DODGE NEON 2000 Service Repair Manual

Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 781 of 1285

(4) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 108). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(5) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(6) Remove connecting rod cap bolts.Do not use

old bolts if reinstalling connecting rod.

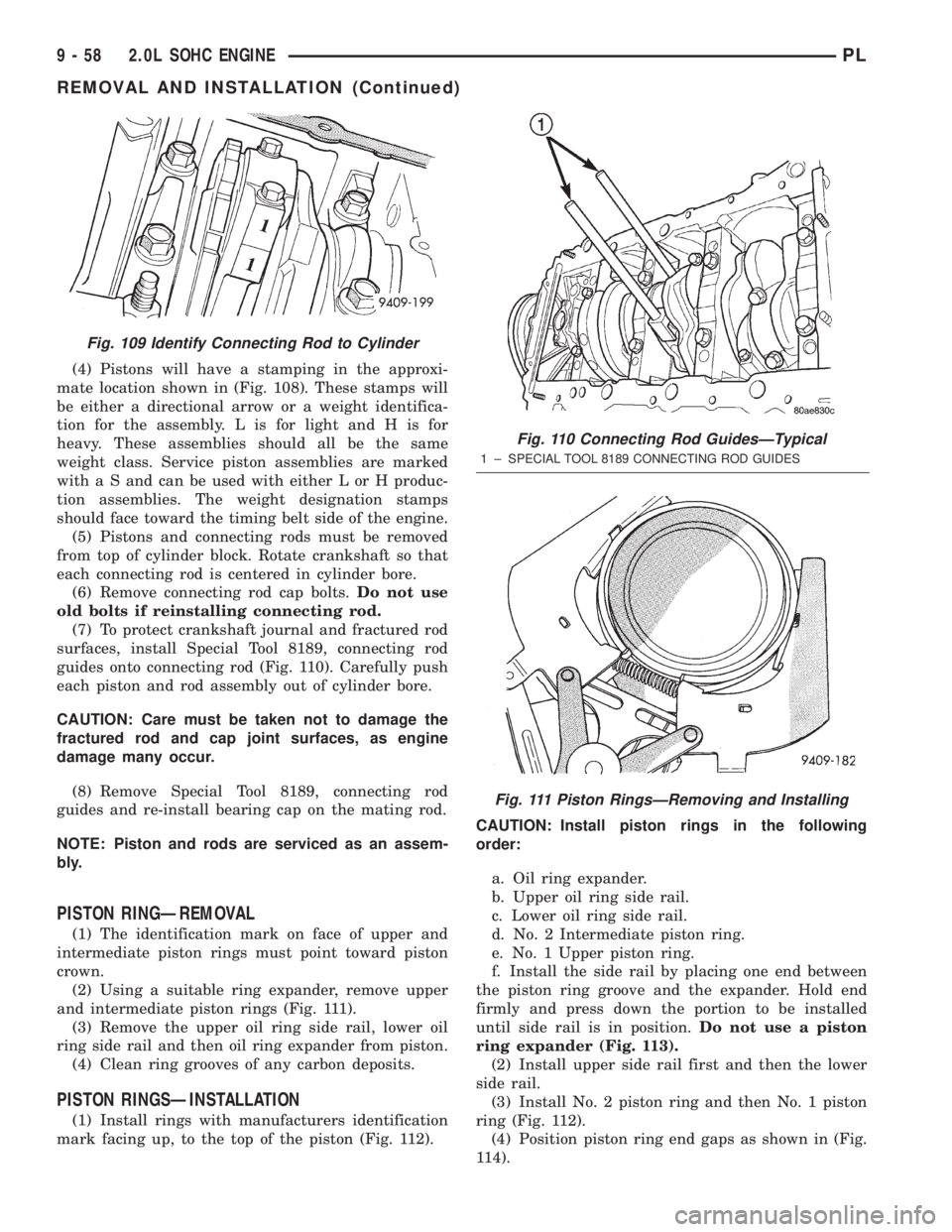

(7) To protect crankshaft journal and fractured rod

surfaces, install Special Tool 8189, connecting rod

guides onto connecting rod (Fig. 110). Carefully push

each piston and rod assembly out of cylinder bore.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint surfaces, as engine

damage many occur.

(8) Remove Special Tool 8189, connecting rod

guides and re-install bearing cap on the mating rod.

NOTE: Piston and rods are serviced as an assem-

bly.

PISTON RINGÐREMOVAL

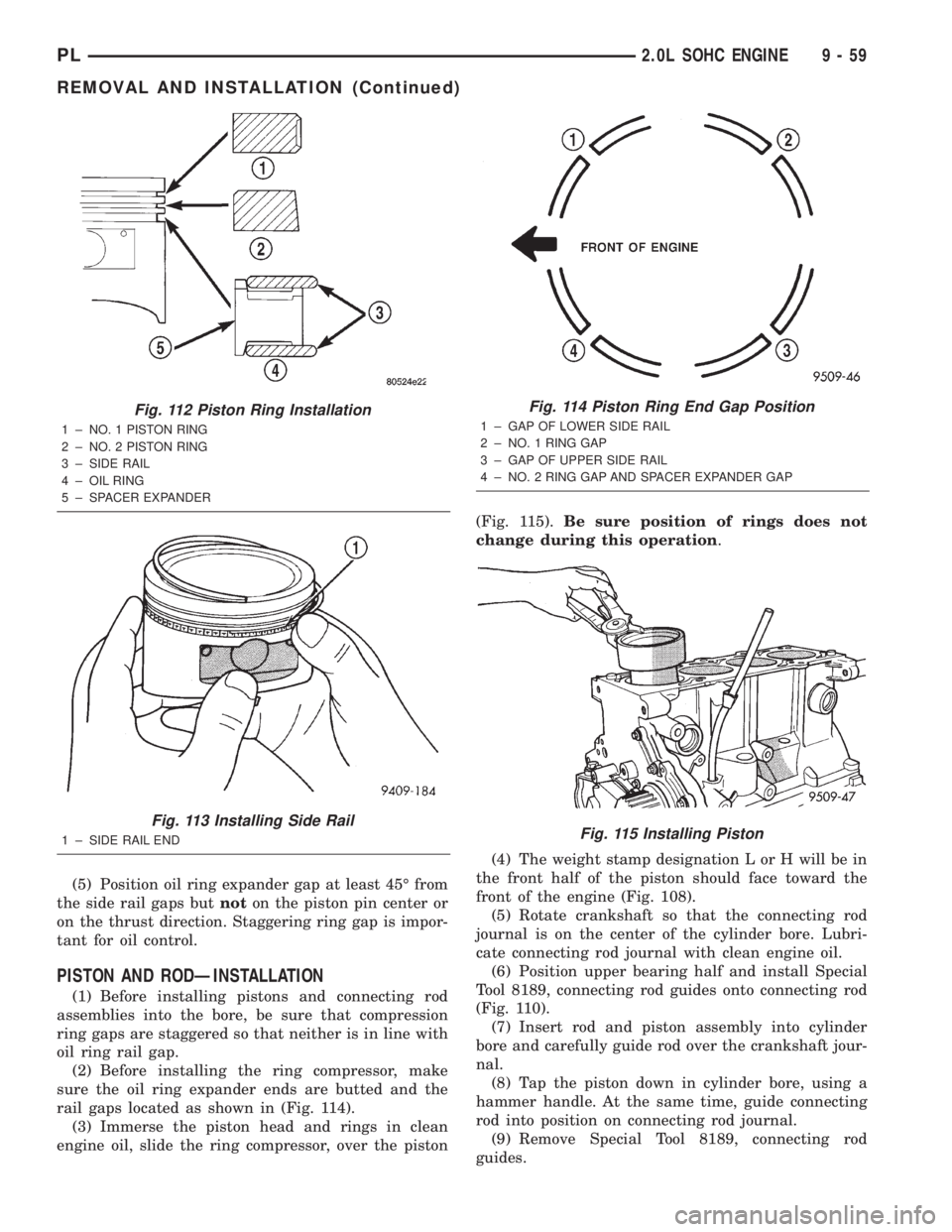

(1) The identification mark on face of upper and

intermediate piston rings must point toward piston

crown.

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 111).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Clean ring grooves of any carbon deposits.

PISTON RINGSÐINSTALLATION

(1) Install rings with manufacturers identification

mark facing up, to the top of the piston (Fig. 112).CAUTION: Install piston rings in the following

order:

a. Oil ring expander.

b. Upper oil ring side rail.

c. Lower oil ring side rail.

d. No. 2 Intermediate piston ring.

e. No. 1 Upper piston ring.

f. Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

firmly and press down the portion to be installed

until side rail is in position.Do not use a piston

ring expander (Fig. 113).

(2) Install upper side rail first and then the lower

side rail.

(3) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 112).

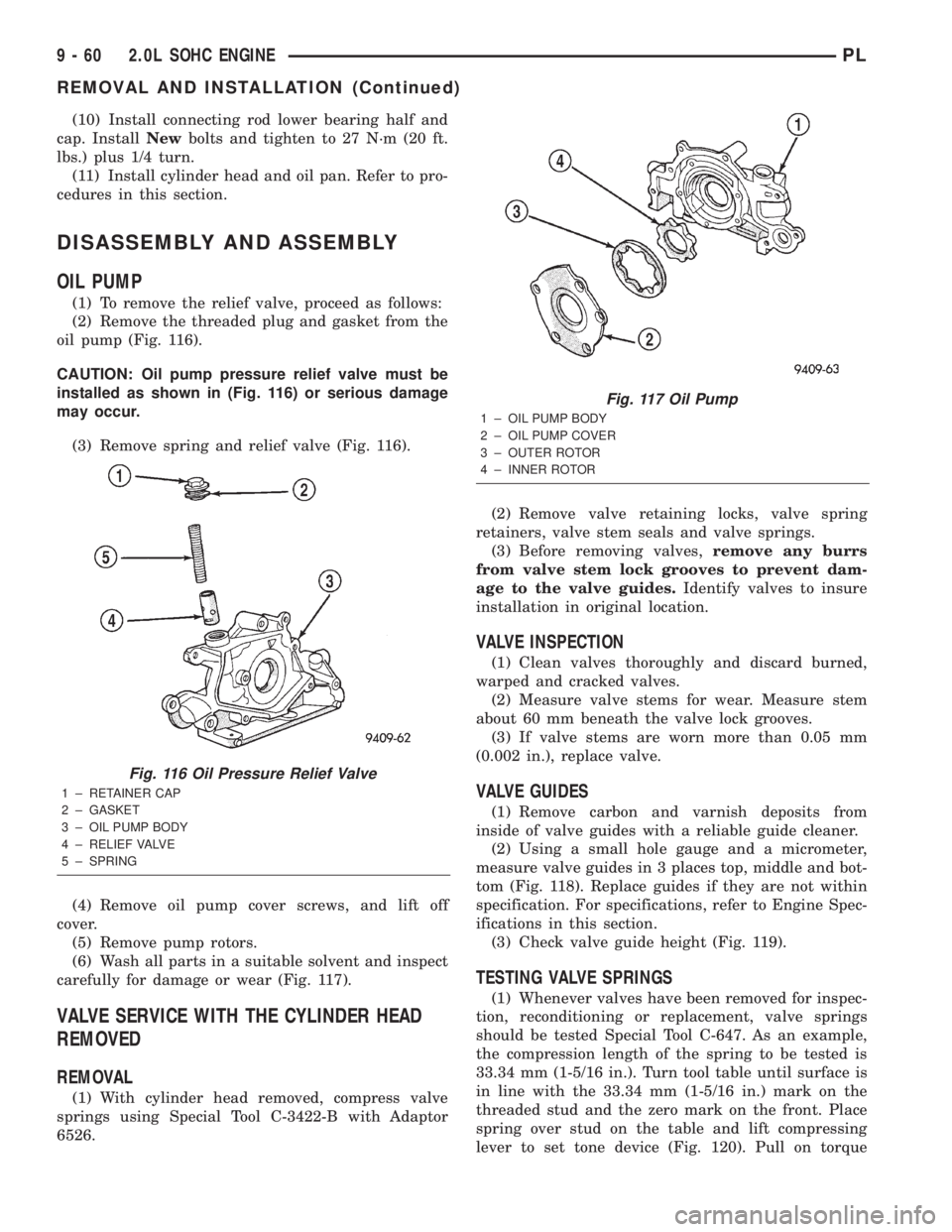

(4) Position piston ring end gaps as shown in (Fig.

114).

Fig. 109 Identify Connecting Rod to Cylinder

Fig. 110 Connecting Rod GuidesÐTypical

1 ± SPECIAL TOOL 8189 CONNECTING ROD GUIDES

Fig. 111 Piston RingsÐRemoving and Installing

9 - 58 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 782 of 1285

(5) Position oil ring expander gap at least 45É from

the side rail gaps butnoton the piston pin center or

on the thrust direction. Staggering ring gap is impor-

tant for oil control.

PISTON AND RODÐINSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 114).

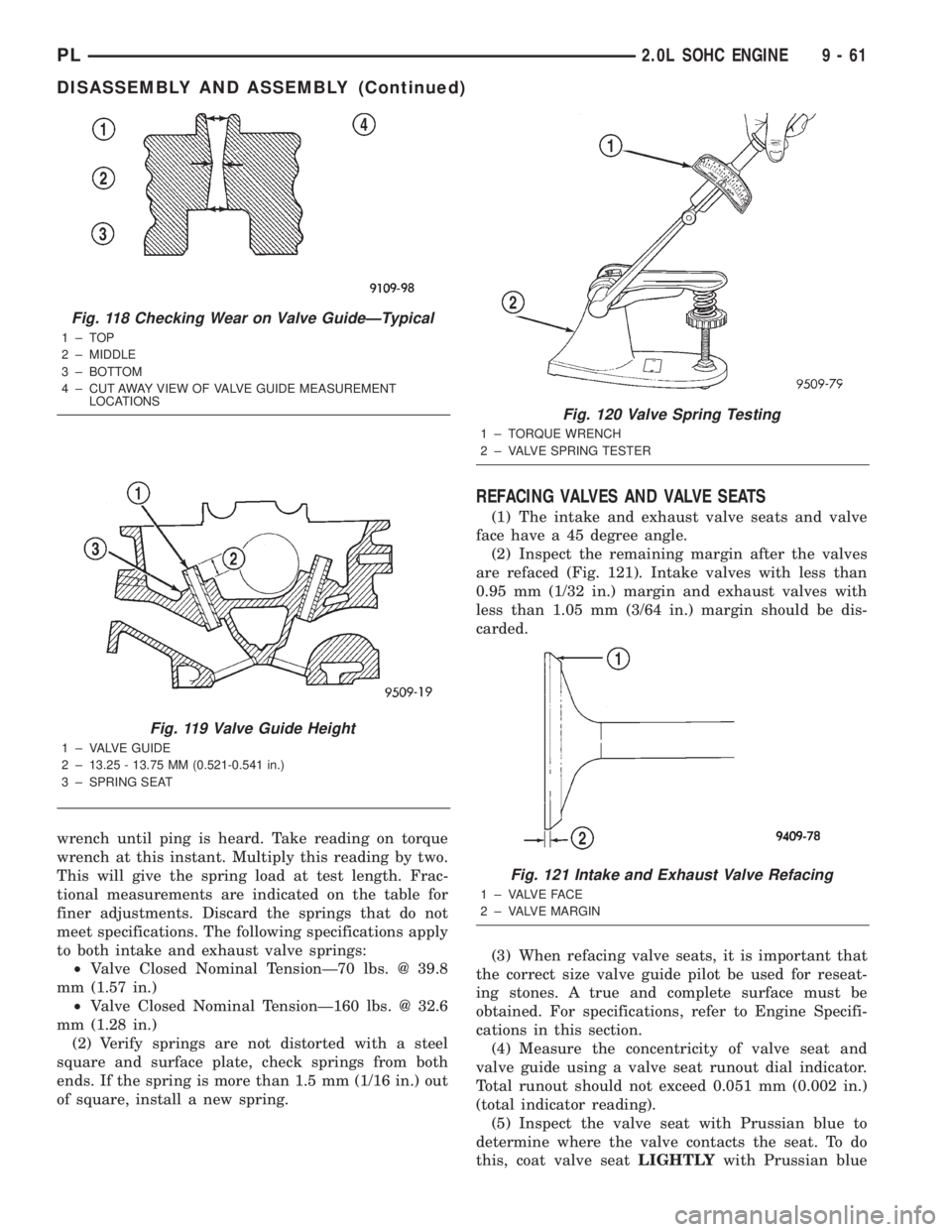

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston(Fig. 115).Be sure position of rings does not

change during this operation.

(4) The weight stamp designation L or H will be in

the front half of the piston should face toward the

front of the engine (Fig. 108).

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Lubri-

cate connecting rod journal with clean engine oil.

(6) Position upper bearing half and install Special

Tool 8189, connecting rod guides onto connecting rod

(Fig. 110).

(7) Insert rod and piston assembly into cylinder

bore and carefully guide rod over the crankshaft jour-

nal.

(8) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(9) Remove Special Tool 8189, connecting rod

guides.

Fig. 112 Piston Ring Installation

1 ± NO. 1 PISTON RING

2 ± NO. 2 PISTON RING

3 ± SIDE RAIL

4 ± OIL RING

5 ± SPACER EXPANDER

Fig. 113 Installing Side Rail

1 ± SIDE RAIL END

Fig. 114 Piston Ring End Gap Position

1 ± GAP OF LOWER SIDE RAIL

2 ± NO. 1 RING GAP

3 ± GAP OF UPPER SIDE RAIL

4 ± NO. 2 RING GAP AND SPACER EXPANDER GAP

Fig. 115 Installing Piston

PL2.0L SOHC ENGINE 9 - 59

REMOVAL AND INSTALLATION (Continued)

Page 783 of 1285

(10) Install connecting rod lower bearing half and

cap. InstallNewbolts and tighten to 27 N´m (20 ft.

lbs.) plus 1/4 turn.

(11) Install cylinder head and oil pan. Refer to pro-

cedures in this section.

DISASSEMBLY AND ASSEMBLY

OIL PUMP

(1) To remove the relief valve, proceed as follows:

(2) Remove the threaded plug and gasket from the

oil pump (Fig. 116).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 116) or serious damage

may occur.

(3) Remove spring and relief valve (Fig. 116).

(4) Remove oil pump cover screws, and lift off

cover.

(5) Remove pump rotors.

(6) Wash all parts in a suitable solvent and inspect

carefully for damage or wear (Fig. 117).

VALVE SERVICE WITH THE CYLINDER HEAD

REMOVED

REMOVAL

(1) With cylinder head removed, compress valve

springs using Special Tool C-3422-B with Adaptor

6526.(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE INSPECTION

(1) Clean valves thoroughly and discard burned,

warped and cracked valves.

(2) Measure valve stems for wear. Measure stem

about 60 mm beneath the valve lock grooves.

(3) If valve stems are worn more than 0.05 mm

(0.002 in.), replace valve.

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 118). Replace guides if they are not within

specification. For specifications, refer to Engine Spec-

ifications in this section.

(3) Check valve guide height (Fig. 119).

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested Special Tool C-647. As an example,

the compression length of the spring to be tested is

33.34 mm (1-5/16 in.). Turn tool table until surface is

in line with the 33.34 mm (1-5/16 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over stud on the table and lift compressing

lever to set tone device (Fig. 120). Pull on torque

Fig. 116 Oil Pressure Relief Valve

1 ± RETAINER CAP

2 ± GASKET

3 ± OIL PUMP BODY

4 ± RELIEF VALVE

5 ± SPRING

Fig. 117 Oil Pump

1 ± OIL PUMP BODY

2 ± OIL PUMP COVER

3 ± OUTER ROTOR

4 ± INNER ROTOR

9 - 60 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 784 of 1285

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.

This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The following specifications apply

to both intake and exhaust valve springs:

²Valve Closed Nominal TensionÐ70 lbs. @ 39.8

mm (1.57 in.)

²Valve Closed Nominal TensionÐ160 lbs. @ 32.6

mm (1.28 in.)

(2) Verify springs are not distorted with a steel

square and surface plate, check springs from both

ends. If the spring is more than 1.5 mm (1/16 in.) out

of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle.

(2) Inspect the remaining margin after the valves

are refaced (Fig. 121). Intake valves with less than

0.95 mm (1/32 in.) margin and exhaust valves with

less than 1.05 mm (3/64 in.) margin should be dis-

carded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained. For specifications, refer to Engine Specifi-

cations in this section.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed 0.051 mm (0.002 in.)

(total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

Fig. 118 Checking Wear on Valve GuideÐTypical

1±TOP

2 ± MIDDLE

3 ± BOTTOM

4 ± CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

Fig. 119 Valve Guide Height

1 ± VALVE GUIDE

2 ± 13.25 - 13.75 MM (0.521-0.541 in.)

3 ± SPRING SEAT

Fig. 120 Valve Spring Testing

1 ± TORQUE WRENCH

2 ± VALVE SPRING TESTER

Fig. 121 Intake and Exhaust Valve Refacing

1 ± VALVE FACE

2 ± VALVE MARGIN

PL2.0L SOHC ENGINE 9 - 61

DISASSEMBLY AND ASSEMBLY (Continued)

Page 785 of 1285

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. The intake valve seat must be ser-

viced when the valve seat width is 2.0 mm (0.079 in.)

or greater. The exhaust valve seat must be serviced

when the valve seat width is 2.5 mm (0.098 in.) or

greater. Otherwise the cylinder head must be

replaced.

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.75±1.25 mm

(0.030±0.049 in.) (Fig. 122).

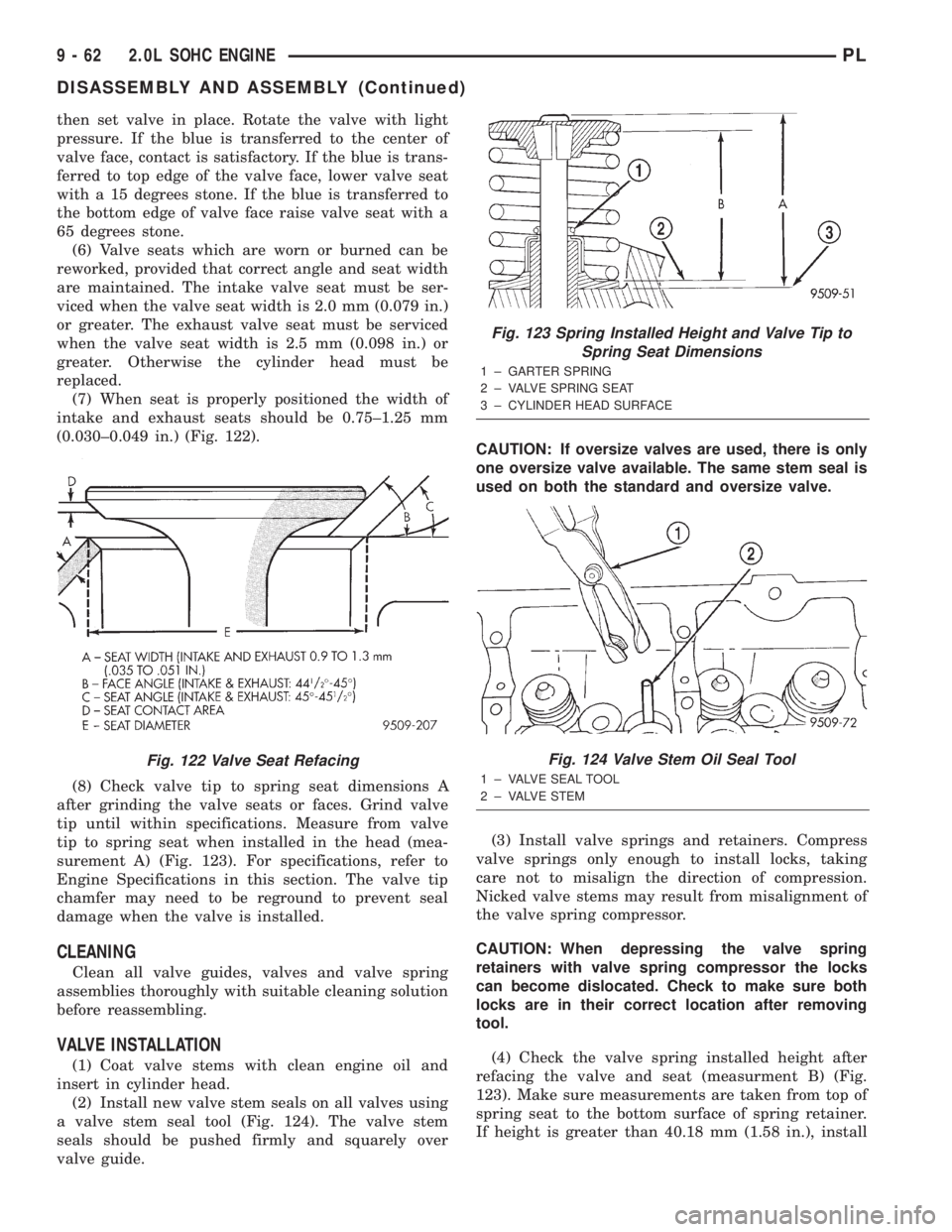

(8) Check valve tip to spring seat dimensions A

after grinding the valve seats or faces. Grind valve

tip until within specifications. Measure from valve

tip to spring seat when installed in the head (mea-

surement A) (Fig. 123). For specifications, refer to

Engine Specifications in this section. The valve tip

chamfer may need to be reground to prevent seal

damage when the valve is installed.

CLEANING

Clean all valve guides, valves and valve spring

assemblies thoroughly with suitable cleaning solution

before reassembling.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

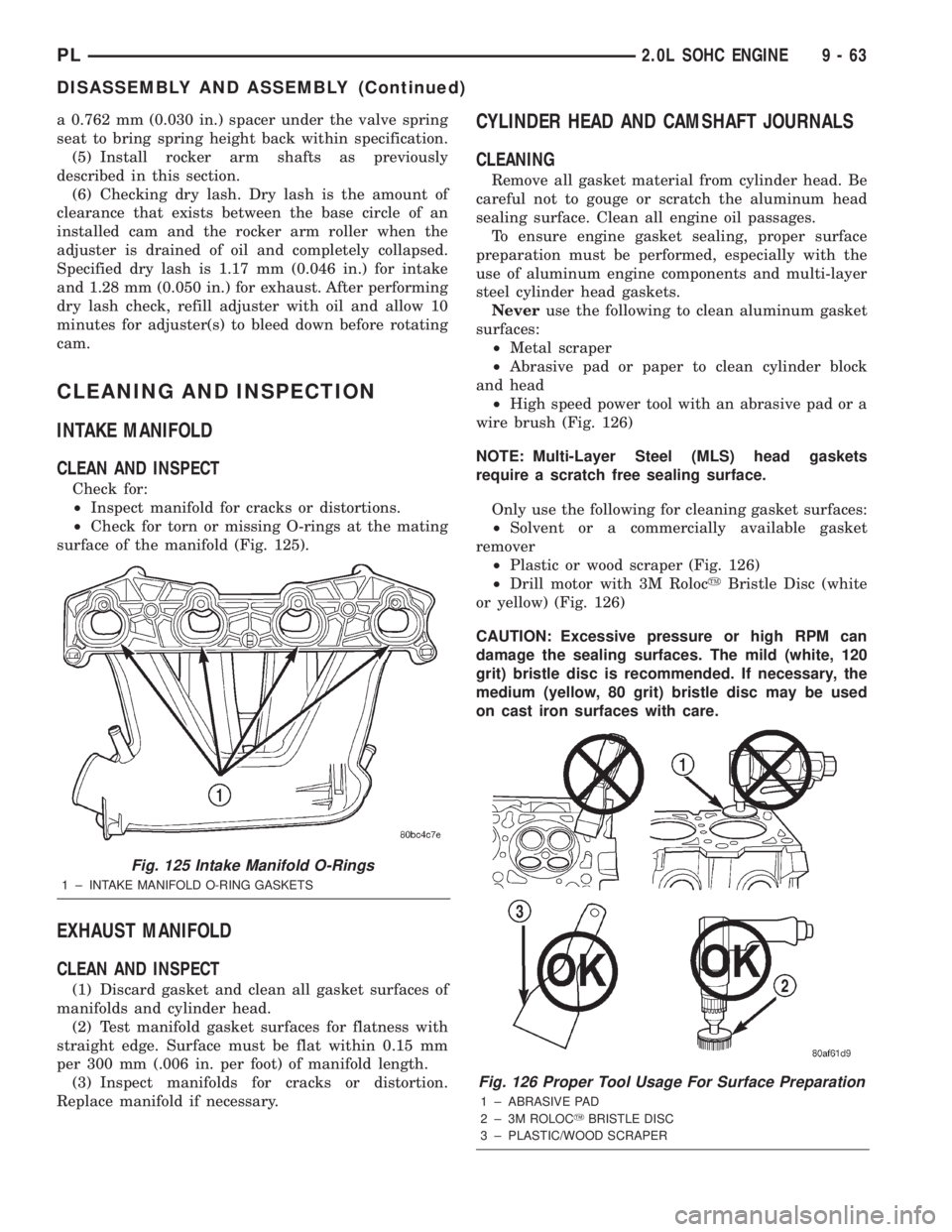

(2) Install new valve stem seals on all valves using

a valve stem seal tool (Fig. 124). The valve stem

seals should be pushed firmly and squarely over

valve guide.CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height after

refacing the valve and seat (measurment B) (Fig.

123). Make sure measurements are taken from top of

spring seat to the bottom surface of spring retainer.

If height is greater than 40.18 mm (1.58 in.), install

Fig. 122 Valve Seat Refacing

Fig. 123 Spring Installed Height and Valve Tip to

Spring Seat Dimensions

1 ± GARTER SPRING

2 ± VALVE SPRING SEAT

3 ± CYLINDER HEAD SURFACE

Fig. 124 Valve Stem Oil Seal Tool

1 ± VALVE SEAL TOOL

2 ± VALVE STEM

9 - 62 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 786 of 1285

a 0.762 mm (0.030 in.) spacer under the valve spring

seat to bring spring height back within specification.

(5) Install rocker arm shafts as previously

described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster(s) to bleed down before rotating

cam.

CLEANING AND INSPECTION

INTAKE MANIFOLD

CLEAN AND INSPECT

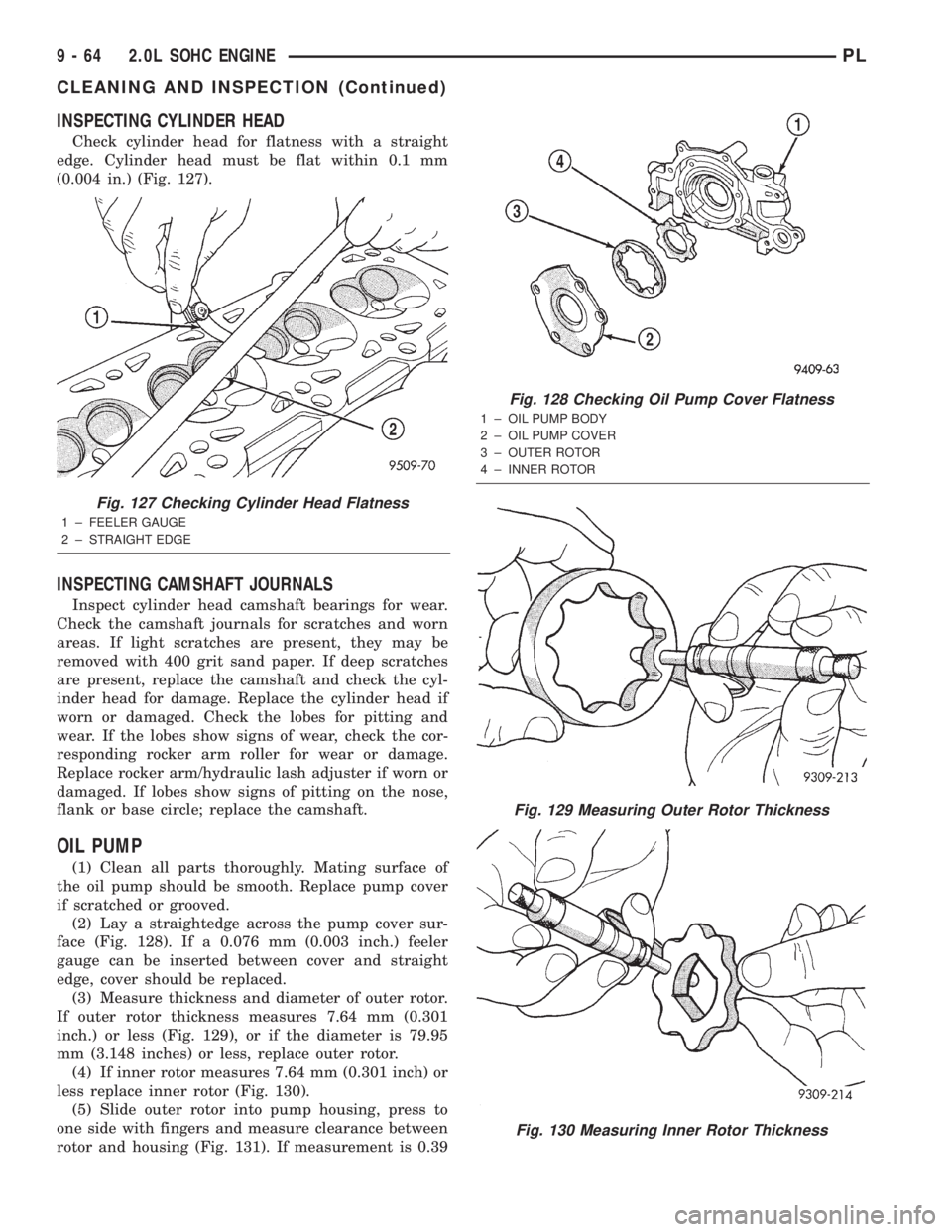

Check for:

²Inspect manifold for cracks or distortions.

²Check for torn or missing O-rings at the mating

surface of the manifold (Fig. 125).

EXHAUST MANIFOLD

CLEAN AND INSPECT

(1) Discard gasket and clean all gasket surfaces of

manifolds and cylinder head.

(2) Test manifold gasket surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (.006 in. per foot) of manifold length.

(3) Inspect manifolds for cracks or distortion.

Replace manifold if necessary.

CYLINDER HEAD AND CAMSHAFT JOURNALS

CLEANING

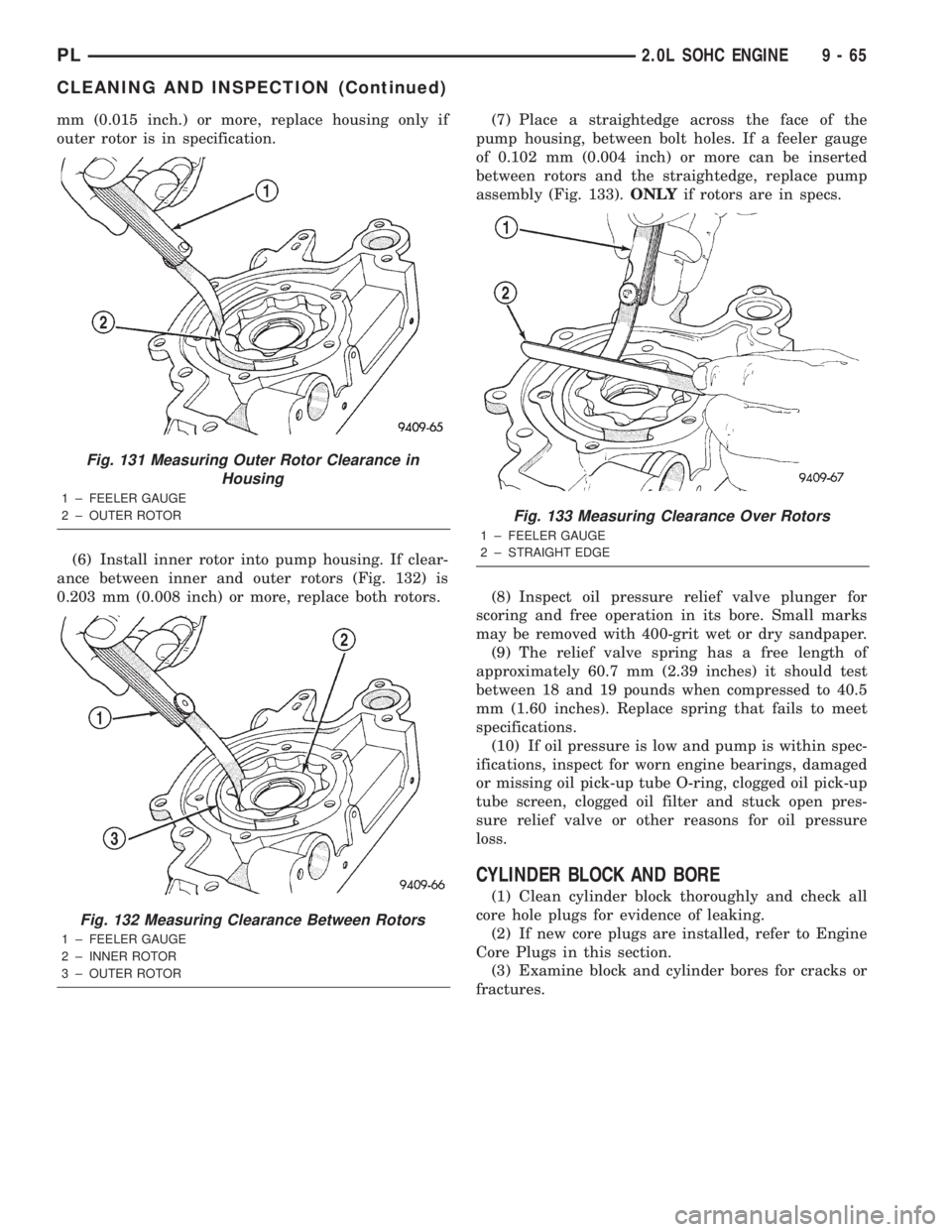

Remove all gasket material from cylinder head. Be

careful not to gouge or scratch the aluminum head

sealing surface. Clean all engine oil passages.

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean aluminum gasket

surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 126)

NOTE: Multi-Layer Steel (MLS) head gaskets

require a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 126)

²Drill motor with 3M RolocyBristle Disc (white

or yellow) (Fig. 126)

CAUTION: Excessive pressure or high RPM can

damage the sealing surfaces. The mild (white, 120

grit) bristle disc is recommended. If necessary, the

medium (yellow, 80 grit) bristle disc may be used

on cast iron surfaces with care.

Fig. 125 Intake Manifold O-Rings

1 ± INTAKE MANIFOLD O-RING GASKETS

Fig. 126 Proper Tool Usage For Surface Preparation

1 ± ABRASIVE PAD

2 ± 3M ROLOCYBRISTLE DISC

3 ± PLASTIC/WOOD SCRAPER

PL2.0L SOHC ENGINE 9 - 63

DISASSEMBLY AND ASSEMBLY (Continued)

Page 787 of 1285

INSPECTING CYLINDER HEAD

Check cylinder head for flatness with a straight

edge. Cylinder head must be flat within 0.1 mm

(0.004 in.) (Fig. 127).

INSPECTING CAMSHAFT JOURNALS

Inspect cylinder head camshaft bearings for wear.

Check the camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head if

worn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.

Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 128). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 129), or if the diameter is 79.95

mm (3.148 inches) or less, replace outer rotor.

(4) If inner rotor measures 7.64 mm (0.301 inch) or

less replace inner rotor (Fig. 130).

(5) Slide outer rotor into pump housing, press to

one side with fingers and measure clearance between

rotor and housing (Fig. 131). If measurement is 0.39

Fig. 127 Checking Cylinder Head Flatness

1 ± FEELER GAUGE

2 ± STRAIGHT EDGE

Fig. 128 Checking Oil Pump Cover Flatness

1 ± OIL PUMP BODY

2 ± OIL PUMP COVER

3 ± OUTER ROTOR

4 ± INNER ROTOR

Fig. 129 Measuring Outer Rotor Thickness

Fig. 130 Measuring Inner Rotor Thickness

9 - 64 2.0L SOHC ENGINEPL

CLEANING AND INSPECTION (Continued)

Page 788 of 1285

mm (0.015 inch.) or more, replace housing only if

outer rotor is in specification.

(6) Install inner rotor into pump housing. If clear-

ance between inner and outer rotors (Fig. 132) is

0.203 mm (0.008 inch) or more, replace both rotors.(7) Place a straightedge across the face of the

pump housing, between bolt holes. If a feeler gauge

of 0.102 mm (0.004 inch) or more can be inserted

between rotors and the straightedge, replace pump

assembly (Fig. 133).ONLYif rotors are in specs.

(8) Inspect oil pressure relief valve plunger for

scoring and free operation in its bore. Small marks

may be removed with 400-grit wet or dry sandpaper.

(9) The relief valve spring has a free length of

approximately 60.7 mm (2.39 inches) it should test

between 18 and 19 pounds when compressed to 40.5

mm (1.60 inches). Replace spring that fails to meet

specifications.

(10) If oil pressure is low and pump is within spec-

ifications, inspect for worn engine bearings, damaged

or missing oil pick-up tube O-ring, clogged oil pick-up

tube screen, clogged oil filter and stuck open pres-

sure relief valve or other reasons for oil pressure

loss.

CYLINDER BLOCK AND BORE

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are installed, refer to Engine

Core Plugs in this section.

(3) Examine block and cylinder bores for cracks or

fractures.

Fig. 131 Measuring Outer Rotor Clearance in

Housing

1 ± FEELER GAUGE

2 ± OUTER ROTOR

Fig. 132 Measuring Clearance Between Rotors

1 ± FEELER GAUGE

2 ± INNER ROTOR

3 ± OUTER ROTOR

Fig. 133 Measuring Clearance Over Rotors

1 ± FEELER GAUGE

2 ± STRAIGHT EDGE

PL2.0L SOHC ENGINE 9 - 65

CLEANING AND INSPECTION (Continued)

Page 789 of 1285

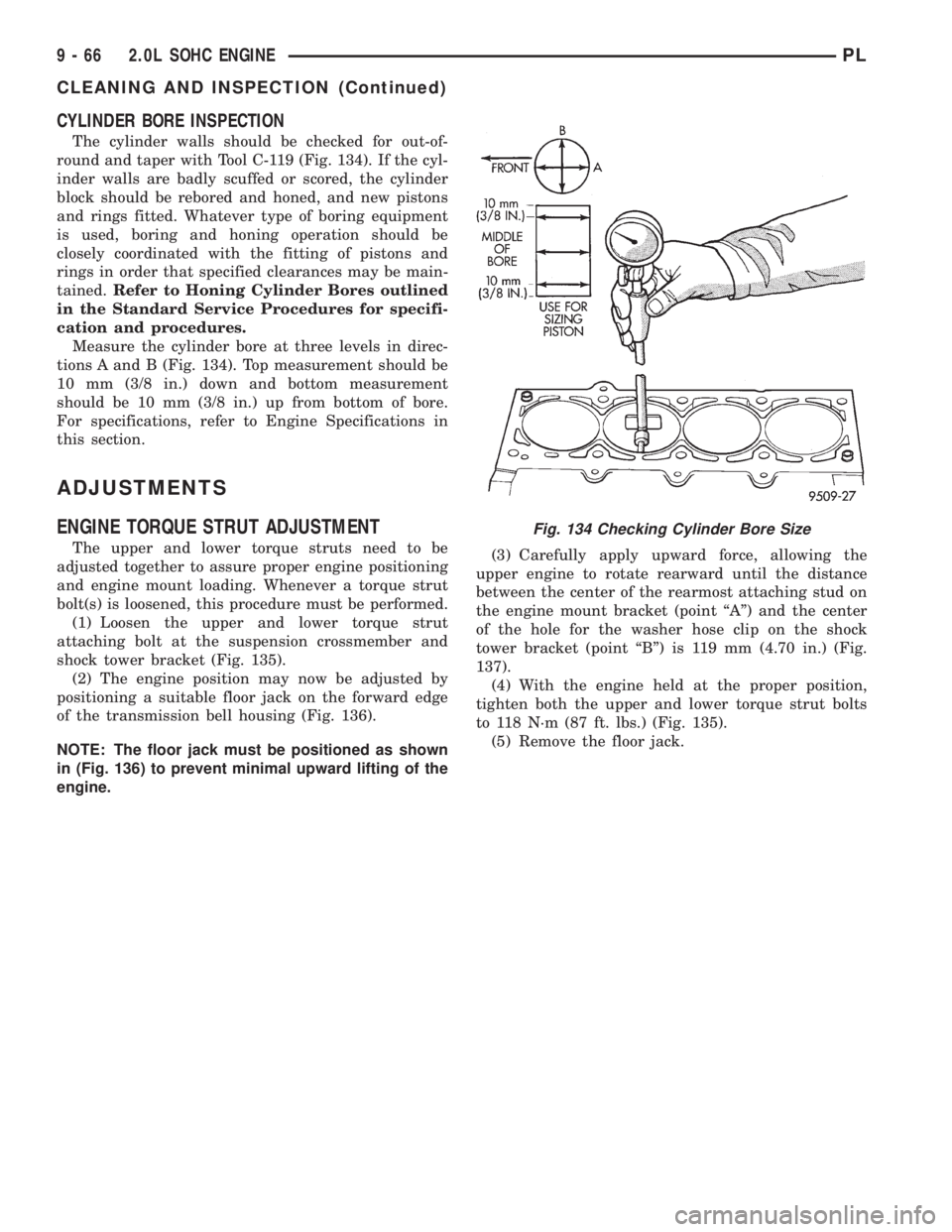

CYLINDER BORE INSPECTION

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 134). If the cyl-

inder walls are badly scuffed or scored, the cylinder

block should be rebored and honed, and new pistons

and rings fitted. Whatever type of boring equipment

is used, boring and honing operation should be

closely coordinated with the fitting of pistons and

rings in order that specified clearances may be main-

tained.Refer to Honing Cylinder Bores outlined

in the Standard Service Procedures for specifi-

cation and procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 134). Top measurement should be

10 mm (3/8 in.) down and bottom measurement

should be 10 mm (3/8 in.) up from bottom of bore.

For specifications, refer to Engine Specifications in

this section.

ADJUSTMENTS

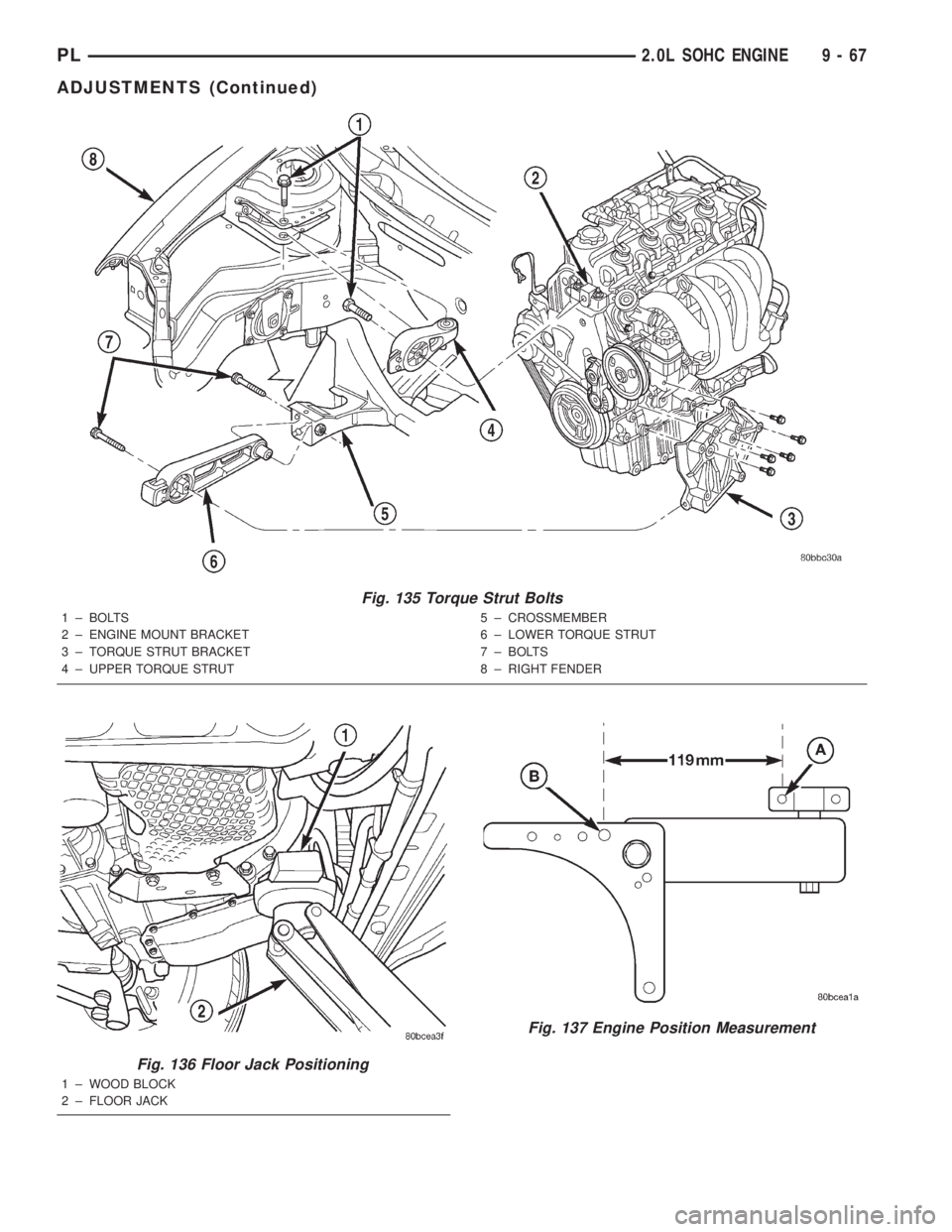

ENGINE TORQUE STRUT ADJUSTMENT

The upper and lower torque struts need to be

adjusted together to assure proper engine positioning

and engine mount loading. Whenever a torque strut

bolt(s) is loosened, this procedure must be performed.

(1) Loosen the upper and lower torque strut

attaching bolt at the suspension crossmember and

shock tower bracket (Fig. 135).

(2) The engine position may now be adjusted by

positioning a suitable floor jack on the forward edge

of the transmission bell housing (Fig. 136).

NOTE: The floor jack must be positioned as shown

in (Fig. 136) to prevent minimal upward lifting of the

engine.(3) Carefully apply upward force, allowing the

upper engine to rotate rearward until the distance

between the center of the rearmost attaching stud on

the engine mount bracket (point ªAº) and the center

of the hole for the washer hose clip on the shock

tower bracket (point ªBº) is 119 mm (4.70 in.) (Fig.

137).

(4) With the engine held at the proper position,

tighten both the upper and lower torque strut bolts

to 118 N´m (87 ft. lbs.) (Fig. 135).

(5) Remove the floor jack.

Fig. 134 Checking Cylinder Bore Size

9 - 66 2.0L SOHC ENGINEPL

CLEANING AND INSPECTION (Continued)

Page 790 of 1285

Fig. 135 Torque Strut Bolts

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET

3 ± TORQUE STRUT BRACKET

4 ± UPPER TORQUE STRUT5 ± CROSSMEMBER

6 ± LOWER TORQUE STRUT

7 ± BOLTS

8 ± RIGHT FENDER

Fig. 136 Floor Jack Positioning

1 ± WOOD BLOCK

2 ± FLOOR JACK

Fig. 137 Engine Position Measurement

PL2.0L SOHC ENGINE 9 - 67

ADJUSTMENTS (Continued)