DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1691 of 2889

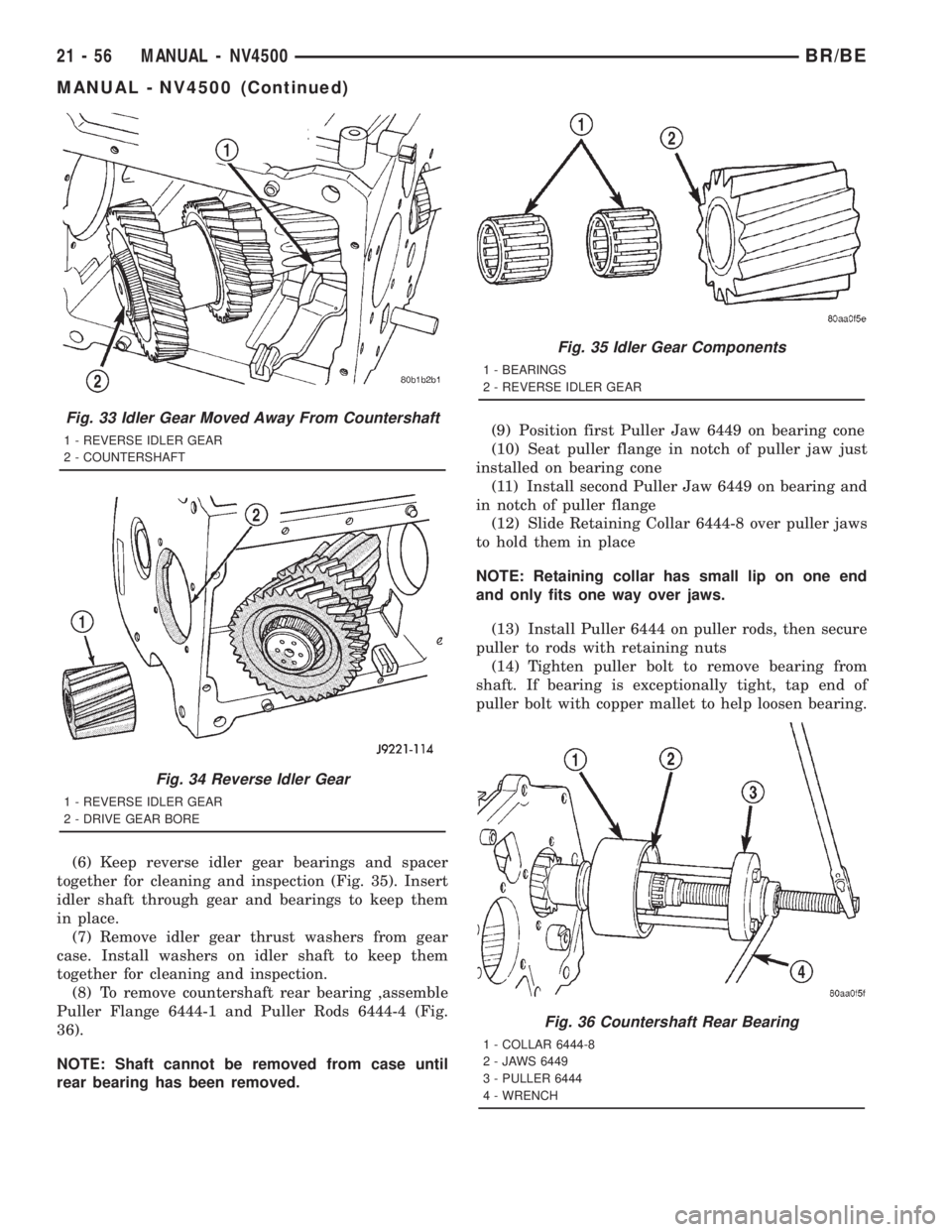

(6) Keep reverse idler gear bearings and spacer

together for cleaning and inspection (Fig. 35). Insert

idler shaft through gear and bearings to keep them

in place.

(7) Remove idler gear thrust washers from gear

case. Install washers on idler shaft to keep them

together for cleaning and inspection.

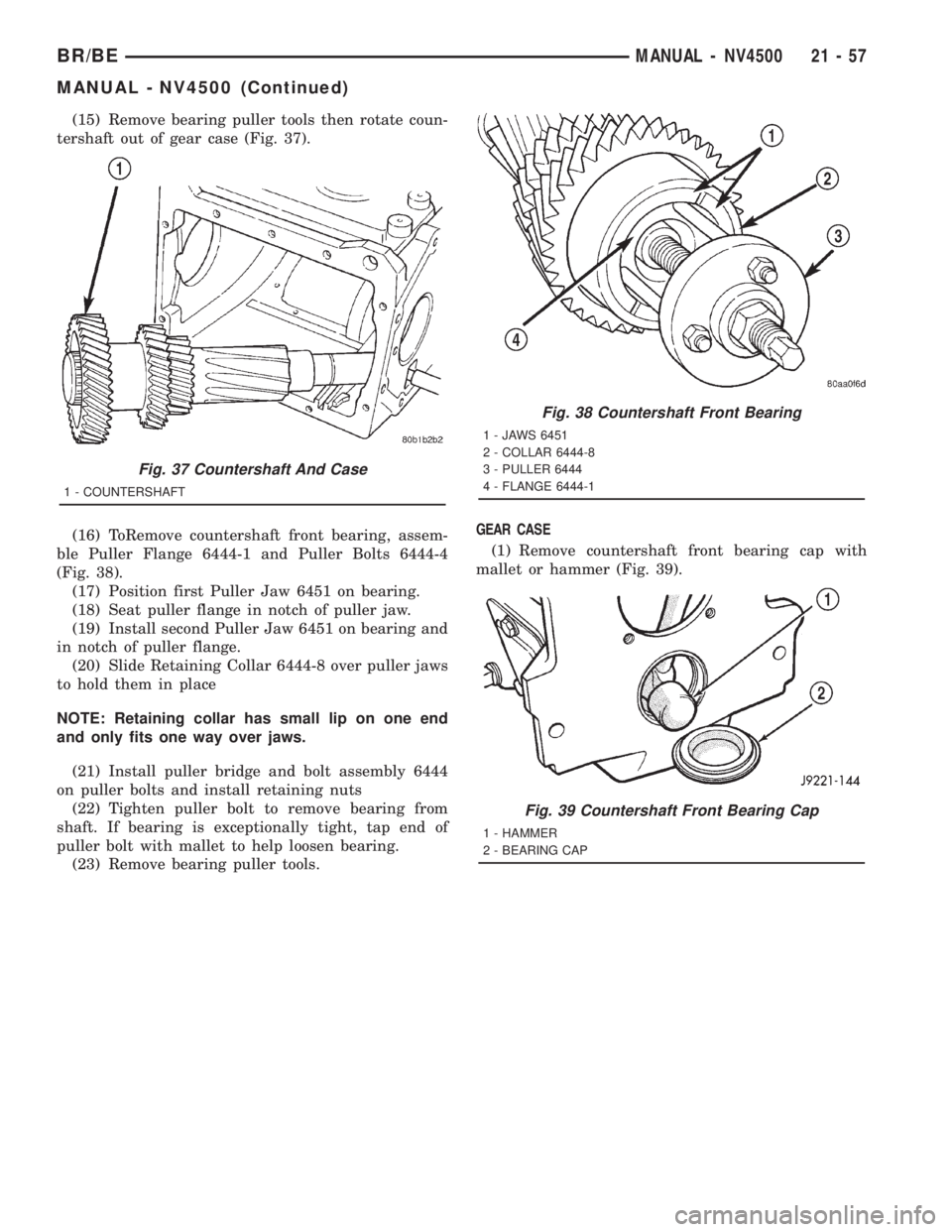

(8) To remove countershaft rear bearing ,assemble

Puller Flange 6444-1 and Puller Rods 6444-4 (Fig.

36).

NOTE: Shaft cannot be removed from case until

rear bearing has been removed.(9) Position first Puller Jaw 6449 on bearing cone

(10) Seat puller flange in notch of puller jaw just

installed on bearing cone

(11) Install second Puller Jaw 6449 on bearing and

in notch of puller flange

(12) Slide Retaining Collar 6444-8 over puller jaws

to hold them in place

NOTE: Retaining collar has small lip on one end

and only fits one way over jaws.

(13) Install Puller 6444 on puller rods, then secure

puller to rods with retaining nuts

(14) Tighten puller bolt to remove bearing from

shaft. If bearing is exceptionally tight, tap end of

puller bolt with copper mallet to help loosen bearing.

Fig. 33 Idler Gear Moved Away From Countershaft

1 - REVERSE IDLER GEAR

2 - COUNTERSHAFT

Fig. 34 Reverse Idler Gear

1 - REVERSE IDLER GEAR

2 - DRIVE GEAR BORE

Fig. 35 Idler Gear Components

1 - BEARINGS

2 - REVERSE IDLER GEAR

Fig. 36 Countershaft Rear Bearing

1 - COLLAR 6444-8

2 - JAWS 6449

3 - PULLER 6444

4 - WRENCH

21 - 56 MANUAL - NV4500BR/BE

MANUAL - NV4500 (Continued)

Page 1692 of 2889

(15) Remove bearing puller tools then rotate coun-

tershaft out of gear case (Fig. 37).

(16) ToRemove countershaft front bearing, assem-

ble Puller Flange 6444-1 and Puller Bolts 6444-4

(Fig. 38).

(17) Position first Puller Jaw 6451 on bearing.

(18) Seat puller flange in notch of puller jaw.

(19) Install second Puller Jaw 6451 on bearing and

in notch of puller flange.

(20) Slide Retaining Collar 6444-8 over puller jaws

to hold them in place

NOTE: Retaining collar has small lip on one end

and only fits one way over jaws.

(21) Install puller bridge and bolt assembly 6444

on puller bolts and install retaining nuts

(22) Tighten puller bolt to remove bearing from

shaft. If bearing is exceptionally tight, tap end of

puller bolt with mallet to help loosen bearing.

(23) Remove bearing puller tools.GEAR CASE

(1) Remove countershaft front bearing cap with

mallet or hammer (Fig. 39).

Fig. 37 Countershaft And Case

1 - COUNTERSHAFT

Fig. 38 Countershaft Front Bearing

1 - JAWS 6451

2 - COLLAR 6444-8

3 - PULLER 6444

4 - FLANGE 6444-1

Fig. 39 Countershaft Front Bearing Cap

1 - HAMMER

2 - BEARING CAP

BR/BEMANUAL - NV4500 21 - 57

MANUAL - NV4500 (Continued)

Page 1693 of 2889

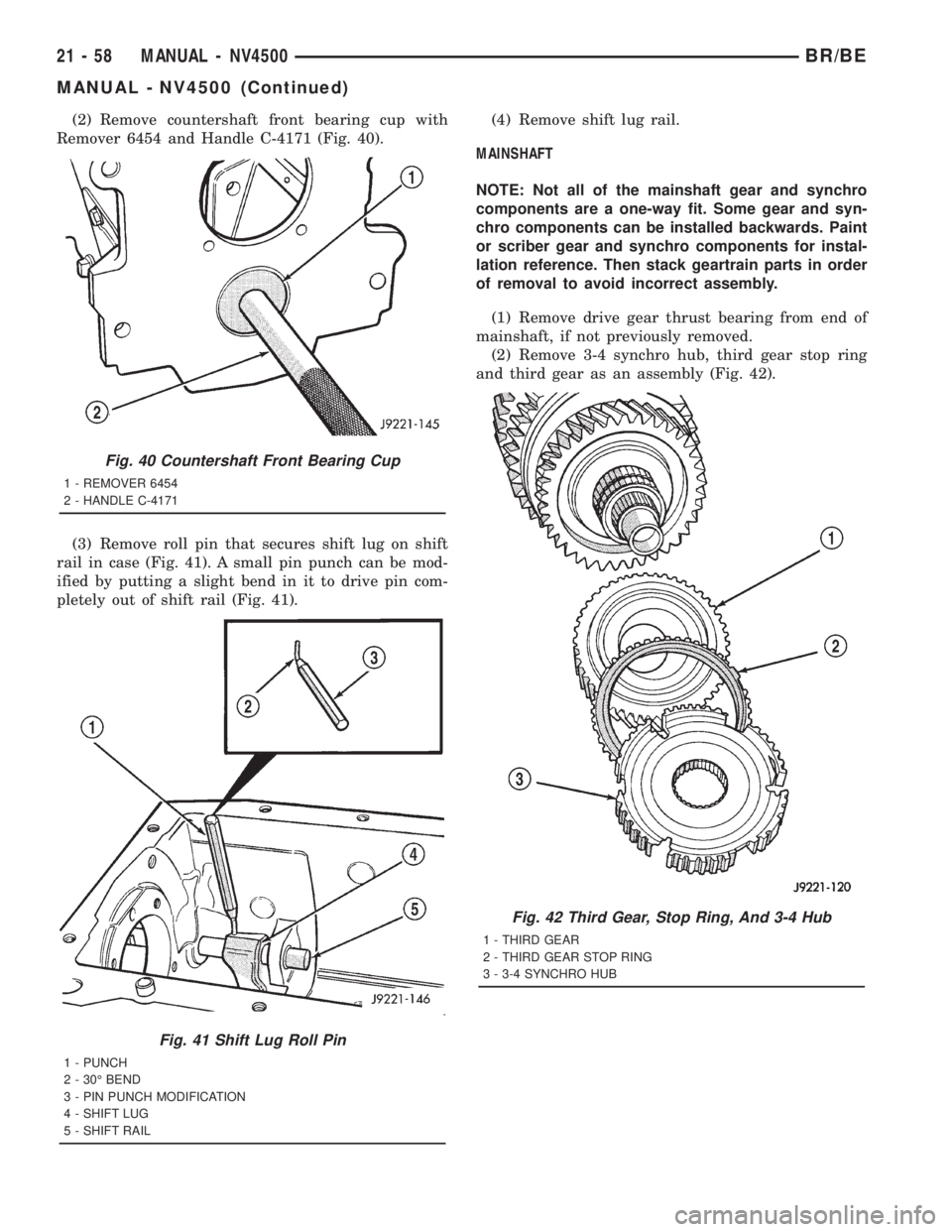

(2) Remove countershaft front bearing cup with

Remover 6454 and Handle C-4171 (Fig. 40).

(3) Remove roll pin that secures shift lug on shift

rail in case (Fig. 41). A small pin punch can be mod-

ified by putting a slight bend in it to drive pin com-

pletely out of shift rail (Fig. 41).(4) Remove shift lug rail.

MAINSHAFT

NOTE: Not all of the mainshaft gear and synchro

components are a one-way fit. Some gear and syn-

chro components can be installed backwards. Paint

or scriber gear and synchro components for instal-

lation reference. Then stack geartrain parts in order

of removal to avoid incorrect assembly.

(1) Remove drive gear thrust bearing from end of

mainshaft, if not previously removed.

(2) Remove 3-4 synchro hub, third gear stop ring

and third gear as an assembly (Fig. 42).

Fig. 40 Countershaft Front Bearing Cup

1 - REMOVER 6454

2 - HANDLE C-4171

Fig. 41 Shift Lug Roll Pin

1 - PUNCH

2 - 30É BEND

3 - PIN PUNCH MODIFICATION

4 - SHIFT LUG

5 - SHIFT RAIL

Fig. 42 Third Gear, Stop Ring, And 3-4 Hub

1 - THIRD GEAR

2 - THIRD GEAR STOP RING

3 - 3-4 SYNCHRO HUB

21 - 58 MANUAL - NV4500BR/BE

MANUAL - NV4500 (Continued)

Page 1694 of 2889

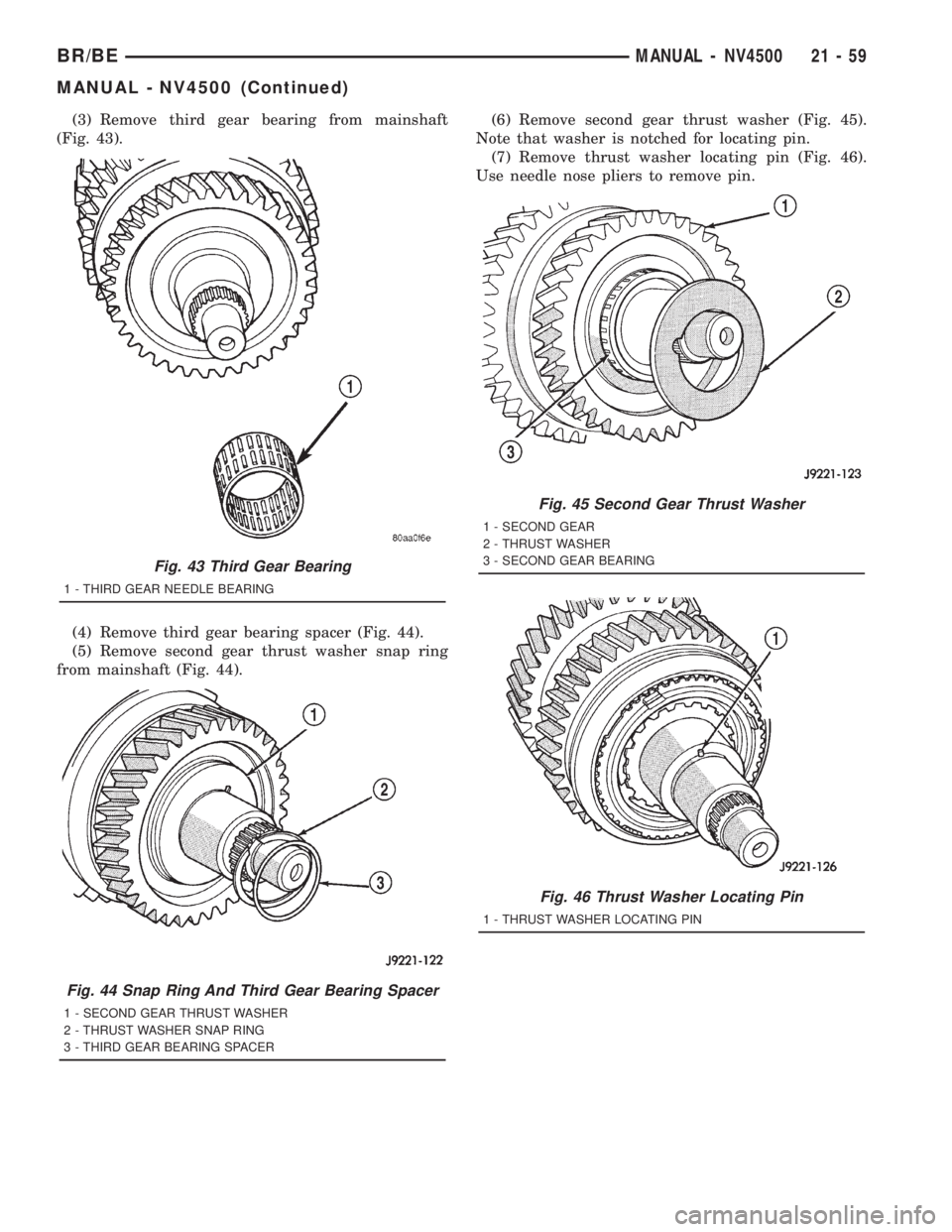

(3) Remove third gear bearing from mainshaft

(Fig. 43).

(4) Remove third gear bearing spacer (Fig. 44).

(5) Remove second gear thrust washer snap ring

from mainshaft (Fig. 44).(6) Remove second gear thrust washer (Fig. 45).

Note that washer is notched for locating pin.

(7) Remove thrust washer locating pin (Fig. 46).

Use needle nose pliers to remove pin.

Fig. 43 Third Gear Bearing

1 - THIRD GEAR NEEDLE BEARING

Fig. 44 Snap Ring And Third Gear Bearing Spacer

1 - SECOND GEAR THRUST WASHER

2 - THRUST WASHER SNAP RING

3 - THIRD GEAR BEARING SPACER

Fig. 45 Second Gear Thrust Washer

1 - SECOND GEAR

2 - THRUST WASHER

3 - SECOND GEAR BEARING

Fig. 46 Thrust Washer Locating Pin

1 - THRUST WASHER LOCATING PIN

BR/BEMANUAL - NV4500 21 - 59

MANUAL - NV4500 (Continued)

Page 1695 of 2889

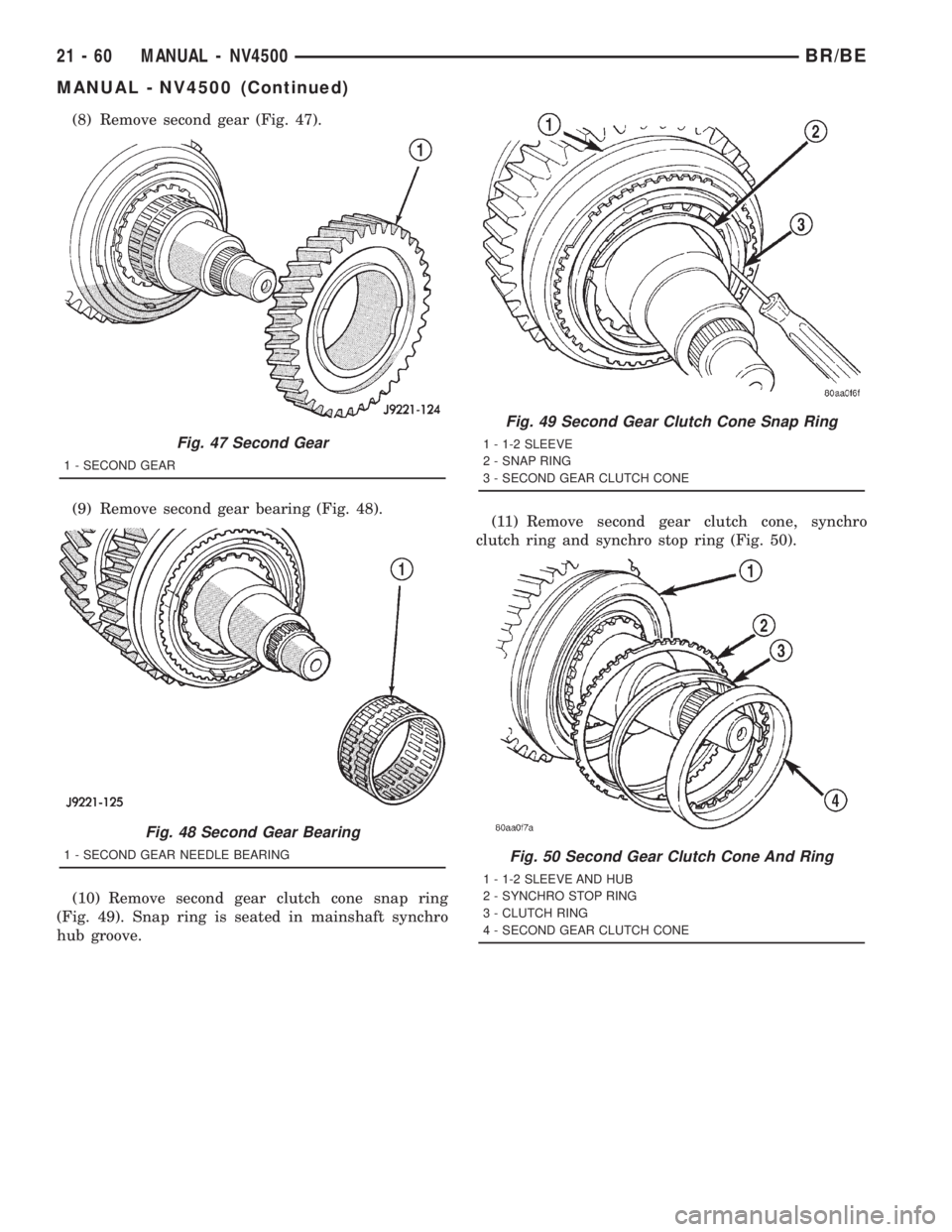

(8) Remove second gear (Fig. 47).

(9) Remove second gear bearing (Fig. 48).

(10) Remove second gear clutch cone snap ring

(Fig. 49). Snap ring is seated in mainshaft synchro

hub groove.(11) Remove second gear clutch cone, synchro

clutch ring and synchro stop ring (Fig. 50).

Fig. 47 Second Gear

1 - SECOND GEAR

Fig. 48 Second Gear Bearing

1 - SECOND GEAR NEEDLE BEARING

Fig. 49 Second Gear Clutch Cone Snap Ring

1 - 1-2 SLEEVE

2 - SNAP RING

3 - SECOND GEAR CLUTCH CONE

Fig. 50 Second Gear Clutch Cone And Ring

1 - 1-2 SLEEVE AND HUB

2 - SYNCHRO STOP RING

3 - CLUTCH RING

4 - SECOND GEAR CLUTCH CONE

21 - 60 MANUAL - NV4500BR/BE

MANUAL - NV4500 (Continued)

Page 1696 of 2889

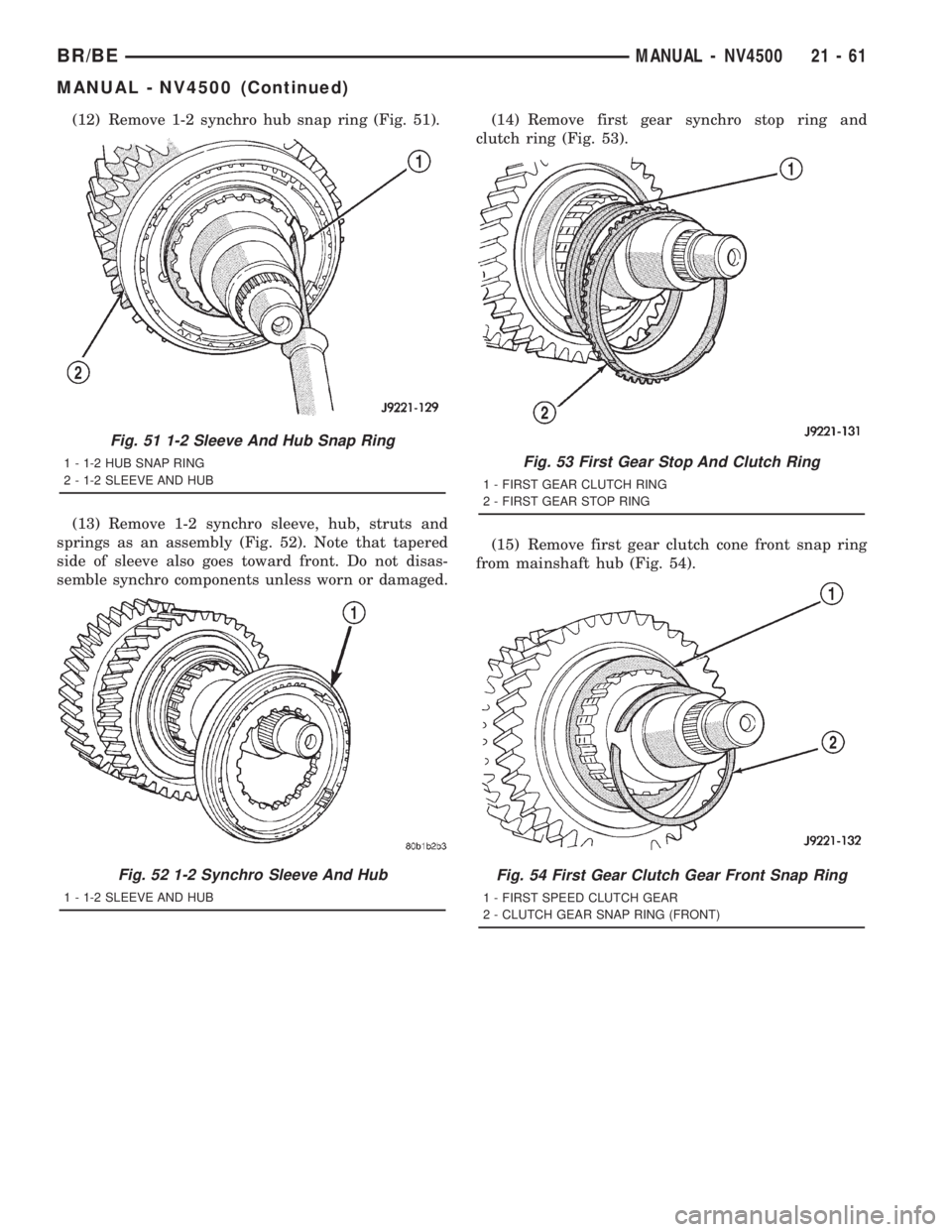

(12) Remove 1-2 synchro hub snap ring (Fig. 51).

(13) Remove 1-2 synchro sleeve, hub, struts and

springs as an assembly (Fig. 52). Note that tapered

side of sleeve also goes toward front. Do not disas-

semble synchro components unless worn or damaged.(14) Remove first gear synchro stop ring and

clutch ring (Fig. 53).

(15) Remove first gear clutch cone front snap ring

from mainshaft hub (Fig. 54).

Fig. 51 1-2 Sleeve And Hub Snap Ring

1 - 1-2 HUB SNAP RING

2 - 1-2 SLEEVE AND HUB

Fig. 52 1-2 Synchro Sleeve And Hub

1 - 1-2 SLEEVE AND HUB

Fig. 53 First Gear Stop And Clutch Ring

1 - FIRST GEAR CLUTCH RING

2 - FIRST GEAR STOP RING

Fig. 54 First Gear Clutch Gear Front Snap Ring

1 - FIRST SPEED CLUTCH GEAR

2 - CLUTCH GEAR SNAP RING (FRONT)

BR/BEMANUAL - NV4500 21 - 61

MANUAL - NV4500 (Continued)

Page 1697 of 2889

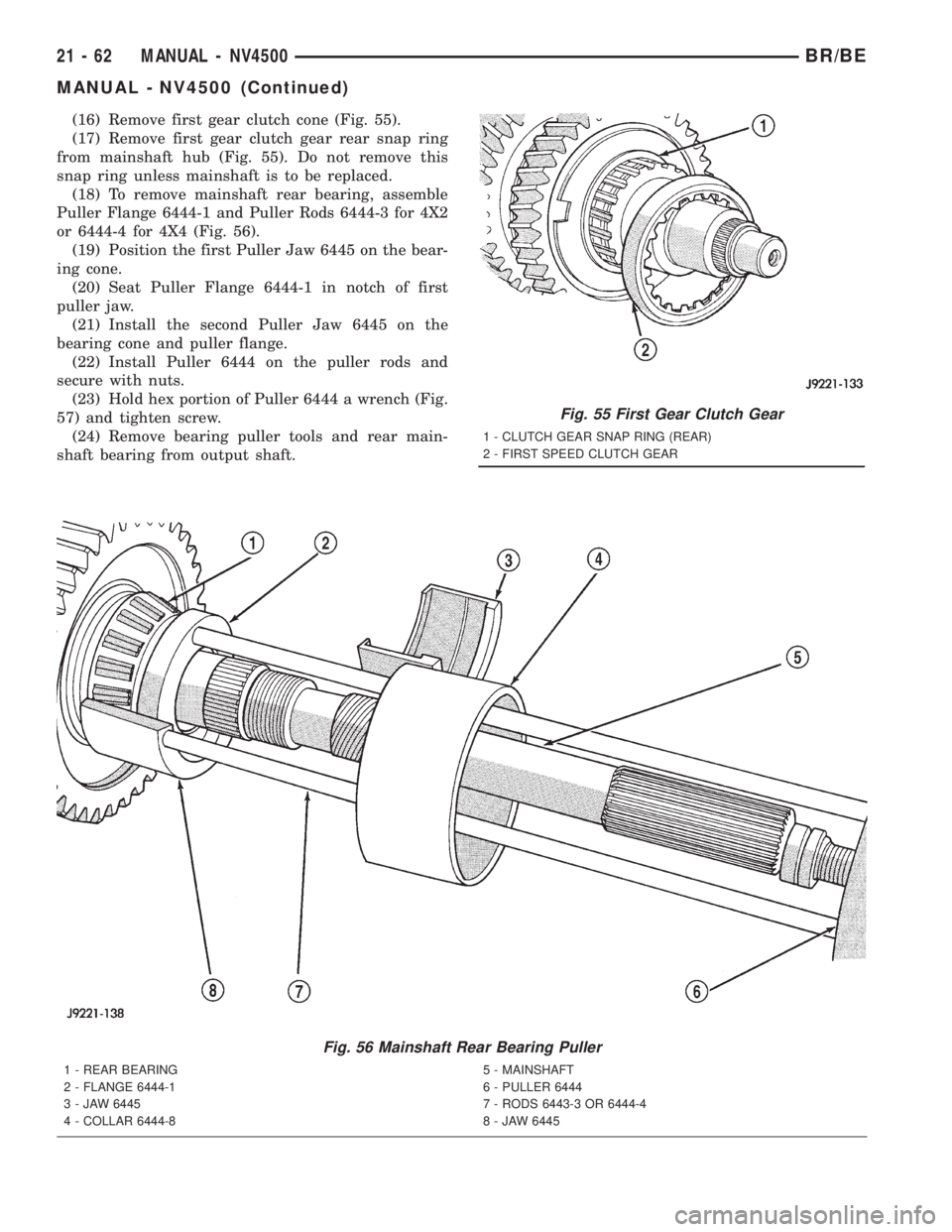

(16) Remove first gear clutch cone (Fig. 55).

(17) Remove first gear clutch gear rear snap ring

from mainshaft hub (Fig. 55). Do not remove this

snap ring unless mainshaft is to be replaced.

(18) To remove mainshaft rear bearing, assemble

Puller Flange 6444-1 and Puller Rods 6444-3 for 4X2

or 6444-4 for 4X4 (Fig. 56).

(19) Position the first Puller Jaw 6445 on the bear-

ing cone.

(20) Seat Puller Flange 6444-1 in notch of first

puller jaw.

(21) Install the second Puller Jaw 6445 on the

bearing cone and puller flange.

(22) Install Puller 6444 on the puller rods and

secure with nuts.

(23) Hold hex portion of Puller 6444 a wrench (Fig.

57) and tighten screw.

(24) Remove bearing puller tools and rear main-

shaft bearing from output shaft.

Fig. 56 Mainshaft Rear Bearing Puller

1 - REAR BEARING

2 - FLANGE 6444-1

3 - JAW 6445

4 - COLLAR 6444-85 - MAINSHAFT

6 - PULLER 6444

7 - RODS 6443-3 OR 6444-4

8 - JAW 6445

Fig. 55 First Gear Clutch Gear

1 - CLUTCH GEAR SNAP RING (REAR)

2 - FIRST SPEED CLUTCH GEAR

21 - 62 MANUAL - NV4500BR/BE

MANUAL - NV4500 (Continued)

Page 1698 of 2889

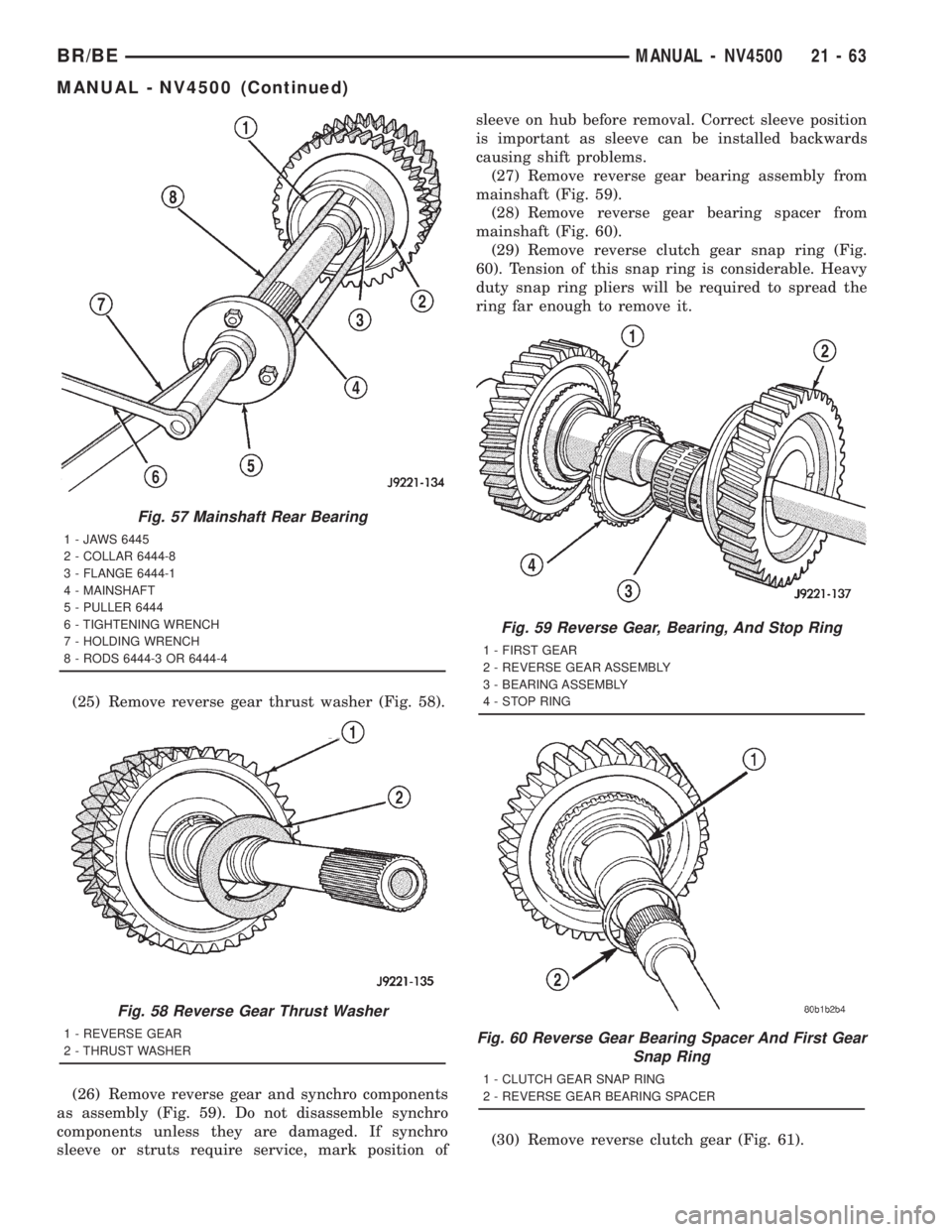

(25) Remove reverse gear thrust washer (Fig. 58).

(26) Remove reverse gear and synchro components

as assembly (Fig. 59). Do not disassemble synchro

components unless they are damaged. If synchro

sleeve or struts require service, mark position ofsleeve on hub before removal. Correct sleeve position

is important as sleeve can be installed backwards

causing shift problems.

(27) Remove reverse gear bearing assembly from

mainshaft (Fig. 59).

(28) Remove reverse gear bearing spacer from

mainshaft (Fig. 60).

(29) Remove reverse clutch gear snap ring (Fig.

60). Tension of this snap ring is considerable. Heavy

duty snap ring pliers will be required to spread the

ring far enough to remove it.

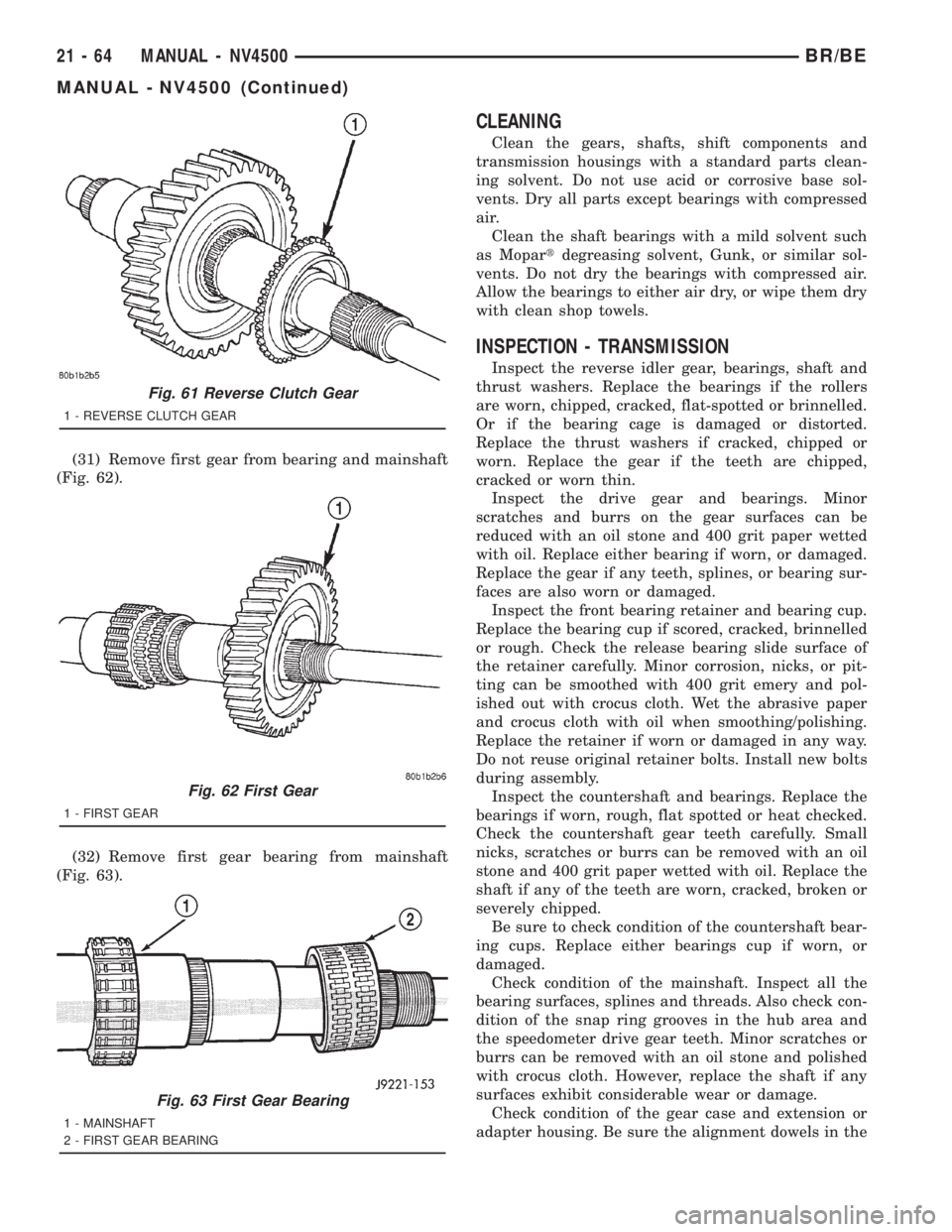

(30) Remove reverse clutch gear (Fig. 61).

Fig. 57 Mainshaft Rear Bearing

1 - JAWS 6445

2 - COLLAR 6444-8

3 - FLANGE 6444-1

4 - MAINSHAFT

5 - PULLER 6444

6 - TIGHTENING WRENCH

7 - HOLDING WRENCH

8 - RODS 6444-3 OR 6444-4

Fig. 58 Reverse Gear Thrust Washer

1 - REVERSE GEAR

2 - THRUST WASHER

Fig. 59 Reverse Gear, Bearing, And Stop Ring

1 - FIRST GEAR

2 - REVERSE GEAR ASSEMBLY

3 - BEARING ASSEMBLY

4 - STOP RING

Fig. 60 Reverse Gear Bearing Spacer And First Gear

Snap Ring

1 - CLUTCH GEAR SNAP RING

2 - REVERSE GEAR BEARING SPACER

BR/BEMANUAL - NV4500 21 - 63

MANUAL - NV4500 (Continued)

Page 1699 of 2889

(31) Remove first gear from bearing and mainshaft

(Fig. 62).

(32) Remove first gear bearing from mainshaft

(Fig. 63).

CLEANING

Clean the gears, shafts, shift components and

transmission housings with a standard parts clean-

ing solvent. Do not use acid or corrosive base sol-

vents. Dry all parts except bearings with compressed

air.

Clean the shaft bearings with a mild solvent such

as Mopartdegreasing solvent, Gunk, or similar sol-

vents. Do not dry the bearings with compressed air.

Allow the bearings to either air dry, or wipe them dry

with clean shop towels.

INSPECTION - TRANSMISSION

Inspect the reverse idler gear, bearings, shaft and

thrust washers. Replace the bearings if the rollers

are worn, chipped, cracked, flat-spotted or brinnelled.

Or if the bearing cage is damaged or distorted.

Replace the thrust washers if cracked, chipped or

worn. Replace the gear if the teeth are chipped,

cracked or worn thin.

Inspect the drive gear and bearings. Minor

scratches and burrs on the gear surfaces can be

reduced with an oil stone and 400 grit paper wetted

with oil. Replace either bearing if worn, or damaged.

Replace the gear if any teeth, splines, or bearing sur-

faces are also worn or damaged.

Inspect the front bearing retainer and bearing cup.

Replace the bearing cup if scored, cracked, brinnelled

or rough. Check the release bearing slide surface of

the retainer carefully. Minor corrosion, nicks, or pit-

ting can be smoothed with 400 grit emery and pol-

ished out with crocus cloth. Wet the abrasive paper

and crocus cloth with oil when smoothing/polishing.

Replace the retainer if worn or damaged in any way.

Do not reuse original retainer bolts. Install new bolts

during assembly.

Inspect the countershaft and bearings. Replace the

bearings if worn, rough, flat spotted or heat checked.

Check the countershaft gear teeth carefully. Small

nicks, scratches or burrs can be removed with an oil

stone and 400 grit paper wetted with oil. Replace the

shaft if any of the teeth are worn, cracked, broken or

severely chipped.

Be sure to check condition of the countershaft bear-

ing cups. Replace either bearings cup if worn, or

damaged.

Check condition of the mainshaft. Inspect all the

bearing surfaces, splines and threads. Also check con-

dition of the snap ring grooves in the hub area and

the speedometer drive gear teeth. Minor scratches or

burrs can be removed with an oil stone and polished

with crocus cloth. However, replace the shaft if any

surfaces exhibit considerable wear or damage.

Check condition of the gear case and extension or

adapter housing. Be sure the alignment dowels in the

Fig. 61 Reverse Clutch Gear

1 - REVERSE CLUTCH GEAR

Fig. 62 First Gear

1 - FIRST GEAR

Fig. 63 First Gear Bearing

1 - MAINSHAFT

2 - FIRST GEAR BEARING

21 - 64 MANUAL - NV4500BR/BE

MANUAL - NV4500 (Continued)

Page 1700 of 2889

case top surface and in the housing/adapter are tight

and in good condition.

Run a tap through the gear case bolt holes if the

threads need minor cleanup. Helicoil inserts can be

used to repair seriously damaged threaded holes if

necessary.

Be sure all case and housing/adapter sealing and

mating surfaces are free of burrs and nicks. This is

especially important as gaskets are not used in the

transmission. Minor nicks and scratches on the seal-

ing surfaces can be dressed off with a fine tooth file

or oil stone.

Replace the gear case or housing/adapter if cracked

or broken. Do not attempt to repair this type of dam-

age by welding or brazing.

Check condition of the countershaft fifth gear com-

ponents. This includes the shift lug and rail located

in the gear case and the rail bushings.

Inspect the gear and hub assembly. Minor burrs

can be cleaned up with an oil stone. However, the

gear and hub assembly should be replaced if the

teeth or splines are excessively worn, or damaged.

The synchro sleeve should also be replaced if worn or

damaged in any way. Do not reuse synchro struts

that are worn or springs that are collapsed or

severely distorted. Replace worn distorted synchro

parts to avoid shift problems after assembly and

installation.

The shift fork should be inspected for evidence of

wear and distortion. Check fit of the sleeve in the

fork to be sure the two parts fit and work smoothly.

Replace the fork if the roll pin holes are worn over-

size or damaged. Do not attempt to salvage a worn

fork. It will cause shift problems later on. Replace

shift fork roll pins if necessary or if doubt exists

about their condition.

The bearings should be examined carefully for

wear, roughness, flat spots, pitting or other damage.

Replace the bearings if necessary.

Inspect the blocker ring and clutch gear. replace

either part if worn or damaged in any way. Also be

sure replacement parts fit properly before proceeding

with assembly.

Examine the 1-2 synchro hub and sleeve for wear

or damage. Replace sleeve and hub if the splines are

worn, chipped or damaged.

Replace the synchro struts if worn, or chipped. Also

replace the springs if collapsed, distorted or broken.

Inspect the mainshaft geartrain components.

Check teeth on all gears, hubs, clutch gears, stop

rings and clutch rings. The teeth must be in good

condition and not worn, cracked or chipped. Replace

any component that exhibits wear or damage.

Examine the synchro stop rings, clutch rings and

clutch gears. Replace any part that exhibits wear,distortion or damage. Replace the clutch rings if the

friction material is burned, flaking off or worn.

Inspect all of the thrust washers and locating pins.

Replace the pins if bent or worn. Replace the wash-

ers if worn or the locating pin notches are distorted.

Check condition of the synchro struts and springs.

Replace these parts if worn, cracked or distorted.

ASSEMBLY

NOTE: Gaskets are not used in the NV4500 trans-

mission. Use MoparTSilicone Sealer or equivalent

on all gear case and extension housing sealing sur-

faces.

COUNTERSHAFT AND REVERSE IDLER GEAR

(1) Install countershaft front bearing cup in case

with Handle C-4171 and Installer 6061-1.

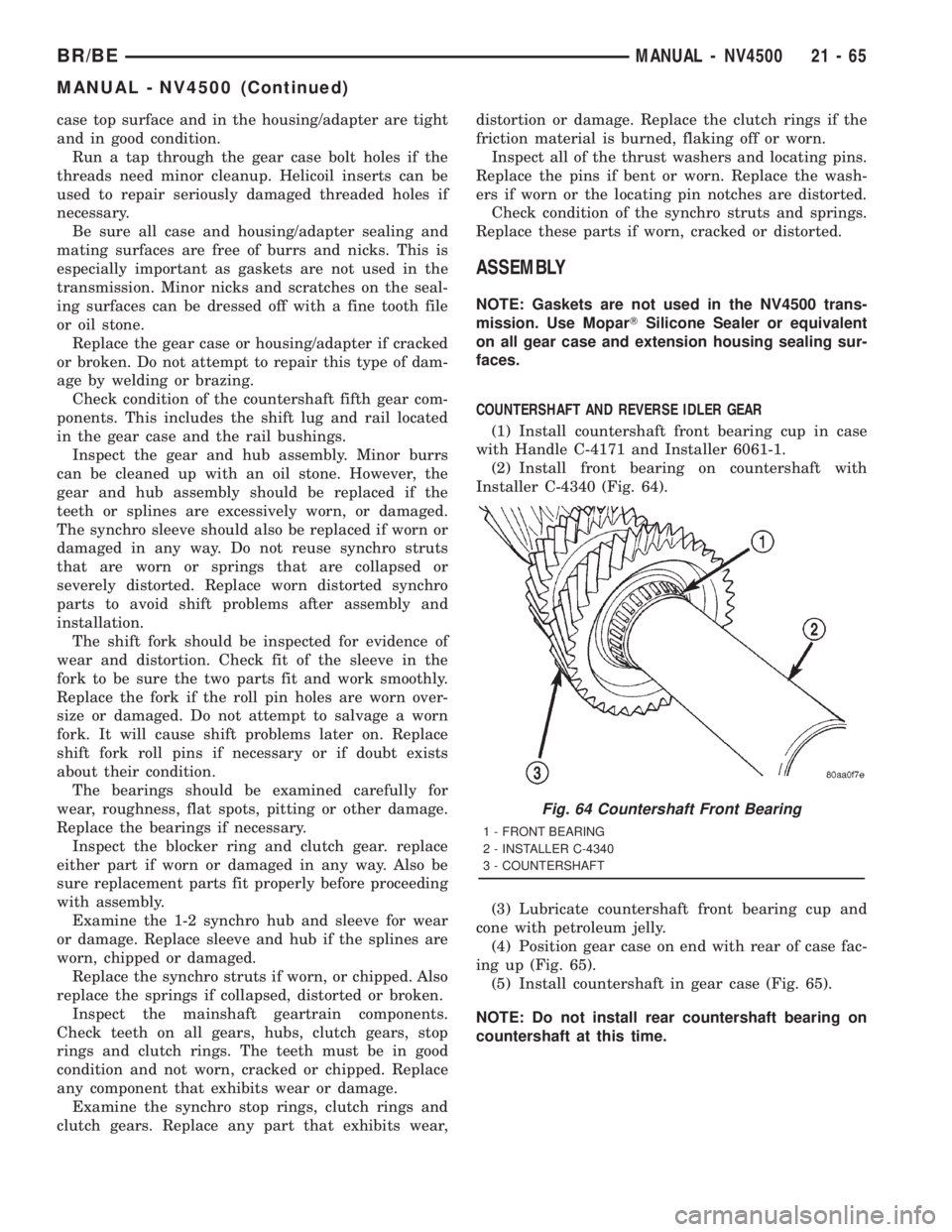

(2) Install front bearing on countershaft with

Installer C-4340 (Fig. 64).

(3) Lubricate countershaft front bearing cup and

cone with petroleum jelly.

(4) Position gear case on end with rear of case fac-

ing up (Fig. 65).

(5) Install countershaft in gear case (Fig. 65).

NOTE: Do not install rear countershaft bearing on

countershaft at this time.

Fig. 64 Countershaft Front Bearing

1 - FRONT BEARING

2 - INSTALLER C-4340

3 - COUNTERSHAFT

BR/BEMANUAL - NV4500 21 - 65

MANUAL - NV4500 (Continued)