torque DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1581 of 2889

OPERATION

High-pressure fuel is supplied from the injection

pump, through a high-pressure fuel line, through a

steel connector and into the fuel injector. When fuel

pressure rises to approximately 31,026 kPa (4,500

psi), the needle valve spring tension is overcome. The

needle valve rises and fuel flows through the spray

holes in the nozzle tip into the combustion chamber.

The pressure required to lift the needle valve is the

nozzle opening pressure. This is sometimes referred

to as the ªpopº pressure setting.

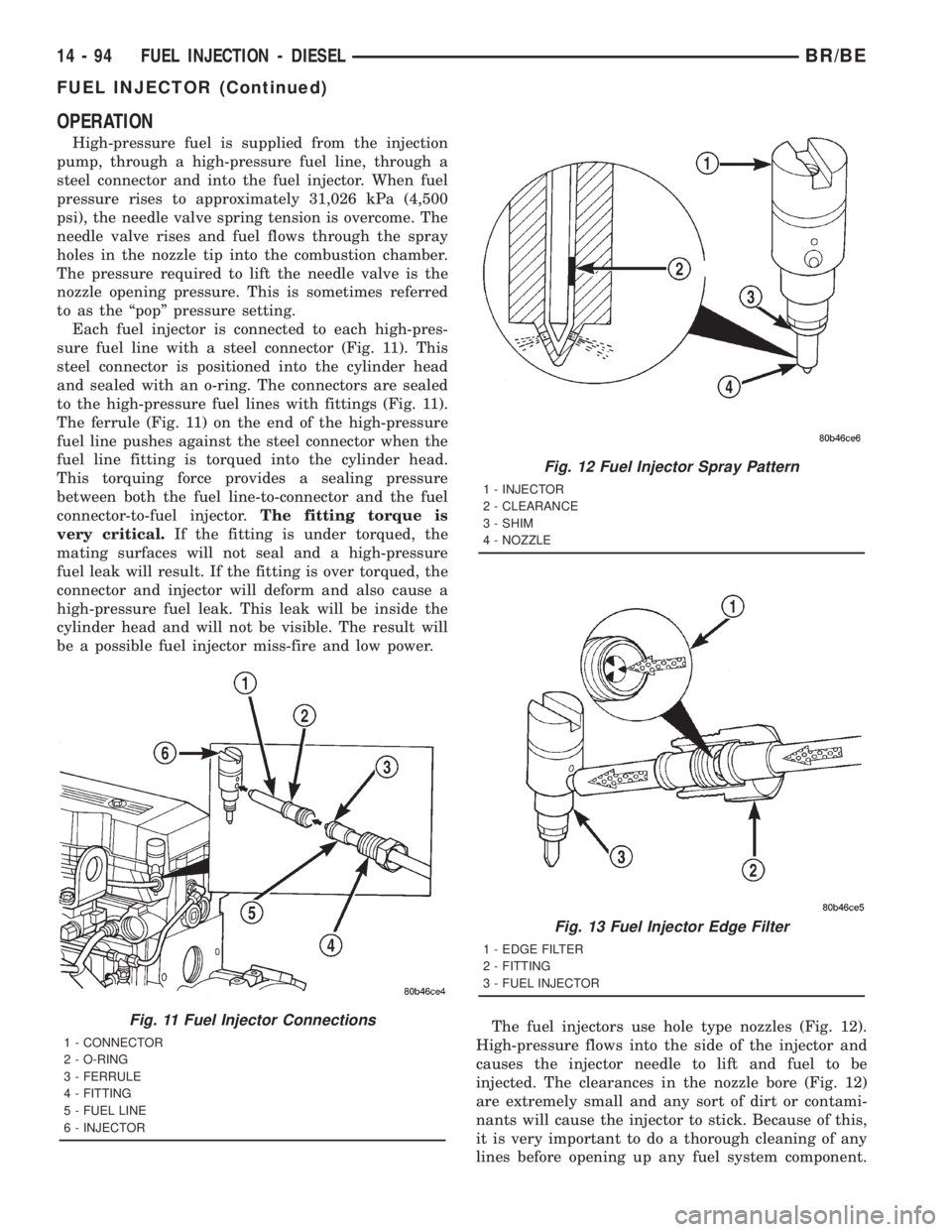

Each fuel injector is connected to each high-pres-

sure fuel line with a steel connector (Fig. 11). This

steel connector is positioned into the cylinder head

and sealed with an o-ring. The connectors are sealed

to the high-pressure fuel lines with fittings (Fig. 11).

The ferrule (Fig. 11) on the end of the high-pressure

fuel line pushes against the steel connector when the

fuel line fitting is torqued into the cylinder head.

This torquing force provides a sealing pressure

between both the fuel line-to-connector and the fuel

connector-to-fuel injector.The fitting torque is

very critical.If the fitting is under torqued, the

mating surfaces will not seal and a high-pressure

fuel leak will result. If the fitting is over torqued, the

connector and injector will deform and also cause a

high-pressure fuel leak. This leak will be inside the

cylinder head and will not be visible. The result will

be a possible fuel injector miss-fire and low power.

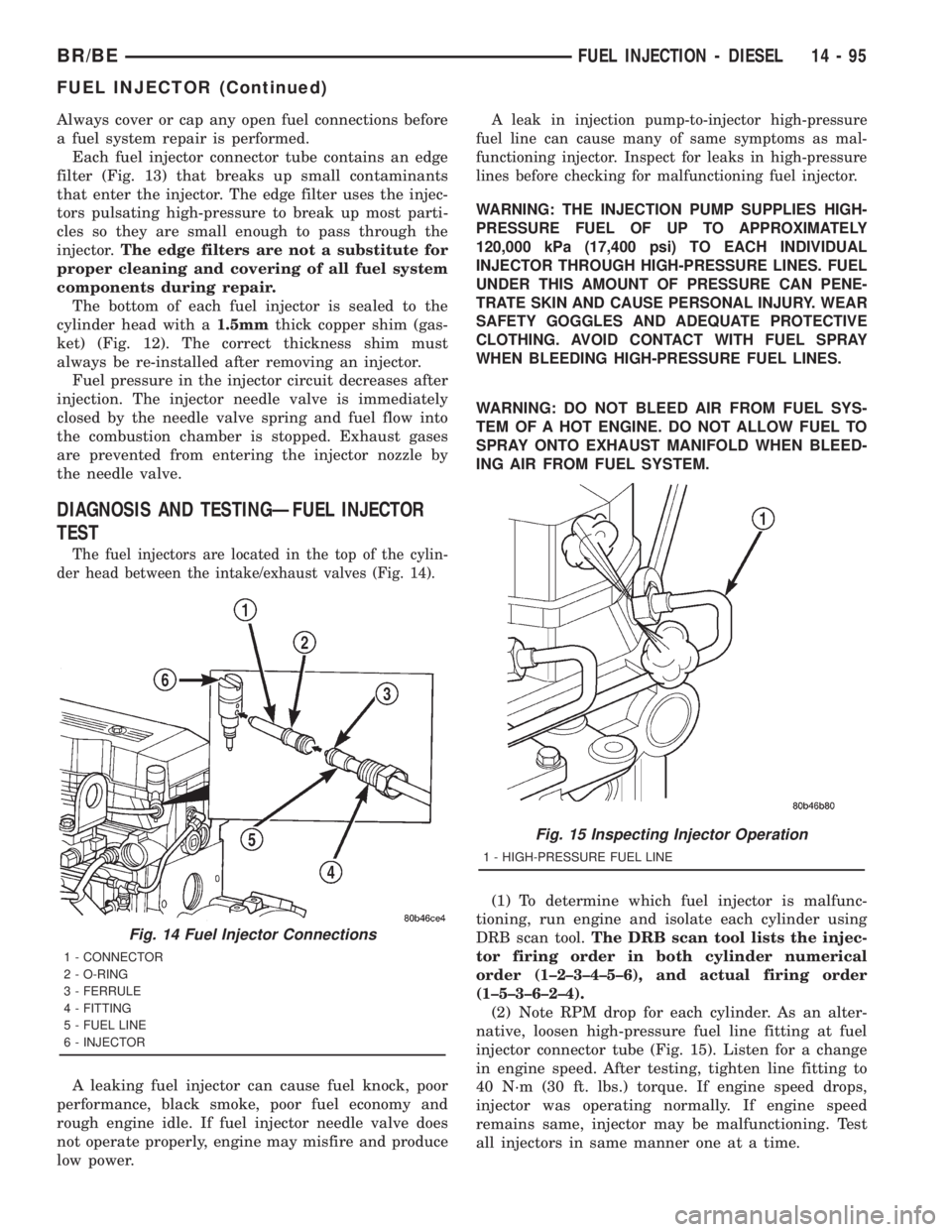

The fuel injectors use hole type nozzles (Fig. 12).

High-pressure flows into the side of the injector and

causes the injector needle to lift and fuel to be

injected. The clearances in the nozzle bore (Fig. 12)

are extremely small and any sort of dirt or contami-

nants will cause the injector to stick. Because of this,

it is very important to do a thorough cleaning of any

lines before opening up any fuel system component.

Fig. 11 Fuel Injector Connections

1 - CONNECTOR

2 - O-RING

3 - FERRULE

4 - FITTING

5 - FUEL LINE

6 - INJECTOR

Fig. 12 Fuel Injector Spray Pattern

1 - INJECTOR

2 - CLEARANCE

3 - SHIM

4 - NOZZLE

Fig. 13 Fuel Injector Edge Filter

1 - EDGE FILTER

2 - FITTING

3 - FUEL INJECTOR

14 - 94 FUEL INJECTION - DIESELBR/BE

FUEL INJECTOR (Continued)

Page 1582 of 2889

Always cover or cap any open fuel connections before

a fuel system repair is performed.

Each fuel injector connector tube contains an edge

filter (Fig. 13) that breaks up small contaminants

that enter the injector. The edge filter uses the injec-

tors pulsating high-pressure to break up most parti-

cles so they are small enough to pass through the

injector.The edge filters are not a substitute for

proper cleaning and covering of all fuel system

components during repair.

The bottom of each fuel injector is sealed to the

cylinder head with a1.5mmthick copper shim (gas-

ket) (Fig. 12). The correct thickness shim must

always be re-installed after removing an injector.

Fuel pressure in the injector circuit decreases after

injection. The injector needle valve is immediately

closed by the needle valve spring and fuel flow into

the combustion chamber is stopped. Exhaust gases

are prevented from entering the injector nozzle by

the needle valve.

DIAGNOSIS AND TESTINGÐFUEL INJECTOR

TEST

The fuel injectors are located in the top of the cylin-

der head between the intake/exhaust valves (Fig. 14).

A leaking fuel injector can cause fuel knock, poor

performance, black smoke, poor fuel economy and

rough engine idle. If fuel injector needle valve does

not operate properly, engine may misfire and produce

low power.

A leak in injection pump-to-injector high-pressure

fuel line can cause many of same symptoms as mal-

functioning injector. Inspect for leaks in high-pressure

lines before checking for malfunctioning fuel injector.

WARNING: THE INJECTION PUMP SUPPLIES HIGH-

PRESSURE FUEL OF UP TO APPROXIMATELY

120,000 kPa (17,400 psi) TO EACH INDIVIDUAL

INJECTOR THROUGH HIGH-PRESSURE LINES. FUEL

UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE SKIN AND CAUSE PERSONAL INJURY. WEAR

SAFETY GOGGLES AND ADEQUATE PROTECTIVE

CLOTHING. AVOID CONTACT WITH FUEL SPRAY

WHEN BLEEDING HIGH-PRESSURE FUEL LINES.

WARNING: DO NOT BLEED AIR FROM FUEL SYS-

TEM OF A HOT ENGINE. DO NOT ALLOW FUEL TO

SPRAY ONTO EXHAUST MANIFOLD WHEN BLEED-

ING AIR FROM FUEL SYSTEM.

(1) To determine which fuel injector is malfunc-

tioning, run engine and isolate each cylinder using

DRB scan tool.The DRB scan tool lists the injec-

tor firing order in both cylinder numerical

order (1±2±3±4±5±6), and actual firing order

(1±5±3±6±2±4).

(2) Note RPM drop for each cylinder. As an alter-

native, loosen high-pressure fuel line fitting at fuel

injector connector tube (Fig. 15). Listen for a change

in engine speed. After testing, tighten line fitting to

40 N´m (30 ft. lbs.) torque. If engine speed drops,

injector was operating normally. If engine speed

remains same, injector may be malfunctioning. Test

all injectors in same manner one at a time.

Fig. 14 Fuel Injector Connections

1 - CONNECTOR

2 - O-RING

3 - FERRULE

4 - FITTING

5 - FUEL LINE

6 - INJECTOR

Fig. 15 Inspecting Injector Operation

1 - HIGH-PRESSURE FUEL LINE

BR/BEFUEL INJECTION - DIESEL 14 - 95

FUEL INJECTOR (Continued)

Page 1586 of 2889

(g) If any of these conditions occur, replace injec-

tor.

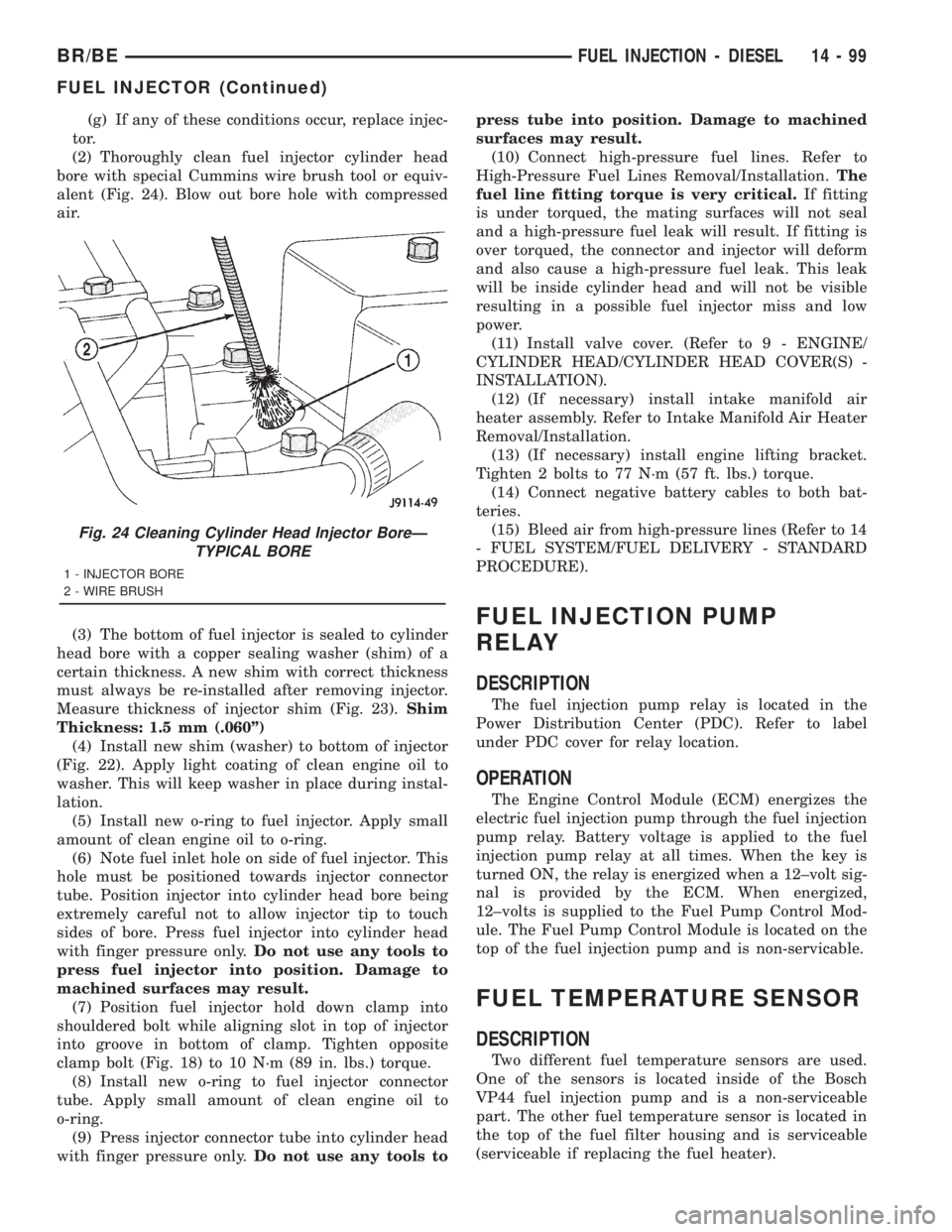

(2) Thoroughly clean fuel injector cylinder head

bore with special Cummins wire brush tool or equiv-

alent (Fig. 24). Blow out bore hole with compressed

air.

(3) The bottom of fuel injector is sealed to cylinder

head bore with a copper sealing washer (shim) of a

certain thickness. A new shim with correct thickness

must always be re-installed after removing injector.

Measure thickness of injector shim (Fig. 23).Shim

Thickness: 1.5 mm (.060º)

(4) Install new shim (washer) to bottom of injector

(Fig. 22). Apply light coating of clean engine oil to

washer. This will keep washer in place during instal-

lation.

(5) Install new o-ring to fuel injector. Apply small

amount of clean engine oil to o-ring.

(6) Note fuel inlet hole on side of fuel injector. This

hole must be positioned towards injector connector

tube. Position injector into cylinder head bore being

extremely careful not to allow injector tip to touch

sides of bore. Press fuel injector into cylinder head

with finger pressure only.Do not use any tools to

press fuel injector into position. Damage to

machined surfaces may result.

(7) Position fuel injector hold down clamp into

shouldered bolt while aligning slot in top of injector

into groove in bottom of clamp. Tighten opposite

clamp bolt (Fig. 18) to 10 N´m (89 in. lbs.) torque.

(8) Install new o-ring to fuel injector connector

tube. Apply small amount of clean engine oil to

o-ring.

(9) Press injector connector tube into cylinder head

with finger pressure only.Do not use any tools topress tube into position. Damage to machined

surfaces may result.

(10) Connect high-pressure fuel lines. Refer to

High-Pressure Fuel Lines Removal/Installation.The

fuel line fitting torque is very critical.If fitting

is under torqued, the mating surfaces will not seal

and a high-pressure fuel leak will result. If fitting is

over torqued, the connector and injector will deform

and also cause a high-pressure fuel leak. This leak

will be inside cylinder head and will not be visible

resulting in a possible fuel injector miss and low

power.

(11) Install valve cover. (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

(12) (If necessary) install intake manifold air

heater assembly. Refer to Intake Manifold Air Heater

Removal/Installation.

(13) (If necessary) install engine lifting bracket.

Tighten 2 bolts to 77 N´m (57 ft. lbs.) torque.

(14) Connect negative battery cables to both bat-

teries.

(15) Bleed air from high-pressure lines (Refer to 14

- FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE).

FUEL INJECTION PUMP

RELAY

DESCRIPTION

The fuel injection pump relay is located in the

Power Distribution Center (PDC). Refer to label

under PDC cover for relay location.

OPERATION

The Engine Control Module (ECM) energizes the

electric fuel injection pump through the fuel injection

pump relay. Battery voltage is applied to the fuel

injection pump relay at all times. When the key is

turned ON, the relay is energized when a 12±volt sig-

nal is provided by the ECM. When energized,

12±volts is supplied to the Fuel Pump Control Mod-

ule. The Fuel Pump Control Module is located on the

top of the fuel injection pump and is non-servicable.

FUEL TEMPERATURE SENSOR

DESCRIPTION

Two different fuel temperature sensors are used.

One of the sensors is located inside of the Bosch

VP44 fuel injection pump and is a non-serviceable

part. The other fuel temperature sensor is located in

the top of the fuel filter housing and is serviceable

(serviceable if replacing the fuel heater).

Fig. 24 Cleaning Cylinder Head Injector BoreÐ

TYPICAL BORE

1 - INJECTOR BORE

2 - WIRE BRUSH

BR/BEFUEL INJECTION - DIESEL 14 - 99

FUEL INJECTOR (Continued)

Page 1588 of 2889

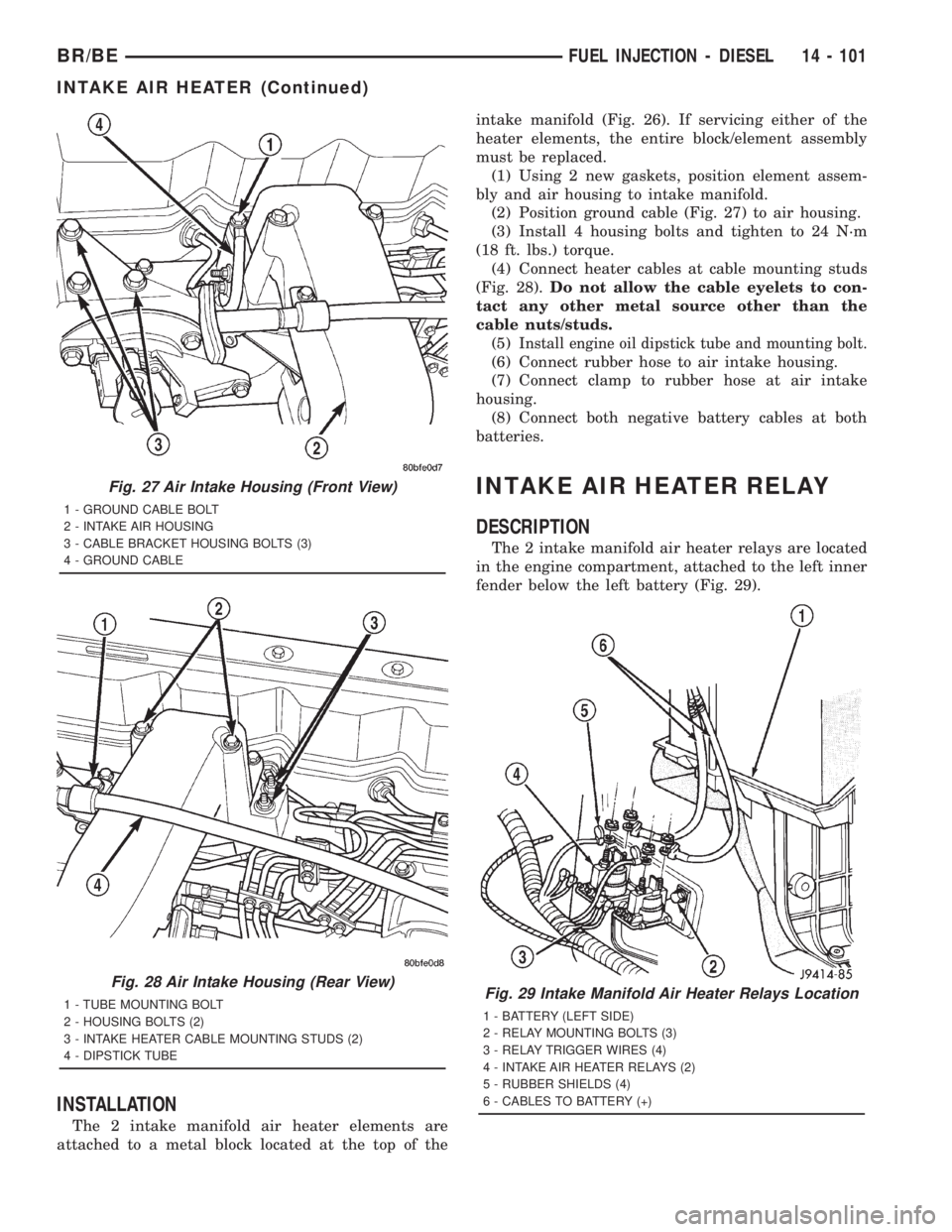

INSTALLATION

The 2 intake manifold air heater elements are

attached to a metal block located at the top of theintake manifold (Fig. 26). If servicing either of the

heater elements, the entire block/element assembly

must be replaced.

(1) Using 2 new gaskets, position element assem-

bly and air housing to intake manifold.

(2) Position ground cable (Fig. 27) to air housing.

(3) Install 4 housing bolts and tighten to 24 N´m

(18 ft. lbs.) torque.

(4) Connect heater cables at cable mounting studs

(Fig. 28).Do not allow the cable eyelets to con-

tact any other metal source other than the

cable nuts/studs.

(5)

Install engine oil dipstick tube and mounting bolt.

(6) Connect rubber hose to air intake housing.

(7) Connect clamp to rubber hose at air intake

housing.

(8) Connect both negative battery cables at both

batteries.

INTAKE AIR HEATER RELAY

DESCRIPTION

The 2 intake manifold air heater relays are located

in the engine compartment, attached to the left inner

fender below the left battery (Fig. 29).

Fig. 27 Air Intake Housing (Front View)

1 - GROUND CABLE BOLT

2 - INTAKE AIR HOUSING

3 - CABLE BRACKET HOUSING BOLTS (3)

4 - GROUND CABLE

Fig. 28 Air Intake Housing (Rear View)

1 - TUBE MOUNTING BOLT

2 - HOUSING BOLTS (2)

3 - INTAKE HEATER CABLE MOUNTING STUDS (2)

4 - DIPSTICK TUBEFig. 29 Intake Manifold Air Heater Relays Location

1 - BATTERY (LEFT SIDE)

2 - RELAY MOUNTING BOLTS (3)

3 - RELAY TRIGGER WIRES (4)

4 - INTAKE AIR HEATER RELAYS (2)

5 - RUBBER SHIELDS (4)

6 - CABLES TO BATTERY (+)

BR/BEFUEL INJECTION - DIESEL 14 - 101

INTAKE AIR HEATER (Continued)

Page 1589 of 2889

OPERATION

The Engine Control Module (ECM) operates the 2

heating elements through the 2 intake manifold air

heater relays.

Refer to Powertrain Diagnostic Procedures for an

electrical operation and complete description of the

intake heaters, including pre-heat and post-heat

cycles.

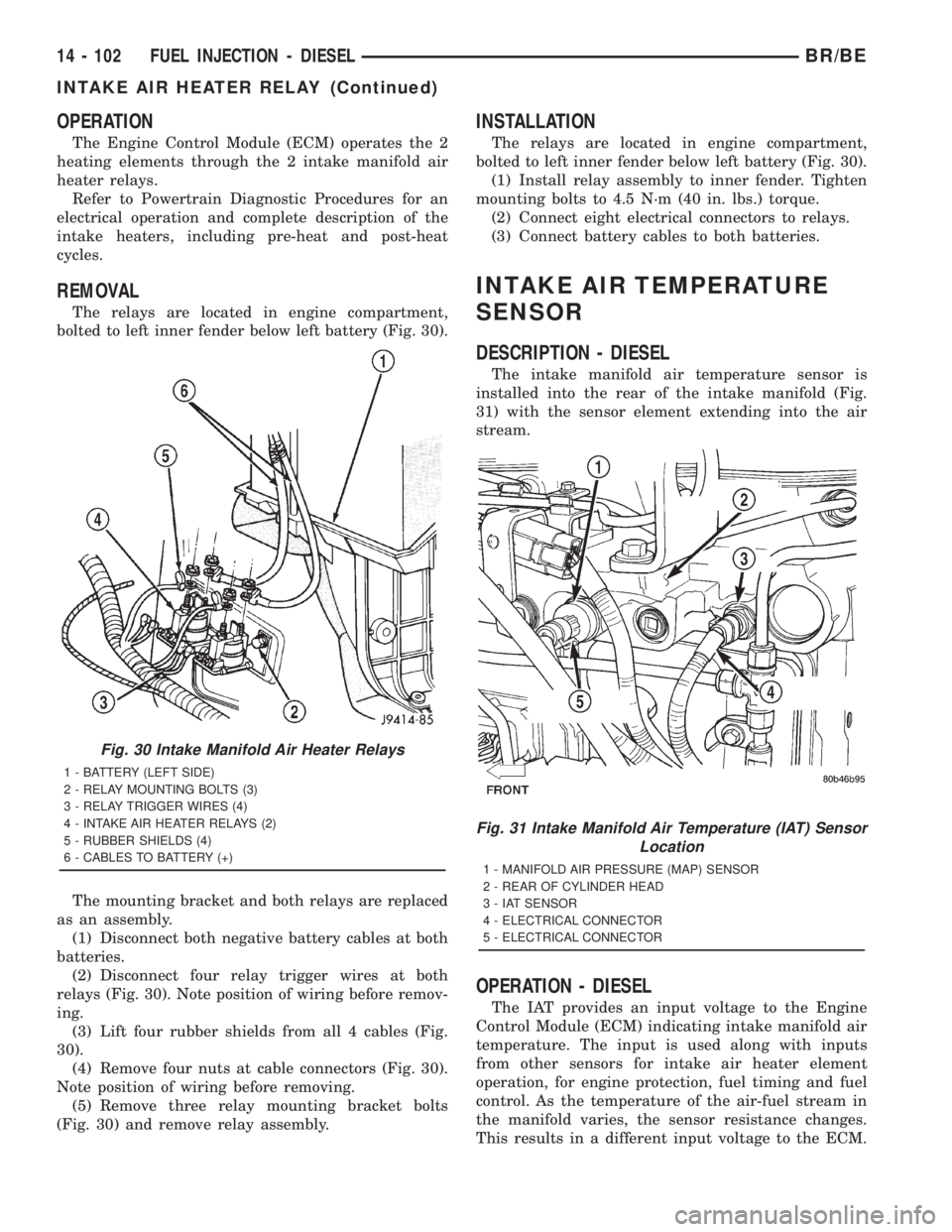

REMOVAL

The relays are located in engine compartment,

bolted to left inner fender below left battery (Fig. 30).

The mounting bracket and both relays are replaced

as an assembly.

(1) Disconnect both negative battery cables at both

batteries.

(2) Disconnect four relay trigger wires at both

relays (Fig. 30). Note position of wiring before remov-

ing.

(3) Lift four rubber shields from all 4 cables (Fig.

30).

(4) Remove four nuts at cable connectors (Fig. 30).

Note position of wiring before removing.

(5) Remove three relay mounting bracket bolts

(Fig. 30) and remove relay assembly.

INSTALLATION

The relays are located in engine compartment,

bolted to left inner fender below left battery (Fig. 30).

(1) Install relay assembly to inner fender. Tighten

mounting bolts to 4.5 N´m (40 in. lbs.) torque.

(2) Connect eight electrical connectors to relays.

(3) Connect battery cables to both batteries.

INTAKE AIR TEMPERATURE

SENSOR

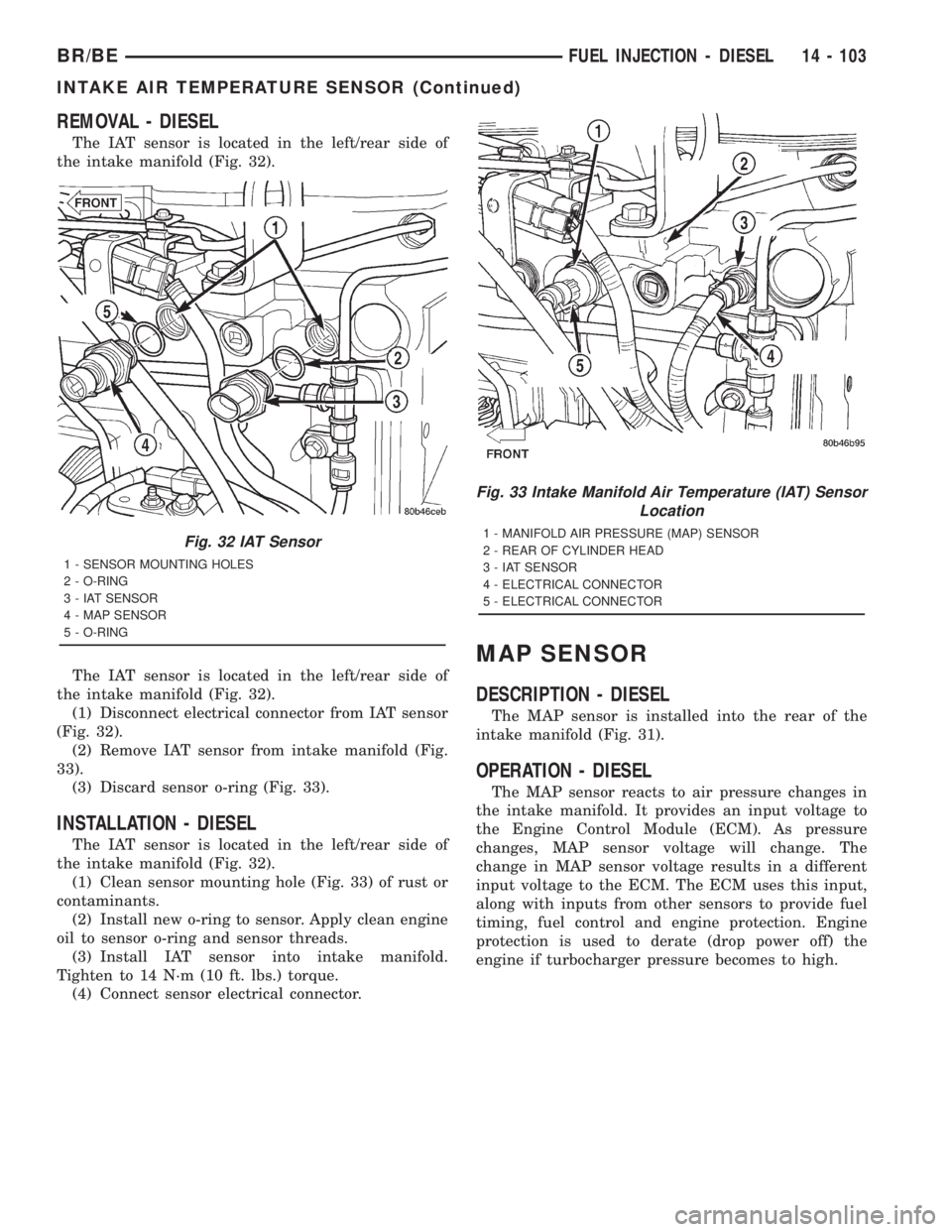

DESCRIPTION - DIESEL

The intake manifold air temperature sensor is

installed into the rear of the intake manifold (Fig.

31) with the sensor element extending into the air

stream.

OPERATION - DIESEL

The IAT provides an input voltage to the Engine

Control Module (ECM) indicating intake manifold air

temperature. The input is used along with inputs

from other sensors for intake air heater element

operation, for engine protection, fuel timing and fuel

control. As the temperature of the air-fuel stream in

the manifold varies, the sensor resistance changes.

This results in a different input voltage to the ECM.

Fig. 30 Intake Manifold Air Heater Relays

1 - BATTERY (LEFT SIDE)

2 - RELAY MOUNTING BOLTS (3)

3 - RELAY TRIGGER WIRES (4)

4 - INTAKE AIR HEATER RELAYS (2)

5 - RUBBER SHIELDS (4)

6 - CABLES TO BATTERY (+)

Fig. 31 Intake Manifold Air Temperature (IAT) Sensor

Location

1 - MANIFOLD AIR PRESSURE (MAP) SENSOR

2 - REAR OF CYLINDER HEAD

3 - IAT SENSOR

4 - ELECTRICAL CONNECTOR

5 - ELECTRICAL CONNECTOR

14 - 102 FUEL INJECTION - DIESELBR/BE

INTAKE AIR HEATER RELAY (Continued)

Page 1590 of 2889

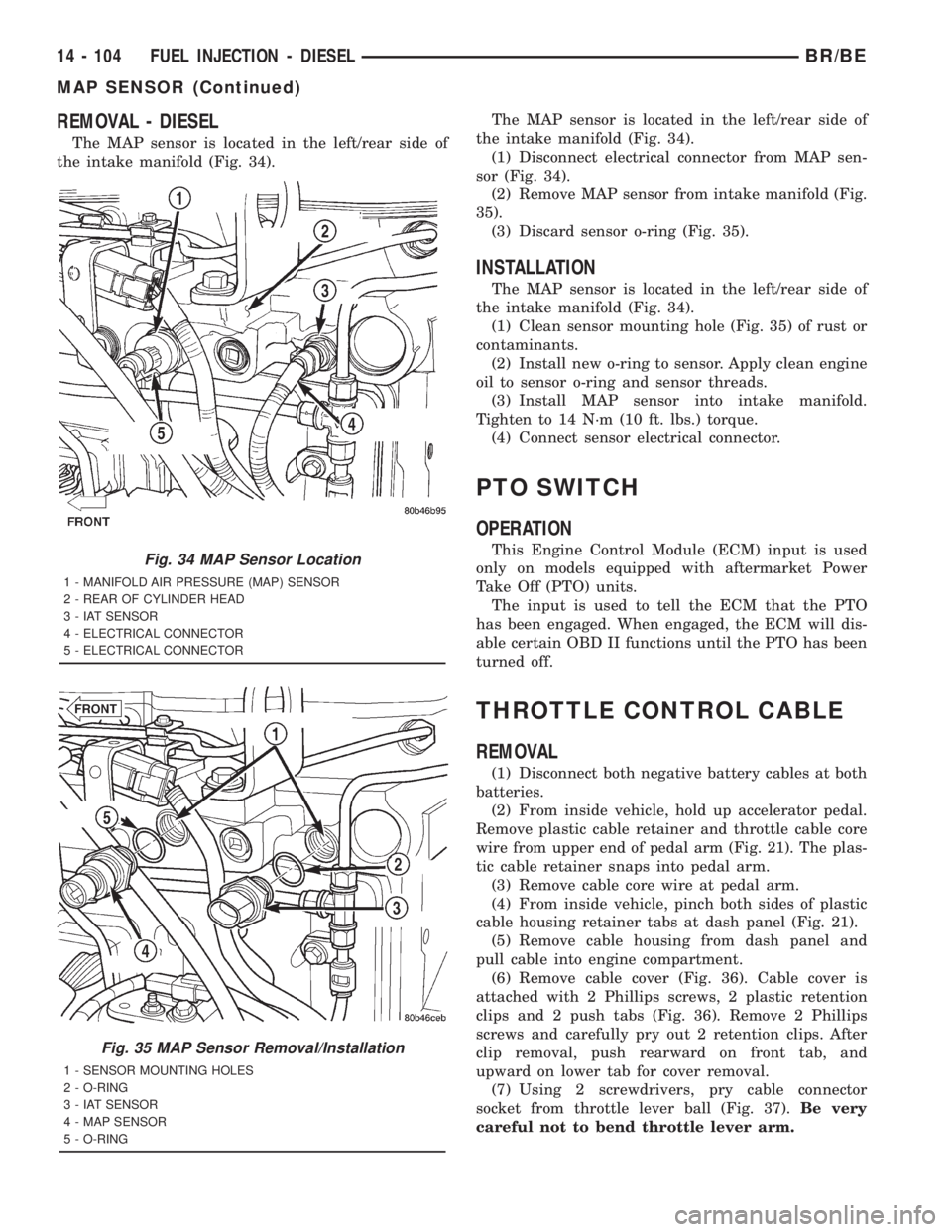

REMOVAL - DIESEL

The IAT sensor is located in the left/rear side of

the intake manifold (Fig. 32).

The IAT sensor is located in the left/rear side of

the intake manifold (Fig. 32).

(1) Disconnect electrical connector from IAT sensor

(Fig. 32).

(2) Remove IAT sensor from intake manifold (Fig.

33).

(3) Discard sensor o-ring (Fig. 33).

INSTALLATION - DIESEL

The IAT sensor is located in the left/rear side of

the intake manifold (Fig. 32).

(1) Clean sensor mounting hole (Fig. 33) of rust or

contaminants.

(2) Install new o-ring to sensor. Apply clean engine

oil to sensor o-ring and sensor threads.

(3) Install IAT sensor into intake manifold.

Tighten to 14 N´m (10 ft. lbs.) torque.

(4) Connect sensor electrical connector.

MAP SENSOR

DESCRIPTION - DIESEL

The MAP sensor is installed into the rear of the

intake manifold (Fig. 31).

OPERATION - DIESEL

The MAP sensor reacts to air pressure changes in

the intake manifold. It provides an input voltage to

the Engine Control Module (ECM). As pressure

changes, MAP sensor voltage will change. The

change in MAP sensor voltage results in a different

input voltage to the ECM. The ECM uses this input,

along with inputs from other sensors to provide fuel

timing, fuel control and engine protection. Engine

protection is used to derate (drop power off) the

engine if turbocharger pressure becomes to high.

Fig. 32 IAT Sensor

1 - SENSOR MOUNTING HOLES

2 - O-RING

3 - IAT SENSOR

4 - MAP SENSOR

5 - O-RING

Fig. 33 Intake Manifold Air Temperature (IAT) Sensor

Location

1 - MANIFOLD AIR PRESSURE (MAP) SENSOR

2 - REAR OF CYLINDER HEAD

3 - IAT SENSOR

4 - ELECTRICAL CONNECTOR

5 - ELECTRICAL CONNECTOR

BR/BEFUEL INJECTION - DIESEL 14 - 103

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1591 of 2889

REMOVAL - DIESEL

The MAP sensor is located in the left/rear side of

the intake manifold (Fig. 34).The MAP sensor is located in the left/rear side of

the intake manifold (Fig. 34).

(1) Disconnect electrical connector from MAP sen-

sor (Fig. 34).

(2) Remove MAP sensor from intake manifold (Fig.

35).

(3) Discard sensor o-ring (Fig. 35).

INSTALLATION

The MAP sensor is located in the left/rear side of

the intake manifold (Fig. 34).

(1) Clean sensor mounting hole (Fig. 35) of rust or

contaminants.

(2) Install new o-ring to sensor. Apply clean engine

oil to sensor o-ring and sensor threads.

(3) Install MAP sensor into intake manifold.

Tighten to 14 N´m (10 ft. lbs.) torque.

(4) Connect sensor electrical connector.

PTO SWITCH

OPERATION

This Engine Control Module (ECM) input is used

only on models equipped with aftermarket Power

Take Off (PTO) units.

The input is used to tell the ECM that the PTO

has been engaged. When engaged, the ECM will dis-

able certain OBD II functions until the PTO has been

turned off.

THROTTLE CONTROL CABLE

REMOVAL

(1) Disconnect both negative battery cables at both

batteries.

(2) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer and throttle cable core

wire from upper end of pedal arm (Fig. 21). The plas-

tic cable retainer snaps into pedal arm.

(3) Remove cable core wire at pedal arm.

(4) From inside vehicle, pinch both sides of plastic

cable housing retainer tabs at dash panel (Fig. 21).

(5) Remove cable housing from dash panel and

pull cable into engine compartment.

(6) Remove cable cover (Fig. 36). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 36). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.

(7) Using 2 screwdrivers, pry cable connector

socket from throttle lever ball (Fig. 37).Be very

careful not to bend throttle lever arm.

Fig. 34 MAP Sensor Location

1 - MANIFOLD AIR PRESSURE (MAP) SENSOR

2 - REAR OF CYLINDER HEAD

3 - IAT SENSOR

4 - ELECTRICAL CONNECTOR

5 - ELECTRICAL CONNECTOR

Fig. 35 MAP Sensor Removal/Installation

1 - SENSOR MOUNTING HOLES

2 - O-RING

3 - IAT SENSOR

4 - MAP SENSOR

5 - O-RING

14 - 104 FUEL INJECTION - DIESELBR/BE

MAP SENSOR (Continued)

Page 1602 of 2889

NOTE: A new grommet should be used when ever

the rod is disconnected from the lever.

(3) Remove the shipping lock pin if necessary.

(4) Install the column through the floor pan.

(5) Position the column bracket breakaway cap-

sules on the mounting studs. Install, butloose

assemblethe two upper bracket nuts.

(6) With the front wheels in the straight-ahead

position. Align steering column shaft to the coupler.

Install anewpinch bolt and tighten to 49 N´m (36

ft. lbs.).

(7) Clip the wiring harness on the steering column.

Connect the multi- function switch wiring and

tighten with 7mm socket.

(8) Install the upper fixed shroud.

(9) Be sure both breakaway capsules are fully

seated in the slots in the column support bracket.

Pull the column rearward then tighten upper bracket

nuts to 12 N´m (105 in. lbs.).

(10) Tighten the toe plate to floor pan attaching

nuts to 22.5 N´m (200 in. lbs.).

(11) Install the wiring connections to the column.

Install the lower fixed shroud.(12) Column shift vehicles, install the PRNDL

driver cable. Place shifter in Park position. If indica-

tor needs adjusting, turn thumb screw on cable

retainer to adjust cable.

(13) Install the lock housing shrouds. Install the

tilt lever (if equipped).

(14) Install the knee blocker and steering column

opening cover, (Refer to 23 - BODY/INSTRUMENT

PANEL/STEERING COLUMN OPENING COVER -

INSTALLATION).

(15) Install steering wheel and tighten nut to 61

N´m (45 ft. lbs.), (Refer to 19 - STEERING/COL-

UMN/STEERING WHEEL - INSTALLATION).

(16) Install the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(17) Column shift vehicles, connect the shift link

rod to the transmission shift lever. Use multi-purpose

lubricant, or an equivalent product, to aid the instal-

lation.

(18) Install the battery ground (negative) cable.

(19) Verify operation of the automatic transmission

shift linkage and adjust as necessary, (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

44RE/GEAR SHIFT CABLE - ADJUSTMENTS).

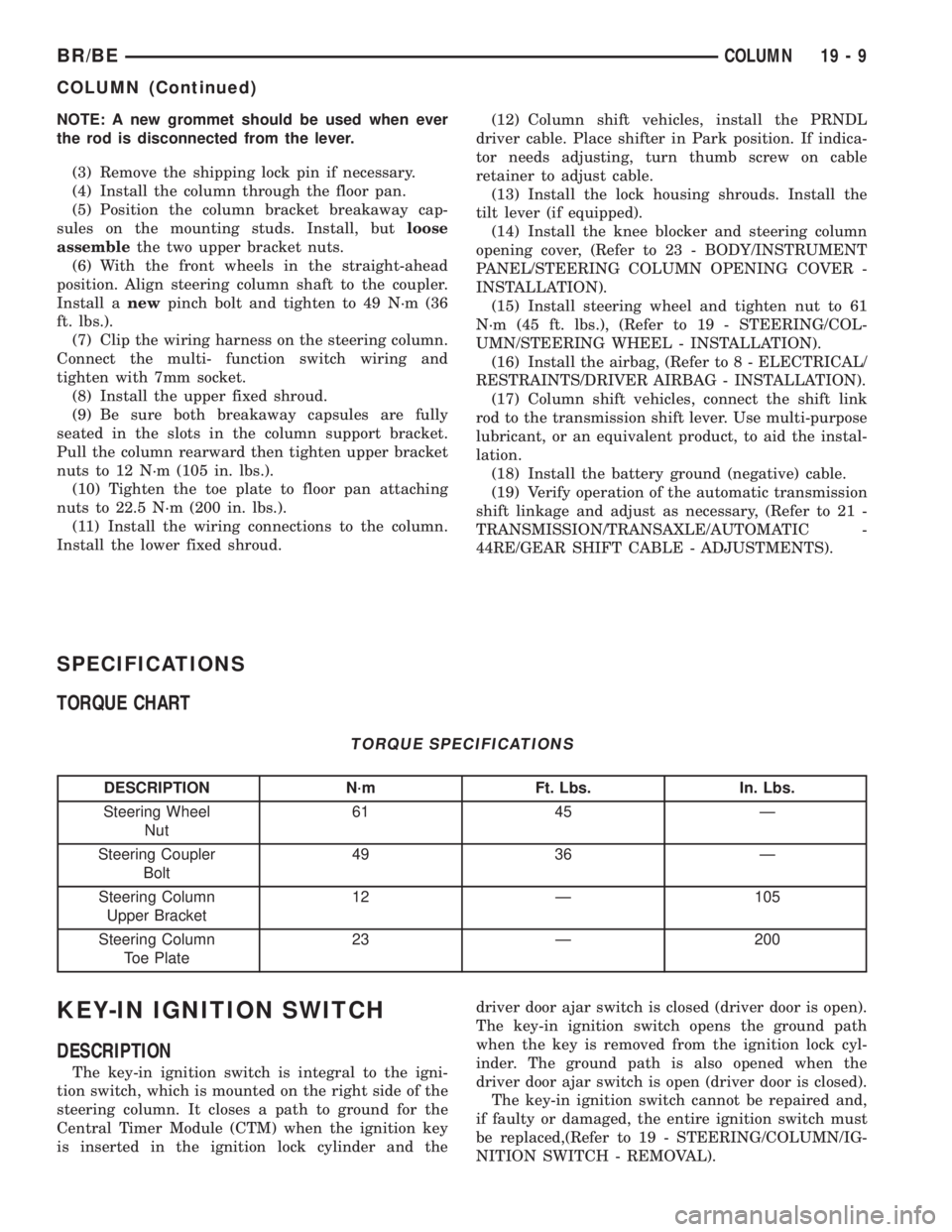

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Wheel

Nut61 45 Ð

Steering Coupler

Bolt49 36 Ð

Steering Column

Upper Bracket12 Ð 105

Steering Column

Toe Plate23 Ð 200

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the right side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition lock cylinder and thedriver door ajar switch is closed (driver door is open).

The key-in ignition switch opens the ground path

when the key is removed from the ignition lock cyl-

inder. The ground path is also opened when the

driver door ajar switch is open (driver door is closed).

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced,(Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

BR/BECOLUMN 19 - 9

COLUMN (Continued)

Page 1609 of 2889

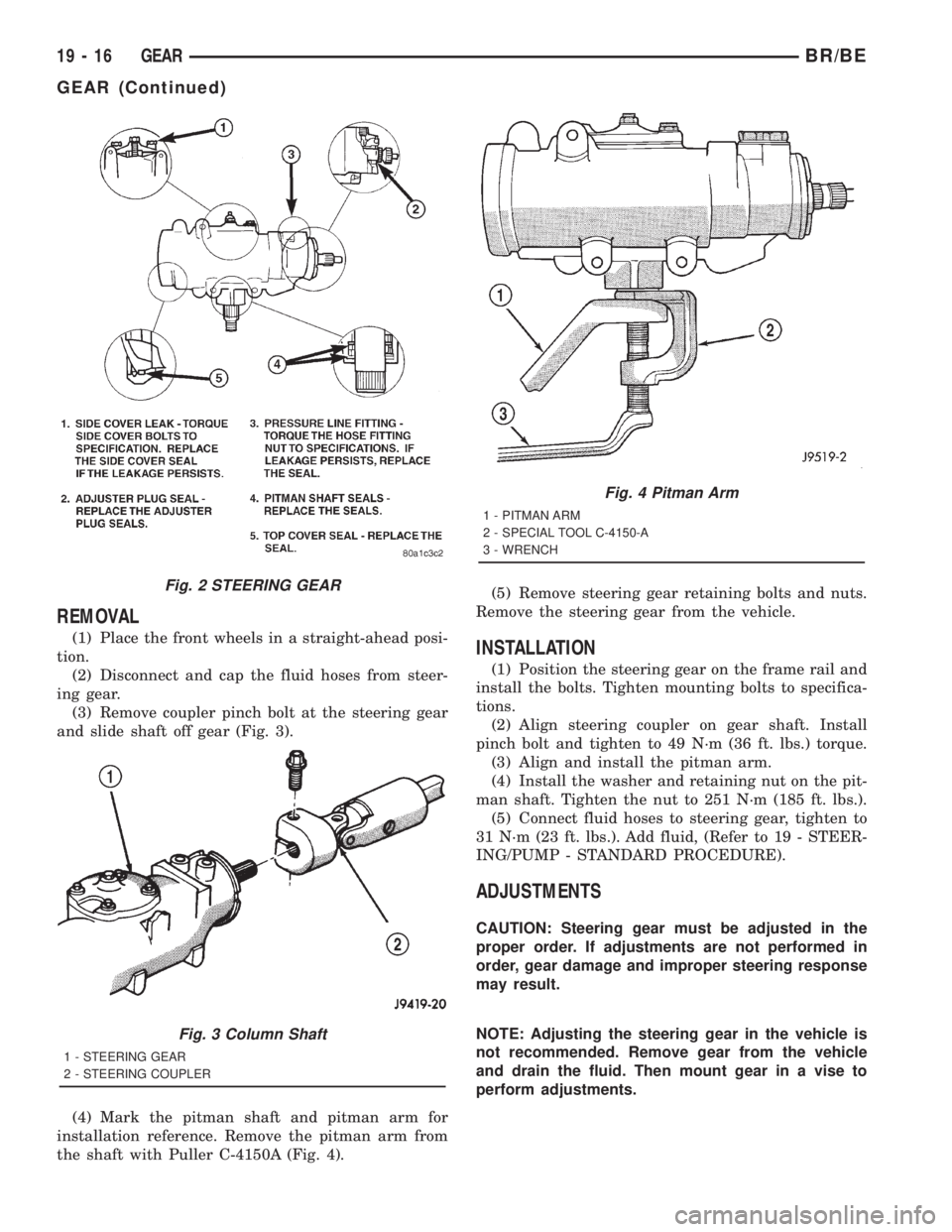

REMOVAL

(1) Place the front wheels in a straight-ahead posi-

tion.

(2) Disconnect and cap the fluid hoses from steer-

ing gear.

(3) Remove coupler pinch bolt at the steering gear

and slide shaft off gear (Fig. 3).

(4) Mark the pitman shaft and pitman arm for

installation reference. Remove the pitman arm from

the shaft with Puller C-4150A (Fig. 4).(5) Remove steering gear retaining bolts and nuts.

Remove the steering gear from the vehicle.INSTALLATION

(1) Position the steering gear on the frame rail and

install the bolts. Tighten mounting bolts to specifica-

tions.

(2) Align steering coupler on gear shaft. Install

pinch bolt and tighten to 49 N´m (36 ft. lbs.) torque.

(3) Align and install the pitman arm.

(4) Install the washer and retaining nut on the pit-

man shaft. Tighten the nut to 251 N´m (185 ft. lbs.).

(5) Connect fluid hoses to steering gear, tighten to

31 N´m (23 ft. lbs.). Add fluid, (Refer to 19 - STEER-

ING/PUMP - STANDARD PROCEDURE).

ADJUSTMENTS

CAUTION: Steering gear must be adjusted in the

proper order. If adjustments are not performed in

order, gear damage and improper steering response

may result.

NOTE: Adjusting the steering gear in the vehicle is

not recommended. Remove gear from the vehicle

and drain the fluid. Then mount gear in a vise to

perform adjustments.

Fig. 2 STEERING GEAR

Fig. 3 Column Shaft

1 - STEERING GEAR

2 - STEERING COUPLER

Fig. 4 Pitman Arm

1 - PITMAN ARM

2 - SPECIAL TOOL C-4150-A

3 - WRENCH

19 - 16 GEARBR/BE

GEAR (Continued)

Page 1610 of 2889

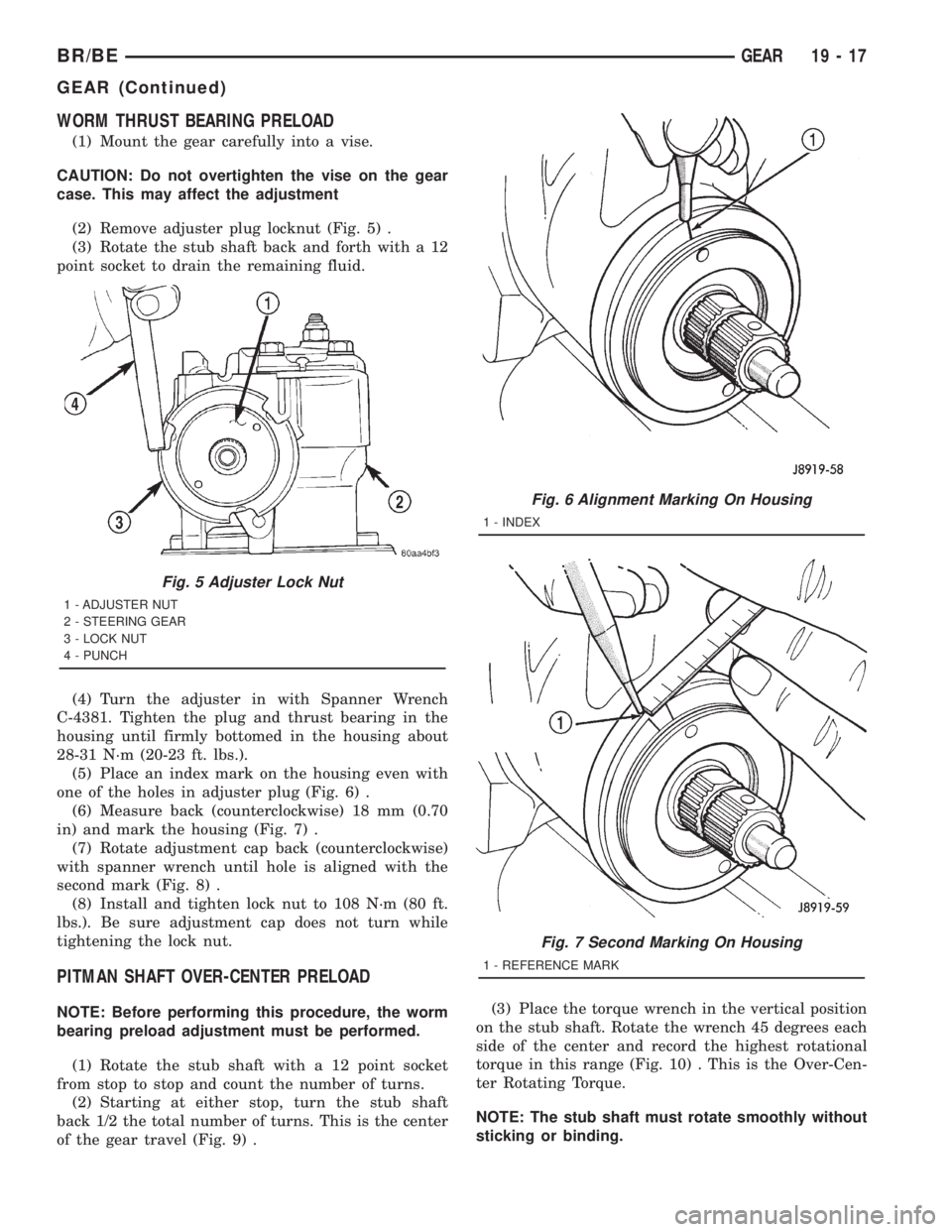

WORM THRUST BEARING PRELOAD

(1) Mount the gear carefully into a vise.

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(2) Remove adjuster plug locknut (Fig. 5) .

(3) Rotate the stub shaft back and forth with a 12

point socket to drain the remaining fluid.

(4) Turn the adjuster in with Spanner Wrench

C-4381. Tighten the plug and thrust bearing in the

housing until firmly bottomed in the housing about

28-31 N´m (20-23 ft. lbs.).

(5) Place an index mark on the housing even with

one of the holes in adjuster plug (Fig. 6) .

(6) Measure back (counterclockwise) 18 mm (0.70

in) and mark the housing (Fig. 7) .

(7) Rotate adjustment cap back (counterclockwise)

with spanner wrench until hole is aligned with the

second mark (Fig. 8) .

(8) Install and tighten lock nut to 108 N´m (80 ft.

lbs.). Be sure adjustment cap does not turn while

tightening the lock nut.

PITMAN SHAFT OVER-CENTER PRELOAD

NOTE: Before performing this procedure, the worm

bearing preload adjustment must be performed.

(1) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns.

(2) Starting at either stop, turn the stub shaft

back 1/2 the total number of turns. This is the center

of the gear travel (Fig. 9) .(3) Place the torque wrench in the vertical position

on the stub shaft. Rotate the wrench 45 degrees each

side of the center and record the highest rotational

torque in this range (Fig. 10) . This is the Over-Cen-

ter Rotating Torque.

NOTE: The stub shaft must rotate smoothly without

sticking or binding.

Fig. 5 Adjuster Lock Nut

1 - ADJUSTER NUT

2 - STEERING GEAR

3 - LOCK NUT

4 - PUNCH

Fig. 6 Alignment Marking On Housing

1 - INDEX

Fig. 7 Second Marking On Housing

1 - REFERENCE MARK

BR/BEGEAR 19 - 17

GEAR (Continued)