DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1651 of 2889

NOTE: The front housing contains the countershaft

front bearing race. The rear housing contains the

countershaft rear bearing race. Be advised that

these components are NOT serviceable items. The

front housing will have to be replaced if the coun-tershaft bearing race is loose, worn, or damaged.

The rear housing will have to be replaced if the

countershaft rear bearing race is loose, worn, or

damaged.

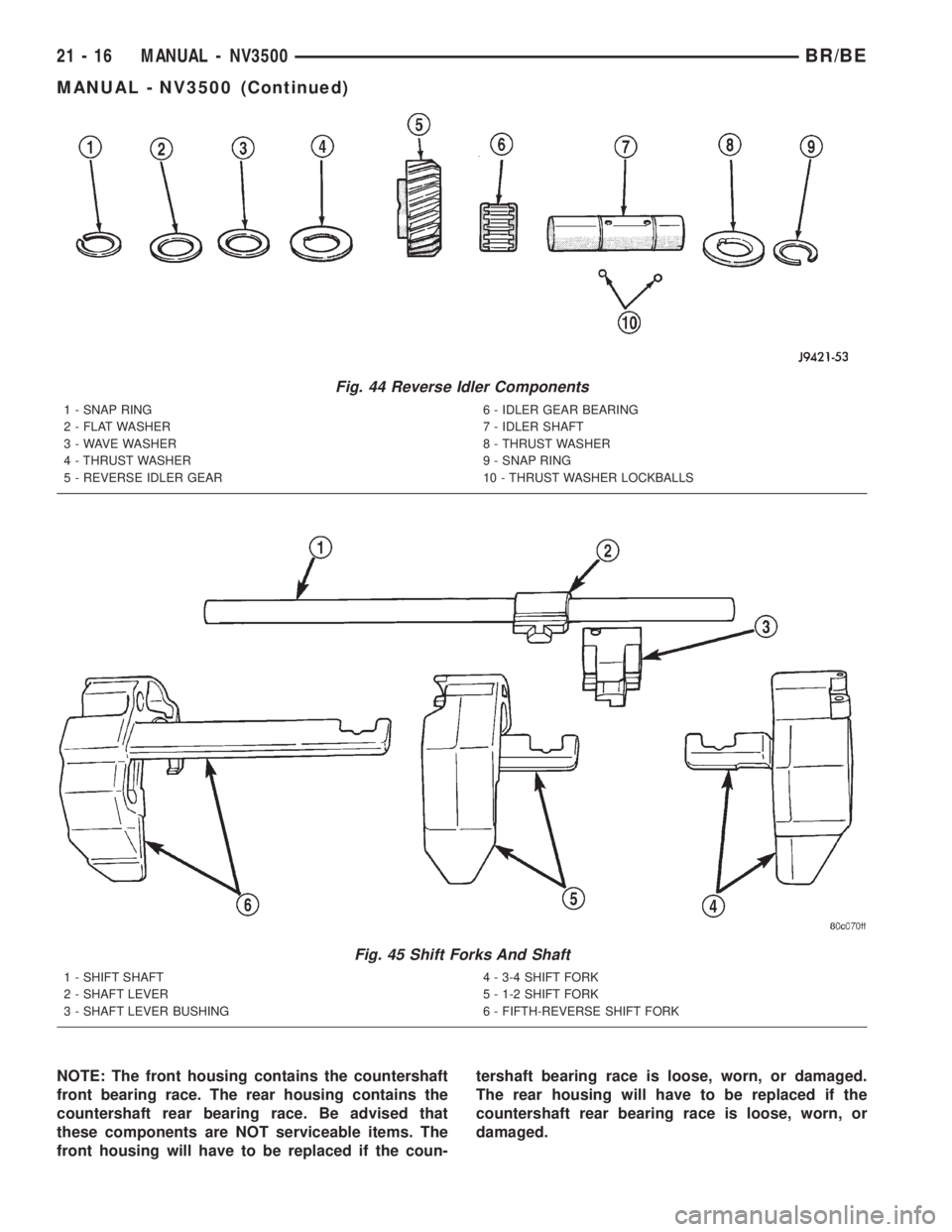

Fig. 44 Reverse Idler Components

1 - SNAP RING

2 - FLAT WASHER

3 - WAVE WASHER

4 - THRUST WASHER

5 - REVERSE IDLER GEAR6 - IDLER GEAR BEARING

7 - IDLER SHAFT

8 - THRUST WASHER

9 - SNAP RING

10 - THRUST WASHER LOCKBALLS

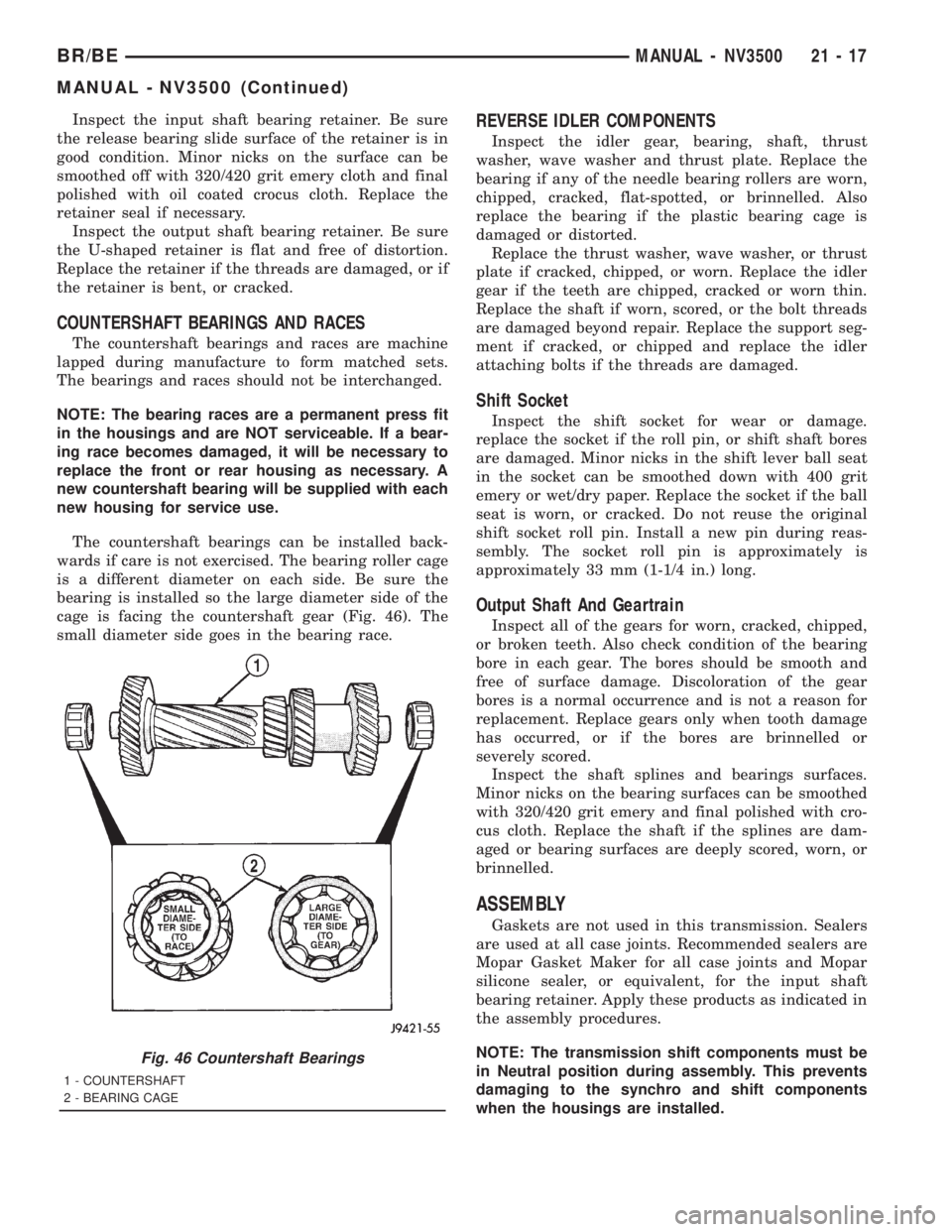

Fig. 45 Shift Forks And Shaft

1 - SHIFT SHAFT

2 - SHAFT LEVER

3 - SHAFT LEVER BUSHING4 - 3-4 SHIFT FORK

5 - 1-2 SHIFT FORK

6 - FIFTH-REVERSE SHIFT FORK

21 - 16 MANUAL - NV3500BR/BE

MANUAL - NV3500 (Continued)

Page 1652 of 2889

Inspect the input shaft bearing retainer. Be sure

the release bearing slide surface of the retainer is in

good condition. Minor nicks on the surface can be

smoothed off with 320/420 grit emery cloth and final

polished with oil coated crocus cloth. Replace the

retainer seal if necessary.

Inspect the output shaft bearing retainer. Be sure

the U-shaped retainer is flat and free of distortion.

Replace the retainer if the threads are damaged, or if

the retainer is bent, or cracked.

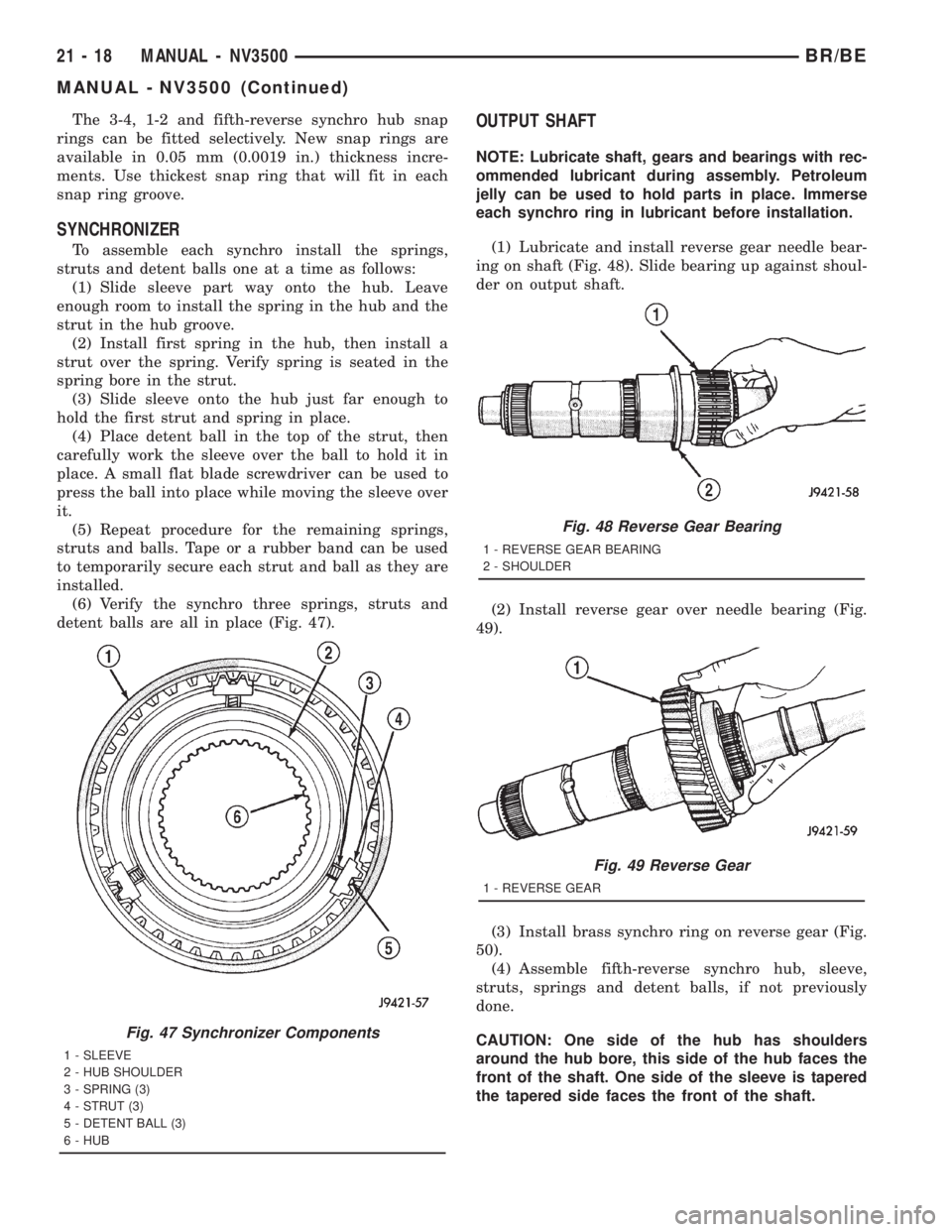

COUNTERSHAFT BEARINGS AND RACES

The countershaft bearings and races are machine

lapped during manufacture to form matched sets.

The bearings and races should not be interchanged.

NOTE: The bearing races are a permanent press fit

in the housings and are NOT serviceable. If a bear-

ing race becomes damaged, it will be necessary to

replace the front or rear housing as necessary. A

new countershaft bearing will be supplied with each

new housing for service use.

The countershaft bearings can be installed back-

wards if care is not exercised. The bearing roller cage

is a different diameter on each side. Be sure the

bearing is installed so the large diameter side of the

cage is facing the countershaft gear (Fig. 46). The

small diameter side goes in the bearing race.

REVERSE IDLER COMPONENTS

Inspect the idler gear, bearing, shaft, thrust

washer, wave washer and thrust plate. Replace the

bearing if any of the needle bearing rollers are worn,

chipped, cracked, flat-spotted, or brinnelled. Also

replace the bearing if the plastic bearing cage is

damaged or distorted.

Replace the thrust washer, wave washer, or thrust

plate if cracked, chipped, or worn. Replace the idler

gear if the teeth are chipped, cracked or worn thin.

Replace the shaft if worn, scored, or the bolt threads

are damaged beyond repair. Replace the support seg-

ment if cracked, or chipped and replace the idler

attaching bolts if the threads are damaged.

Shift Socket

Inspect the shift socket for wear or damage.

replace the socket if the roll pin, or shift shaft bores

are damaged. Minor nicks in the shift lever ball seat

in the socket can be smoothed down with 400 grit

emery or wet/dry paper. Replace the socket if the ball

seat is worn, or cracked. Do not reuse the original

shift socket roll pin. Install a new pin during reas-

sembly. The socket roll pin is approximately is

approximately 33 mm (1-1/4 in.) long.

Output Shaft And Geartrain

Inspect all of the gears for worn, cracked, chipped,

or broken teeth. Also check condition of the bearing

bore in each gear. The bores should be smooth and

free of surface damage. Discoloration of the gear

bores is a normal occurrence and is not a reason for

replacement. Replace gears only when tooth damage

has occurred, or if the bores are brinnelled or

severely scored.

Inspect the shaft splines and bearings surfaces.

Minor nicks on the bearing surfaces can be smoothed

with 320/420 grit emery and final polished with cro-

cus cloth. Replace the shaft if the splines are dam-

aged or bearing surfaces are deeply scored, worn, or

brinnelled.

ASSEMBLY

Gaskets are not used in this transmission. Sealers

are used at all case joints. Recommended sealers are

Mopar Gasket Maker for all case joints and Mopar

silicone sealer, or equivalent, for the input shaft

bearing retainer. Apply these products as indicated in

the assembly procedures.

NOTE: The transmission shift components must be

in Neutral position during assembly. This prevents

damaging to the synchro and shift components

when the housings are installed.

Fig. 46 Countershaft Bearings

1 - COUNTERSHAFT

2 - BEARING CAGE

BR/BEMANUAL - NV3500 21 - 17

MANUAL - NV3500 (Continued)

Page 1653 of 2889

The 3-4, 1-2 and fifth-reverse synchro hub snap

rings can be fitted selectively. New snap rings are

available in 0.05 mm (0.0019 in.) thickness incre-

ments. Use thickest snap ring that will fit in each

snap ring groove.

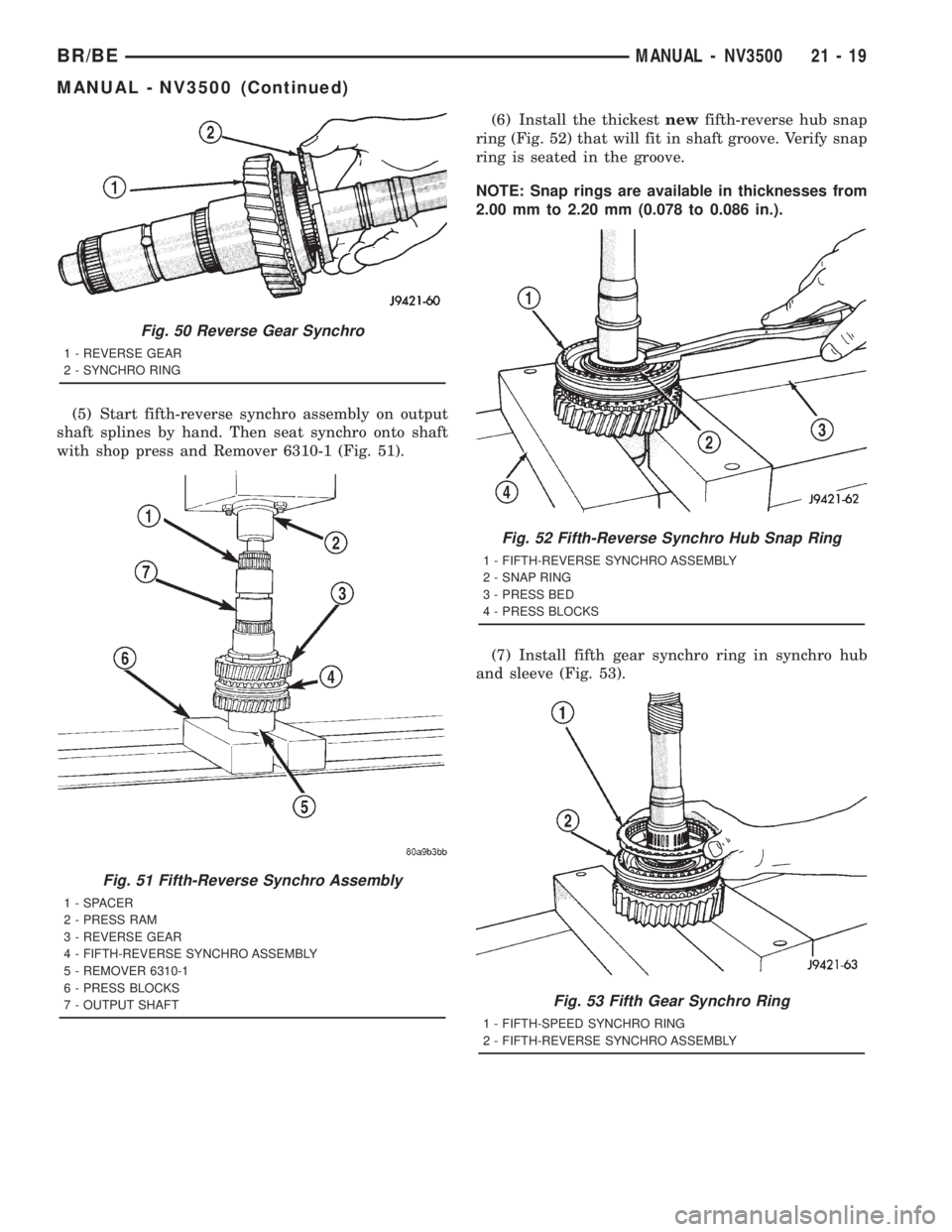

SYNCHRONIZER

To assemble each synchro install the springs,

struts and detent balls one at a time as follows:

(1) Slide sleeve part way onto the hub. Leave

enough room to install the spring in the hub and the

strut in the hub groove.

(2) Install first spring in the hub, then install a

strut over the spring. Verify spring is seated in the

spring bore in the strut.

(3) Slide sleeve onto the hub just far enough to

hold the first strut and spring in place.

(4) Place detent ball in the top of the strut, then

carefully work the sleeve over the ball to hold it in

place. A small flat blade screwdriver can be used to

press the ball into place while moving the sleeve over

it.

(5) Repeat procedure for the remaining springs,

struts and balls. Tape or a rubber band can be used

to temporarily secure each strut and ball as they are

installed.

(6) Verify the synchro three springs, struts and

detent balls are all in place (Fig. 47).

OUTPUT SHAFT

NOTE: Lubricate shaft, gears and bearings with rec-

ommended lubricant during assembly. Petroleum

jelly can be used to hold parts in place. Immerse

each synchro ring in lubricant before installation.

(1) Lubricate and install reverse gear needle bear-

ing on shaft (Fig. 48). Slide bearing up against shoul-

der on output shaft.

(2) Install reverse gear over needle bearing (Fig.

49).

(3) Install brass synchro ring on reverse gear (Fig.

50).

(4) Assemble fifth-reverse synchro hub, sleeve,

struts, springs and detent balls, if not previously

done.

CAUTION: One side of the hub has shoulders

around the hub bore, this side of the hub faces the

front of the shaft. One side of the sleeve is tapered

the tapered side faces the front of the shaft.

Fig. 47 Synchronizer Components

1 - SLEEVE

2 - HUB SHOULDER

3 - SPRING (3)

4 - STRUT (3)

5 - DETENT BALL (3)

6 - HUB

Fig. 48 Reverse Gear Bearing

1 - REVERSE GEAR BEARING

2 - SHOULDER

Fig. 49 Reverse Gear

1 - REVERSE GEAR

21 - 18 MANUAL - NV3500BR/BE

MANUAL - NV3500 (Continued)

Page 1654 of 2889

(5) Start fifth-reverse synchro assembly on output

shaft splines by hand. Then seat synchro onto shaft

with shop press and Remover 6310-1 (Fig. 51).(6) Install the thickestnewfifth-reverse hub snap

ring (Fig. 52) that will fit in shaft groove. Verify snap

ring is seated in the groove.

NOTE: Snap rings are available in thicknesses from

2.00 mm to 2.20 mm (0.078 to 0.086 in.).

(7) Install fifth gear synchro ring in synchro hub

and sleeve (Fig. 53).

Fig. 50 Reverse Gear Synchro

1 - REVERSE GEAR

2 - SYNCHRO RING

Fig. 51 Fifth-Reverse Synchro Assembly

1 - SPACER

2 - PRESS RAM

3 - REVERSE GEAR

4 - FIFTH-REVERSE SYNCHRO ASSEMBLY

5 - REMOVER 6310-1

6 - PRESS BLOCKS

7 - OUTPUT SHAFT

Fig. 52 Fifth-Reverse Synchro Hub Snap Ring

1 - FIFTH-REVERSE SYNCHRO ASSEMBLY

2 - SNAP RING

3 - PRESS BED

4 - PRESS BLOCKS

Fig. 53 Fifth Gear Synchro Ring

1 - FIFTH-SPEED SYNCHRO RING

2 - FIFTH-REVERSE SYNCHRO ASSEMBLY

BR/BEMANUAL - NV3500 21 - 19

MANUAL - NV3500 (Continued)

Page 1655 of 2889

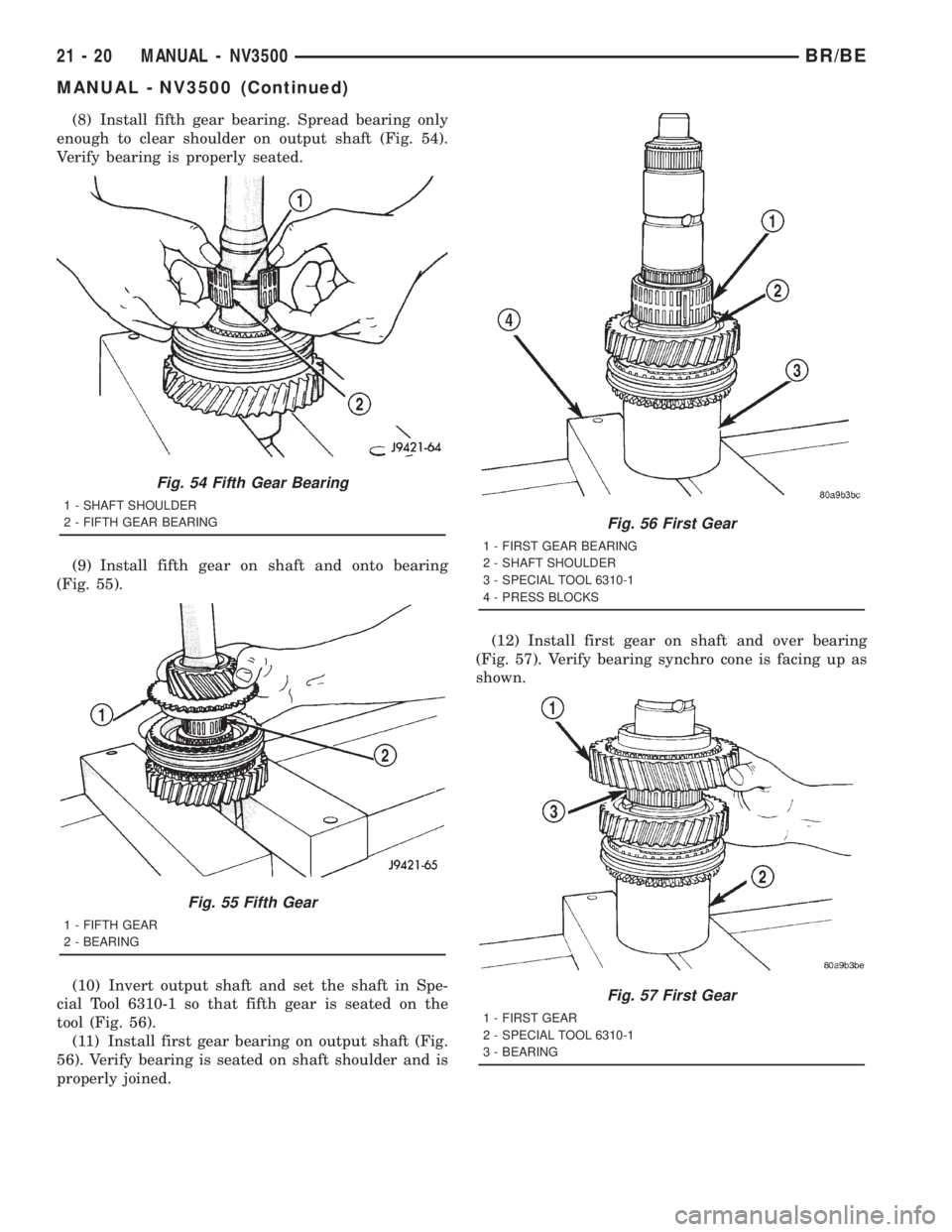

(8) Install fifth gear bearing. Spread bearing only

enough to clear shoulder on output shaft (Fig. 54).

Verify bearing is properly seated.

(9) Install fifth gear on shaft and onto bearing

(Fig. 55).

(10) Invert output shaft and set the shaft in Spe-

cial Tool 6310-1 so that fifth gear is seated on the

tool (Fig. 56).

(11) Install first gear bearing on output shaft (Fig.

56). Verify bearing is seated on shaft shoulder and is

properly joined.(12) Install first gear on shaft and over bearing

(Fig. 57). Verify bearing synchro cone is facing up as

shown.

Fig. 54 Fifth Gear Bearing

1 - SHAFT SHOULDER

2 - FIFTH GEAR BEARING

Fig. 55 Fifth Gear

1 - FIFTH GEAR

2 - BEARING

Fig. 56 First Gear

1 - FIRST GEAR BEARING

2 - SHAFT SHOULDER

3 - SPECIAL TOOL 6310-1

4 - PRESS BLOCKS

Fig. 57 First Gear

1 - FIRST GEAR

2 - SPECIAL TOOL 6310-1

3 - BEARING

21 - 20 MANUAL - NV3500BR/BE

MANUAL - NV3500 (Continued)

Page 1656 of 2889

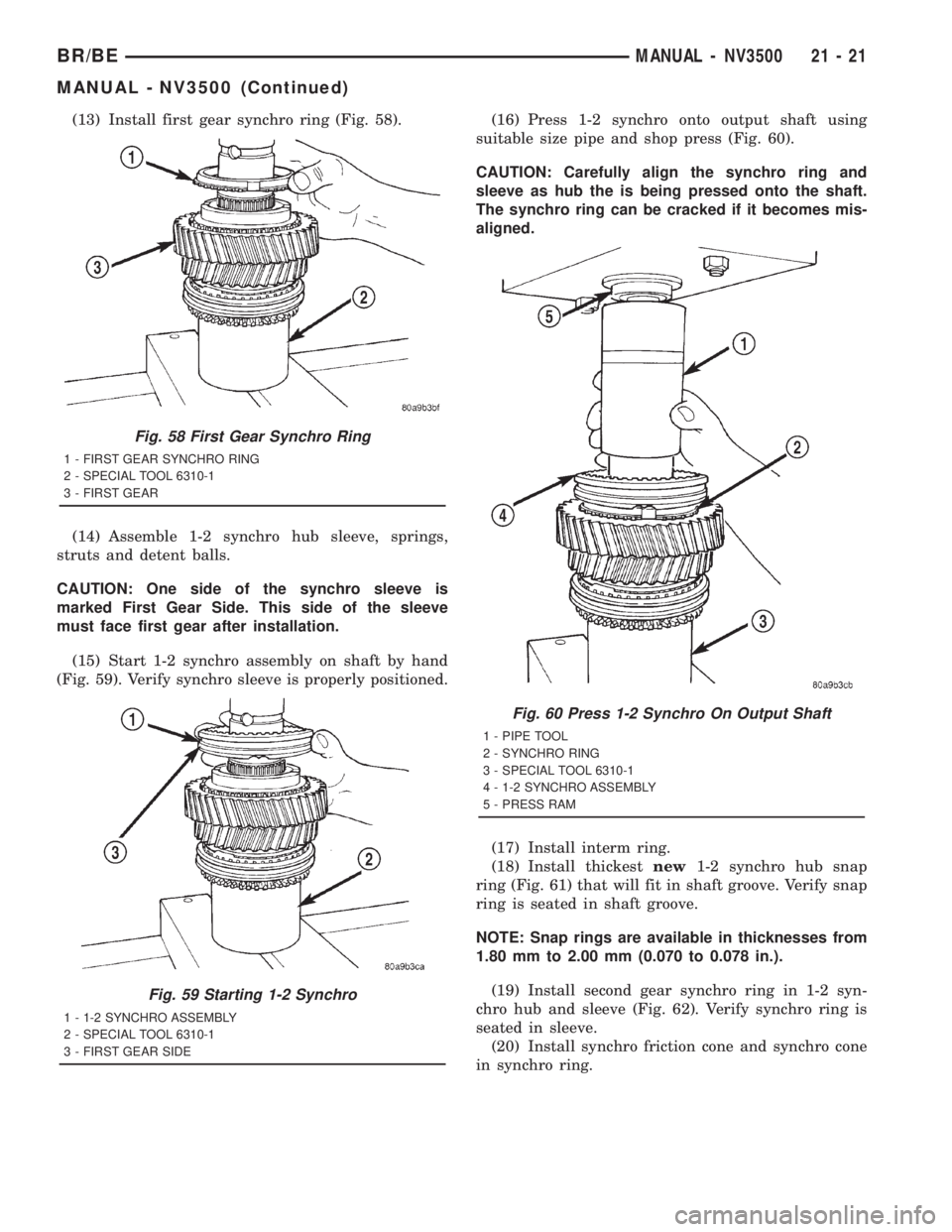

(13) Install first gear synchro ring (Fig. 58).

(14) Assemble 1-2 synchro hub sleeve, springs,

struts and detent balls.

CAUTION: One side of the synchro sleeve is

marked First Gear Side. This side of the sleeve

must face first gear after installation.

(15) Start 1-2 synchro assembly on shaft by hand

(Fig. 59). Verify synchro sleeve is properly positioned.(16) Press 1-2 synchro onto output shaft using

suitable size pipe and shop press (Fig. 60).

CAUTION: Carefully align the synchro ring and

sleeve as hub the is being pressed onto the shaft.

The synchro ring can be cracked if it becomes mis-

aligned.

(17) Install interm ring.

(18) Install thickestnew1-2 synchro hub snap

ring (Fig. 61) that will fit in shaft groove. Verify snap

ring is seated in shaft groove.

NOTE: Snap rings are available in thicknesses from

1.80 mm to 2.00 mm (0.070 to 0.078 in.).

(19) Install second gear synchro ring in 1-2 syn-

chro hub and sleeve (Fig. 62). Verify synchro ring is

seated in sleeve.

(20) Install synchro friction cone and synchro cone

in synchro ring.

Fig. 58 First Gear Synchro Ring

1 - FIRST GEAR SYNCHRO RING

2 - SPECIAL TOOL 6310-1

3 - FIRST GEAR

Fig. 59 Starting 1-2 Synchro

1 - 1-2 SYNCHRO ASSEMBLY

2 - SPECIAL TOOL 6310-1

3 - FIRST GEAR SIDE

Fig. 60 Press 1-2 Synchro On Output Shaft

1 - PIPE TOOL

2 - SYNCHRO RING

3 - SPECIAL TOOL 6310-1

4 - 1-2 SYNCHRO ASSEMBLY

5 - PRESS RAM

BR/BEMANUAL - NV3500 21 - 21

MANUAL - NV3500 (Continued)

Page 1657 of 2889

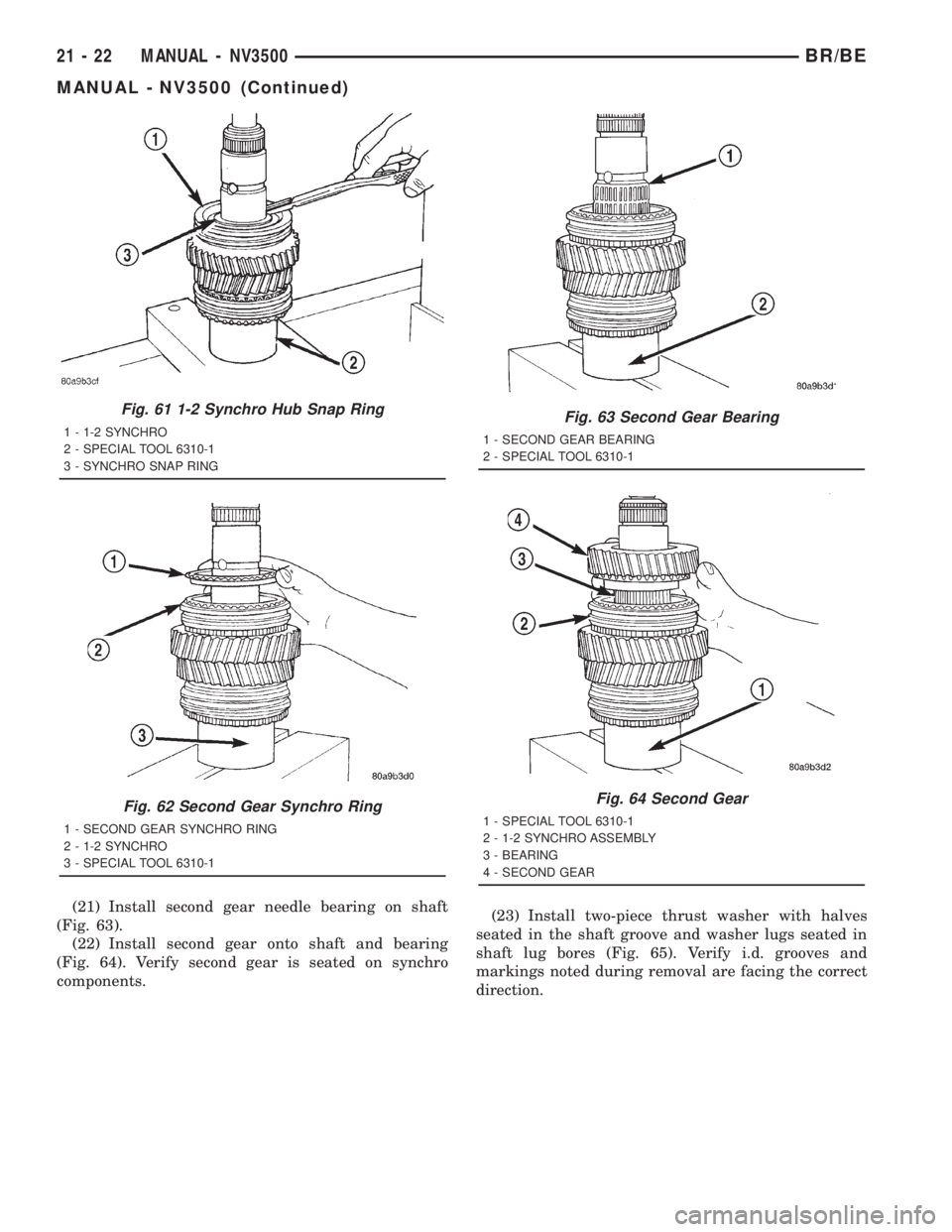

(21) Install second gear needle bearing on shaft

(Fig. 63).

(22) Install second gear onto shaft and bearing

(Fig. 64). Verify second gear is seated on synchro

components.(23) Install two-piece thrust washer with halves

seated in the shaft groove and washer lugs seated in

shaft lug bores (Fig. 65). Verify i.d. grooves and

markings noted during removal are facing the correct

direction.

Fig. 61 1-2 Synchro Hub Snap Ring

1 - 1-2 SYNCHRO

2 - SPECIAL TOOL 6310-1

3 - SYNCHRO SNAP RING

Fig. 62 Second Gear Synchro Ring

1 - SECOND GEAR SYNCHRO RING

2 - 1-2 SYNCHRO

3 - SPECIAL TOOL 6310-1

Fig. 63 Second Gear Bearing

1 - SECOND GEAR BEARING

2 - SPECIAL TOOL 6310-1

Fig. 64 Second Gear

1 - SPECIAL TOOL 6310-1

2 - 1-2 SYNCHRO ASSEMBLY

3 - BEARING

4 - SECOND GEAR

21 - 22 MANUAL - NV3500BR/BE

MANUAL - NV3500 (Continued)

Page 1658 of 2889

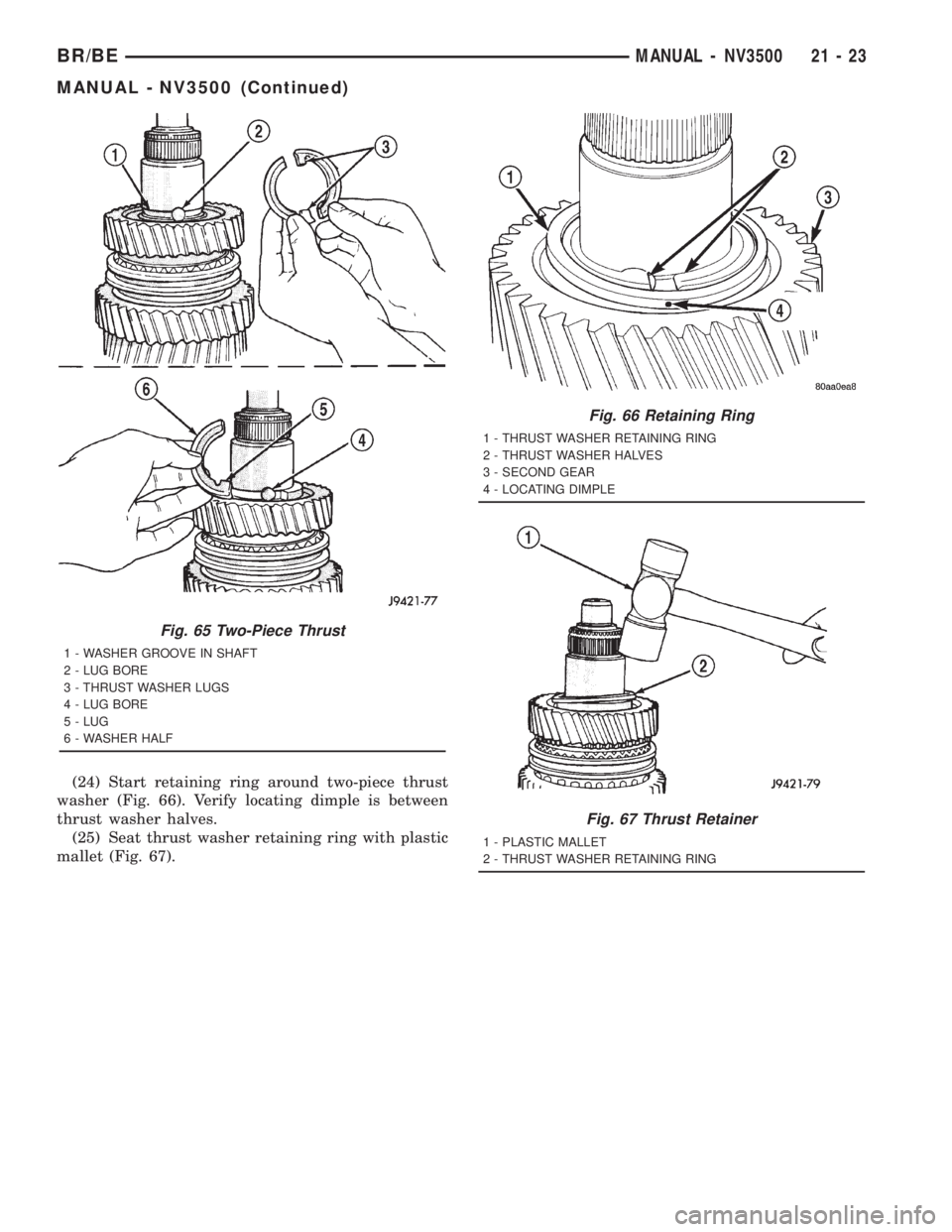

(24) Start retaining ring around two-piece thrust

washer (Fig. 66). Verify locating dimple is between

thrust washer halves.

(25) Seat thrust washer retaining ring with plastic

mallet (Fig. 67).

Fig. 65 Two-Piece Thrust

1 - WASHER GROOVE IN SHAFT

2 - LUG BORE

3 - THRUST WASHER LUGS

4 - LUG BORE

5 - LUG

6 - WASHER HALF

Fig. 66 Retaining Ring

1 - THRUST WASHER RETAINING RING

2 - THRUST WASHER HALVES

3 - SECOND GEAR

4 - LOCATING DIMPLE

Fig. 67 Thrust Retainer

1 - PLASTIC MALLET

2 - THRUST WASHER RETAINING RING

BR/BEMANUAL - NV3500 21 - 23

MANUAL - NV3500 (Continued)

Page 1659 of 2889

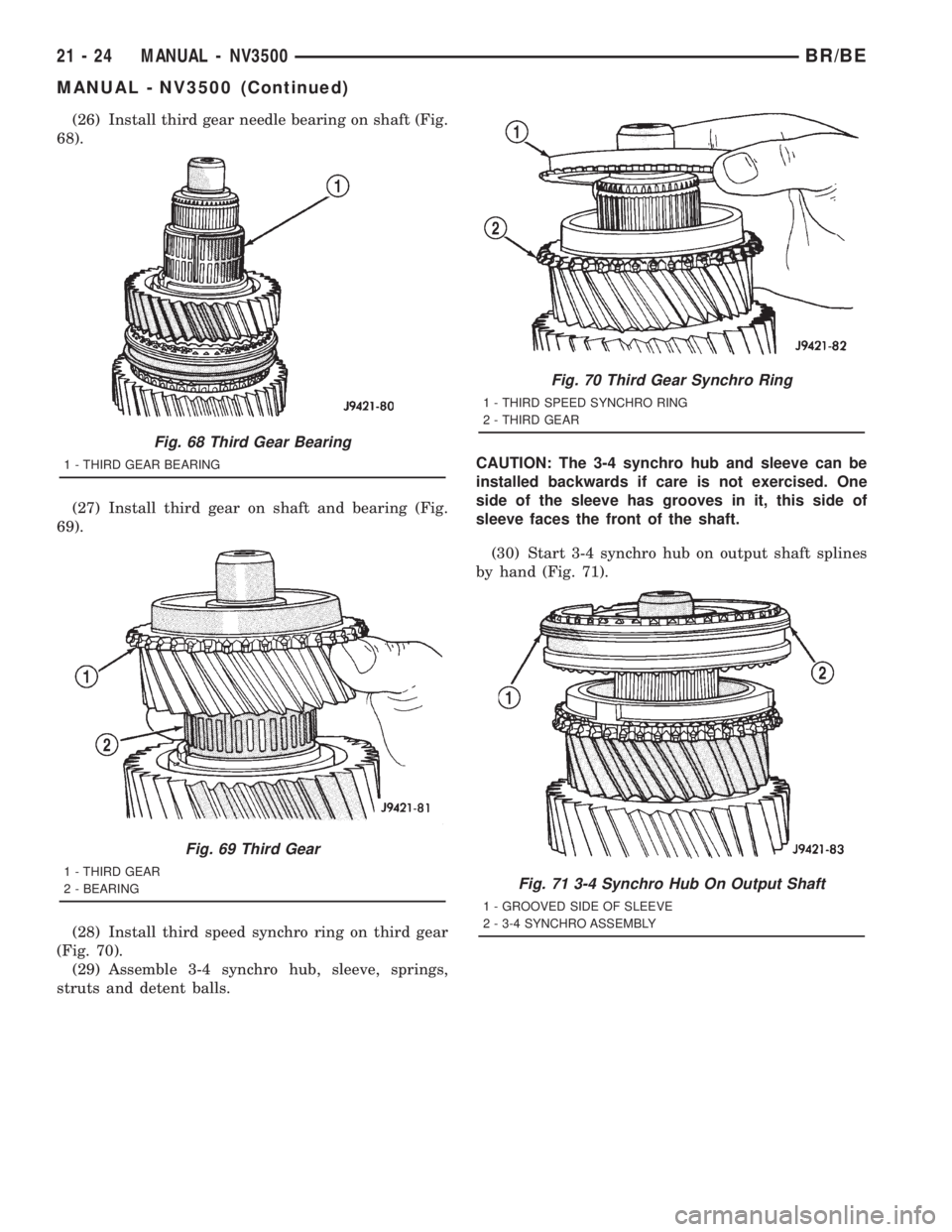

(26) Install third gear needle bearing on shaft (Fig.

68).

(27) Install third gear on shaft and bearing (Fig.

69).

(28) Install third speed synchro ring on third gear

(Fig. 70).

(29) Assemble 3-4 synchro hub, sleeve, springs,

struts and detent balls.CAUTION: The 3-4 synchro hub and sleeve can be

installed backwards if care is not exercised. One

side of the sleeve has grooves in it, this side of

sleeve faces the front of the shaft.

(30) Start 3-4 synchro hub on output shaft splines

by hand (Fig. 71).

Fig. 68 Third Gear Bearing

1 - THIRD GEAR BEARING

Fig. 69 Third Gear

1 - THIRD GEAR

2 - BEARING

Fig. 70 Third Gear Synchro Ring

1 - THIRD SPEED SYNCHRO RING

2 - THIRD GEAR

Fig. 71 3-4 Synchro Hub On Output Shaft

1 - GROOVED SIDE OF SLEEVE

2 - 3-4 SYNCHRO ASSEMBLY

21 - 24 MANUAL - NV3500BR/BE

MANUAL - NV3500 (Continued)

Page 1660 of 2889

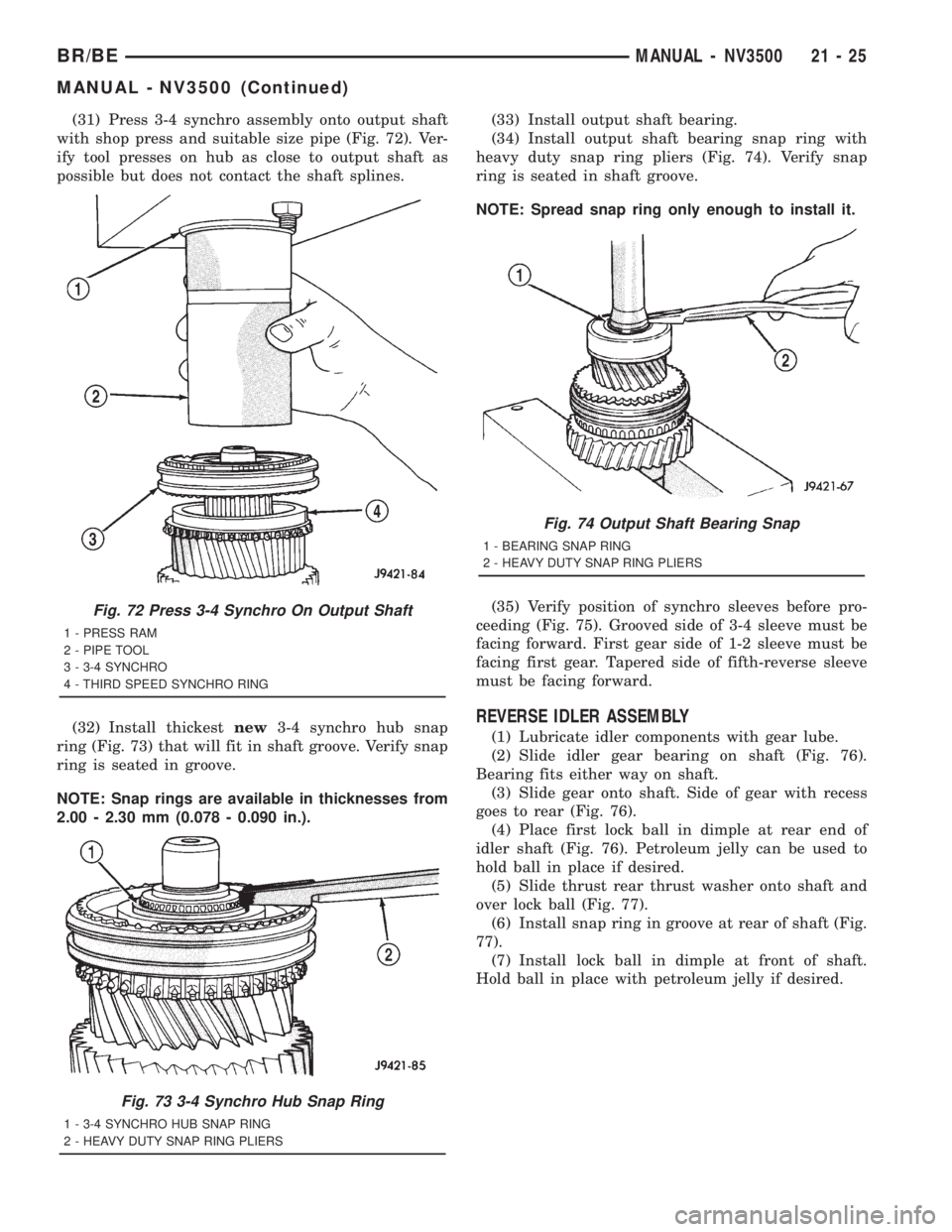

(31) Press 3-4 synchro assembly onto output shaft

with shop press and suitable size pipe (Fig. 72). Ver-

ify tool presses on hub as close to output shaft as

possible but does not contact the shaft splines.

(32) Install thickestnew3-4 synchro hub snap

ring (Fig. 73) that will fit in shaft groove. Verify snap

ring is seated in groove.

NOTE: Snap rings are available in thicknesses from

2.00 - 2.30 mm (0.078 - 0.090 in.).(33) Install output shaft bearing.

(34) Install output shaft bearing snap ring with

heavy duty snap ring pliers (Fig. 74). Verify snap

ring is seated in shaft groove.

NOTE: Spread snap ring only enough to install it.

(35) Verify position of synchro sleeves before pro-

ceeding (Fig. 75). Grooved side of 3-4 sleeve must be

facing forward. First gear side of 1-2 sleeve must be

facing first gear. Tapered side of fifth-reverse sleeve

must be facing forward.

REVERSE IDLER ASSEMBLY

(1) Lubricate idler components with gear lube.

(2) Slide idler gear bearing on shaft (Fig. 76).

Bearing fits either way on shaft.

(3) Slide gear onto shaft. Side of gear with recess

goes to rear (Fig. 76).

(4) Place first lock ball in dimple at rear end of

idler shaft (Fig. 76). Petroleum jelly can be used to

hold ball in place if desired.

(5) Slide thrust rear thrust washer onto shaft and

over lock ball (Fig. 77).

(6) Install snap ring in groove at rear of shaft (Fig.

77).

(7) Install lock ball in dimple at front of shaft.

Hold ball in place with petroleum jelly if desired.

Fig. 72 Press 3-4 Synchro On Output Shaft

1 - PRESS RAM

2 - PIPE TOOL

3 - 3-4 SYNCHRO

4 - THIRD SPEED SYNCHRO RING

Fig. 73 3-4 Synchro Hub Snap Ring

1 - 3-4 SYNCHRO HUB SNAP RING

2 - HEAVY DUTY SNAP RING PLIERS

Fig. 74 Output Shaft Bearing Snap

1 - BEARING SNAP RING

2 - HEAVY DUTY SNAP RING PLIERS

BR/BEMANUAL - NV3500 21 - 25

MANUAL - NV3500 (Continued)