tow DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1296 of 2889

REMOVAL

The service seal is a two piece, Viton seal. The

upper seal half can be installed with crankshaft

removed from engine or with crankshaft installed.

When a new upper seal is installed, install a new

lower seal. The lower seal half can be installed only

with the rear main bearing cap removed.

UPPER SEAL ÐCRANKSHAFT REMOVED

(1) Remove the crankshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT - REMOVAL). Dis-

card the old upper seal.

UPPER SEALÐCRANKSHAFT INSTALLED

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

(3) Remove the rear main bearing cap. Remove

and discard the old lower oil seal.

(4) Carefully remove and discard the old upper oil

seal.

LOWER SEAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

(3) Remove the rear main bearing cap and discard

the old lower seal.

INSTALLATION

The service seal is a two piece, Viton seal. The

upper seal half can be installed with crankshaft

removed from engine or with crankshaft installed.

When a new upper seal is installed, install a new

lower seal. The lower seal half can be installed only

with the rear main bearing cap removed.

UPPER SEAL ÐCRANKSHAFT REMOVED

(1) Clean the cylinder block rear cap mating sur-

face. Be sure the seal groove is free of debris. Check

for burrs at the oil hole on the cylinder block mating

surface to rear cap.

(2) Lightly oil the new upper seal lips with engine

oil.

(3) Install the new upper rear bearing oil seal with

the white paint facing toward the rear of the engine.

(4) Position the crankshaft into the cylinder block.

(5) Lightly oil the new lower seal lips with engine

oil.

(6) Install the new lower rear bearing oil seal into

the bearing cap with the white paint facing towards

the rear of the engine.

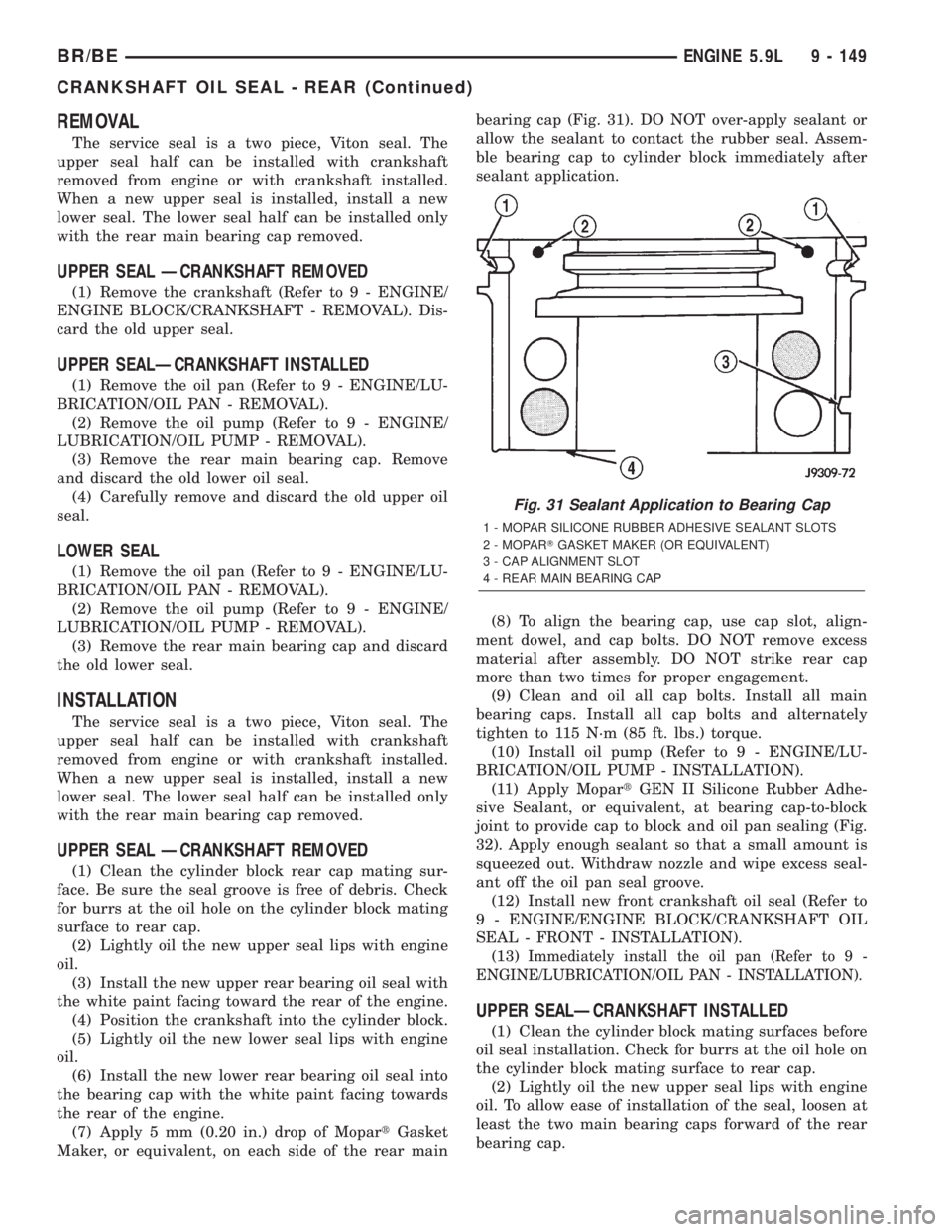

(7) Apply 5 mm (0.20 in.) drop of MopartGasket

Maker, or equivalent, on each side of the rear mainbearing cap (Fig. 31). DO NOT over-apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

(8) To align the bearing cap, use cap slot, align-

ment dowel, and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than two times for proper engagement.

(9) Clean and oil all cap bolts. Install all main

bearing caps. Install all cap bolts and alternately

tighten to 115 N´m (85 ft. lbs.) torque.

(10) Install oil pump (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

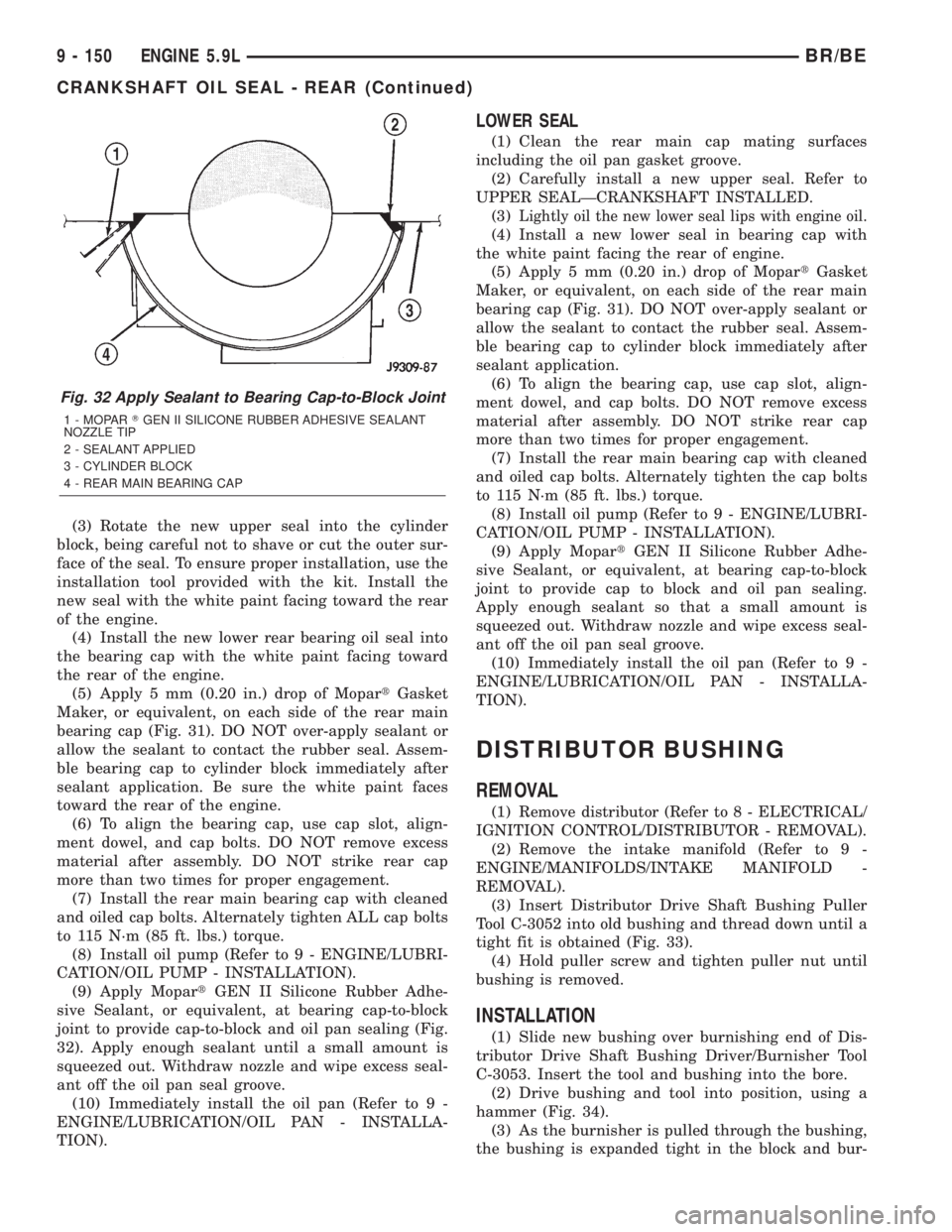

(11) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, at bearing cap-to-block

joint to provide cap to block and oil pan sealing (Fig.

32). Apply enough sealant so that a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(12) Install new front crankshaft oil seal (Refer to

9 - ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION).

(13)

Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLATION).

UPPER SEALÐCRANKSHAFT INSTALLED

(1) Clean the cylinder block mating surfaces before

oil seal installation. Check for burrs at the oil hole on

the cylinder block mating surface to rear cap.

(2) Lightly oil the new upper seal lips with engine

oil. To allow ease of installation of the seal, loosen at

least the two main bearing caps forward of the rear

bearing cap.

Fig. 31 Sealant Application to Bearing Cap

1 - MOPAR SILICONE RUBBER ADHESIVE SEALANT SLOTS

2 - MOPARTGASKET MAKER (OR EQUIVALENT)

3 - CAP ALIGNMENT SLOT

4 - REAR MAIN BEARING CAP

BR/BEENGINE 5.9L 9 - 149

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1297 of 2889

(3) Rotate the new upper seal into the cylinder

block, being careful not to shave or cut the outer sur-

face of the seal. To ensure proper installation, use the

installation tool provided with the kit. Install the

new seal with the white paint facing toward the rear

of the engine.

(4) Install the new lower rear bearing oil seal into

the bearing cap with the white paint facing toward

the rear of the engine.

(5) Apply 5 mm (0.20 in.) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 31). DO NOT over-apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application. Be sure the white paint faces

toward the rear of the engine.

(6) To align the bearing cap, use cap slot, align-

ment dowel, and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than two times for proper engagement.

(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten ALL cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - INSTALLATION).

(9) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, at bearing cap-to-block

joint to provide cap-to-block and oil pan sealing (Fig.

32). Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10) Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

LOWER SEAL

(1) Clean the rear main cap mating surfaces

including the oil pan gasket groove.

(2) Carefully install a new upper seal. Refer to

UPPER SEALÐCRANKSHAFT INSTALLED.

(3)

Lightly oil the new lower seal lips with engine oil.

(4) Install a new lower seal in bearing cap with

the white paint facing the rear of engine.

(5) Apply 5 mm (0.20 in.) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 31). DO NOT over-apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

(6) To align the bearing cap, use cap slot, align-

ment dowel, and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than two times for proper engagement.

(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten the cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - INSTALLATION).

(9) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, at bearing cap-to-block

joint to provide cap to block and oil pan sealing.

Apply enough sealant so that a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10) Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

DISTRIBUTOR BUSHING

REMOVAL

(1) Remove distributor (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/DISTRIBUTOR - REMOVAL).

(2) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(3) Insert Distributor Drive Shaft Bushing Puller

Tool C-3052 into old bushing and thread down until a

tight fit is obtained (Fig. 33).

(4) Hold puller screw and tighten puller nut until

bushing is removed.

INSTALLATION

(1) Slide new bushing over burnishing end of Dis-

tributor Drive Shaft Bushing Driver/Burnisher Tool

C-3053. Insert the tool and bushing into the bore.

(2) Drive bushing and tool into position, using a

hammer (Fig. 34).

(3) As the burnisher is pulled through the bushing,

the bushing is expanded tight in the block and bur-

Fig. 32 Apply Sealant to Bearing Cap-to-Block Joint

1 - MOPARTGEN II SILICONE RUBBER ADHESIVE SEALANT

NOZZLE TIP

2 - SEALANT APPLIED

3 - CYLINDER BLOCK

4 - REAR MAIN BEARING CAP

9 - 150 ENGINE 5.9LBR/BE

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1300 of 2889

(2) Install tappets and push rods in their original

positions. Ensure that the oil feed hole in the side of

the tappet body faces up (away from the crankshaft).

(3) Install aligning yokes with ARROW toward

camshaft.

(4) Install yoke retainer. Tighten the bolts to 23

N´m (200 in. lbs.) torque. Install intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - INSTALLATION).

(5) Install push rods in original positions.

(6) Install rocker arms.

(7) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(8) Install air cleaner assembly and air in-let hose.

(9) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

PISTON & CONNECTING ROD

DESCRIPTION

The pistons are made of aluminum and have three

ring grooves, the top two grooves are for the compres-

sion rings and the bottom groove is for the oil control

ring. The connecting rods are forged steel and are

coined prior to heat treat. The piston pins are press fit.

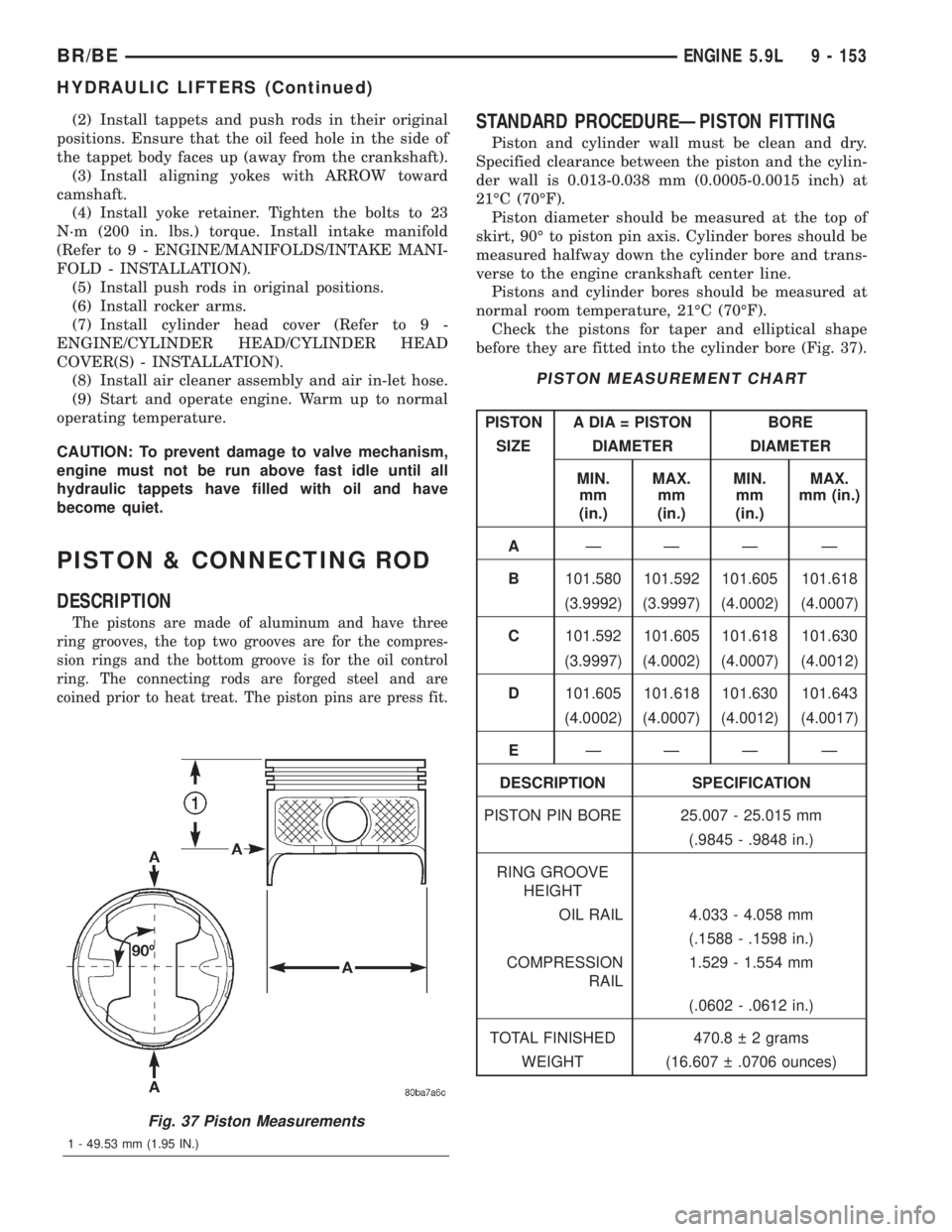

STANDARD PROCEDUREÐPISTON FITTING

Piston and cylinder wall must be clean and dry.

Specified clearance between the piston and the cylin-

der wall is 0.013-0.038 mm (0.0005-0.0015 inch) at

21ÉC (70ÉF).

Piston diameter should be measured at the top of

skirt, 90É to piston pin axis. Cylinder bores should be

measured halfway down the cylinder bore and trans-

verse to the engine crankshaft center line.

Pistons and cylinder bores should be measured at

normal room temperature, 21ÉC (70ÉF).

Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore (Fig. 37).

PISTON MEASUREMENT CHART

PISTON A DIA = PISTON BORE

SIZE DIAMETER DIAMETER

MIN. MAX. MIN. MAX.

mm

(in.)mm

(in.)mm

(in.)mm (in.)

AÐÐÐ Ð

B101.580 101.592 101.605 101.618

(3.9992) (3.9997) (4.0002) (4.0007)

C101.592 101.605 101.618 101.630

(3.9997) (4.0002) (4.0007) (4.0012)

D101.605 101.618 101.630 101.643

(4.0002) (4.0007) (4.0012) (4.0017)

EÐÐÐ Ð

DESCRIPTION SPECIFICATION

PISTON PIN BORE 25.007 - 25.015 mm

(.9845 - .9848 in.)

RING GROOVE

HEIGHT

OIL RAIL 4.033 - 4.058 mm

(.1588 - .1598 in.)

COMPRESSION

RAIL1.529 - 1.554 mm

(.0602 - .0612 in.)

TOTAL FINISHED 470.8 2 grams

WEIGHT (16.607 .0706 ounces)

Fig. 37 Piston Measurements

1 - 49.53 mm (1.95 IN.)

BR/BEENGINE 5.9L 9 - 153

HYDRAULIC LIFTERS (Continued)

Page 1301 of 2889

REMOVAL

(1) Remove the engine from the vehicle (Refer to 9

- ENGINE - REMOVAL).

(2) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block. Be sure to keep tops of pistons covered

during this operation.

(5) Be sure each connecting rod and connecting rod

cap is identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing the

assemblies from the engine, rotate crankshaft so that

the connecting rod is centered in cylinder bore and at

BDC.Be careful not to nick crankshaft journals.

(7) After removal, install bearing cap on the mat-

ing rod.

CLEANING

Clean the piston and connecting rod assembly

using a suitable solvent.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

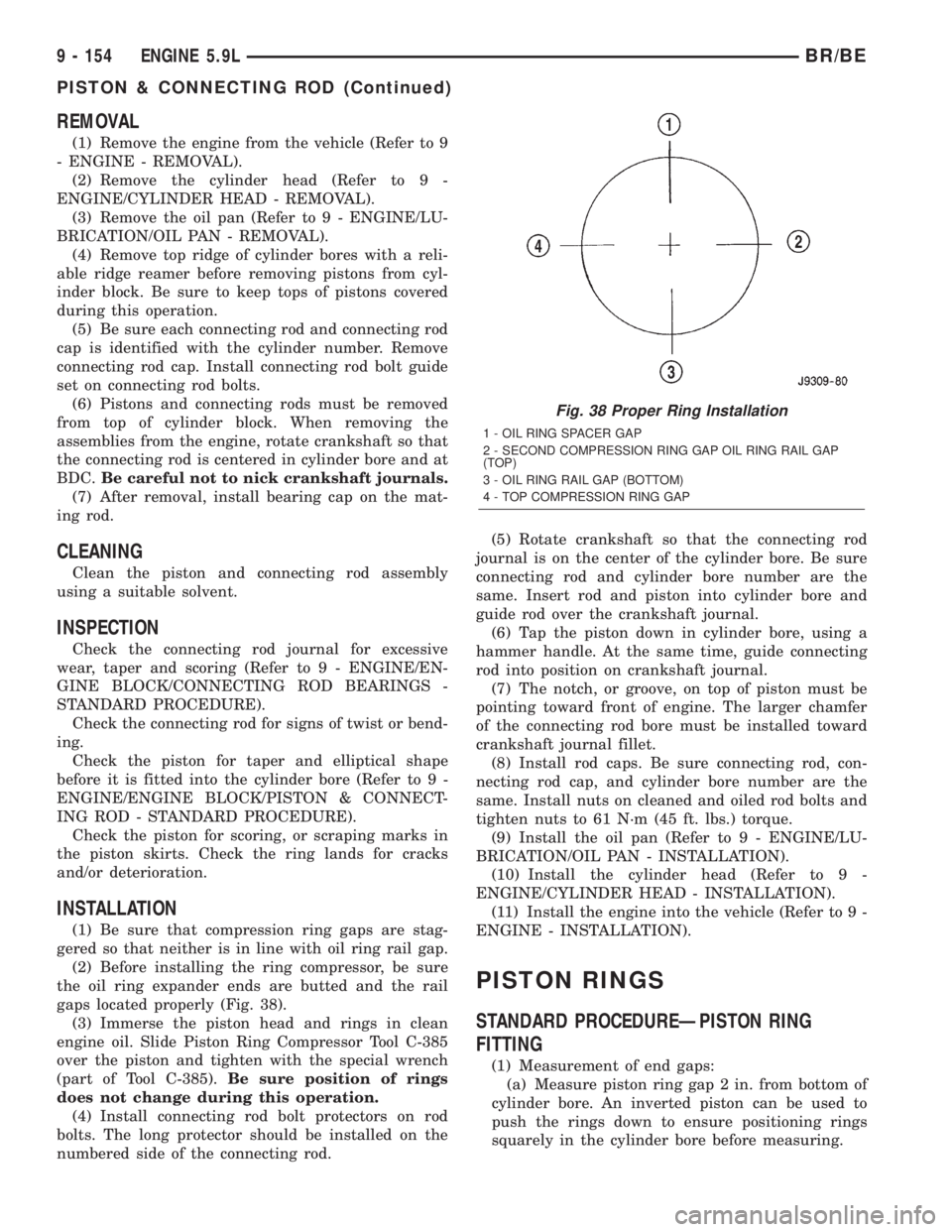

(1) Be sure that compression ring gaps are stag-

gered so that neither is in line with oil ring rail gap.

(2) Before installing the ring compressor, be sure

the oil ring expander ends are butted and the rail

gaps located properly (Fig. 38).

(3) Immerse the piston head and rings in clean

engine oil. Slide Piston Ring Compressor Tool C-385

over the piston and tighten with the special wrench

(part of Tool C-385).Be sure position of rings

does not change during this operation.

(4) Install connecting rod bolt protectors on rod

bolts. The long protector should be installed on the

numbered side of the connecting rod.(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Be sure

connecting rod and cylinder bore number are the

same. Insert rod and piston into cylinder bore and

guide rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on crankshaft journal.

(7) The notch, or groove, on top of piston must be

pointing toward front of engine. The larger chamfer

of the connecting rod bore must be installed toward

crankshaft journal fillet.

(8) Install rod caps. Be sure connecting rod, con-

necting rod cap, and cylinder bore number are the

same. Install nuts on cleaned and oiled rod bolts and

tighten nuts to 61 N´m (45 ft. lbs.) torque.

(9) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(10) Install the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION).

(11) Install the engine into the vehicle (Refer to 9 -

ENGINE - INSTALLATION).

PISTON RINGS

STANDARD PROCEDUREÐPISTON RING

FITTING

(1) Measurement of end gaps:

(a) Measure piston ring gap 2 in. from bottom of

cylinder bore. An inverted piston can be used to

push the rings down to ensure positioning rings

squarely in the cylinder bore before measuring.

Fig. 38 Proper Ring Installation

1 - OIL RING SPACER GAP

2 - SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 - OIL RING RAIL GAP (BOTTOM)

4 - TOP COMPRESSION RING GAP

9 - 154 ENGINE 5.9LBR/BE

PISTON & CONNECTING ROD (Continued)

Page 1302 of 2889

(b) Insert feeler gauge in the gap. The top com-

pression ring gap should be between 0.254-0.508

mm (0.010-0.020 in.). The second compression ring

gap should be between 0.508-0.762 mm

(0.020-0.030 in.). The oil ring gap should be 0.254-

1.270 mm (0.010-0.050 in.).

(c) Rings with insufficient end gap may be prop-

erly filed to the correct dimension. Rings with

excess gaps should not be used.

(2) Install rings, and confirm ring side clearance:

(a)

Install oil rings being careful not to nick or

scratch the piston. Install the oil control rings accord-

ing to instructions in the package. It is not necessary

to use a tool to install the upper and lower rails.

Insert oil rail spacer first, then side rails.

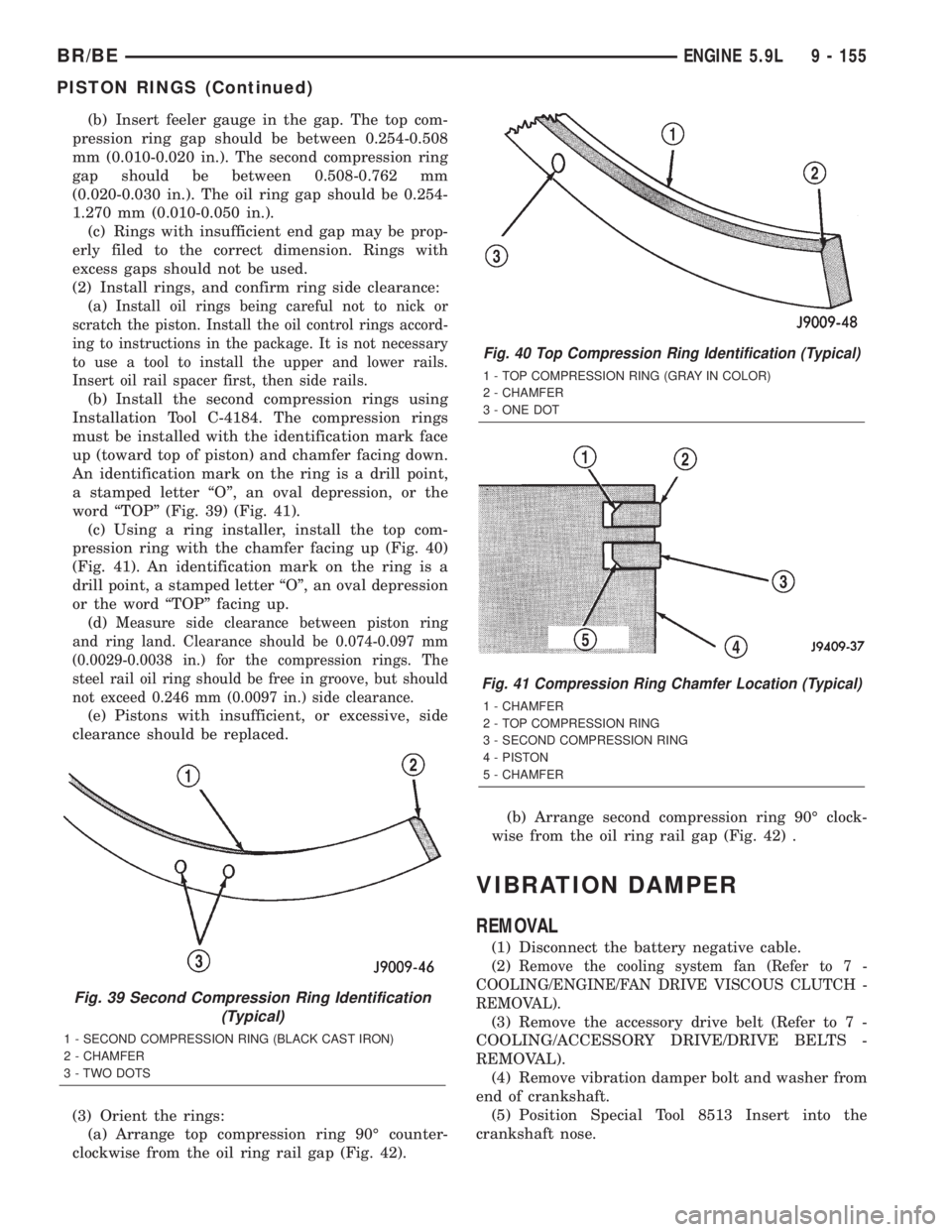

(b) Install the second compression rings using

Installation Tool C-4184. The compression rings

must be installed with the identification mark face

up (toward top of piston) and chamfer facing down.

An identification mark on the ring is a drill point,

a stamped letter ªOº, an oval depression, or the

word ªTOPº (Fig. 39) (Fig. 41).

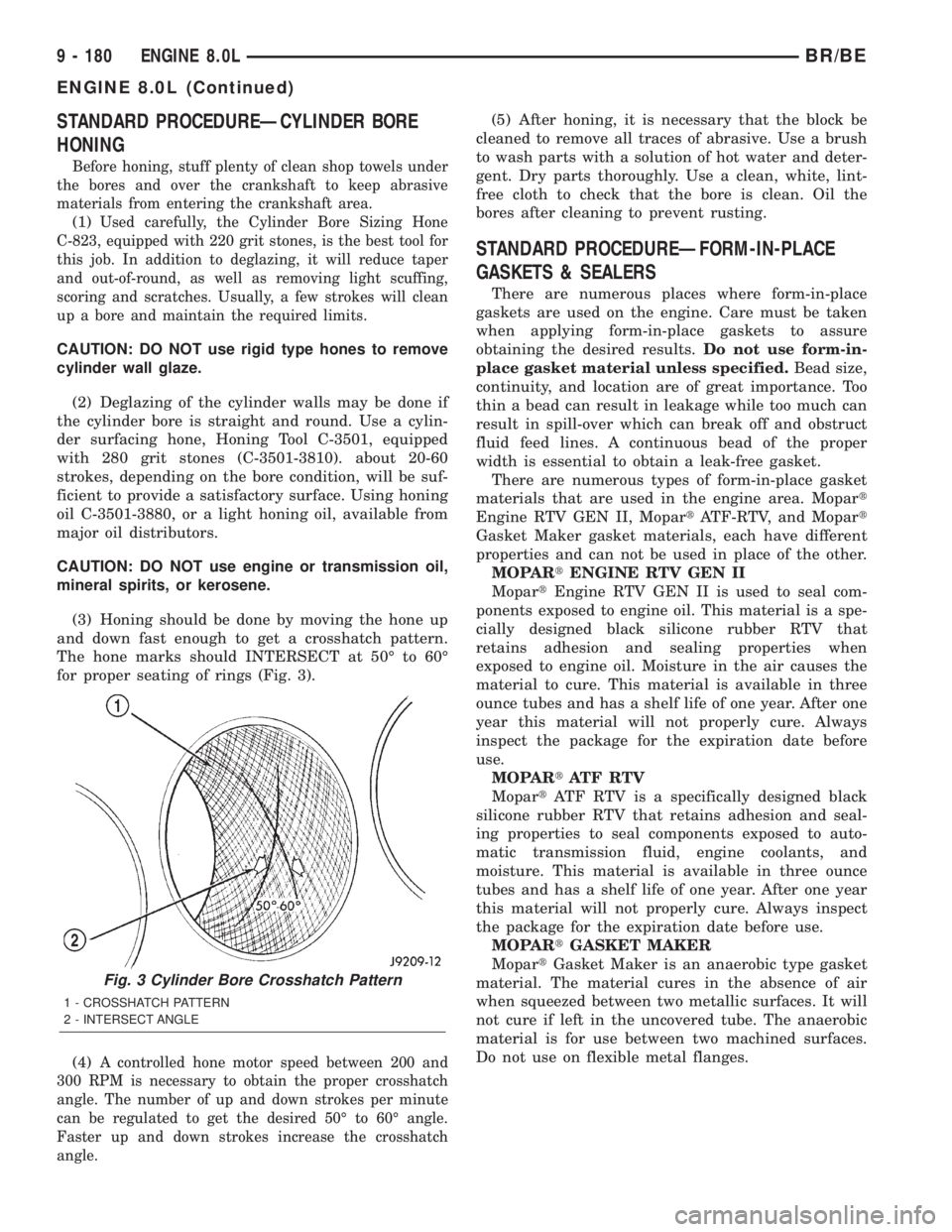

(c) Using a ring installer, install the top com-

pression ring with the chamfer facing up (Fig. 40)

(Fig. 41). An identification mark on the ring is a

drill point, a stamped letter ªOº, an oval depression

or the word ªTOPº facing up.

(d)

Measure side clearance between piston ring

and ring land. Clearance should be 0.074-0.097 mm

(0.0029-0.0038 in.) for the compression rings. The

steel rail oil ring should be free in groove, but should

not exceed 0.246 mm (0.0097 in.) side clearance.

(e) Pistons with insufficient, or excessive, side

clearance should be replaced.

(3) Orient the rings:

(a) Arrange top compression ring 90É counter-

clockwise from the oil ring rail gap (Fig. 42).(b) Arrange second compression ring 90É clock-

wise from the oil ring rail gap (Fig. 42) .

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery negative cable.

(2)

Remove the cooling system fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove vibration damper bolt and washer from

end of crankshaft.

(5) Position Special Tool 8513 Insert into the

crankshaft nose.

Fig. 39 Second Compression Ring Identification

(Typical)

1 - SECOND COMPRESSION RING (BLACK CAST IRON)

2 - CHAMFER

3 - TWO DOTS

Fig. 40 Top Compression Ring Identification (Typical)

1 - TOP COMPRESSION RING (GRAY IN COLOR)

2 - CHAMFER

3 - ONE DOT

Fig. 41 Compression Ring Chamfer Location (Typical)

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

BR/BEENGINE 5.9L 9 - 155

PISTON RINGS (Continued)

Page 1327 of 2889

STANDARD PROCEDUREÐCYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels under

the bores and over the crankshaft to keep abrasive

materials from entering the crankshaft area.

(1)Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool for

this job. In addition to deglazing, it will reduce taper

and out-of-round, as well as removing light scuffing,

scoring and scratches. Usually, a few strokes will clean

up a bore and maintain the required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

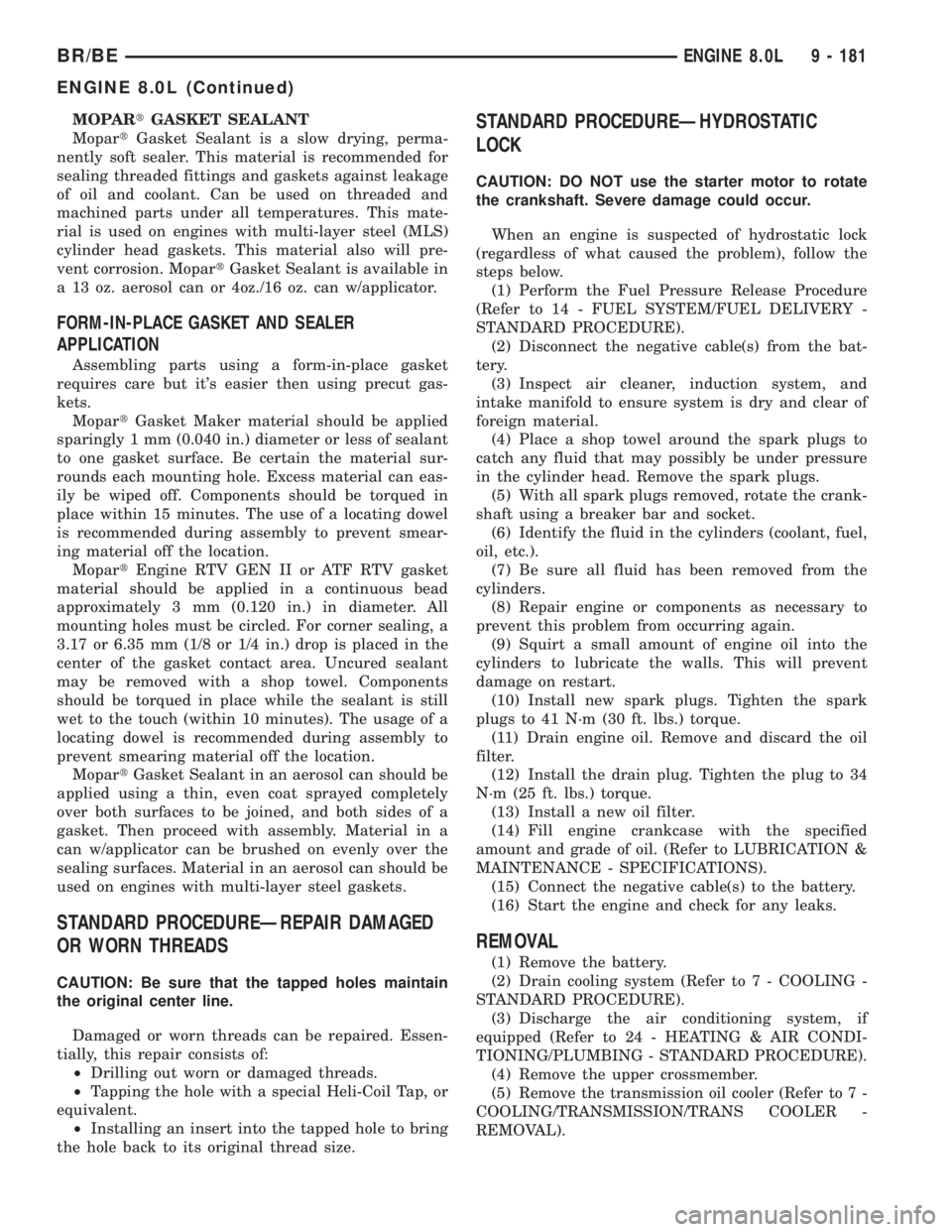

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 3).

(4)

A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper crosshatch

angle. The number of up and down strokes per minute

can be regulated to get the desired 50É to 60É angle.

Faster up and down strokes increase the crosshatch

angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

STANDARD PROCEDUREÐFORM-IN-PLACE

GASKETS & SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

9 - 180 ENGINE 8.0LBR/BE

ENGINE 8.0L (Continued)

Page 1328 of 2889

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDUREÐREPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

REMOVAL

(1) Remove the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Discharge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(4) Remove the upper crossmember.

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

BR/BEENGINE 8.0L 9 - 181

ENGINE 8.0L (Continued)

Page 1356 of 2889

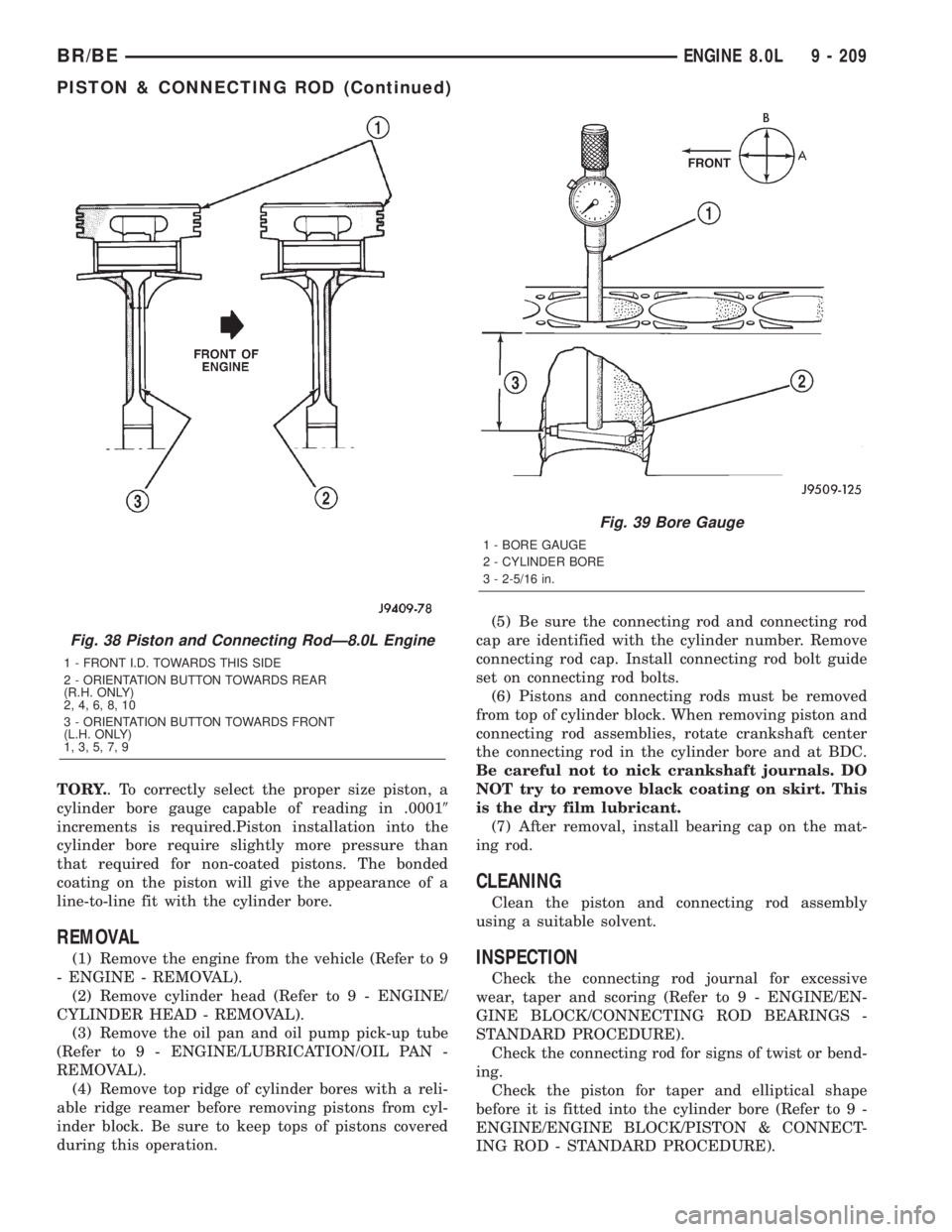

TORY.. To correctly select the proper size piston, a

cylinder bore gauge capable of reading in .00019

increments is required.Piston installation into the

cylinder bore require slightly more pressure than

that required for non-coated pistons. The bonded

coating on the piston will give the appearance of a

line-to-line fit with the cylinder bore.

REMOVAL

(1) Remove the engine from the vehicle (Refer to 9

- ENGINE - REMOVAL).

(2) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan and oil pump pick-up tube

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block. Be sure to keep tops of pistons covered

during this operation.(5) Be sure the connecting rod and connecting rod

cap are identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing piston and

connecting rod assemblies, rotate crankshaft center

the connecting rod in the cylinder bore and at BDC.

Be careful not to nick crankshaft journals. DO

NOT try to remove black coating on skirt. This

is the dry film lubricant.

(7) After removal, install bearing cap on the mat-

ing rod.

CLEANING

Clean the piston and connecting rod assembly

using a suitable solvent.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Fig. 38 Piston and Connecting RodÐ8.0L Engine

1 - FRONT I.D. TOWARDS THIS SIDE

2 - ORIENTATION BUTTON TOWARDS REAR

(R.H. ONLY)

2, 4, 6, 8, 10

3 - ORIENTATION BUTTON TOWARDS FRONT

(L.H. ONLY)

1, 3, 5, 7, 9

Fig. 39 Bore Gauge

1 - BORE GAUGE

2 - CYLINDER BORE

3 - 2-5/16 in.

BR/BEENGINE 8.0L 9 - 209

PISTON & CONNECTING ROD (Continued)

Page 1357 of 2889

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Check the crankshaft connecting rod journal

for excessive wear, taper and scoring.

(2) Check the cylinder block bore for out-of-round,

taper, scoring and scuffing.

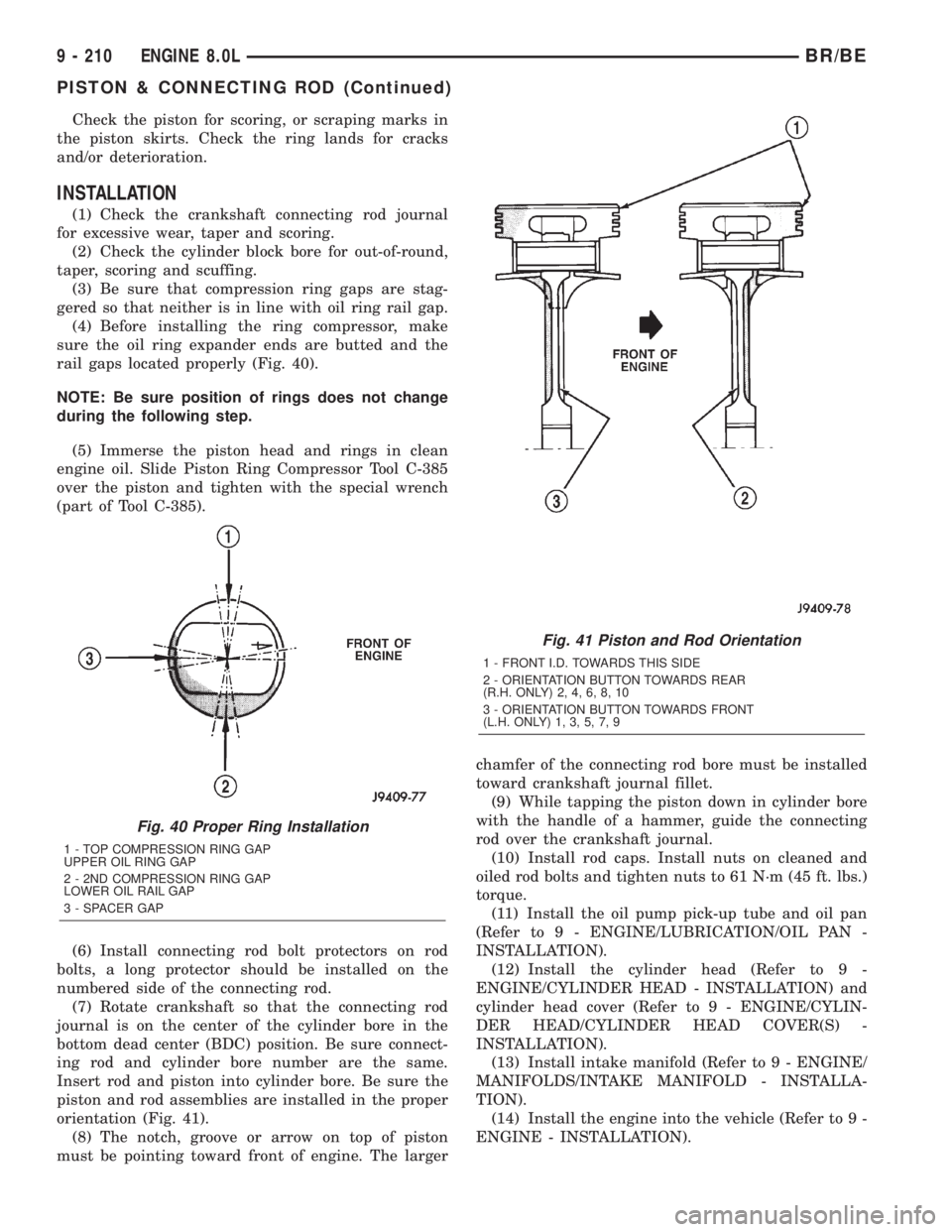

(3) Be sure that compression ring gaps are stag-

gered so that neither is in line with oil ring rail gap.

(4) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located properly (Fig. 40).

NOTE: Be sure position of rings does not change

during the following step.

(5) Immerse the piston head and rings in clean

engine oil. Slide Piston Ring Compressor Tool C-385

over the piston and tighten with the special wrench

(part of Tool C-385).

(6) Install connecting rod bolt protectors on rod

bolts, a long protector should be installed on the

numbered side of the connecting rod.

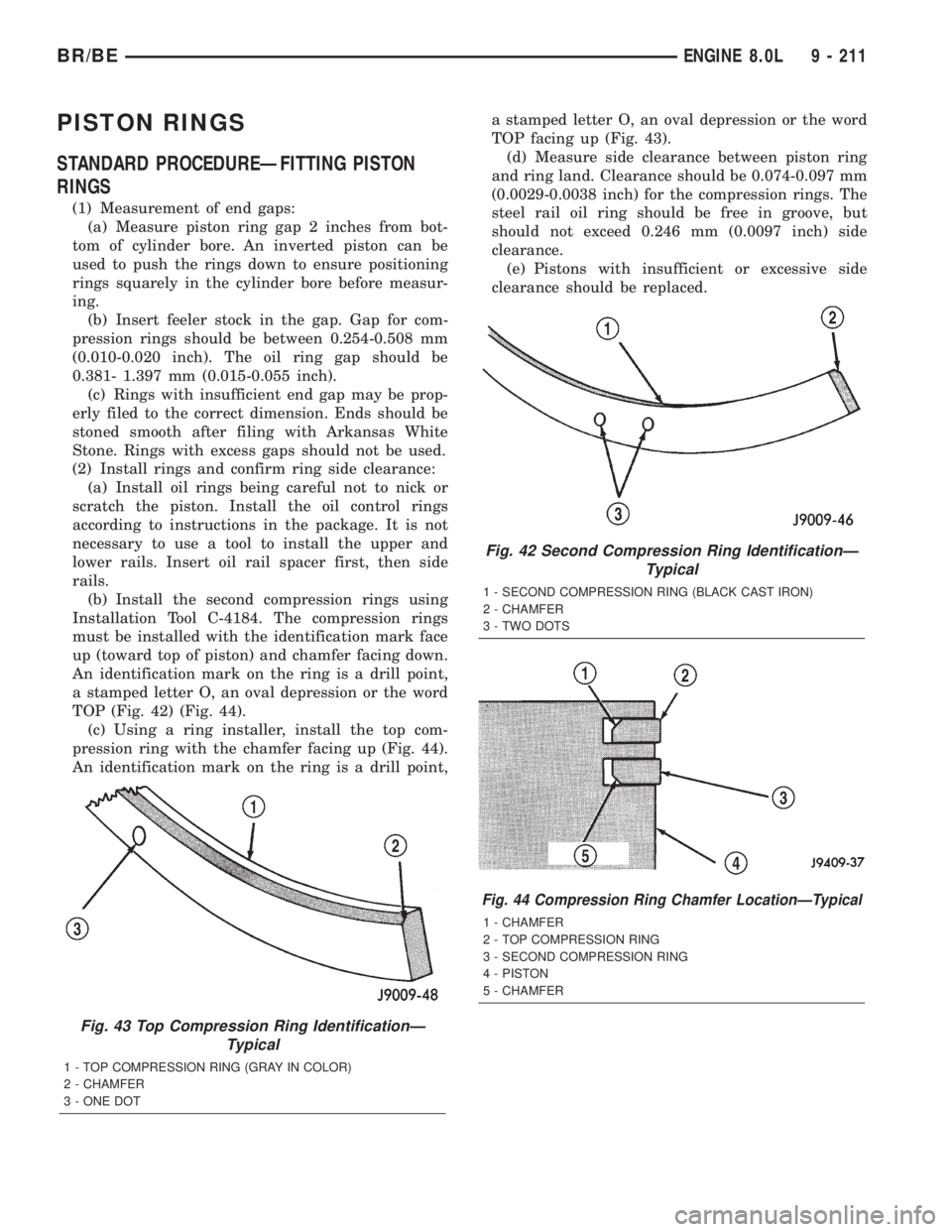

(7) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore in the

bottom dead center (BDC) position. Be sure connect-

ing rod and cylinder bore number are the same.

Insert rod and piston into cylinder bore. Be sure the

piston and rod assemblies are installed in the proper

orientation (Fig. 41).

(8) The notch, groove or arrow on top of piston

must be pointing toward front of engine. The largerchamfer of the connecting rod bore must be installed

toward crankshaft journal fillet.

(9) While tapping the piston down in cylinder bore

with the handle of a hammer, guide the connecting

rod over the crankshaft journal.

(10) Install rod caps. Install nuts on cleaned and

oiled rod bolts and tighten nuts to 61 N´m (45 ft. lbs.)

torque.

(11) Install the oil pump pick-up tube and oil pan

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

INSTALLATION).

(12) Install the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION) and

cylinder head cover (Refer to 9 - ENGINE/CYLIN-

DER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

(13) Install intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

(14) Install the engine into the vehicle (Refer to 9 -

ENGINE - INSTALLATION).

Fig. 40 Proper Ring Installation

1 - TOP COMPRESSION RING GAP

UPPER OIL RING GAP

2 - 2ND COMPRESSION RING GAP

LOWER OIL RAIL GAP

3 - SPACER GAP

Fig. 41 Piston and Rod Orientation

1 - FRONT I.D. TOWARDS THIS SIDE

2 - ORIENTATION BUTTON TOWARDS REAR

(R.H. ONLY) 2, 4, 6, 8, 10

3 - ORIENTATION BUTTON TOWARDS FRONT

(L.H. ONLY) 1, 3, 5, 7, 9

9 - 210 ENGINE 8.0LBR/BE

PISTON & CONNECTING ROD (Continued)

Page 1358 of 2889

PISTON RINGS

STANDARD PROCEDUREÐFITTING PISTON

RINGS

(1) Measurement of end gaps:

(a) Measure piston ring gap 2 inches from bot-

tom of cylinder bore. An inverted piston can be

used to push the rings down to ensure positioning

rings squarely in the cylinder bore before measur-

ing.

(b) Insert feeler stock in the gap. Gap for com-

pression rings should be between 0.254-0.508 mm

(0.010-0.020 inch). The oil ring gap should be

0.381- 1.397 mm (0.015-0.055 inch).

(c) Rings with insufficient end gap may be prop-

erly filed to the correct dimension. Ends should be

stoned smooth after filing with Arkansas White

Stone. Rings with excess gaps should not be used.

(2) Install rings and confirm ring side clearance:

(a) Install oil rings being careful not to nick or

scratch the piston. Install the oil control rings

according to instructions in the package. It is not

necessary to use a tool to install the upper and

lower rails. Insert oil rail spacer first, then side

rails.

(b) Install the second compression rings using

Installation Tool C-4184. The compression rings

must be installed with the identification mark face

up (toward top of piston) and chamfer facing down.

An identification mark on the ring is a drill point,

a stamped letter O, an oval depression or the word

TOP (Fig. 42) (Fig. 44).

(c) Using a ring installer, install the top com-

pression ring with the chamfer facing up (Fig. 44).

An identification mark on the ring is a drill point,a stamped letter O, an oval depression or the word

TOP facing up (Fig. 43).

(d) Measure side clearance between piston ring

and ring land. Clearance should be 0.074-0.097 mm

(0.0029-0.0038 inch) for the compression rings. The

steel rail oil ring should be free in groove, but

should not exceed 0.246 mm (0.0097 inch) side

clearance.

(e) Pistons with insufficient or excessive side

clearance should be replaced.

Fig. 43 Top Compression Ring IdentificationÐ

Typical

1 - TOP COMPRESSION RING (GRAY IN COLOR)

2 - CHAMFER

3 - ONE DOT

Fig. 42 Second Compression Ring IdentificationÐ

Typical

1 - SECOND COMPRESSION RING (BLACK CAST IRON)

2 - CHAMFER

3 - TWO DOTS

Fig. 44 Compression Ring Chamfer LocationÐTypical

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

BR/BEENGINE 8.0L 9 - 211