Heater core DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 402 of 2889

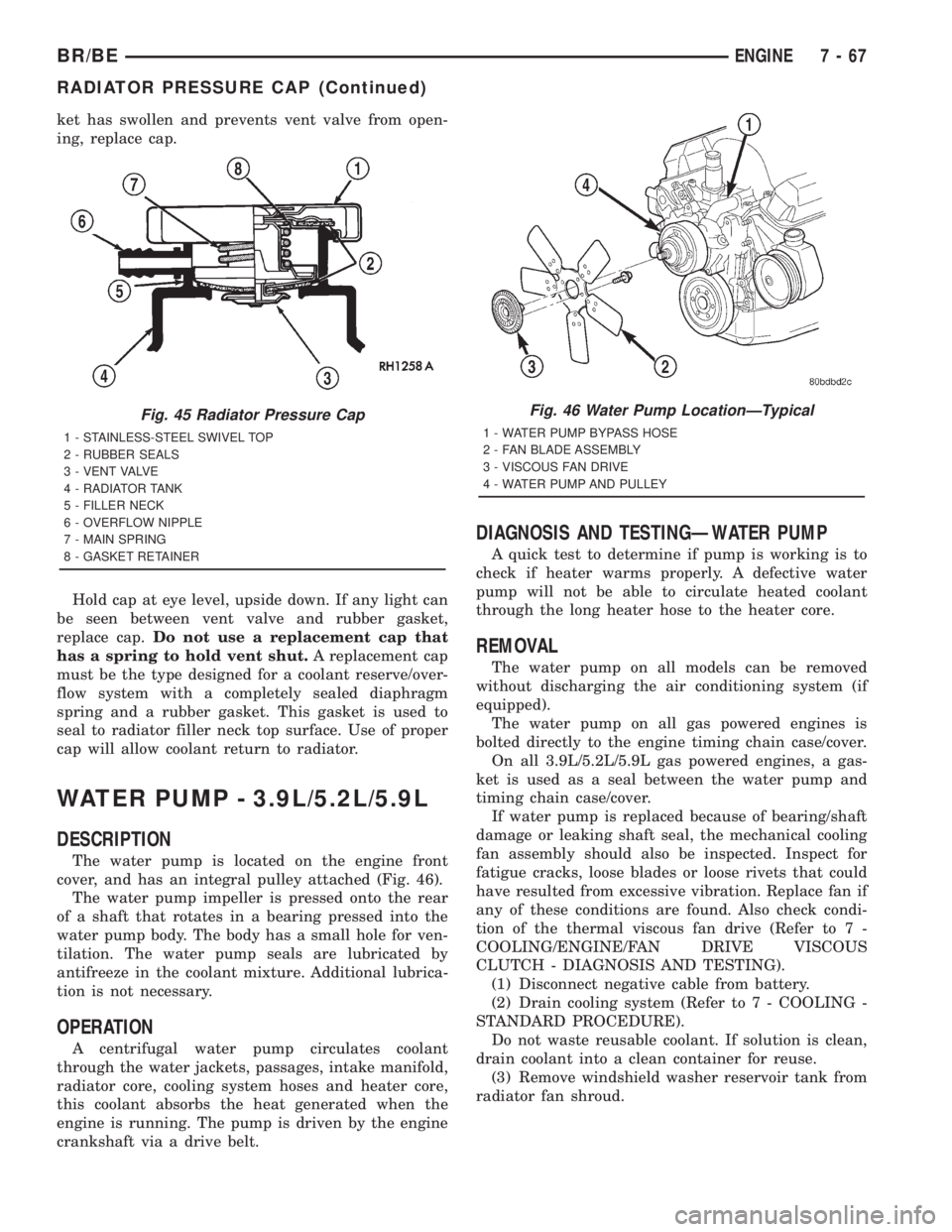

ket has swollen and prevents vent valve from open-

ing, replace cap.

Hold cap at eye level, upside down. If any light can

be seen between vent valve and rubber gasket,

replace cap.Do not use a replacement cap that

has a spring to hold vent shut.A replacement cap

must be the type designed for a coolant reserve/over-

flow system with a completely sealed diaphragm

spring and a rubber gasket. This gasket is used to

seal to radiator filler neck top surface. Use of proper

cap will allow coolant return to radiator.

WATER PUMP - 3.9L/5.2L/5.9L

DESCRIPTION

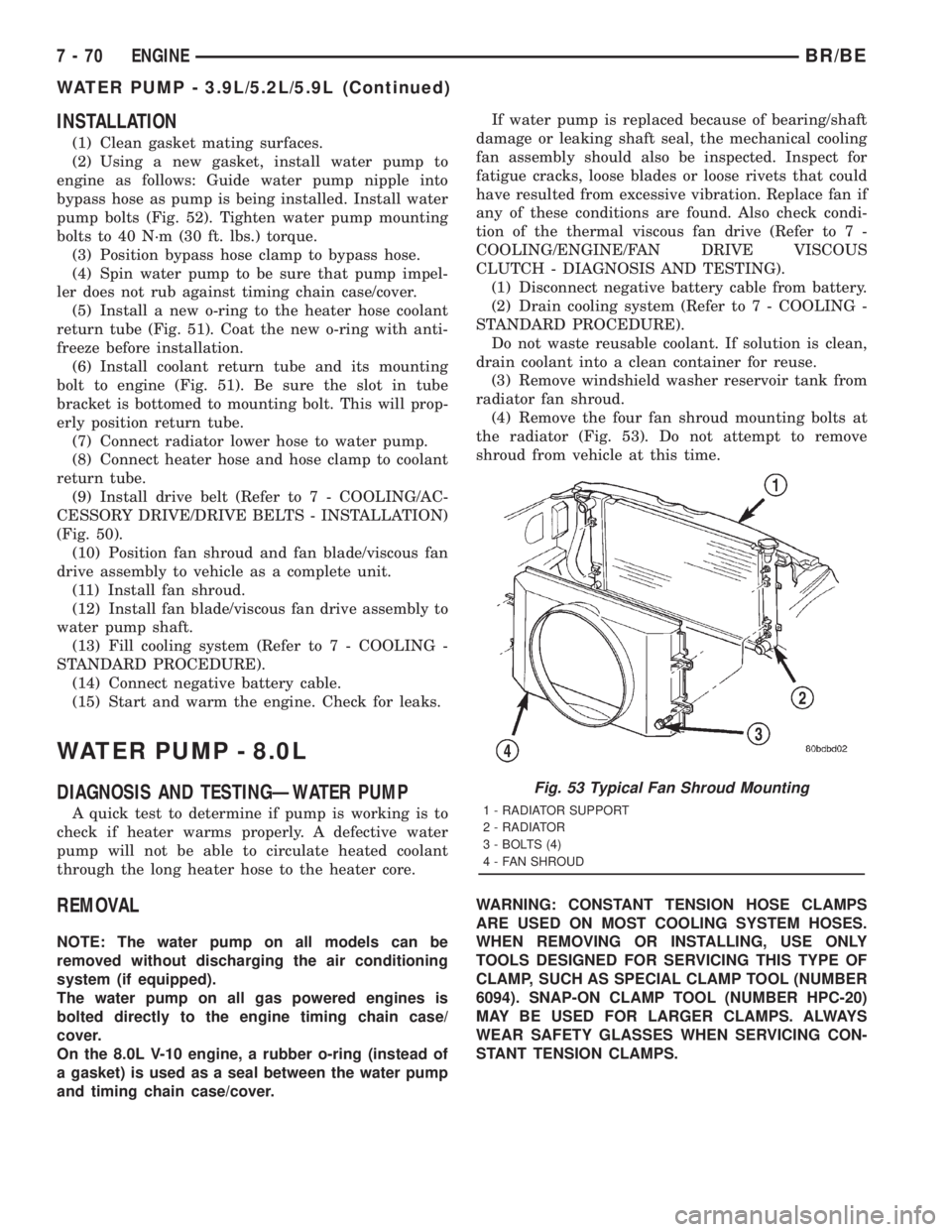

The water pump is located on the engine front

cover, and has an integral pulley attached (Fig. 46).

The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven-

tilation. The water pump seals are lubricated by

antifreeze in the coolant mixture. Additional lubrica-

tion is not necessary.

OPERATION

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core,

this coolant absorbs the heat generated when the

engine is running. The pump is driven by the engine

crankshaft via a drive belt.

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

The water pump on all models can be removed

without discharging the air conditioning system (if

equipped).

The water pump on all gas powered engines is

bolted directly to the engine timing chain case/cover.

On all 3.9L/5.2L/5.9L gas powered engines, a gas-

ket is used as a seal between the water pump and

timing chain case/cover.

If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for

fatigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if

any of these conditions are found. Also check condi-

tion of the thermal viscous fan drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - DIAGNOSIS AND TESTING).

(1) Disconnect negative cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3) Remove windshield washer reservoir tank from

radiator fan shroud.

Fig. 45 Radiator Pressure Cap

1 - STAINLESS-STEEL SWIVEL TOP

2 - RUBBER SEALS

3 - VENT VALVE

4 - RADIATOR TANK

5 - FILLER NECK

6 - OVERFLOW NIPPLE

7 - MAIN SPRING

8 - GASKET RETAINER

Fig. 46 Water Pump LocationÐTypical

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

BR/BEENGINE 7 - 67

RADIATOR PRESSURE CAP (Continued)

Page 405 of 2889

INSTALLATION

(1) Clean gasket mating surfaces.

(2) Using a new gasket, install water pump to

engine as follows: Guide water pump nipple into

bypass hose as pump is being installed. Install water

pump bolts (Fig. 52). Tighten water pump mounting

bolts to 40 N´m (30 ft. lbs.) torque.

(3) Position bypass hose clamp to bypass hose.

(4) Spin water pump to be sure that pump impel-

ler does not rub against timing chain case/cover.

(5) Install a new o-ring to the heater hose coolant

return tube (Fig. 51). Coat the new o-ring with anti-

freeze before installation.

(6) Install coolant return tube and its mounting

bolt to engine (Fig. 51). Be sure the slot in tube

bracket is bottomed to mounting bolt. This will prop-

erly position return tube.

(7) Connect radiator lower hose to water pump.

(8) Connect heater hose and hose clamp to coolant

return tube.

(9) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLATION)

(Fig. 50).

(10) Position fan shroud and fan blade/viscous fan

drive assembly to vehicle as a complete unit.

(11) Install fan shroud.

(12) Install fan blade/viscous fan drive assembly to

water pump shaft.

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect negative battery cable.

(15) Start and warm the engine. Check for leaks.

WATER PUMP - 8.0L

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

NOTE: The water pump on all models can be

removed without discharging the air conditioning

system (if equipped).

The water pump on all gas powered engines is

bolted directly to the engine timing chain case/

cover.

On the 8.0L V-10 engine, a rubber o-ring (instead of

a gasket) is used as a seal between the water pump

and timing chain case/cover.If water pump is replaced because of bearing/shaft

damage or leaking shaft seal, the mechanical cooling

fan assembly should also be inspected. Inspect for

fatigue cracks, loose blades or loose rivets that could

have resulted from excessive vibration. Replace fan if

any of these conditions are found. Also check condi-

tion of the thermal viscous fan drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - DIAGNOSIS AND TESTING).

(1) Disconnect negative battery cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

(3) Remove windshield washer reservoir tank from

radiator fan shroud.

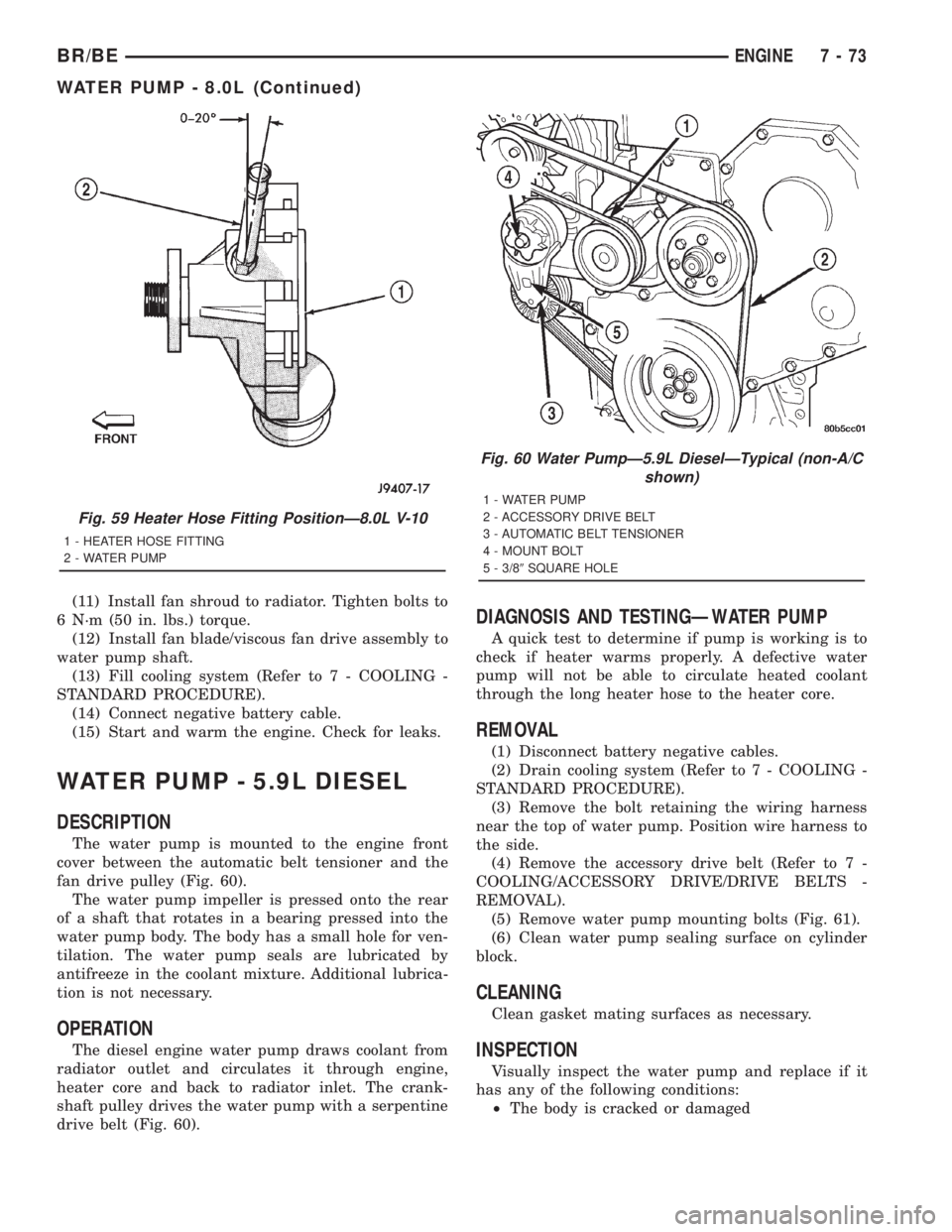

(4) Remove the four fan shroud mounting bolts at

the radiator (Fig. 53). Do not attempt to remove

shroud from vehicle at this time.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

Fig. 53 Typical Fan Shroud Mounting

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

7 - 70 ENGINEBR/BE

WATER PUMP - 3.9L/5.2L/5.9L (Continued)

Page 408 of 2889

(11) Install fan shroud to radiator. Tighten bolts to

6 N´m (50 in. lbs.) torque.

(12) Install fan blade/viscous fan drive assembly to

water pump shaft.

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect negative battery cable.

(15) Start and warm the engine. Check for leaks.

WATER PUMP - 5.9L DIESEL

DESCRIPTION

The water pump is mounted to the engine front

cover between the automatic belt tensioner and the

fan drive pulley (Fig. 60).

The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven-

tilation. The water pump seals are lubricated by

antifreeze in the coolant mixture. Additional lubrica-

tion is not necessary.

OPERATION

The diesel engine water pump draws coolant from

radiator outlet and circulates it through engine,

heater core and back to radiator inlet. The crank-

shaft pulley drives the water pump with a serpentine

drive belt (Fig. 60).

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

(1) Disconnect battery negative cables.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the bolt retaining the wiring harness

near the top of water pump. Position wire harness to

the side.

(4) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Remove water pump mounting bolts (Fig. 61).

(6) Clean water pump sealing surface on cylinder

block.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

Fig. 59 Heater Hose Fitting PositionÐ8.0L V-10

1 - HEATER HOSE FITTING

2 - WATER PUMP

Fig. 60 Water PumpÐ5.9L DieselÐTypical (non-A/C

shown)

1 - WATER PUMP

2 - ACCESSORY DRIVE BELT

3 - AUTOMATIC BELT TENSIONER

4 - MOUNT BOLT

5 - 3/89SQUARE HOLE

BR/BEENGINE 7 - 73

WATER PUMP - 8.0L (Continued)

Page 424 of 2889

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................2

AUDIO................................2

SPECIAL TOOLS..........................4

ANTENNA BODY & CABLE

DESCRIPTION............................4

OPERATION.............................4

DIAGNOSIS AND TESTING..................5

ANTENNA.............................5

REMOVAL...............................6

INSTALLATION............................7

RADIO CHOKE RELAY

DESCRIPTION............................8

OPERATION.............................8

DIAGNOSIS AND TESTING..................8

RADIO CHOKE RELAY....................8

REMOVAL...............................9

INSTALLATION............................9

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL...............................9

INSTALLATION...........................10

RADIO

DESCRIPTION...........................10

OPERATION.............................10

DIAGNOSIS AND TESTING.................10

RADIO...............................10

REMOVAL..............................11

INSTALLATION...........................12

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION...........................12

DIAGNOSIS AND TESTING.................12

RADIO NOISE SUPPRESSION

COMPONENTS.........................12ENGINE-TO-BODY GROUND STRAP

REMOVAL..............................13

INSTALLATION...........................13

CAB-TO- BED GROUND STRAP

REMOVAL..............................14

INSTALLATION...........................14

HEATER CORE GROUND STRAP

REMOVAL..............................14

INSTALLATION...........................15

REMOTE SWITCHES

DESCRIPTION...........................15

OPERATION.............................15

DIAGNOSIS AND TESTING.................16

REMOTE SWITCHES....................16

REMOVAL..............................16

INSTALLATION...........................17

SPEAKER

DESCRIPTION...........................17

OPERATION.............................17

DIAGNOSIS AND TESTING.................18

SPEAKER............................18

A-PILLAR TWEETER SPEAKER

REMOVAL..............................19

INSTALLATION...........................19

FRONT DOOR SPEAKER

REMOVAL..............................20

INSTALLATION...........................20

REAR CAB SIDE PANEL SPEAKER

REMOVAL..............................20

INSTALLATION...........................21

REAR DOOR SPEAKER

REMOVAL..............................21

INSTALLATION...........................21

AUDIO

DESCRIPTION

An audio system is standard factory-installed equip-

ment on this model, unless the vehicle is ordered with

an available radio delete option. The standard equip-

ment audio system includes an AM/FM/cassette (RAS

sales code) receiver, and speakers in four locations. Sev-

eral combinations of radio receivers and speaker systems

are offered as optional equipment on this model. The

audio system uses an ignition switched source of battery

current so that the system will only operate when theignition switch is in the On or Accessory positions. The

audio system includes the following components:

²Antenna

²Clockspring (with remote radio switches only)

²Filter, choke and speaker relay (with premium

speaker system only)

²High-line or premium Central Timer Module

(CTM) (with remote radio switches)

²Radio noise suppression components

²Radio receiver

²Remote radio switches (optional with RAZ radio

receiver only)

²Speakers

BR/BEAUDIO 8A - 1

Page 435 of 2889

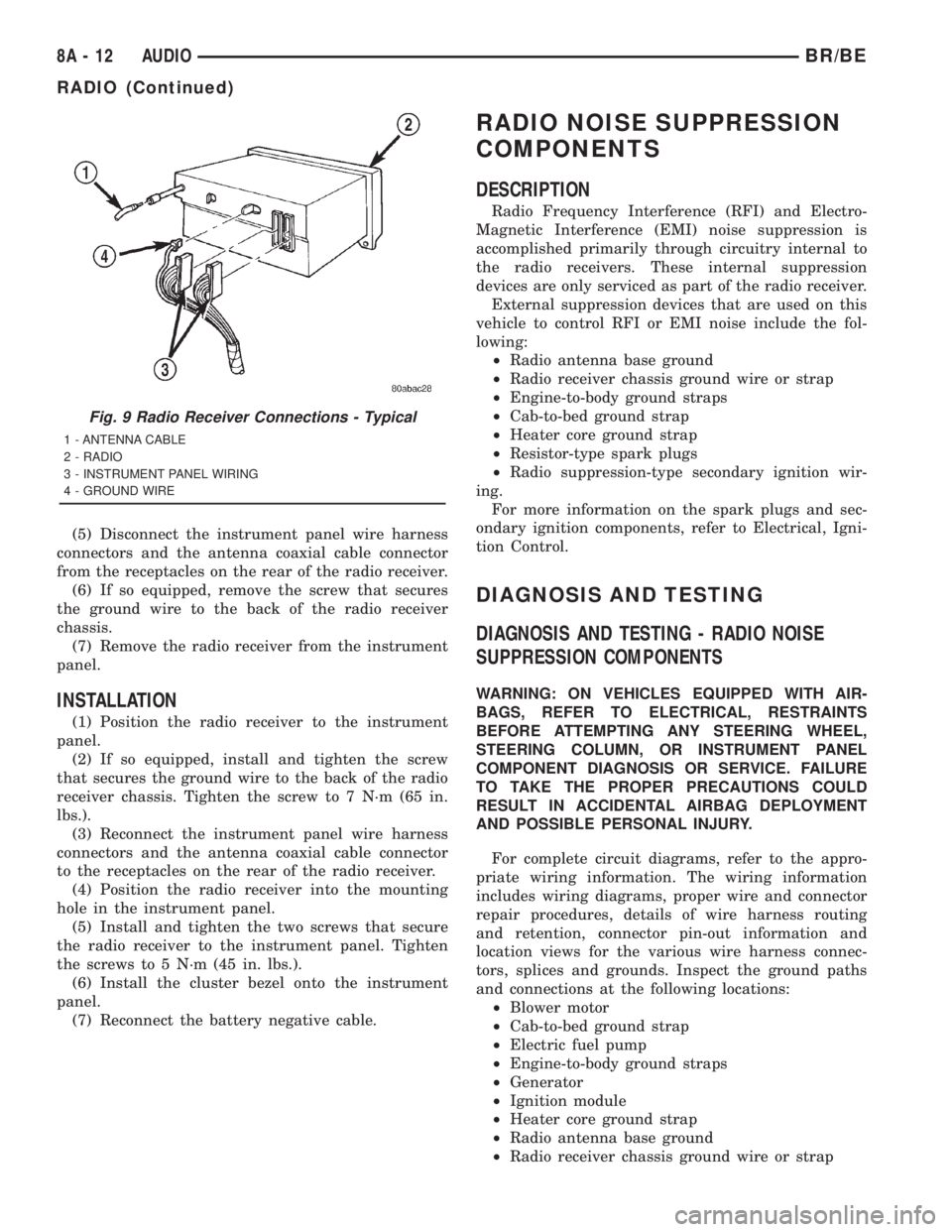

(5) Disconnect the instrument panel wire harness

connectors and the antenna coaxial cable connector

from the receptacles on the rear of the radio receiver.

(6) If so equipped, remove the screw that secures

the ground wire to the back of the radio receiver

chassis.

(7) Remove the radio receiver from the instrument

panel.

INSTALLATION

(1) Position the radio receiver to the instrument

panel.

(2) If so equipped, install and tighten the screw

that secures the ground wire to the back of the radio

receiver chassis. Tighten the screw to 7 N´m (65 in.

lbs.).

(3) Reconnect the instrument panel wire harness

connectors and the antenna coaxial cable connector

to the receptacles on the rear of the radio receiver.

(4) Position the radio receiver into the mounting

hole in the instrument panel.

(5) Install and tighten the two screws that secure

the radio receiver to the instrument panel. Tighten

the screws to 5 N´m (45 in. lbs.).

(6) Install the cluster bezel onto the instrument

panel.

(7) Reconnect the battery negative cable.

RADIO NOISE SUPPRESSION

COMPONENTS

DESCRIPTION

Radio Frequency Interference (RFI) and Electro-

Magnetic Interference (EMI) noise suppression is

accomplished primarily through circuitry internal to

the radio receivers. These internal suppression

devices are only serviced as part of the radio receiver.

External suppression devices that are used on this

vehicle to control RFI or EMI noise include the fol-

lowing:

²Radio antenna base ground

²Radio receiver chassis ground wire or strap

²Engine-to-body ground straps

²Cab-to-bed ground strap

²Heater core ground strap

²Resistor-type spark plugs

²Radio suppression-type secondary ignition wir-

ing.

For more information on the spark plugs and sec-

ondary ignition components, refer to Electrical, Igni-

tion Control.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - RADIO NOISE

SUPPRESSION COMPONENTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds. Inspect the ground paths

and connections at the following locations:

²Blower motor

²Cab-to-bed ground strap

²Electric fuel pump

²Engine-to-body ground straps

²Generator

²Ignition module

²Heater core ground strap

²Radio antenna base ground

²Radio receiver chassis ground wire or strap

Fig. 9 Radio Receiver Connections - Typical

1 - ANTENNA CABLE

2 - RADIO

3 - INSTRUMENT PANEL WIRING

4 - GROUND WIRE

8A - 12 AUDIOBR/BE

RADIO (Continued)

Page 437 of 2889

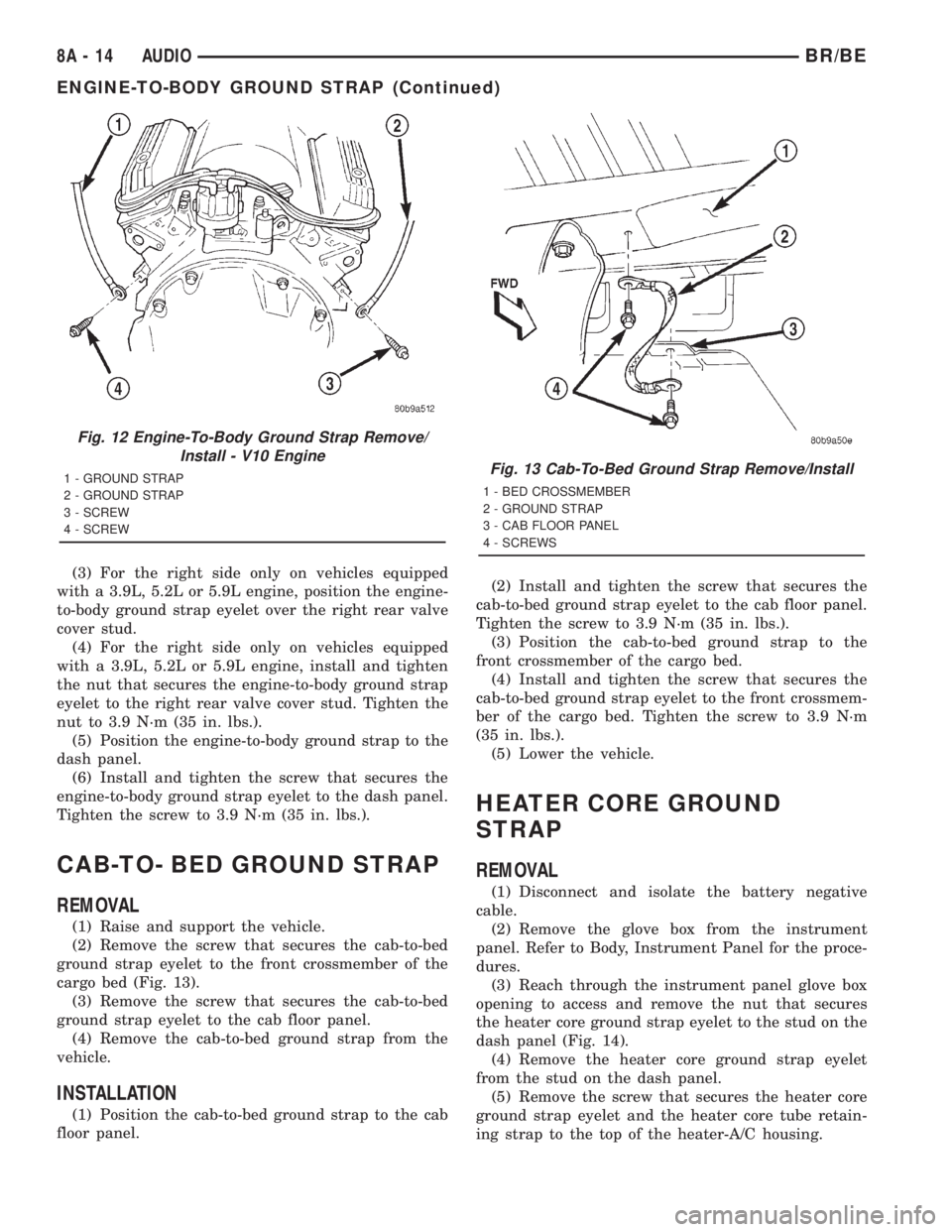

(3) For the right side only on vehicles equipped

with a 3.9L, 5.2L or 5.9L engine, position the engine-

to-body ground strap eyelet over the right rear valve

cover stud.

(4) For the right side only on vehicles equipped

with a 3.9L, 5.2L or 5.9L engine, install and tighten

the nut that secures the engine-to-body ground strap

eyelet to the right rear valve cover stud. Tighten the

nut to 3.9 N´m (35 in. lbs.).

(5) Position the engine-to-body ground strap to the

dash panel.

(6) Install and tighten the screw that secures the

engine-to-body ground strap eyelet to the dash panel.

Tighten the screw to 3.9 N´m (35 in. lbs.).

CAB-TO- BED GROUND STRAP

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the screw that secures the cab-to-bed

ground strap eyelet to the front crossmember of the

cargo bed (Fig. 13).

(3) Remove the screw that secures the cab-to-bed

ground strap eyelet to the cab floor panel.

(4) Remove the cab-to-bed ground strap from the

vehicle.

INSTALLATION

(1) Position the cab-to-bed ground strap to the cab

floor panel.(2) Install and tighten the screw that secures the

cab-to-bed ground strap eyelet to the cab floor panel.

Tighten the screw to 3.9 N´m (35 in. lbs.).

(3) Position the cab-to-bed ground strap to the

front crossmember of the cargo bed.

(4) Install and tighten the screw that secures the

cab-to-bed ground strap eyelet to the front crossmem-

ber of the cargo bed. Tighten the screw to 3.9 N´m

(35 in. lbs.).

(5) Lower the vehicle.

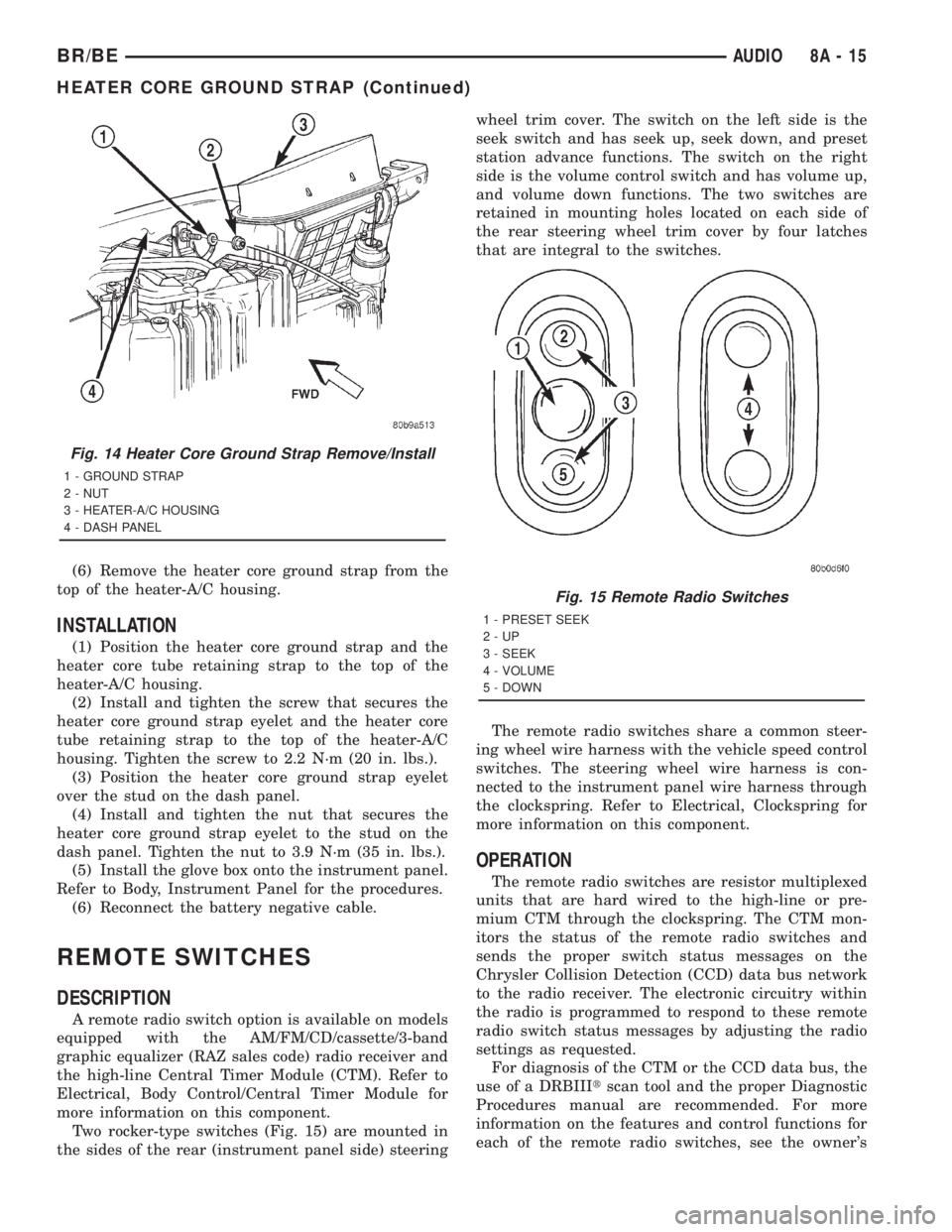

HEATER CORE GROUND

STRAP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel. Refer to Body, Instrument Panel for the proce-

dures.

(3) Reach through the instrument panel glove box

opening to access and remove the nut that secures

the heater core ground strap eyelet to the stud on the

dash panel (Fig. 14).

(4) Remove the heater core ground strap eyelet

from the stud on the dash panel.

(5) Remove the screw that secures the heater core

ground strap eyelet and the heater core tube retain-

ing strap to the top of the heater-A/C housing.

Fig. 12 Engine-To-Body Ground Strap Remove/

Install - V10 Engine

1 - GROUND STRAP

2 - GROUND STRAP

3 - SCREW

4 - SCREWFig. 13 Cab-To-Bed Ground Strap Remove/Install

1 - BED CROSSMEMBER

2 - GROUND STRAP

3 - CAB FLOOR PANEL

4 - SCREWS

8A - 14 AUDIOBR/BE

ENGINE-TO-BODY GROUND STRAP (Continued)

Page 438 of 2889

(6) Remove the heater core ground strap from the

top of the heater-A/C housing.

INSTALLATION

(1) Position the heater core ground strap and the

heater core tube retaining strap to the top of the

heater-A/C housing.

(2) Install and tighten the screw that secures the

heater core ground strap eyelet and the heater core

tube retaining strap to the top of the heater-A/C

housing. Tighten the screw to 2.2 N´m (20 in. lbs.).

(3) Position the heater core ground strap eyelet

over the stud on the dash panel.

(4) Install and tighten the nut that secures the

heater core ground strap eyelet to the stud on the

dash panel. Tighten the nut to 3.9 N´m (35 in. lbs.).

(5) Install the glove box onto the instrument panel.

Refer to Body, Instrument Panel for the procedures.

(6) Reconnect the battery negative cable.

REMOTE SWITCHES

DESCRIPTION

A remote radio switch option is available on models

equipped with the AM/FM/CD/cassette/3-band

graphic equalizer (RAZ sales code) radio receiver and

the high-line Central Timer Module (CTM). Refer to

Electrical, Body Control/Central Timer Module for

more information on this component.

Two rocker-type switches (Fig. 15) are mounted in

the sides of the rear (instrument panel side) steeringwheel trim cover. The switch on the left side is the

seek switch and has seek up, seek down, and preset

station advance functions. The switch on the right

side is the volume control switch and has volume up,

and volume down functions. The two switches are

retained in mounting holes located on each side of

the rear steering wheel trim cover by four latches

that are integral to the switches.

The remote radio switches share a common steer-

ing wheel wire harness with the vehicle speed control

switches. The steering wheel wire harness is con-

nected to the instrument panel wire harness through

the clockspring. Refer to Electrical, Clockspring for

more information on this component.

OPERATION

The remote radio switches are resistor multiplexed

units that are hard wired to the high-line or pre-

mium CTM through the clockspring. The CTM mon-

itors the status of the remote radio switches and

sends the proper switch status messages on the

Chrysler Collision Detection (CCD) data bus network

to the radio receiver. The electronic circuitry within

the radio is programmed to respond to these remote

radio switch status messages by adjusting the radio

settings as requested.

For diagnosis of the CTM or the CCD data bus, the

use of a DRBIIItscan tool and the proper Diagnostic

Procedures manual are recommended. For more

information on the features and control functions for

each of the remote radio switches, see the owner's

Fig. 14 Heater Core Ground Strap Remove/Install

1 - GROUND STRAP

2 - NUT

3 - HEATER-A/C HOUSING

4 - DASH PANEL

Fig. 15 Remote Radio Switches

1 - PRESET SEEK

2-UP

3 - SEEK

4 - VOLUME

5 - DOWN

BR/BEAUDIO 8A - 15

HEATER CORE GROUND STRAP (Continued)

Page 593 of 2889

above the temperature gauge. The voltage gauge con-

sists of a movable gauge needle or pointer controlled

by the instrument cluster circuitry and a fixed 90

degree scale on the cluster overlay that reads left-to-

right from 8 volts to 18 volts. An International Con-

trol and Display Symbol icon for ªBattery Charging

Conditionº is located directly below the lowest grad-

uation of the gauge scale. The voltage gauge graphics

are white against a black field except for a single red

graduation at each end of the gauge scale, making

them clearly visible within the instrument cluster in

daylight. When illuminated from behind by the panel

lamps dimmer controlled cluster illumination lighting

with the exterior lamps turned On, the white graph-

ics appear blue-green and the red graphics appear

red. The orange gauge needle is internally illumi-

nated. Gauge illumination is provided by replaceable

incandescent bulb and bulb holder units located on

the instrument cluster electronic circuit board. The

voltage gauge is serviced as a unit with the instru-

ment cluster.

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon the cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Chrysler

Collision Detection (CCD) data bus. The voltage

gauge is an air core magnetic unit that receives bat-

tery current on the instrument cluster electronic cir-

cuit board through the fused ignition switch output

(st-run) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Charge Fail Message- Each time the cluster

receives a message from the PCM indicating a charge

fail condition (system voltage is 10.8 volts or lower),

the gauge needle is moved to the 8 volt graduation

on the gauge scale and the check gauges indicator is

illuminated. The gauge needle remains on the 8 volt

graduation and the check gauges indicator remains

illuminated until the cluster receives a message from

the PCM indicating there is no charge fail condition

(system voltage is 10.9 volts or higher, but lower

than 16.7 volts), or until the ignition switch is turned

to the Off position, whichever occurs first. On models

equipped with the optional diesel engine, the instru-

ment cluster is programmed to support the voltmeter

gauge needle above the low end of normal graduation

and suppress the check gauges indicator operationuntil ten seconds after the engine intake manifold air

heater has completed its cycle.

²Voltage High Message- Each time the cluster

receives a message from the PCM indicating a volt-

age high condition (system voltage is 16.7 volts or

higher), the gauge needle is moved to the 18 volt

graduation on the gauge scale and the check gauges

indicator is illuminated. The gauge needle remains

on the 18 volt graduation and the check gauges indi-

cator remains illuminated until the cluster receives a

message from the PCM indicating there is no voltage

high condition (system voltage is 16.6 volts or lower,

but higher than 10.9 volts), or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Message Failure- If the cluster fails to receive

a system voltage message, it will hold the gauge nee-

dle at the last indication until a new message is

received, or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept to several calibration points on the gauge scale

in a prescribed sequence in order to confirm the func-

tionality of the gauge and the cluster control cir-

cuitry.

The PCM continually monitors the system voltage

to control the generator output. The PCM then sends

the proper system voltage messages to the instru-

ment cluster. For further diagnosis of the voltage

gauge or the instrument cluster circuitry that con-

trols the gauge, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING). If

the instrument cluster turns on the check gauges

indicator due to a charge fail or voltage high condi-

tion, it may indicate that the charging system

requires service. For proper diagnosis of the charging

system, the CCD data bus, or the message inputs to

the instrument cluster that control the voltage

gauge, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is standard equipment on

all instrument clusters, but is only functional in vehi-

cles equipped with an optional diesel engine. The

wait-to-start indicator is located near the lower edge

of the instrument cluster overlay, to the right of cen-

ter. The wait-to-start indicator consists of a stenciled

cutout of the text ªWAIT TO STARTº in the opaque

layer of the cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. A red lens located

8J - 34 INSTRUMENT CLUSTERBR/BE

VOLTAGE GAUGE (Continued)

Page 1159 of 2889

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the upper crossmember and top core

support.

(4) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).(5) Discharge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove the A/C compressor with the lines

attached. Set aside.

(8) If equipped, remove the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(9) Remove the washer bottle.

(10) Remove the fan and fan shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(11) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(12) Remove the generator with the wire connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - REMOVAL).

(13) Remove the air cleaner box.

(14) Disconnect the throttle linkage.

(15) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(16) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(17) Remove the distributor cap and wiring.

(18) Disconnect the heater hoses.

(19) Disconnect the power steering hoses, if

equipped.

(20) Perform the Fuel System Pressure release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).Disconnect

the fuel supply line (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/QUICK CONNECT FITTING -

STANDARD PROCEDURE).

(21) On Manual Transmission vehicles, remove the

shift lever.

(22) Raise and support the vehicle on a hoist.

(23) Remove the drain plug and drain the engine

oil.

(24) Remove engine front mount through-bolt nuts.

(25)Automatic TransmissionRemove the trans-

mission cooler line brackets from oil pan.

(26) Disconnect exhaust pipe at manifold.

(27) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(28)Manual TransmissionRemove the transmis-

sion.(Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL - REMOVAL).

(29) Lower the vehicle.

CAUTION: DO NOT lift the engine by the intake

manifold.

(30) Install an engine lifting fixture.

9 - 12 ENGINE 3.9LBR/BE

ENGINE 3.9L (Continued)

Page 1160 of 2889

(31) Remove engine from vehicle and install

engine assembly on a repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the

through-bolt into the support cushion brackets.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4)Manual TransmissionInstall the transmis-

sion (Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL - INSTALLATION).

(5) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(6) Install exhaust pipe to manifold.

(7)Automatic TransmissionInstall the trans-

mission cooler line brackets on oil pan.

(8) Install engine front mount through-bolt nuts.

Tighten the nuts.

(9) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(10) Lower the vehicle.

(11) Remove engine-lifting fixture.

(12) On Manual Transmission vehicles, install the

shift lever.

(13) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(14) Connect the power steering hoses, if equipped.

(15) Connect the heater hoses.

(16) Install the distributor cap and wiring.

(17) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Connect the throttle linkage.

(20) Install the air cleaner box.

(21) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION).

(22) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(23) Install the fan and fan shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(24) Install the washer bottle.

(25) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(26) Install the A/C compressor with the lines

attached.

(27) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(28) Evacuate and charge the air conditioning sys-

tem, if equipped (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(29) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(30) Install the upper crossmember and top core

support.

(31) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(32) Connect the negative cable to the battery.

(33) Start engine and check for leaks.

BR/BEENGINE 3.9L 9 - 13

ENGINE 3.9L (Continued)