tow DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1650 of 2889

REVERSE IDLER

(1) Remove idler gear snap rings (Fig. 44).

(2) Remove thrust washer, wave washer, thrust

plate and idler gear from shaft.

(3) Remove idler gear needle bearing from shaft.

CLEANING

Clean the gears, shafts, shift components and trans-

mission housings with a standard parts cleaning sol-

vent. Do not use acid or corrosive base solvents. Dry

all parts except bearings with compressed air.

Clean the shaft bearings with a mild solvent such

as Mopartdegreasing solvent, Gunk, or similar sol-

vents. Do not dry the bearings with compressed air.

Allow the bearings to either air dry, or wipe them dry

with clean shop towels.

INSPECTION

SHIFT LEVER ASSEMBLY

The shift lever assembly is not serviceable. Replace

the lever and shift tower as an assembly if the tower,

lever, lever ball, or internal components are worn, or

damaged.

SHIFT SHAFT AND FORKS

Inspect the shift fork interlock arms and synchro

sleeve contact surfaces (Fig. 45). Replace any fork

exhibiting wear or damage in these areas. Do not

attempt to salvage shift forks.

Check condition of the shift shaft detent plunger

and spring. The plunger should be smooth and free of

nicks, or scores. The plunger spring should be straight

and not collapsed, or distorted. Minor scratches, or

nicks on the plunger can be smoothed with 320/400

grit emery soaked in oil. Replace the plunger and

spring if in doubt about condition. Check condition of

detent plunger bushings. Replace if damaged.

Inspect the shift shaft, shift shaft bushing and

bearing, the shaft lever, and the lever bushing that

fits over the lever. Replace the shaft if bent, cracked,

or severely scored. Minor burrs, nicks, or scratches

can be smoothed off with 320/400 grit emery cloth

followed by polishing with crocus cloth. Replace the

shift shaft bushing or bearing if damaged.

Replace the shaft lever and bushing if either part

is deformed, or worn. Do not attempt to salvage these

parts as shift fork binding will occur. Replace the roll

pin that secures the lever to the shaft.

FRONT/REAR HOUSINGS AND BEARING

RETAINERS

Inspect the housings carefully. Look for cracks,

stripped threads, scored mating surfaces, damaged

bearing bores, or worn dowel pin holes. Minor nicks

on mating surfaces can be dressed off with a fine file,

or emery cloth. Damaged threads can be renewed by

either re-tapping or installing Helicoil inserts.

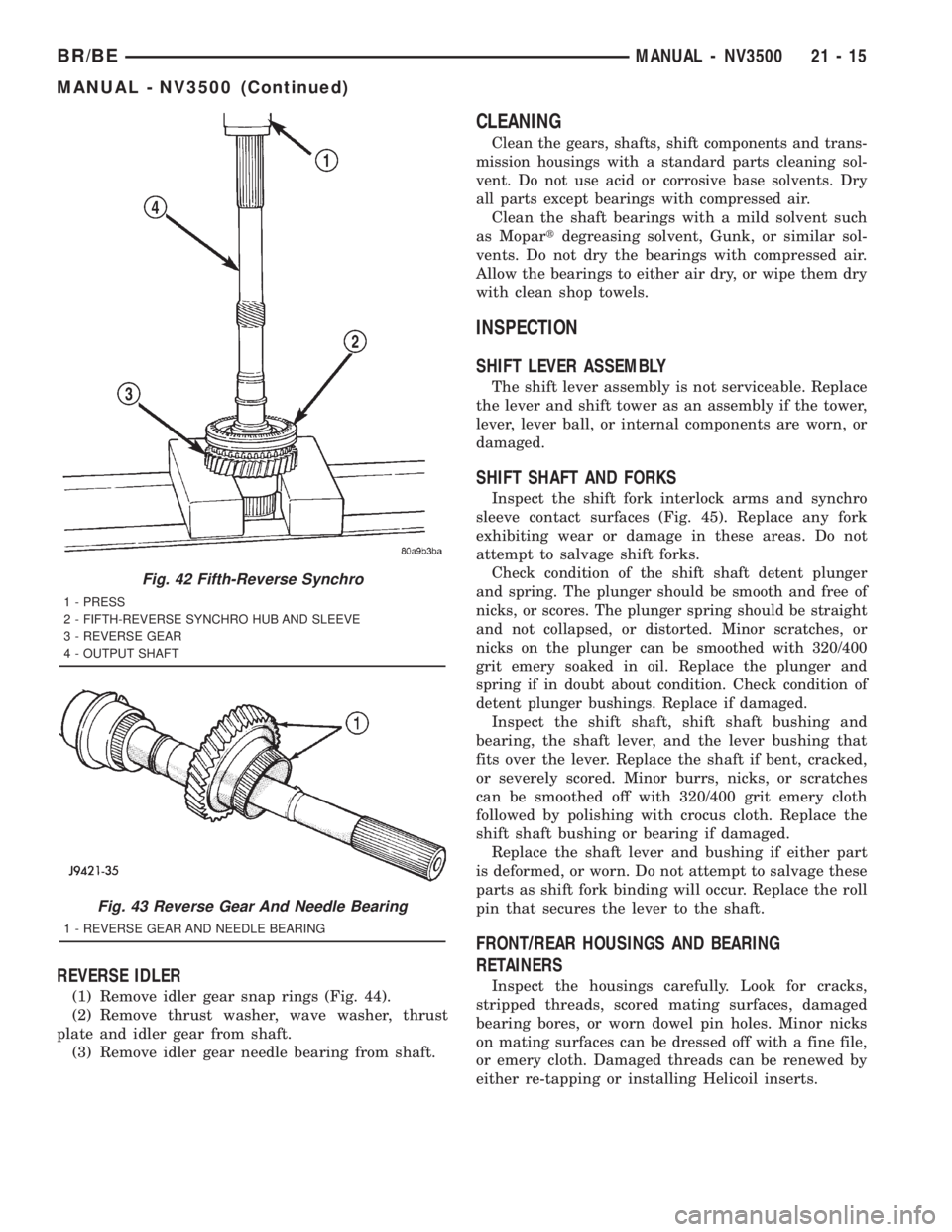

Fig. 42 Fifth-Reverse Synchro

1 - PRESS

2 - FIFTH-REVERSE SYNCHRO HUB AND SLEEVE

3 - REVERSE GEAR

4 - OUTPUT SHAFT

Fig. 43 Reverse Gear And Needle Bearing

1 - REVERSE GEAR AND NEEDLE BEARING

BR/BEMANUAL - NV3500 21 - 15

MANUAL - NV3500 (Continued)

Page 1661 of 2889

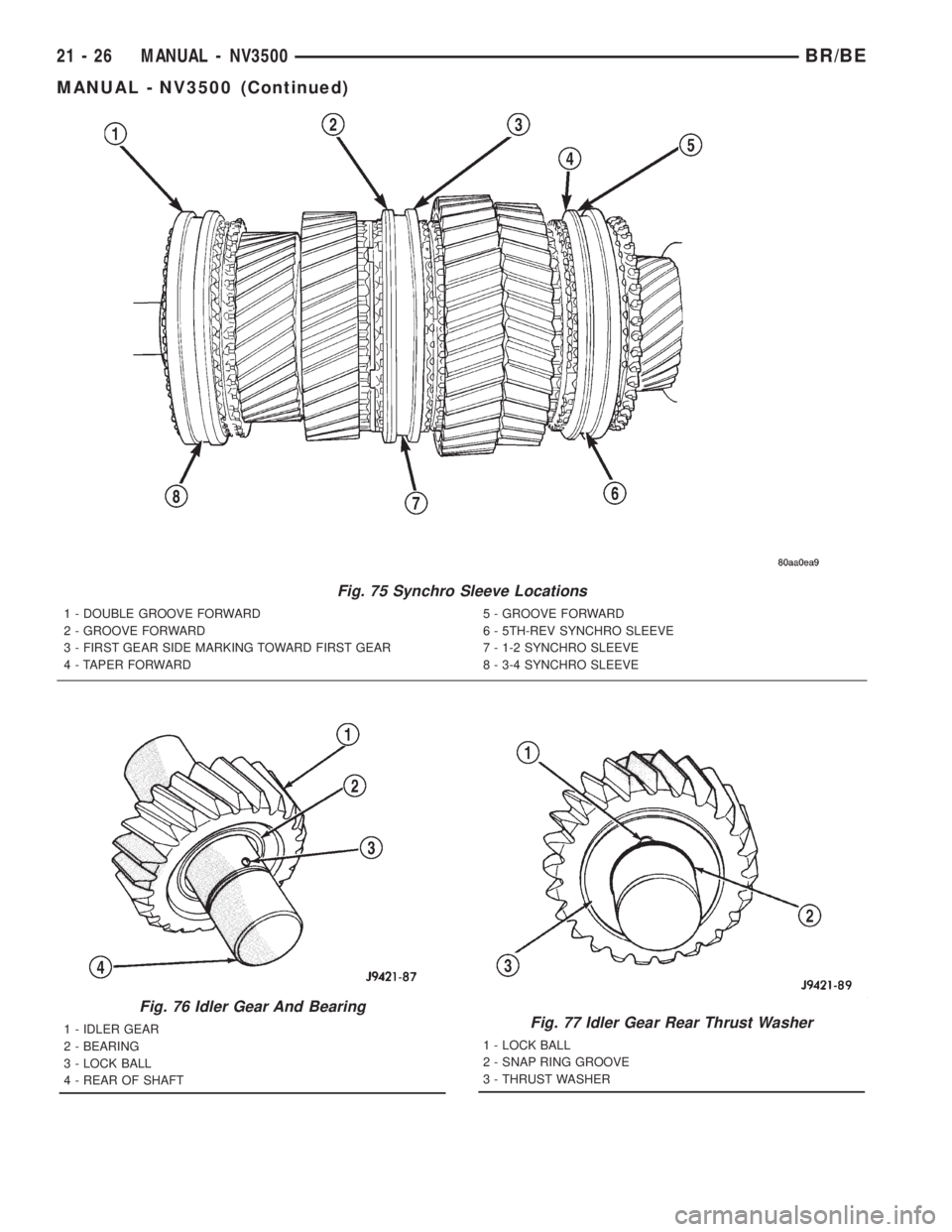

Fig. 75 Synchro Sleeve Locations

1 - DOUBLE GROOVE FORWARD

2 - GROOVE FORWARD

3 - FIRST GEAR SIDE MARKING TOWARD FIRST GEAR

4 - TAPER FORWARD5 - GROOVE FORWARD

6 - 5TH-REV SYNCHRO SLEEVE

7 - 1-2 SYNCHRO SLEEVE

8 - 3-4 SYNCHRO SLEEVE

Fig. 76 Idler Gear And Bearing

1 - IDLER GEAR

2 - BEARING

3 - LOCK BALL

4 - REAR OF SHAFTFig. 77 Idler Gear Rear Thrust Washer

1 - LOCK BALL

2 - SNAP RING GROOVE

3 - THRUST WASHER

21 - 26 MANUAL - NV3500BR/BE

MANUAL - NV3500 (Continued)

Page 1662 of 2889

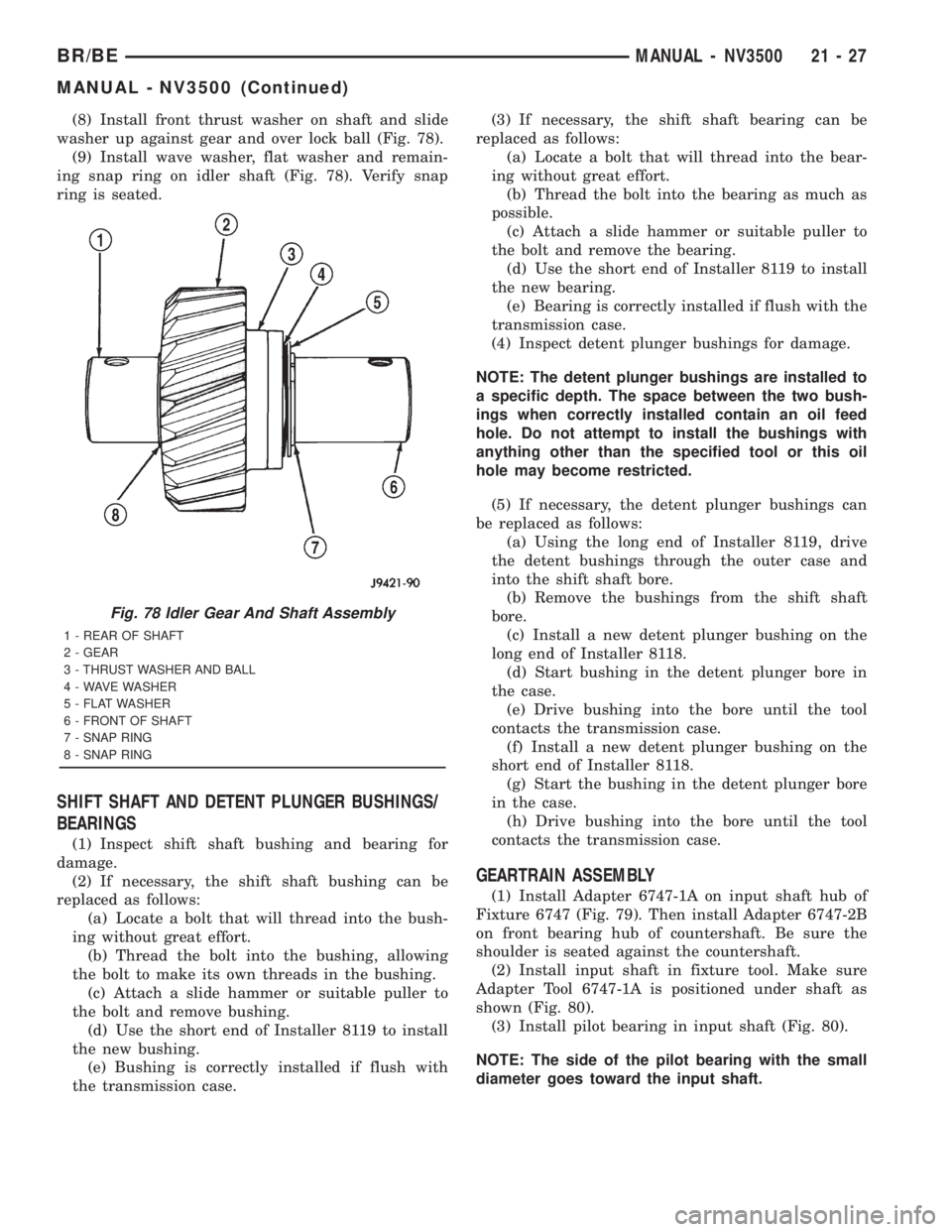

(8) Install front thrust washer on shaft and slide

washer up against gear and over lock ball (Fig. 78).

(9) Install wave washer, flat washer and remain-

ing snap ring on idler shaft (Fig. 78). Verify snap

ring is seated.

SHIFT SHAFT AND DETENT PLUNGER BUSHINGS/

BEARINGS

(1) Inspect shift shaft bushing and bearing for

damage.

(2) If necessary, the shift shaft bushing can be

replaced as follows:

(a) Locate a bolt that will thread into the bush-

ing without great effort.

(b) Thread the bolt into the bushing, allowing

the bolt to make its own threads in the bushing.

(c) Attach a slide hammer or suitable puller to

the bolt and remove bushing.

(d) Use the short end of Installer 8119 to install

the new bushing.

(e) Bushing is correctly installed if flush with

the transmission case.(3) If necessary, the shift shaft bearing can be

replaced as follows:

(a) Locate a bolt that will thread into the bear-

ing without great effort.

(b) Thread the bolt into the bearing as much as

possible.

(c) Attach a slide hammer or suitable puller to

the bolt and remove the bearing.

(d) Use the short end of Installer 8119 to install

the new bearing.

(e) Bearing is correctly installed if flush with the

transmission case.

(4) Inspect detent plunger bushings for damage.

NOTE: The detent plunger bushings are installed to

a specific depth. The space between the two bush-

ings when correctly installed contain an oil feed

hole. Do not attempt to install the bushings with

anything other than the specified tool or this oil

hole may become restricted.

(5) If necessary, the detent plunger bushings can

be replaced as follows:

(a) Using the long end of Installer 8119, drive

the detent bushings through the outer case and

into the shift shaft bore.

(b) Remove the bushings from the shift shaft

bore.

(c) Install a new detent plunger bushing on the

long end of Installer 8118.

(d) Start bushing in the detent plunger bore in

the case.

(e) Drive bushing into the bore until the tool

contacts the transmission case.

(f) Install a new detent plunger bushing on the

short end of Installer 8118.

(g) Start the bushing in the detent plunger bore

in the case.

(h) Drive bushing into the bore until the tool

contacts the transmission case.

GEARTRAIN ASSEMBLY

(1) Install Adapter 6747-1A on input shaft hub of

Fixture 6747 (Fig. 79). Then install Adapter 6747-2B

on front bearing hub of countershaft. Be sure the

shoulder is seated against the countershaft.

(2) Install input shaft in fixture tool. Make sure

Adapter Tool 6747-1A is positioned under shaft as

shown (Fig. 80).

(3) Install pilot bearing in input shaft (Fig. 80).

NOTE: The side of the pilot bearing with the small

diameter goes toward the input shaft.

Fig. 78 Idler Gear And Shaft Assembly

1 - REAR OF SHAFT

2 - GEAR

3 - THRUST WASHER AND BALL

4 - WAVE WASHER

5 - FLAT WASHER

6 - FRONT OF SHAFT

7 - SNAP RING

8 - SNAP RING

BR/BEMANUAL - NV3500 21 - 27

MANUAL - NV3500 (Continued)

Page 1664 of 2889

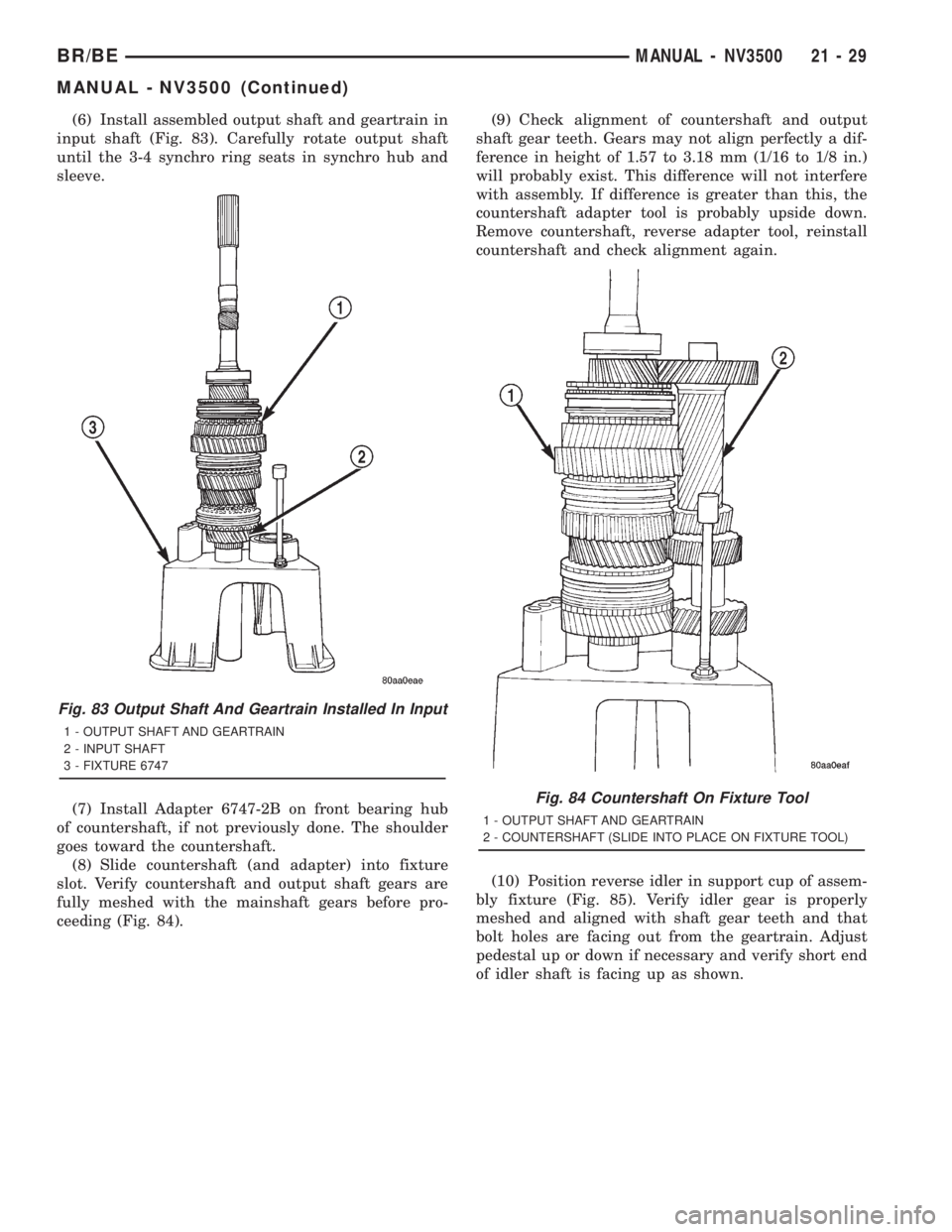

(6) Install assembled output shaft and geartrain in

input shaft (Fig. 83). Carefully rotate output shaft

until the 3-4 synchro ring seats in synchro hub and

sleeve.

(7) Install Adapter 6747-2B on front bearing hub

of countershaft, if not previously done. The shoulder

goes toward the countershaft.

(8) Slide countershaft (and adapter) into fixture

slot. Verify countershaft and output shaft gears are

fully meshed with the mainshaft gears before pro-

ceeding (Fig. 84).(9) Check alignment of countershaft and output

shaft gear teeth. Gears may not align perfectly a dif-

ference in height of 1.57 to 3.18 mm (1/16 to 1/8 in.)

will probably exist. This difference will not interfere

with assembly. If difference is greater than this, the

countershaft adapter tool is probably upside down.

Remove countershaft, reverse adapter tool, reinstall

countershaft and check alignment again.

(10) Position reverse idler in support cup of assem-

bly fixture (Fig. 85). Verify idler gear is properly

meshed and aligned with shaft gear teeth and that

bolt holes are facing out from the geartrain. Adjust

pedestal up or down if necessary and verify short end

of idler shaft is facing up as shown.

Fig. 83 Output Shaft And Geartrain Installed In Input

1 - OUTPUT SHAFT AND GEARTRAIN

2 - INPUT SHAFT

3 - FIXTURE 6747

Fig. 84 Countershaft On Fixture Tool

1 - OUTPUT SHAFT AND GEARTRAIN

2 - COUNTERSHAFT (SLIDE INTO PLACE ON FIXTURE TOOL)

BR/BEMANUAL - NV3500 21 - 29

MANUAL - NV3500 (Continued)

Page 1671 of 2889

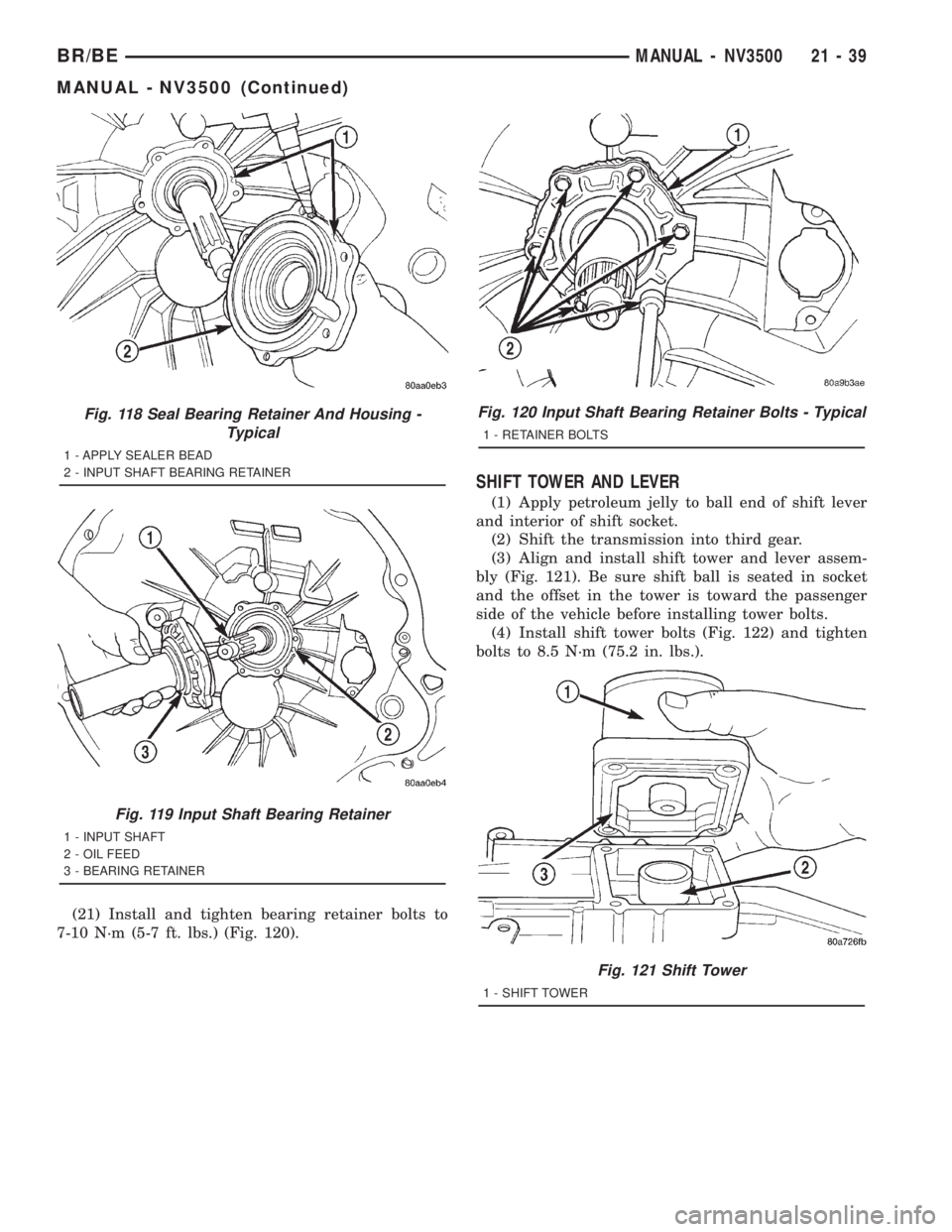

FRONT HOUSING AND INPUT SHAFT BEARING

RETAINER

(1) If previously removed, install input shaft bear-

ing in front housing bore (Fig. 109). Install snap ring

and use plastic mallet to seat bearing. Bearing goes

in from front side of housing only.

(2) Apply liberal quantity of petroleum jelly to

countershaft front bearing. Then insert bearing in

front housing race (Fig. 109). Large diameter side of

bearing cage goes toward countershaft (Fig. 110).

Small diameter side goes toward bearing race in

housing.(3) Reach into countershaft front bearing with fin-

ger and push each bearing roller outward against

race. Then apply extra petroleum jelly to hold rollers

in place during housing installation.

(4) Apply small amount of petroleum jelly to shift

shaft bushing in front housing.

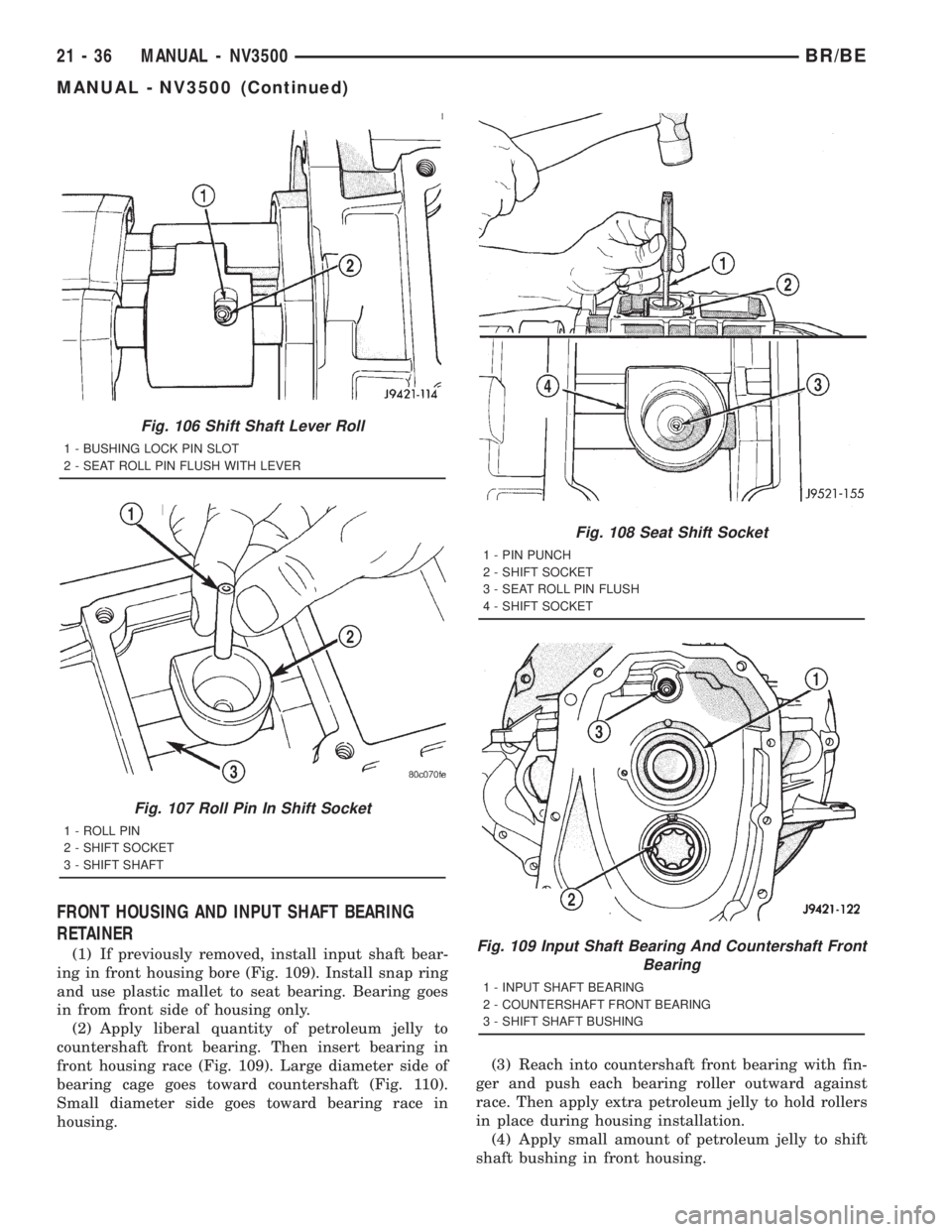

Fig. 106 Shift Shaft Lever Roll

1 - BUSHING LOCK PIN SLOT

2 - SEAT ROLL PIN FLUSH WITH LEVER

Fig. 107 Roll Pin In Shift Socket

1 - ROLL PIN

2 - SHIFT SOCKET

3 - SHIFT SHAFT

Fig. 108 Seat Shift Socket

1 - PIN PUNCH

2 - SHIFT SOCKET

3 - SEAT ROLL PIN FLUSH

4 - SHIFT SOCKET

Fig. 109 Input Shaft Bearing And Countershaft Front

Bearing

1 - INPUT SHAFT BEARING

2 - COUNTERSHAFT FRONT BEARING

3 - SHIFT SHAFT BUSHING

21 - 36 MANUAL - NV3500BR/BE

MANUAL - NV3500 (Continued)

Page 1674 of 2889

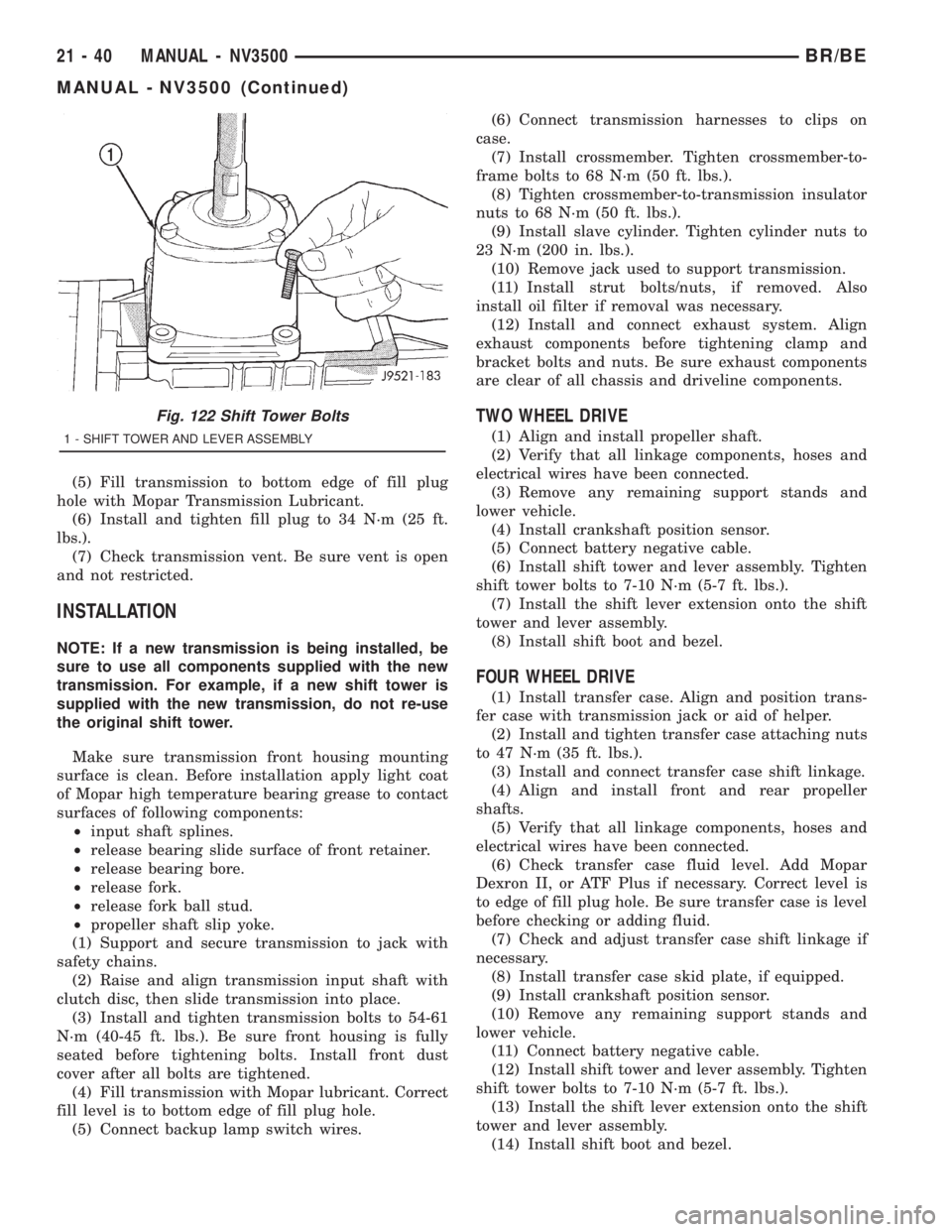

(21) Install and tighten bearing retainer bolts to

7-10 N´m (5-7 ft. lbs.) (Fig. 120).

SHIFT TOWER AND LEVER

(1) Apply petroleum jelly to ball end of shift lever

and interior of shift socket.

(2) Shift the transmission into third gear.

(3) Align and install shift tower and lever assem-

bly (Fig. 121). Be sure shift ball is seated in socket

and the offset in the tower is toward the passenger

side of the vehicle before installing tower bolts.

(4) Install shift tower bolts (Fig. 122) and tighten

bolts to 8.5 N´m (75.2 in. lbs.).

Fig. 118 Seal Bearing Retainer And Housing -

Typical

1 - APPLY SEALER BEAD

2 - INPUT SHAFT BEARING RETAINER

Fig. 119 Input Shaft Bearing Retainer

1 - INPUT SHAFT

2 - OIL FEED

3 - BEARING RETAINER

Fig. 120 Input Shaft Bearing Retainer Bolts - Typical

1 - RETAINER BOLTS

Fig. 121 Shift Tower

1 - SHIFT TOWER

BR/BEMANUAL - NV3500 21 - 39

MANUAL - NV3500 (Continued)

Page 1675 of 2889

(5) Fill transmission to bottom edge of fill plug

hole with Mopar Transmission Lubricant.

(6) Install and tighten fill plug to 34 N´m (25 ft.

lbs.).

(7) Check transmission vent. Be sure vent is open

and not restricted.

INSTALLATION

NOTE: If a new transmission is being installed, be

sure to use all components supplied with the new

transmission. For example, if a new shift tower is

supplied with the new transmission, do not re-use

the original shift tower.

Make sure transmission front housing mounting

surface is clean. Before installation apply light coat

of Mopar high temperature bearing grease to contact

surfaces of following components:

²input shaft splines.

²release bearing slide surface of front retainer.

²release bearing bore.

²release fork.

²release fork ball stud.

²propeller shaft slip yoke.

(1) Support and secure transmission to jack with

safety chains.

(2) Raise and align transmission input shaft with

clutch disc, then slide transmission into place.

(3) Install and tighten transmission bolts to 54-61

N´m (40-45 ft. lbs.). Be sure front housing is fully

seated before tightening bolts. Install front dust

cover after all bolts are tightened.

(4) Fill transmission with Mopar lubricant. Correct

fill level is to bottom edge of fill plug hole.

(5) Connect backup lamp switch wires.(6) Connect transmission harnesses to clips on

case.

(7) Install crossmember. Tighten crossmember-to-

frame bolts to 68 N´m (50 ft. lbs.).

(8) Tighten crossmember-to-transmission insulator

nuts to 68 N´m (50 ft. lbs.).

(9) Install slave cylinder. Tighten cylinder nuts to

23 N´m (200 in. lbs.).

(10) Remove jack used to support transmission.

(11) Install strut bolts/nuts, if removed. Also

install oil filter if removal was necessary.

(12) Install and connect exhaust system. Align

exhaust components before tightening clamp and

bracket bolts and nuts. Be sure exhaust components

are clear of all chassis and driveline components.

TWO WHEEL DRIVE

(1) Align and install propeller shaft.

(2) Verify that all linkage components, hoses and

electrical wires have been connected.

(3) Remove any remaining support stands and

lower vehicle.

(4) Install crankshaft position sensor.

(5) Connect battery negative cable.

(6) Install shift tower and lever assembly. Tighten

shift tower bolts to 7-10 N´m (5-7 ft. lbs.).

(7) Install the shift lever extension onto the shift

tower and lever assembly.

(8) Install shift boot and bezel.

FOUR WHEEL DRIVE

(1) Install transfer case. Align and position trans-

fer case with transmission jack or aid of helper.

(2) Install and tighten transfer case attaching nuts

to 47 N´m (35 ft. lbs.).

(3) Install and connect transfer case shift linkage.

(4) Align and install front and rear propeller

shafts.

(5) Verify that all linkage components, hoses and

electrical wires have been connected.

(6) Check transfer case fluid level. Add Mopar

Dexron II, or ATF Plus if necessary. Correct level is

to edge of fill plug hole. Be sure transfer case is level

before checking or adding fluid.

(7) Check and adjust transfer case shift linkage if

necessary.

(8) Install transfer case skid plate, if equipped.

(9) Install crankshaft position sensor.

(10) Remove any remaining support stands and

lower vehicle.

(11) Connect battery negative cable.

(12) Install shift tower and lever assembly. Tighten

shift tower bolts to 7-10 N´m (5-7 ft. lbs.).

(13) Install the shift lever extension onto the shift

tower and lever assembly.

(14) Install shift boot and bezel.

Fig. 122 Shift Tower Bolts

1 - SHIFT TOWER AND LEVER ASSEMBLY

21 - 40 MANUAL - NV3500BR/BE

MANUAL - NV3500 (Continued)

Page 1676 of 2889

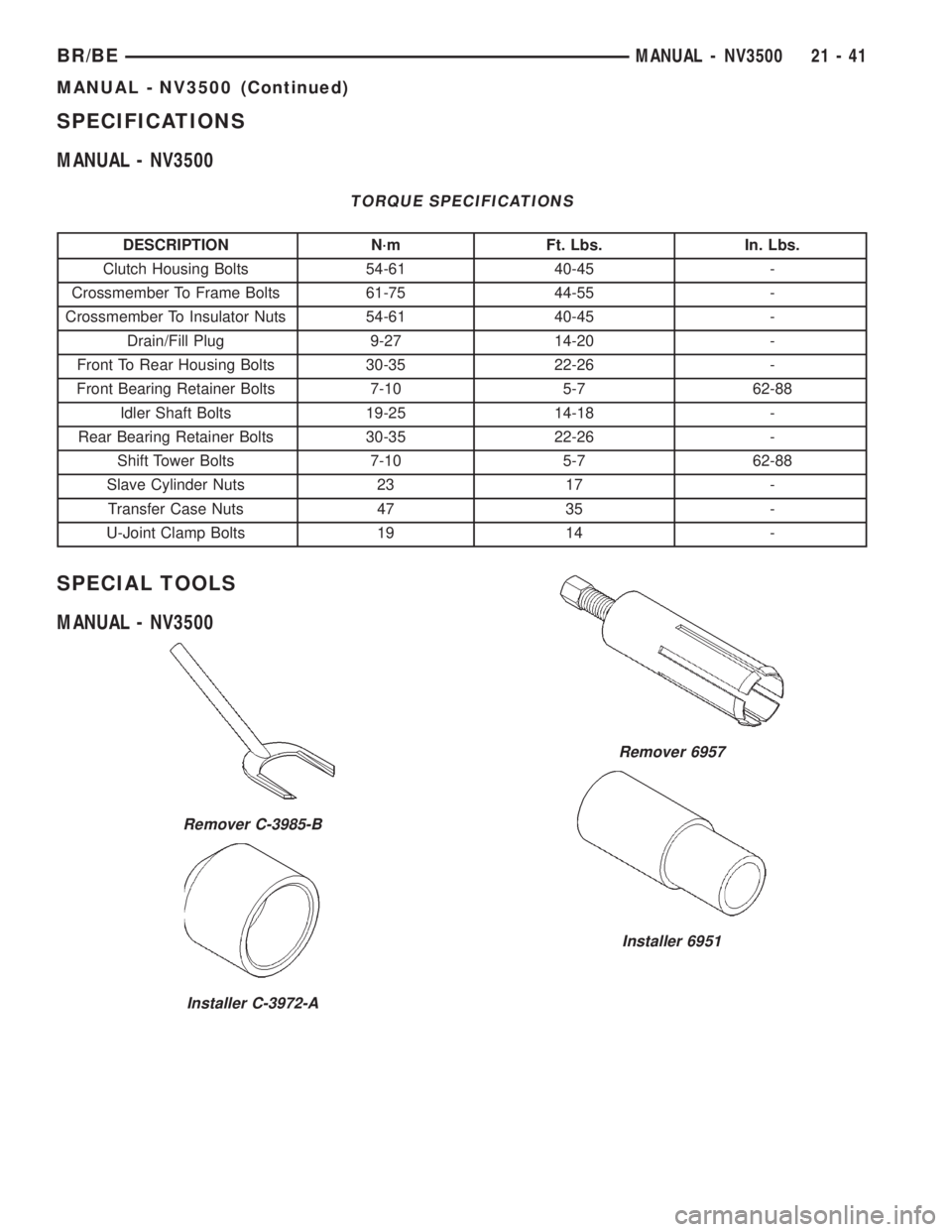

SPECIFICATIONS

MANUAL - NV3500

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Clutch Housing Bolts 54-61 40-45 -

Crossmember To Frame Bolts 61-75 44-55 -

Crossmember To Insulator Nuts 54-61 40-45 -

Drain/Fill Plug 9-27 14-20 -

Front To Rear Housing Bolts 30-35 22-26 -

Front Bearing Retainer Bolts 7-10 5-7 62-88

Idler Shaft Bolts 19-25 14-18 -

Rear Bearing Retainer Bolts 30-35 22-26 -

Shift Tower Bolts 7-10 5-7 62-88

Slave Cylinder Nuts 23 17 -

Transfer Case Nuts 47 35 -

U-Joint Clamp Bolts 19 14 -

SPECIAL TOOLS

MANUAL - NV3500

Remover C-3985-B

Installer C-3972-A

Remover 6957

Installer 6951

BR/BEMANUAL - NV3500 21 - 41

MANUAL - NV3500 (Continued)

Page 1679 of 2889

MANUAL - NV4500

TABLE OF CONTENTS

page page

MANUAL - NV4500

DESCRIPTION...........................44

OPERATION.............................46

DIAGNOSIS AND TESTING.................46

MANUAL TRANSMISSION................46

REMOVAL..............................47

DISASSEMBLY...........................48

CLEANING..............................64

INSPECTION............................64

ASSEMBLY.............................65

INSTALLATION...........................82

SPECIFICATIONS........................83

SPECIAL TOOLS.........................83ADAPTER HOUSING SEAL

REMOVAL..............................87

INSTALLATION...........................87

EXTENSION HOUSING SEAL

REMOVAL..............................87

INSTALLATION...........................87

SHIFT MECHANISM

REMOVAL..............................88

INSTALLATION...........................89

SHIFT COVER

REMOVAL..............................90

INSTALLATION...........................90

MANUAL - NV4500

DESCRIPTION

The NV4500 is a five speed constant mesh manual

transmission (Fig. 1). All gear ranges including

reverse are synchronized. Fifth gear is an overdrive

range. The transmission has a cast iron gear case

and aluminum shift cover.

Two versions are used, a standard duty for 5.9L

applications and a heavy duty for V10 and Cummins

diesel applications. Main differences are the larger

diameter input shaft, output shaft, and mainshaft

fifth gear in the heavy duty model.Tapered roller bearings support the drive gear,

mainshaft and countershaft in the gear case. Roller

bearings in the drive gear support the forward end of

the mainshaft. The mainshaft gears are all supported

on caged type roller bearings. Drive gear thrust reac-

tion is controlled by a needle type thrust bearing.

The bearing is located at the forward end of the

mainshaft.

The transmission is a top loader style. The shift

lever is located in a shifter tower which is bolted to

the shift cover and operates the shift forks and rails

directly. The shift forks and rails are all located

within the aluminum cover which is bolted to the top

of the gear case.

21 - 44 MANUAL - NV4500BR/BE

Page 1682 of 2889

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal.

Lubricant may be seen dripping from the clutch

housing after extended operation. If the leak is

severe, it may also contaminate the clutch disc caus-

ing the disc to slip, grab and or chatter.

A correct lubricant level check can only be made

when the vehicle is level. Also allow the lubricant to

settle for a minute or so before checking. These rec-

ommendations will ensure an accurate check and

avoid an underfill or overfill condition. Always check

the lubricant level after any addition of fluid to avoid

an incorrect lubricant level condition.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants. The con-

sequence of using non-recommended lubricants is

noise, excessive wear, internal bind and hard shift-

ing. Substantial lubricant leaks can result in gear,

shift rail, synchro, and bearing damage. If a leak

goes undetected for an extended period, the first indi-

cations of component damage are usually hard shift-

ing and noise.

Component damage, incorrect clutch adjustment or

damaged clutch pressure plate or disc are additional

probable causes of increased shift effort. Incorrect

adjustment or a worn/damaged pressure plate or disc

can cause incorrect release. If clutch problem is

advanced, gear clash during shifts can result. Worn

or damaged synchro rings can cause gear clash when

shifting into any forward gear. In some new or

rebuilt transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible, but generally only at extreme

speeds.

Severe highly audible transmission noise is gener-

ally the initial indicator of a lubricant problem.

Insufficient, improper or contaminated lubricant will

promote rapid wear of gears, synchros, shift rails,

forks and bearings. The overheating caused by a

lubricant problem, can also lead to gear breakage.

REMOVAL

(1) Disconnect battery negative cable.

(2) Shift transmission into Neutral.

(3) Remove shift boot screws from floorpan and

slide boot upward on the shift lever.

(4) Remove shift lever extension from shift tower

and lever assembly.(5) Remove shift tower bolts holding tower to iso-

lator plate and transmission shift cover.

(6) Remove shift tower and isolator plate from

transmission shift cover.

(7) Raise and support vehicle.

(8) Remove skid plate, if equipped.

(9) Mark propeller shaft and axle yokes for instal-

lation reference and remove shaft/shafts.

(10) Remove exhaust system Y-pipe.

(11) Disconnect speed sensor and backup light

switch connectors.

(12) Support engine with safety stand and a wood

block.

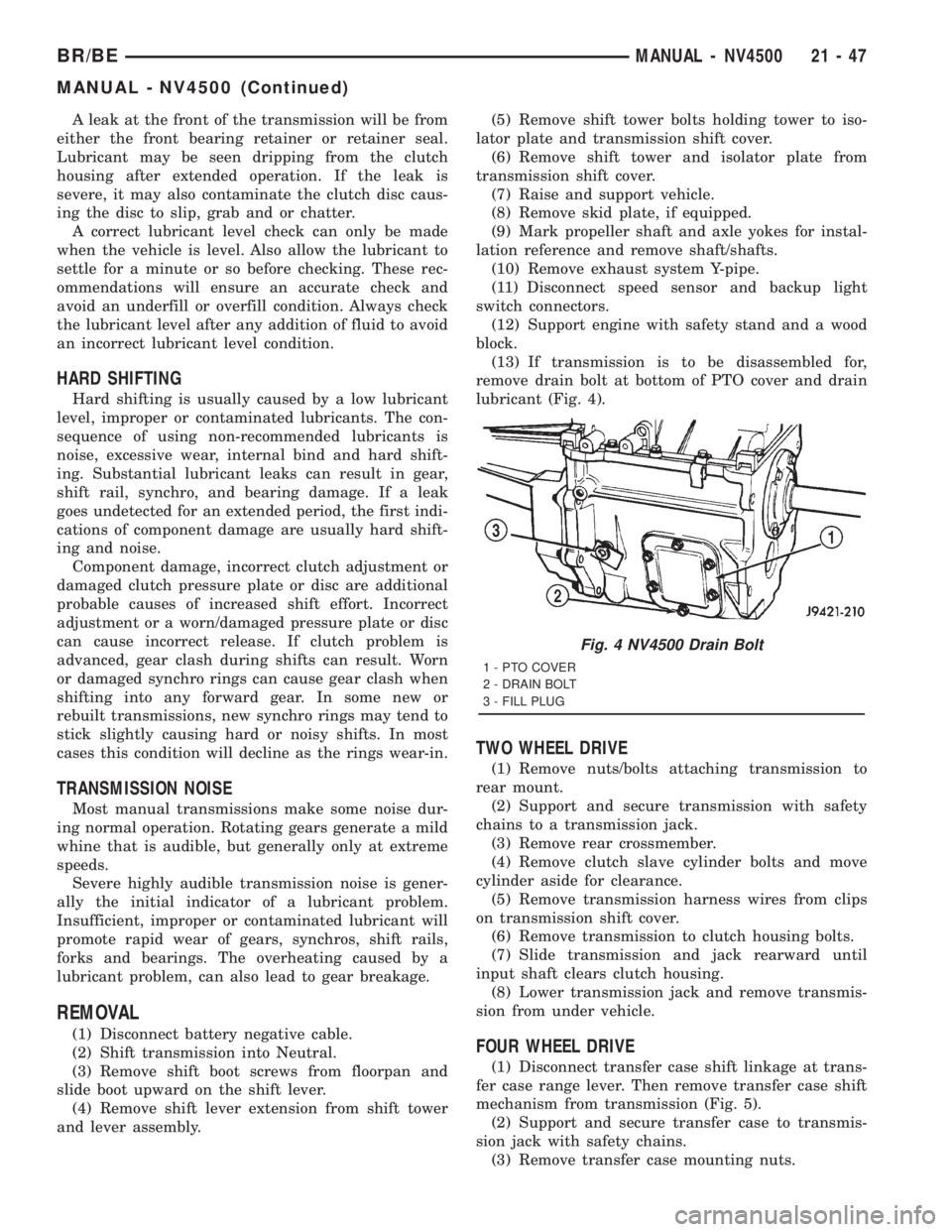

(13) If transmission is to be disassembled for,

remove drain bolt at bottom of PTO cover and drain

lubricant (Fig. 4).

TWO WHEEL DRIVE

(1) Remove nuts/bolts attaching transmission to

rear mount.

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember.

(4) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

(5) Remove transmission harness wires from clips

on transmission shift cover.

(6) Remove transmission to clutch housing bolts.

(7) Slide transmission and jack rearward until

input shaft clears clutch housing.

(8) Lower transmission jack and remove transmis-

sion from under vehicle.

FOUR WHEEL DRIVE

(1) Disconnect transfer case shift linkage at trans-

fer case range lever. Then remove transfer case shift

mechanism from transmission (Fig. 5).

(2) Support and secure transfer case to transmis-

sion jack with safety chains.

(3) Remove transfer case mounting nuts.

Fig. 4 NV4500 Drain Bolt

1 - PTO COVER

2 - DRAIN BOLT

3 - FILL PLUG

BR/BEMANUAL - NV4500 21 - 47

MANUAL - NV4500 (Continued)