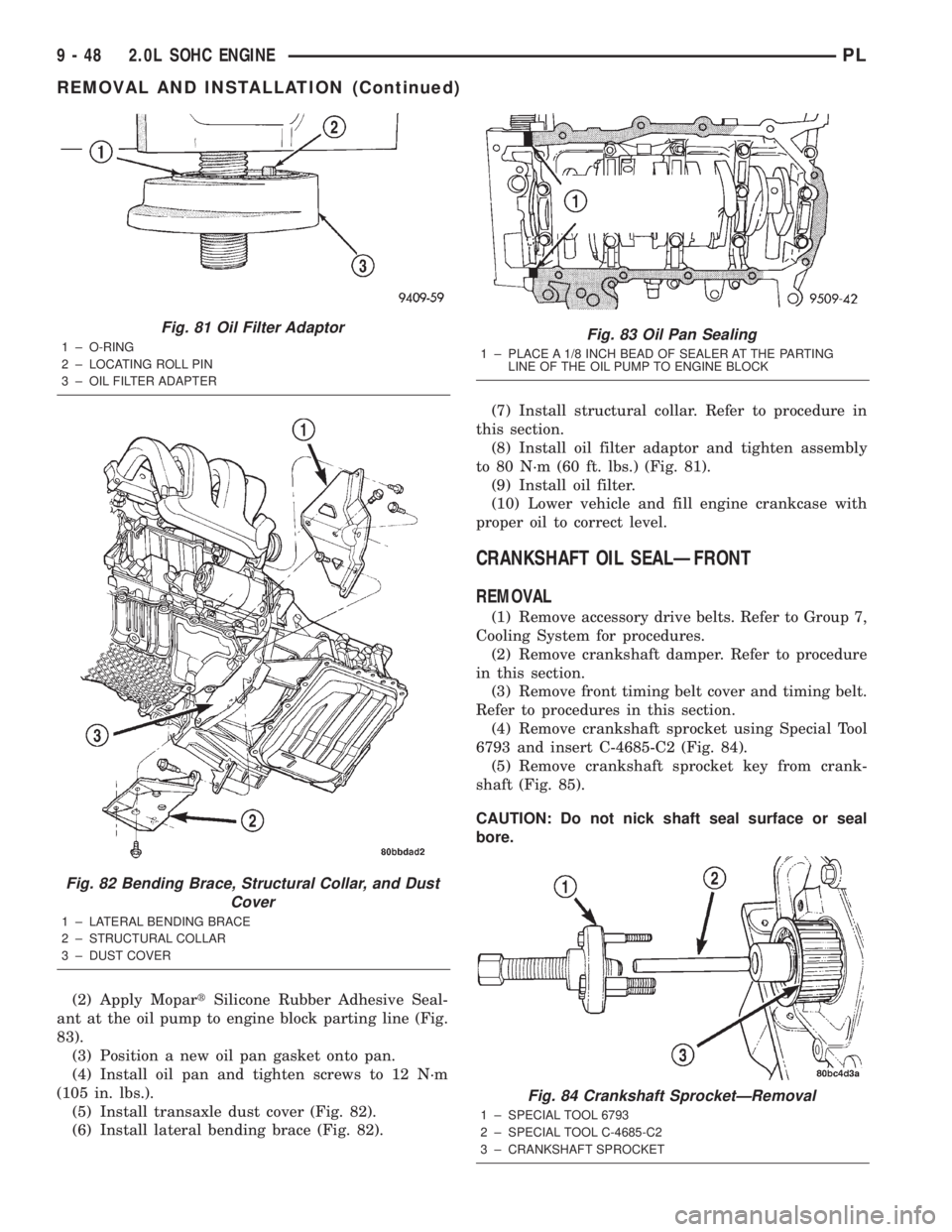

(4) Remove oil filter adaptor from engine block

(Fig. 81).

(5) Remove structural collar. Refer to procedure in

this section.

(6) Remove lateral bending brace attaching bolts

(Fig. 82).

(7) Remove lateral bending brace (Fig. 82).

(8) Remove transaxle dust cover (Fig. 82).

(9) Remove oil pan bolts.

(10) Remove oil pan.

INSTALLATION

(1) Clean oil pan and all sealing surfaces.

Fig. 78 Timing Belt Tensioner AssemblyÐRemoval/

Installation

1 ± TIMING BELT TENSIONER ASSEMBLY

2 ± TENSIONER ASSEMBLY ATTACHING BOLTS

Fig. 79 Modification to Special Tool

1 ± GRIND LOCATION

2 ± 12.7 MM (1/2 IN.)

3 ± 50.8 MM (2 IN.)

Fig. 80 Camshaft Oil SealÐInstallation

1 ± SPECIAL TOOL MD 998306

PL2.0L SOHC ENGINE 9 - 47

REMOVAL AND INSTALLATION (Continued)

Page 771 of 1285

(2) Apply MopartSilicone Rubber Adhesive Seal-

ant at the oil pump to engine block parting line (Fig.

83).

(3) Position a new oil pan gasket onto pan.

(4) Install oil pan and tighten screws to 12 N´m

(105 in. lbs.).

(5) Install transaxle dust cover (Fig. 82).

(6) Install lateral bending brace (Fig. 82).(7) Install structural collar. Refer to procedure in

this section.

(8) Install oil filter adaptor and tighten assembly

to 80 N´m (60 ft. lbs.) (Fig. 81).

(9) Install oil filter.

(10) Lower vehicle and fill engine crankcase with

proper oil to correct level.

CRANKSHAFT OIL SEALÐFRONT

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedures.

(2) Remove crankshaft damper. Refer to procedure

in this section.

(3) Remove front timing belt cover and timing belt.

Refer to procedures in this section.

(4) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 84).

(5) Remove crankshaft sprocket key from crank-

shaft (Fig. 85).

CAUTION: Do not nick shaft seal surface or seal

bore.

Fig. 81 Oil Filter Adaptor

1 ± O-RING

2 ± LOCATING ROLL PIN

3 ± OIL FILTER ADAPTER

Fig. 82 Bending Brace, Structural Collar, and Dust

Cover

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 83 Oil Pan Sealing

1 ± PLACE A 1/8 INCH BEAD OF SEALER AT THE PARTING

LINE OF THE OIL PUMP TO ENGINE BLOCK

Fig. 84 Crankshaft SprocketÐRemoval

1 ± SPECIAL TOOL 6793

2 ± SPECIAL TOOL C-4685-C2

3 ± CRANKSHAFT SPROCKET

9 - 48 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 773 of 1285

(4) Install timing belt and cover. Refer to proce-

dures in this section.

(5) Install crankshaft damper. Refer to procedure

in this section.

(6) Install accessory drive belts. Refer to Group 7,

Cooling System for procedure.

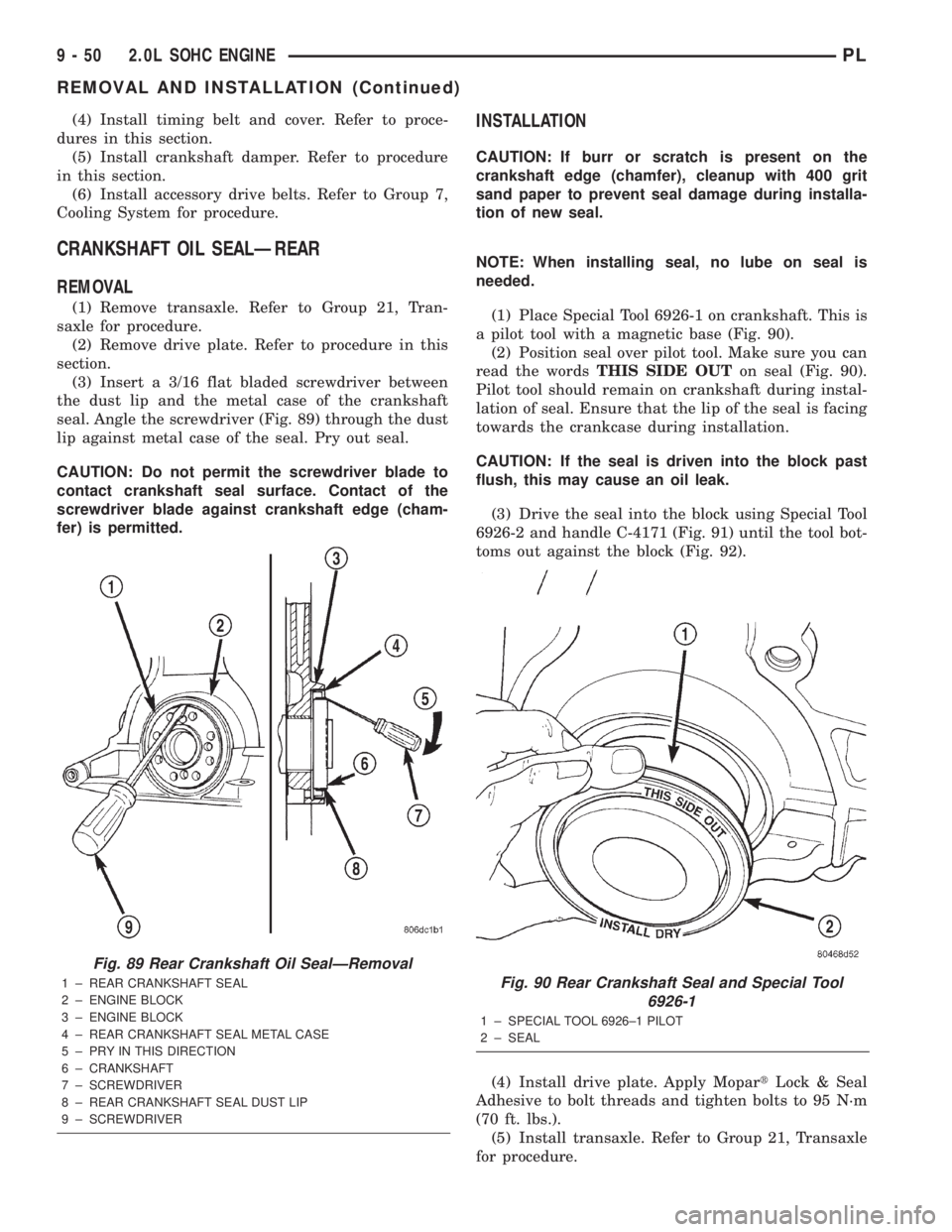

CRANKSHAFT OIL SEALÐREAR

REMOVAL

(1) Remove transaxle. Refer to Group 21, Tran-

saxle for procedure.

(2) Remove drive plate. Refer to procedure in this

section.

(3) Insert a 3/16 flat bladed screwdriver between

the dust lip and the metal case of the crankshaft

seal. Angle the screwdriver (Fig. 89) through the dust

lip against metal case of the seal. Pry out seal.

CAUTION: Do not permit the screwdriver blade to

contact crankshaft seal surface. Contact of the

screwdriver blade against crankshaft edge (cham-

fer) is permitted.

INSTALLATION

CAUTION: If burr or scratch is present on the

crankshaft edge (chamfer), cleanup with 400 grit

sand paper to prevent seal damage during installa-

tion of new seal.

NOTE: When installing seal, no lube on seal is

needed.

(1) Place Special Tool 6926-1 on crankshaft. This is

a pilot tool with a magnetic base (Fig. 90).

(2) Position seal over pilot tool. Make sure you can

read the wordsTHIS SIDE OUTon seal (Fig. 90).

Pilot tool should remain on crankshaft during instal-

lation of seal. Ensure that the lip of the seal is facing

towards the crankcase during installation.

CAUTION: If the seal is driven into the block past

flush, this may cause an oil leak.

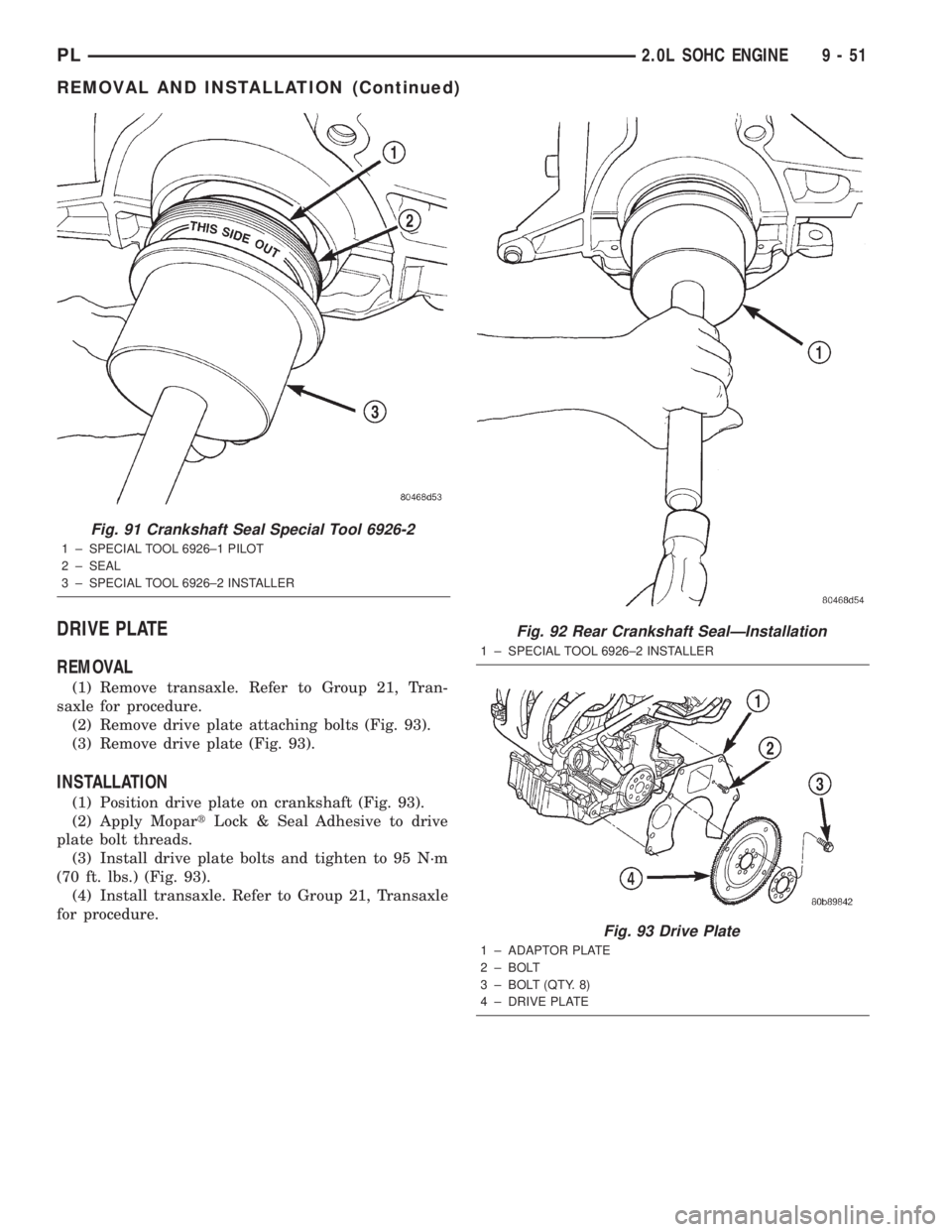

(3) Drive the seal into the block using Special Tool

6926-2 and handle C-4171 (Fig. 91) until the tool bot-

toms out against the block (Fig. 92).

(4) Install drive plate. Apply MopartLock & Seal

Adhesive to bolt threads and tighten bolts to 95 N´m

(70 ft. lbs.).

(5) Install transaxle. Refer to Group 21, Transaxle

for procedure.

Fig. 89 Rear Crankshaft Oil SealÐRemoval

1 ± REAR CRANKSHAFT SEAL

2 ± ENGINE BLOCK

3 ± ENGINE BLOCK

4 ± REAR CRANKSHAFT SEAL METAL CASE

5 ± PRY IN THIS DIRECTION

6 ± CRANKSHAFT

7 ± SCREWDRIVER

8 ± REAR CRANKSHAFT SEAL DUST LIP

9 ± SCREWDRIVERFig. 90 Rear Crankshaft Seal and Special Tool

6926-1

1 ± SPECIAL TOOL 6926±1 PILOT

2 ± SEAL

9 - 50 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 774 of 1285

DRIVE PLATE

REMOVAL

(1) Remove transaxle. Refer to Group 21, Tran-

saxle for procedure.

(2) Remove drive plate attaching bolts (Fig. 93).

(3) Remove drive plate (Fig. 93).

INSTALLATION

(1) Position drive plate on crankshaft (Fig. 93).

(2) Apply MopartLock & Seal Adhesive to drive

plate bolt threads.

(3) Install drive plate bolts and tighten to 95 N´m

(70 ft. lbs.) (Fig. 93).

(4) Install transaxle. Refer to Group 21, Transaxle

for procedure.

Fig. 91 Crankshaft Seal Special Tool 6926-2

1 ± SPECIAL TOOL 6926±1 PILOT

2 ± SEAL

3 ± SPECIAL TOOL 6926±2 INSTALLER

Fig. 92 Rear Crankshaft SealÐInstallation

1 ± SPECIAL TOOL 6926±2 INSTALLER

Fig. 93 Drive Plate

1 ± ADAPTOR PLATE

2 ± BOLT

3 ± BOLT (QTY. 8)

4 ± DRIVE PLATE

PL2.0L SOHC ENGINE 9 - 51

REMOVAL AND INSTALLATION (Continued)

Page 776 of 1285

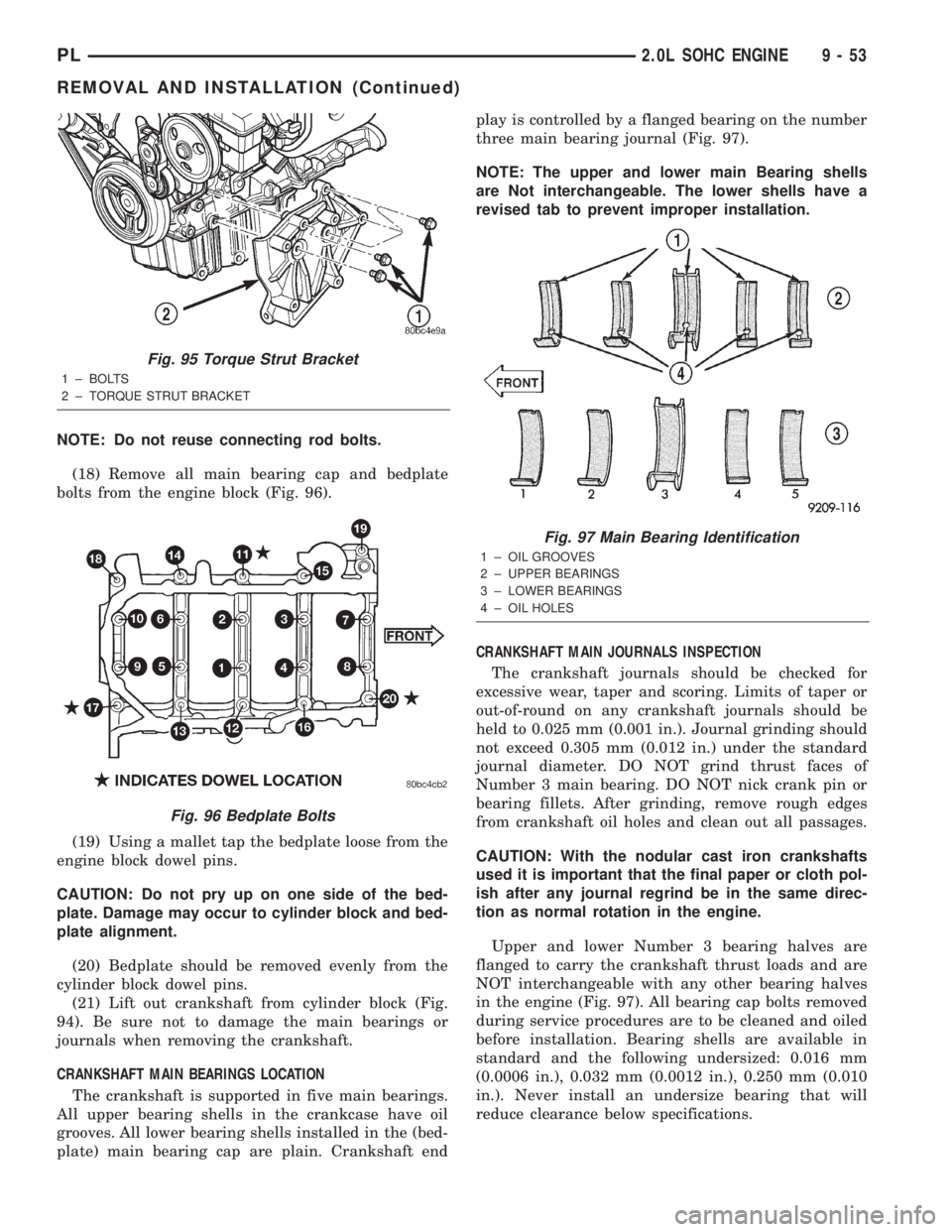

NOTE: Do not reuse connecting rod bolts.

(18) Remove all main bearing cap and bedplate

bolts from the engine block (Fig. 96).

(19) Using a mallet tap the bedplate loose from the

engine block dowel pins.

CAUTION: Do not pry up on one side of the bed-

plate. Damage may occur to cylinder block and bed-

plate alignment.

(20) Bedplate should be removed evenly from the

cylinder block dowel pins.

(21) Lift out crankshaft from cylinder block (Fig.

94). Be sure not to damage the main bearings or

journals when removing the crankshaft.

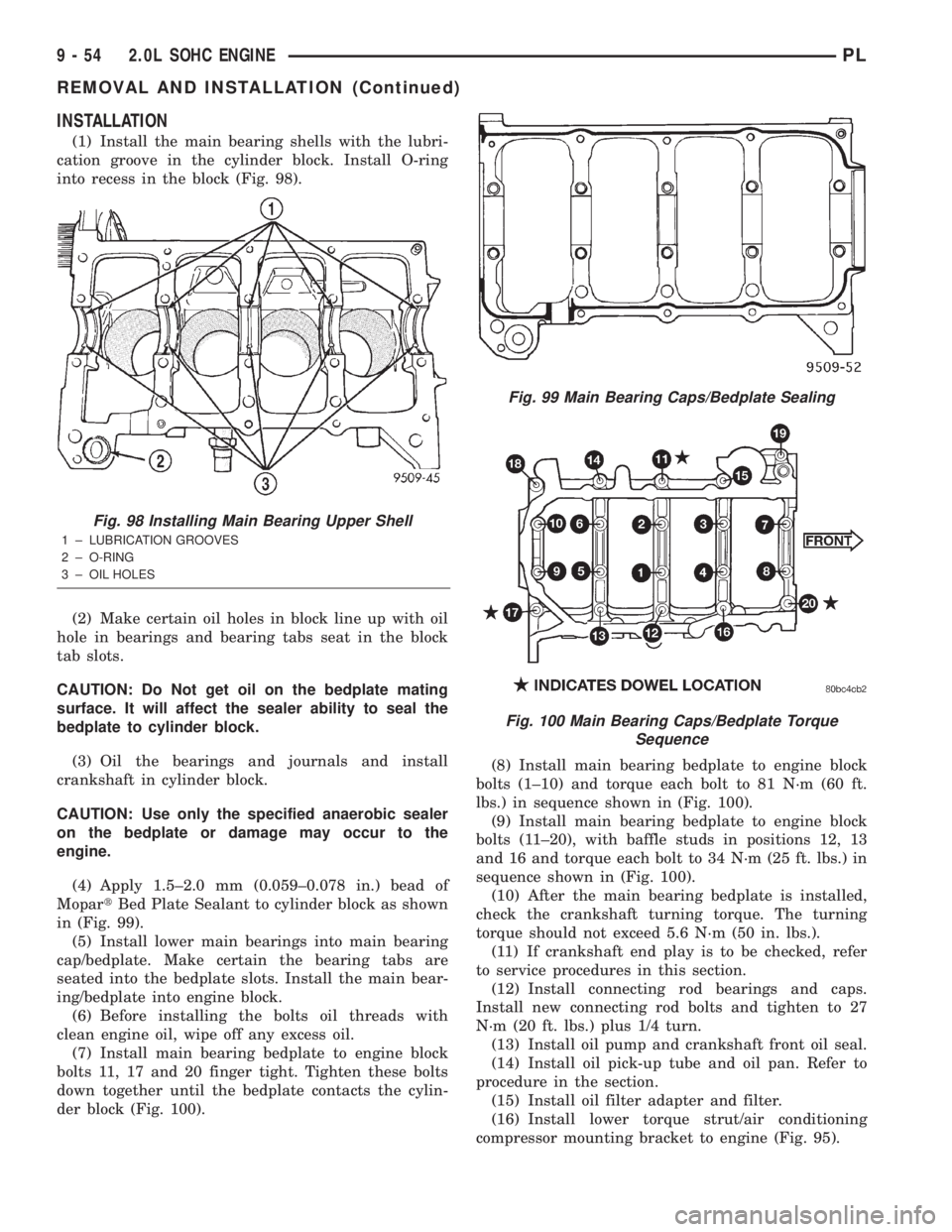

CRANKSHAFT MAIN BEARINGS LOCATION

The crankshaft is supported in five main bearings.

All upper bearing shells in the crankcase have oil

grooves. All lower bearing shells installed in the (bed-

plate) main bearing cap are plain. Crankshaft endplay is controlled by a flanged bearing on the number

three main bearing journal (Fig. 97).

NOTE: The upper and lower main Bearing shells

are Not interchangeable. The lower shells have a

revised tab to prevent improper installation.

CRANKSHAFT MAIN JOURNALS INSPECTION

The crankshaft journals should be checked for

excessive wear, taper and scoring. Limits of taper or

out-of-round on any crankshaft journals should be

held to 0.025 mm (0.001 in.). Journal grinding should

not exceed 0.305 mm (0.012 in.) under the standard

journal diameter. DO NOT grind thrust faces of

Number 3 main bearing. DO NOT nick crank pin or

bearing fillets. After grinding, remove rough edges

from crankshaft oil holes and clean out all passages.

CAUTION: With the nodular cast iron crankshafts

used it is important that the final paper or cloth pol-

ish after any journal regrind be in the same direc-

tion as normal rotation in the engine.

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 97). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.016 mm

(0.0006 in.), 0.032 mm (0.0012 in.), 0.250 mm (0.010

in.). Never install an undersize bearing that will

reduce clearance below specifications.

Fig. 95 Torque Strut Bracket

1 ± BOLTS

2 ± TORQUE STRUT BRACKET

Fig. 96 Bedplate Bolts

Fig. 97 Main Bearing Identification

1 ± OIL GROOVES

2 ± UPPER BEARINGS

3 ± LOWER BEARINGS

4 ± OIL HOLES

PL2.0L SOHC ENGINE 9 - 53

REMOVAL AND INSTALLATION (Continued)

Page 777 of 1285

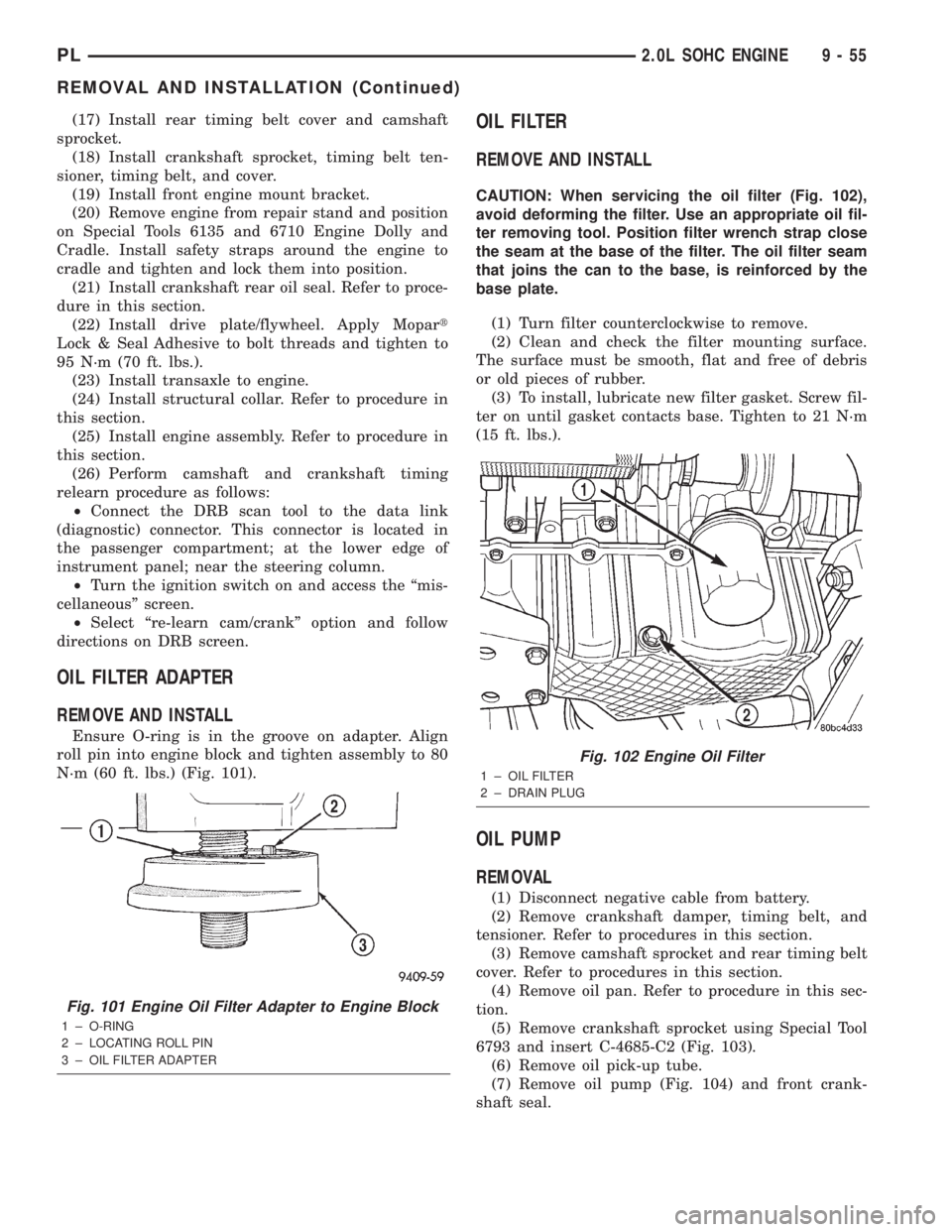

INSTALLATION

(1) Install the main bearing shells with the lubri-

cation groove in the cylinder block. Install O-ring

into recess in the block (Fig. 98).

(2) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block

tab slots.

CAUTION: Do Not get oil on the bedplate mating

surface. It will affect the sealer ability to seal the

bedplate to cylinder block.

(3) Oil the bearings and journals and install

crankshaft in cylinder block.

CAUTION: Use only the specified anaerobic sealer

on the bedplate or damage may occur to the

engine.

(4) Apply 1.5±2.0 mm (0.059±0.078 in.) bead of

MopartBed Plate Sealant to cylinder block as shown

in (Fig. 99).

(5) Install lower main bearings into main bearing

cap/bedplate. Make certain the bearing tabs are

seated into the bedplate slots. Install the main bear-

ing/bedplate into engine block.

(6) Before installing the bolts oil threads with

clean engine oil, wipe off any excess oil.

(7) Install main bearing bedplate to engine block

bolts 11, 17 and 20 finger tight. Tighten these bolts

down together until the bedplate contacts the cylin-

der block (Fig. 100).(8) Install main bearing bedplate to engine block

bolts (1±10) and torque each bolt to 81 N´m (60 ft.

lbs.) in sequence shown in (Fig. 100).

(9) Install main bearing bedplate to engine block

bolts (11±20), with baffle studs in positions 12, 13

and 16 and torque each bolt to 34 N´m (25 ft. lbs.) in

sequence shown in (Fig. 100).

(10) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(11) If crankshaft end play is to be checked, refer

to service procedures in this section.

(12) Install connecting rod bearings and caps.

Install new connecting rod bolts and tighten to 27

N´m (20 ft. lbs.) plus 1/4 turn.

(13) Install oil pump and crankshaft front oil seal.

(14) Install oil pick-up tube and oil pan. Refer to

procedure in the section.

(15) Install oil filter adapter and filter.

(16) Install lower torque strut/air conditioning

compressor mounting bracket to engine (Fig. 95).

Fig. 98 Installing Main Bearing Upper Shell

1 ± LUBRICATION GROOVES

2 ± O-RING

3 ± OIL HOLES

Fig. 99 Main Bearing Caps/Bedplate Sealing

Fig. 100 Main Bearing Caps/Bedplate Torque

Sequence

9 - 54 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 778 of 1285

(17) Install rear timing belt cover and camshaft

sprocket.

(18) Install crankshaft sprocket, timing belt ten-

sioner, timing belt, and cover.

(19) Install front engine mount bracket.

(20) Remove engine from repair stand and position

on Special Tools 6135 and 6710 Engine Dolly and

Cradle. Install safety straps around the engine to

cradle and tighten and lock them into position.

(21) Install crankshaft rear oil seal. Refer to proce-

dure in this section.

(22) Install drive plate/flywheel. Apply Mopart

Lock & Seal Adhesive to bolt threads and tighten to

95 N´m (70 ft. lbs.).

(23) Install transaxle to engine.

(24) Install structural collar. Refer to procedure in

this section.

(25) Install engine assembly. Refer to procedure in

this section.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 101).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 102),

avoid deforming the filter. Use an appropriate oil fil-

ter removing tool. Position filter wrench strap close

the seam at the base of the filter. The oil filter seam

that joins the can to the base, is reinforced by the

base plate.

(1) Turn filter counterclockwise to remove.

(2) Clean and check the filter mounting surface.

The surface must be smooth, flat and free of debris

or old pieces of rubber.

(3) To install, lubricate new filter gasket. Screw fil-

ter on until gasket contacts base. Tighten to 21 N´m

(15 ft. lbs.).

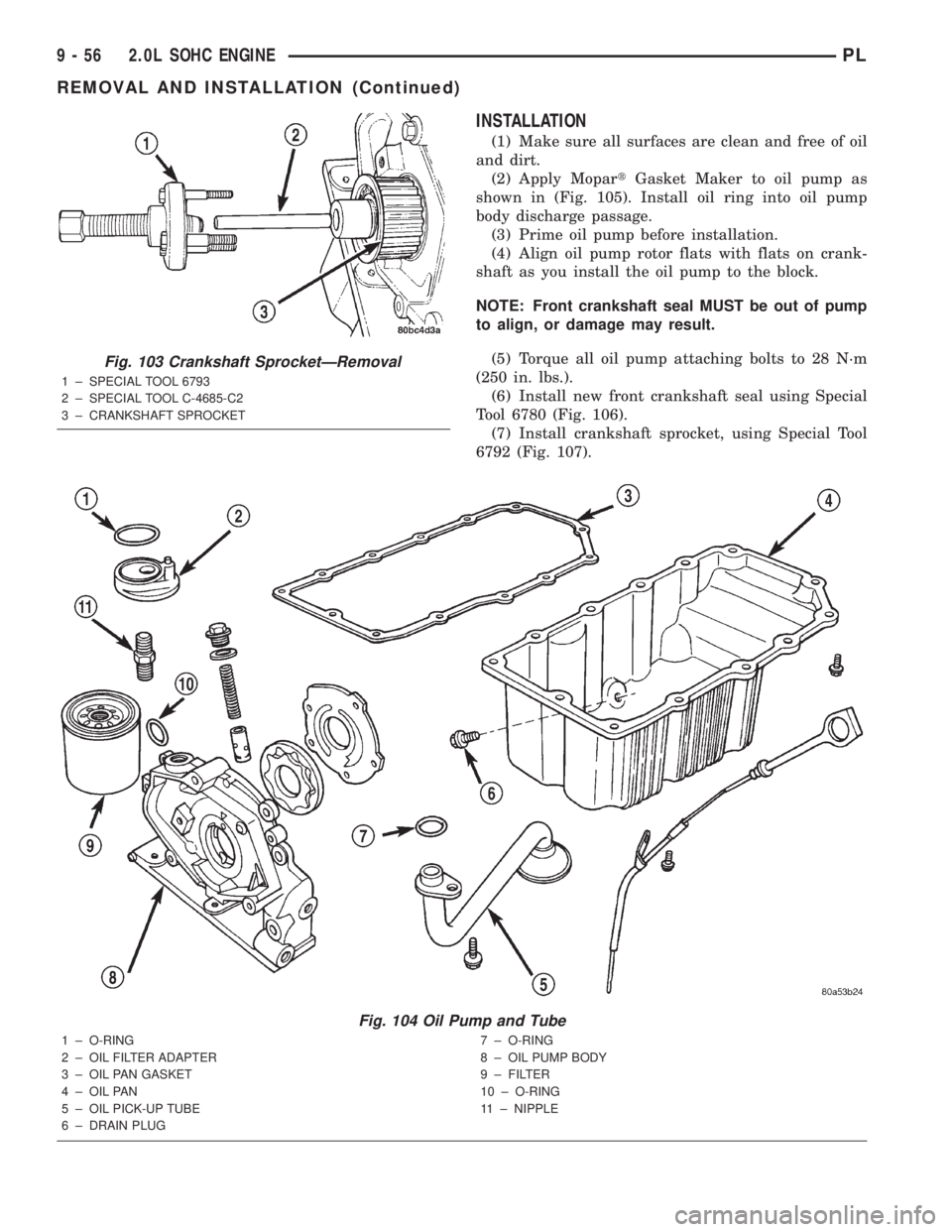

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove crankshaft damper, timing belt, and

tensioner. Refer to procedures in this section.

(3) Remove camshaft sprocket and rear timing belt

cover. Refer to procedures in this section.

(4) Remove oil pan. Refer to procedure in this sec-

tion.

(5) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 103).

(6) Remove oil pick-up tube.

(7) Remove oil pump (Fig. 104) and front crank-

shaft seal.

Fig. 101 Engine Oil Filter Adapter to Engine Block

1 ± O-RING

2 ± LOCATING ROLL PIN

3 ± OIL FILTER ADAPTER

Fig. 102 Engine Oil Filter

1 ± OIL FILTER

2 ± DRAIN PLUG

PL2.0L SOHC ENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 779 of 1285

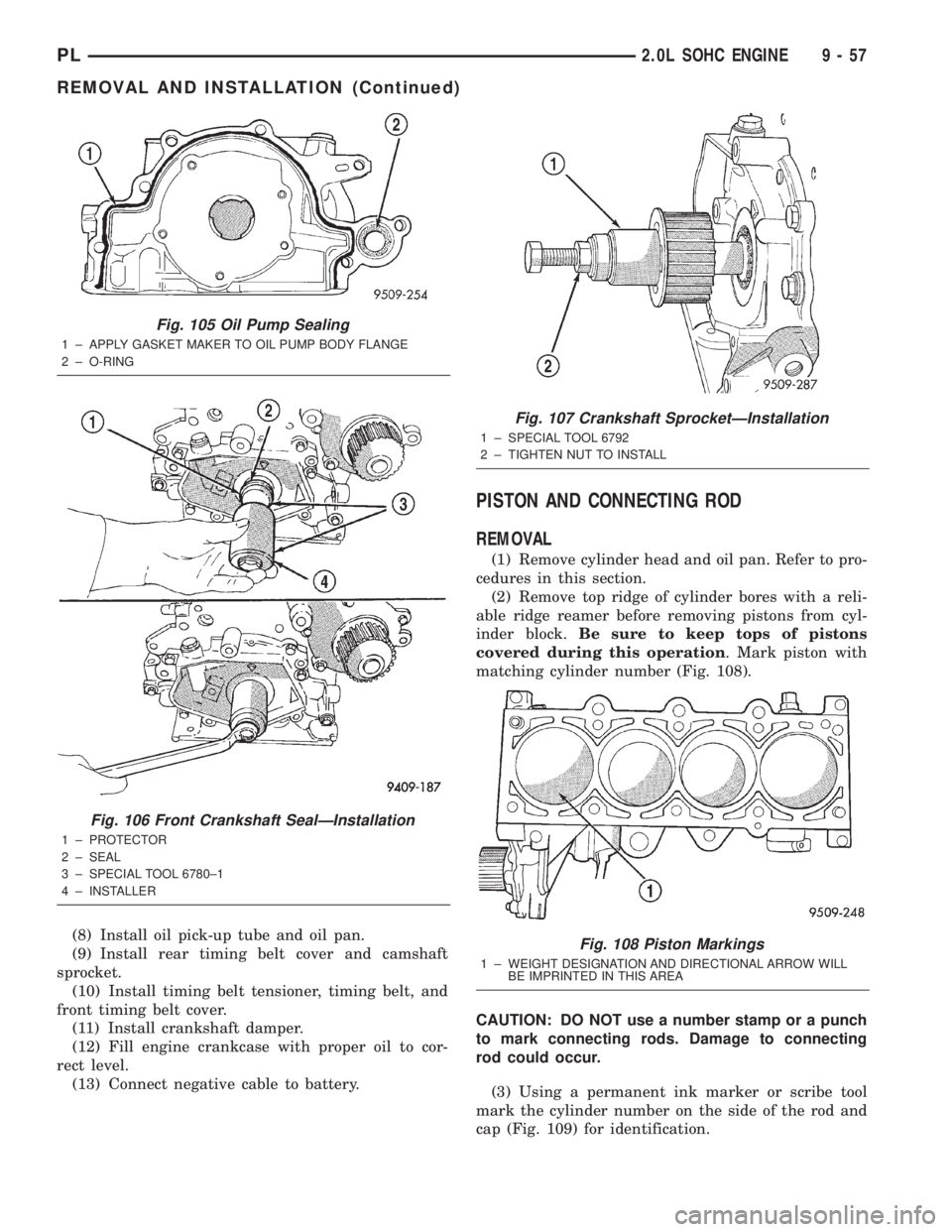

INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.

(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 105). Install oil ring into oil pump

body discharge passage.

(3) Prime oil pump before installation.

(4) Align oil pump rotor flats with flats on crank-

shaft as you install the oil pump to the block.

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.).

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 106).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 107).

Fig. 104 Oil Pump and Tube

1 ± O-RING

2 ± OIL FILTER ADAPTER

3 ± OIL PAN GASKET

4 ± OIL PAN

5 ± OIL PICK-UP TUBE

6 ± DRAIN PLUG7 ± O-RING

8 ± OIL PUMP BODY

9 ± FILTER

10 ± O-RING

11 ± NIPPLE

Fig. 103 Crankshaft SprocketÐRemoval

1 ± SPECIAL TOOL 6793

2 ± SPECIAL TOOL C-4685-C2

3 ± CRANKSHAFT SPROCKET

9 - 56 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 780 of 1285

(8) Install oil pick-up tube and oil pan.

(9) Install rear timing belt cover and camshaft

sprocket.

(10) Install timing belt tensioner, timing belt, and

front timing belt cover.

(11) Install crankshaft damper.

(12) Fill engine crankcase with proper oil to cor-

rect level.

(13) Connect negative cable to battery.

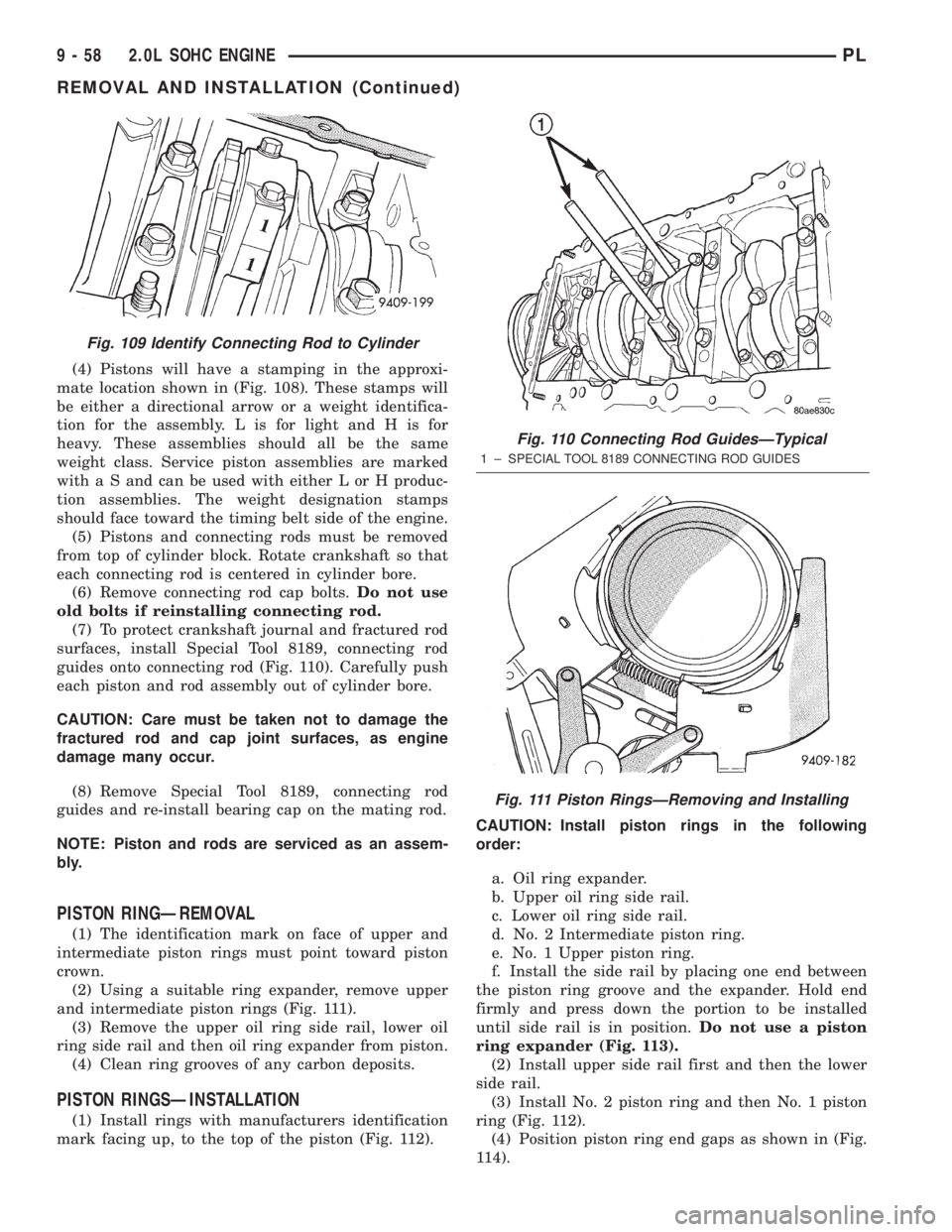

PISTON AND CONNECTING ROD

REMOVAL

(1) Remove cylinder head and oil pan. Refer to pro-

cedures in this section.

(2) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 108).

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(3) Using a permanent ink marker or scribe tool

mark the cylinder number on the side of the rod and

cap (Fig. 109) for identification.

Fig. 105 Oil Pump Sealing

1 ± APPLY GASKET MAKER TO OIL PUMP BODY FLANGE

2 ± O-RING

Fig. 106 Front Crankshaft SealÐInstallation

1 ± PROTECTOR

2 ± SEAL

3 ± SPECIAL TOOL 6780±1

4 ± INSTALLER

Fig. 107 Crankshaft SprocketÐInstallation

1 ± SPECIAL TOOL 6792

2 ± TIGHTEN NUT TO INSTALL

Fig. 108 Piston Markings

1 ± WEIGHT DESIGNATION AND DIRECTIONAL ARROW WILL

BE IMPRINTED IN THIS AREA

PL2.0L SOHC ENGINE 9 - 57

REMOVAL AND INSTALLATION (Continued)

Page 781 of 1285

(4) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 108). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(5) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(6) Remove connecting rod cap bolts.Do not use

old bolts if reinstalling connecting rod.

(7) To protect crankshaft journal and fractured rod

surfaces, install Special Tool 8189, connecting rod

guides onto connecting rod (Fig. 110). Carefully push

each piston and rod assembly out of cylinder bore.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint surfaces, as engine

damage many occur.

(8) Remove Special Tool 8189, connecting rod

guides and re-install bearing cap on the mating rod.

NOTE: Piston and rods are serviced as an assem-

bly.

PISTON RINGÐREMOVAL

(1) The identification mark on face of upper and

intermediate piston rings must point toward piston

crown.

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 111).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Clean ring grooves of any carbon deposits.

PISTON RINGSÐINSTALLATION

(1) Install rings with manufacturers identification

mark facing up, to the top of the piston (Fig. 112).CAUTION: Install piston rings in the following

order:

a. Oil ring expander.

b. Upper oil ring side rail.

c. Lower oil ring side rail.

d. No. 2 Intermediate piston ring.

e. No. 1 Upper piston ring.

f. Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

firmly and press down the portion to be installed

until side rail is in position.Do not use a piston

ring expander (Fig. 113).

(2) Install upper side rail first and then the lower

side rail.

(3) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 112).

(4) Position piston ring end gaps as shown in (Fig.

114).

Fig. 109 Identify Connecting Rod to Cylinder

Fig. 110 Connecting Rod GuidesÐTypical

1 ± SPECIAL TOOL 8189 CONNECTING ROD GUIDES

Fig. 111 Piston RingsÐRemoving and Installing

9 - 58 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)