mirror DODGE RAM 2001 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2659 of 2889

EXTERIOR

TABLE OF CONTENTS

page page

EXTERIOR

DESCRIPTION...........................86

OPERATION.............................86

BODY SIDE MOLDINGS

REMOVAL..............................87

INSTALLATION...........................87

BODY STRIPES AND DECALS

REMOVAL..............................87

INSTALLATION...........................87

TAPE STRIPE

REMOVAL..............................88

INSTALLATION...........................88

EXTERIOR NAME PLATES

REMOVAL..............................89

INSTALLATION...........................89

COWL GRILLE

REMOVAL..............................90

INSTALLATION...........................90

ROOF JOINT MOLDING

REMOVAL..............................91

INSTALLATION...........................91

GRILLE

REMOVAL..............................91

INSTALLATION...........................91

GRILLE FRAME

REMOVAL..............................91

INSTALLATION...........................92

FRONT END SPLASH SHIELDS

REMOVAL..............................92

INSTALLATION...........................92LEFT FRONT FENDER

REMOVAL..............................92

INSTALLATION...........................93

RIGHT FRONT FENDER

REMOVAL..............................94

INSTALLATION...........................94

FUEL FILL DOOR

REMOVAL..............................95

INSTALLATION...........................95

REAR FENDER

REMOVAL..............................95

INSTALLATION...........................95

REAR SPLASH SHIELD

REMOVAL..............................96

INSTALLATION...........................96

REAR WHEELHOUSE LINER

REMOVAL..............................96

INSTALLATION...........................96

CARGO BOX

REMOVAL..............................96

INSTALLATION...........................97

SIDE VIEW MIRROR

REMOVAL..............................97

INSTALLATION...........................97

SIDE VIEW MIRROR - LOW MOUNTED

REMOVAL..............................98

INSTALLATION...........................98

SIDE VIEW MIRROR GLASS

REMOVAL..............................98

INSTALLATION...........................98

EXTERIOR

DESCRIPTION

Exterior sheet metal components make up the

exterior of the vehicle. Some exterior metal systems

are welded assemblies, such as doors and hoods.

Some exterior trim items are made of composite.

OPERATION

The exterior is finished in various metal stampings

and composite moldings. These assemblies give the

vehicle a finished appearance and protect the occu-

pants from the elements. Some components are partof the energy absorbing system used to protect the

occupants in collisions. The exterior sheet metal is

repairable and adjustable for fit and finish. Welded

and bonded component systems are adjustable as a

system. Trim components made of composite are

stamped with the type of material used. Daimler-

Chrysler uses various fasteners to retain trim items.

At times, it is not possible to remove trim items

without damaging the fastener. If it is not possible to

remove an item without damaging a component, cut

or break the fasteners and use new ones when

installing the component.

23 - 86 EXTERIORBR/BE

Page 2670 of 2889

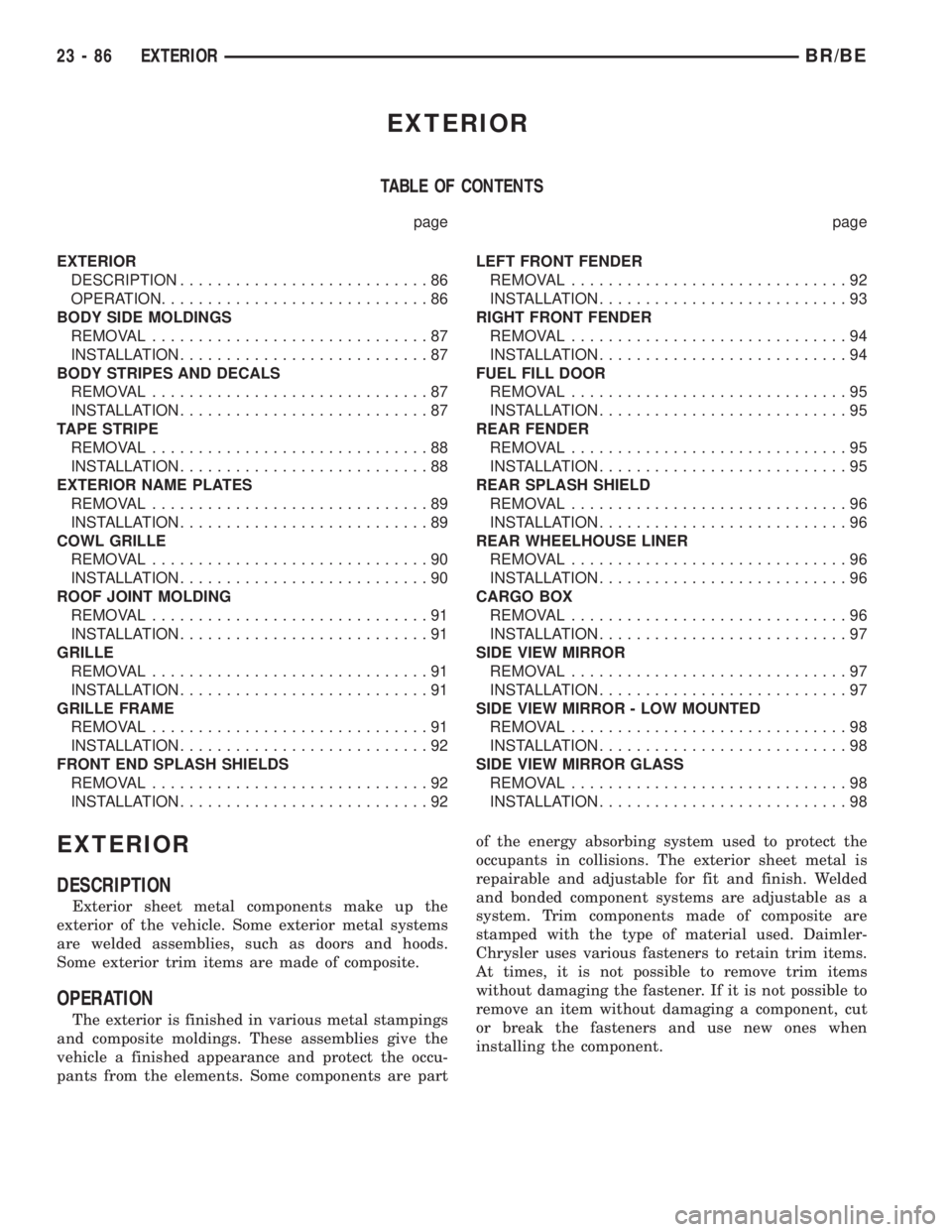

(6) Using a suitable lifting device, separate cargo

box from vehicle.

INSTALLATION

(1) Using a suitable lifting device, position cargo

box on vehicle.

(2) Installnewbolts attaching cargo box to frame

rails. Tighten bolts to 54 N´m (40 ft. lbs.) torque.

(3) Engage tail lamp wire connector to main body

harness at left rear frame rail.

(4) Install fuel fill neck.

SIDE VIEW MIRROR

REMOVAL

(1) Remove door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL).

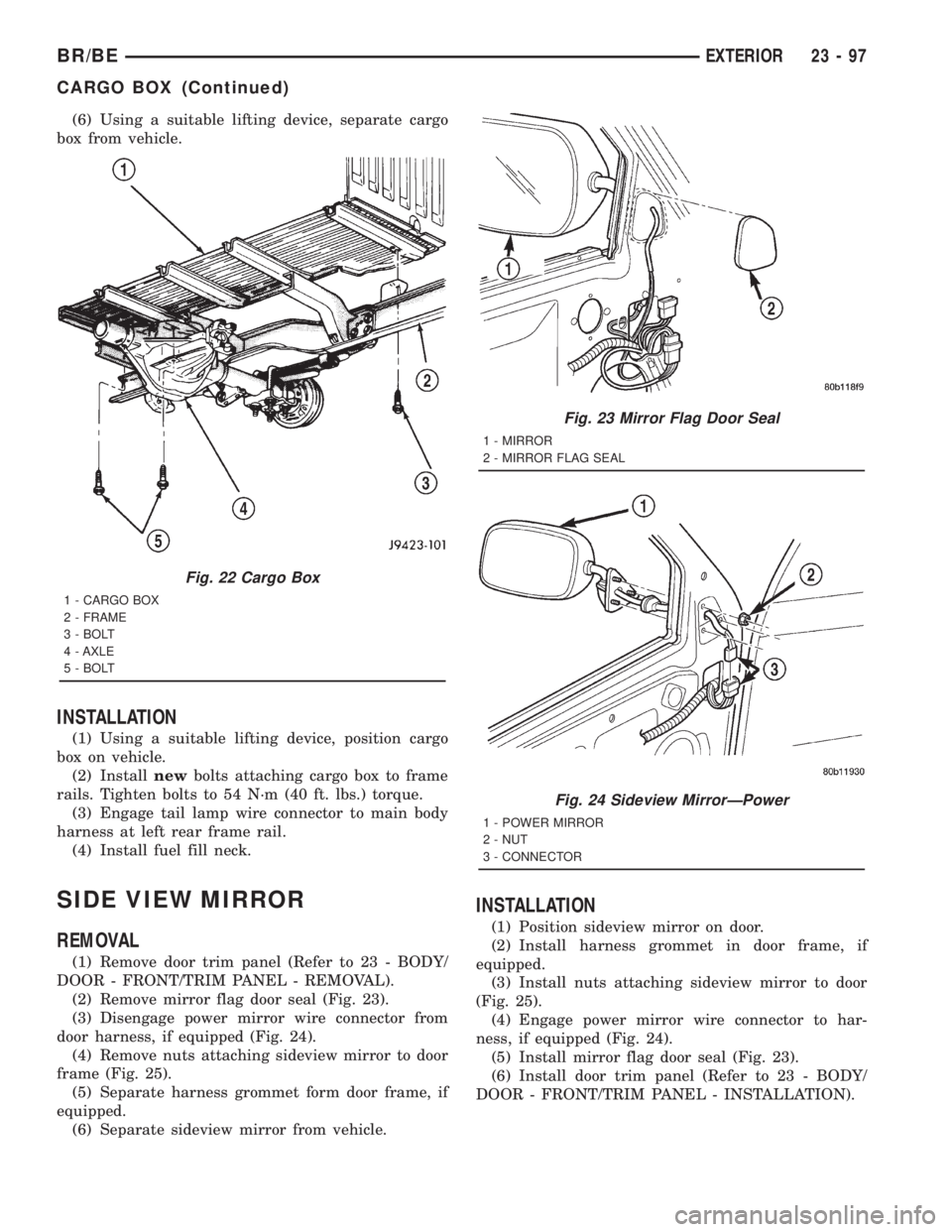

(2) Remove mirror flag door seal (Fig. 23).

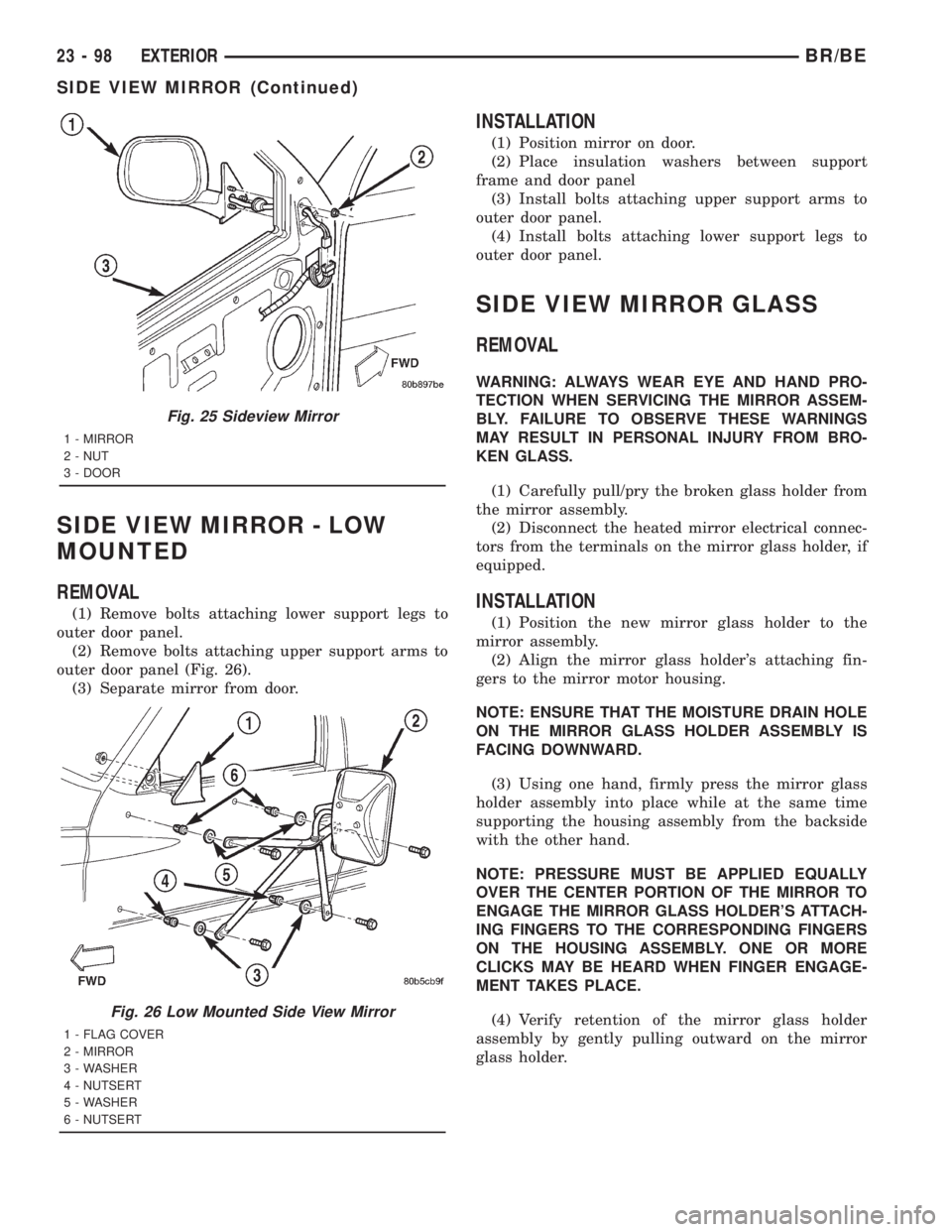

(3) Disengage power mirror wire connector from

door harness, if equipped (Fig. 24).

(4) Remove nuts attaching sideview mirror to door

frame (Fig. 25).

(5) Separate harness grommet form door frame, if

equipped.

(6) Separate sideview mirror from vehicle.

INSTALLATION

(1) Position sideview mirror on door.

(2) Install harness grommet in door frame, if

equipped.

(3) Install nuts attaching sideview mirror to door

(Fig. 25).

(4) Engage power mirror wire connector to har-

ness, if equipped (Fig. 24).

(5) Install mirror flag door seal (Fig. 23).

(6) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

Fig. 22 Cargo Box

1 - CARGO BOX

2 - FRAME

3 - BOLT

4 - AXLE

5 - BOLT

Fig. 23 Mirror Flag Door Seal

1 - MIRROR

2 - MIRROR FLAG SEAL

Fig. 24 Sideview MirrorÐPower

1 - POWER MIRROR

2 - NUT

3 - CONNECTOR

BR/BEEXTERIOR 23 - 97

CARGO BOX (Continued)

Page 2671 of 2889

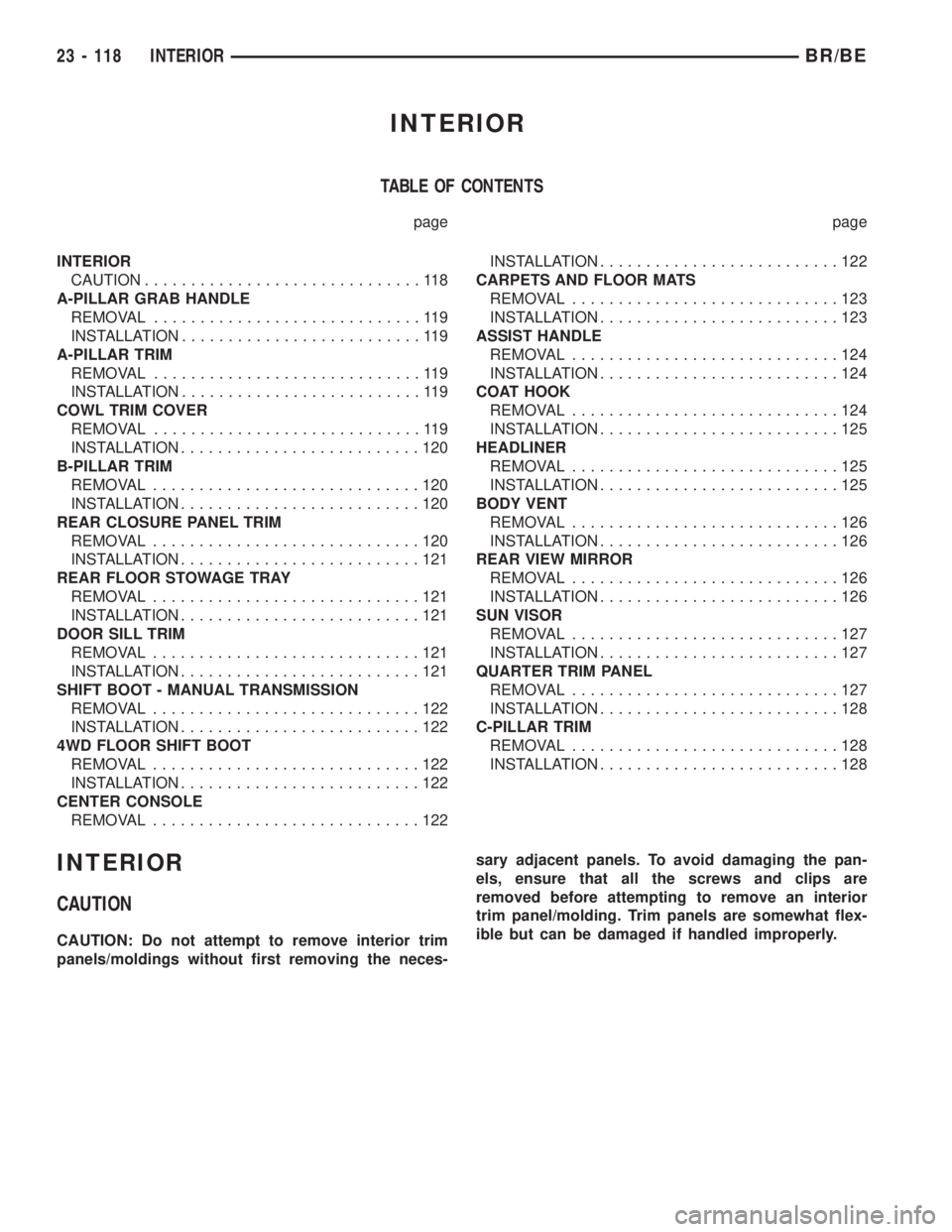

SIDE VIEW MIRROR - LOW

MOUNTED

REMOVAL

(1) Remove bolts attaching lower support legs to

outer door panel.

(2) Remove bolts attaching upper support arms to

outer door panel (Fig. 26).

(3) Separate mirror from door.

INSTALLATION

(1) Position mirror on door.

(2) Place insulation washers between support

frame and door panel

(3) Install bolts attaching upper support arms to

outer door panel.

(4) Install bolts attaching lower support legs to

outer door panel.

SIDE VIEW MIRROR GLASS

REMOVAL

WARNING: ALWAYS WEAR EYE AND HAND PRO-

TECTION WHEN SERVICING THE MIRROR ASSEM-

BLY. FAILURE TO OBSERVE THESE WARNINGS

MAY RESULT IN PERSONAL INJURY FROM BRO-

KEN GLASS.

(1) Carefully pull/pry the broken glass holder from

the mirror assembly.

(2) Disconnect the heated mirror electrical connec-

tors from the terminals on the mirror glass holder, if

equipped.

INSTALLATION

(1) Position the new mirror glass holder to the

mirror assembly.

(2) Align the mirror glass holder's attaching fin-

gers to the mirror motor housing.

NOTE: ENSURE THAT THE MOISTURE DRAIN HOLE

ON THE MIRROR GLASS HOLDER ASSEMBLY IS

FACING DOWNWARD.

(3) Using one hand, firmly press the mirror glass

holder assembly into place while at the same time

supporting the housing assembly from the backside

with the other hand.

NOTE: PRESSURE MUST BE APPLIED EQUALLY

OVER THE CENTER PORTION OF THE MIRROR TO

ENGAGE THE MIRROR GLASS HOLDER'S ATTACH-

ING FINGERS TO THE CORRESPONDING FINGERS

ON THE HOUSING ASSEMBLY. ONE OR MORE

CLICKS MAY BE HEARD WHEN FINGER ENGAGE-

MENT TAKES PLACE.

(4) Verify retention of the mirror glass holder

assembly by gently pulling outward on the mirror

glass holder.

Fig. 25 Sideview Mirror

1 - MIRROR

2 - NUT

3 - DOOR

Fig. 26 Low Mounted Side View Mirror

1 - FLAG COVER

2 - MIRROR

3 - WASHER

4 - NUTSERT

5 - WASHER

6 - NUTSERT

23 - 98 EXTERIORBR/BE

SIDE VIEW MIRROR (Continued)

Page 2691 of 2889

INTERIOR

TABLE OF CONTENTS

page page

INTERIOR

CAUTION..............................118

A-PILLAR GRAB HANDLE

REMOVAL.............................119

INSTALLATION..........................119

A-PILLAR TRIM

REMOVAL.............................119

INSTALLATION..........................119

COWL TRIM COVER

REMOVAL.............................119

INSTALLATION..........................120

B-PILLAR TRIM

REMOVAL.............................120

INSTALLATION..........................120

REAR CLOSURE PANEL TRIM

REMOVAL.............................120

INSTALLATION..........................121

REAR FLOOR STOWAGE TRAY

REMOVAL.............................121

INSTALLATION..........................121

DOOR SILL TRIM

REMOVAL.............................121

INSTALLATION..........................121

SHIFT BOOT - MANUAL TRANSMISSION

REMOVAL.............................122

INSTALLATION..........................122

4WD FLOOR SHIFT BOOT

REMOVAL.............................122

INSTALLATION..........................122

CENTER CONSOLE

REMOVAL.............................122INSTALLATION..........................122

CARPETS AND FLOOR MATS

REMOVAL.............................123

INSTALLATION..........................123

ASSIST HANDLE

REMOVAL.............................124

INSTALLATION..........................124

COAT HOOK

REMOVAL.............................124

INSTALLATION..........................125

HEADLINER

REMOVAL.............................125

INSTALLATION..........................125

BODY VENT

REMOVAL.............................126

INSTALLATION..........................126

REAR VIEW MIRROR

REMOVAL.............................126

INSTALLATION..........................126

SUN VISOR

REMOVAL.............................127

INSTALLATION..........................127

QUARTER TRIM PANEL

REMOVAL.............................127

INSTALLATION..........................128

C-PILLAR TRIM

REMOVAL.............................128

INSTALLATION..........................128

INTERIOR

CAUTION

CAUTION: Do not attempt to remove interior trim

panels/moldings without first removing the neces-sary adjacent panels. To avoid damaging the pan-

els, ensure that all the screws and clips are

removed before attempting to remove an interior

trim panel/molding. Trim panels are somewhat flex-

ible but can be damaged if handled improperly.

23 - 118 INTERIORBR/BE

Page 2699 of 2889

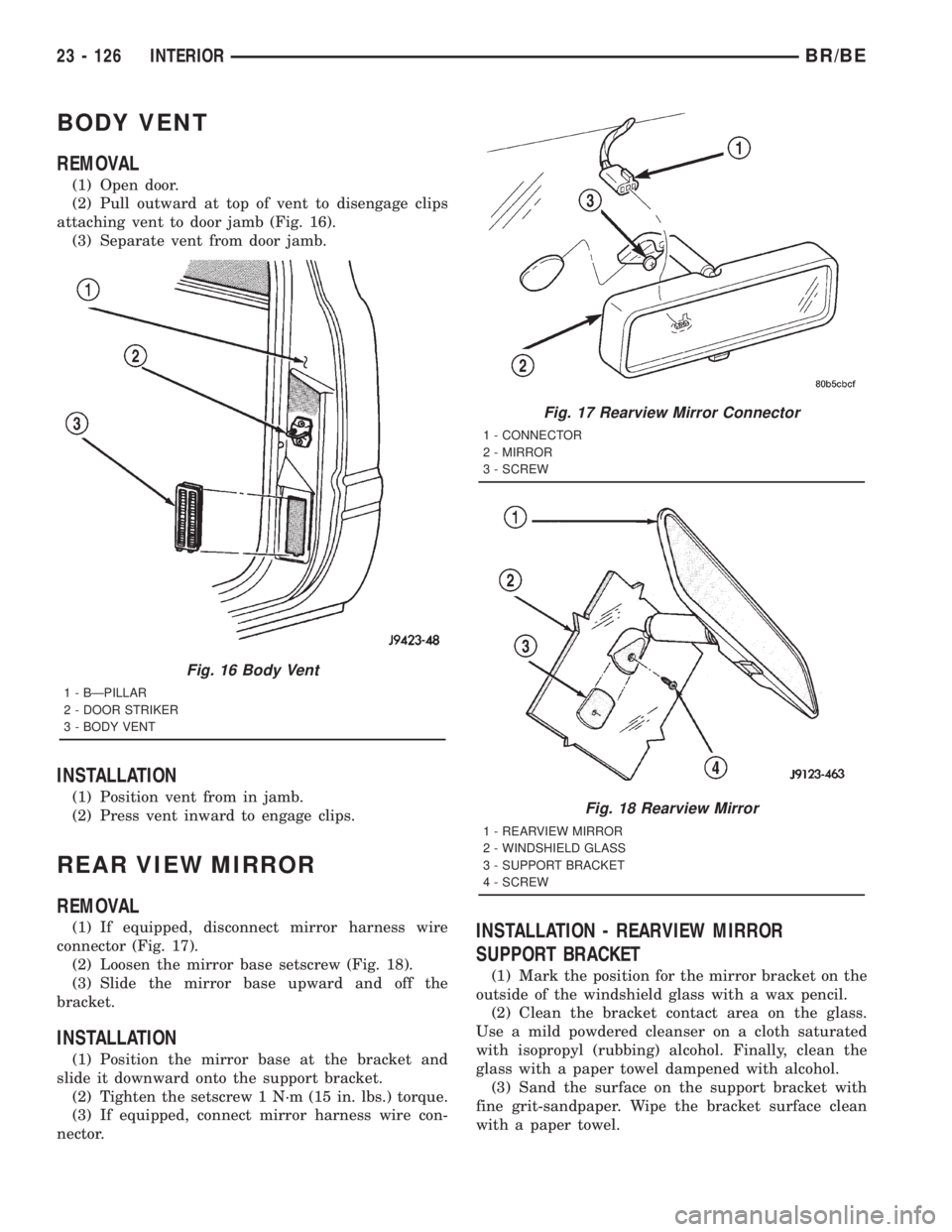

BODY VENT

REMOVAL

(1) Open door.

(2) Pull outward at top of vent to disengage clips

attaching vent to door jamb (Fig. 16).

(3) Separate vent from door jamb.

INSTALLATION

(1) Position vent from in jamb.

(2) Press vent inward to engage clips.

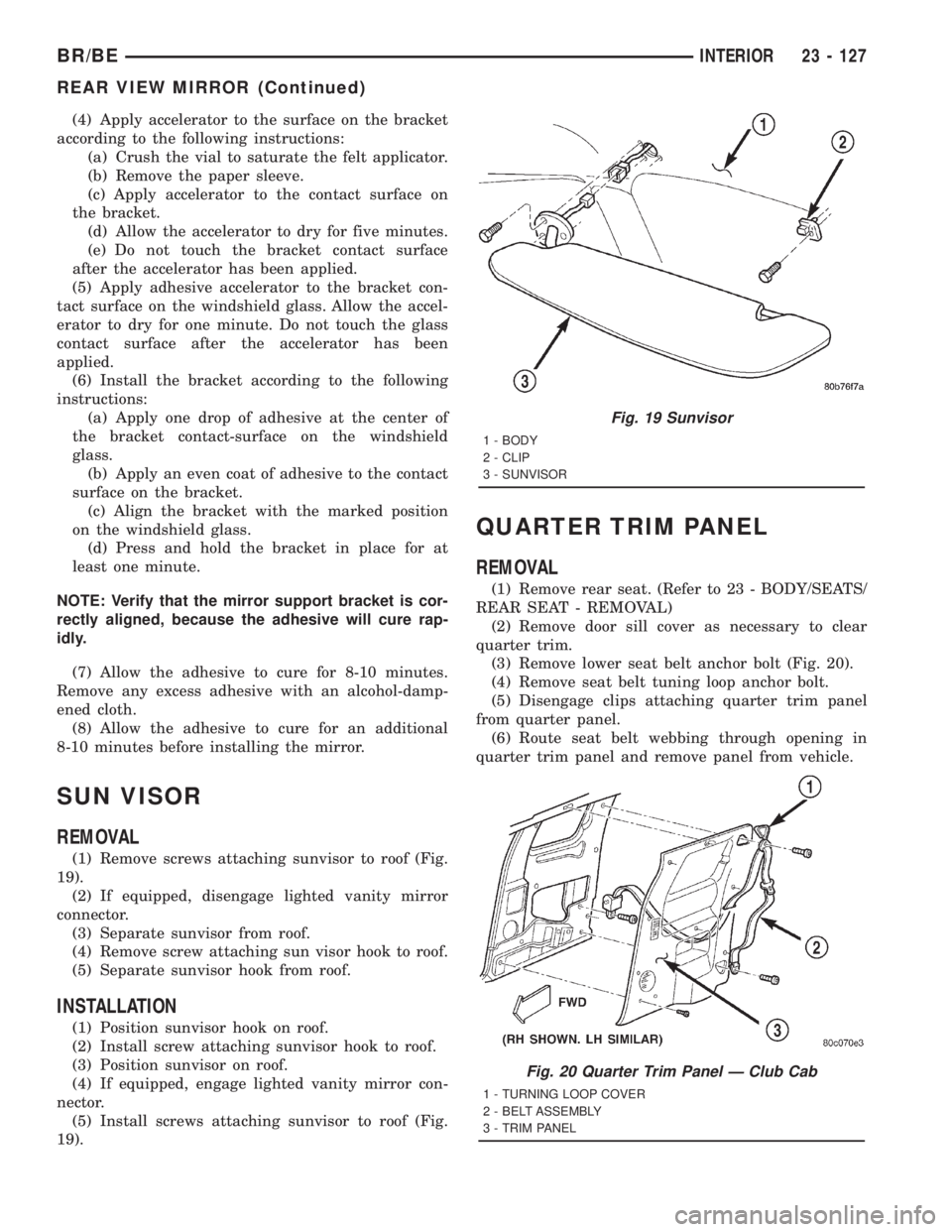

REAR VIEW MIRROR

REMOVAL

(1) If equipped, disconnect mirror harness wire

connector (Fig. 17).

(2) Loosen the mirror base setscrew (Fig. 18).

(3) Slide the mirror base upward and off the

bracket.

INSTALLATION

(1) Position the mirror base at the bracket and

slide it downward onto the support bracket.

(2) Tighten the setscrew 1 N´m (15 in. lbs.) torque.

(3) If equipped, connect mirror harness wire con-

nector.

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET

(1) Mark the position for the mirror bracket on the

outside of the windshield glass with a wax pencil.

(2) Clean the bracket contact area on the glass.

Use a mild powdered cleanser on a cloth saturated

with isopropyl (rubbing) alcohol. Finally, clean the

glass with a paper towel dampened with alcohol.

(3) Sand the surface on the support bracket with

fine grit-sandpaper. Wipe the bracket surface clean

with a paper towel.

Fig. 16 Body Vent

1 - BÐPILLAR

2 - DOOR STRIKER

3 - BODY VENT

Fig. 17 Rearview Mirror Connector

1 - CONNECTOR

2 - MIRROR

3 - SCREW

Fig. 18 Rearview Mirror

1 - REARVIEW MIRROR

2 - WINDSHIELD GLASS

3 - SUPPORT BRACKET

4 - SCREW

23 - 126 INTERIORBR/BE

Page 2700 of 2889

(4) Apply accelerator to the surface on the bracket

according to the following instructions:

(a) Crush the vial to saturate the felt applicator.

(b) Remove the paper sleeve.

(c) Apply accelerator to the contact surface on

the bracket.

(d) Allow the accelerator to dry for five minutes.

(e) Do not touch the bracket contact surface

after the accelerator has been applied.

(5) Apply adhesive accelerator to the bracket con-

tact surface on the windshield glass. Allow the accel-

erator to dry for one minute. Do not touch the glass

contact surface after the accelerator has been

applied.

(6) Install the bracket according to the following

instructions:

(a) Apply one drop of adhesive at the center of

the bracket contact-surface on the windshield

glass.

(b) Apply an even coat of adhesive to the contact

surface on the bracket.

(c) Align the bracket with the marked position

on the windshield glass.

(d) Press and hold the bracket in place for at

least one minute.

NOTE: Verify that the mirror support bracket is cor-

rectly aligned, because the adhesive will cure rap-

idly.

(7) Allow the adhesive to cure for 8-10 minutes.

Remove any excess adhesive with an alcohol-damp-

ened cloth.

(8) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror.

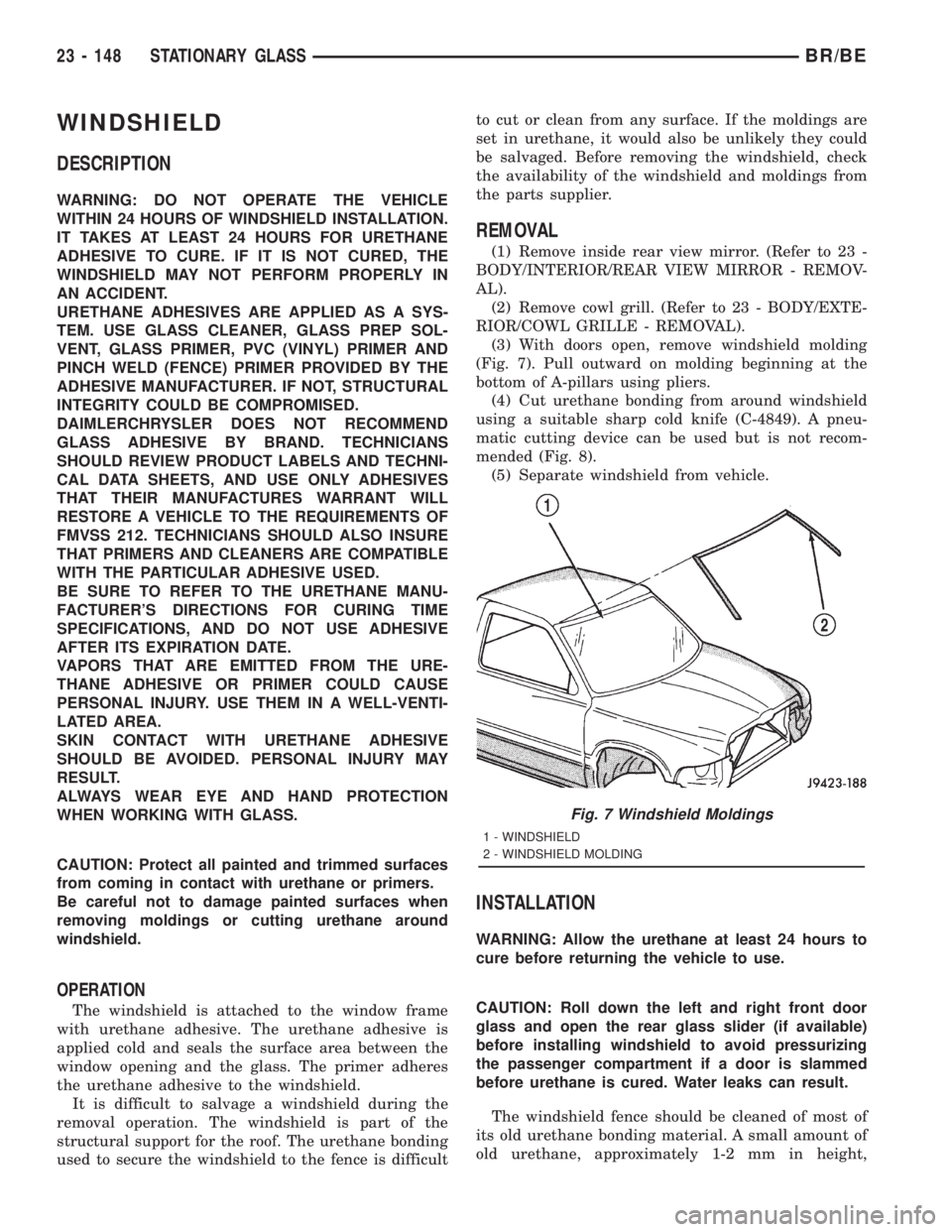

SUN VISOR

REMOVAL

(1) Remove screws attaching sunvisor to roof (Fig.

19).

(2) If equipped, disengage lighted vanity mirror

connector.

(3) Separate sunvisor from roof.

(4) Remove screw attaching sun visor hook to roof.

(5) Separate sunvisor hook from roof.

INSTALLATION

(1) Position sunvisor hook on roof.

(2) Install screw attaching sunvisor hook to roof.

(3) Position sunvisor on roof.

(4) If equipped, engage lighted vanity mirror con-

nector.

(5) Install screws attaching sunvisor to roof (Fig.

19).

QUARTER TRIM PANEL

REMOVAL

(1) Remove rear seat. (Refer to 23 - BODY/SEATS/

REAR SEAT - REMOVAL)

(2) Remove door sill cover as necessary to clear

quarter trim.

(3) Remove lower seat belt anchor bolt (Fig. 20).

(4) Remove seat belt tuning loop anchor bolt.

(5) Disengage clips attaching quarter trim panel

from quarter panel.

(6) Route seat belt webbing through opening in

quarter trim panel and remove panel from vehicle.

Fig. 19 Sunvisor

1 - BODY

2 - CLIP

3 - SUNVISOR

Fig. 20 Quarter Trim Panel Ð Club Cab

1 - TURNING LOOP COVER

2 - BELT ASSEMBLY

3 - TRIM PANEL

BR/BEINTERIOR 23 - 127

REAR VIEW MIRROR (Continued)

Page 2721 of 2889

WINDSHIELD

DESCRIPTION

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, PVC (VINYL) PRIMER AND

PINCH WELD (FENCE) PRIMER PROVIDED BY THE

ADHESIVE MANUFACTURER. IF NOT, STRUCTURAL

INTEGRITY COULD BE COMPROMISED.

DAIMLERCHRYSLER DOES NOT RECOMMEND

GLASS ADHESIVE BY BRAND. TECHNICIANS

SHOULD REVIEW PRODUCT LABELS AND TECHNI-

CAL DATA SHEETS, AND USE ONLY ADHESIVES

THAT THEIR MANUFACTURES WARRANT WILL

RESTORE A VEHICLE TO THE REQUIREMENTS OF

FMVSS 212. TECHNICIANS SHOULD ALSO INSURE

THAT PRIMERS AND CLEANERS ARE COMPATIBLE

WITH THE PARTICULAR ADHESIVE USED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

OPERATION

The windshield is attached to the window frame

with urethane adhesive. The urethane adhesive is

applied cold and seals the surface area between the

window opening and the glass. The primer adheres

the urethane adhesive to the windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the

structural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficultto cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

REMOVAL

(1) Remove inside rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR - REMOV-

AL).

(2) Remove cowl grill. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - REMOVAL).

(3) With doors open, remove windshield molding

(Fig. 7). Pull outward on molding beginning at the

bottom of A-pillars using pliers.

(4) Cut urethane bonding from around windshield

using a suitable sharp cold knife (C-4849). A pneu-

matic cutting device can be used but is not recom-

mended (Fig. 8).

(5) Separate windshield from vehicle.

INSTALLATION

WARNING: Allow the urethane at least 24 hours to

cure before returning the vehicle to use.

CAUTION: Roll down the left and right front door

glass and open the rear glass slider (if available)

before installing windshield to avoid pressurizing

the passenger compartment if a door is slammed

before urethane is cured. Water leaks can result.

The windshield fence should be cleaned of most of

its old urethane bonding material. A small amount of

old urethane, approximately 1-2 mm in height,

Fig. 7 Windshield Moldings

1 - WINDSHIELD

2 - WINDSHIELD MOLDING

23 - 148 STATIONARY GLASSBR/BE

Page 2723 of 2889

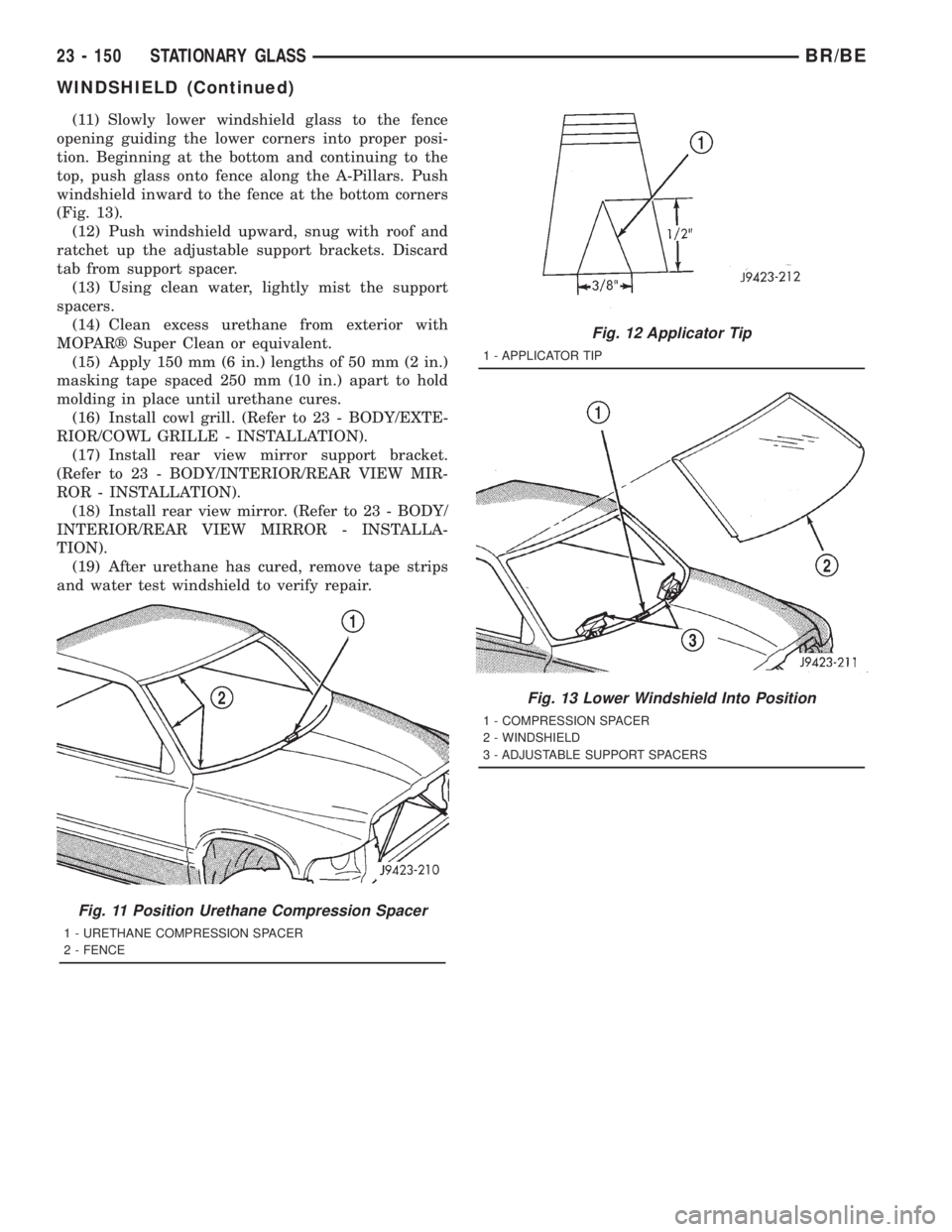

(11) Slowly lower windshield glass to the fence

opening guiding the lower corners into proper posi-

tion. Beginning at the bottom and continuing to the

top, push glass onto fence along the A-Pillars. Push

windshield inward to the fence at the bottom corners

(Fig. 13).

(12) Push windshield upward, snug with roof and

ratchet up the adjustable support brackets. Discard

tab from support spacer.

(13) Using clean water, lightly mist the support

spacers.

(14) Clean excess urethane from exterior with

MOPARž Super Clean or equivalent.

(15) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(16) Install cowl grill. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - INSTALLATION).

(17) Install rear view mirror support bracket.

(Refer to 23 - BODY/INTERIOR/REAR VIEW MIR-

ROR - INSTALLATION).

(18) Install rear view mirror. (Refer to 23 - BODY/

INTERIOR/REAR VIEW MIRROR - INSTALLA-

TION).

(19) After urethane has cured, remove tape strips

and water test windshield to verify repair.

Fig. 11 Position Urethane Compression Spacer

1 - URETHANE COMPRESSION SPACER

2 - FENCE

Fig. 12 Applicator Tip

1 - APPLICATOR TIP

Fig. 13 Lower Windshield Into Position

1 - COMPRESSION SPACER

2 - WINDSHIELD

3 - ADJUSTABLE SUPPORT SPACERS

23 - 150 STATIONARY GLASSBR/BE

WINDSHIELD (Continued)

Page 2727 of 2889

INSTALLATION

(1) Press door glass run weatherstrip into channel

around window opening (Fig. 4).

(2) Install inner door belt weatherstrip. (Refer to

23 - BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - INSTALLATION)

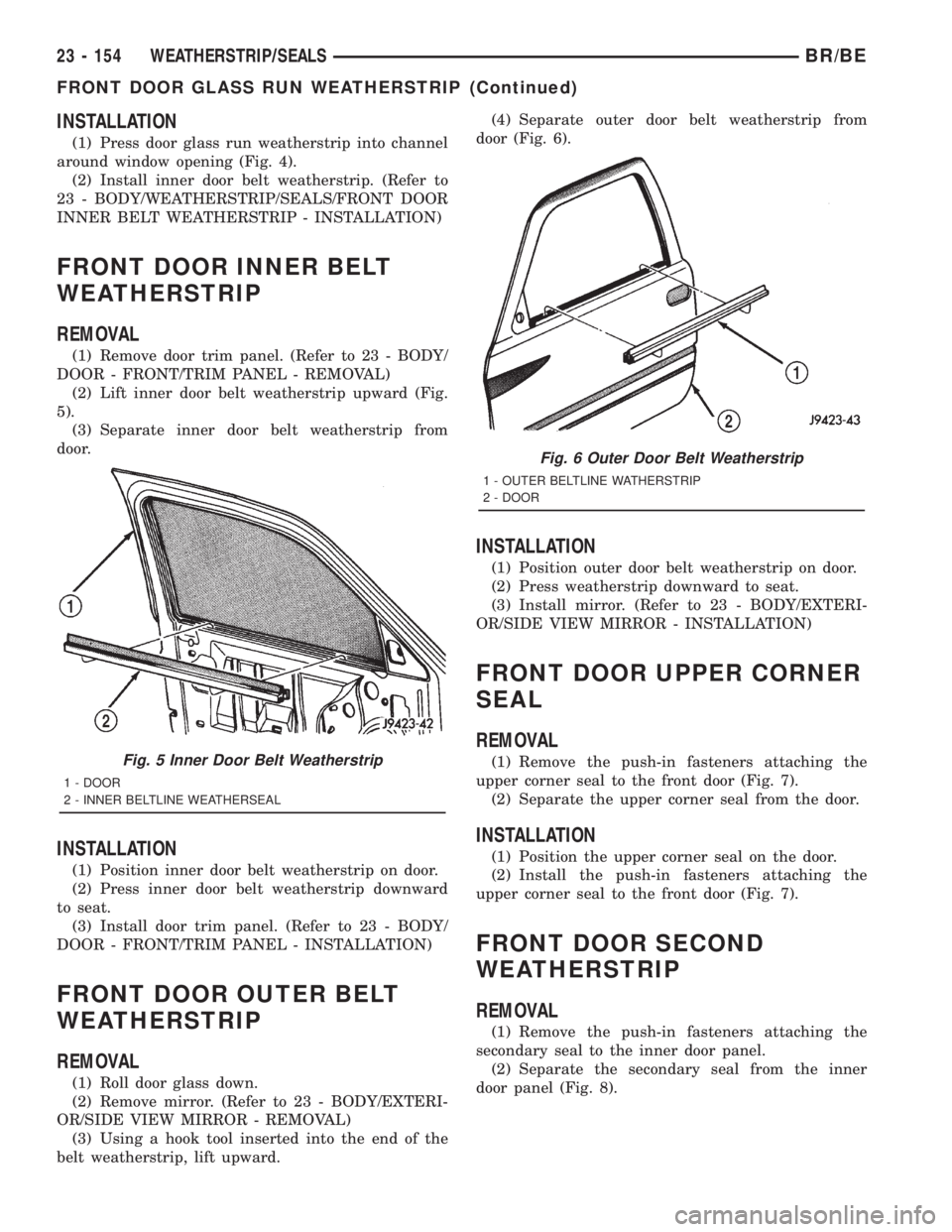

FRONT DOOR INNER BELT

WEATHERSTRIP

REMOVAL

(1) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Lift inner door belt weatherstrip upward (Fig.

5).

(3) Separate inner door belt weatherstrip from

door.

INSTALLATION

(1) Position inner door belt weatherstrip on door.

(2) Press inner door belt weatherstrip downward

to seat.

(3) Install door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

FRONT DOOR OUTER BELT

WEATHERSTRIP

REMOVAL

(1) Roll door glass down.

(2) Remove mirror. (Refer to 23 - BODY/EXTERI-

OR/SIDE VIEW MIRROR - REMOVAL)

(3) Using a hook tool inserted into the end of the

belt weatherstrip, lift upward.(4) Separate outer door belt weatherstrip from

door (Fig. 6).

INSTALLATION

(1) Position outer door belt weatherstrip on door.

(2) Press weatherstrip downward to seat.

(3) Install mirror. (Refer to 23 - BODY/EXTERI-

OR/SIDE VIEW MIRROR - INSTALLATION)

FRONT DOOR UPPER CORNER

SEAL

REMOVAL

(1) Remove the push-in fasteners attaching the

upper corner seal to the front door (Fig. 7).

(2) Separate the upper corner seal from the door.

INSTALLATION

(1) Position the upper corner seal on the door.

(2) Install the push-in fasteners attaching the

upper corner seal to the front door (Fig. 7).

FRONT DOOR SECOND

WEATHERSTRIP

REMOVAL

(1) Remove the push-in fasteners attaching the

secondary seal to the inner door panel.

(2) Separate the secondary seal from the inner

door panel (Fig. 8).

Fig. 5 Inner Door Belt Weatherstrip

1 - DOOR

2 - INNER BELTLINE WEATHERSEAL

Fig. 6 Outer Door Belt Weatherstrip

1 - OUTER BELTLINE WATHERSTRIP

2 - DOOR

23 - 154 WEATHERSTRIP/SEALSBR/BE

FRONT DOOR GLASS RUN WEATHERSTRIP (Continued)

Page 2747 of 2889

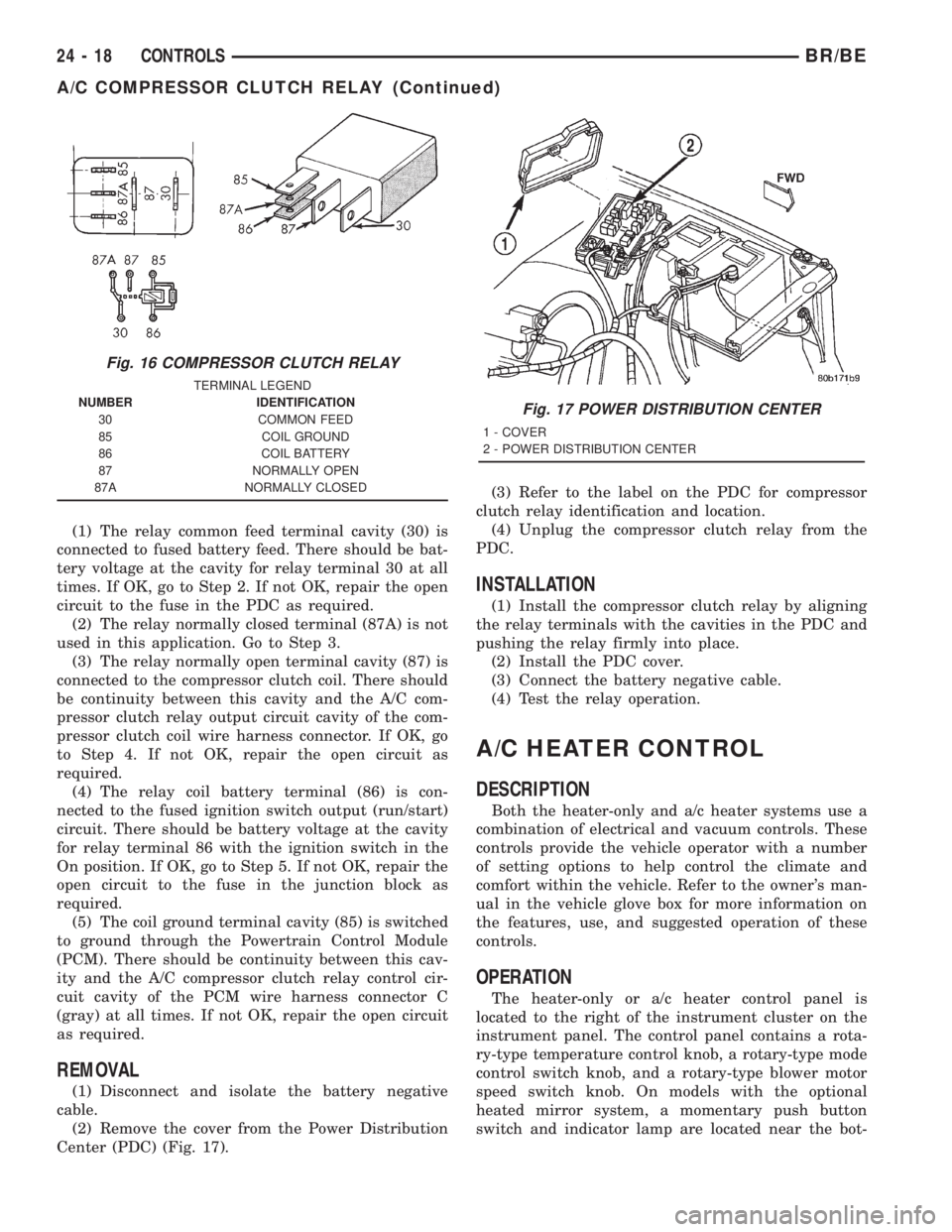

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)

circuit. There should be battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 17).(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

Both the heater-only and a/c heater systems use a

combination of electrical and vacuum controls. These

controls provide the vehicle operator with a number

of setting options to help control the climate and

comfort within the vehicle. Refer to the owner's man-

ual in the vehicle glove box for more information on

the features, use, and suggested operation of these

controls.

OPERATION

The heater-only or a/c heater control panel is

located to the right of the instrument cluster on the

instrument panel. The control panel contains a rota-

ry-type temperature control knob, a rotary-type mode

control switch knob, and a rotary-type blower motor

speed switch knob. On models with the optional

heated mirror system, a momentary push button

switch and indicator lamp are located near the bot-

Fig. 16 COMPRESSOR CLUTCH RELAY

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 17 POWER DISTRIBUTION CENTER

1 - COVER

2 - POWER DISTRIBUTION CENTER

24 - 18 CONTROLSBR/BE

A/C COMPRESSOR CLUTCH RELAY (Continued)