DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1721 of 2889

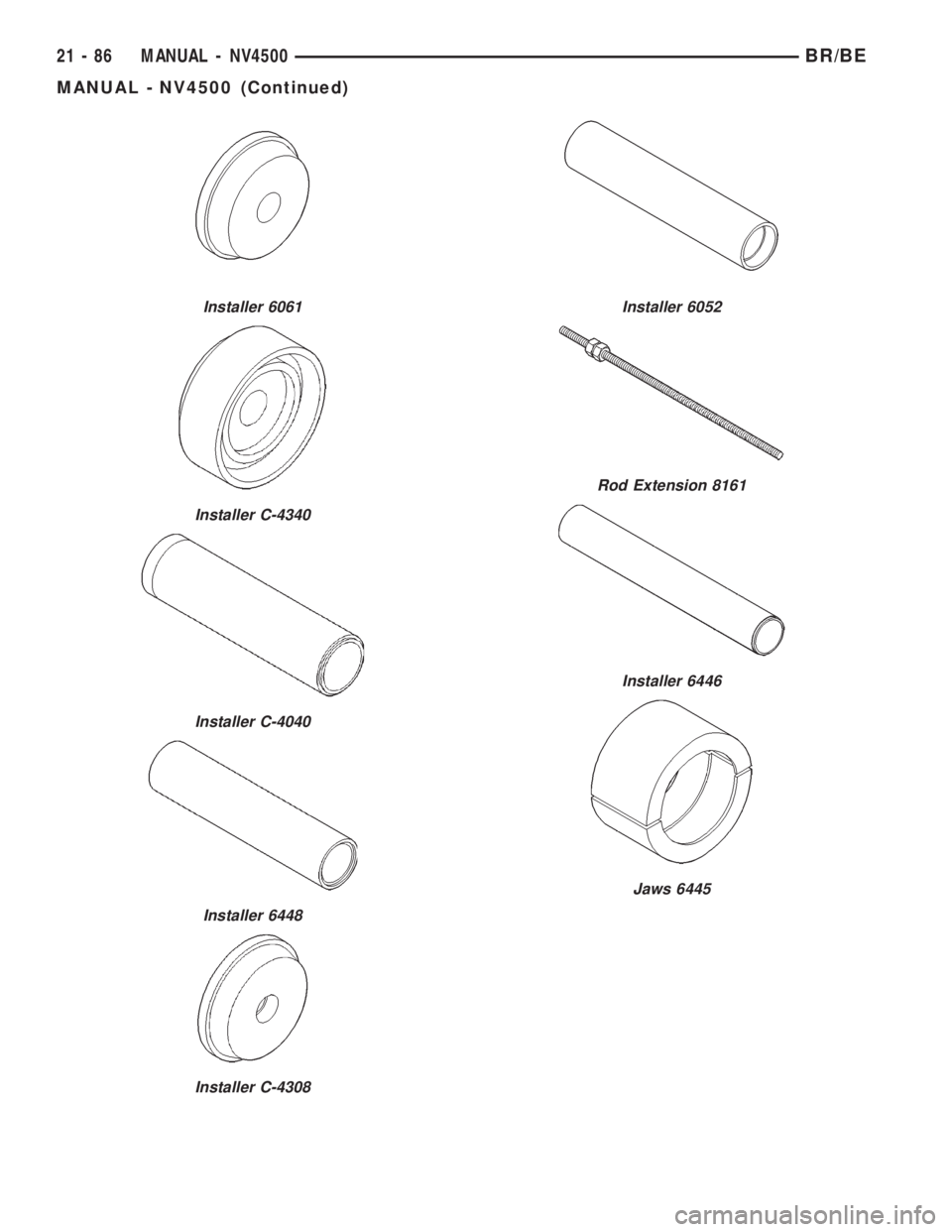

Installer 6061

Installer C-4340

Installer C-4040

Installer 6448

Installer C-4308

Installer 6052

Rod Extension 8161

Installer 6446

Jaws 6445

21 - 86 MANUAL - NV4500BR/BE

MANUAL - NV4500 (Continued)

Page 1722 of 2889

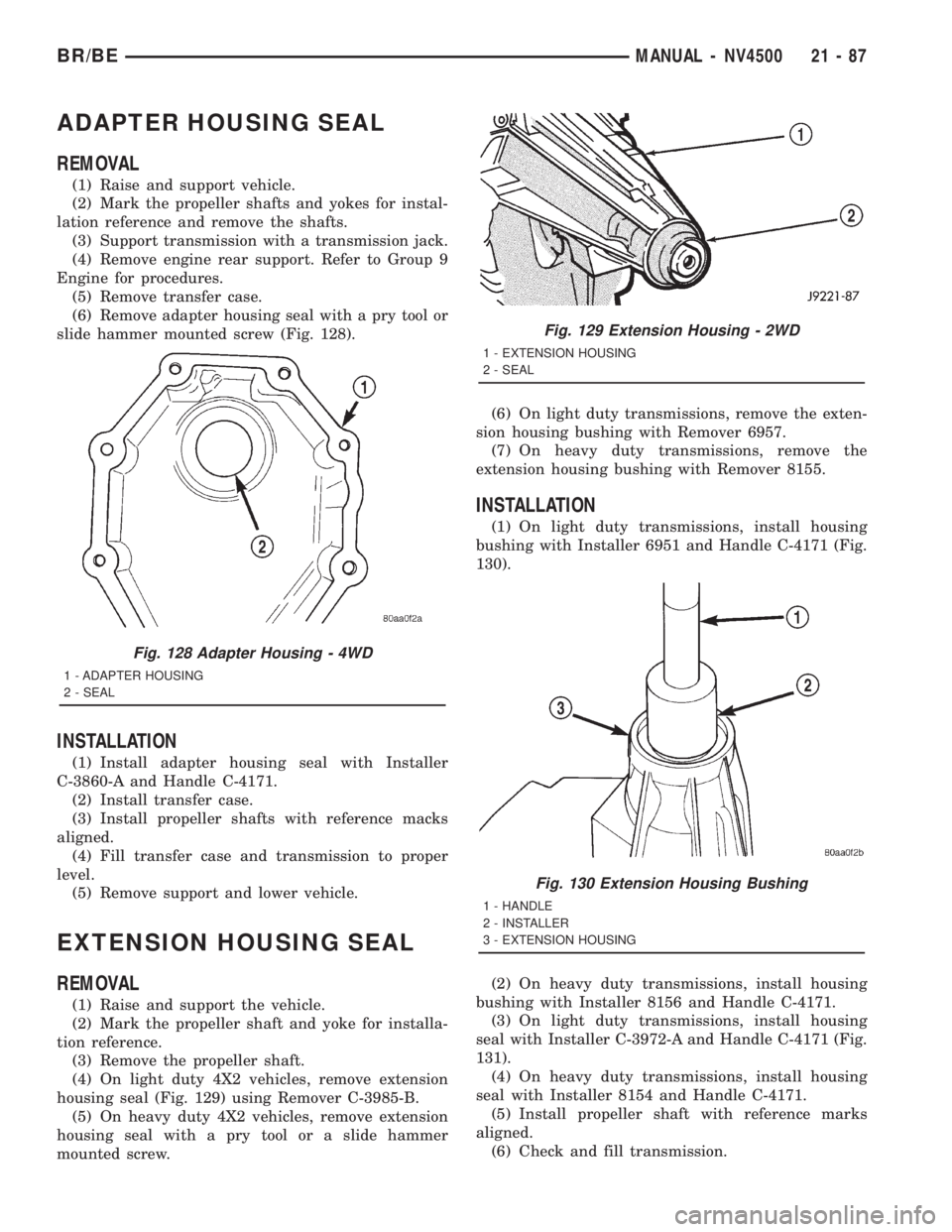

ADAPTER HOUSING SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Mark the propeller shafts and yokes for instal-

lation reference and remove the shafts.

(3) Support transmission with a transmission jack.

(4) Remove engine rear support. Refer to Group 9

Engine for procedures.

(5) Remove transfer case.

(6) Remove adapter housing seal with a pry tool or

slide hammer mounted screw (Fig. 128).

INSTALLATION

(1) Install adapter housing seal with Installer

C-3860-A and Handle C-4171.

(2) Install transfer case.

(3) Install propeller shafts with reference macks

aligned.

(4) Fill transfer case and transmission to proper

level.

(5) Remove support and lower vehicle.

EXTENSION HOUSING SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the propeller shaft and yoke for installa-

tion reference.

(3) Remove the propeller shaft.

(4) On light duty 4X2 vehicles, remove extension

housing seal (Fig. 129) using Remover C-3985-B.

(5) On heavy duty 4X2 vehicles, remove extension

housing seal with a pry tool or a slide hammer

mounted screw.(6) On light duty transmissions, remove the exten-

sion housing bushing with Remover 6957.

(7) On heavy duty transmissions, remove the

extension housing bushing with Remover 8155.

INSTALLATION

(1) On light duty transmissions, install housing

bushing with Installer 6951 and Handle C-4171 (Fig.

130).

(2) On heavy duty transmissions, install housing

bushing with Installer 8156 and Handle C-4171.

(3) On light duty transmissions, install housing

seal with Installer C-3972-A and Handle C-4171 (Fig.

131).

(4) On heavy duty transmissions, install housing

seal with Installer 8154 and Handle C-4171.

(5) Install propeller shaft with reference marks

aligned.

(6) Check and fill transmission.

Fig. 128 Adapter Housing - 4WD

1 - ADAPTER HOUSING

2 - SEAL

Fig. 129 Extension Housing - 2WD

1 - EXTENSION HOUSING

2 - SEAL

Fig. 130 Extension Housing Bushing

1 - HANDLE

2 - INSTALLER

3 - EXTENSION HOUSING

BR/BEMANUAL - NV4500 21 - 87

Page 1723 of 2889

(7) Remove support and lower vehicle.

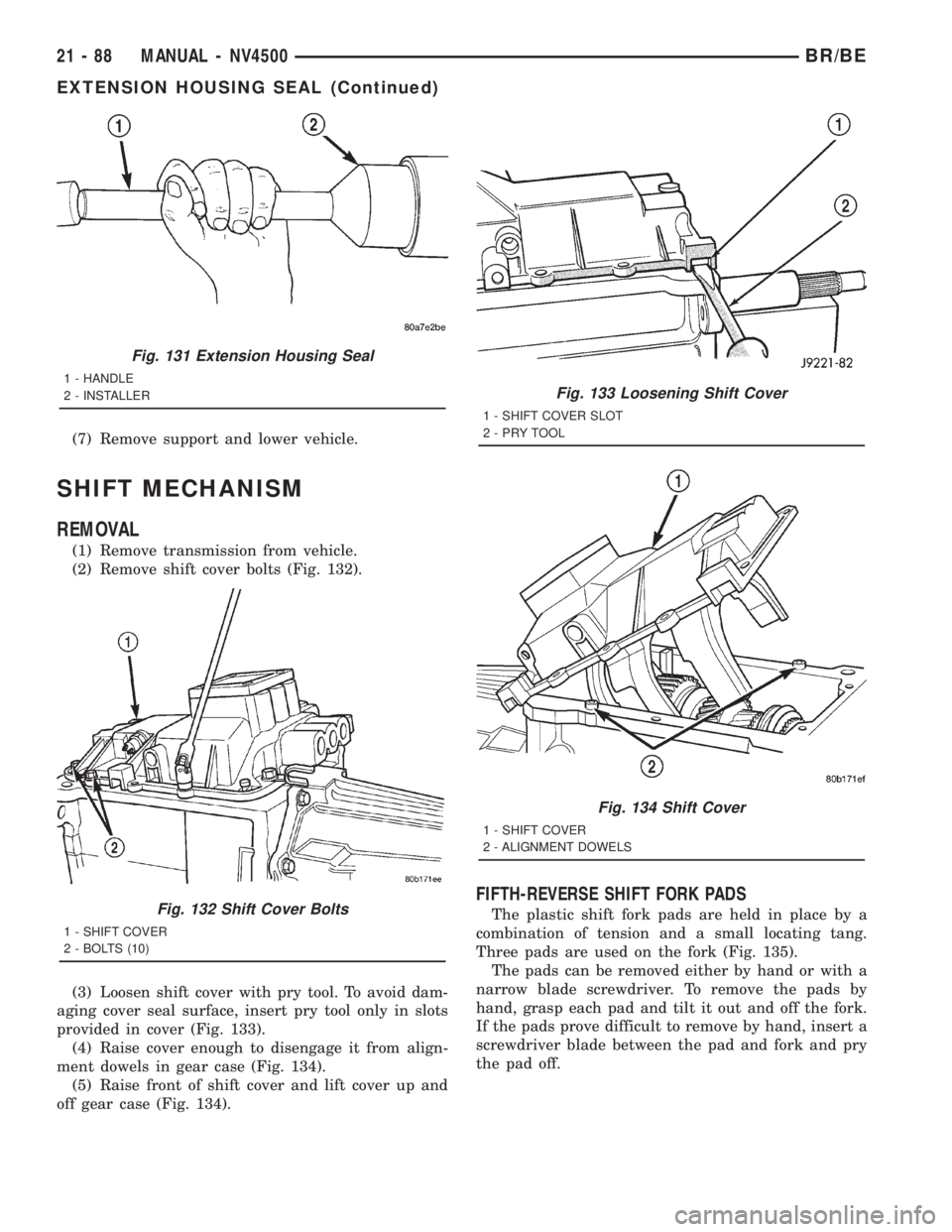

SHIFT MECHANISM

REMOVAL

(1) Remove transmission from vehicle.

(2) Remove shift cover bolts (Fig. 132).

(3) Loosen shift cover with pry tool. To avoid dam-

aging cover seal surface, insert pry tool only in slots

provided in cover (Fig. 133).

(4) Raise cover enough to disengage it from align-

ment dowels in gear case (Fig. 134).

(5) Raise front of shift cover and lift cover up and

off gear case (Fig. 134).

FIFTH-REVERSE SHIFT FORK PADS

The plastic shift fork pads are held in place by a

combination of tension and a small locating tang.

Three pads are used on the fork (Fig. 135).

The pads can be removed either by hand or with a

narrow blade screwdriver. To remove the pads by

hand, grasp each pad and tilt it out and off the fork.

If the pads prove difficult to remove by hand, insert a

screwdriver blade between the pad and fork and pry

the pad off.

Fig. 131 Extension Housing Seal

1 - HANDLE

2 - INSTALLER

Fig. 132 Shift Cover Bolts

1 - SHIFT COVER

2 - BOLTS (10)

Fig. 133 Loosening Shift Cover

1 - SHIFT COVER SLOT

2-PRYTOOL

Fig. 134 Shift Cover

1 - SHIFT COVER

2 - ALIGNMENT DOWELS

21 - 88 MANUAL - NV4500BR/BE

EXTENSION HOUSING SEAL (Continued)

Page 1724 of 2889

EXPANSION PLUG

The expansion plugs at the rear of the shift rail

bores (Fig. 136) can be replaced if loose and/or leak-

ing.

(1) Drill 6 mm (1/4 in.) diameter hole in center of

each plug to be removed.

(2) Pry plug out of cover with tapered punch.

(3) Clean all chips from shift cover and plug bores.

Then clean plug bores with solvent and dry with

clean shop towel.

INSTALLATION

EXPANSION PLUG

(1) Apply small bead of sealer to outer edge of

each new plug. Use Mopartsilicone adhesive/sealer,

or equivalent.

(2) Position each new plug in bore and tap into

place with hammer and suitable size punch or socket.

FIFTH-REVERSE SHIFT FORK PADS

(1) Align pad locating tab.

(2) Snap pads into place and verify locating tabs

are locked-in.

SHIFT COVER

(1) Clean mating surfaces of shift cover and gear

case with wax and grease remover.

(2) Apply MopartSilicone Sealer, or equivalent, to

sealing surface of shift cover or gear case. Do not

over±apply sealer material. Excess can be squeezed

into gear case and could block lubricant feed holes in

time.

(3) Lubricate synchro sleeves with Castrol Syntorq

gear lubricant. Then apply light coat of petroleum

jelly to shift fork contact surfaces.

(4) Verify that the shift fork pads (Fig. 137) are

properly and securely positioned on the fifth-reverse

fork

(5) Verify that 1-2 and 3-4 synchro sleeves are in

neutral position. Also verify that forks in shift cover

are in neutral position.

(6) Align and install shift cover. If cover will not

seat, it is either not aligned on gear case dowels, or

shift forks are not aligned with sleeves and shift lug.

(7) Apply MopartLock N' Seal, or equivalent, to

threads of shift cover bolts.

(8) Install and tighten shift cover bolts to 27-31

N´m (216-276 in. lbs.).

(9) Install backup lamp switch and gasket in cover.

Apply sealer to switch threads before installation and

tighten switch to 22-34 N´m (193-265 in. lbs.).

(10) Install vent assembly, if removed. Apply an

adhesive/sealer to vent tube to help secure it in cover.

(11) Install transmission.

Fig. 135 Shift Fork Pad Locations

1 - SHIFT FORK PADS

2 - FIFTH-REVERSE FORK

Fig. 136 Expansion Plug Location

1 - EXPANSION PLUGS

Fig. 137 Fifth-Reverse Shift Fork Pads

1 - SHIFT FORK PADS

2 - FIFTH-REVERSE FORK

BR/BEMANUAL - NV4500 21 - 89

SHIFT MECHANISM (Continued)

Page 1725 of 2889

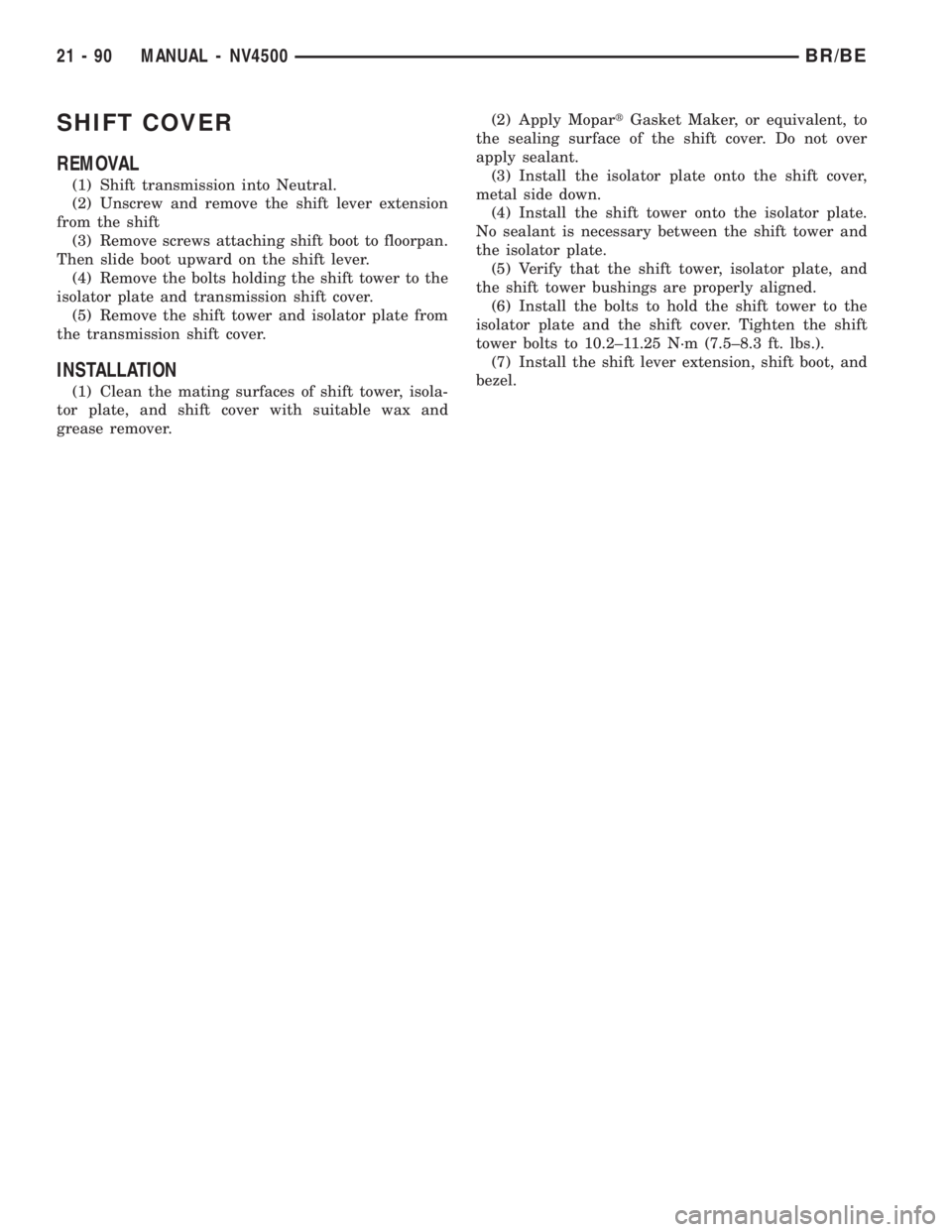

SHIFT COVER

REMOVAL

(1) Shift transmission into Neutral.

(2) Unscrew and remove the shift lever extension

from the shift

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.

(4) Remove the bolts holding the shift tower to the

isolator plate and transmission shift cover.

(5) Remove the shift tower and isolator plate from

the transmission shift cover.

INSTALLATION

(1) Clean the mating surfaces of shift tower, isola-

tor plate, and shift cover with suitable wax and

grease remover.(2) Apply MopartGasket Maker, or equivalent, to

the sealing surface of the shift cover. Do not over

apply sealant.

(3) Install the isolator plate onto the shift cover,

metal side down.

(4) Install the shift tower onto the isolator plate.

No sealant is necessary between the shift tower and

the isolator plate.

(5) Verify that the shift tower, isolator plate, and

the shift tower bushings are properly aligned.

(6) Install the bolts to hold the shift tower to the

isolator plate and the shift cover. Tighten the shift

tower bolts to 10.2±11.25 N´m (7.5±8.3 ft. lbs.).

(7) Install the shift lever extension, shift boot, and

bezel.

21 - 90 MANUAL - NV4500BR/BE

Page 1726 of 2889

MANUAL - NV5600

TABLE OF CONTENTS

page page

MANUAL - NV5600

DESCRIPTION...........................91

OPERATION.............................93

DIAGNOSIS AND TESTING.................93

MANUAL TRANSMISSION................93

REMOVAL..............................94

DISASSEMBLY...........................95

CLEANING.............................109

INSPECTION...........................109

ASSEMBLY.............................110

INSTALLATION..........................125SPECIFICATIONS........................126

SPECIAL TOOLS........................127

ADAPTER HOUSING SEAL

REMOVAL.............................132

INSTALLATION..........................132

EXTENSION HOUSING SEAL

REMOVAL.............................132

INSTALLATION..........................132

SHIFT COVER

REMOVAL.............................132

INSTALLATION..........................133

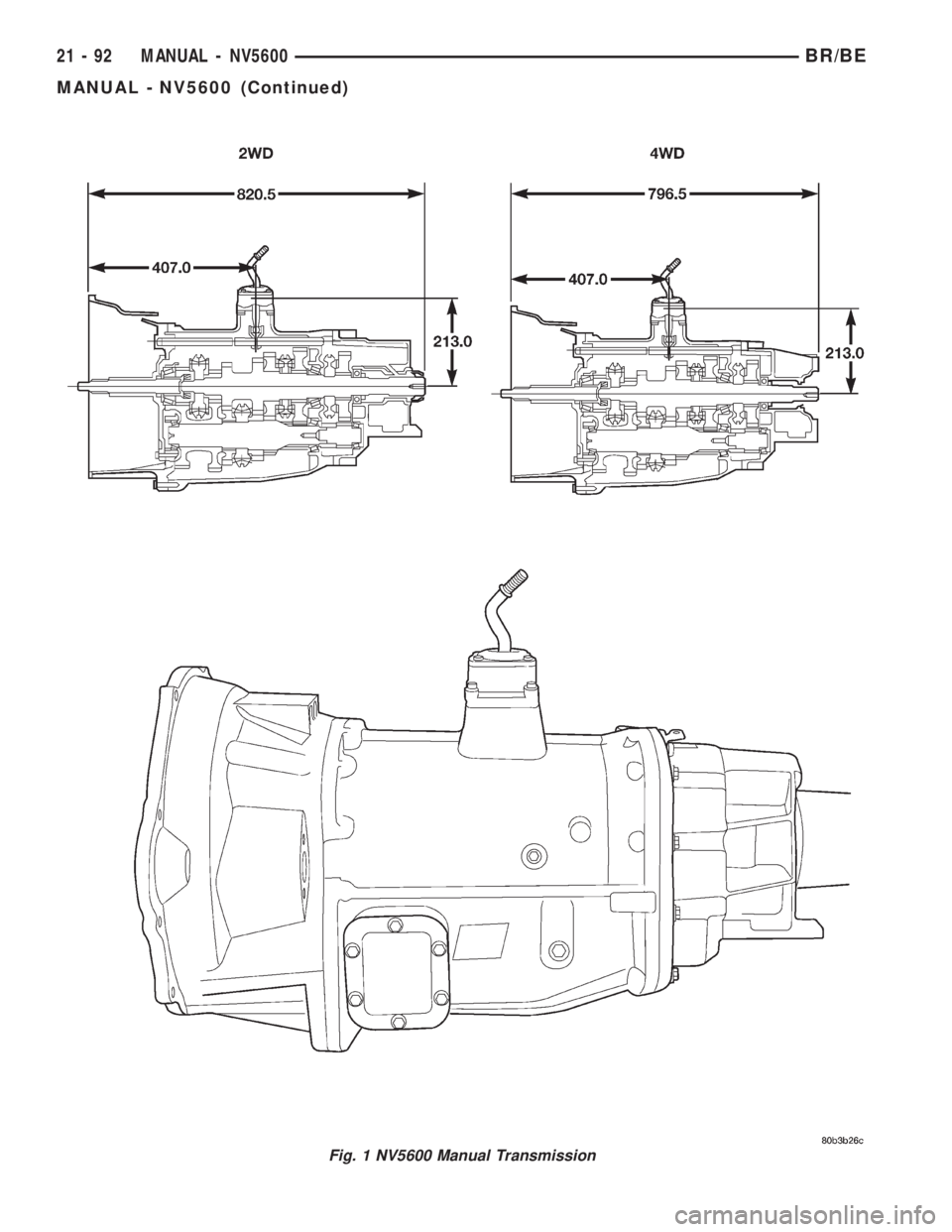

MANUAL - NV5600

DESCRIPTION

The NV5600 is a six speed constant mesh manual

transmission (Fig. 1). All gear ranges including

reverse are synchronized. First and second gears uti-

lize dual cone synchronizers in order to aid shifting.Sixth gear is an overdrive range. The transmission

uses cast iron for the gear case and extension/

adapter housing and aluminum for the clutch hous-

ing.

The transmission is a end loader transmission. The

shift lever is located in a shifter tower which is

bolted to the gear case and operates the shift shaft.

BR/BEMANUAL - NV5600 21 - 91

Page 1727 of 2889

Fig. 1 NV5600 Manual Transmission

21 - 92 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1728 of 2889

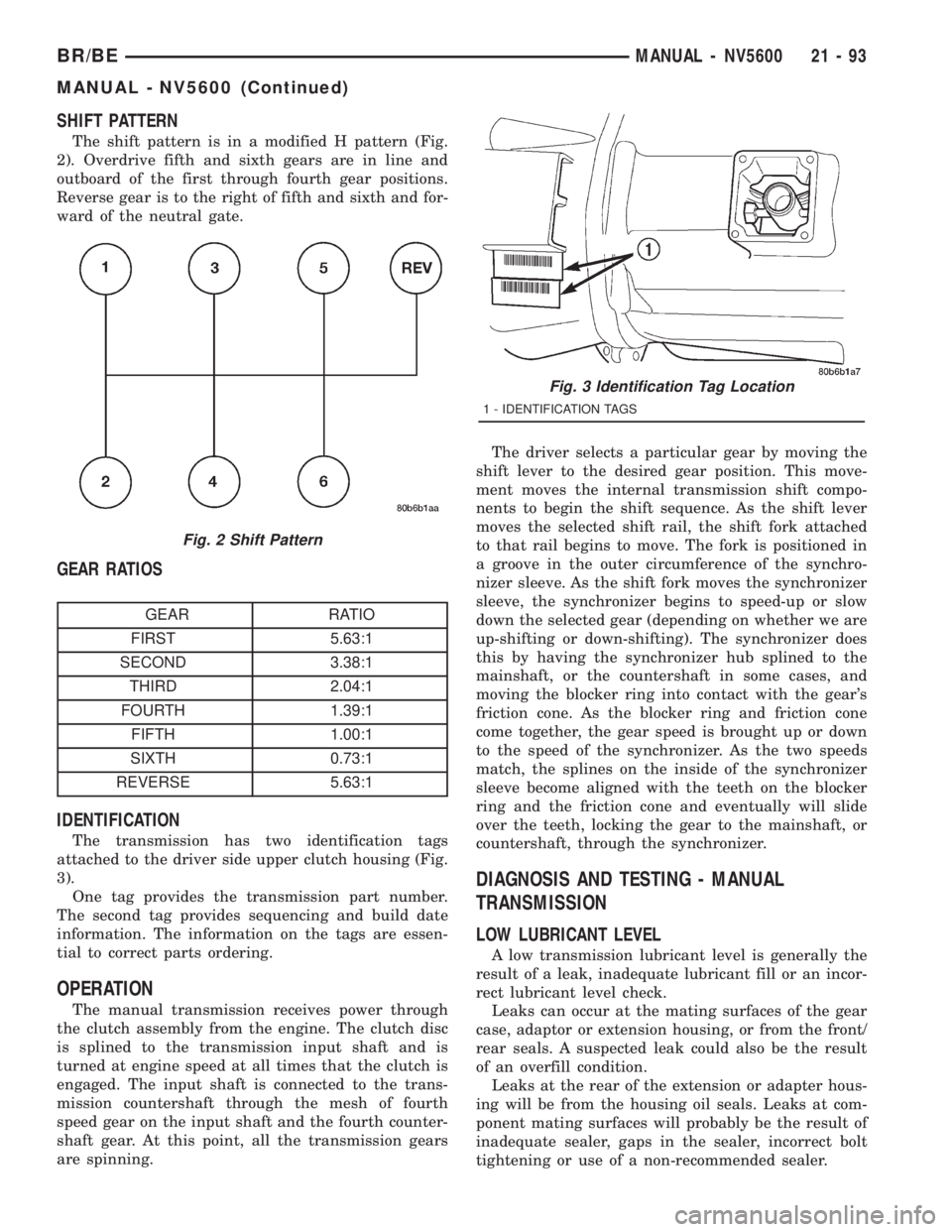

SHIFT PATTERN

The shift pattern is in a modified H pattern (Fig.

2). Overdrive fifth and sixth gears are in line and

outboard of the first through fourth gear positions.

Reverse gear is to the right of fifth and sixth and for-

ward of the neutral gate.

GEAR RATIOS

GEAR RATIO

FIRST 5.63:1

SECOND 3.38:1

THIRD 2.04:1

FOURTH 1.39:1

FIFTH 1.00:1

SIXTH 0.73:1

REVERSE 5.63:1

IDENTIFICATION

The transmission has two identification tags

attached to the driver side upper clutch housing (Fig.

3).

One tag provides the transmission part number.

The second tag provides sequencing and build date

information. The information on the tags are essen-

tial to correct parts ordering.

OPERATION

The manual transmission receives power through

the clutch assembly from the engine. The clutch disc

is splined to the transmission input shaft and is

turned at engine speed at all times that the clutch is

engaged. The input shaft is connected to the trans-

mission countershaft through the mesh of fourth

speed gear on the input shaft and the fourth counter-

shaft gear. At this point, all the transmission gears

are spinning.The driver selects a particular gear by moving the

shift lever to the desired gear position. This move-

ment moves the internal transmission shift compo-

nents to begin the shift sequence. As the shift lever

moves the selected shift rail, the shift fork attached

to that rail begins to move. The fork is positioned in

a groove in the outer circumference of the synchro-

nizer sleeve. As the shift fork moves the synchronizer

sleeve, the synchronizer begins to speed-up or slow

down the selected gear (depending on whether we are

up-shifting or down-shifting). The synchronizer does

this by having the synchronizer hub splined to the

mainshaft, or the countershaft in some cases, and

moving the blocker ring into contact with the gear's

friction cone. As the blocker ring and friction cone

come together, the gear speed is brought up or down

to the speed of the synchronizer. As the two speeds

match, the splines on the inside of the synchronizer

sleeve become aligned with the teeth on the blocker

ring and the friction cone and eventually will slide

over the teeth, locking the gear to the mainshaft, or

countershaft, through the synchronizer.

DIAGNOSIS AND TESTING - MANUAL

TRANSMISSION

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill or an incor-

rect lubricant level check.

Leaks can occur at the mating surfaces of the gear

case, adaptor or extension housing, or from the front/

rear seals. A suspected leak could also be the result

of an overfill condition.

Leaks at the rear of the extension or adapter hous-

ing will be from the housing oil seals. Leaks at com-

ponent mating surfaces will probably be the result of

inadequate sealer, gaps in the sealer, incorrect bolt

tightening or use of a non-recommended sealer.

Fig. 2 Shift Pattern

Fig. 3 Identification Tag Location

1 - IDENTIFICATION TAGS

BR/BEMANUAL - NV5600 21 - 93

MANUAL - NV5600 (Continued)

Page 1729 of 2889

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal.

Lubricant may be seen dripping from the clutch

housing after extended operation. If the leak is

severe, it may also contaminate the clutch disc caus-

ing the disc to slip, grab and or chatter.

A correct lubricant level check can only be made

when the vehicle is level. Also allow the lubricant to

settle for a minute or so before checking. These rec-

ommendations will ensure an accurate check and

avoid an underfill or overfill condition. Always check

the lubricant level after any addition of fluid to avoid

an incorrect lubricant level condition.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants. The con-

sequence of using non-recommended lubricants is

noise, excessive wear, internal bind and hard shift-

ing. Substantial lubricant leaks can result in gear,

shift rail, synchro, and bearing damage. If a leak

goes undetected for an extended period, the first indi-

cations of component damage are usually hard shift-

ing and noise.

Component damage, incorrect clutch adjustment or

damaged clutch pressure plate or disc are additional

probable causes of increased shift effort. Incorrect

adjustment or a worn/damaged pressure plate or disc

can cause incorrect release. If clutch problem is

advanced, gear clash during shifts can result. Worn

or damaged synchro rings can cause gear clash when

shifting into any forward gear. In some new or

rebuilt transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible, but generally only at extreme

speeds.

Severe highly audible transmission noise is gener-

ally the initial indicator of a lubricant problem.

Insufficient, improper or contaminated lubricant will

promote rapid wear of gears, synchros, shift rails,

forks and bearings. The overheating caused by a

lubricant problem, can also lead to gear breakage.

REMOVAL

NOTE: Use a heavy duty scissors style transmis-

sion jack for remove of the transmission.

(1) Disconnect battery negative cable.

(2) Shift transmission into Neutral.

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.(4) Remove the bolts holding the shift tower to the

isolator plate and transmission gear case.

(5) Remove the shift tower and isolator plate from

the transmission gear case.

(6) Raise and support vehicle.

(7) Remove skid plate, if equipped.

(8) Mark propeller shaft/shafts and axle yokes for

installation reference.

(9) Remove propeller shaft.

(10) Disconnect and remove exhaust system as

necessary.

(11) Disconnect wires at backup light switch.

(12) Support engine with adjustable safety stand

and wood block.

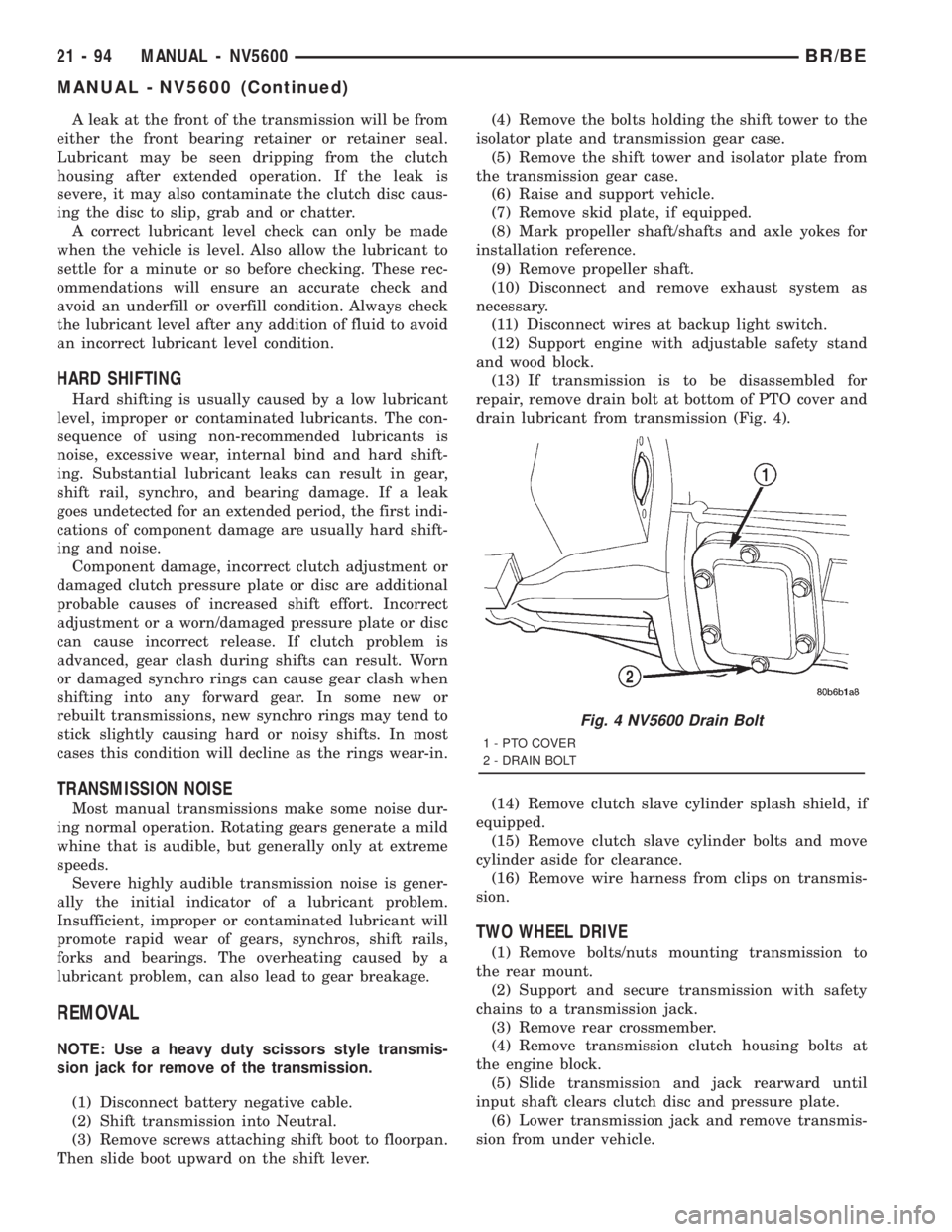

(13) If transmission is to be disassembled for

repair, remove drain bolt at bottom of PTO cover and

drain lubricant from transmission (Fig. 4).

(14) Remove clutch slave cylinder splash shield, if

equipped.

(15) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

(16) Remove wire harness from clips on transmis-

sion.

TWO WHEEL DRIVE

(1) Remove bolts/nuts mounting transmission to

the rear mount.

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember.

(4) Remove transmission clutch housing bolts at

the engine block.

(5) Slide transmission and jack rearward until

input shaft clears clutch disc and pressure plate.

(6) Lower transmission jack and remove transmis-

sion from under vehicle.

Fig. 4 NV5600 Drain Bolt

1 - PTO COVER

2 - DRAIN BOLT

21 - 94 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1730 of 2889

FOUR WHEEL DRIVE

(1) Disconnect transfer case shift linkage at trans-

fer case range lever.

(2) Support and secure transfer case with safety

chains to a transmission jack.

(3) Remove transfer case mounting nuts.

(4) Move transfer case rearward until input gear

clears transmission mainshaft.

(5) Lower transfer case assembly and move it from

under vehicle.

(6) Support and secure transmission with safety

chains to a transmission jack.

(7) Remove bolts/nuts attaching transmission

mount to rear crossmember.

(8) Remove rear crossmember.

(9) Remove transmission clutch housing bolts at

the engine block.

(10) Move transmission rearward until input shaft

clears clutch disc.

(11) Lower transmission and remove it from under

vehicle.

DISASSEMBLY

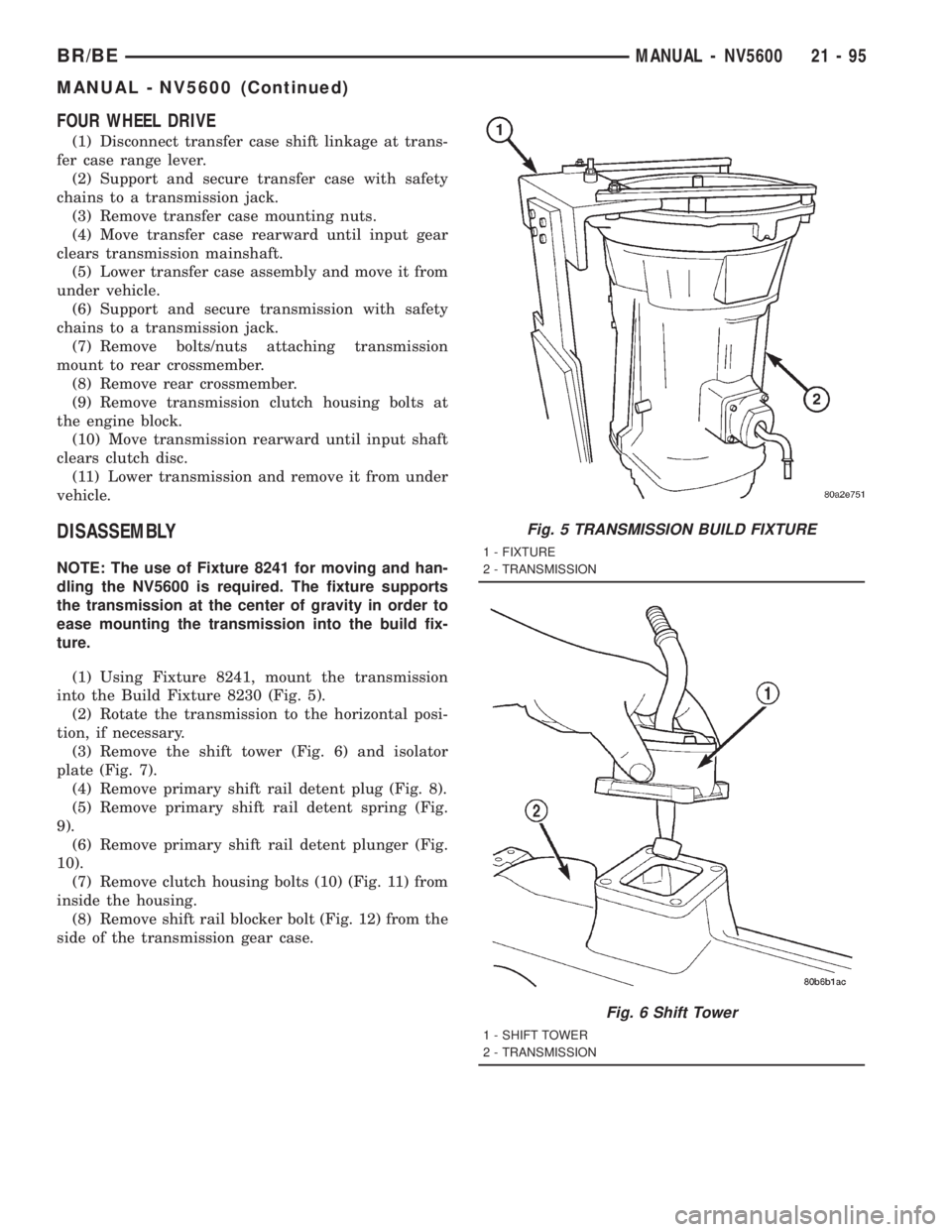

NOTE: The use of Fixture 8241 for moving and han-

dling the NV5600 is required. The fixture supports

the transmission at the center of gravity in order to

ease mounting the transmission into the build fix-

ture.

(1) Using Fixture 8241, mount the transmission

into the Build Fixture 8230 (Fig. 5).

(2) Rotate the transmission to the horizontal posi-

tion, if necessary.

(3) Remove the shift tower (Fig. 6) and isolator

plate (Fig. 7).

(4) Remove primary shift rail detent plug (Fig. 8).

(5) Remove primary shift rail detent spring (Fig.

9).

(6) Remove primary shift rail detent plunger (Fig.

10).

(7) Remove clutch housing bolts (10) (Fig. 11) from

inside the housing.

(8) Remove shift rail blocker bolt (Fig. 12) from the

side of the transmission gear case.

Fig. 5 TRANSMISSION BUILD FIXTURE

1 - FIXTURE

2 - TRANSMISSION

Fig. 6 Shift Tower

1 - SHIFT TOWER

2 - TRANSMISSION

BR/BEMANUAL - NV5600 21 - 95

MANUAL - NV5600 (Continued)