DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2471 of 2889

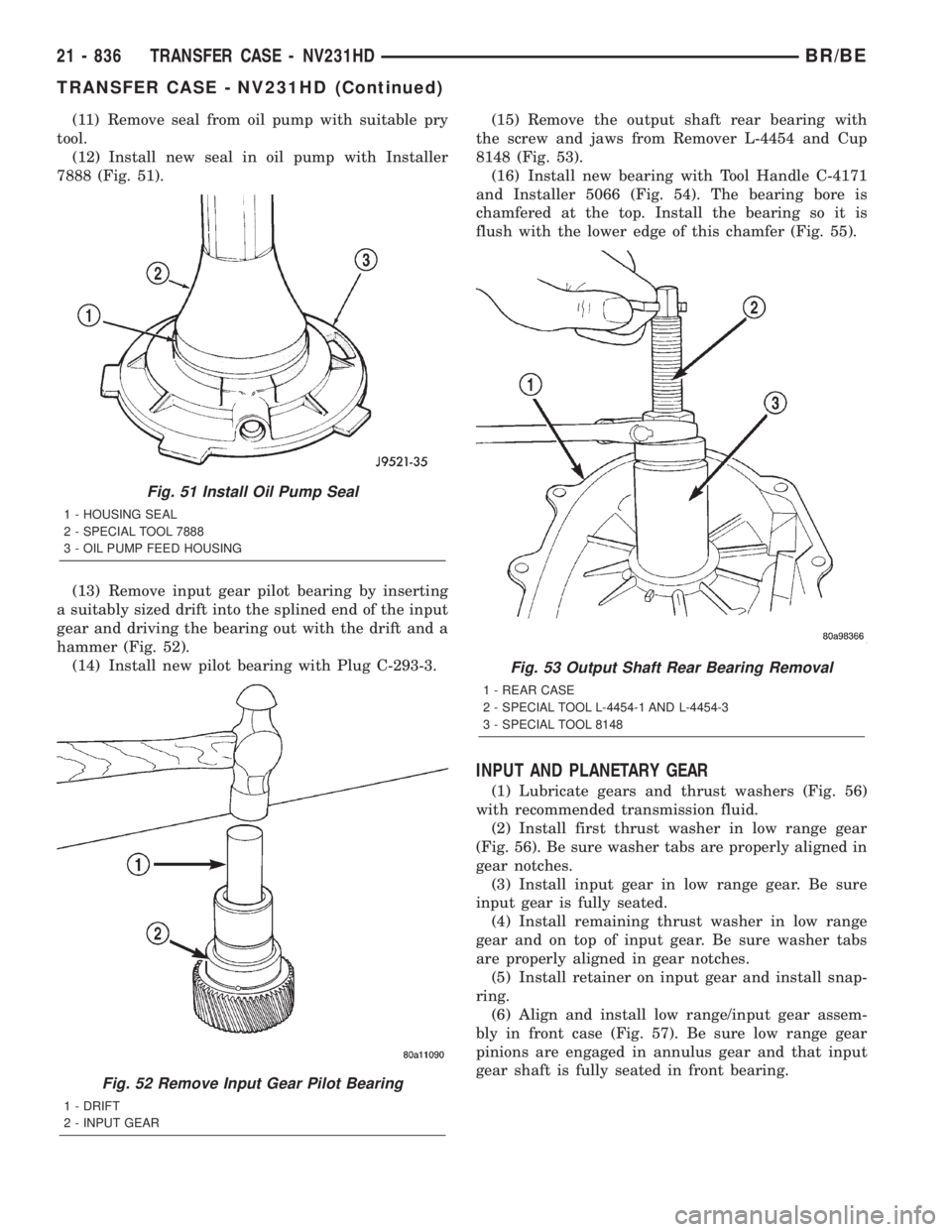

(11) Remove seal from oil pump with suitable pry

tool.

(12) Install new seal in oil pump with Installer

7888 (Fig. 51).

(13) Remove input gear pilot bearing by inserting

a suitably sized drift into the splined end of the input

gear and driving the bearing out with the drift and a

hammer (Fig. 52).

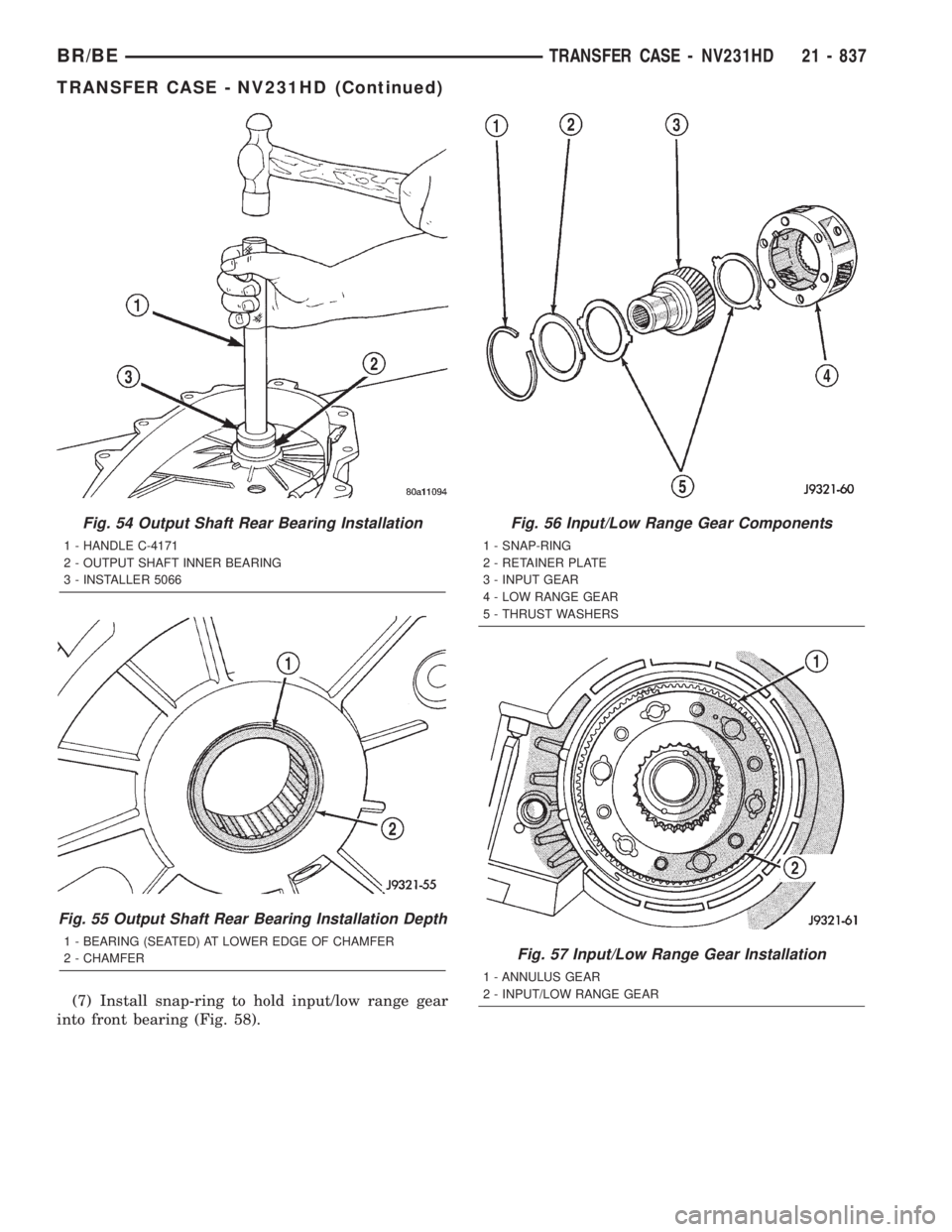

(14) Install new pilot bearing with Plug C-293-3.(15) Remove the output shaft rear bearing with

the screw and jaws from Remover L-4454 and Cup

8148 (Fig. 53).

(16) Install new bearing with Tool Handle C-4171

and Installer 5066 (Fig. 54). The bearing bore is

chamfered at the top. Install the bearing so it is

flush with the lower edge of this chamfer (Fig. 55).

INPUT AND PLANETARY GEAR

(1) Lubricate gears and thrust washers (Fig. 56)

with recommended transmission fluid.

(2) Install first thrust washer in low range gear

(Fig. 56). Be sure washer tabs are properly aligned in

gear notches.

(3) Install input gear in low range gear. Be sure

input gear is fully seated.

(4) Install remaining thrust washer in low range

gear and on top of input gear. Be sure washer tabs

are properly aligned in gear notches.

(5) Install retainer on input gear and install snap-

ring.

(6) Align and install low range/input gear assem-

bly in front case (Fig. 57). Be sure low range gear

pinions are engaged in annulus gear and that input

gear shaft is fully seated in front bearing.

Fig. 51 Install Oil Pump Seal

1 - HOUSING SEAL

2 - SPECIAL TOOL 7888

3 - OIL PUMP FEED HOUSING

Fig. 52 Remove Input Gear Pilot Bearing

1 - DRIFT

2 - INPUT GEAR

Fig. 53 Output Shaft Rear Bearing Removal

1 - REAR CASE

2 - SPECIAL TOOL L-4454-1 AND L-4454-3

3 - SPECIAL TOOL 8148

21 - 836 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2472 of 2889

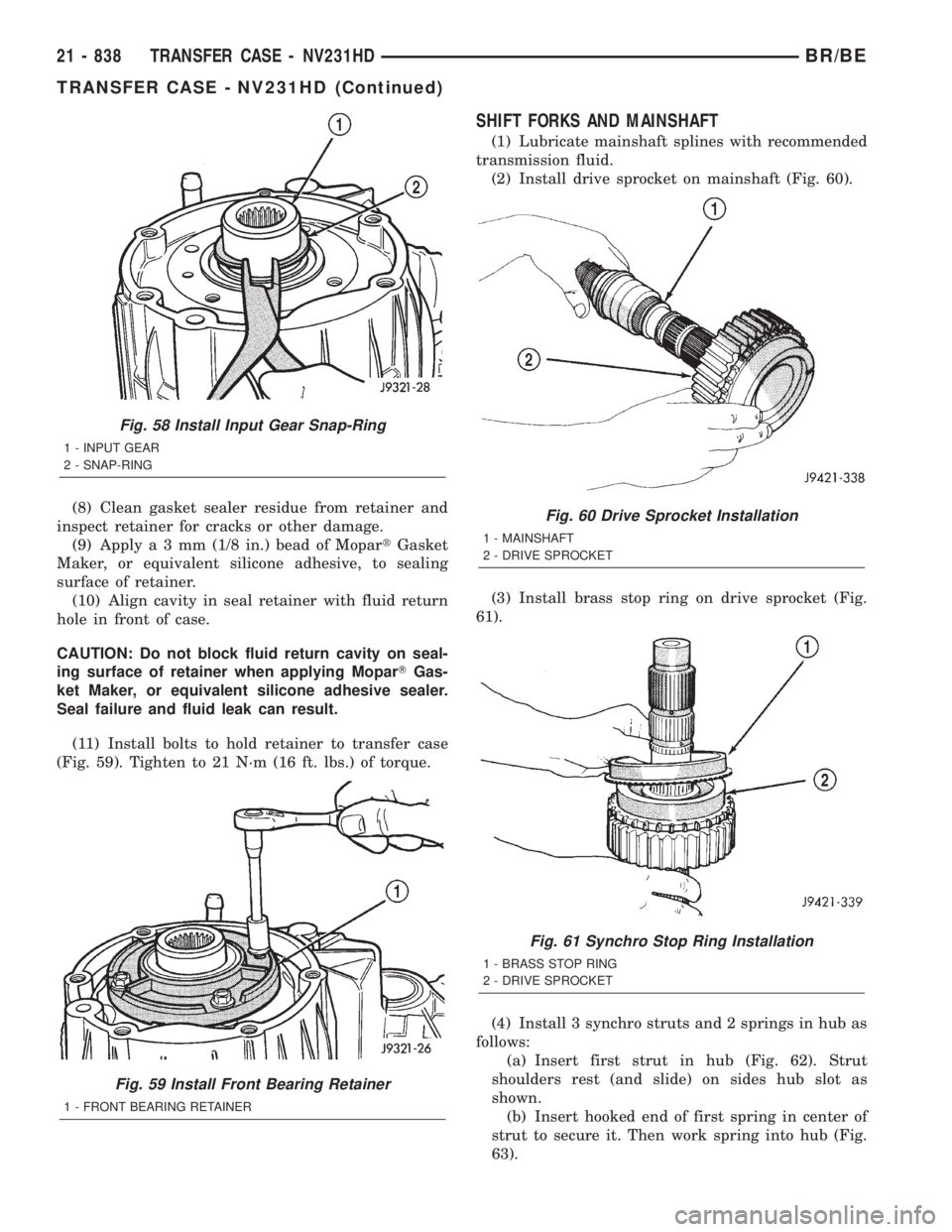

(7) Install snap-ring to hold input/low range gear

into front bearing (Fig. 58).

Fig. 54 Output Shaft Rear Bearing Installation

1 - HANDLE C-4171

2 - OUTPUT SHAFT INNER BEARING

3 - INSTALLER 5066

Fig. 55 Output Shaft Rear Bearing Installation Depth

1 - BEARING (SEATED) AT LOWER EDGE OF CHAMFER

2 - CHAMFER

Fig. 56 Input/Low Range Gear Components

1 - SNAP-RING

2 - RETAINER PLATE

3 - INPUT GEAR

4 - LOW RANGE GEAR

5 - THRUST WASHERS

Fig. 57 Input/Low Range Gear Installation

1 - ANNULUS GEAR

2 - INPUT/LOW RANGE GEAR

BR/BETRANSFER CASE - NV231HD 21 - 837

TRANSFER CASE - NV231HD (Continued)

Page 2473 of 2889

(8) Clean gasket sealer residue from retainer and

inspect retainer for cracks or other damage.

(9) Applya3mm(1/8 in.) bead of MopartGasket

Maker, or equivalent silicone adhesive, to sealing

surface of retainer.

(10) Align cavity in seal retainer with fluid return

hole in front of case.

CAUTION: Do not block fluid return cavity on seal-

ing surface of retainer when applying MoparTGas-

ket Maker, or equivalent silicone adhesive sealer.

Seal failure and fluid leak can result.

(11) Install bolts to hold retainer to transfer case

(Fig. 59). Tighten to 21 N´m (16 ft. lbs.) of torque.

SHIFT FORKS AND MAINSHAFT

(1) Lubricate mainshaft splines with recommended

transmission fluid.

(2) Install drive sprocket on mainshaft (Fig. 60).

(3) Install brass stop ring on drive sprocket (Fig.

61).

(4) Install 3 synchro struts and 2 springs in hub as

follows:

(a) Insert first strut in hub (Fig. 62). Strut

shoulders rest (and slide) on sides hub slot as

shown.

(b) Insert hooked end of first spring in center of

strut to secure it. Then work spring into hub (Fig.

63).

Fig. 58 Install Input Gear Snap-Ring

1 - INPUT GEAR

2 - SNAP-RING

Fig. 59 Install Front Bearing Retainer

1 - FRONT BEARING RETAINER

Fig. 60 Drive Sprocket Installation

1 - MAINSHAFT

2 - DRIVE SPROCKET

Fig. 61 Synchro Stop Ring Installation

1 - BRASS STOP RING

2 - DRIVE SPROCKET

21 - 838 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2474 of 2889

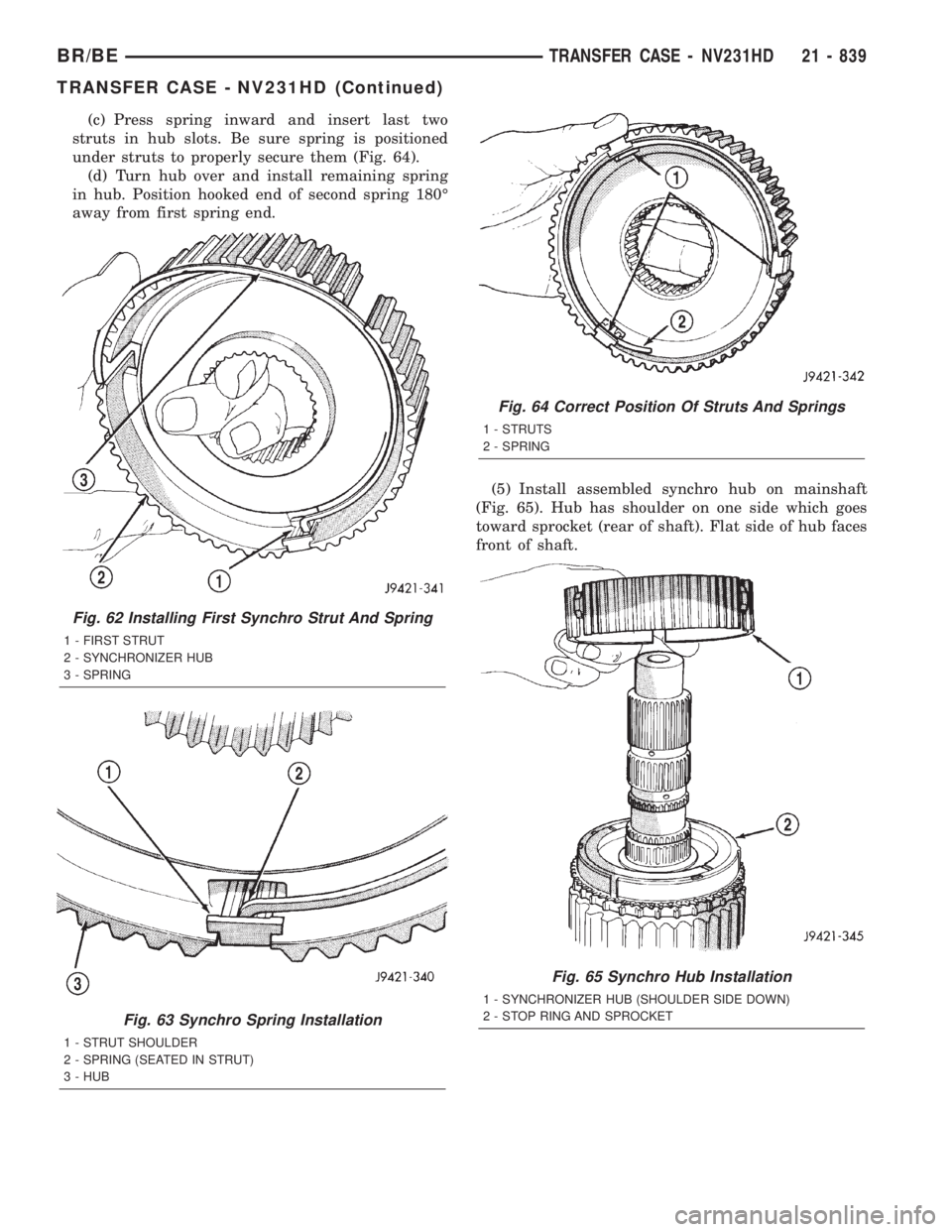

(c) Press spring inward and insert last two

struts in hub slots. Be sure spring is positioned

under struts to properly secure them (Fig. 64).

(d) Turn hub over and install remaining spring

in hub. Position hooked end of second spring 180É

away from first spring end.

(5) Install assembled synchro hub on mainshaft

(Fig. 65). Hub has shoulder on one side which goes

toward sprocket (rear of shaft). Flat side of hub faces

front of shaft.

Fig. 62 Installing First Synchro Strut And Spring

1 - FIRST STRUT

2 - SYNCHRONIZER HUB

3 - SPRING

Fig. 63 Synchro Spring Installation

1 - STRUT SHOULDER

2 - SPRING (SEATED IN STRUT)

3 - HUB

Fig. 64 Correct Position Of Struts And Springs

1 - STRUTS

2 - SPRING

Fig. 65 Synchro Hub Installation

1 - SYNCHRONIZER HUB (SHOULDER SIDE DOWN)

2 - STOP RING AND SPROCKET

BR/BETRANSFER CASE - NV231HD 21 - 839

TRANSFER CASE - NV231HD (Continued)

Page 2475 of 2889

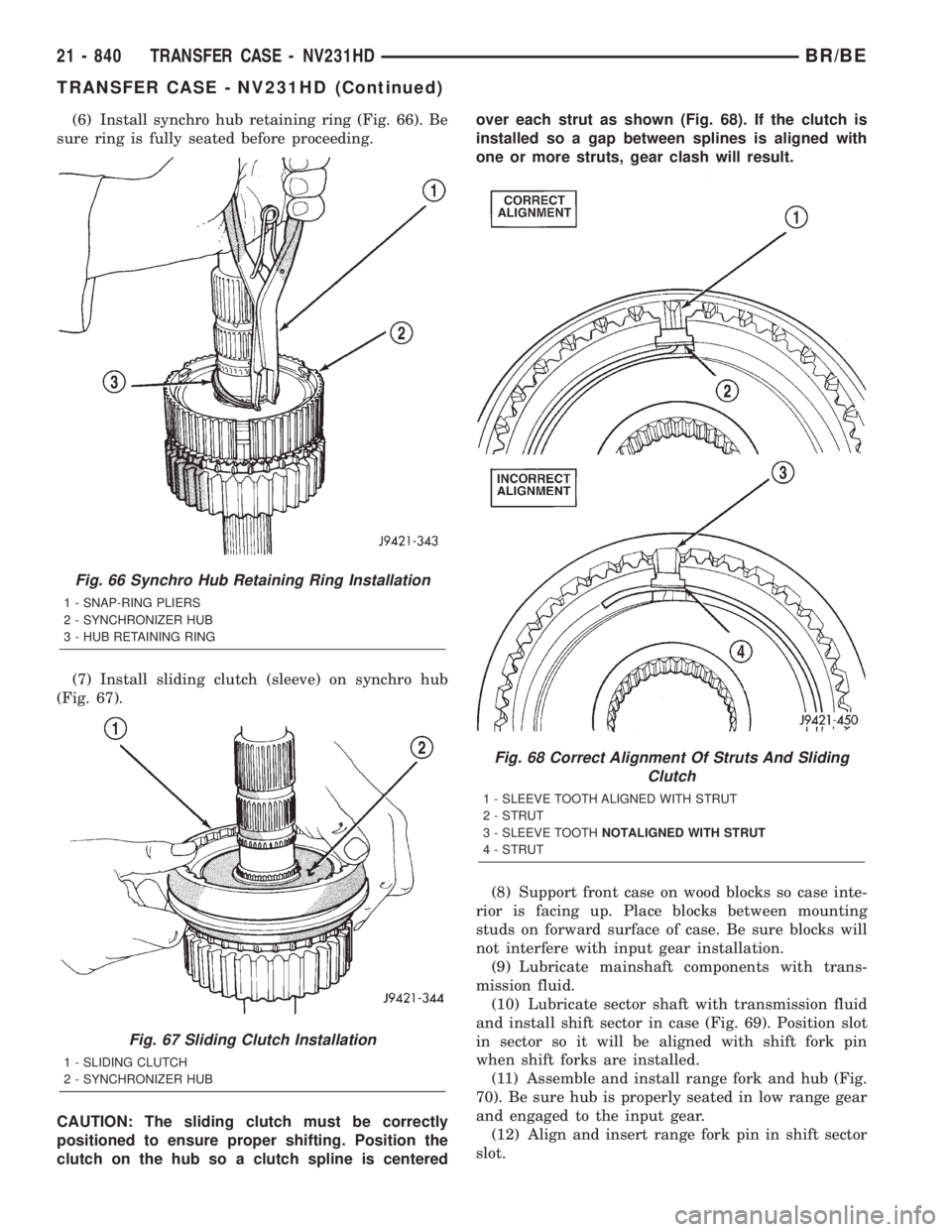

(6) Install synchro hub retaining ring (Fig. 66). Be

sure ring is fully seated before proceeding.

(7) Install sliding clutch (sleeve) on synchro hub

(Fig. 67).

CAUTION: The sliding clutch must be correctly

positioned to ensure proper shifting. Position the

clutch on the hub so a clutch spline is centeredover each strut as shown (Fig. 68). If the clutch is

installed so a gap between splines is aligned with

one or more struts, gear clash will result.

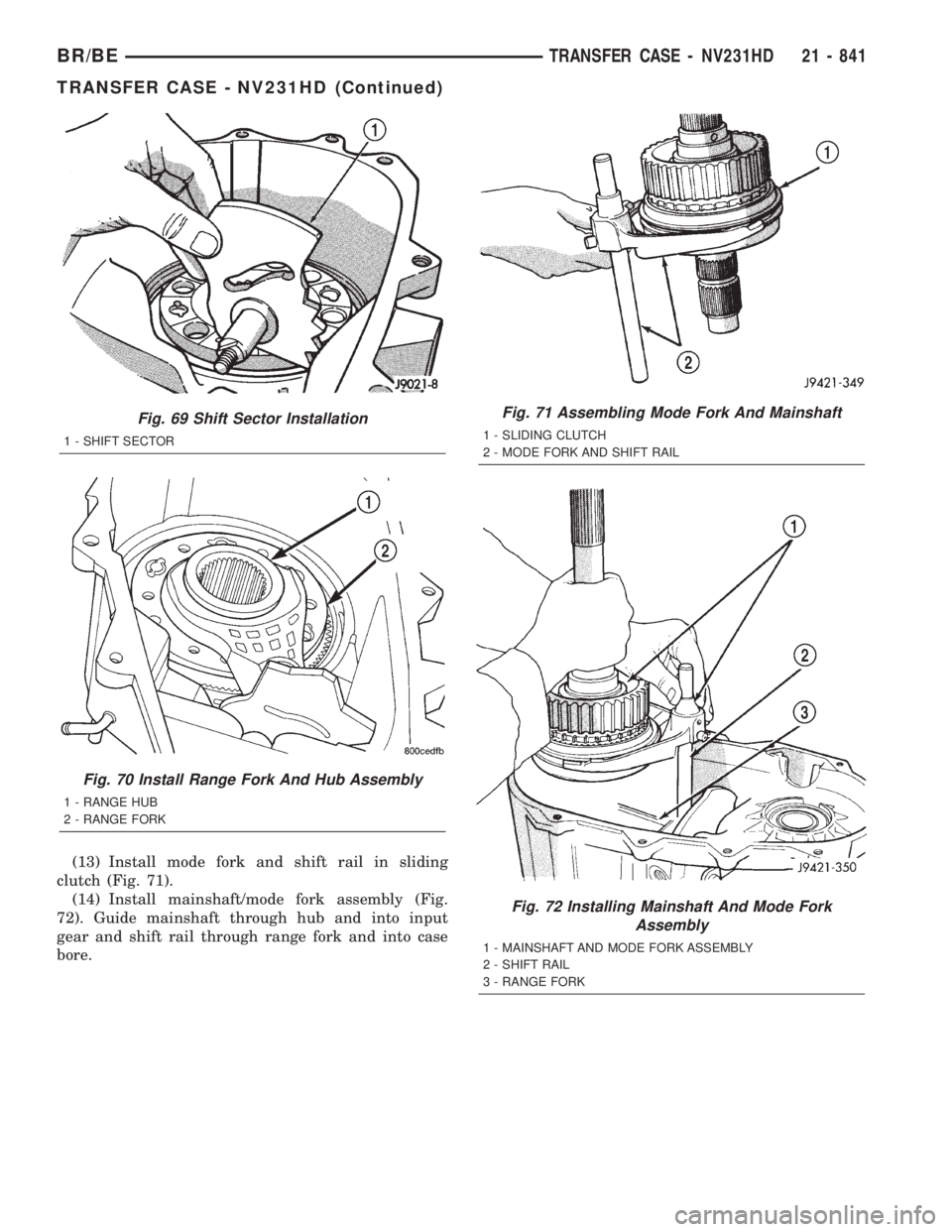

(8) Support front case on wood blocks so case inte-

rior is facing up. Place blocks between mounting

studs on forward surface of case. Be sure blocks will

not interfere with input gear installation.

(9) Lubricate mainshaft components with trans-

mission fluid.

(10) Lubricate sector shaft with transmission fluid

and install shift sector in case (Fig. 69). Position slot

in sector so it will be aligned with shift fork pin

when shift forks are installed.

(11) Assemble and install range fork and hub (Fig.

70). Be sure hub is properly seated in low range gear

and engaged to the input gear.

(12) Align and insert range fork pin in shift sector

slot.

Fig. 66 Synchro Hub Retaining Ring Installation

1 - SNAP-RING PLIERS

2 - SYNCHRONIZER HUB

3 - HUB RETAINING RING

Fig. 67 Sliding Clutch Installation

1 - SLIDING CLUTCH

2 - SYNCHRONIZER HUB

Fig. 68 Correct Alignment Of Struts And Sliding

Clutch

1 - SLEEVE TOOTH ALIGNED WITH STRUT

2 - STRUT

3 - SLEEVE TOOTHNOTALIGNED WITH STRUT

4 - STRUT

21 - 840 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2476 of 2889

(13) Install mode fork and shift rail in sliding

clutch (Fig. 71).

(14) Install mainshaft/mode fork assembly (Fig.

72). Guide mainshaft through hub and into input

gear and shift rail through range fork and into case

bore.

Fig. 69 Shift Sector Installation

1 - SHIFT SECTOR

Fig. 70 Install Range Fork And Hub Assembly

1 - RANGE HUB

2 - RANGE FORK

Fig. 71 Assembling Mode Fork And Mainshaft

1 - SLIDING CLUTCH

2 - MODE FORK AND SHIFT RAIL

Fig. 72 Installing Mainshaft And Mode Fork

Assembly

1 - MAINSHAFT AND MODE FORK ASSEMBLY

2 - SHIFT RAIL

3 - RANGE FORK

BR/BETRANSFER CASE - NV231HD 21 - 841

TRANSFER CASE - NV231HD (Continued)

Page 2477 of 2889

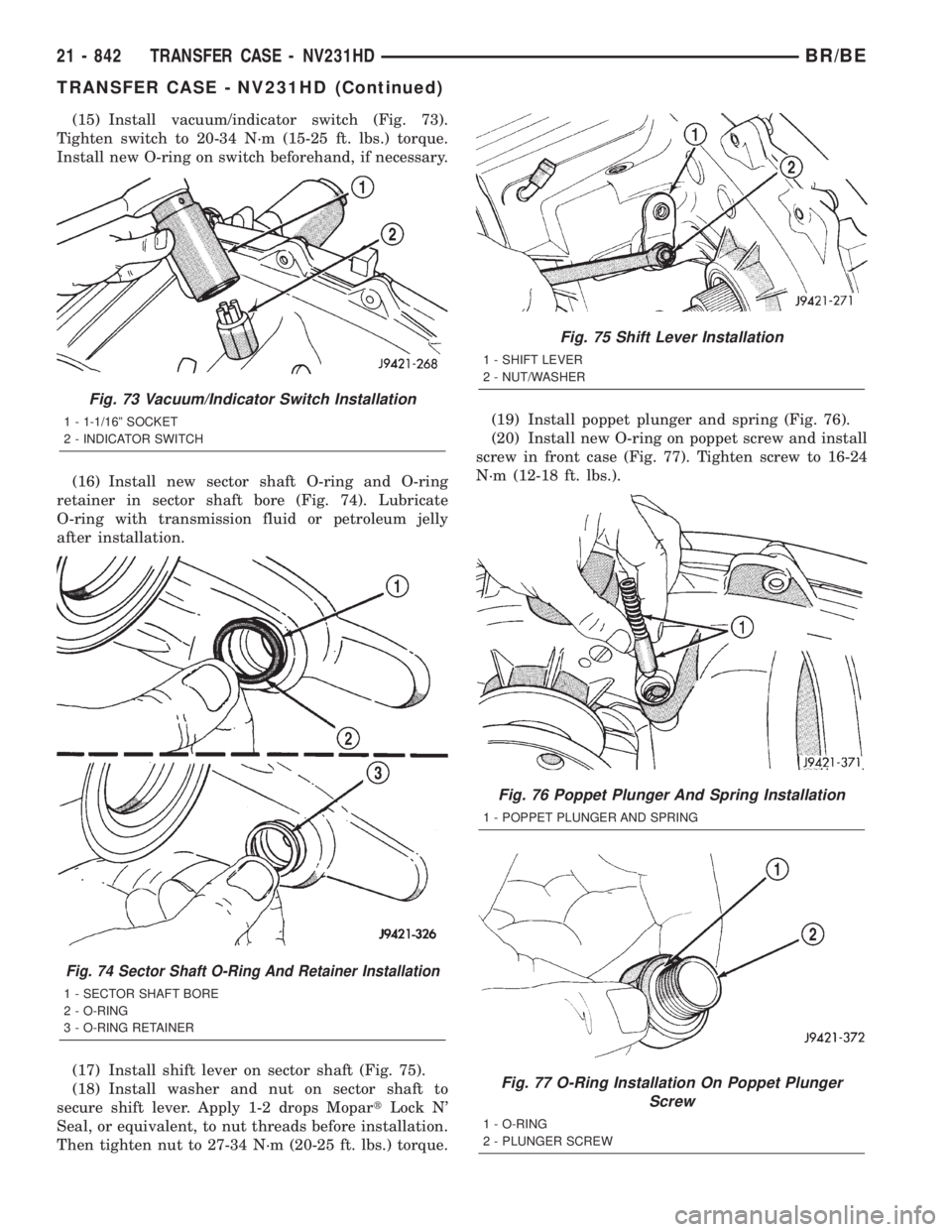

(15) Install vacuum/indicator switch (Fig. 73).

Tighten switch to 20-34 N´m (15-25 ft. lbs.) torque.

Install new O-ring on switch beforehand, if necessary.

(16) Install new sector shaft O-ring and O-ring

retainer in sector shaft bore (Fig. 74). Lubricate

O-ring with transmission fluid or petroleum jelly

after installation.

(17) Install shift lever on sector shaft (Fig. 75).

(18) Install washer and nut on sector shaft to

secure shift lever. Apply 1-2 drops MopartLock N'

Seal, or equivalent, to nut threads before installation.

Then tighten nut to 27-34 N´m (20-25 ft. lbs.) torque.(19) Install poppet plunger and spring (Fig. 76).

(20) Install new O-ring on poppet screw and install

screw in front case (Fig. 77). Tighten screw to 16-24

N´m (12-18 ft. lbs.).

Fig. 73 Vacuum/Indicator Switch Installation

1 - 1-1/16º SOCKET

2 - INDICATOR SWITCH

Fig. 74 Sector Shaft O-Ring And Retainer Installation

1 - SECTOR SHAFT BORE

2 - O-RING

3 - O-RING RETAINER

Fig. 75 Shift Lever Installation

1 - SHIFT LEVER

2 - NUT/WASHER

Fig. 76 Poppet Plunger And Spring Installation

1 - POPPET PLUNGER AND SPRING

Fig. 77 O-Ring Installation On Poppet Plunger

Screw

1 - O-RING

2 - PLUNGER SCREW

21 - 842 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2478 of 2889

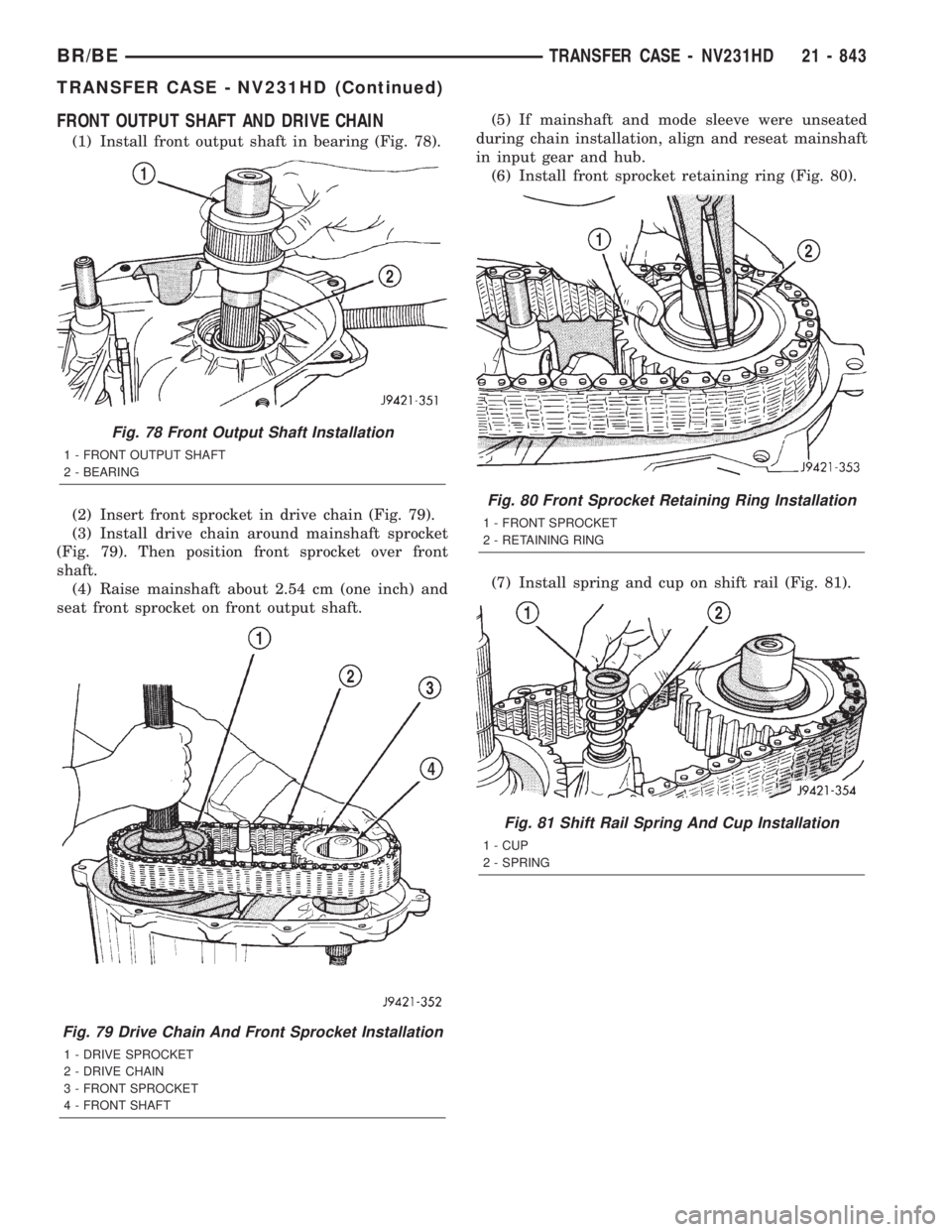

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Install front output shaft in bearing (Fig. 78).

(2) Insert front sprocket in drive chain (Fig. 79).

(3) Install drive chain around mainshaft sprocket

(Fig. 79). Then position front sprocket over front

shaft.

(4) Raise mainshaft about 2.54 cm (one inch) and

seat front sprocket on front output shaft.(5) If mainshaft and mode sleeve were unseated

during chain installation, align and reseat mainshaft

in input gear and hub.

(6) Install front sprocket retaining ring (Fig. 80).

(7) Install spring and cup on shift rail (Fig. 81).

Fig. 78 Front Output Shaft Installation

1 - FRONT OUTPUT SHAFT

2 - BEARING

Fig. 79 Drive Chain And Front Sprocket Installation

1 - DRIVE SPROCKET

2 - DRIVE CHAIN

3 - FRONT SPROCKET

4 - FRONT SHAFT

Fig. 80 Front Sprocket Retaining Ring Installation

1 - FRONT SPROCKET

2 - RETAINING RING

Fig. 81 Shift Rail Spring And Cup Installation

1 - CUP

2 - SPRING

BR/BETRANSFER CASE - NV231HD 21 - 843

TRANSFER CASE - NV231HD (Continued)

Page 2479 of 2889

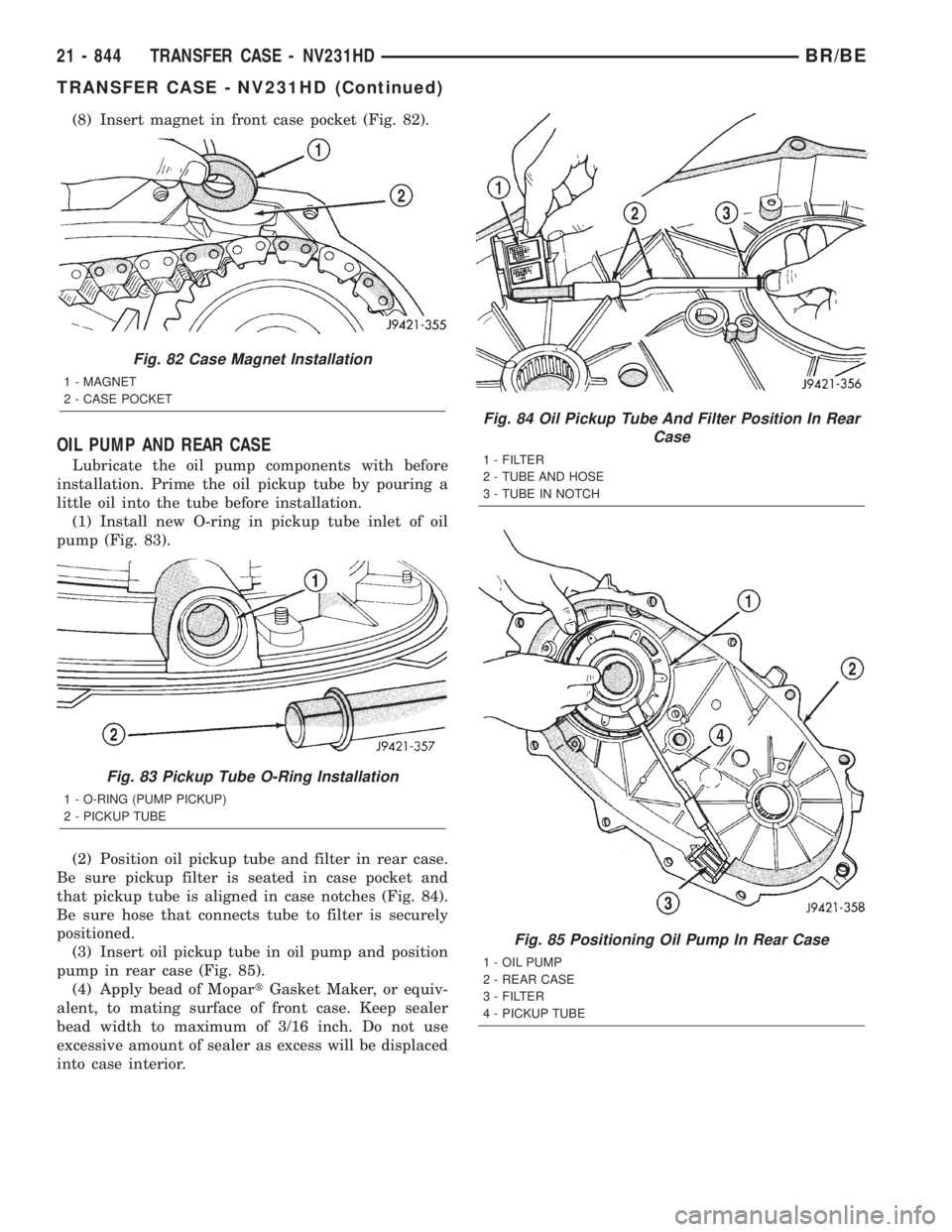

(8) Insert magnet in front case pocket (Fig. 82).

OIL PUMP AND REAR CASE

Lubricate the oil pump components with before

installation. Prime the oil pickup tube by pouring a

little oil into the tube before installation.

(1) Install new O-ring in pickup tube inlet of oil

pump (Fig. 83).

(2) Position oil pickup tube and filter in rear case.

Be sure pickup filter is seated in case pocket and

that pickup tube is aligned in case notches (Fig. 84).

Be sure hose that connects tube to filter is securely

positioned.

(3) Insert oil pickup tube in oil pump and position

pump in rear case (Fig. 85).

(4) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.

Fig. 82 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

Fig. 83 Pickup Tube O-Ring Installation

1 - O-RING (PUMP PICKUP)

2 - PICKUP TUBE

Fig. 84 Oil Pickup Tube And Filter Position In Rear

Case

1 - FILTER

2 - TUBE AND HOSE

3 - TUBE IN NOTCH

Fig. 85 Positioning Oil Pump In Rear Case

1 - OIL PUMP

2 - REAR CASE

3 - FILTER

4 - PICKUP TUBE

21 - 844 TRANSFER CASE - NV231HDBR/BE

TRANSFER CASE - NV231HD (Continued)

Page 2480 of 2889

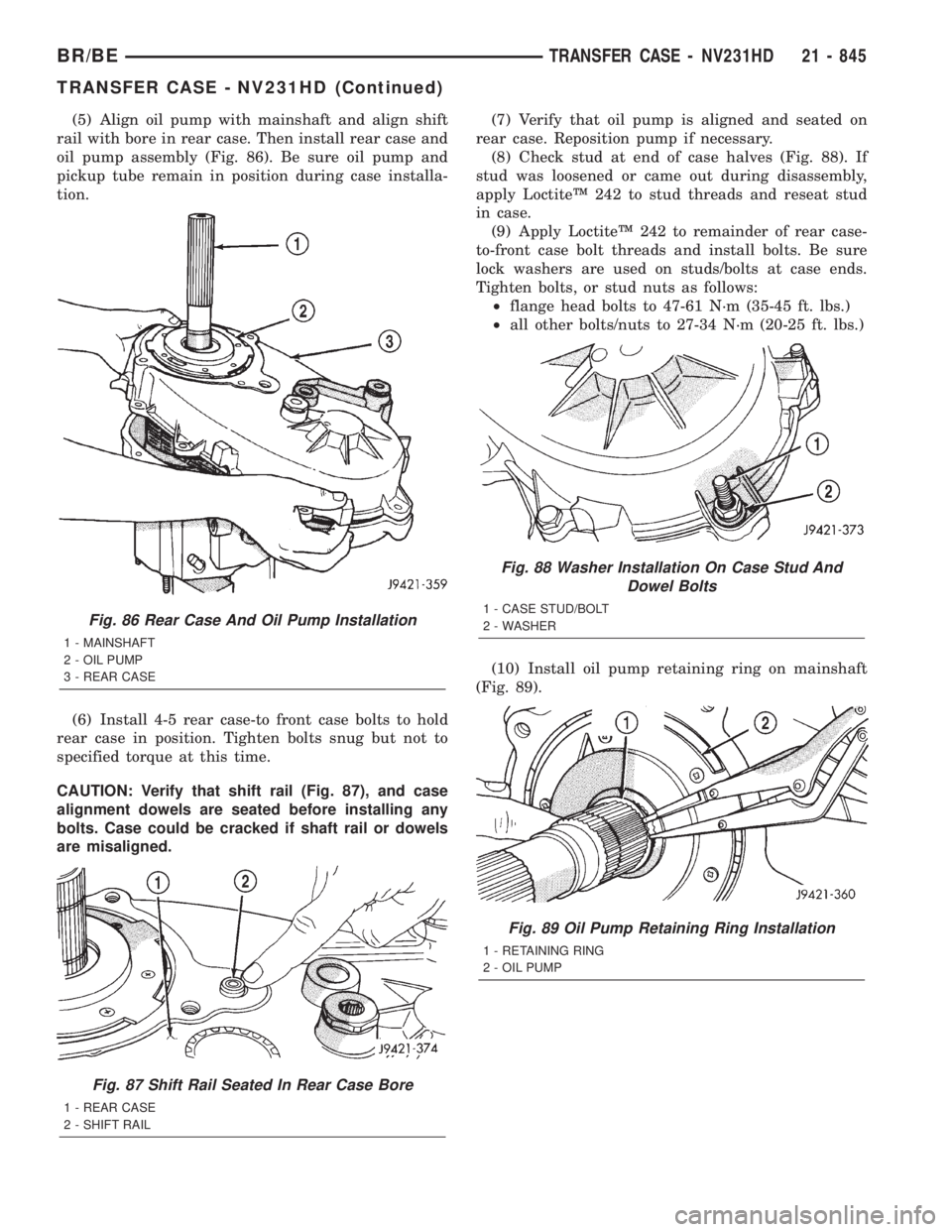

(5) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 86). Be sure oil pump and

pickup tube remain in position during case installa-

tion.

(6) Install 4-5 rear case-to front case bolts to hold

rear case in position. Tighten bolts snug but not to

specified torque at this time.

CAUTION: Verify that shift rail (Fig. 87), and case

alignment dowels are seated before installing any

bolts. Case could be cracked if shaft rail or dowels

are misaligned.(7) Verify that oil pump is aligned and seated on

rear case. Reposition pump if necessary.

(8) Check stud at end of case halves (Fig. 88). If

stud was loosened or came out during disassembly,

apply LoctiteŸ 242 to stud threads and reseat stud

in case.

(9) Apply LoctiteŸ 242 to remainder of rear case-

to-front case bolt threads and install bolts. Be sure

lock washers are used on studs/bolts at case ends.

Tighten bolts, or stud nuts as follows:

²flange head bolts to 47-61 N´m (35-45 ft. lbs.)

²all other bolts/nuts to 27-34 N´m (20-25 ft. lbs.)

(10) Install oil pump retaining ring on mainshaft

(Fig. 89).

Fig. 86 Rear Case And Oil Pump Installation

1 - MAINSHAFT

2 - OIL PUMP

3 - REAR CASE

Fig. 87 Shift Rail Seated In Rear Case Bore

1 - REAR CASE

2 - SHIFT RAIL

Fig. 88 Washer Installation On Case Stud And

Dowel Bolts

1 - CASE STUD/BOLT

2 - WASHER

Fig. 89 Oil Pump Retaining Ring Installation

1 - RETAINING RING

2 - OIL PUMP

BR/BETRANSFER CASE - NV231HD 21 - 845

TRANSFER CASE - NV231HD (Continued)