torque DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1530 of 2889

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air cleaner assembly.

INSTALLATION - 8.0L

The IAC motor is located on the back of the throt-

tle body (Fig. 33).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air cleaner housing to throttle body.

(5) Install 4 air cleaner housing mounting nuts.

Tighten nuts to 11 N´m (96 in. lbs.) torque.

(6) Install air cleaner housing cover.

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION - 3.9L/5.2L/5.9L/8.0L

The 2±wire Intake Manifold Air Temperature (IAT)

sensor is installed in the intake manifold with the

sensor element extending into the air stream.

The IAT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as intake mani-

fold temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION - 3.9L/5.2L/5.9L/8.0L

The IAT sensor provides an input voltage to the

Powertrain Control Module (PCM) indicating the

density of the air entering the intake manifold based

upon intake manifold temperature. At key-on, a

5±volt power circuit is supplied to the sensor from

the PCM. The sensor is grounded at the PCM

through a low-noise, sensor-return circuit.

The PCM uses this input to calculate the following:

²Injector pulse-width

²Adjustment of spark timing (to help prevent

spark knock with high intake manifold air-charge

temperatures)

The resistance values of the IAT sensor is the same

as for the Engine Coolant Temperature (ECT) sensor.

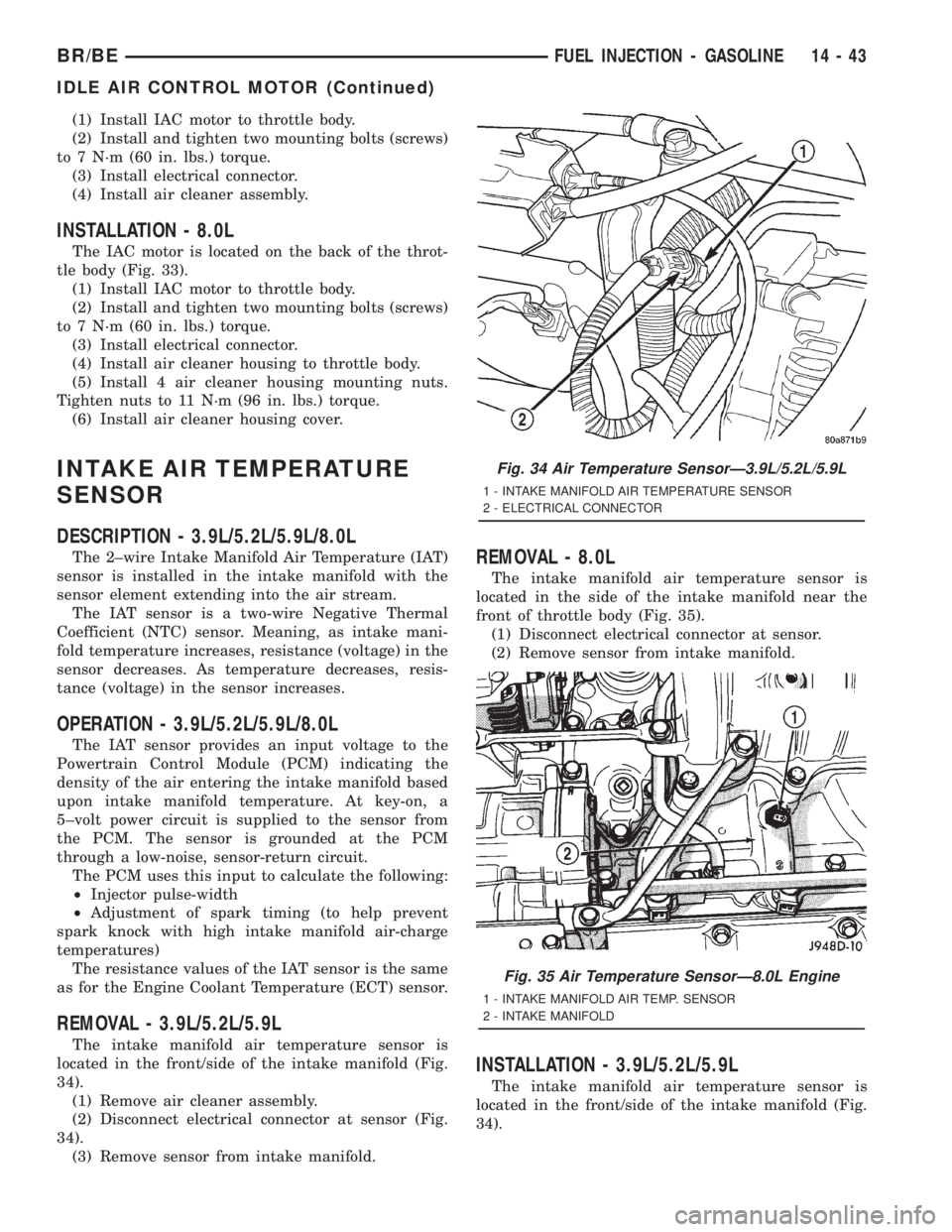

REMOVAL - 3.9L/5.2L/5.9L

The intake manifold air temperature sensor is

located in the front/side of the intake manifold (Fig.

34).

(1) Remove air cleaner assembly.

(2) Disconnect electrical connector at sensor (Fig.

34).

(3) Remove sensor from intake manifold.

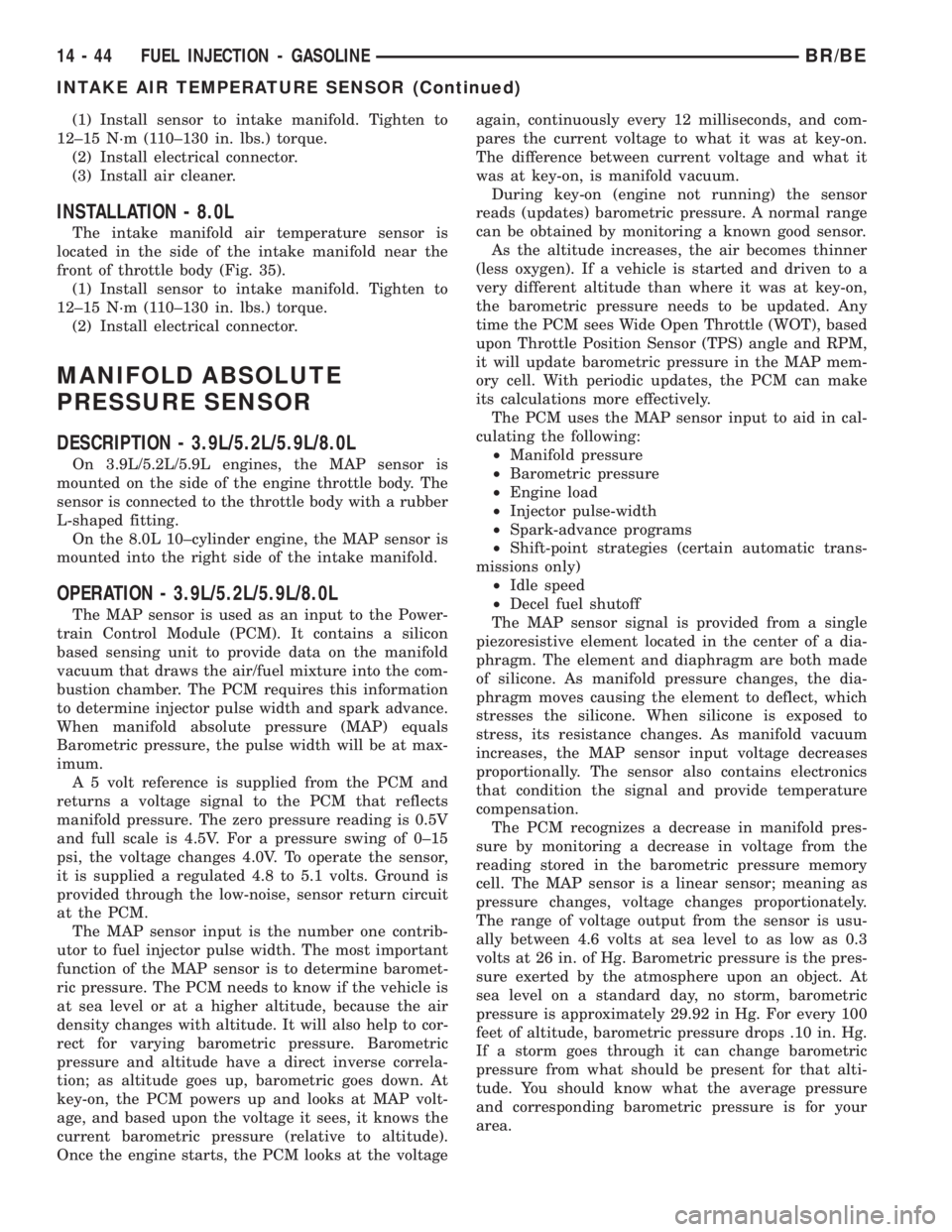

REMOVAL - 8.0L

The intake manifold air temperature sensor is

located in the side of the intake manifold near the

front of throttle body (Fig. 35).

(1) Disconnect electrical connector at sensor.

(2) Remove sensor from intake manifold.

INSTALLATION - 3.9L/5.2L/5.9L

The intake manifold air temperature sensor is

located in the front/side of the intake manifold (Fig.

34).

Fig. 34 Air Temperature SensorÐ3.9L/5.2L/5.9L

1 - INTAKE MANIFOLD AIR TEMPERATURE SENSOR

2 - ELECTRICAL CONNECTOR

Fig. 35 Air Temperature SensorÐ8.0L Engine

1 - INTAKE MANIFOLD AIR TEMP. SENSOR

2 - INTAKE MANIFOLD

BR/BEFUEL INJECTION - GASOLINE 14 - 43

IDLE AIR CONTROL MOTOR (Continued)

Page 1531 of 2889

(1) Install sensor to intake manifold. Tighten to

12±15 N´m (110±130 in. lbs.) torque.

(2) Install electrical connector.

(3) Install air cleaner.

INSTALLATION - 8.0L

The intake manifold air temperature sensor is

located in the side of the intake manifold near the

front of throttle body (Fig. 35).

(1) Install sensor to intake manifold. Tighten to

12±15 N´m (110±130 in. lbs.) torque.

(2) Install electrical connector.

MANIFOLD ABSOLUTE

PRESSURE SENSOR

DESCRIPTION - 3.9L/5.2L/5.9L/8.0L

On 3.9L/5.2L/5.9L engines, the MAP sensor is

mounted on the side of the engine throttle body. The

sensor is connected to the throttle body with a rubber

L-shaped fitting.

On the 8.0L 10±cylinder engine, the MAP sensor is

mounted into the right side of the intake manifold.

OPERATION - 3.9L/5.2L/5.9L/8.0L

The MAP sensor is used as an input to the Power-

train Control Module (PCM). It contains a silicon

based sensing unit to provide data on the manifold

vacuum that draws the air/fuel mixture into the com-

bustion chamber. The PCM requires this information

to determine injector pulse width and spark advance.

When manifold absolute pressure (MAP) equals

Barometric pressure, the pulse width will be at max-

imum.

A 5 volt reference is supplied from the PCM and

returns a voltage signal to the PCM that reflects

manifold pressure. The zero pressure reading is 0.5V

and full scale is 4.5V. For a pressure swing of 0±15

psi, the voltage changes 4.0V. To operate the sensor,

it is supplied a regulated 4.8 to 5.1 volts. Ground is

provided through the low-noise, sensor return circuit

at the PCM.

The MAP sensor input is the number one contrib-

utor to fuel injector pulse width. The most important

function of the MAP sensor is to determine baromet-

ric pressure. The PCM needs to know if the vehicle is

at sea level or at a higher altitude, because the air

density changes with altitude. It will also help to cor-

rect for varying barometric pressure. Barometric

pressure and altitude have a direct inverse correla-

tion; as altitude goes up, barometric goes down. At

key-on, the PCM powers up and looks at MAP volt-

age, and based upon the voltage it sees, it knows the

current barometric pressure (relative to altitude).

Once the engine starts, the PCM looks at the voltageagain, continuously every 12 milliseconds, and com-

pares the current voltage to what it was at key-on.

The difference between current voltage and what it

was at key-on, is manifold vacuum.

During key-on (engine not running) the sensor

reads (updates) barometric pressure. A normal range

can be obtained by monitoring a known good sensor.

As the altitude increases, the air becomes thinner

(less oxygen). If a vehicle is started and driven to a

very different altitude than where it was at key-on,

the barometric pressure needs to be updated. Any

time the PCM sees Wide Open Throttle (WOT), based

upon Throttle Position Sensor (TPS) angle and RPM,

it will update barometric pressure in the MAP mem-

ory cell. With periodic updates, the PCM can make

its calculations more effectively.

The PCM uses the MAP sensor input to aid in cal-

culating the following:

²Manifold pressure

²Barometric pressure

²Engine load

²Injector pulse-width

²Spark-advance programs

²Shift-point strategies (certain automatic trans-

missions only)

²Idle speed

²Decel fuel shutoff

The MAP sensor signal is provided from a single

piezoresistive element located in the center of a dia-

phragm. The element and diaphragm are both made

of silicone. As manifold pressure changes, the dia-

phragm moves causing the element to deflect, which

stresses the silicone. When silicone is exposed to

stress, its resistance changes. As manifold vacuum

increases, the MAP sensor input voltage decreases

proportionally. The sensor also contains electronics

that condition the signal and provide temperature

compensation.

The PCM recognizes a decrease in manifold pres-

sure by monitoring a decrease in voltage from the

reading stored in the barometric pressure memory

cell. The MAP sensor is a linear sensor; meaning as

pressure changes, voltage changes proportionately.

The range of voltage output from the sensor is usu-

ally between 4.6 volts at sea level to as low as 0.3

volts at 26 in. of Hg. Barometric pressure is the pres-

sure exerted by the atmosphere upon an object. At

sea level on a standard day, no storm, barometric

pressure is approximately 29.92 in Hg. For every 100

feet of altitude, barometric pressure drops .10 in. Hg.

If a storm goes through it can change barometric

pressure from what should be present for that alti-

tude. You should know what the average pressure

and corresponding barometric pressure is for your

area.

14 - 44 FUEL INJECTION - GASOLINEBR/BE

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1533 of 2889

(3) Install MAP sensor mounting bolts (screws).

Tighten screws to 3 N´m (25 in. lbs.) torque.

(4) Install air cleaner.

INSTALLATION - 8.0L

The MAP sensor is mounted into the right upper

side of the intake manifold (Fig. 38). A rubber gasket

is used to seal the sensor to the intake manifold. The

rubber gasket is part of the sensor and is not ser-

viced separately.

(1) Check the condition of the sensor seal. Clean

the sensor and lubricate the rubber gasket with clean

engine oil.

(2) Clean the sensor opening in the intake mani-

fold.

(3) Install the sensor into the intake manifold.

(4) Install sensor mounting bolts. Tighten bolts to

2 N´m (20 in. lbs.) torque.

(5) Install the electrical connector to sensor.

O2 SENSOR

DESCRIPTION

The Oxygen Sensors (O2S) are attached to, and

protrude into the vehicle exhaust system. Depending

on the emission package, the vehicle may use a total

of either 2 or 4 sensors.

3.9L/5.2L/Light Duty 5.9L Engine:Four sensors

are used: 2 upstream (referred to as 1/1 and 2/1) and

2 downstream (referred to as 1/2 and 2/2). With this

emission package, the right upstream sensor (2/1) is

located in the right exhaust downpipe just before the

mini-catalytic convertor. The left upstream sensor

(1/1) is located in the left exhaust downpipe just

before the mini-catalytic convertor. The right down-

stream sensor (2/2) is located in the right exhaust

downpipe just after the mini-catalytic convertor, and

before the main catalytic convertor. The left down-

stream sensor (1/2) is located in the left exhaust

downpipe just after the mini-catalytic convertor, and

before the main catalytic convertor.

Medium and Heavy Duty 8.0L V-10 Engine:

Four sensors are used (2 upstream, 1 pre-catalyst

and 1 post-catalyst). With this emission package, the

1/1 upstream sensor (left side) is located in the left

exhaust downpipe before both the pre-catalyst sensor

(1/2), and the main catalytic convertor. The 2/1

upstream sensor (right side) is located in the right

exhaust downpipe before both the pre-catalyst sensor

(1/2), and the main catalytic convertor. The pre-cata-

lyst sensor (1/2) is located after the 1/1 and 2/1 sen-

sors, and just before the main catalytic convertor.

The post-catalyst sensor (1/3) is located just after the

main catalytic convertor.Heavy Duty 5.9L Engine:Two sensors are used.

They arebothreferred to as upstream sensors (left

side is referred to as 1/1 and right side is referred to

as 2/1). With this emission package, a sensor is

located in each of the exhaust downpipes before the

main catalytic convertor.

OPERATION

An O2 sensor is a galvanic battery that provides

the PCM with a voltage signal (0-1 volt) inversely

proportional to the amount of oxygen in the exhaust.

In other words, if the oxygen content is low, the volt-

age output is high; if the oxygen content is high the

output voltage is low. The PCM uses this information

to adjust injector pulse-width to achieve the

14.7±to±1 air/fuel ratio necessary for proper engine

operation and to control emissions.

The O2 sensor must have a source of oxygen from

outside of the exhaust stream for comparison. Cur-

rent O2 sensors receive their fresh oxygen (outside

air) supply through the wire harness. This is why it

is important to never solder an O2 sensor connector,

or pack the connector with grease.

Four wires (circuits) are used on each O2 sensor: a

12±volt feed circuit for the sensor heating element; a

ground circuit for the heater element; a low-noise

sensor return circuit to the PCM, and an input cir-

cuit from the sensor back to the PCM to detect sen-

sor operation.

Oxygen Sensor Heaters/Heater Relays:

Depending on the emissions package, the heating ele-

ments within the sensors will be supplied voltage

from either the ASD relay, or 2 separate oxygen sen-

sor relays. Refer to 8, Wiring Diagrams to determine

which relays are used.

The O2 sensor uses a Positive Thermal Co-efficient

(PTC) heater element. As temperature increases,

resistance increases. At ambient temperatures

around 70ÉF, the resistance of the heating element is

approximately 4.5 ohms. As the sensor's temperature

increases, resistance in the heater element increases.

This allows the heater to maintain the optimum

operating temperature of approximately 930É-1100ÉF

(500É-600É C). Although the sensors operate the

same, there are physical differences, due to the envi-

ronment that they operate in, that keep them from

being interchangeable.

Maintaining correct sensor temperature at all times

allows the system to enter into closed loop operation

sooner. Also, it allows the system to remain in closed

loop operation during periods of extended idle.

In Closed Loop operation, the PCM monitors cer-

tain O2 sensor input(s) along with other inputs, and

adjusts the injector pulse width accordingly. During

Open Loop operation, the PCM ignores the O2 sensor

input. The PCM adjusts injector pulse width based

14 - 46 FUEL INJECTION - GASOLINEBR/BE

MANIFOLD ABSOLUTE PRESSURE SENSOR (Continued)

Page 1535 of 2889

WARNING: THE EXHAUST MANIFOLD, EXHAUST

PIPES AND CATALYTIC CONVERTER BECOME

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

(1) Raise and support the vehicle.

(2) Disconnect the wire connector from the O2S

sensor.

CAUTION: When disconnecting the sensor electrical

connector, do not pull directly on wire going into

sensor.

(3) Remove the O2S sensor with an oxygen sensor

removal and installation tool.

INSTALLATION

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

the threads of a new oxygen sensor.

(1) Install the O2S sensor. Tighten to 30 N´m (22

ft. lbs.) torque.

(2) Connect the O2S sensor wire connector.

(3) Lower the vehicle.

PTO SWITCH

DESCRIPTION

This Powertrain Control Module (PCM) input is

used only on models equipped with aftermarket

Power Take Off (PTO) units.

OPERATION

The input is used only to tell the PCM that the

PTO has been engaged. The PCM will disable (tem-

porarily shut down) certain OBD II diagnostic trou-

ble codes when the PTO is engaged.

When the aftermarket PTO switch has been

engaged, a 12V + signal is sent through circuit G113

to PCM pin A13. The PCM will then sense and deter-

mine that the PTO has been activated.

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

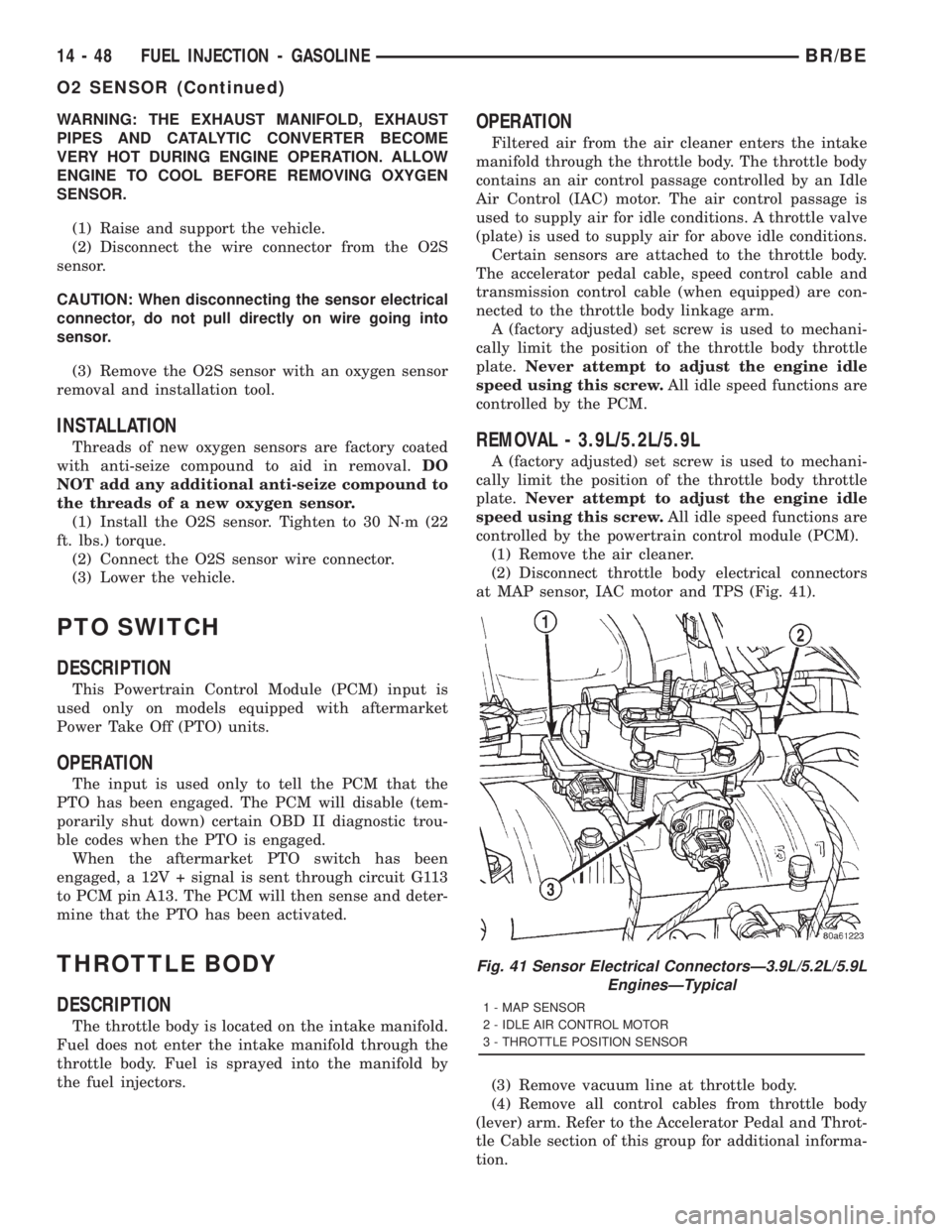

REMOVAL - 3.9L/5.2L/5.9L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Remove the air cleaner.

(2) Disconnect throttle body electrical connectors

at MAP sensor, IAC motor and TPS (Fig. 41).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section of this group for additional informa-

tion.

Fig. 41 Sensor Electrical ConnectorsÐ3.9L/5.2L/5.9L

EnginesÐTypical

1 - MAP SENSOR

2 - IDLE AIR CONTROL MOTOR

3 - THROTTLE POSITION SENSOR

14 - 48 FUEL INJECTION - GASOLINEBR/BE

O2 SENSOR (Continued)

Page 1536 of 2889

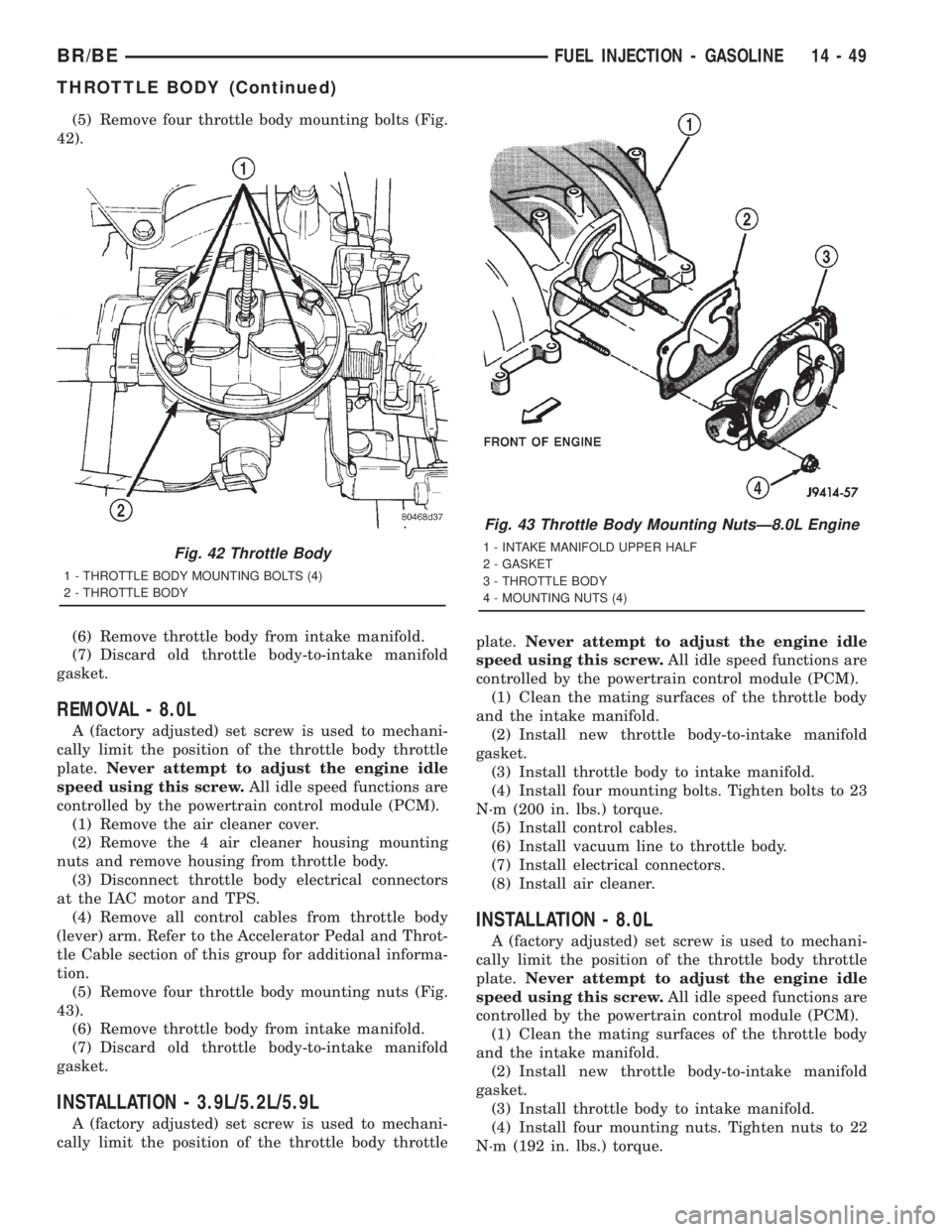

(5) Remove four throttle body mounting bolts (Fig.

42).

(6) Remove throttle body from intake manifold.

(7) Discard old throttle body-to-intake manifold

gasket.

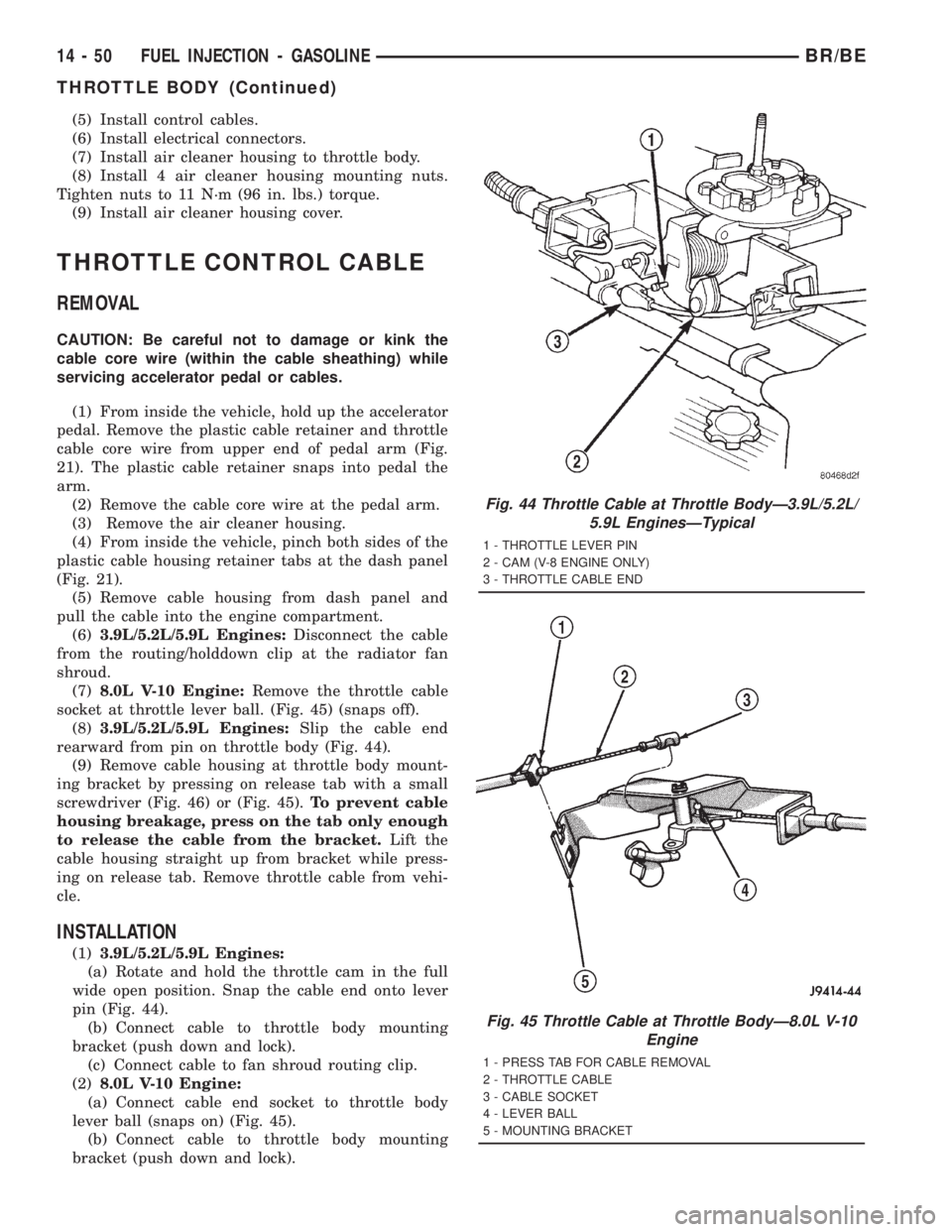

REMOVAL - 8.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Remove the air cleaner cover.

(2) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(3) Disconnect throttle body electrical connectors

at the IAC motor and TPS.

(4) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section of this group for additional informa-

tion.

(5) Remove four throttle body mounting nuts (Fig.

43).

(6) Remove throttle body from intake manifold.

(7) Discard old throttle body-to-intake manifold

gasket.

INSTALLATION - 3.9L/5.2L/5.9L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttleplate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Clean the mating surfaces of the throttle body

and the intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting bolts. Tighten bolts to 23

N´m (200 in. lbs.) torque.

(5) Install control cables.

(6) Install vacuum line to throttle body.

(7) Install electrical connectors.

(8) Install air cleaner.

INSTALLATION - 8.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Clean the mating surfaces of the throttle body

and the intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting nuts. Tighten nuts to 22

N´m (192 in. lbs.) torque.

Fig. 42 Throttle Body

1 - THROTTLE BODY MOUNTING BOLTS (4)

2 - THROTTLE BODY

Fig. 43 Throttle Body Mounting NutsÐ8.0L Engine

1 - INTAKE MANIFOLD UPPER HALF

2 - GASKET

3 - THROTTLE BODY

4 - MOUNTING NUTS (4)

BR/BEFUEL INJECTION - GASOLINE 14 - 49

THROTTLE BODY (Continued)

Page 1537 of 2889

(5) Install control cables.

(6) Install electrical connectors.

(7) Install air cleaner housing to throttle body.

(8) Install 4 air cleaner housing mounting nuts.

Tighten nuts to 11 N´m (96 in. lbs.) torque.

(9) Install air cleaner housing cover.

THROTTLE CONTROL CABLE

REMOVAL

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or cables.

(1) From inside the vehicle, hold up the accelerator

pedal. Remove the plastic cable retainer and throttle

cable core wire from upper end of pedal arm (Fig.

21). The plastic cable retainer snaps into pedal the

arm.

(2) Remove the cable core wire at the pedal arm.

(3) Remove the air cleaner housing.

(4) From inside the vehicle, pinch both sides of the

plastic cable housing retainer tabs at the dash panel

(Fig. 21).

(5) Remove cable housing from dash panel and

pull the cable into the engine compartment.

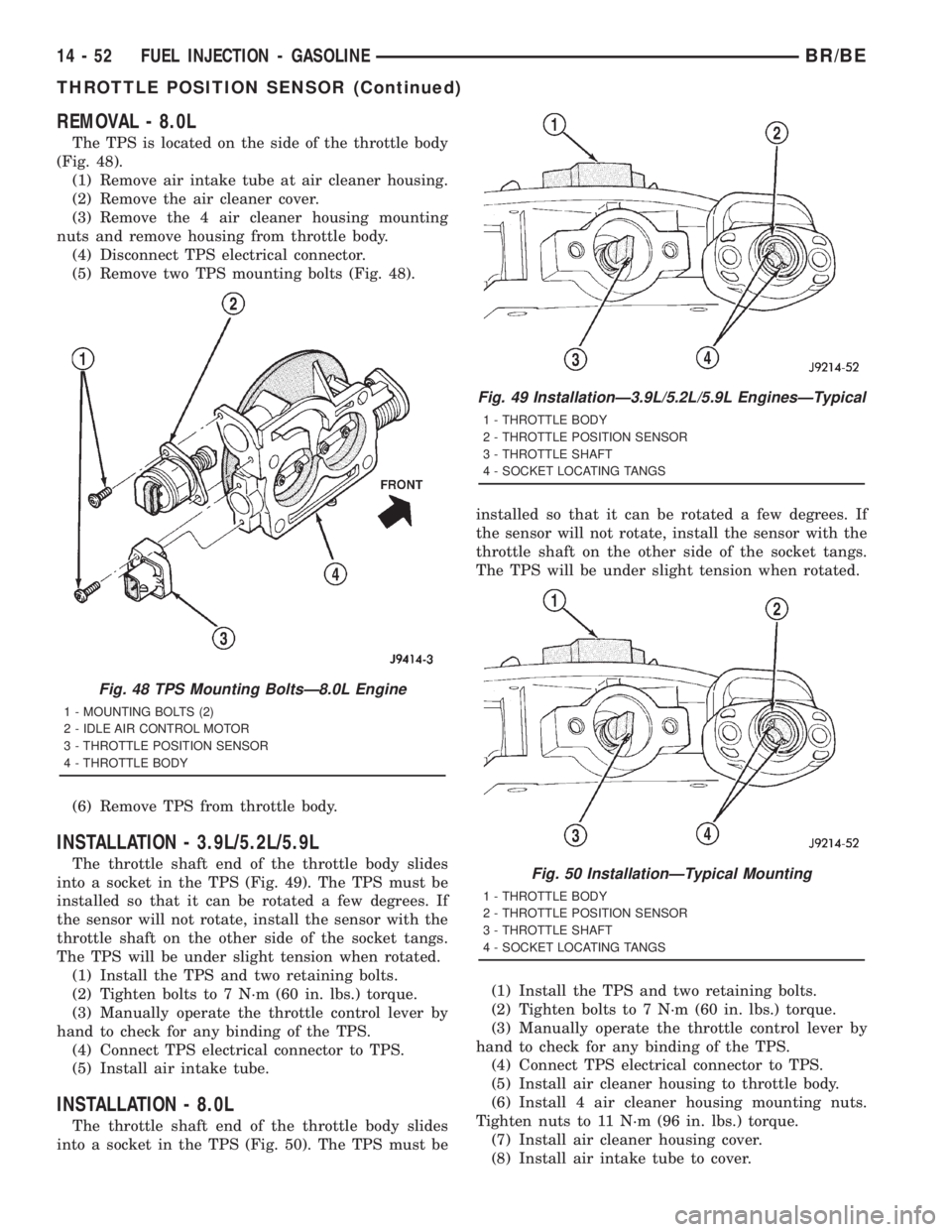

(6)3.9L/5.2L/5.9L Engines:Disconnect the cable

from the routing/holddown clip at the radiator fan

shroud.

(7)8.0L V-10 Engine:Remove the throttle cable

socket at throttle lever ball. (Fig. 45) (snaps off).

(8)3.9L/5.2L/5.9L Engines:Slip the cable end

rearward from pin on throttle body (Fig. 44).

(9) Remove cable housing at throttle body mount-

ing bracket by pressing on release tab with a small

screwdriver (Fig. 46) or (Fig. 45).To prevent cable

housing breakage, press on the tab only enough

to release the cable from the bracket.Lift the

cable housing straight up from bracket while press-

ing on release tab. Remove throttle cable from vehi-

cle.

INSTALLATION

(1)3.9L/5.2L/5.9L Engines:

(a) Rotate and hold the throttle cam in the full

wide open position. Snap the cable end onto lever

pin (Fig. 44).

(b) Connect cable to throttle body mounting

bracket (push down and lock).

(c) Connect cable to fan shroud routing clip.

(2)8.0L V-10 Engine:

(a) Connect cable end socket to throttle body

lever ball (snaps on) (Fig. 45).

(b) Connect cable to throttle body mounting

bracket (push down and lock).

Fig. 44 Throttle Cable at Throttle BodyÐ3.9L/5.2L/

5.9L EnginesÐTypical

1 - THROTTLE LEVER PIN

2 - CAM (V-8 ENGINE ONLY)

3 - THROTTLE CABLE END

Fig. 45 Throttle Cable at Throttle BodyÐ8.0L V-10

Engine

1 - PRESS TAB FOR CABLE REMOVAL

2 - THROTTLE CABLE

3 - CABLE SOCKET

4 - LEVER BALL

5 - MOUNTING BRACKET

14 - 50 FUEL INJECTION - GASOLINEBR/BE

THROTTLE BODY (Continued)

Page 1539 of 2889

REMOVAL - 8.0L

The TPS is located on the side of the throttle body

(Fig. 48).

(1) Remove air intake tube at air cleaner housing.

(2) Remove the air cleaner cover.

(3) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(4) Disconnect TPS electrical connector.

(5) Remove two TPS mounting bolts (Fig. 48).

(6) Remove TPS from throttle body.

INSTALLATION - 3.9L/5.2L/5.9L

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 49). The TPS must be

installed so that it can be rotated a few degrees. If

the sensor will not rotate, install the sensor with the

throttle shaft on the other side of the socket tangs.

The TPS will be under slight tension when rotated.

(1) Install the TPS and two retaining bolts.

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate the throttle control lever by

hand to check for any binding of the TPS.

(4) Connect TPS electrical connector to TPS.

(5) Install air intake tube.

INSTALLATION - 8.0L

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 50). The TPS must beinstalled so that it can be rotated a few degrees. If

the sensor will not rotate, install the sensor with the

throttle shaft on the other side of the socket tangs.

The TPS will be under slight tension when rotated.

(1) Install the TPS and two retaining bolts.

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate the throttle control lever by

hand to check for any binding of the TPS.

(4) Connect TPS electrical connector to TPS.

(5) Install air cleaner housing to throttle body.

(6) Install 4 air cleaner housing mounting nuts.

Tighten nuts to 11 N´m (96 in. lbs.) torque.

(7) Install air cleaner housing cover.

(8) Install air intake tube to cover.

Fig. 48 TPS Mounting BoltsÐ8.0L Engine

1 - MOUNTING BOLTS (2)

2 - IDLE AIR CONTROL MOTOR

3 - THROTTLE POSITION SENSOR

4 - THROTTLE BODY

Fig. 49 InstallationÐ3.9L/5.2L/5.9L EnginesÐTypical

1 - THROTTLE BODY

2 - THROTTLE POSITION SENSOR

3 - THROTTLE SHAFT

4 - SOCKET LOCATING TANGS

Fig. 50 InstallationÐTypical Mounting

1 - THROTTLE BODY

2 - THROTTLE POSITION SENSOR

3 - THROTTLE SHAFT

4 - SOCKET LOCATING TANGS

14 - 52 FUEL INJECTION - GASOLINEBR/BE

THROTTLE POSITION SENSOR (Continued)

Page 1544 of 2889

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM PARTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

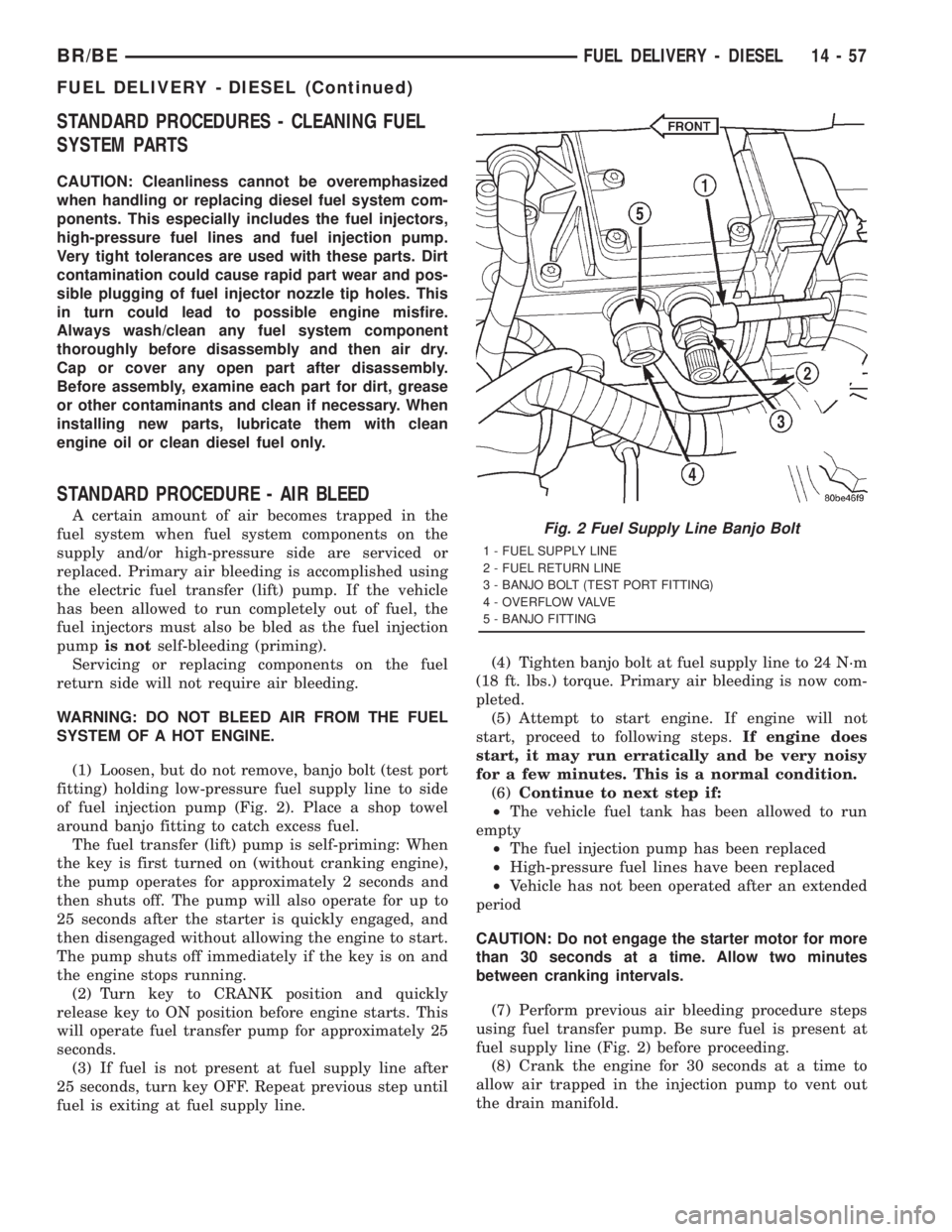

STANDARD PROCEDURE - AIR BLEED

A certain amount of air becomes trapped in the

fuel system when fuel system components on the

supply and/or high-pressure side are serviced or

replaced. Primary air bleeding is accomplished using

the electric fuel transfer (lift) pump. If the vehicle

has been allowed to run completely out of fuel, the

fuel injectors must also be bled as the fuel injection

pumpis notself-bleeding (priming).

Servicing or replacing components on the fuel

return side will not require air bleeding.

WARNING: DO NOT BLEED AIR FROM THE FUEL

SYSTEM OF A HOT ENGINE.

(1) Loosen, but do not remove, banjo bolt (test port

fitting) holding low-pressure fuel supply line to side

of fuel injection pump (Fig. 2). Place a shop towel

around banjo fitting to catch excess fuel.

The fuel transfer (lift) pump is self-priming: When

the key is first turned on (without cranking engine),

the pump operates for approximately 2 seconds and

then shuts off. The pump will also operate for up to

25 seconds after the starter is quickly engaged, and

then disengaged without allowing the engine to start.

The pump shuts off immediately if the key is on and

the engine stops running.

(2) Turn key to CRANK position and quickly

release key to ON position before engine starts. This

will operate fuel transfer pump for approximately 25

seconds.

(3) If fuel is not present at fuel supply line after

25 seconds, turn key OFF. Repeat previous step until

fuel is exiting at fuel supply line.(4) Tighten banjo bolt at fuel supply line to 24 N´m

(18 ft. lbs.) torque. Primary air bleeding is now com-

pleted.

(5) Attempt to start engine. If engine will not

start, proceed to following steps.If engine does

start, it may run erratically and be very noisy

for a few minutes. This is a normal condition.

(6)Continue to next step if:

²The vehicle fuel tank has been allowed to run

empty

²The fuel injection pump has been replaced

²High-pressure fuel lines have been replaced

²Vehicle has not been operated after an extended

period

CAUTION: Do not engage the starter motor for more

than 30 seconds at a time. Allow two minutes

between cranking intervals.

(7) Perform previous air bleeding procedure steps

using fuel transfer pump. Be sure fuel is present at

fuel supply line (Fig. 2) before proceeding.

(8) Crank the engine for 30 seconds at a time to

allow air trapped in the injection pump to vent out

the drain manifold.Fig. 2 Fuel Supply Line Banjo Bolt

1 - FUEL SUPPLY LINE

2 - FUEL RETURN LINE

3 - BANJO BOLT (TEST PORT FITTING)

4 - OVERFLOW VALVE

5 - BANJO FITTING

BR/BEFUEL DELIVERY - DIESEL 14 - 57

FUEL DELIVERY - DIESEL (Continued)

Page 1545 of 2889

WARNING: THE FUEL INJECTION PUMP SUPPLIES

EXTREMELY HIGH FUEL PRESSURE TO EACH INDI-

VIDUAL INJECTOR THROUGH THE HIGH-PRES-

SURE LINES. FUEL UNDER THIS AMOUNT OF

PRESSURE CAN PENETRATE THE SKIN AND

CAUSE PERSONAL INJURY. WEAR SAFETY GOG-

GLES AND ADEQUATE PROTECTIVE CLOTHING

AND AVOID CONTACT WITH FUEL SPRAY WHEN

BLEEDING HIGH-PRESSURE FUEL LINES.

WARNING: ENGINE MAY START WHILE CRANKING

STARTER MOTOR.

Engine may start, may run erratically and be

very noisy for a few minutes. This is a normal

condition.

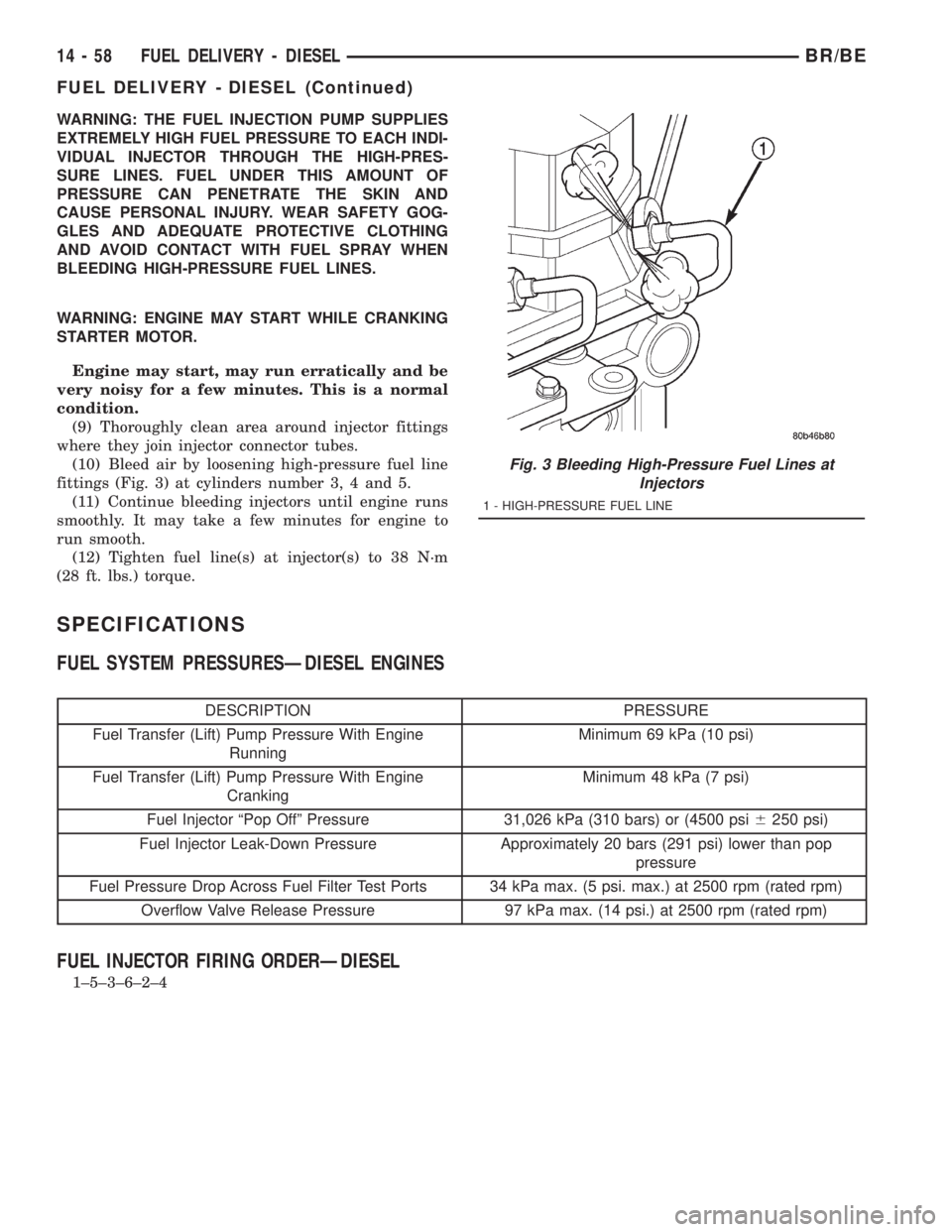

(9) Thoroughly clean area around injector fittings

where they join injector connector tubes.

(10) Bleed air by loosening high-pressure fuel line

fittings (Fig. 3) at cylinders number 3, 4 and 5.

(11) Continue bleeding injectors until engine runs

smoothly. It may take a few minutes for engine to

run smooth.

(12) Tighten fuel line(s) at injector(s) to 38 N´m

(28 ft. lbs.) torque.

SPECIFICATIONS

FUEL SYSTEM PRESSURESÐDIESEL ENGINES

DESCRIPTION PRESSURE

Fuel Transfer (Lift) Pump Pressure With Engine

RunningMinimum 69 kPa (10 psi)

Fuel Transfer (Lift) Pump Pressure With Engine

CrankingMinimum 48 kPa (7 psi)

Fuel Injector ªPop Offº Pressure 31,026 kPa (310 bars) or (4500 psi6250 psi)

Fuel Injector Leak-Down Pressure Approximately 20 bars (291 psi) lower than pop

pressure

Fuel Pressure Drop Across Fuel Filter Test Ports 34 kPa max. (5 psi. max.) at 2500 rpm (rated rpm)

Overflow Valve Release Pressure 97 kPa max. (14 psi.) at 2500 rpm (rated rpm)

FUEL INJECTOR FIRING ORDERÐDIESEL

1±5±3±6±2±4

Fig. 3 Bleeding High-Pressure Fuel Lines at

Injectors

1 - HIGH-PRESSURE FUEL LINE

14 - 58 FUEL DELIVERY - DIESELBR/BE

FUEL DELIVERY - DIESEL (Continued)

Page 1548 of 2889

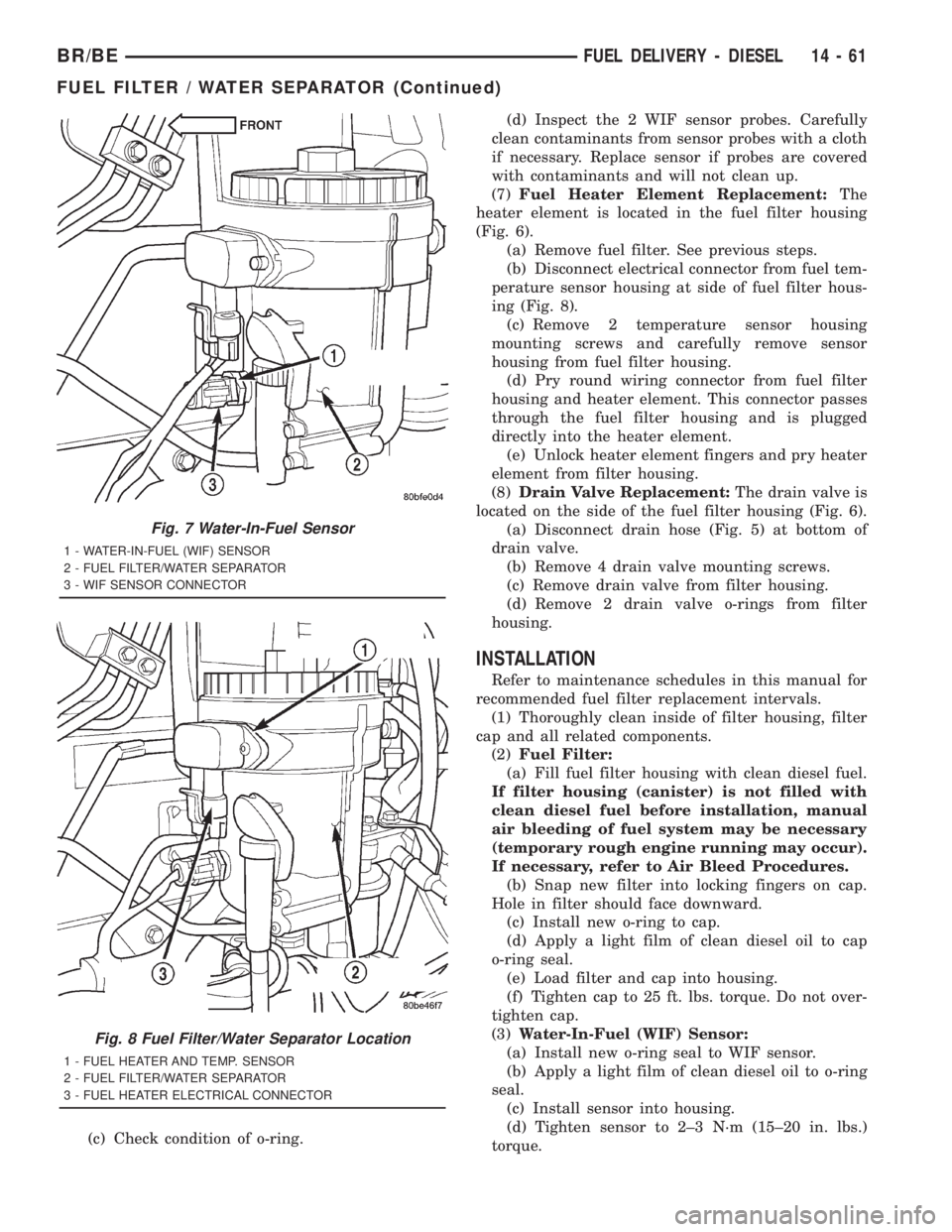

(c) Check condition of o-ring.(d) Inspect the 2 WIF sensor probes. Carefully

clean contaminants from sensor probes with a cloth

if necessary. Replace sensor if probes are covered

with contaminants and will not clean up.

(7)Fuel Heater Element Replacement:The

heater element is located in the fuel filter housing

(Fig. 6).

(a) Remove fuel filter. See previous steps.

(b) Disconnect electrical connector from fuel tem-

perature sensor housing at side of fuel filter hous-

ing (Fig. 8).

(c) Remove 2 temperature sensor housing

mounting screws and carefully remove sensor

housing from fuel filter housing.

(d) Pry round wiring connector from fuel filter

housing and heater element. This connector passes

through the fuel filter housing and is plugged

directly into the heater element.

(e) Unlock heater element fingers and pry heater

element from filter housing.

(8)Drain Valve Replacement:The drain valve is

located on the side of the fuel filter housing (Fig. 6).

(a) Disconnect drain hose (Fig. 5) at bottom of

drain valve.

(b) Remove 4 drain valve mounting screws.

(c) Remove drain valve from filter housing.

(d) Remove 2 drain valve o-rings from filter

housing.

INSTALLATION

Refer to maintenance schedules in this manual for

recommended fuel filter replacement intervals.

(1) Thoroughly clean inside of filter housing, filter

cap and all related components.

(2)Fuel Filter:

(a) Fill fuel filter housing with clean diesel fuel.

If filter housing (canister) is not filled with

clean diesel fuel before installation, manual

air bleeding of fuel system may be necessary

(temporary rough engine running may occur).

If necessary, refer to Air Bleed Procedures.

(b) Snap new filter into locking fingers on cap.

Hole in filter should face downward.

(c) Install new o-ring to cap.

(d) Apply a light film of clean diesel oil to cap

o-ring seal.

(e) Load filter and cap into housing.

(f) Tighten cap to 25 ft. lbs. torque. Do not over-

tighten cap.

(3)Water-In-Fuel (WIF) Sensor:

(a) Install new o-ring seal to WIF sensor.

(b) Apply a light film of clean diesel oil to o-ring

seal.

(c) Install sensor into housing.

(d) Tighten sensor to 2±3 N´m (15±20 in. lbs.)

torque.

Fig. 7 Water-In-Fuel Sensor

1 - WATER-IN-FUEL (WIF) SENSOR

2 - FUEL FILTER/WATER SEPARATOR

3 - WIF SENSOR CONNECTOR

Fig. 8 Fuel Filter/Water Separator Location

1 - FUEL HEATER AND TEMP. SENSOR

2 - FUEL FILTER/WATER SEPARATOR

3 - FUEL HEATER ELECTRICAL CONNECTOR

BR/BEFUEL DELIVERY - DIESEL 14 - 61

FUEL FILTER / WATER SEPARATOR (Continued)