DODGE NEON 2000 Service Repair Manual

Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 821 of 1285

Page 822 of 1285

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL DELIVERY SYSTEM.................... 1FUEL INJECTION SYSTEM.................. 21

FUEL DELIVERY SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

FUEL REQUIREMENTS.....................1

GASOLINE/OXYGENATE BLENDS.............2

FUEL DELIVERY SYSTEM...................3

FUEL PUMP MODULE......................3

ELECTRIC FUEL PUMP.....................4

FUEL GAUGE SENDING UNIT................4

FUEL FILTER/FUEL PRESSURE REGULATOR....4

FUEL TANK..............................4

FUEL RAIL...............................4

FUEL INJECTORS.........................5

PRESSURE-VACUUM FILLER CAP............5

ONBOARD REFUELING VAPOR RECOVERY....6

CONTROL VALVE/PRESSURE RELIEF.........6

QUICK-CONNECT FITTINGS.................6

ROLLOVER VALVES.......................7

FUEL TUBES/LINES/HOSES AND CLAMPS......8

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE...........................8INJECTOR CONNECTOR....................8

DRAINING FUEL TANK.....................9

HOSES AND CLAMPS......................9

QUICK-CONNECT FITTINGS.................9

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY............12

FUEL PUMP RELAY.......................12

FUEL PUMP MODULE.....................12

FUEL FILTER / PRESSURE REGULATOR......13

FUEL PUMP INLET STRAINER..............14

FUEL LEVEL SENSOR.....................14

FUEL INJECTORS........................15

FUEL TANK.............................16

FUEL FILLER NECK.......................17

ACCELERATOR PEDAL....................18

THROTTLE CABLE.......................19

SPECIFICATIONS

TORQUE...............................20

DESCRIPTION AND OPERATION

FUEL REQUIREMENTS

OPERATION

Your engine is designed to meet all emissions reg-

ulations and provide excellent fuel economy and per-

formance when using high quality unleaded gasoline

having an octane rating of 87. The use of premium

gasoline is not recommended. The use of premium

gasoline will provide no benefit over high quality reg-

ular gasoline, and in some circumstances may result

in poorer performance.

Light spark knock at low engine speeds is not

harmful to your engine. However, continued heavyspark knock at high speeds can cause damage and

immediate service is required. Engine damage result-

ing from operation with a heavy spark knock may

not be covered by the new vehicle warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling and hesitations. If you experi-

ence these symptoms, try another brand of gasoline

before considering service for the vehicle.

The American Automobile Manufacturers Associa-

tion, AAMA, has issued gasoline specifications to

define the minimum fuel properties necessary to

deliver enhanced performance and durability for your

vehicle. DaimlerChrysler Corporation recommends

the use of gasoline that meet the AAMA specifica-

tions if they are available.

PLFUEL SYSTEM 14 - 1

Page 823 of 1285

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as ªreformulat-

edº gasoline. Reformulated gasoline contain oxygen-

ates, and are specifically blended to reduce vehicle

emissions and improve air quality.

DaimlerChrysler Corporation strongly supports the

use of reformulated gasoline. Properly blended refor-

mulated gasoline will provide excellent performance

and durability for the engine and fuel system compo-

nents.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as 10% ethanol, MTBE, and ETBE.

Oxygenates are required in some areas of the country

during the winter months to reduce carbon monoxide

emissions. Fuels blended with these oxygenates may

be used in your vehicle.

CAUTION: DO NOT use gasoline containing METH-

ANOL. Gasoline containing methanol may damage

critical fuel system components.

MMT

MMT is a manganese-containing metallic additive

that is blended into some gasoline to increase octane.

Gasoline blended with MMT provide no performance

advantage beyond gasoline of the same octane num-

ber without MMT. Gasoline blended with MMT

reduce spark plug life and reduce emission system

performance in some vehicles. DaimlerChrysler rec-

ommends that gasoline without MMT be used in your

vehicle. The MMT content of gasoline may not be

indicated on the gasoline pump; therefore, you should

ask your gasoline retailer whether or not his/her gas-

oline contains MMT.

It is even more important to look for gasoline with-

out MMT in Canada because MMT can be used at

levels higher than allowed in the United States.

MMT is prohibited in Federal and California refor-

mulated gasoline.

SULFUR IN GASOLINE

If you live in the northeast United States, your

vehicle may have been designed to meet California

low emission standards with clean-burning, low-sul-

fur, California gasoline. Gasoline sold outside of Cal-

ifornia is permitted to have higher sulfur levels

which may affect the performance of the vehicle's cat-

alytic converter. This may cause the Check Engine or

Service Engine Soon light to illuminate.

Illumination of either light while operating on high

sulfur gasoline does not necessarily mean your emis-

sion control system is malfunctioning. DaimlerChrysler

recommends that you try a different brand of unleadedgasoline having lower sulfur to determine if the prob-

lem is fuel related prior to returning your vehicle to an

authorized dealer for service.

CAUTION: If the Check Engine or Service Engine

Soon light is flashing, immediate service is

required; see on-board diagnostics system section.

MATERIALS ADDED TO FUEL

All gasoline sold in the United States and Canada

are required to contain effective detergent additives.

Use of additional detergents or other additives is not

needed under normal conditions.

FUEL SYSTEM CAUTIONS

CAUTION: Follow these guidelines to maintain your

vehicle's performance:

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of

DaimlerChrysler Corporation and may not be covered

under the new vehicle warranty.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

GASOLINE/OXYGENATE BLENDS

OPERATION

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

(Methyl Tertiary Butyl Ether) and ETBE (Ethyl Ter-

tiary Butyl Ether). Oxygenates are required in some

areas of the country during winter months to reduce

14 - 2 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 824 of 1285

carbon monoxide emissions. The type and amount of

oxygenate used in the blend is important.

The following are generally used in gasoline

blends:

Ethanol- (Ethyl or Grain Alcohol) properly

blended, is used as a mixture of 10 percent ethanol

and 90 percent gasoline. Gasoline blended with etha-

nol may be used in your vehicle.

MTBE/ETBE- Gasoline and MTBE (Methyl Ter-

tiary Butyl Ether) blends are a mixture of unleaded

gasoline and up to 15 percent MTBE. Gasoline and

ETBE (Ethyl Tertiary Butyl Ether) are blends of gas-

oline and up to 17 percent ETBE. Gasoline blended

with MTBE or ETBE may be used in your vehicle.

Methanol- Methanol (Methyl or Wood Alcohol) is

used in a variety of concentrations blended with

unleaded gasoline. You may encounter fuels contain-

ing 3 percent or more methanol along with other

alcohols called cosolvents.

DO NOT USE GASOLINE CONTAINING

METHANOL.

Use of methanol/gasoline blends may result in

starting and driveability problems and damage criti-

cal fuel system components.

Problems that are the result of using methanol/

gasoline blends are not the responsibility of

DaimlerChrysler Corporation and may not be covered

by the vehicle warranty.

Reformulated Gasoline

Many areas of the country are requiring the use of

cleaner-burning fuel referred to asReformulated

Gasoline. Reformulated gasoline are specially

blended to reduce vehicle emissions and improve air

quality.

DaimlerChrysler Corporation strongly supports the

use of reformulated gasoline whenever available.

Although your vehicle was designed to provide opti-

mum performance and lowest emissions operating on

high quality unleaded gasoline, it will perform

equally well and produce even lower emissions when

operating on reformulated gasoline.

Materials Added to Fuel

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials intended

for gum and varnish removal may contain active sol-

vents of similar ingredients that can be harmful to

fuel system gasket and diaphragm materials.

FUEL DELIVERY SYSTEM

OPERATION

The fuel delivery system consists of: the electric

fuel pump, fuel filter/fuel pressure regulator, fuel

tubes/lines/hoses, fuel rail, fuel injectors, fuel tank,

accelerator pedal and throttle cable.A fuel return system is used on all models (all

engines). Fuel is returned through the fuel pump

module and back into the fuel tank through the fuel

filter/fuel pressure regulator. A separate fuel return

line from the engine to the tank is no longer used

with any engine.

The fuel tank assembly consists of: the fuel tank,

filler tube, fuel gauge sending unit/electric fuel pump

module, a rollover valve(s) and a pressure-vacuum

filler cap.

Also to be considered part of the fuel system is the

evaporation control system or Onboard Refueling

Vapor recovery (ORVR). This is designed to reduce

the emission of fuel vapors into the atmosphere. The

description and function of the Evaporative Control

System is found in the Emission Control Systems

section.

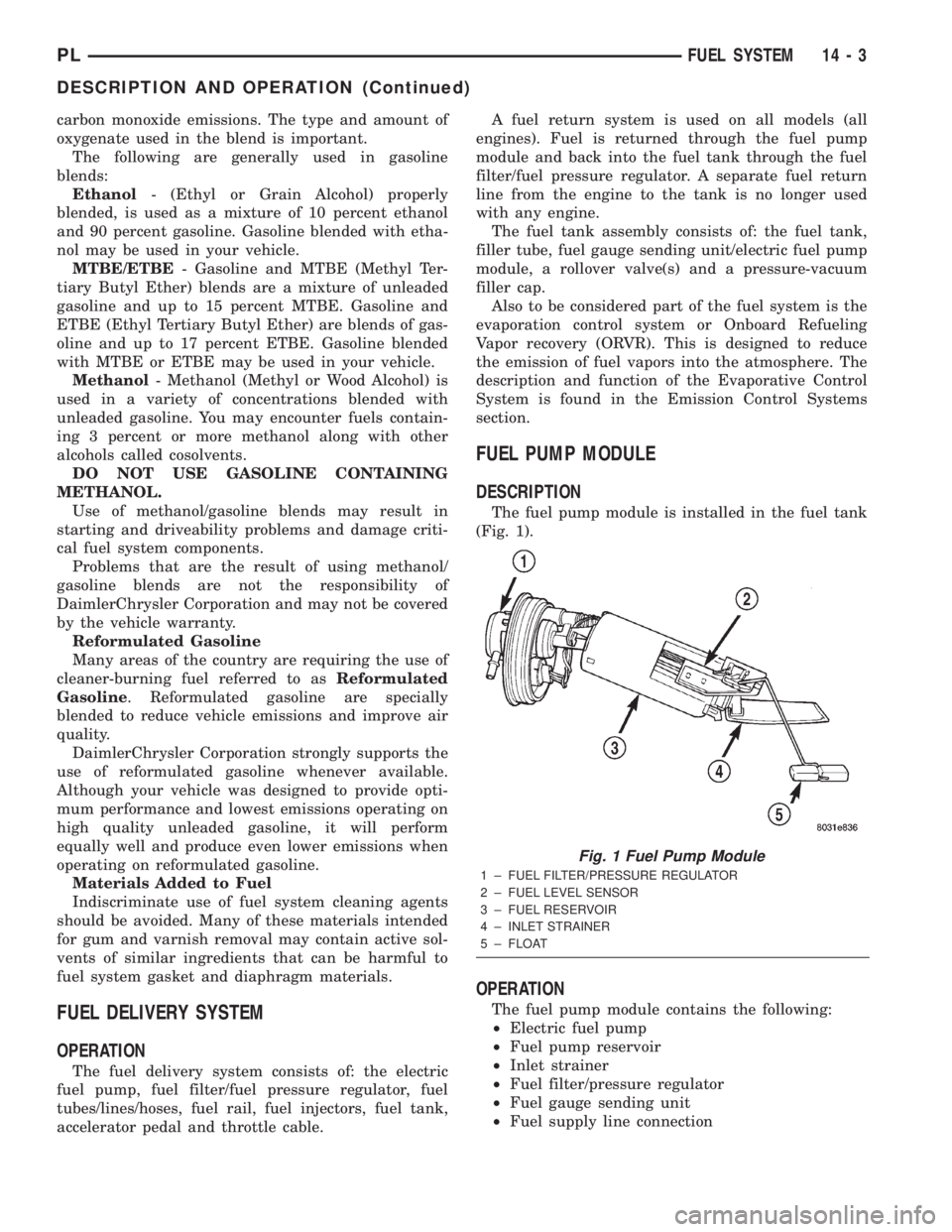

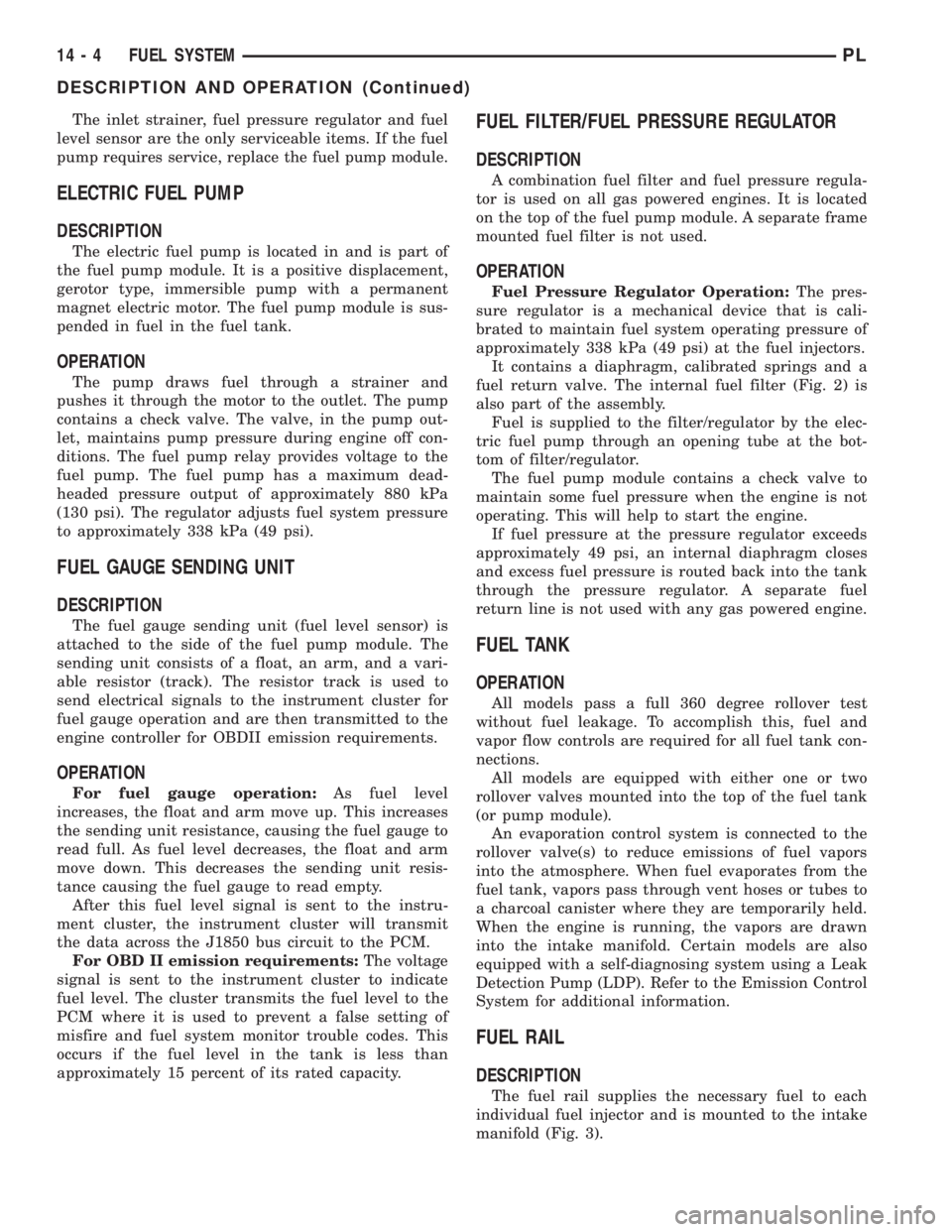

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module is installed in the fuel tank

(Fig. 1).

OPERATION

The fuel pump module contains the following:

²Electric fuel pump

²Fuel pump reservoir

²Inlet strainer

²Fuel filter/pressure regulator

²Fuel gauge sending unit

²Fuel supply line connection

Fig. 1 Fuel Pump Module

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± FUEL LEVEL SENSOR

3 ± FUEL RESERVOIR

4 ± INLET STRAINER

5 ± FLOAT

PLFUEL SYSTEM 14 - 3

DESCRIPTION AND OPERATION (Continued)

Page 825 of 1285

The inlet strainer, fuel pressure regulator and fuel

level sensor are the only serviceable items. If the fuel

pump requires service, replace the fuel pump module.

ELECTRIC FUEL PUMP

DESCRIPTION

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor. The fuel pump module is sus-

pended in fuel in the fuel tank.

OPERATION

The pump draws fuel through a strainer and

pushes it through the motor to the outlet. The pump

contains a check valve. The valve, in the pump out-

let, maintains pump pressure during engine off con-

ditions. The fuel pump relay provides voltage to the

fuel pump. The fuel pump has a maximum dead-

headed pressure output of approximately 880 kPa

(130 psi). The regulator adjusts fuel system pressure

to approximately 338 kPa (49 psi).

FUEL GAUGE SENDING UNIT

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel pump module. The

sending unit consists of a float, an arm, and a vari-

able resistor (track). The resistor track is used to

send electrical signals to the instrument cluster for

fuel gauge operation and are then transmitted to the

engine controller for OBDII emission requirements.

OPERATION

For fuel gauge operation:As fuel level

increases, the float and arm move up. This increases

the sending unit resistance, causing the fuel gauge to

read full. As fuel level decreases, the float and arm

move down. This decreases the sending unit resis-

tance causing the fuel gauge to read empty.

After this fuel level signal is sent to the instru-

ment cluster, the instrument cluster will transmit

the data across the J1850 bus circuit to the PCM.

For OBD II emission requirements:The voltage

signal is sent to the instrument cluster to indicate

fuel level. The cluster transmits the fuel level to the

PCM where it is used to prevent a false setting of

misfire and fuel system monitor trouble codes. This

occurs if the fuel level in the tank is less than

approximately 15 percent of its rated capacity.

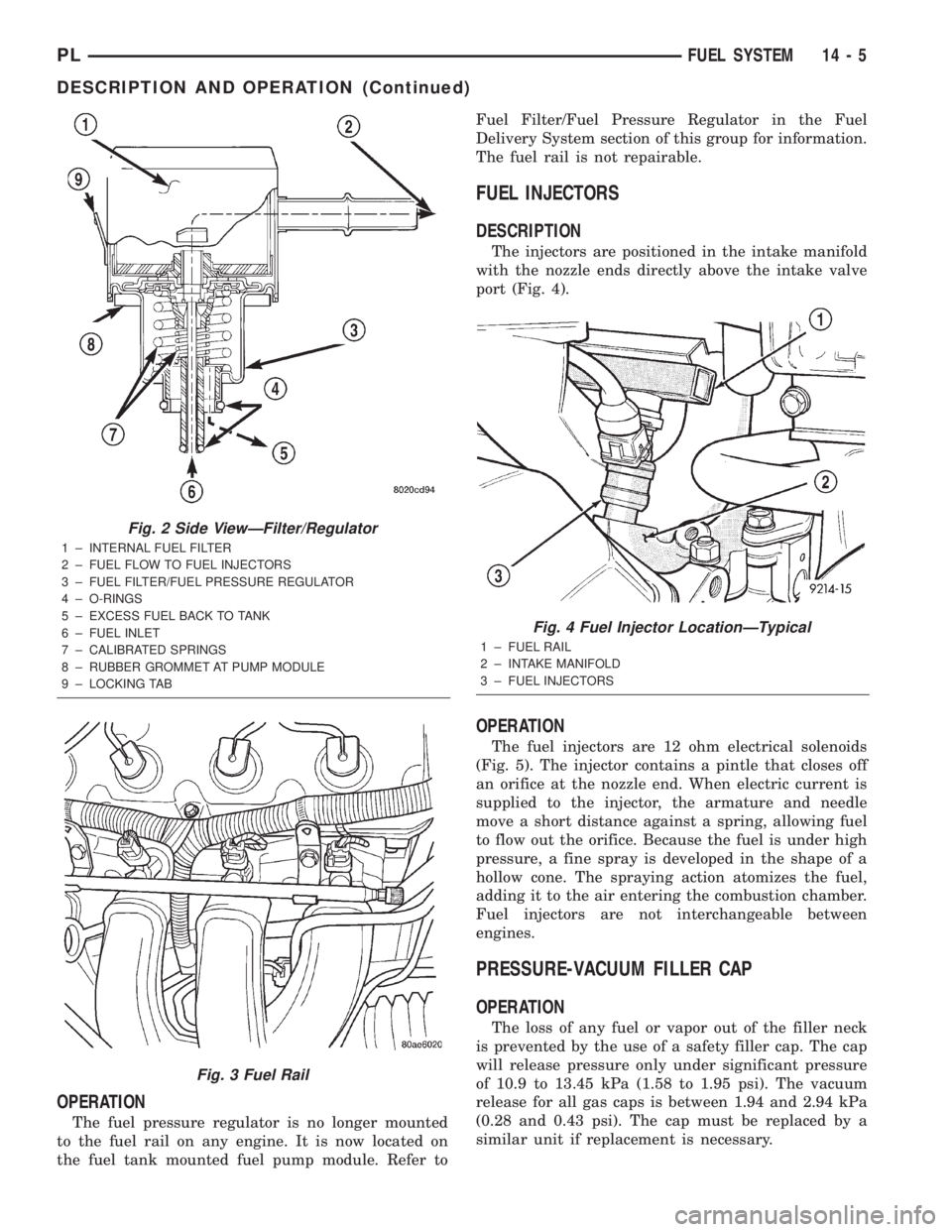

FUEL FILTER/FUEL PRESSURE REGULATOR

DESCRIPTION

A combination fuel filter and fuel pressure regula-

tor is used on all gas powered engines. It is located

on the top of the fuel pump module. A separate frame

mounted fuel filter is not used.

OPERATION

Fuel Pressure Regulator Operation:The pres-

sure regulator is a mechanical device that is cali-

brated to maintain fuel system operating pressure of

approximately 338 kPa (49 psi) at the fuel injectors.

It contains a diaphragm, calibrated springs and a

fuel return valve. The internal fuel filter (Fig. 2) is

also part of the assembly.

Fuel is supplied to the filter/regulator by the elec-

tric fuel pump through an opening tube at the bot-

tom of filter/regulator.

The fuel pump module contains a check valve to

maintain some fuel pressure when the engine is not

operating. This will help to start the engine.

If fuel pressure at the pressure regulator exceeds

approximately 49 psi, an internal diaphragm closes

and excess fuel pressure is routed back into the tank

through the pressure regulator. A separate fuel

return line is not used with any gas powered engine.

FUEL TANK

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.

All models are equipped with either one or two

rollover valves mounted into the top of the fuel tank

(or pump module).

An evaporation control system is connected to the

rollover valve(s) to reduce emissions of fuel vapors

into the atmosphere. When fuel evaporates from the

fuel tank, vapors pass through vent hoses or tubes to

a charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP). Refer to the Emission Control

System for additional information.

FUEL RAIL

DESCRIPTION

The fuel rail supplies the necessary fuel to each

individual fuel injector and is mounted to the intake

manifold (Fig. 3).

14 - 4 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 826 of 1285

OPERATION

The fuel pressure regulator is no longer mounted

to the fuel rail on any engine. It is now located on

the fuel tank mounted fuel pump module. Refer toFuel Filter/Fuel Pressure Regulator in the Fuel

Delivery System section of this group for information.

The fuel rail is not repairable.

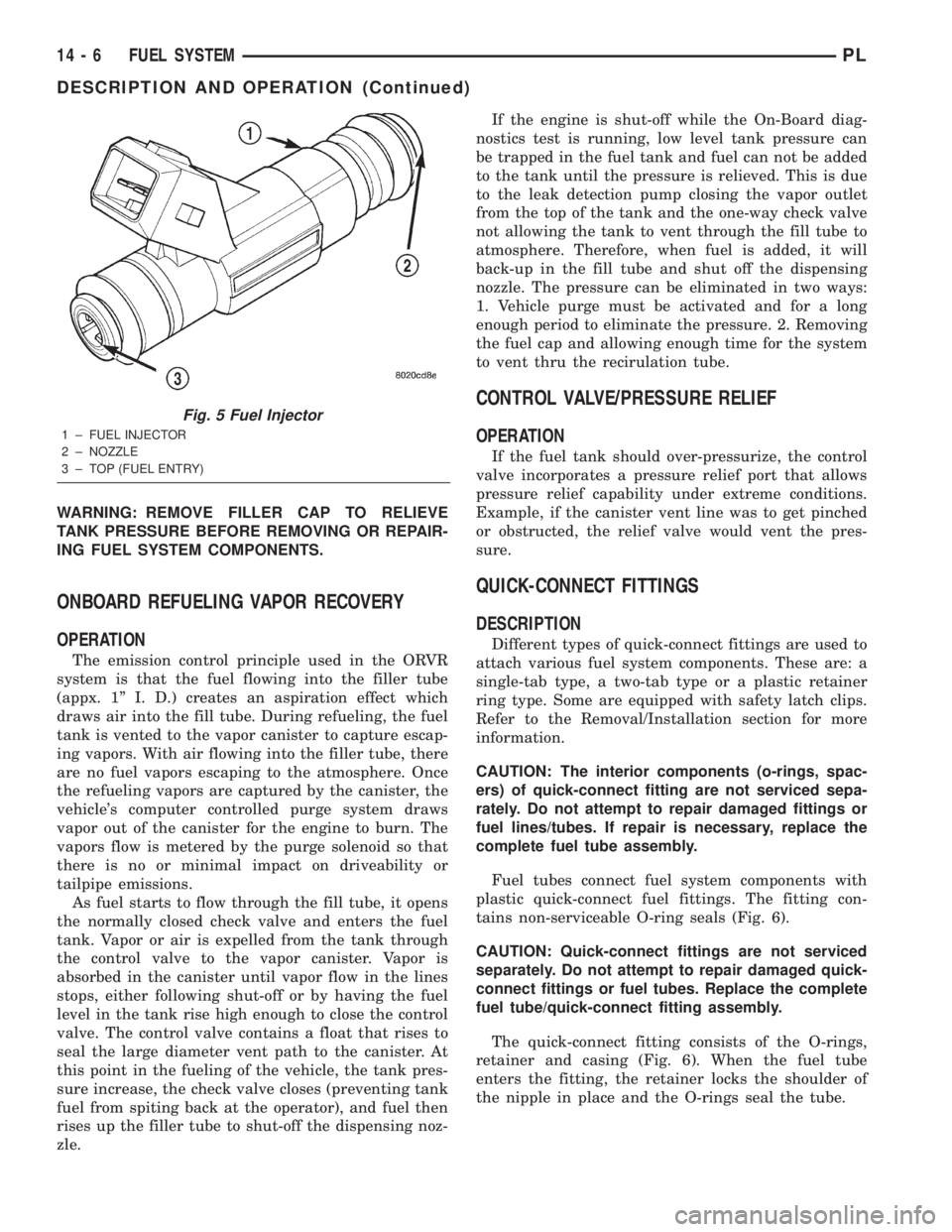

FUEL INJECTORS

DESCRIPTION

The injectors are positioned in the intake manifold

with the nozzle ends directly above the intake valve

port (Fig. 4).

OPERATION

The fuel injectors are 12 ohm electrical solenoids

(Fig. 5). The injector contains a pintle that closes off

an orifice at the nozzle end. When electric current is

supplied to the injector, the armature and needle

move a short distance against a spring, allowing fuel

to flow out the orifice. Because the fuel is under high

pressure, a fine spray is developed in the shape of a

hollow cone. The spraying action atomizes the fuel,

adding it to the air entering the combustion chamber.

Fuel injectors are not interchangeable between

engines.

PRESSURE-VACUUM FILLER CAP

OPERATION

The loss of any fuel or vapor out of the filler neck

is prevented by the use of a safety filler cap. The cap

will release pressure only under significant pressure

of 10.9 to 13.45 kPa (1.58 to 1.95 psi). The vacuum

release for all gas caps is between 1.94 and 2.94 kPa

(0.28 and 0.43 psi). The cap must be replaced by a

similar unit if replacement is necessary.

Fig. 2 Side ViewÐFilter/Regulator

1 ± INTERNAL FUEL FILTER

2 ± FUEL FLOW TO FUEL INJECTORS

3 ± FUEL FILTER/FUEL PRESSURE REGULATOR

4 ± O-RINGS

5 ± EXCESS FUEL BACK TO TANK

6 ± FUEL INLET

7 ± CALIBRATED SPRINGS

8 ± RUBBER GROMMET AT PUMP MODULE

9 ± LOCKING TAB

Fig. 3 Fuel Rail

Fig. 4 Fuel Injector LocationÐTypical

1 ± FUEL RAIL

2 ± INTAKE MANIFOLD

3 ± FUEL INJECTORS

PLFUEL SYSTEM 14 - 5

DESCRIPTION AND OPERATION (Continued)

Page 827 of 1285

WARNING: REMOVE FILLER CAP TO RELIEVE

TANK PRESSURE BEFORE REMOVING OR REPAIR-

ING FUEL SYSTEM COMPONENTS.

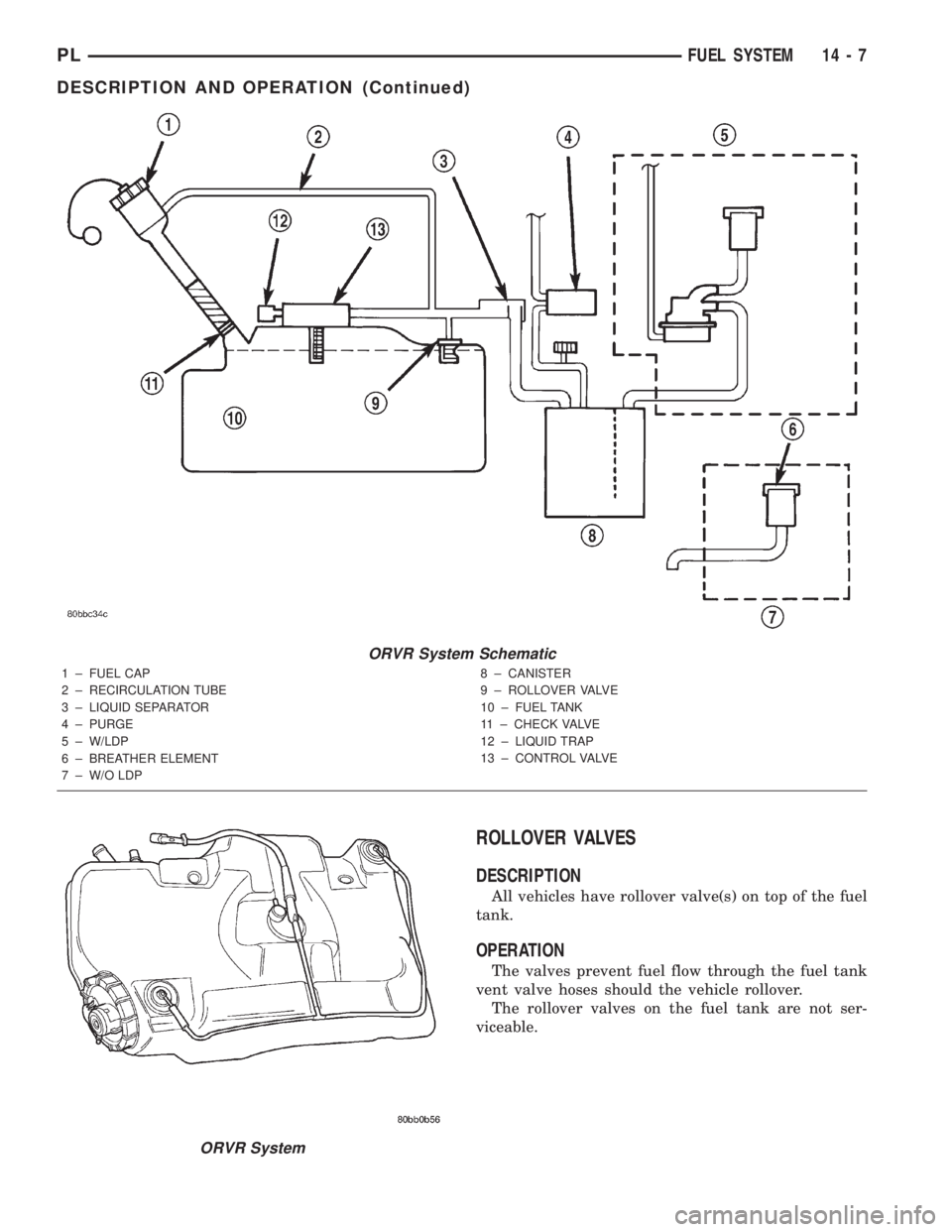

ONBOARD REFUELING VAPOR RECOVERY

OPERATION

The emission control principle used in the ORVR

system is that the fuel flowing into the filler tube

(appx. 1º I. D.) creates an aspiration effect which

draws air into the fill tube. During refueling, the fuel

tank is vented to the vapor canister to capture escap-

ing vapors. With air flowing into the filler tube, there

are no fuel vapors escaping to the atmosphere. Once

the refueling vapors are captured by the canister, the

vehicle's computer controlled purge system draws

vapor out of the canister for the engine to burn. The

vapors flow is metered by the purge solenoid so that

there is no or minimal impact on driveability or

tailpipe emissions.

As fuel starts to flow through the fill tube, it opens

the normally closed check valve and enters the fuel

tank. Vapor or air is expelled from the tank through

the control valve to the vapor canister. Vapor is

absorbed in the canister until vapor flow in the lines

stops, either following shut-off or by having the fuel

level in the tank rise high enough to close the control

valve. The control valve contains a float that rises to

seal the large diameter vent path to the canister. At

this point in the fueling of the vehicle, the tank pres-

sure increase, the check valve closes (preventing tank

fuel from spiting back at the operator), and fuel then

rises up the filler tube to shut-off the dispensing noz-

zle.If the engine is shut-off while the On-Board diag-

nostics test is running, low level tank pressure can

be trapped in the fuel tank and fuel can not be added

to the tank until the pressure is relieved. This is due

to the leak detection pump closing the vapor outlet

from the top of the tank and the one-way check valve

not allowing the tank to vent through the fill tube to

atmosphere. Therefore, when fuel is added, it will

back-up in the fill tube and shut off the dispensing

nozzle. The pressure can be eliminated in two ways:

1. Vehicle purge must be activated and for a long

enough period to eliminate the pressure. 2. Removing

the fuel cap and allowing enough time for the system

to vent thru the recirulation tube.

CONTROL VALVE/PRESSURE RELIEF

OPERATION

If the fuel tank should over-pressurize, the control

valve incorporates a pressure relief port that allows

pressure relief capability under extreme conditions.

Example, if the canister vent line was to get pinched

or obstructed, the relief valve would vent the pres-

sure.

QUICK-CONNECT FITTINGS

DESCRIPTION

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type. Some are equipped with safety latch clips.

Refer to the Removal/Installation section for more

information.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

Fuel tubes connect fuel system components with

plastic quick-connect fuel fittings. The fitting con-

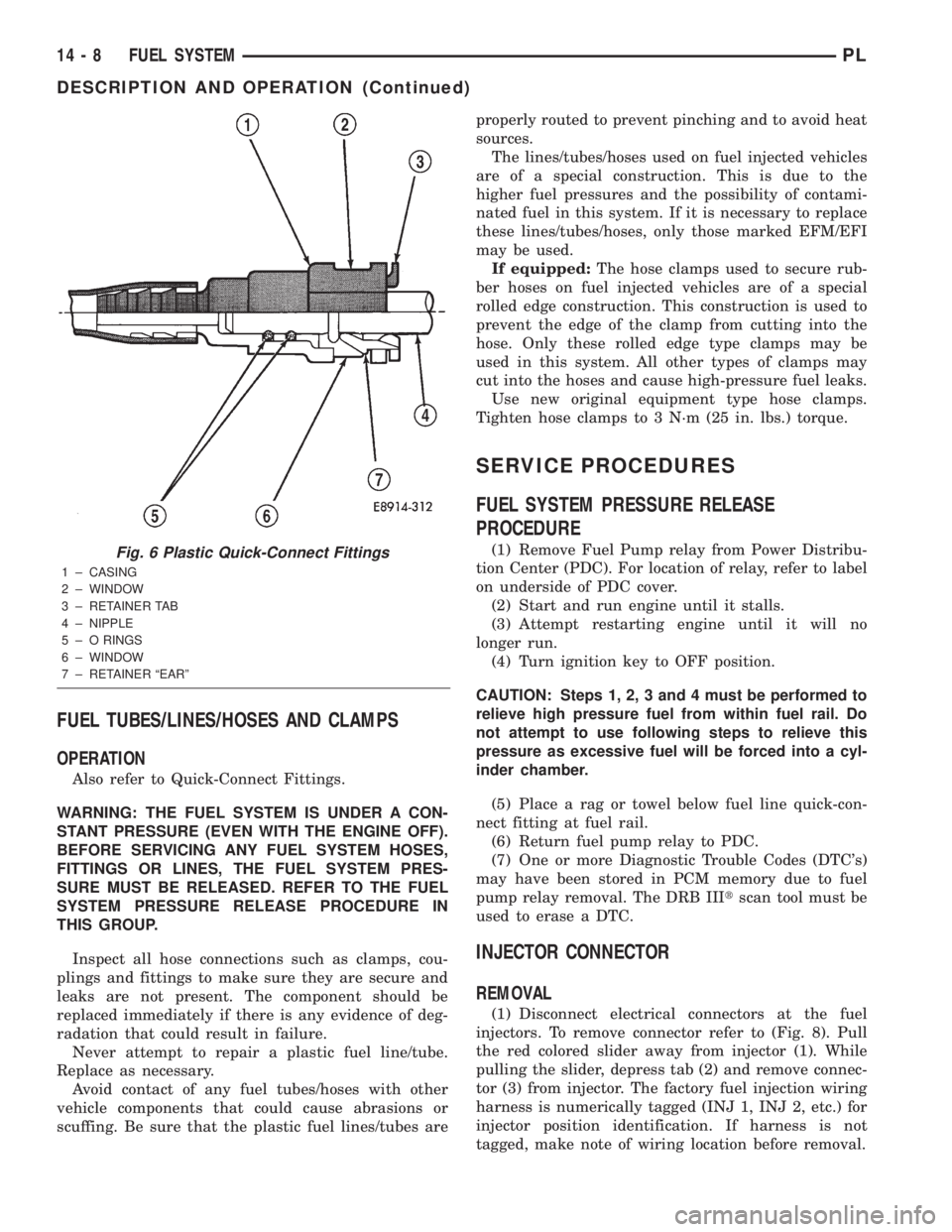

tains non-serviceable O-ring seals (Fig. 6).

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

The quick-connect fitting consists of the O-rings,

retainer and casing (Fig. 6). When the fuel tube

enters the fitting, the retainer locks the shoulder of

the nipple in place and the O-rings seal the tube.

Fig. 5 Fuel Injector

1 ± FUEL INJECTOR

2 ± NOZZLE

3 ± TOP (FUEL ENTRY)

14 - 6 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 828 of 1285

ROLLOVER VALVES

DESCRIPTION

All vehicles have rollover valve(s) on top of the fuel

tank.

OPERATION

The valves prevent fuel flow through the fuel tank

vent valve hoses should the vehicle rollover.

The rollover valves on the fuel tank are not ser-

viceable.

ORVR System Schematic

1 ± FUEL CAP

2 ± RECIRCULATION TUBE

3 ± LIQUID SEPARATOR

4 ± PURGE

5 ± W/LDP

6 ± BREATHER ELEMENT

7 ± W/O LDP8 ± CANISTER

9 ± ROLLOVER VALVE

10 ± FUEL TANK

11 ± CHECK VALVE

12 ± LIQUID TRAP

13 ± CONTROL VALVE

ORVR System

PLFUEL SYSTEM 14 - 7

DESCRIPTION AND OPERATION (Continued)

Page 829 of 1285

FUEL TUBES/LINES/HOSES AND CLAMPS

OPERATION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube.

Replace as necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the plastic fuel lines/tubes areproperly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

Tighten hose clamps to 3 N´m (25 in. lbs.) torque.

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE

(1) Remove Fuel Pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(2) Start and run engine until it stalls.

(3) Attempt restarting engine until it will no

longer run.

(4) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(5) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(6) Return fuel pump relay to PDC.

(7) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRB IIItscan tool must be

used to erase a DTC.

INJECTOR CONNECTOR

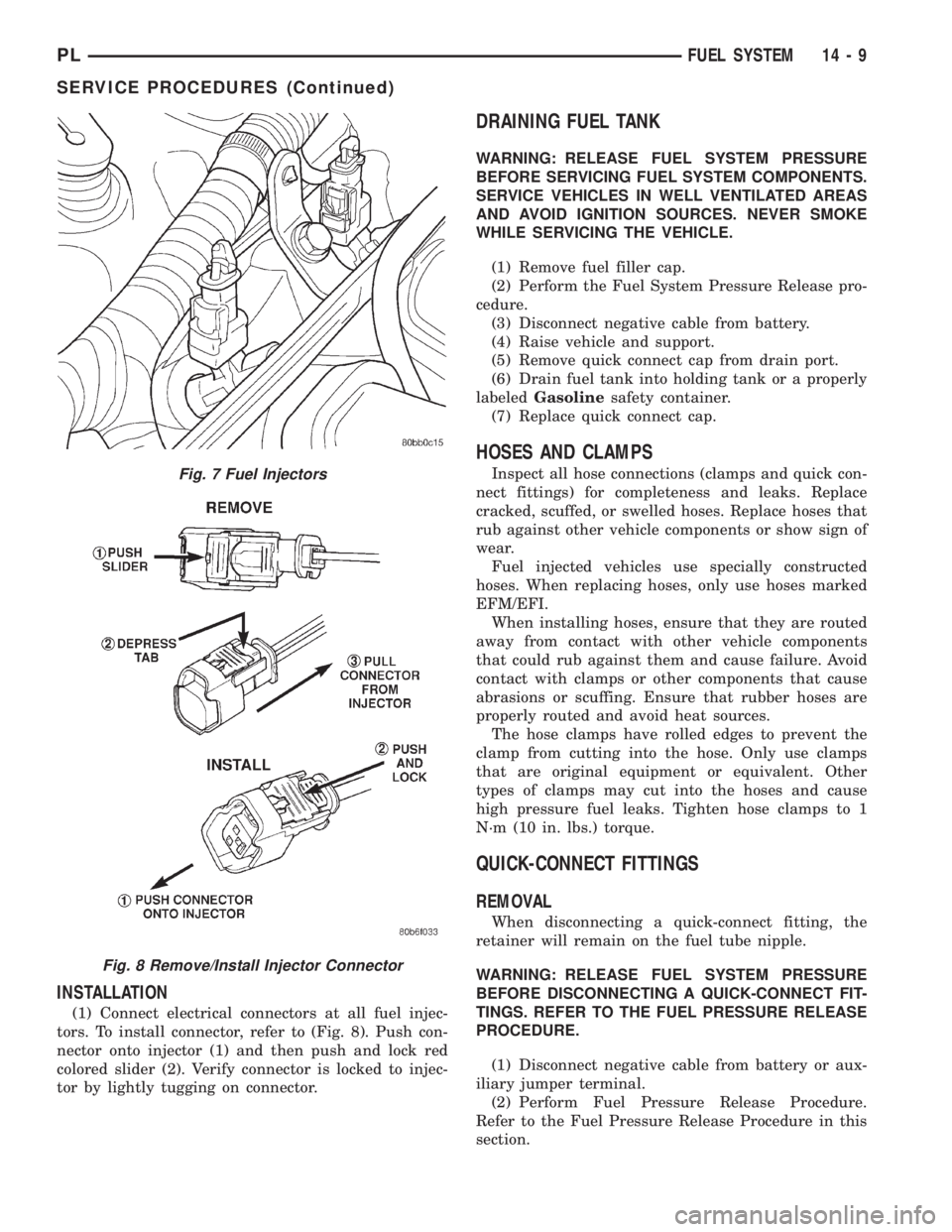

REMOVAL

(1) Disconnect electrical connectors at the fuel

injectors. To remove connector refer to (Fig. 8). Pull

the red colored slider away from injector (1). While

pulling the slider, depress tab (2) and remove connec-

tor (3) from injector. The factory fuel injection wiring

harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, make note of wiring location before removal.

Fig. 6 Plastic Quick-Connect Fittings

1 ± CASING

2 ± WINDOW

3 ± RETAINER TAB

4 ± NIPPLE

5 ± O RINGS

6 ± WINDOW

7 ± RETAINER ªEARº

14 - 8 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 830 of 1285

INSTALLATION

(1) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 8). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

DRAINING FUEL TANK

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap.

(2) Perform the Fuel System Pressure Release pro-

cedure.

(3) Disconnect negative cable from battery.

(4) Raise vehicle and support.

(5) Remove quick connect cap from drain port.

(6) Drain fuel tank into holding tank or a properly

labeledGasolinesafety container.

(7) Replace quick connect cap.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

Fig. 7 Fuel Injectors

Fig. 8 Remove/Install Injector Connector

PLFUEL SYSTEM 14 - 9

SERVICE PROCEDURES (Continued)