light DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1443 of 2889

²Milky discoloration indicates coolant dilution.

(4) Clean the area around the oil filter head.

Remove the filter (Refer to 9 - ENGINE/LUBRICA-

TION/OIL FILTER - REMOVAL).

(5) Install new oil filter (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION).

(6) Clean the drain plug and the sealing surface of

the pan. Check the condition of the threads and seal-

ing surface on the oil pan and drain plug.

(7) Install the drain plug. Tighten the plug to 60

N´m (44 ft. lbs.) torque.

(8) Use only High-Quality Multi-Viscosity lubricat-

ing oil in the Cummins Turbo Diesel engine. Choose

the correct oil for the operating conditions (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(9) Fill the engine with the correct grade of new oil

(Refer to LUBRICATION & MAINTENANCE/FLUID

CAPACITIES - SPECIFICATIONS).

(10) Start the engine and operate it at idle for sev-

eral minutes. Check for leaks at the filter and drain

plug.

(11) Stop engine. Wait several minutes to allow the

oil to drain back to the pan and check the level

again.

USED ENGINE OIL DISPOSAL Care should be

exercised when disposing of used engine oil after

it has been drained from a vehicle's engine.

OIL COOLER & LINES

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter using a 90-95 mm filter wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional ó turn.

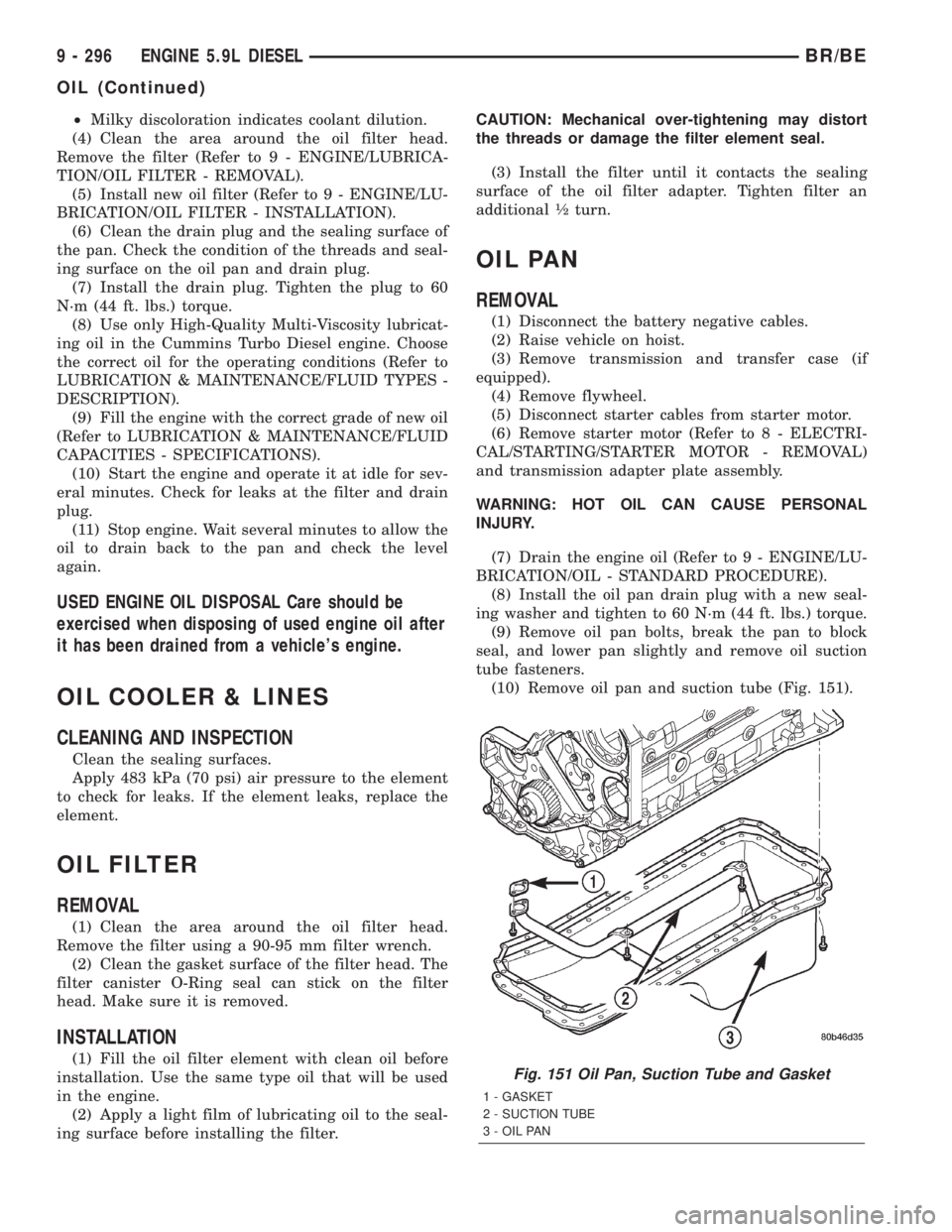

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove transmission and transfer case (if

equipped).

(4) Remove flywheel.

(5) Disconnect starter cables from starter motor.

(6) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(7) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).

(8) Install the oil pan drain plug with a new seal-

ing washer and tighten to 60 N´m (44 ft. lbs.) torque.

(9) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(10) Remove oil pan and suction tube (Fig. 151).

Fig. 151 Oil Pan, Suction Tube and Gasket

1 - GASKET

2 - SUCTION TUBE

3 - OIL PAN

9 - 296 ENGINE 5.9L DIESELBR/BE

OIL (Continued)

Page 1456 of 2889

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION............................1

DIAGNOSIS AND TESTING..................4

GAS ENGINE...........................4

DIESEL ENGINE........................4

SPECIFICATIONS.........................5

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

DESCRIPTION............................5

OPERATION.............................5

REMOVAL...............................5

INSPECTION.............................5

INSTALLATION............................5

CATALYTIC CONVERTER - 5.9L HEAVY

DUTY/8.0L

DESCRIPTION............................6

OPERATION.............................6

REMOVAL...............................6

INSPECTION.............................7

INSTALLATION............................7

EXHAUST PIPE - 3.9L/5.2L/5.9L

REMOVAL...............................7

INSPECTION.............................7

INSTALLATION............................7

EXHAUST PIPE - 5.9L HEAVY DUTY/8.0L

REMOVAL...............................8

INSPECTION.............................9

INSTALLATION............................9

EXHAUST PIPE - 5.9L DIESEL

REMOVAL...............................9

INSPECTION.............................9

INSTALLATION...........................10

HEAT SHIELDS

DESCRIPTION...........................10

REMOVAL..............................10

INSTALLATION...........................10MUFFLER - 3.9L/5.2L/5.9L/8.0L

REMOVAL..............................10

INSTALLATION...........................11

MUFFLER - 5.9L DIESEL

REMOVAL..............................11

INSTALLATION...........................11

TAILPIPE - 3.9L/5.2L/5.9L

REMOVAL..............................11

INSPECTION............................11

INSTALLATION...........................12

TAILPIPE - 5.9L HEAVY DUTY/8.0L

REMOVAL..............................12

INSPECTION............................12

INSTALLATION...........................12

TAILPIPE - 5.9L DIESEL

REMOVAL..............................12

INSPECTION............................12

INSTALLATION...........................12

RESONATOR

REMOVAL..............................13

INSTALLATION...........................13

TURBOCHARGER

DESCRIPTION...........................13

OPERATION.............................13

REMOVAL..............................15

CLEANING..............................16

INSPECTION............................16

INSTALLATION...........................16

CHARGE AIR COOLER AND PLUMBING

DESCRIPTION...........................17

OPERATION.............................17

REMOVAL..............................17

CLEANING..............................18

INSPECTION............................18

INSTALLATION...........................18

EXHAUST SYSTEM

DESCRIPTIONÐ3.9L/5.2L/5.9/8.0L

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

BR/BEEXHAUST SYSTEM 11 - 1

Page 1458 of 2889

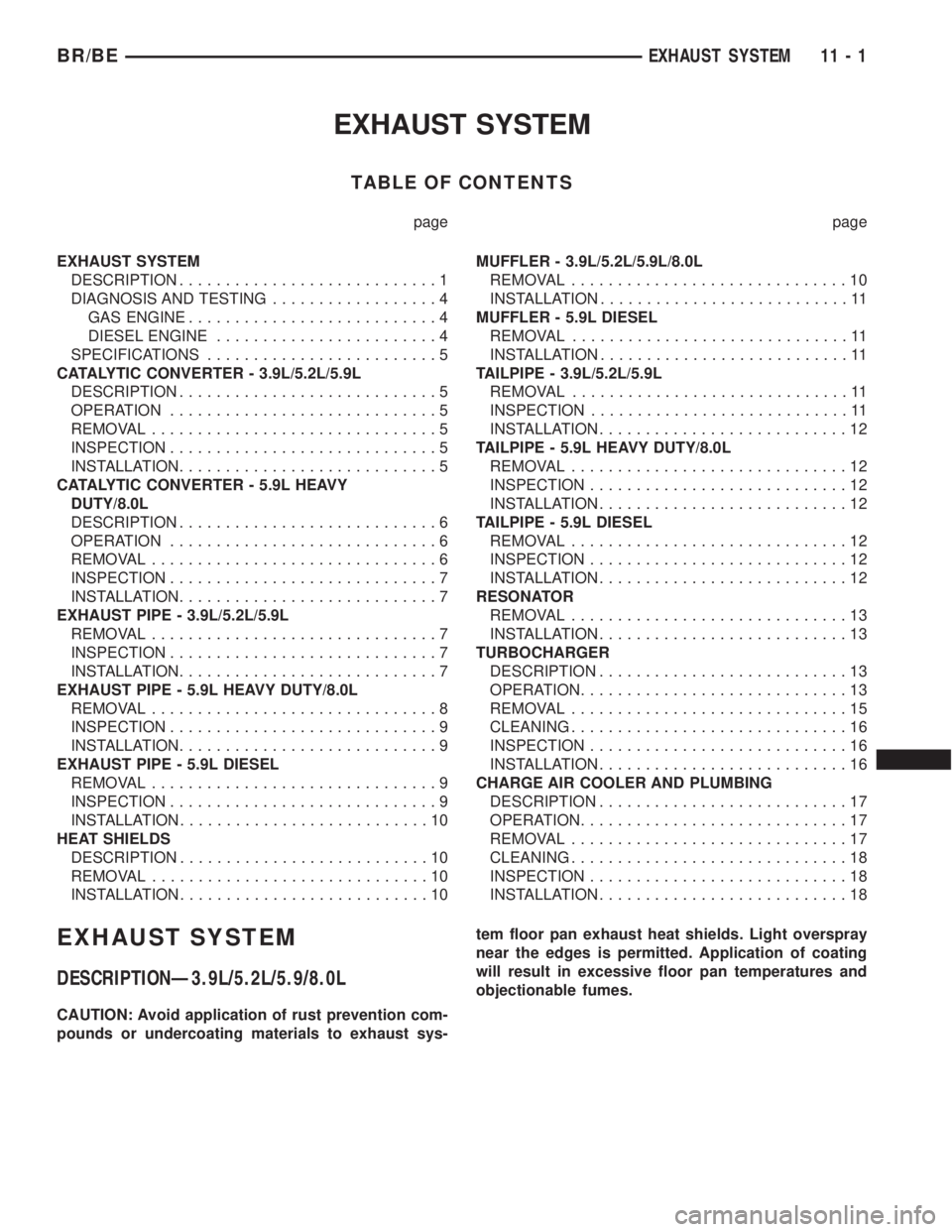

DESCRIPTIONÐ5.9L DIESEL

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

The diesel engine exhaust system consists of an

engine exhaust manifold, turbocharger, exhaust pipe,

resonator, extension pipe (if needed), muffler and

exhaust tailpipe.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. The

exhaust components should be kept a minimum of

25.4 mm (1.0 in.) away from the body and frame. If

the system contacts any body panel, it may amplify

objectionable noises from the engine or body.

Fig. 2 Catalytic Converter with Pipes and Mini

Catalytic Converters

1 - BOLT

2 - RETAINER

3 - EXHAUST MANIFOLD

4 - NUT

5 - MINI CATALYTIC CONVERTER

6 - CATALYTIC CONVERTER WITH PIPES

BR/BEEXHAUST SYSTEM 11 - 3

EXHAUST SYSTEM (Continued)

Page 1460 of 2889

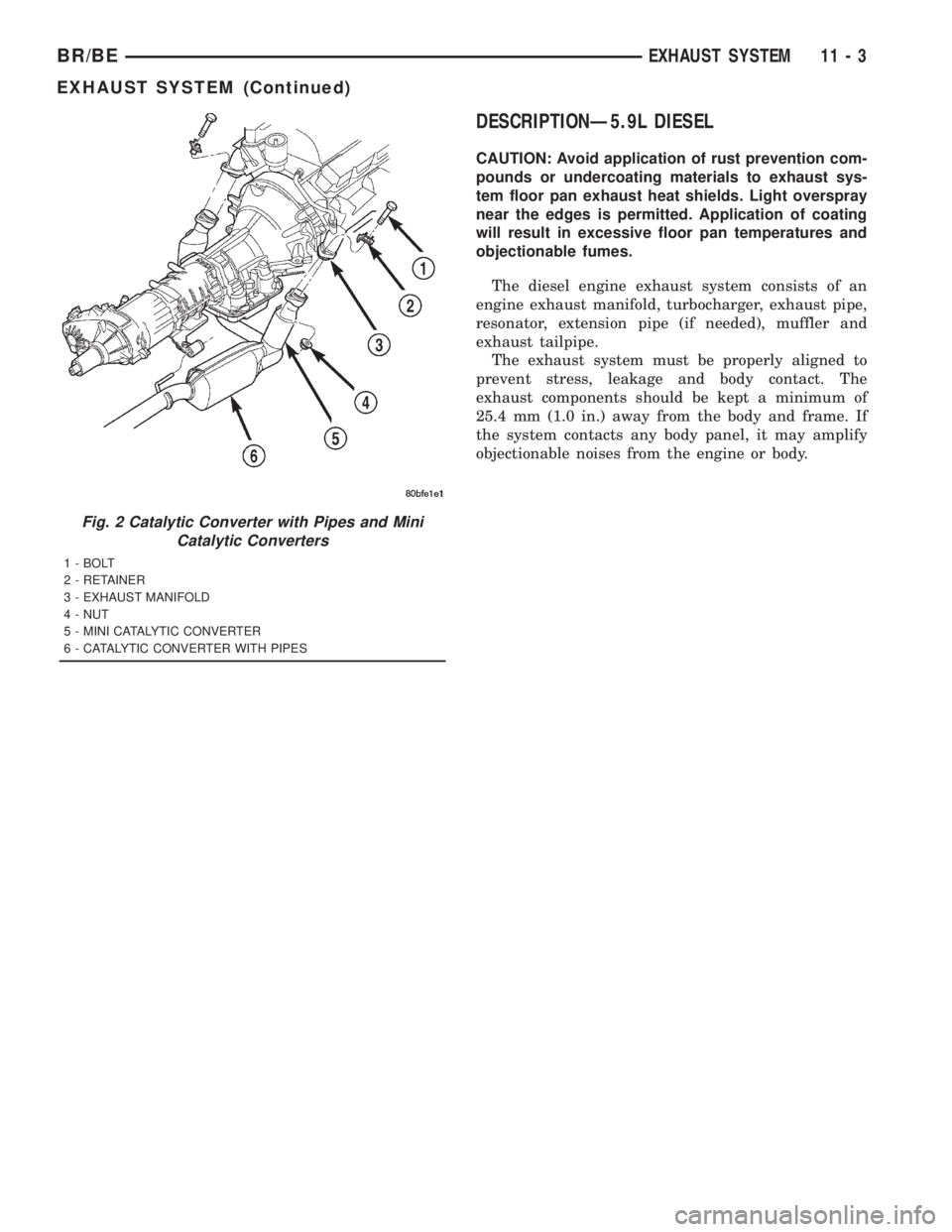

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Adjusting StrapÐBolt 23 Ð 200

Air Heater Power SupplyÐ

Nuts14 Ð 124

Air Inlet HousingÐBolts 24 18 Ð

Cab Heater Supply/Return

LineÐNuts24 18 Ð

Exhaust ClampÐNuts 48 35 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(Diesel Engine) 43 32 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(3.9L/5.2L/5.9L) 31 23 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(8.0L) 22 Ð 195

Exhaust Pipe to ManifoldÐ

Bolts31 23 Ð

Generator MountingÐBolts 41 30 Ð

Charge Air Cooler

MountingÐBolts2Ð17

Charge Air Cooler DuctÐ

Nuts8Ð72

Heat ShieldÐNuts and Bolts 11 Ð 100

Turbocharger MountingÐ

Nuts32 24 Ð

Turbocharger Oil Drain

TubeÐBolts24 18 Ð

Turbocharger Oil Supply

LineÐFitting15 Ð 133

Turbocharger V-Band

ClampÐNut9Ð75

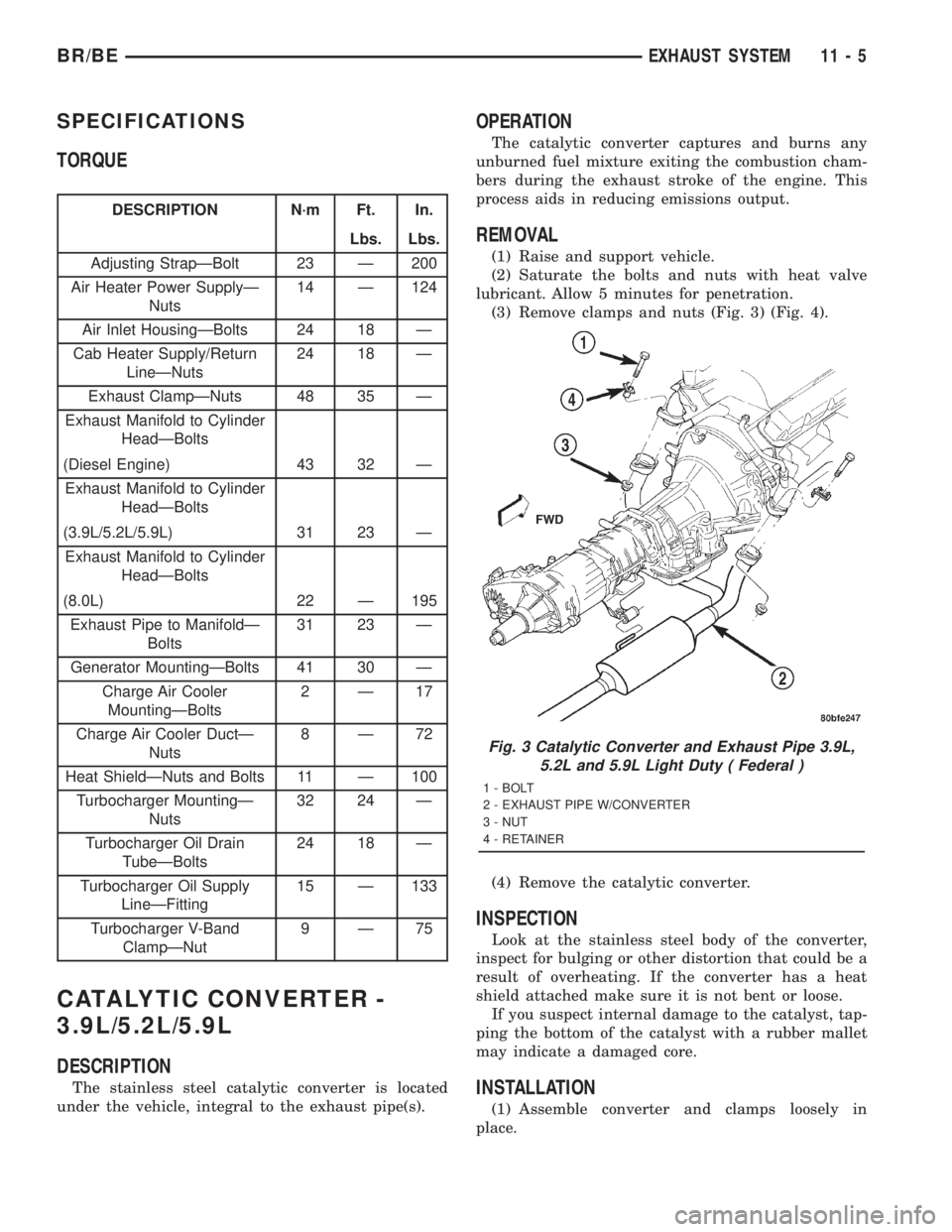

CATALYTIC CONVERTER -

3.9L/5.2L/5.9L

DESCRIPTION

The stainless steel catalytic converter is located

under the vehicle, integral to the exhaust pipe(s).

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion cham-

bers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

REMOVAL

(1) Raise and support vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove clamps and nuts (Fig. 3) (Fig. 4).

(4) Remove the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

(1) Assemble converter and clamps loosely in

place.

Fig. 3 Catalytic Converter and Exhaust Pipe 3.9L,

5.2L and 5.9L Light Duty ( Federal )

1 - BOLT

2 - EXHAUST PIPE W/CONVERTER

3 - NUT

4 - RETAINER

BR/BEEXHAUST SYSTEM 11 - 5

Page 1461 of 2889

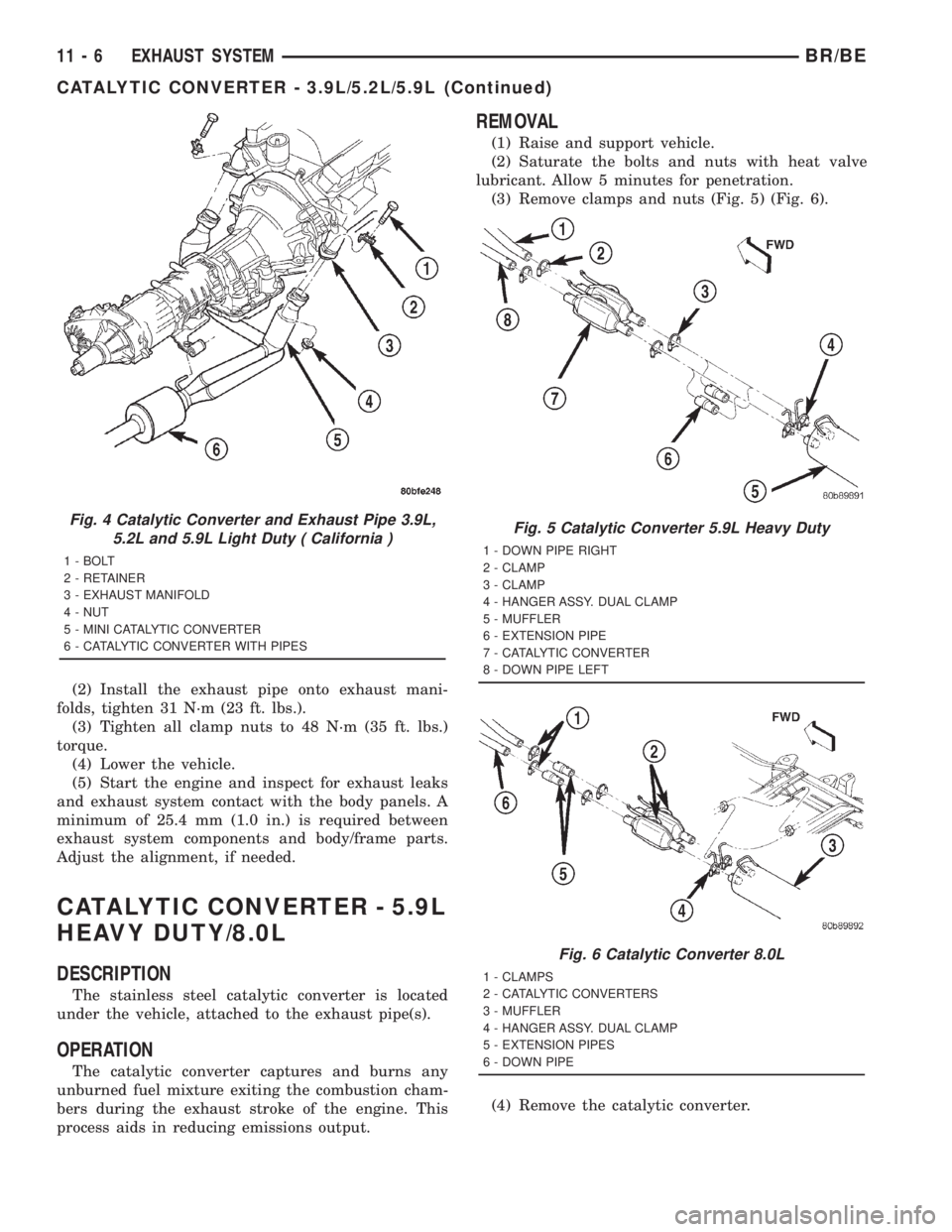

(2) Install the exhaust pipe onto exhaust mani-

folds, tighten 31 N´m (23 ft. lbs.).

(3) Tighten all clamp nuts to 48 N´m (35 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels. A

minimum of 25.4 mm (1.0 in.) is required between

exhaust system components and body/frame parts.

Adjust the alignment, if needed.

CATALYTIC CONVERTER - 5.9L

HEAVY DUTY/8.0L

DESCRIPTION

The stainless steel catalytic converter is located

under the vehicle, attached to the exhaust pipe(s).

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion cham-

bers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

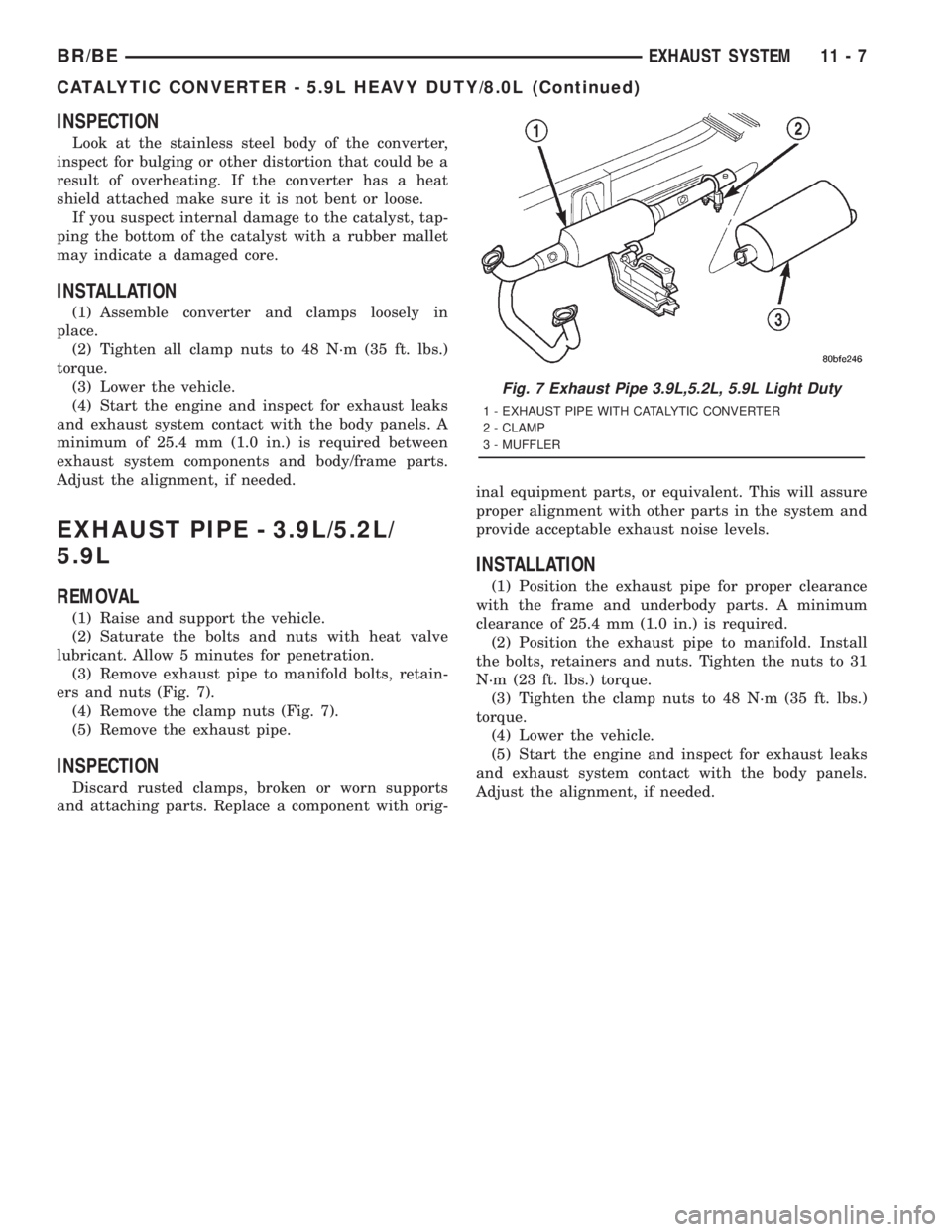

REMOVAL

(1) Raise and support vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove clamps and nuts (Fig. 5) (Fig. 6).

(4) Remove the catalytic converter.

Fig. 4 Catalytic Converter and Exhaust Pipe 3.9L,

5.2L and 5.9L Light Duty ( California )

1 - BOLT

2 - RETAINER

3 - EXHAUST MANIFOLD

4 - NUT

5 - MINI CATALYTIC CONVERTER

6 - CATALYTIC CONVERTER WITH PIPES

Fig. 5 Catalytic Converter 5.9L Heavy Duty

1 - DOWN PIPE RIGHT

2 - CLAMP

3 - CLAMP

4 - HANGER ASSY. DUAL CLAMP

5 - MUFFLER

6 - EXTENSION PIPE

7 - CATALYTIC CONVERTER

8 - DOWN PIPE LEFT

Fig. 6 Catalytic Converter 8.0L

1 - CLAMPS

2 - CATALYTIC CONVERTERS

3 - MUFFLER

4 - HANGER ASSY. DUAL CLAMP

5 - EXTENSION PIPES

6 - DOWN PIPE

11 - 6 EXHAUST SYSTEMBR/BE

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L (Continued)

Page 1462 of 2889

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

(1) Assemble converter and clamps loosely in

place.

(2) Tighten all clamp nuts to 48 N´m (35 ft. lbs.)

torque.

(3) Lower the vehicle.

(4) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels. A

minimum of 25.4 mm (1.0 in.) is required between

exhaust system components and body/frame parts.

Adjust the alignment, if needed.

EXHAUST PIPE - 3.9L/5.2L/

5.9L

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove exhaust pipe to manifold bolts, retain-

ers and nuts (Fig. 7).

(4) Remove the clamp nuts (Fig. 7).

(5) Remove the exhaust pipe.

INSPECTION

Discard rusted clamps, broken or worn supports

and attaching parts. Replace a component with orig-inal equipment parts, or equivalent. This will assure

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

INSTALLATION

(1) Position the exhaust pipe for proper clearance

with the frame and underbody parts. A minimum

clearance of 25.4 mm (1.0 in.) is required.

(2) Position the exhaust pipe to manifold. Install

the bolts, retainers and nuts. Tighten the nuts to 31

N´m (23 ft. lbs.) torque.

(3) Tighten the clamp nuts to 48 N´m (35 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

Fig. 7 Exhaust Pipe 3.9L,5.2L, 5.9L Light Duty

1 - EXHAUST PIPE WITH CATALYTIC CONVERTER

2 - CLAMP

3 - MUFFLER

BR/BEEXHAUST SYSTEM 11 - 7

CATALYTIC CONVERTER - 5.9L HEAVY DUTY/8.0L (Continued)

Page 1465 of 2889

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

INSTALLATION

(1) Install the exhaust pipe into the transmission

support and onto the turbocharger flange (Fig. 11).

(2) Install the exhaust pipe-to-turbocharger elbow

bolts and tighten to 31 N´m (23 ft. lbs.) torque.

(3) Install the extension pipe and clamp to the

exhaust pipe using a new clamp and tighten the

clamp nuts to 48 N´m (35 ft. lbs.) torque.

(4) Lower the vehicle.

(5) Connect the battery negative cables.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels. A

minimum of 25.4 mm (1.0 in.) is required. Adjust the

alignment, if needed.

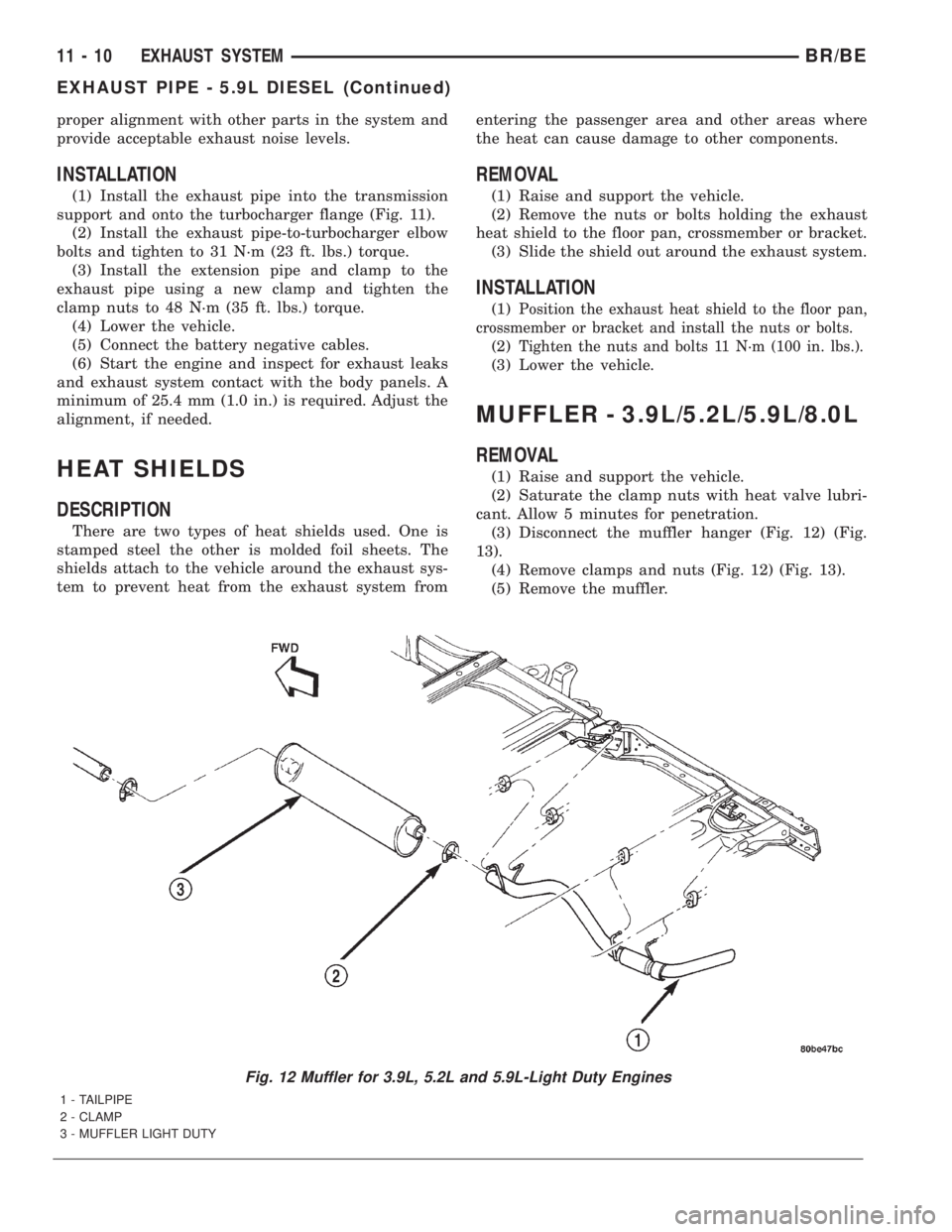

HEAT SHIELDS

DESCRIPTION

There are two types of heat shields used. One is

stamped steel the other is molded foil sheets. The

shields attach to the vehicle around the exhaust sys-

tem to prevent heat from the exhaust system fromentering the passenger area and other areas where

the heat can cause damage to other components.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the nuts or bolts holding the exhaust

heat shield to the floor pan, crossmember or bracket.

(3) Slide the shield out around the exhaust system.

INSTALLATION

(1)Position the exhaust heat shield to the floor pan,

crossmember or bracket and install the nuts or bolts.

(2)Tighten the nuts and bolts 11 N´m (100 in. lbs.).

(3) Lower the vehicle.

MUFFLER - 3.9L/5.2L/5.9L/8.0L

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the clamp nuts with heat valve lubri-

cant. Allow 5 minutes for penetration.

(3) Disconnect the muffler hanger (Fig. 12) (Fig.

13).

(4) Remove clamps and nuts (Fig. 12) (Fig. 13).

(5) Remove the muffler.

Fig. 12 Muffler for 3.9L, 5.2L and 5.9L-Light Duty Engines

1 - TAILPIPE

2 - CLAMP

3 - MUFFLER LIGHT DUTY

11 - 10 EXHAUST SYSTEMBR/BE

EXHAUST PIPE - 5.9L DIESEL (Continued)

Page 1473 of 2889

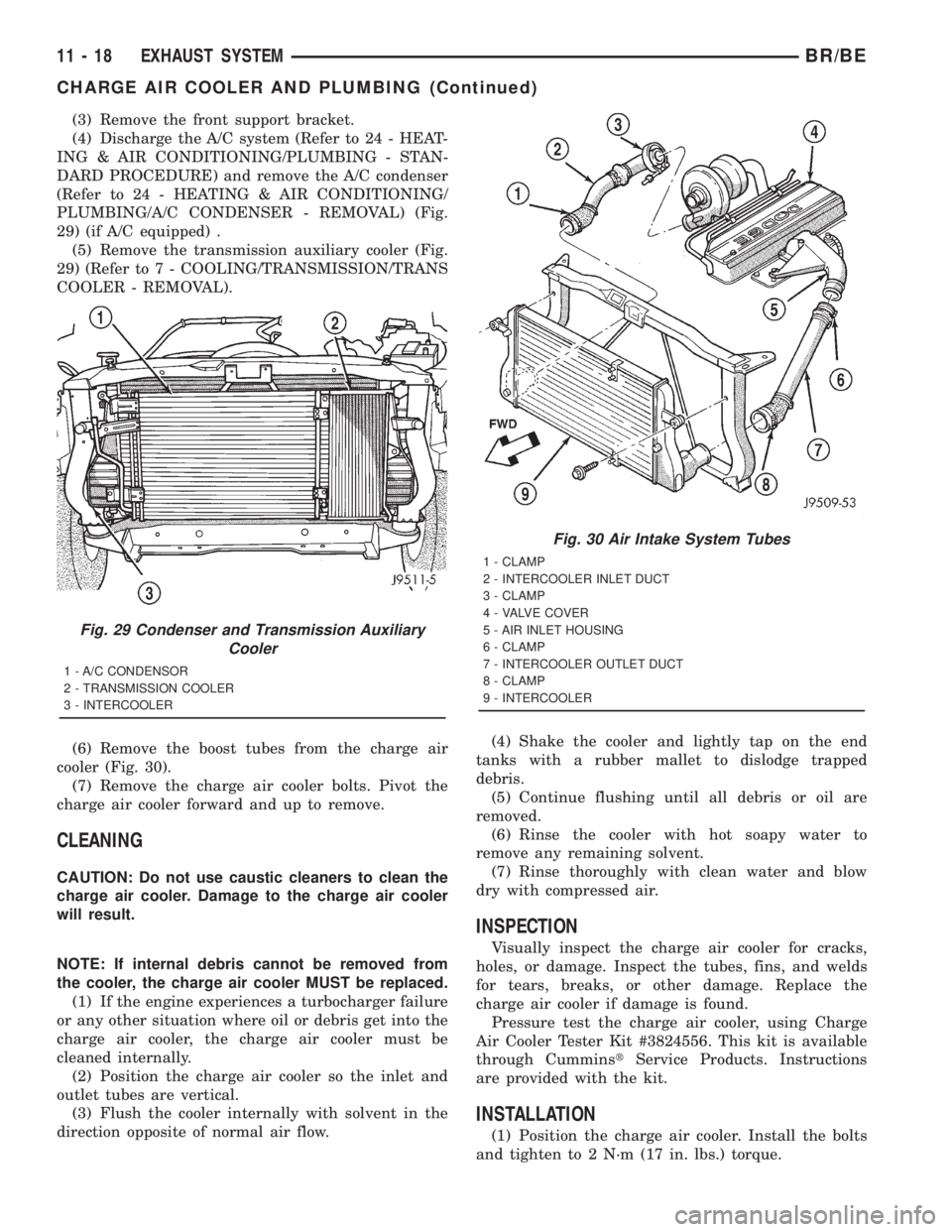

(3) Remove the front support bracket.

(4) Discharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (Fig.

29) (if A/C equipped) .

(5) Remove the transmission auxiliary cooler (Fig.

29) (Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - REMOVAL).

(6) Remove the boost tubes from the charge air

cooler (Fig. 30).

(7) Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.

(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.(4) Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped

debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit #3824556. This kit is available

through CumminstService Products. Instructions

are provided with the kit.

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

Fig. 29 Condenser and Transmission Auxiliary

Cooler

1 - A/C CONDENSOR

2 - TRANSMISSION COOLER

3 - INTERCOOLER

Fig. 30 Air Intake System Tubes

1 - CLAMP

2 - INTERCOOLER INLET DUCT

3 - CLAMP

4 - VALVE COVER

5 - AIR INLET HOUSING

6 - CLAMP

7 - INTERCOOLER OUTLET DUCT

8 - CLAMP

9 - INTERCOOLER

11 - 18 EXHAUST SYSTEMBR/BE

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1476 of 2889

FRAME & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

DESCRIPTION............................1

FRONT AIR DAM

REMOVAL...............................1

INSTALLATION............................2

FRONT FASCIA

REMOVAL...............................2

INSTALLATION............................2

ADJUSTMENT............................2

FRONT LOWER FASCIA

REMOVAL...............................3

INSTALLATION............................3

FRONT FASCIAÐSPORT

REMOVAL...............................3

INSTALLATION............................3

FRONT BUMPER

REMOVAL...............................3

INSTALLATION............................4

FRONT BUMPERÐSPORT

REMOVAL...............................4

INSTALLATION............................4REAR BUMPER

REMOVAL...............................5

INSTALLATION............................5

FRAME

DESCRIPTION............................6

SPECIFICATIONS.........................7

CAB CHASSIS ADAPTER BRACKET

REMOVAL...............................9

INSTALLATION............................9

FRONT TOW HOOK

REMOVAL...............................9

INSTALLATION...........................10

SPARE TIRE WINCH

REMOVAL..............................10

INSTALLATION...........................10

TRAILER HITCH

REMOVAL..............................10

INSTALLATION...........................10

TRANSFER CASE SKID PLATE

REMOVAL..............................11

INSTALLATION...........................11

BUMPERS

DESCRIPTION

Bumpers are used at the front and rear of the

vehicle. Bumpers may be chrome or painted.

Bumpers are designed to protect the exterior sheet-

metal in low impact situations. The bumpers are

attached to the frame and provide mounting points

for some optional accessories such as fog lights and

tow hooks.

FRONT AIR DAM

REMOVAL

(1) Remove Pin-type fasteners attaching air dam

to bottom of front bumper (Fig. 1).

(2) Remove screws attaching air dam to bottom of

front bumper.

(3) Separate air dam from bumper.

BR/BEFRAME & BUMPERS 13 - 1

Page 1498 of 2889

(1) Be sure fuel tank contains fuel before starting

test. If tank is empty or near empty, amperage read-

ings will be incorrect.

(2) Obtain LCS adapter.

(3) Plug cable from LCS adapter into DRB scan

tool at SET 1 receptacle.

(4) Plug DRB into vehicle 16±way connector (data

link connector).

(5) Connect (-) and (+) test cable leads into LCS

adapter receptacles. Use10 amp (10A +)receptacle

and common (-) receptacles.

(6) Gain access to MAIN MENU on DRB screen.

(7) Press DVOM button on DRB.

(8) Using left/right arrow keys, highlight CHAN-

NEL 1 function on DRB screen.

(9) Press ENTER three times.

(10) Using up/down arrow keys, highlight RANGE

on DRB screen (screen will default to 2 amp scale).

(11) Press ENTER to change 2 amp scale to 10

amp scale.This step must be done to prevent

damage to DRB scan tool or LCS adapter

(blown fuse).

(12) Remove cover from Power Distribution Center

(PDC).

(13) Remove fuel pump relay from PDC. Refer to

label on PDC cover for relay location.

WARNING: BEFORE PROCEEDING TO NEXT STEP,

NOTE THE FUEL PUMP WILL BE ACTIVATED AND

SYSTEM PRESSURE WILL BE PRESENT. THIS WILL

OCCUR AFTER CONNECTING TEST LEADS FROM

LCS ADAPTER INTO FUEL PUMP RELAY CAVITIES.

THE FUEL PUMP WILL OPERATE EVEN WITH IGNI-

TION KEY IN OFF POSITION. BEFORE ATTACHING

TEST LEADS, BE SURE ALL FUEL LINES AND

FUEL SYSTEM COMPONENTS ARE CONNECTED.

CAUTION: To prevent possible damage to the vehi-

cle electrical system and LCS adapter, the test

leads must be connected into relay cavities exactly

as shown in following steps.

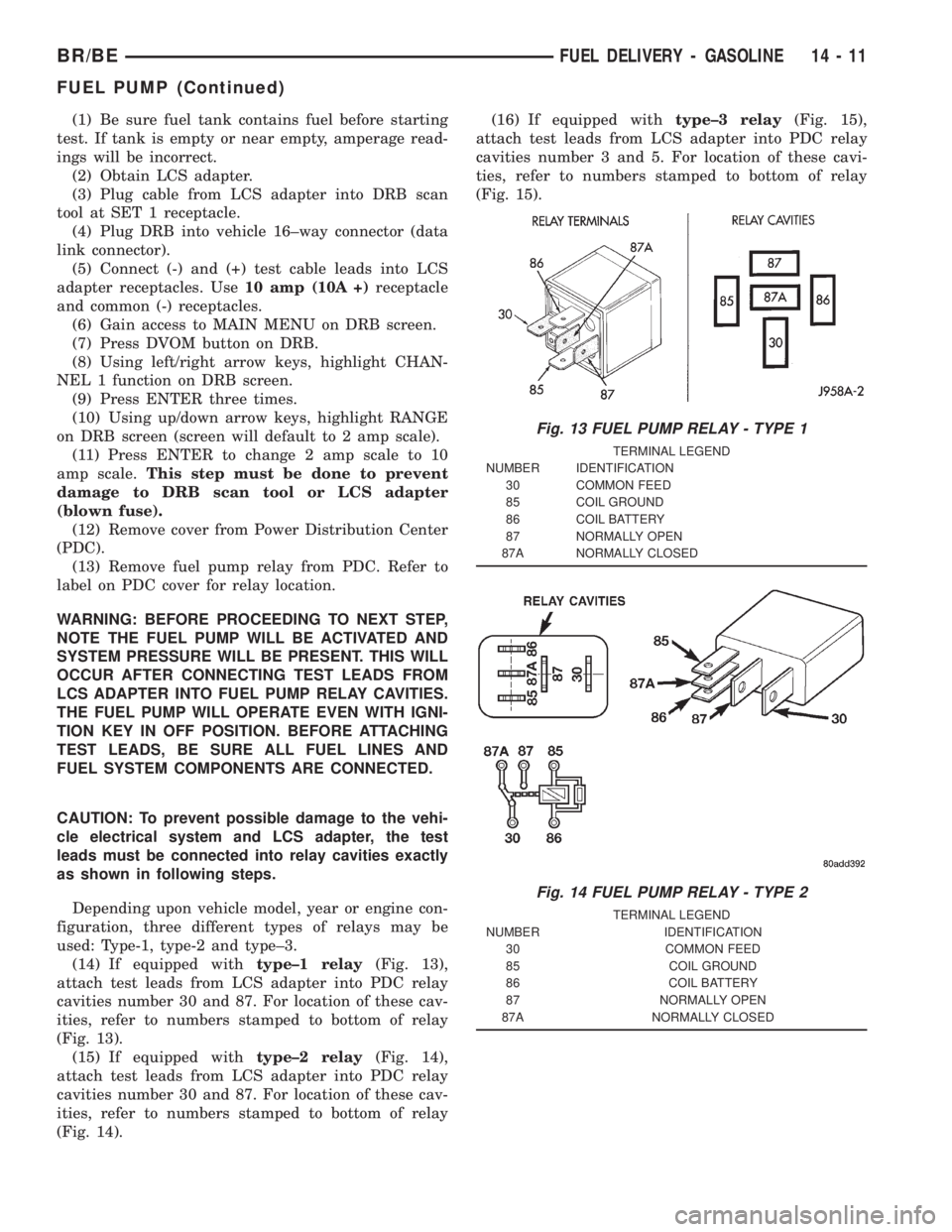

Depending upon vehicle model, year or engine con-

figuration, three different types of relays may be

used: Type-1, type-2 and type±3.

(14) If equipped withtype±1 relay(Fig. 13),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 13).

(15) If equipped withtype±2 relay(Fig. 14),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 14).(16) If equipped withtype±3 relay(Fig. 15),

attach test leads from LCS adapter into PDC relay

cavities number 3 and 5. For location of these cavi-

ties, refer to numbers stamped to bottom of relay

(Fig. 15).

Fig. 13 FUEL PUMP RELAY - TYPE 1

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 14 FUEL PUMP RELAY - TYPE 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

BR/BEFUEL DELIVERY - GASOLINE 14 - 11

FUEL PUMP (Continued)