mirror DODGE RAM 2001 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2748 of 2889

tom of the a/c heater control panel. Refer to Heated

Mirrors for more information on this feature.

The heater-only or a/c heater control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The control knobs and the illumi-

nation lamps are available for service replacement.

DIAGNOSIS AND TESTING - A/C HEATER

CONTROL

Satisfactory heater and air conditioner perfor-

mance depends upon proper operation and adjust-

ment of all operating controls and refrigeration

system components. For circuit descriptions and dia-

grams, (Refer to Appropriate Wiring Information).

These inspections, tests, and adjustments should be

used to locate the cause of a malfunction.

Operation must be tested as described in the fol-

lowing sequence:

(1) Inspect and adjust the serpentine drive belt.

Refer to Cooling for the procedures.

(2) Start the engine and hold the idle speed at

1,300 rpm.

(3) On vehicles with air conditioning, turn the

temperature control knob to the extreme counter-

clockwise (Cool) position, and set the mode control

switch knob to the Bi-Level (A/C) position. The out-

side (recirculation) air door should be open to outside

air. If not OK, (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS - DIAGNOSIS AND TEST-

ING - VACUUM SYSTEM).

(4) Open the vehicle windows. Test the blower

motor operation in all speeds. If not OK, (Refer to 24

- HEATING & AIR CONDITIONING/DISTRIBU-

TION/BLOWER MOTOR - DIAGNOSIS AND TEST-

ING).

(5) On vehicles with air conditioning, the compres-

sor should be running and the air conditioning sys-

tem in operation unless the ambient air temperature

is below about -1É C (30É F). If not OK, (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE).

(6) Check the mode control switch operation. The

heater and air conditioner systems should respond as

described in the owner's manual in the vehicle glove

box to each mode selected. Reduce the engine speed

to normal idle. The vacuum will be high at low idle

and the vacuum actuators should respond quickly. If

not OK, (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - DIAGNOSIS AND TEST-

ING - VACUUM SYSTEM).

(7) If the vacuum tests, and the electrical compo-

nent and circuit tests reveal no problems, disassem-

ble the HVAC housing to inspect for mechanical

misalignment or binding of the mode doors. (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION/HVAC HOUSING - DISASSEMBLY)

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the instrument panel near the

driver side of the floor panel transmission tunnel and

unplug the a/c heater control to HVAC housing vac-

uum harness connector.

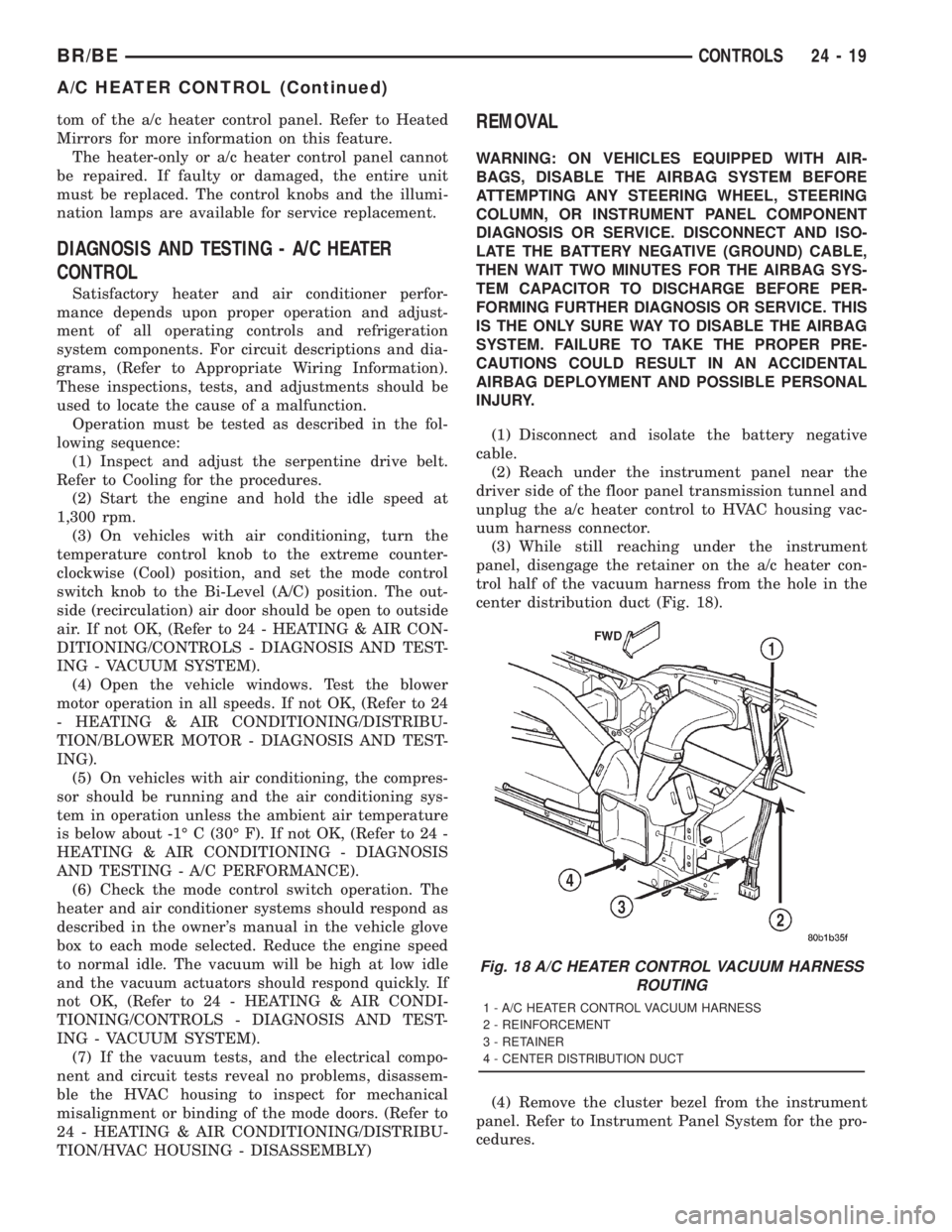

(3) While still reaching under the instrument

panel, disengage the retainer on the a/c heater con-

trol half of the vacuum harness from the hole in the

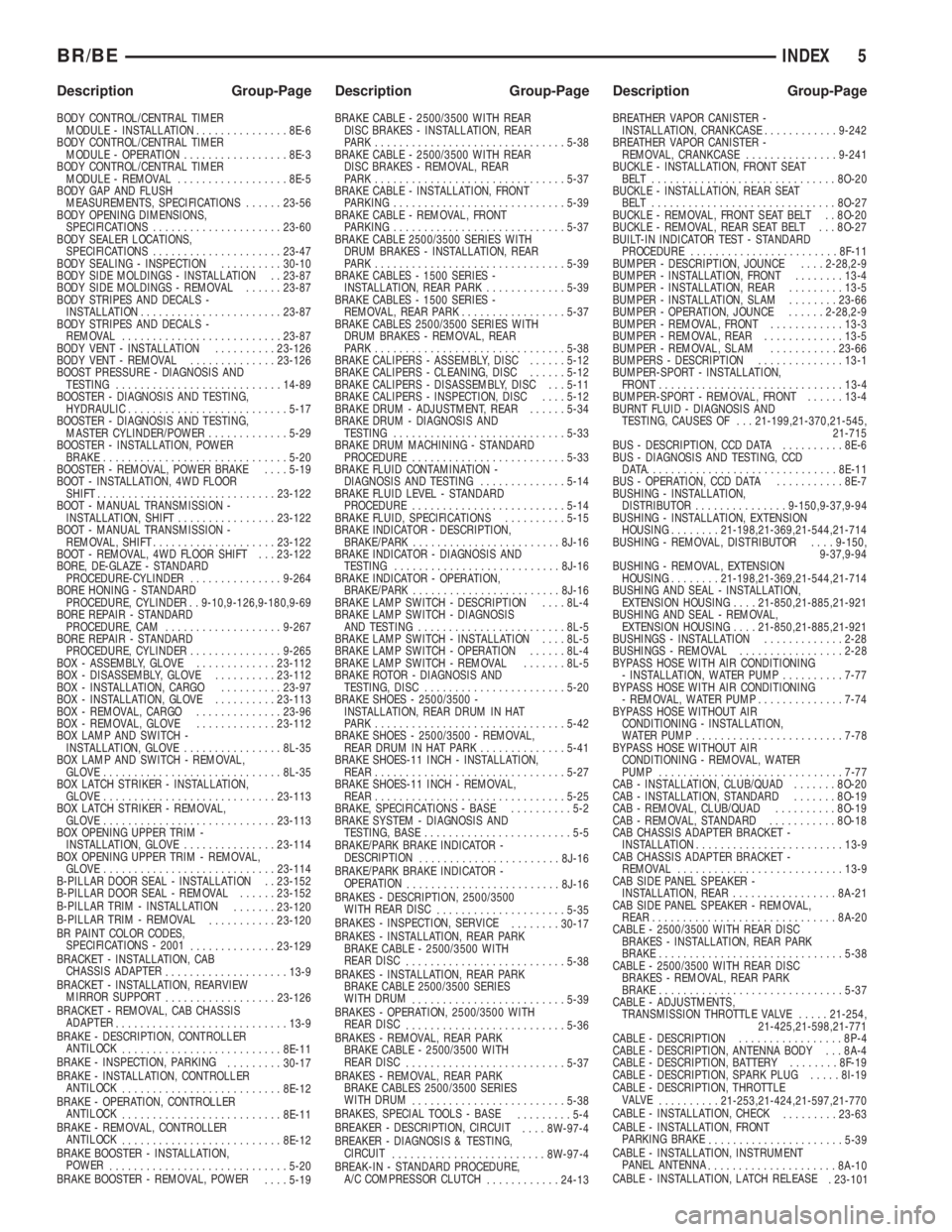

center distribution duct (Fig. 18).

(4) Remove the cluster bezel from the instrument

panel. Refer to Instrument Panel System for the pro-

cedures.

Fig. 18 A/C HEATER CONTROL VACUUM HARNESS

ROUTING

1 - A/C HEATER CONTROL VACUUM HARNESS

2 - REINFORCEMENT

3 - RETAINER

4 - CENTER DISTRIBUTION DUCT

BR/BECONTROLS 24 - 19

A/C HEATER CONTROL (Continued)

Page 2749 of 2889

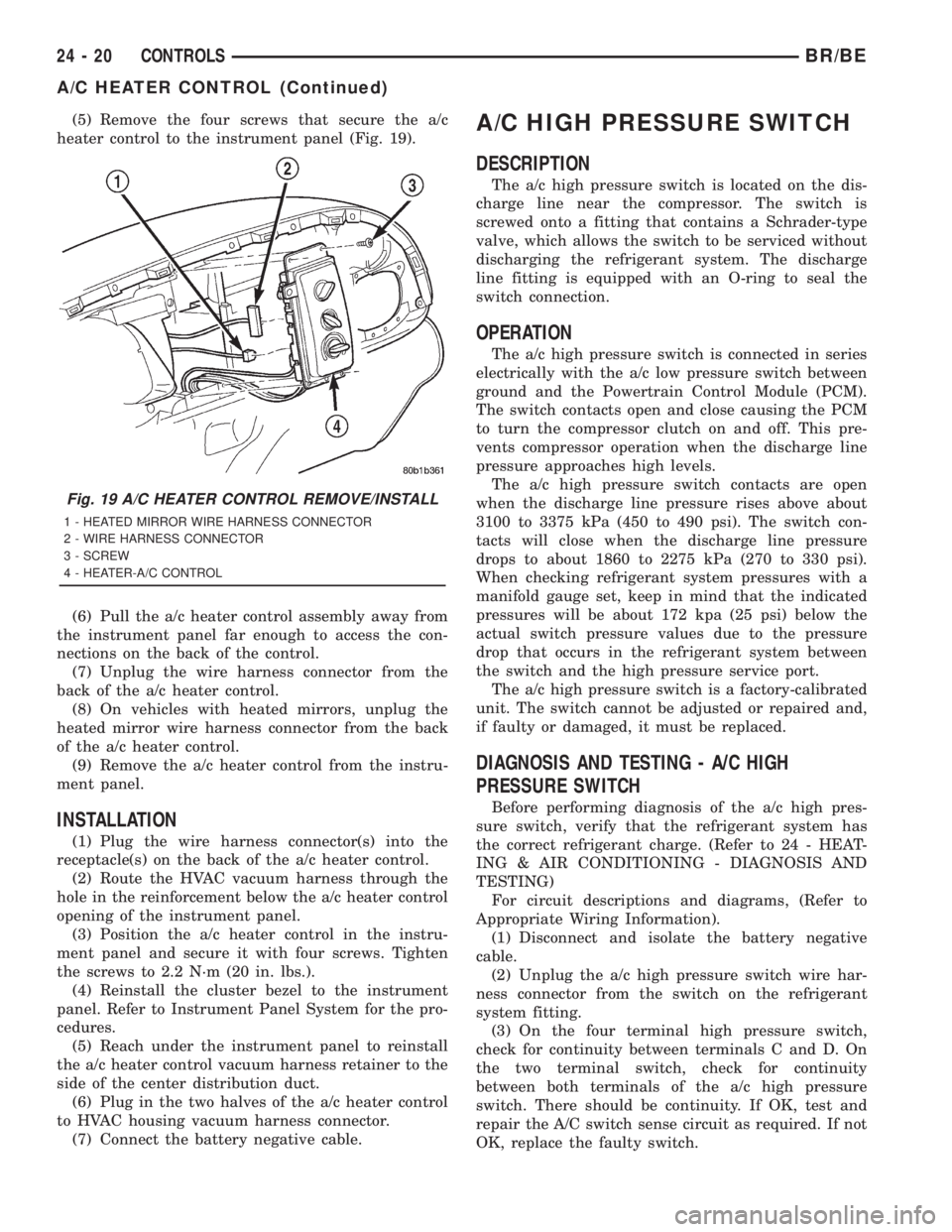

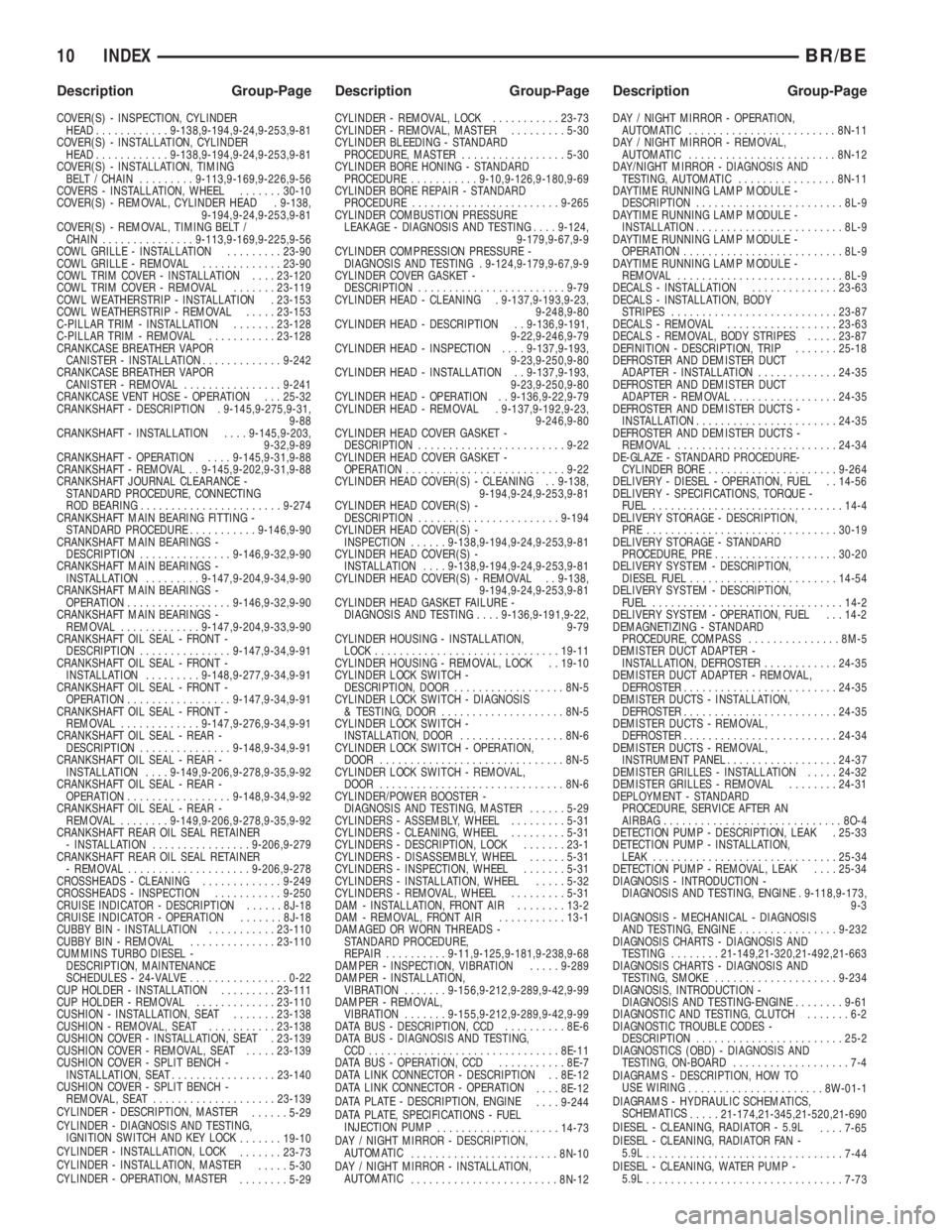

(5) Remove the four screws that secure the a/c

heater control to the instrument panel (Fig. 19).

(6) Pull the a/c heater control assembly away from

the instrument panel far enough to access the con-

nections on the back of the control.

(7) Unplug the wire harness connector from the

back of the a/c heater control.

(8) On vehicles with heated mirrors, unplug the

heated mirror wire harness connector from the back

of the a/c heater control.

(9) Remove the a/c heater control from the instru-

ment panel.

INSTALLATION

(1) Plug the wire harness connector(s) into the

receptacle(s) on the back of the a/c heater control.

(2) Route the HVAC vacuum harness through the

hole in the reinforcement below the a/c heater control

opening of the instrument panel.

(3) Position the a/c heater control in the instru-

ment panel and secure it with four screws. Tighten

the screws to 2.2 N´m (20 in. lbs.).

(4) Reinstall the cluster bezel to the instrument

panel. Refer to Instrument Panel System for the pro-

cedures.

(5) Reach under the instrument panel to reinstall

the a/c heater control vacuum harness retainer to the

side of the center distribution duct.

(6) Plug in the two halves of the a/c heater control

to HVAC housing vacuum harness connector.

(7) Connect the battery negative cable.

A/C HIGH PRESSURE SWITCH

DESCRIPTION

The a/c high pressure switch is located on the dis-

charge line near the compressor. The switch is

screwed onto a fitting that contains a Schrader-type

valve, which allows the switch to be serviced without

discharging the refrigerant system. The discharge

line fitting is equipped with an O-ring to seal the

switch connection.

OPERATION

The a/c high pressure switch is connected in series

electrically with the a/c low pressure switch between

ground and the Powertrain Control Module (PCM).

The switch contacts open and close causing the PCM

to turn the compressor clutch on and off. This pre-

vents compressor operation when the discharge line

pressure approaches high levels.

The a/c high pressure switch contacts are open

when the discharge line pressure rises above about

3100 to 3375 kPa (450 to 490 psi). The switch con-

tacts will close when the discharge line pressure

drops to about 1860 to 2275 kPa (270 to 330 psi).

When checking refrigerant system pressures with a

manifold gauge set, keep in mind that the indicated

pressures will be about 172 kpa (25 psi) below the

actual switch pressure values due to the pressure

drop that occurs in the refrigerant system between

the switch and the high pressure service port.

The a/c high pressure switch is a factory-calibrated

unit. The switch cannot be adjusted or repaired and,

if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - A/C HIGH

PRESSURE SWITCH

Before performing diagnosis of the a/c high pres-

sure switch, verify that the refrigerant system has

the correct refrigerant charge. (Refer to 24 - HEAT-

ING & AIR CONDITIONING - DIAGNOSIS AND

TESTING)

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the a/c high pressure switch wire har-

ness connector from the switch on the refrigerant

system fitting.

(3) On the four terminal high pressure switch,

check for continuity between terminals C and D. On

the two terminal switch, check for continuity

between both terminals of the a/c high pressure

switch. There should be continuity. If OK, test and

repair the A/C switch sense circuit as required. If not

OK, replace the faulty switch.

Fig. 19 A/C HEATER CONTROL REMOVE/INSTALL

1 - HEATED MIRROR WIRE HARNESS CONNECTOR

2 - WIRE HARNESS CONNECTOR

3 - SCREW

4 - HEATER-A/C CONTROL

24 - 20 CONTROLSBR/BE

A/C HEATER CONTROL (Continued)

Page 2828 of 2889

Items found requiring adjustment and/or repair

should be corrected before delivery of the vehicle.

NOTE: It is the dealer's responsibility to protect

new vehicles from damage and deterioration prior

to retail delivery both before and after new vehicle

preparation.

The information includes the following features:

Inspection points are cross-referenced to the New

Vehicle Preparation Form as follows:

²Titles indicate the general area being inspected

or the types of checks being made (i.e., underhood,

body-exterior, road test, etc.).

²Sub-Titles identify the types of items to be

inspected in that area (i.e., lines/hoses, wiring, etc.).

Procedures follow a logical order to prevent dupli-

cation and wasted effort.

Tips to help you do a better job are found as

NOTES.

RECEIVING

INSPECTION

The following procedures are recommended for

your own protection upon receipt of new vehicles.

When a new car is delivered by the carrier, it should

be inspected to ensure that it is in good condition

and to determine if there is any shortage or transpor-

tation damage.

EXTERIOR

Upon receipt of a new vehicle, check immediately

for:

²Under carriage damage

²Chipped or cracked windshield, broken windows,

and loose or missing moldings and name-plates

²Dents, scrapes, scratches, chips, dirt in paints or

other damage to the body exterior

²Damaged or missing side view mirror(s)

²Missing wheel nuts

²Broken or missing lenses

²Chafing, bruises, cuts, or scrapes on tire side-

walls or tread

²Missing underhood items

²Missing fuel filler cap

²Shipped loose items-license plate bracket, spare

tire, jack and tire wrench, radio antenna, floor mats,

wheel covers, cargo nets, fuses and other items²Ensure that IOD fuse is removed

²Check battery test indicator when easily visible,

or use voltmeter (battery must be at 12.4 volts or

greater). Charge to ensure green dot-visibility, per-

manent damage may occur if battery remains in a

discharged state for any length of time.

INTERIOR

Check interior items such as:

²Rearview mirror

²Accessory control knobs

²Smokers package items

²Keys

²Radio

²Special equipment items listed on shipper

²Owner's Manual and Consumer information Bro-

chures (normally stored in the glove box).

²Cuts, abrasions or stains on interior trim.

NOTE: Remember a careful look at new vehicles

when they are received may prevent problems when

preparing vehicles for delivery to your customers.

MAJOR INSPECTION POINTS

(1) Check operation of hood latch and safety catch-

adjust as required.

(2) Check all fluids for proper level and top off

with the proper fluid as required-engine oil, auto-

matic transmission fluid, brake master cylinder,

clutch master cylinder, power steering, windshield

washer, and cooling system. (Vehicle must be at nor-

mal operating temperature for some of these checks.)

(3) Check brake, clutch, fuel, and power steering

lines and hoses for leaks and clearance from moving

and hot objects-reroute to the proper location and

tighten as required.

(4) Check battery state of charge-recharge if neces-

sary, to ensure green dot is visible or instrument

panel voltmeter indicates 12.4 volts or greater.

(5) Check routing and connections of underhood

wiring, vacuum hoses, refrigerant lines and coolant

hoses for leaks, loose connections and clearance from

moving objects reroute and tighten connections as

required. Install IOD fuse on applicable vehicles.

NOTE: Reset radio, clock, compass, etc., after

installing, if vehicle is being delivered.

BR/BENEW VEHICLE PREPARATION 30 - 3

INTRODUCTION (Continued)

Page 2837 of 2889

BODY INTERIOR

INSPECTION - COMPASS

NOTE: Set variance after calibration.

(1) Calibrate and set compass variance (Fig. 26), if

so equipped (use appropriate procedures in service

information).

(2) Remove protective film from overhead console,

if equipped.

INSPECTION - FIT AND FINISH

(1) Remove any interior covers.

(2) Inspect the instrument panel, glove box door

(Fig. 27) and interior moldings for even gaps and

alignments.

(3) Check that the door panel material is clean,

free from wrinkles and installed correctly.

(4) Check that the seat material is clean, secure

and free of wrinkles.

(5) Check that the carpet is clean, secure and free

of wrinkles.

(6) Check that the headliner is clean, free of lint

and dirt smudges.

INSPECTION - LIGHTS AND SWITCHES

(1) Remove protective film from all switch bezels.

(2) Operate and visually inspect all interior lights

and switches, including:

²Dome/map lamps

²Vanity mirror lamps

²Glove box light²Ashtray light

²Cigar lighter light

²All gauge lights

²Radio display

²Door-mounted lights, if equipped

²Illuminated entry system, if equipped

(3) Visually inspect and operate all exterior lights

and their switches, including:

NOTE: Headlamp aim is preset during vehicle

assembly.

²Headlights, including high beam, optical horn

(ªflash to passº) and daylight running lamps (DRL's)

(Fig. 28)

²Tail/stop lamps (including center high-mounted

stop lamp)

²Parking lights Turn signals Brake lights (includ-

ing center high mounted stop lamp)

²Emergency flashers (Fig. 29)

²Fog/driving lights, if equipped

²Off-road or other lights, if equipped

²Cargo bed lights, if equipped

(4) Check ignition switch for proper operation in

all positions (accessory, lock, on, start and off).

INSPECTION - SEAT BELTS, SHOULDER

BELTS, RETRACTORS AND HEAD RESTRAINTS

(1) Inspect all seat belts and harnesses to ensure

that they connect and hold properly.

(2) Inspect the condition of the belts and anchors.

(3) Inspect for proper seat belt retraction.

Fig. 26 COMPASS OPERATION

Fig. 27 GLOVE BOX DOOR

30 - 12 NEW VEHICLE PREPARATIONBR/BE

Page 2840 of 2889

ROAD TEST

DESCRIPTION - ROAD TEST INSPECTION

The following items must be inspected during the

road test portion of the new vehicle inspection.

²Check neutral safety switch operation

²Check operation of shift/clutch interlock system

²Check operation of gauges and warning lights

²Check horn operation

²Check operation of turn signals and emergency

flashers

²Check all mirror adjustments, including day/

night function

²Check windshield wipers for proper wipe pattern

and intermittent mode (if equipped)

²Check washer spray pattern

²Check heater, defroster and air conditioning for

proper operation

²Check that the fan operates quietly

²Check the rear window defroster (if equipped)

²Leave air selection lever in the fresh air position

²Check the rear heater and air conditioning for

proper operation

²Check the rear air register locations

²Check that the indicator lamps operate properly

²Check the operation of the radio, cassette and/or

compact disc player, and that sound quality is good

²Ensure that the clock displays the correct time

²Check that the trip computer/maintenance

reminder operates in all modes

²Check all speed control functions

²Check the service brakes to ensure that they

stop the vehicle in a straight line, without noise,

shudder or vibration

²Check the brake warning light

²Check the parking brake operation

²Check the engine's performance

²Check the transmission's performance for

smooth, quiet operation. If the vehicle is a 4x4, check

that the transfer case shifts easily among all ranges

²Check Autostick function (if equipped)

²Check the vehicle's steering and handling

²The steering wheel should be centered when

traveling in a straight line

²The vehicle should not pull or vibrate

²Check for squeaks, rattles and wind noise

²Check any other vehicle aspects you believe are

important, but that may not be included on the New

Vehicle Preparation Form

²Fill fuel tank with specified grade of fuel

INSPECTION - FUEL

Fill fuel tank with specified grade of gasoline (reg-

ular, midgrade or premium).

INSPECTION - OTHER

As part of DaimlerChrysler's Customer One philos-

ophy, the ªOtherº blank is provided on the New Vehi-

cle Preparation Form. This is designed to encourage

you to check any aspects of vehicle operation that

you believe are important to your customers, but that

do not appear elsewhere on the form.

INSPECTION - SQUEAKS, RATTLES AND WIND

NOISE

(1) Make sure that the instrument panel, glove

box, seats, steering wheel and column are free from

squeaks and rattles. Tighten any obvious loose fas-

teners.

(2) Check that the windows and doors are free

from squeaks, rattles and wind noise.

(3) Check that the vehicle exterior is free from

squeaks, rattles and noise, front and rear.

(4) Make sure that all interior panels are free from

squeaks and rattles.

INSPECTION - STEERING AND HANDLING

(1) Check that the power assist works properly (if

equipped). Steering should not require excessive

effort.

(2) Make sure the steering wheel does not vibrate

at idle or road speed.

(3) Ensure that the steering wheel is centered

when traveling straight ahead.

(4) Check that the vehicle does not drift to one

side.

(5) Make sure that the vehicle does not vibrate/

shake.

INSPECTION - TRANSMISSION/TRANSFER

CASE

AUTOMATIC TRANSMISSION

(1) Make sure that the park lock holds the vehicle

With the vehicle on a grade, put automatic trans-

mission in PARK and slowly release the service

brake to see if park lock holds. If it does not hold, the

transmission requires further service.

(2) Make sure shift lever operates easily/ smoothly

(Fig. 36).

Check for smooth shifting. Check for proper

upshifting and downshifting.

MANUAL TRANSMISSION

(1) Check that the shifter operates easily (Fig. 38).

(2) Make sure that the clutch operates smoothly

(Fig. 37).

(3) Look for proper synchronization.

The gears should not grind.

BR/BENEW VEHICLE PREPARATION 30 - 15

Page 2844 of 2889

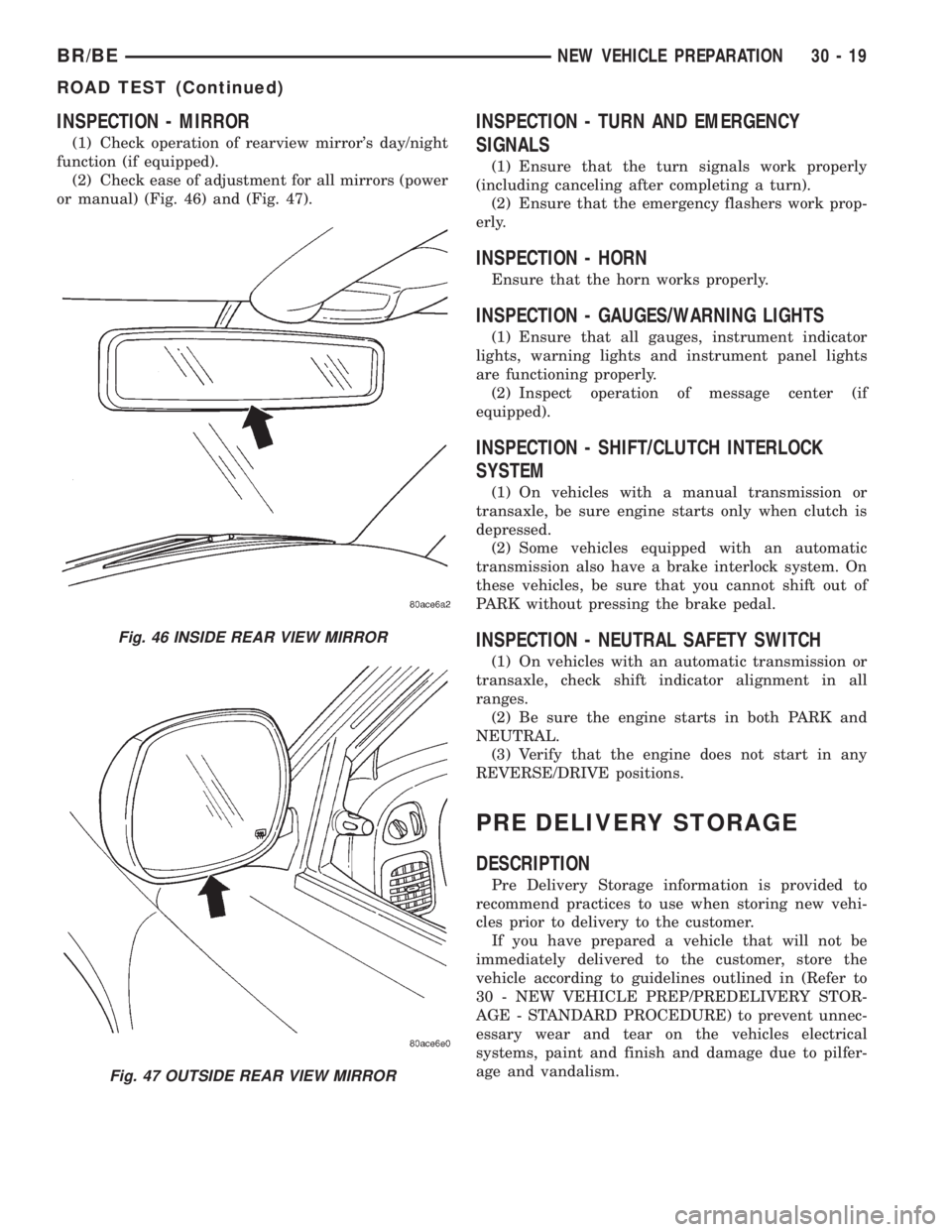

INSPECTION - MIRROR

(1) Check operation of rearview mirror's day/night

function (if equipped).

(2) Check ease of adjustment for all mirrors (power

or manual) (Fig. 46) and (Fig. 47).

INSPECTION - TURN AND EMERGENCY

SIGNALS

(1) Ensure that the turn signals work properly

(including canceling after completing a turn).

(2) Ensure that the emergency flashers work prop-

erly.

INSPECTION - HORN

Ensure that the horn works properly.

INSPECTION - GAUGES/WARNING LIGHTS

(1) Ensure that all gauges, instrument indicator

lights, warning lights and instrument panel lights

are functioning properly.

(2) Inspect operation of message center (if

equipped).

INSPECTION - SHIFT/CLUTCH INTERLOCK

SYSTEM

(1) On vehicles with a manual transmission or

transaxle, be sure engine starts only when clutch is

depressed.

(2) Some vehicles equipped with an automatic

transmission also have a brake interlock system. On

these vehicles, be sure that you cannot shift out of

PARK without pressing the brake pedal.

INSPECTION - NEUTRAL SAFETY SWITCH

(1) On vehicles with an automatic transmission or

transaxle, check shift indicator alignment in all

ranges.

(2) Be sure the engine starts in both PARK and

NEUTRAL.

(3) Verify that the engine does not start in any

REVERSE/DRIVE positions.

PRE DELIVERY STORAGE

DESCRIPTION

Pre Delivery Storage information is provided to

recommend practices to use when storing new vehi-

cles prior to delivery to the customer.

If you have prepared a vehicle that will not be

immediately delivered to the customer, store the

vehicle according to guidelines outlined in (Refer to

30 - NEW VEHICLE PREP/PREDELIVERY STOR-

AGE - STANDARD PROCEDURE) to prevent unnec-

essary wear and tear on the vehicles electrical

systems, paint and finish and damage due to pilfer-

age and vandalism.

Fig. 46 INSIDE REAR VIEW MIRROR

Fig. 47 OUTSIDE REAR VIEW MIRROR

BR/BENEW VEHICLE PREPARATION 30 - 19

ROAD TEST (Continued)

Page 2846 of 2889

Remote Keyless Entry (RKE). The horn chirps when

the vehicle is locked with the RKE transmitter.

HEADLAMP FLASH

NOTE: This feature can be enabled with or without

the horn chirp feature.

The headlamp flash function is a feature that can

be enabled or disabled on vehicles equipped with

Remote Keyless Entry (RKE). The headlamps flash

once when the vehicle is locked with the RKE trans-

mitter, and flash twice when the vehicle is unlocked

with the RKE transmitter.

LOW FUEL CHIME

All vehicles equipped with the audible low fuel

chime are shipped with this feature enabled.

REMOTE KEYLESS ENTRY (RKE) DOOR UNLOCK

SEQUENCE

Two door unlock sequences are provided on vehi-

cles equipped with this feature. When using the RKE

transmitter to unlock the doors, pressing the unlock

button once when the feature is enabled unlocks only

the driver's door. Pushing the RKE transmitter

unlock button a second time unlocks the remaining

doors. When the RKE door unlock feature is disabled,

all doors unlock with one press of the RKE transmit-

ter unlock button.

HEADLIGHTS ON AUTOMATICALLY WITH WIPERS

This feature appears on vehicles that have, as an

option, automatic headlights. When the windshield

wipers are turned on, the headlights automatically

turn on.

12V POWER OUTLET

This feature currently appears on Caravan/Voyag-

er/Town and Country vehicles. The vehicles are

shipped with the 12V power outlets turned off with

the ignition key. The relay can be changed to make

the outlets powered at all times. This feature may be

of interest to customers with cell phones.

TURN SIGNAL CHIME

This feature is an audible turn signal warning

chime. The chime sounds if the turn signal is on, the

vehicle has traveled one mile and vehicle speed has

exceeded 40 Km/h (25 mph).

REMOTE UNLOCK

The remote unlock function is a feature that can be

enabled or disabled on vehicles equipped with

Remote Keyless Entry (RKE). With the first press of

the RKE transmitter to unlock the doors, the driver's

door only unlocks. With the second press of the RKEtransmitter, the remaining doors and the liftgate

unlock. With the remote unlock feature enabled, the

first press of the RKE transmitter unlocks all doors.

REMOTE LINKED TO MEMORY

The remote linked to memory function is currently

only available only on Jeep Grand Cherokee Limited

vehicles. When enabled, this feature recalls a mem-

ory of seats, mirror and radio presets and positions

when unlocking the vehicle with the RKE transmit-

ter.

HEADLAMP DELAY

Currently available only on Jeep Grand Cherokee

vehicles, the headlamp delay timeout can be set to

30, 60 or 90 seconds. This timeout only occurs when

the ignition is turned off prior to turning the head-

lamps off, or when leaving the headlamps in AUTO

mode.

SERVICE INTERVAL

Currently available only on Jeep Grand Cherokee

vehicles, the interval for the service reminder mes-

sage can be set from 3,219 kilometers to 12,070 kilo-

meters (2,000 miles to 7,500 miles).

EASY EXIT SEAT

Currently available only on Jeep Grand Cherokee

Limited vehicles, the driver's seat will reposition

55mm (2.1 inches) rearward, or the end of travel if

less than 55mm (2.1 inches) and full downward when

the key is removed from the ignition. This feature

allows ease of exiting the vehicle. The seat will repo-

sition itself to the memory location when the vehicle

is unlocked using the RKE transmitter or by pressing

the memory buttons on the door panel.

APPEARANCE TIPS

CLEANING

(1) Before delivering the new vehicle to the cus-

tomer, the following checks on appearance details are

recommended:

²Wash the vehicle to remove all traces of road

grime and other dirt on the car from new vehicle

preparation operations

²Clean the tire sidewalls

²Clean exterior and interior glass surfaces

²Remove all protective covers

²Remove undercoat overspray, excess window

sealer, and excess weatherstrip adhesive

²Inspect interior trim, seats, carpeting, and mold-

ings. Clean as necessary

²Remove shipping and inspection stickers

BR/BENEW VEHICLE PREPARATION 30 - 21

PROGRAMMABLE ELECTRONIC FEATURES (Continued)

Page 2849 of 2889

AIR PUMP FILTER - INSTALLATION......25-29

AIR PUMP FILTER - REMOVAL..........25-29

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION - DIAGNOSIS

AND TESTING................21-490,21-661

AIR TO OIL COOLER - INSTALLATION.....7-88

AIR TO OIL COOLER - REMOVAL.........7-87

AIRBAG - ASSEMBLY, DRIVER..........8O-17

AIRBAG - DESCRIPTION, DRIVER........8O-14

AIRBAG - DESCRIPTION, PASSENGER....8O-21

AIRBAG - DISASSEMBLY, DRIVER.......8O-15

AIRBAG - INSTALLATION, DRIVER.......8O-18

AIRBAG - INSTALLATION, PASSENGER . . . 8O-23

AIRBAG - OPERATION, DRIVER.........8O-14

AIRBAG - OPERATION, PASSENGER......8O-21

AIRBAG - REMOVAL, DRIVER...........8O-14

AIRBAG - REMOVAL, PASSENGER.......8O-21

AIRBAG CONTROL MODULE -

DESCRIPTION........................8O-6

AIRBAG CONTROL MODULE -

INSTALLATION.......................8O-8

AIRBAG CONTROL MODULE -

OPERATION..........................8O-6

AIRBAG CONTROL MODULE - REMOVAL . . . 8O-7

AIRBAG DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN........8O-4

AIRBAG INDICATOR - DESCRIPTION......8J-15

AIRBAG INDICATOR - OPERATION.......8J-15

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-23

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-25

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-24

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-24

AIRBAG SYSTEM - DIAGNOSIS AND

TESTING............................8O-4

AIRBAG SYSTEM - SPECIAL TOOLS.......8O-6

AIRBAGS - STANDARD PROCEDURE,

HANDLING NON-DEPLOYED.............8O-4

AIRFLOW - DESCRIPTION, HVAC

SYSTEM............................24-31

AJAR SWITCH - DESCRIPTION, DOOR....8L-34

AJAR SWITCH - DIAGNOSIS AND

TESTING, DOOR.....................8L-34

AJAR SWITCH - INSTALLATION, DOOR . . . 8L-35

AJAR SWITCH - REMOVAL, DOOR.......8L-35

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT I.F.S. - STANDARD

PROCEDURES.........................2-2

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURES...............2-5

ALIGNMENT, SPECIAL TOOLS -

HEADLAMP..........................8L-4

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD

PROCEDURE.....21-159,21-330,21-502,21-673

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-11

AMBIENT TEMP SENSOR -

INSTALLATION......................8M-13

AMBIENT TEMP SENSOR - OPERATION . . 8M-11

AMBIENT TEMP SENSOR - REMOVAL

....8M-12

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS & TESTING

...............8M-12

AMPERAGE TEST - DIAGNOSIS AND

TESTING, FUEL PUMP

.................14-10

AN AIRBAG DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER

...........8O-4

ANTENNA - DIAGNOSIS AND TESTING

.....8A-5

ANTENNA BODY & CABLE -

DESCRIPTION

........................8A-4

ANTENNA BODY & CABLE - OPERATION

. . . 8A-4

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL

.................8A-10

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL

..................8A-9

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER

.......................8E-11

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER

.......................8E-12

ANTILOCK BRAKE - OPERATION,

CONTROLLER

.......................8E-11

ANTILOCK BRAKE - REMOVAL,

CONTROLLER

.......................8E-12A-PILLAR GRAB HANDLE -

INSTALLATION......................23-119

A-PILLAR GRAB HANDLE - REMOVAL . . . 23-119

A-PILLAR TRIM - INSTALLATION.......23-119

A-PILLAR TRIM - REMOVAL...........23-119

A-PILLAR TWEETER SPEAKER -

INSTALLATION.......................8A-19

A-PILLAR TWEETER SPEAKER -

REMOVAL..........................8A-19

APPEARANCE TIPS - CLEANING.........30-21

APPLICATION TABLE, SPECIFICATIONS -

A/C ................................24-8

APPLIQUE - INSTALLATION........23-62,23-67

APPLIQUE - REMOVAL...........23-62,23-67

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL..................9-10

ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER................9-85

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER...................9-85

ARM / ADJUSTER ASSY - CLEANING,

ROCKER............................9-262

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER............................9-261

ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-262

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER.....9-142,9-200,9-263

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER.................9-142,9-200,9-261

ARM - DESCRIPTION, WIPER...........8R-11

ARM - INSTALLATION, LOWER

CONTROL.......................2-10,2-20

ARM - INSTALLATION, UPPER

CONTROL.......................2-13,2-24

ARM - INSTALLATION, WIPER..........8R-12

ARM - OPERATION, WIPER............8R-12

ARM - REMOVAL, LOWER CONTROL . . 2-10,2-20

ARM - REMOVAL, UPPER CONTROL . . 2-13,2-23

ARM - REMOVAL, WIPER..............8R-12

ARMREST/CONSOLE - INSTALLATION,

CENTER SEAT......................23-132

ARMREST/CONSOLE - REMOVAL,

CENTER SEAT......................23-132

ARMREST/LATCH COVER -

INSTALLATION, CENTER SEAT.........23-132

ARMREST/LATCH COVER - REMOVAL,

CENTER SEAT......................23-132

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-3

ASD SENSE - PCM INPUT - OPERATION....8I-3

ASH RECEIVER - INSTALLATION........23-109

ASH RECEIVER - REMOVAL...........23-108

ASSEMBLE, OIL PUMP...........9-109,9-165

ASSEMBLY - INSTALLATION, ROCKER

ARM / ADJUSTER.....................9-85

ASSEMBLY - REMOVAL, ROCKER ARM /

ADJUSTER...........................9-85

ASSEMBLY, AUTOMATIC

TRANSMISSION - 42RE...............21-166

ASSEMBLY, AUTOMATIC

TRANSMISSION - 44RE...............21-337

ASSEMBLY, AUTOMATIC

TRANSMISSION - 46RE...............21-510

ASSEMBLY, AUTOMATIC

TRANSMISSION - 47RE...............21-681

ASSEMBLY, AXLE VACUUM MOTOR . . . 3-33,3-65

ASSEMBLY, DIFFERENTIAL . . . 3-128,3-159,3-188,

3-37,3-69,3-98

ASSEMBLY, DIFFERENTIAL - POWR-LOK . . 3-163

ASSEMBLY, DIFFERENTIAL - TRAC-LOK . . . 3-101,

3-132,3-190

ASSEMBLY, DISC BRAKE CALIPERS.......5-12

ASSEMBLY, DRIVER AIRBAG...........8O-17

ASSEMBLY, FLYWHEEL.................6-17

ASSEMBLY, FRONT CLUTCH.....21-206,21-376,

21-550,21-721

ASSEMBLY, FRONT SERVO......21-208,21-379,

21-553,21-723

ASSEMBLY, GLOVE BOX..............23-112

ASSEMBLY, HVAC HOUSING............24-36

ASSEMBLY, INSTRUMENT CLUSTER......8J-13

ASSEMBLY, MANUAL - NV3500

.........21-17

ASSEMBLY, MANUAL - NV4500

.........21-65

ASSEMBLY, MANUAL - NV5600

........21-110

ASSEMBLY, OIL PUMP

.................9-51

ASSEMBLY, OIL PUMP

. . . 21-212,21-382,21-558,

21-729ASSEMBLY, OVERDRIVE UNIT . . . 21-225,21-395,

21-569,21-742

ASSEMBLY, OVERHEAD CONSOLE -

OVERHEAD CONSOLE.................8M-7

ASSEMBLY, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER.......21-236,21-406,21-581,21-752

ASSEMBLY, PLANETARY GEARTRAIN/

OUTPUT SHAFT . . . 21-241,21-412,21-588,21-760

ASSEMBLY, REAR CLUTCH......21-248,21-419,

21-593,21-766

ASSEMBLY, REAR SERVO.......21-251,21-422,

21-595,21-768

ASSEMBLY, TRANS COOLER -

3.9L/5.2L/5.9L........................7-82

ASSEMBLY, TRANSFER CASE - NV231HD . 21-834

ASSEMBLY, TRANSFER CASE - NV241HD . 21-904

ASSEMBLY, TRANSFER CASE - NV241LD . 21-869

ASSEMBLY, VALVE BODY . 21-294,21-466,21-638,

21-810

ASSEMBLY, WHEEL CYLINDERS..........5-31

ASSIST HANDLE - INSTALLATION.......23-124

ASSIST HANDLE - REMOVAL..........23-124

ASSY - CLEANING, ROCKER ARM /

ADJUSTER..........................9-262

ASSY - DESCRIPTION, ROCKER ARM /

ADJUSTER..........................9-261

ASSY - INSPECTION, ROCKER ARM /

ADJUSTER..........................9-262

ASSY - INSTALLATION, ROCKER ARM /

ADJUSTER................9-142,9-200,9-263

ASSY - REMOVAL, ROCKER ARM /

ADJUSTER................9-142,9-200,9-261

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-2

AUDIO SYSTEMS, SPECIAL TOOLS.......8A-4

AUGAT - INSTALLATION, CONNECTOR . . 8W-01-8

AUGAT - REMOVAL, CONNECTOR.....8W-01-8

AUTO. TRANS. - INSTALLATION, DIESEL

WITH..........................8P-11,8P-4

AUTO. TRANS. - REMOVAL, DIESEL

WITH...........................8P-4,8P-8

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-10

AUTOMATIC DAY / NIGHT MIRROR -

INSTALLATION......................8N-12

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-12

AUTOMATIC DAY/NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-11

AUTOMATIC SHUT DOWN RELAY -

INSTALLATION........................8I-5

AUTOMATIC SHUT DOWN RELAY -

REMOVAL............................8I-4

AUTOMATIC TRANSMISSION - 42RE -

ASSEMBLY.........................21-166

AUTOMATIC TRANSMISSION - 42RE -

CLEANING.........................21-165

AUTOMATIC TRANSMISSION - 42RE -

DESCRIPTION

......................21-135

AUTOMATIC TRANSMISSION - 42RE -

DISASSEMBLY

......................21-160

AUTOMATIC TRANSMISSION - 42RE -

INSPECTION

.......................21-165

AUTOMATIC TRANSMISSION - 42RE -

INSTALLATION

......................21-173

AUTOMATIC TRANSMISSION - 42RE -

OPERATION

........................21-137

AUTOMATIC TRANSMISSION - 42RE -

REMOVAL

.........................21-159

AUTOMATIC TRANSMISSION - 44RE -

ASSEMBLY

.........................21-337

AUTOMATIC TRANSMISSION - 44RE -

CLEANING

.........................21-336

AUTOMATIC TRANSMISSION - 44RE -

DESCRIPTION

......................21-306

AUTOMATIC TRANSMISSION - 44RE -

DISASSEMBLY

......................21-331

AUTOMATIC TRANSMISSION - 44RE -

INSPECTION

.......................21-337

AUTOMATIC TRANSMISSION - 44RE -

INSTALLATION

......................21-344

AUTOMATIC TRANSMISSION - 44RE -

OPERATION

........................21-308

2 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2852 of 2889

BODY CONTROL/CENTRAL TIMER

MODULE - INSTALLATION...............8E-6

BODY CONTROL/CENTRAL TIMER

MODULE - OPERATION.................8E-3

BODY CONTROL/CENTRAL TIMER

MODULE - REMOVAL..................8E-5

BODY GAP AND FLUSH

MEASUREMENTS, SPECIFICATIONS......23-56

BODY OPENING DIMENSIONS,

SPECIFICATIONS.....................23-60

BODY SEALER LOCATIONS,

SPECIFICATIONS.....................23-47

BODY SEALING - INSPECTION..........30-10

BODY SIDE MOLDINGS - INSTALLATION . . 23-87

BODY SIDE MOLDINGS - REMOVAL......23-87

BODY STRIPES AND DECALS -

INSTALLATION.......................23-87

BODY STRIPES AND DECALS -

REMOVAL..........................23-87

BODY VENT - INSTALLATION..........23-126

BODY VENT - REMOVAL..............23-126

BOOST PRESSURE - DIAGNOSIS AND

TESTING...........................14-89

BOOSTER - DIAGNOSIS AND TESTING,

HYDRAULIC..........................5-17

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-29

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-20

BOOSTER - REMOVAL, POWER BRAKE....5-19

BOOT - INSTALLATION, 4WD FLOOR

SHIFT..............................23-122

BOOT - MANUAL TRANSMISSION -

INSTALLATION, SHIFT................23-122

BOOT - MANUAL TRANSMISSION -

REMOVAL, SHIFT....................23-122

BOOT - REMOVAL, 4WD FLOOR SHIFT . . . 23-122

BORE, DE-GLAZE - STANDARD

PROCEDURE-CYLINDER...............9-264

BORE HONING - STANDARD

PROCEDURE, CYLINDER . . 9-10,9-126,9-180,9-69

BORE REPAIR - STANDARD

PROCEDURE, CAM...................9-267

BORE REPAIR - STANDARD

PROCEDURE, CYLINDER...............9-265

BOX - ASSEMBLY, GLOVE.............23-112

BOX - DISASSEMBLY, GLOVE..........23-112

BOX - INSTALLATION, CARGO..........23-97

BOX - INSTALLATION, GLOVE..........23-113

BOX - REMOVAL, CARGO..............23-96

BOX - REMOVAL, GLOVE.............23-112

BOX LAMP AND SWITCH -

INSTALLATION, GLOVE................8L-35

BOX LAMP AND SWITCH - REMOVAL,

GLOVE.............................8L-35

BOX LATCH STRIKER - INSTALLATION,

GLOVE............................23-113

BOX LATCH STRIKER - REMOVAL,

GLOVE............................23-113

BOX OPENING UPPER TRIM -

INSTALLATION, GLOVE...............23-114

BOX OPENING UPPER TRIM - REMOVAL,

GLOVE............................23-114

B-PILLAR DOOR SEAL - INSTALLATION . . 23-152

B-PILLAR DOOR SEAL - REMOVAL......23-152

B-PILLAR TRIM - INSTALLATION

.......23-120

B-PILLAR TRIM - REMOVAL

...........23-120

BR PAINT COLOR CODES,

SPECIFICATIONS - 2001

..............23-129

BRACKET - INSTALLATION, CAB

CHASSIS ADAPTER

....................13-9

BRACKET - INSTALLATION, REARVIEW

MIRROR SUPPORT

..................23-126

BRACKET - REMOVAL, CAB CHASSIS

ADAPTER

............................13-9

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK

..........................8E-11

BRAKE - INSPECTION, PARKING

.........30-17

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK

..........................8E-12

BRAKE - OPERATION, CONTROLLER

ANTILOCK

..........................8E-11

BRAKE - REMOVAL, CONTROLLER

ANTILOCK

..........................8E-12

BRAKE BOOSTER - INSTALLATION,

POWER

.............................5-20

BRAKE BOOSTER - REMOVAL, POWER

....5-19BRAKE CABLE - 2500/3500 WITH REAR

DISC BRAKES - INSTALLATION, REAR

PARK...............................5-38

BRAKE CABLE - 2500/3500 WITH REAR

DISC BRAKES - REMOVAL, REAR

PARK...............................5-37

BRAKE CABLE - INSTALLATION, FRONT

PARKING............................5-39

BRAKE CABLE - REMOVAL, FRONT

PARKING............................5-37

BRAKE CABLE 2500/3500 SERIES WITH

DRUM BRAKES - INSTALLATION, REAR

PARK...............................5-39

BRAKE CABLES - 1500 SERIES -

INSTALLATION, REAR PARK.............5-39

BRAKE CABLES - 1500 SERIES -

REMOVAL, REAR PARK.................5-37

BRAKE CABLES 2500/3500 SERIES WITH

DRUM BRAKES - REMOVAL, REAR

PARK...............................5-38

BRAKE CALIPERS - ASSEMBLY, DISC......5-12

BRAKE CALIPERS - CLEANING, DISC......5-12

BRAKE CALIPERS - DISASSEMBLY, DISC . . . 5-11

BRAKE CALIPERS - INSPECTION, DISC....5-12

BRAKE DRUM - ADJUSTMENT, REAR......5-34

BRAKE DRUM - DIAGNOSIS AND

TESTING............................5-33

BRAKE DRUM MACHINING - STANDARD

PROCEDURE.........................5-33

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-14

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-14

BRAKE FLUID, SPECIFICATIONS..........5-15

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-16

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-16

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-16

BRAKE LAMP SWITCH - DESCRIPTION....8L-4

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING........................8L-5

BRAKE LAMP SWITCH - INSTALLATION....8L-5

BRAKE LAMP SWITCH - OPERATION......8L-4

BRAKE LAMP SWITCH - REMOVAL.......8L-5

BRAKE ROTOR - DIAGNOSIS AND

TESTING, DISC.......................5-20

BRAKE SHOES - 2500/3500 -

INSTALLATION, REAR DRUM IN HAT

PARK...............................5-42

BRAKE SHOES - 2500/3500 - REMOVAL,

REAR DRUM IN HAT PARK..............5-41

BRAKE SHOES-11 INCH - INSTALLATION,

REAR...............................5-27

BRAKE SHOES-11 INCH - REMOVAL,

REAR...............................5-25

BRAKE, SPECIFICATIONS - BASE..........5-2

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-5

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION

.......................8J-16

BRAKE/PARK BRAKE INDICATOR -

OPERATION

.........................8J-16

BRAKES - DESCRIPTION, 2500/3500

WITH REAR DISC

.....................5-35

BRAKES - INSPECTION, SERVICE

........30-17

BRAKES - INSTALLATION, REAR PARK

BRAKE CABLE - 2500/3500 WITH

REAR DISC

..........................5-38

BRAKES - INSTALLATION, REAR PARK

BRAKE CABLE 2500/3500 SERIES

WITH DRUM

.........................5-39

BRAKES - OPERATION, 2500/3500 WITH

REAR DISC

..........................5-36

BRAKES - REMOVAL, REAR PARK

BRAKE CABLE - 2500/3500 WITH

REAR DISC

..........................5-37

BRAKES - REMOVAL, REAR PARK

BRAKE CABLES 2500/3500 SERIES

WITH DRUM

.........................5-38

BRAKES, SPECIAL TOOLS - BASE

.........5-4

BREAKER - DESCRIPTION, CIRCUIT

....8W-97-4

BREAKER - DIAGNOSIS & TESTING,

CIRCUIT

.........................8W-97-4

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH

............24-13BREATHER VAPOR CANISTER -

INSTALLATION, CRANKCASE............9-242

BREATHER VAPOR CANISTER -

REMOVAL, CRANKCASE...............9-241

BUCKLE - INSTALLATION, FRONT SEAT

BELT ..............................8O-20

BUCKLE - INSTALLATION, REAR SEAT

BELT ..............................8O-27

BUCKLE - REMOVAL, FRONT SEAT BELT . . 8O-20

BUCKLE - REMOVAL, REAR SEAT BELT . . . 8O-27

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE........................8F-11

BUMPER - DESCRIPTION, JOUNCE....2-28,2-9

BUMPER - INSTALLATION, FRONT........13-4

BUMPER - INSTALLATION, REAR.........13-5

BUMPER - INSTALLATION, SLAM........23-66

BUMPER - OPERATION, JOUNCE......2-28,2-9

BUMPER - REMOVAL, FRONT............13-3

BUMPER - REMOVAL, REAR.............13-5

BUMPER - REMOVAL, SLAM...........23-66

BUMPERS - DESCRIPTION..............13-1

BUMPER-SPORT - INSTALLATION,

FRONT..............................13-4

BUMPER-SPORT - REMOVAL, FRONT......13-4

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF . . . 21-199,21-370,21-545,

21-715

BUS - DESCRIPTION, CCD DATA..........8E-6

BUS - DIAGNOSIS AND TESTING, CCD

D ATA................................8E-11

BUS - OPERATION, CCD DATA...........8E-7

BUSHING - INSTALLATION,

DISTRIBUTOR...............9-150,9-37,9-94

BUSHING - INSTALLATION, EXTENSION

HOUSING........21-198,21-369,21-544,21-714

BUSHING - REMOVAL, DISTRIBUTOR....9-150,

9-37,9-94

BUSHING - REMOVAL, EXTENSION

HOUSING........21-198,21-369,21-544,21-714

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING....21-850,21-885,21-921

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING....21-850,21-885,21-921

BUSHINGS - INSTALLATION.............2-28

BUSHINGS - REMOVAL.................2-28

BYPASS HOSE WITH AIR CONDITIONING

- INSTALLATION, WATER PUMP..........7-77

BYPASS HOSE WITH AIR CONDITIONING

- REMOVAL, WATER PUMP..............7-74

BYPASS HOSE WITHOUT AIR

CONDITIONING - INSTALLATION,

WATER PUMP........................7-78

BYPASS HOSE WITHOUT AIR

CONDITIONING - REMOVAL, WATER

PUMP..............................7-77

CAB - INSTALLATION, CLUB/QUAD.......8O-20

CAB - INSTALLATION, STANDARD.......8O-19

CAB - REMOVAL, CLUB/QUAD..........8O-19

CAB - REMOVAL, STANDARD...........8O-18

CAB CHASSIS ADAPTER BRACKET -

INSTALLATION........................13-9

CAB CHASSIS ADAPTER BRACKET -

REMOVAL...........................13-9

CAB SIDE PANEL SPEAKER -

INSTALLATION, REAR.................8A-21

CAB SIDE PANEL SPEAKER - REMOVAL,

REAR..............................8A-20

CABLE - 2500/3500 WITH REAR DISC

BRAKES - INSTALLATION, REAR PARK

BRAKE..............................5-38

CABLE - 2500/3500 WITH REAR DISC

BRAKES - REMOVAL, REAR PARK

BRAKE..............................5-37

CABLE - ADJUSTMENTS,

TRANSMISSION THROTTLE VALVE.....21-254,

21-425,21-598,21-771

CABLE - DESCRIPTION.................8P-4

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, BATTERY........8F-19

CABLE - DESCRIPTION, SPARK PLUG.....8I-19

CABLE - DESCRIPTION, THROTTLE

VALVE

..........21-253,21-424,21-597,21-770

CABLE - INSTALLATION, CHECK

.........23-63

CABLE - INSTALLATION, FRONT

PARKING BRAKE

......................5-39

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA

.....................8A-10

CABLE - INSTALLATION, LATCH RELEASE

. 23-101

BR/BEINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2857 of 2889

COVER(S) - INSPECTION, CYLINDER

HEAD............9-138,9-194,9-24,9-253,9-81

COVER(S) - INSTALLATION, CYLINDER

HEAD............9-138,9-194,9-24,9-253,9-81

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN.........9-113,9-169,9-226,9-56

COVERS - INSTALLATION, WHEEL.......30-10

COVER(S) - REMOVAL, CYLINDER HEAD . 9-138,

9-194,9-24,9-253,9-81

COVER(S) - REMOVAL, TIMING BELT /

CHAIN...............9-113,9-169,9-225,9-56

COWL GRILLE - INSTALLATION.........23-90

COWL GRILLE - REMOVAL.............23-90

COWL TRIM COVER - INSTALLATION....23-120

COWL TRIM COVER - REMOVAL.......23-119

COWL WEATHERSTRIP - INSTALLATION . 23-153

COWL WEATHERSTRIP - REMOVAL.....23-153

C-PILLAR TRIM - INSTALLATION.......23-128

C-PILLAR TRIM - REMOVAL...........23-128

CRANKCASE BREATHER VAPOR

CANISTER - INSTALLATION.............9-242

CRANKCASE BREATHER VAPOR

CANISTER - REMOVAL................9-241

CRANKCASE VENT HOSE - OPERATION . . . 25-32

CRANKSHAFT - DESCRIPTION . 9-145,9-275,9-31,

9-88

CRANKSHAFT - INSTALLATION....9-145,9-203,

9-32,9-89

CRANKSHAFT - OPERATION....9-145,9-31,9-88

CRANKSHAFT - REMOVAL . . 9-145,9-202,9-31,9-88

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE, CONNECTING

ROD BEARING.......................9-274

CRANKSHAFT MAIN BEARING FITTING -

STANDARD PROCEDURE...........9-146,9-90

CRANKSHAFT MAIN BEARINGS -

DESCRIPTION...............9-146,9-32,9-90

CRANKSHAFT MAIN BEARINGS -

INSTALLATION.........9-147,9-204,9-34,9-90

CRANKSHAFT MAIN BEARINGS -

OPERATION.................9-146,9-32,9-90

CRANKSHAFT MAIN BEARINGS -

REMOVAL.............9-147,9-204,9-33,9-90

CRANKSHAFT OIL SEAL - FRONT -

DESCRIPTION...............9-147,9-34,9-91

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION.........9-148,9-277,9-34,9-91

CRANKSHAFT OIL SEAL - FRONT -

OPERATION.................9-147,9-34,9-91

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL.............9-147,9-276,9-34,9-91

CRANKSHAFT OIL SEAL - REAR -

DESCRIPTION...............9-148,9-34,9-91

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION....9-149,9-206,9-278,9-35,9-92

CRANKSHAFT OIL SEAL - REAR -

OPERATION.................9-148,9-34,9-92

CRANKSHAFT OIL SEAL - REAR -

REMOVAL........9-149,9-206,9-278,9-35,9-92

CRANKSHAFT REAR OIL SEAL RETAINER

- INSTALLATION................9-206,9-279

CRANKSHAFT REAR OIL SEAL RETAINER

- REMOVAL....................9-206,9-278

CROSSHEADS - CLEANING.............9-249

CROSSHEADS - INSPECTION...........9-250

CRUISE INDICATOR - DESCRIPTION......8J-18

CRUISE INDICATOR - OPERATION.......8J-18

CUBBY BIN - INSTALLATION...........23-110

CUBBY BIN - REMOVAL..............23-110

CUMMINS TURBO DIESEL -

DESCRIPTION, MAINTENANCE

SCHEDULES - 24-VALVE................0-22

CUP HOLDER - INSTALLATION.........23-111

CUP HOLDER - REMOVAL.............23-110

CUSHION - INSTALLATION, SEAT.......23-138

CUSHION - REMOVAL, SEAT...........23-138

CUSHION COVER - INSTALLATION, SEAT . 23-139

CUSHION COVER - REMOVAL, SEAT.....23-139

CUSHION COVER - SPLIT BENCH -

INSTALLATION, SEAT.................23-140

CUSHION COVER - SPLIT BENCH -

REMOVAL, SEAT....................23-139

CYLINDER - DESCRIPTION, MASTER

......5-29

CYLINDER - DIAGNOSIS AND TESTING,

IGNITION SWITCH AND KEY LOCK

.......19-10

CYLINDER - INSTALLATION, LOCK

.......23-73

CYLINDER - INSTALLATION, MASTER

.....5-30

CYLINDER - OPERATION, MASTER

........5-29CYLINDER - REMOVAL, LOCK...........23-73

CYLINDER - REMOVAL, MASTER.........5-30

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-30

CYLINDER BORE HONING - STANDARD

PROCEDURE...........9-10,9-126,9-180,9-69

CYLINDER BORE REPAIR - STANDARD

PROCEDURE........................9-265

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING....9-124,

9-179,9-67,9-9

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING . 9-124,9-179,9-67,9-9

CYLINDER COVER GASKET -

DESCRIPTION........................9-79

CYLINDER HEAD - CLEANING . 9-137,9-193,9-23,

9-248,9-80

CYLINDER HEAD - DESCRIPTION . . 9-136,9-191,

9-22,9-246,9-79

CYLINDER HEAD - INSPECTION....9-137,9-193,

9-23,9-250,9-80

CYLINDER HEAD - INSTALLATION . . 9-137,9-193,

9-23,9-250,9-80

CYLINDER HEAD - OPERATION . . 9-136,9-22,9-79

CYLINDER HEAD - REMOVAL . 9-137,9-192,9-23,

9-246,9-80

CYLINDER HEAD COVER GASKET -

DESCRIPTION........................9-22

CYLINDER HEAD COVER GASKET -

OPERATION..........................9-22

CYLINDER HEAD COVER(S) - CLEANING . . 9-138,

9-194,9-24,9-253,9-81

CYLINDER HEAD COVER(S) -

DESCRIPTION.......................9-194

CYLINDER HEAD COVER(S) -

INSPECTION......9-138,9-194,9-24,9-253,9-81

CYLINDER HEAD COVER(S) -

INSTALLATION....9-138,9-194,9-24,9-253,9-81

CYLINDER HEAD COVER(S) - REMOVAL . . 9-138,

9-194,9-24,9-253,9-81

CYLINDER HEAD GASKET FAILURE -

DIAGNOSIS AND TESTING....9-136,9-191,9-22,

9-79

CYLINDER HOUSING - INSTALLATION,

LOCK..............................19-11

CYLINDER HOUSING - REMOVAL, LOCK . . 19-10

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR..................8N-5

CYLINDER LOCK SWITCH - DIAGNOSIS

& TESTING, DOOR....................8N-5

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8N-6

CYLINDER LOCK SWITCH - OPERATION,

DOOR..............................8N-5

CYLINDER LOCK SWITCH - REMOVAL,

DOOR..............................8N-6

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER......5-29

CYLINDERS - ASSEMBLY, WHEEL.........5-31

CYLINDERS - CLEANING, WHEEL.........5-31

CYLINDERS - DESCRIPTION, LOCK.......23-1

CYLINDERS - DISASSEMBLY, WHEEL......5-31

CYLINDERS - INSPECTION, WHEEL.......5-31

CYLINDERS - INSTALLATION, WHEEL.....5-32

CYLINDERS - REMOVAL, WHEEL.........5-31

DAM - INSTALLATION, FRONT AIR........13-2

DAM - REMOVAL, FRONT AIR...........13-1

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE,

REPAIR ..........9-11,9-125,9-181,9-238,9-68

DAMPER - INSPECTION, VIBRATION.....9-289

DAMPER - INSTALLATION,

VIBRATION.......9-156,9-212,9-289,9-42,9-99

DAMPER - REMOVAL,

VIBRATION.......9-155,9-212,9-289,9-42,9-99

DATA BUS - DESCRIPTION, CCD..........8E-6

DATA BUS - DIAGNOSIS AND TESTING,

CCD ...............................8E-11

DATA BUS - OPERATION, CCD...........8E-7

DATA LINK CONNECTOR - DESCRIPTION . . 8E-12

DATA LINK CONNECTOR - OPERATION

....8E-12

DATA PLATE - DESCRIPTION, ENGINE

....9-244

DATA PLATE, SPECIFICATIONS - FUEL

INJECTION PUMP

....................14-73

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC

........................8N-10

DAY / NIGHT MIRROR - INSTALLATION,

AUTOMATIC

........................8N-12DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-11

DAY / NIGHT MIRROR - REMOVAL,

AUTOMATIC........................8N-12

DAY/NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-11

DAYTIME RUNNING LAMP MODULE -

DESCRIPTION........................8L-9

DAYTIME RUNNING LAMP MODULE -

INSTALLATION........................8L-9

DAYTIME RUNNING LAMP MODULE -

OPERATION..........................8L-9

DAYTIME RUNNING LAMP MODULE -

REMOVAL...........................8L-9

DECALS - INSTALLATION..............23-63

DECALS - INSTALLATION, BODY

STRIPES...........................23-87

DECALS - REMOVAL..................23-63

DECALS - REMOVAL, BODY STRIPES.....23-87

DEFINITION - DESCRIPTION, TRIP.......25-18

DEFROSTER AND DEMISTER DUCT

ADAPTER - INSTALLATION.............24-35

DEFROSTER AND DEMISTER DUCT

ADAPTER - REMOVAL.................24-35

DEFROSTER AND DEMISTER DUCTS -

INSTALLATION.......................24-35

DEFROSTER AND DEMISTER DUCTS -

REMOVAL..........................24-34

DE-GLAZE - STANDARD PROCEDURE-

CYLINDER BORE.....................9-264

DELIVERY - DIESEL - OPERATION, FUEL . . 14-56

DELIVERY - SPECIFICATIONS, TORQUE -

FUEL...............................14-4

DELIVERY STORAGE - DESCRIPTION,

PRE ...............................30-19

DELIVERY STORAGE - STANDARD

PROCEDURE, PRE....................30-20

DELIVERY SYSTEM - DESCRIPTION,

DIESEL FUEL........................14-54

DELIVERY SYSTEM - DESCRIPTION,

FUEL...............................14-2

DELIVERY SYSTEM - OPERATION, FUEL . . . 14-2

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-5

DEMISTER DUCT ADAPTER -

INSTALLATION, DEFROSTER............24-35

DEMISTER DUCT ADAPTER - REMOVAL,

DEFROSTER.........................24-35

DEMISTER DUCTS - INSTALLATION,

DEFROSTER.........................24-35

DEMISTER DUCTS - REMOVAL,

DEFROSTER.........................24-34

DEMISTER DUCTS - REMOVAL,

INSTRUMENT PANEL..................24-37

DEMISTER GRILLES - INSTALLATION.....24-32

DEMISTER GRILLES - REMOVAL........24-31

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN

AIRBAG.............................8O-4

DETECTION PUMP - DESCRIPTION, LEAK . 25-33

DETECTION PUMP - INSTALLATION,

LEAK..............................25-34

DETECTION PUMP - REMOVAL, LEAK....25-34

DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING, ENGINE . 9-118,9-173,

9-3

DIAGNOSIS - MECHANICAL - DIAGNOSIS

AND TESTING, ENGINE................9-232

DIAGNOSIS CHARTS - DIAGNOSIS AND

TESTING........21-149,21-320,21-492,21-663

DIAGNOSIS CHARTS - DIAGNOSIS AND

TESTING, SMOKE....................9-234

DIAGNOSIS, INTRODUCTION -

DIAGNOSIS AND TESTING-ENGINE........9-61

DIAGNOSTIC AND TESTING, CLUTCH.......6-2

DIAGNOSTIC TROUBLE CODES -

DESCRIPTION........................25-2

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-4

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING

......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS

.....21-174,21-345,21-520,21-690

DIESEL - CLEANING, RADIATOR - 5.9L

....7-65

DIESEL - CLEANING, RADIATOR FAN -

5.9L

................................7-44

DIESEL - CLEANING, WATER PUMP -

5.9L

................................7-73

10 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page