DODGE RAM 2002 Service Repair Manual

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 151 of 2255

DIFFERENTIAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove axle shafts.

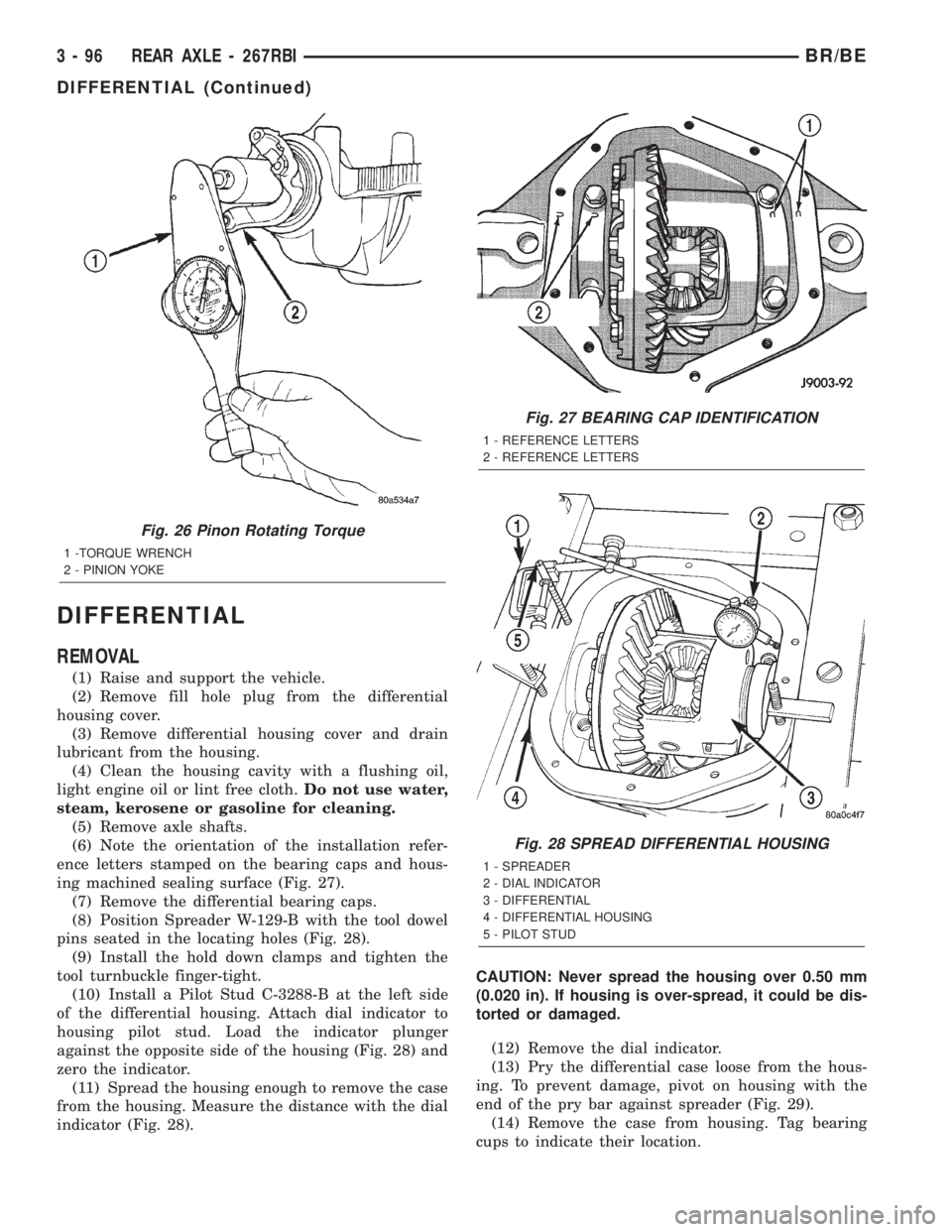

(6) Note the orientation of the installation refer-

ence letters stamped on the bearing caps and hous-

ing machined sealing surface (Fig. 27).

(7) Remove the differential bearing caps.

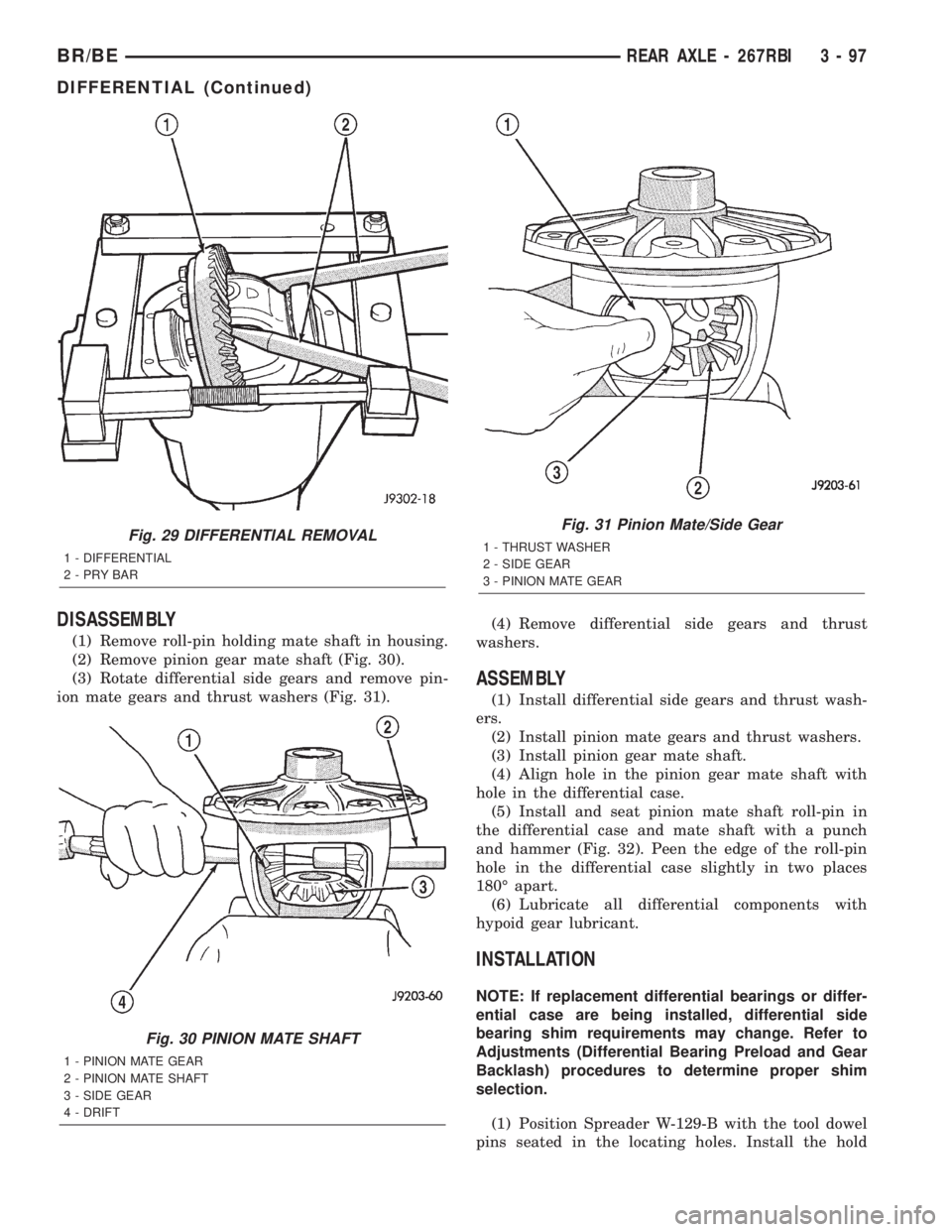

(8) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 28).

(9) Install the hold down clamps and tighten the

tool turnbuckle finger-tight.

(10) Install a Pilot Stud C-3288-B at the left side

of the differential housing. Attach dial indicator to

housing pilot stud. Load the indicator plunger

against the opposite side of the housing (Fig. 28) and

zero the indicator.

(11) Spread the housing enough to remove the case

from the housing. Measure the distance with the dial

indicator (Fig. 28).CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If housing is over-spread, it could be dis-

torted or damaged.

(12) Remove the dial indicator.

(13) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 29).

(14) Remove the case from housing. Tag bearing

cups to indicate their location.

Fig. 26 Pinon Rotating Torque

1 -TORQUE WRENCH

2 - PINION YOKE

Fig. 27 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 28 SPREAD DIFFERENTIAL HOUSING

1 - SPREADER

2 - DIAL INDICATOR

3 - DIFFERENTIAL

4 - DIFFERENTIAL HOUSING

5 - PILOT STUD

3 - 96 REAR AXLE - 267RBIBR/BE

DIFFERENTIAL (Continued)

Page 152 of 2255

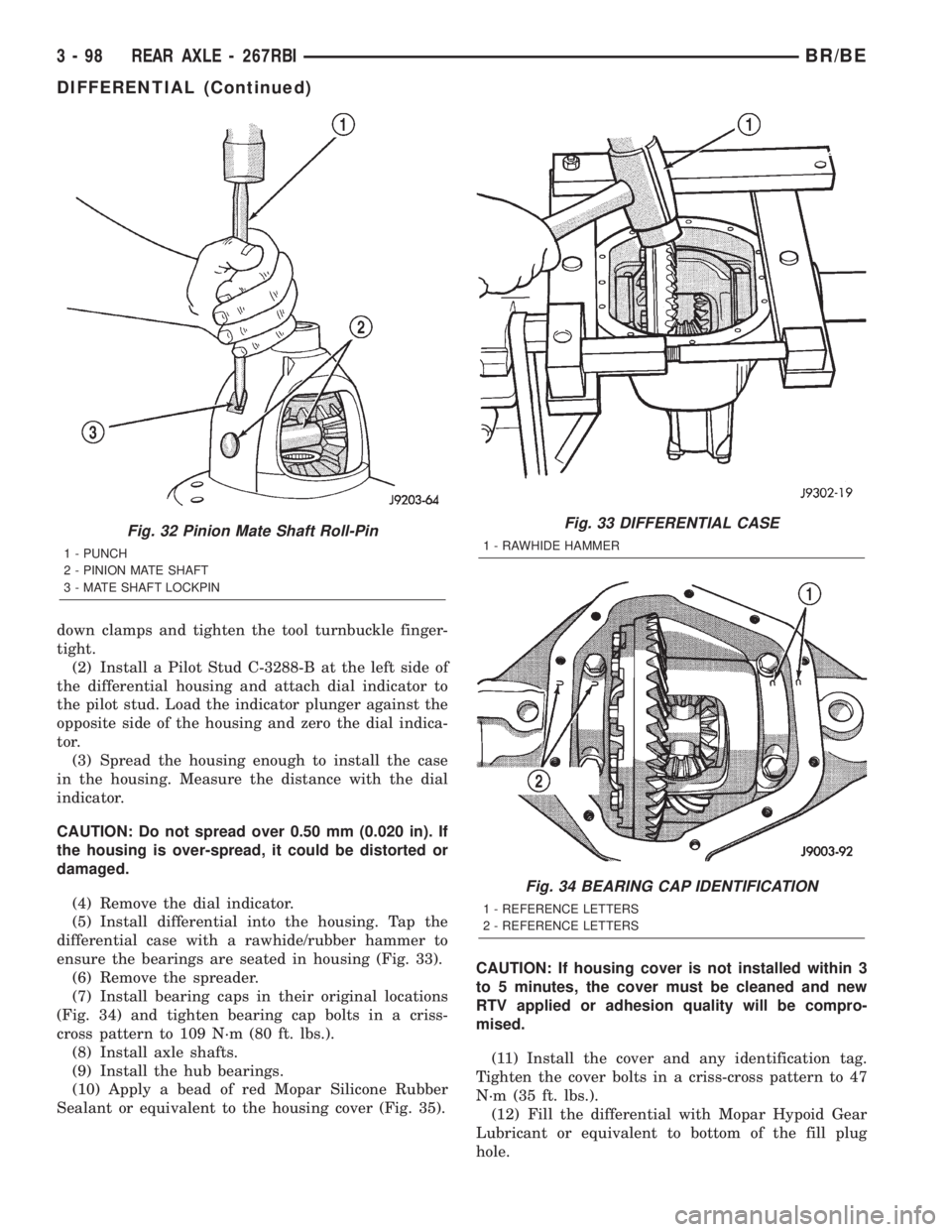

DISASSEMBLY

(1) Remove roll-pin holding mate shaft in housing.

(2) Remove pinion gear mate shaft (Fig. 30).

(3) Rotate differential side gears and remove pin-

ion mate gears and thrust washers (Fig. 31).(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install pinion mate gears and thrust washers.

(3) Install pinion gear mate shaft.

(4) Align hole in the pinion gear mate shaft with

hole in the differential case.

(5) Install and seat pinion mate shaft roll-pin in

the differential case and mate shaft with a punch

and hammer (Fig. 32). Peen the edge of the roll-pin

hole in the differential case slightly in two places

180É apart.

(6) Lubricate all differential components with

hypoid gear lubricant.

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer to

Adjustments (Differential Bearing Preload and Gear

Backlash) procedures to determine proper shim

selection.

(1) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes. Install the hold

Fig. 29 DIFFERENTIAL REMOVAL

1 - DIFFERENTIAL

2-PRYBAR

Fig. 30 PINION MATE SHAFT

1 - PINION MATE GEAR

2 - PINION MATE SHAFT

3 - SIDE GEAR

4 - DRIFT

Fig. 31 Pinion Mate/Side Gear

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEAR

BR/BEREAR AXLE - 267RBI 3 - 97

DIFFERENTIAL (Continued)

Page 153 of 2255

down clamps and tighten the tool turnbuckle finger-

tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing and attach dial indicator to

the pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the dial indica-

tor.

(3) Spread the housing enough to install the case

in the housing. Measure the distance with the dial

indicator.

CAUTION: Do not spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(4) Remove the dial indicator.

(5) Install differential into the housing. Tap the

differential case with a rawhide/rubber hammer to

ensure the bearings are seated in housing (Fig. 33).

(6) Remove the spreader.

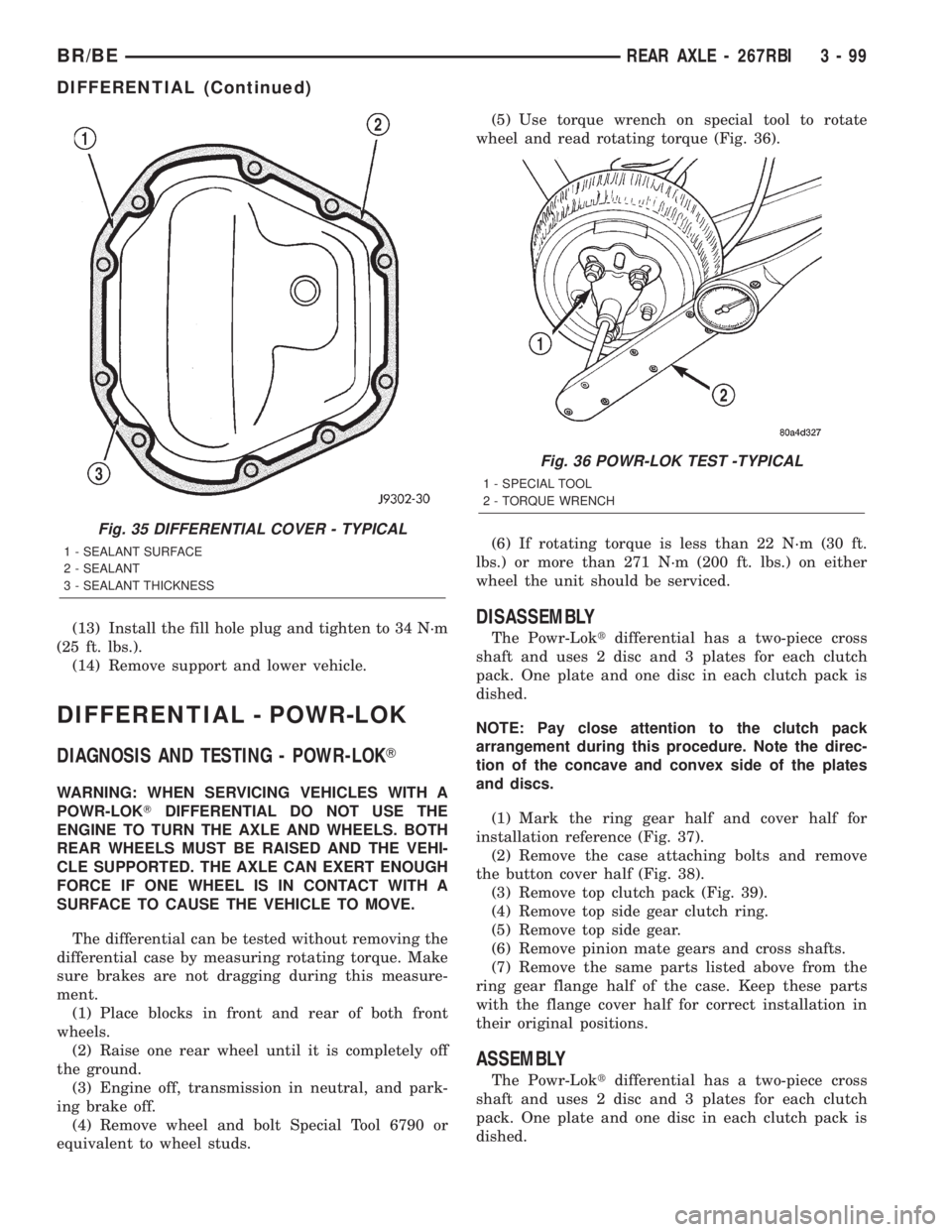

(7) Install bearing caps in their original locations

(Fig. 34) and tighten bearing cap bolts in a criss-

cross pattern to 109 N´m (80 ft. lbs.).

(8) Install axle shafts.

(9) Install the hub bearings.

(10) Apply a bead of red Mopar Silicone Rubber

Sealant or equivalent to the housing cover (Fig. 35).CAUTION: If housing cover is not installed within 3

to 5 minutes, the cover must be cleaned and new

RTV applied or adhesion quality will be compro-

mised.

(11) Install the cover and any identification tag.

Tighten the cover bolts in a criss-cross pattern to 47

N´m (35 ft. lbs.).

(12) Fill the differential with Mopar Hypoid Gear

Lubricant or equivalent to bottom of the fill plug

hole.

Fig. 32 Pinion Mate Shaft Roll-Pin

1 - PUNCH

2 - PINION MATE SHAFT

3 - MATE SHAFT LOCKPIN

Fig. 33 DIFFERENTIAL CASE

1 - RAWHIDE HAMMER

Fig. 34 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

3 - 98 REAR AXLE - 267RBIBR/BE

DIFFERENTIAL (Continued)

Page 154 of 2255

(13) Install the fill hole plug and tighten to 34 N´m

(25 ft. lbs.).

(14) Remove support and lower vehicle.

DIFFERENTIAL - POWR-LOK

DIAGNOSIS AND TESTING - POWR-LOKT

WARNING: WHEN SERVICING VEHICLES WITH A

POWR-LOKTDIFFERENTIAL DO NOT USE THE

ENGINE TO TURN THE AXLE AND WHEELS. BOTH

REAR WHEELS MUST BE RAISED AND THE VEHI-

CLE SUPPORTED. THE AXLE CAN EXERT ENOUGH

FORCE IF ONE WHEEL IS IN CONTACT WITH A

SURFACE TO CAUSE THE VEHICLE TO MOVE.

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent to wheel studs.(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 36).

(6) If rotating torque is less than 22 N´m (30 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

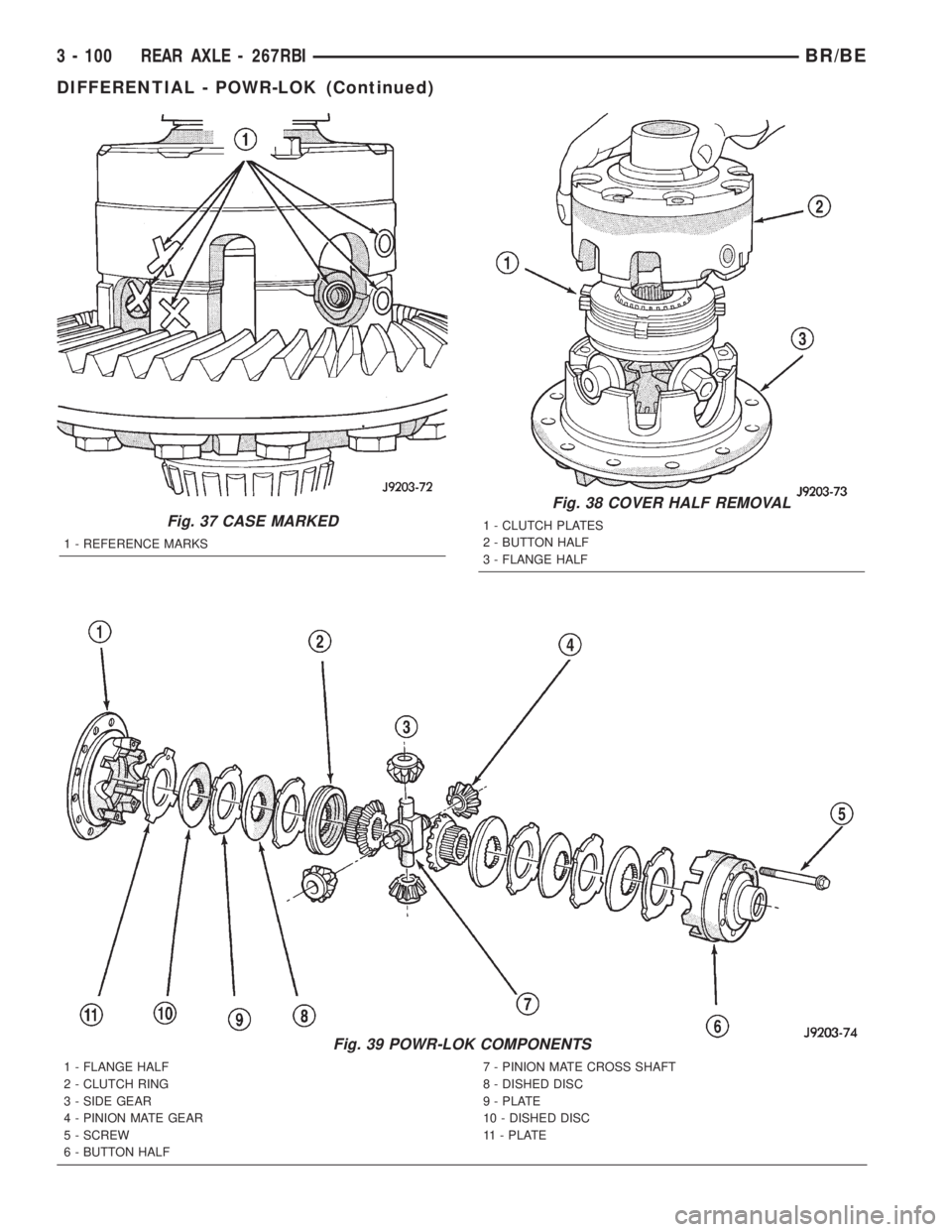

DISASSEMBLY

The Powr-Loktdifferential has a two-piece cross

shaft and uses 2 disc and 3 plates for each clutch

pack. One plate and one disc in each clutch pack is

dished.

NOTE: Pay close attention to the clutch pack

arrangement during this procedure. Note the direc-

tion of the concave and convex side of the plates

and discs.

(1) Mark the ring gear half and cover half for

installation reference (Fig. 37).

(2) Remove the case attaching bolts and remove

the button cover half (Fig. 38).

(3) Remove top clutch pack (Fig. 39).

(4) Remove top side gear clutch ring.

(5) Remove top side gear.

(6) Remove pinion mate gears and cross shafts.

(7) Remove the same parts listed above from the

ring gear flange half of the case. Keep these parts

with the flange cover half for correct installation in

their original positions.

ASSEMBLY

The Powr-Loktdifferential has a two-piece cross

shaft and uses 2 disc and 3 plates for each clutch

pack. One plate and one disc in each clutch pack is

dished.

Fig. 35 DIFFERENTIAL COVER - TYPICAL

1 - SEALANT SURFACE

2 - SEALANT

3 - SEALANT THICKNESS

Fig. 36 POWR-LOK TEST -TYPICAL

1 - SPECIAL TOOL

2 - TORQUE WRENCH

BR/BEREAR AXLE - 267RBI 3 - 99

DIFFERENTIAL (Continued)

Page 155 of 2255

Fig. 39 POWR-LOK COMPONENTS

1 - FLANGE HALF

2 - CLUTCH RING

3 - SIDE GEAR

4 - PINION MATE GEAR

5 - SCREW

6 - BUTTON HALF7 - PINION MATE CROSS SHAFT

8 - DISHED DISC

9 - PLATE

10 - DISHED DISC

11 - PLATE

Fig. 37 CASE MARKED

1 - REFERENCE MARKS

Fig. 38 COVER HALF REMOVAL

1 - CLUTCH PLATES

2 - BUTTON HALF

3 - FLANGE HALF

3 - 100 REAR AXLE - 267RBIBR/BE

DIFFERENTIAL - POWR-LOK (Continued)

Page 156 of 2255

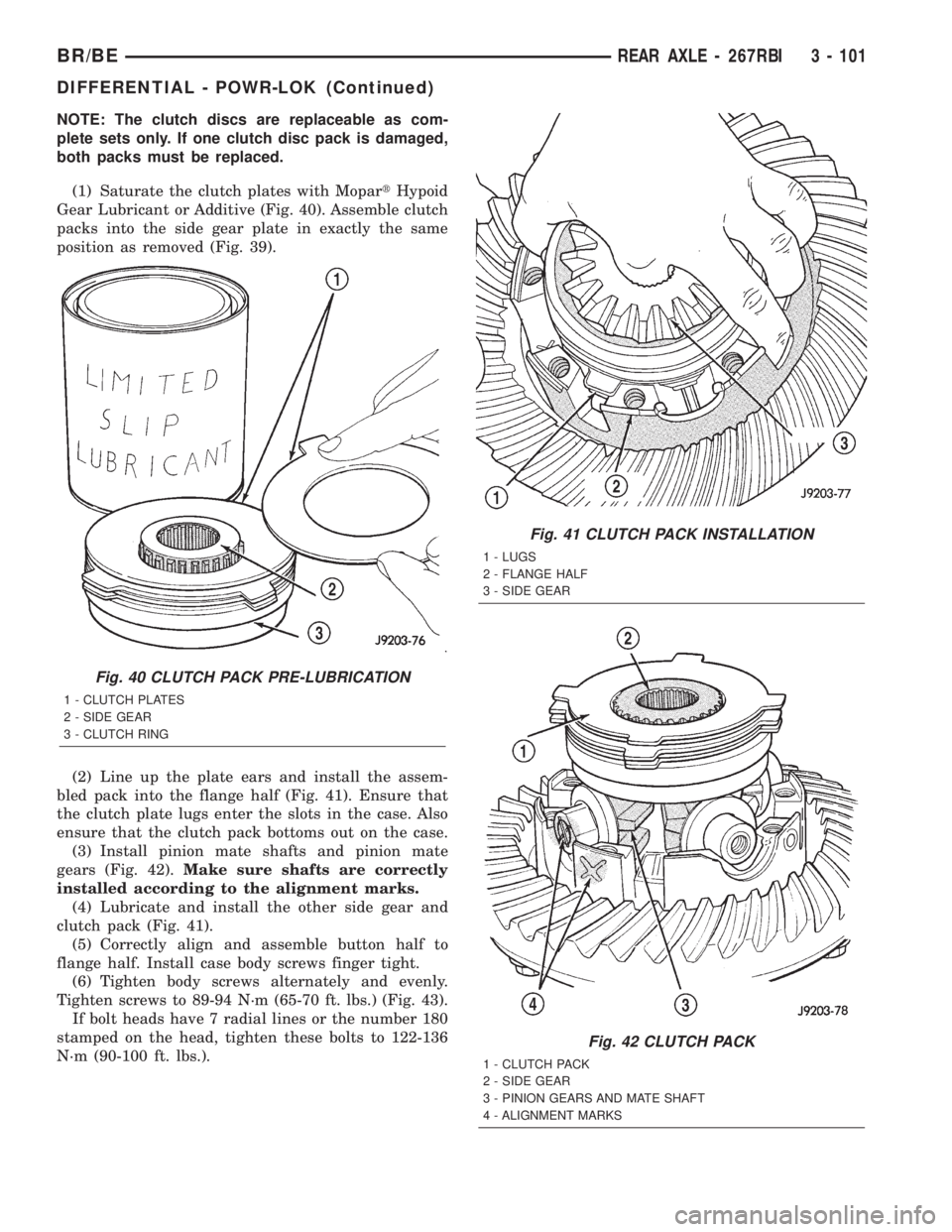

NOTE: The clutch discs are replaceable as com-

plete sets only. If one clutch disc pack is damaged,

both packs must be replaced.

(1) Saturate the clutch plates with MopartHypoid

Gear Lubricant or Additive (Fig. 40). Assemble clutch

packs into the side gear plate in exactly the same

position as removed (Fig. 39).

(2) Line up the plate ears and install the assem-

bled pack into the flange half (Fig. 41). Ensure that

the clutch plate lugs enter the slots in the case. Also

ensure that the clutch pack bottoms out on the case.

(3) Install pinion mate shafts and pinion mate

gears (Fig. 42).Make sure shafts are correctly

installed according to the alignment marks.

(4) Lubricate and install the other side gear and

clutch pack (Fig. 41).

(5) Correctly align and assemble button half to

flange half. Install case body screws finger tight.

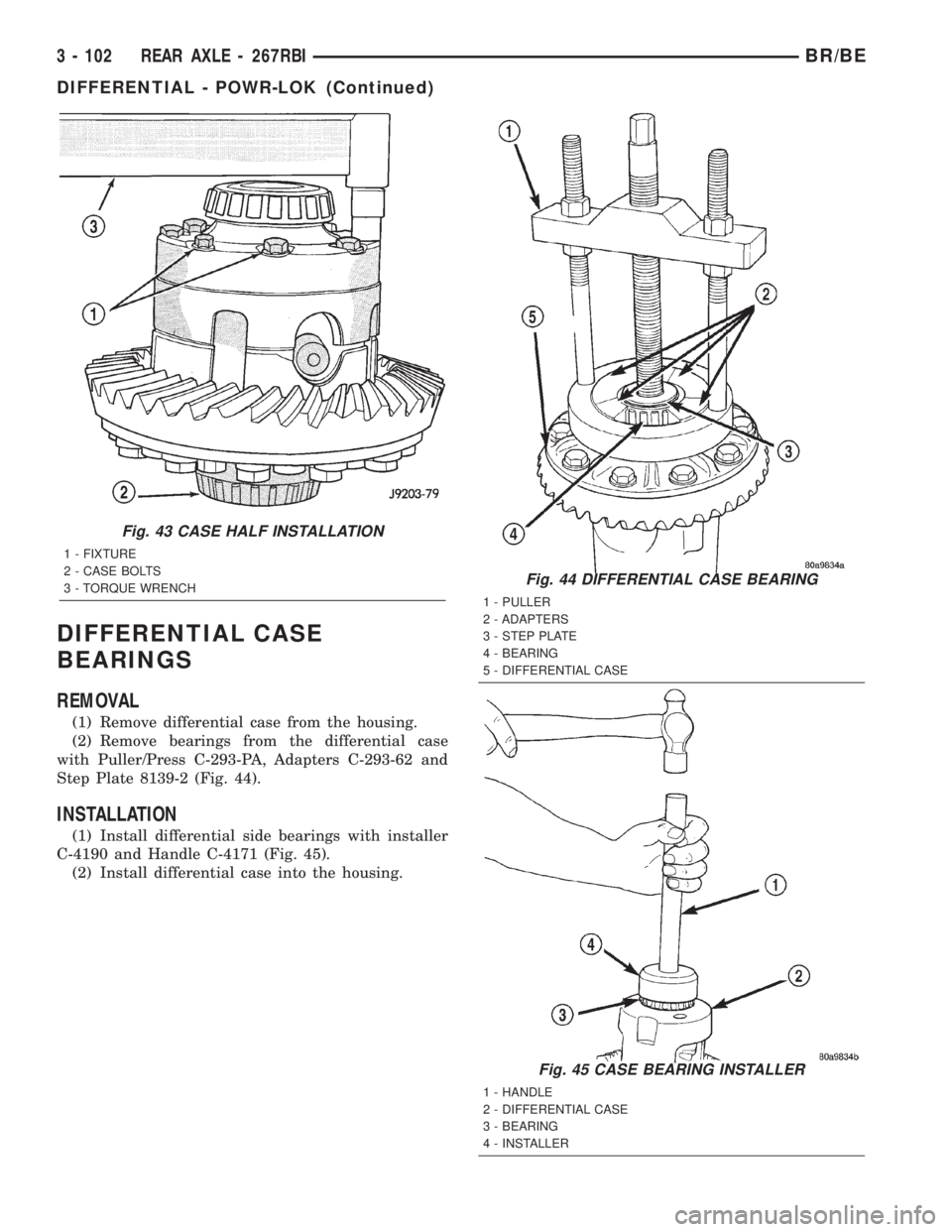

(6) Tighten body screws alternately and evenly.

Tighten screws to 89-94 N´m (65-70 ft. lbs.) (Fig. 43).

If bolt heads have 7 radial lines or the number 180

stamped on the head, tighten these bolts to 122-136

N´m (90-100 ft. lbs.).

Fig. 40 CLUTCH PACK PRE-LUBRICATION

1 - CLUTCH PLATES

2 - SIDE GEAR

3 - CLUTCH RING

Fig. 41 CLUTCH PACK INSTALLATION

1 - LUGS

2 - FLANGE HALF

3 - SIDE GEAR

Fig. 42 CLUTCH PACK

1 - CLUTCH PACK

2 - SIDE GEAR

3 - PINION GEARS AND MATE SHAFT

4 - ALIGNMENT MARKS

BR/BEREAR AXLE - 267RBI 3 - 101

DIFFERENTIAL - POWR-LOK (Continued)

Page 157 of 2255

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential case from the housing.

(2) Remove bearings from the differential case

with Puller/Press C-293-PA, Adapters C-293-62 and

Step Plate 8139-2 (Fig. 44).

INSTALLATION

(1) Install differential side bearings with installer

C-4190 and Handle C-4171 (Fig. 45).

(2) Install differential case into the housing.

Fig. 44 DIFFERENTIAL CASE BEARING

1 - PULLER

2 - ADAPTERS

3 - STEP PLATE

4 - BEARING

5 - DIFFERENTIAL CASE

Fig. 45 CASE BEARING INSTALLER

1 - HANDLE

2 - DIFFERENTIAL CASE

3 - BEARING

4 - INSTALLER

Fig. 43 CASE HALF INSTALLATION

1 - FIXTURE

2 - CASE BOLTS

3 - TORQUE WRENCH

3 - 102 REAR AXLE - 267RBIBR/BE

DIFFERENTIAL - POWR-LOK (Continued)

Page 158 of 2255

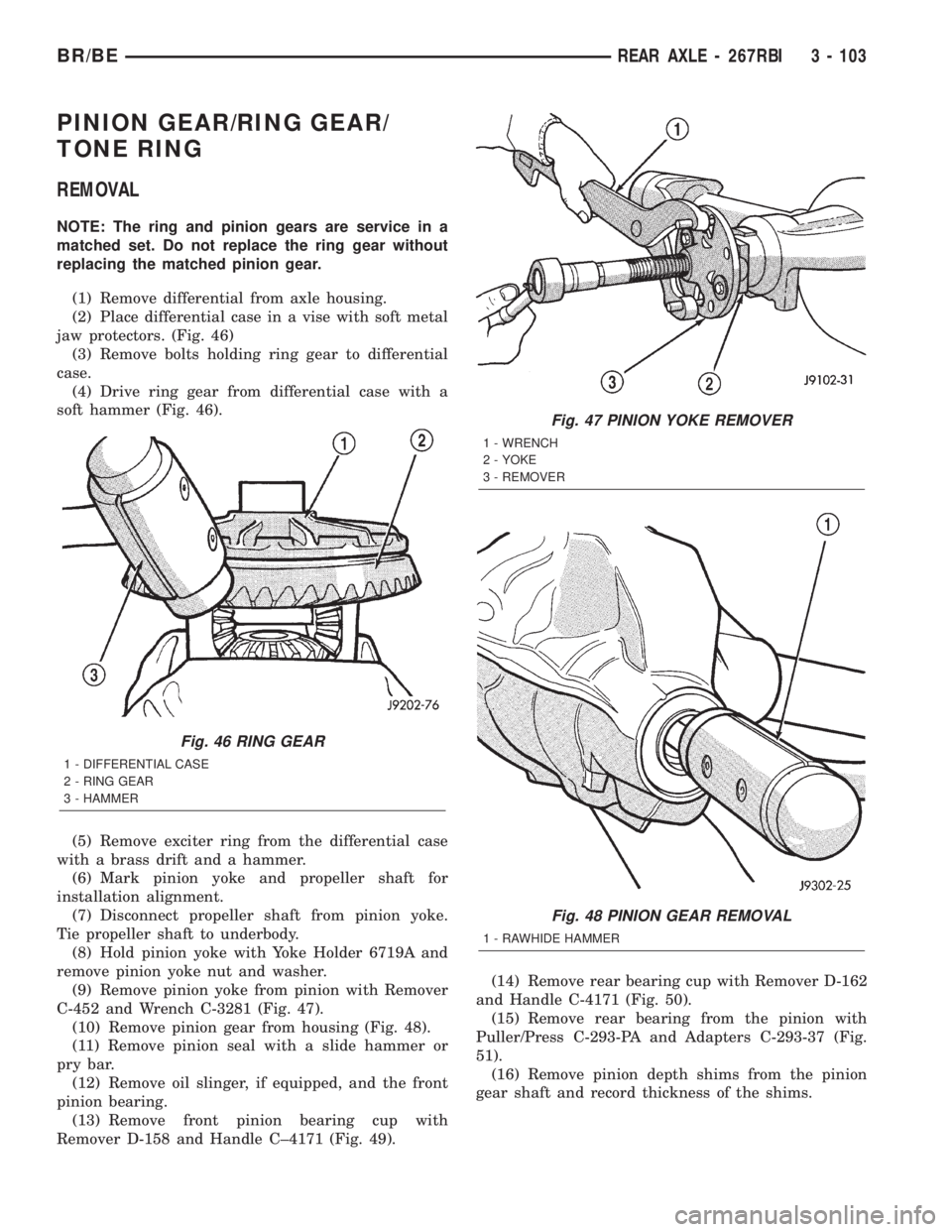

PINION GEAR/RING GEAR/

TONE RING

REMOVAL

NOTE: The ring and pinion gears are service in a

matched set. Do not replace the ring gear without

replacing the matched pinion gear.

(1) Remove differential from axle housing.

(2) Place differential case in a vise with soft metal

jaw protectors. (Fig. 46)

(3) Remove bolts holding ring gear to differential

case.

(4) Drive ring gear from differential case with a

soft hammer (Fig. 46).

(5) Remove exciter ring from the differential case

with a brass drift and a hammer.

(6) Mark pinion yoke and propeller shaft for

installation alignment.

(7) Disconnect propeller shaft from pinion yoke.

Tie propeller shaft to underbody.

(8) Hold pinion yoke with Yoke Holder 6719A and

remove pinion yoke nut and washer.

(9) Remove pinion yoke from pinion with Remover

C-452 and Wrench C-3281 (Fig. 47).

(10) Remove pinion gear from housing (Fig. 48).

(11) Remove pinion seal with a slide hammer or

pry bar.

(12) Remove oil slinger, if equipped, and the front

pinion bearing.

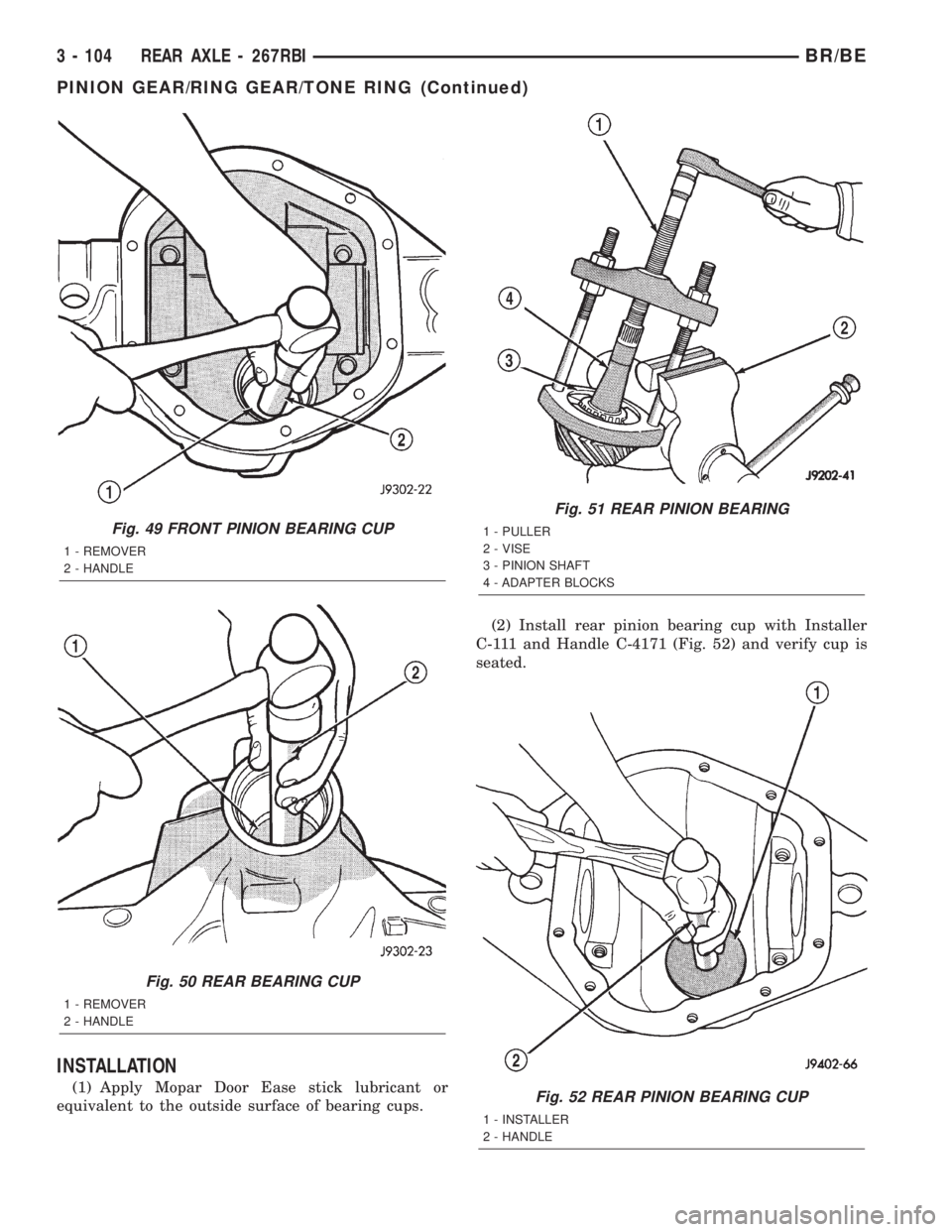

(13) Remove front pinion bearing cup with

Remover D-158 and Handle C±4171 (Fig. 49).(14) Remove rear bearing cup with Remover D-162

and Handle C-4171 (Fig. 50).

(15) Remove rear bearing from the pinion with

Puller/Press C-293-PA and Adapters C-293-37 (Fig.

51).

(16) Remove pinion depth shims from the pinion

gear shaft and record thickness of the shims.

Fig. 46 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - HAMMER

Fig. 47 PINION YOKE REMOVER

1 - WRENCH

2 - YOKE

3 - REMOVER

Fig. 48 PINION GEAR REMOVAL

1 - RAWHIDE HAMMER

BR/BEREAR AXLE - 267RBI 3 - 103

Page 159 of 2255

INSTALLATION

(1) Apply Mopar Door Ease stick lubricant or

equivalent to the outside surface of bearing cups.(2) Install rear pinion bearing cup with Installer

C-111 and Handle C-4171 (Fig. 52) and verify cup is

seated.

Fig. 49 FRONT PINION BEARING CUP

1 - REMOVER

2 - HANDLE

Fig. 50 REAR BEARING CUP

1 - REMOVER

2 - HANDLE

Fig. 51 REAR PINION BEARING

1 - PULLER

2 - VISE

3 - PINION SHAFT

4 - ADAPTER BLOCKS

Fig. 52 REAR PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

3 - 104 REAR AXLE - 267RBIBR/BE

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 160 of 2255

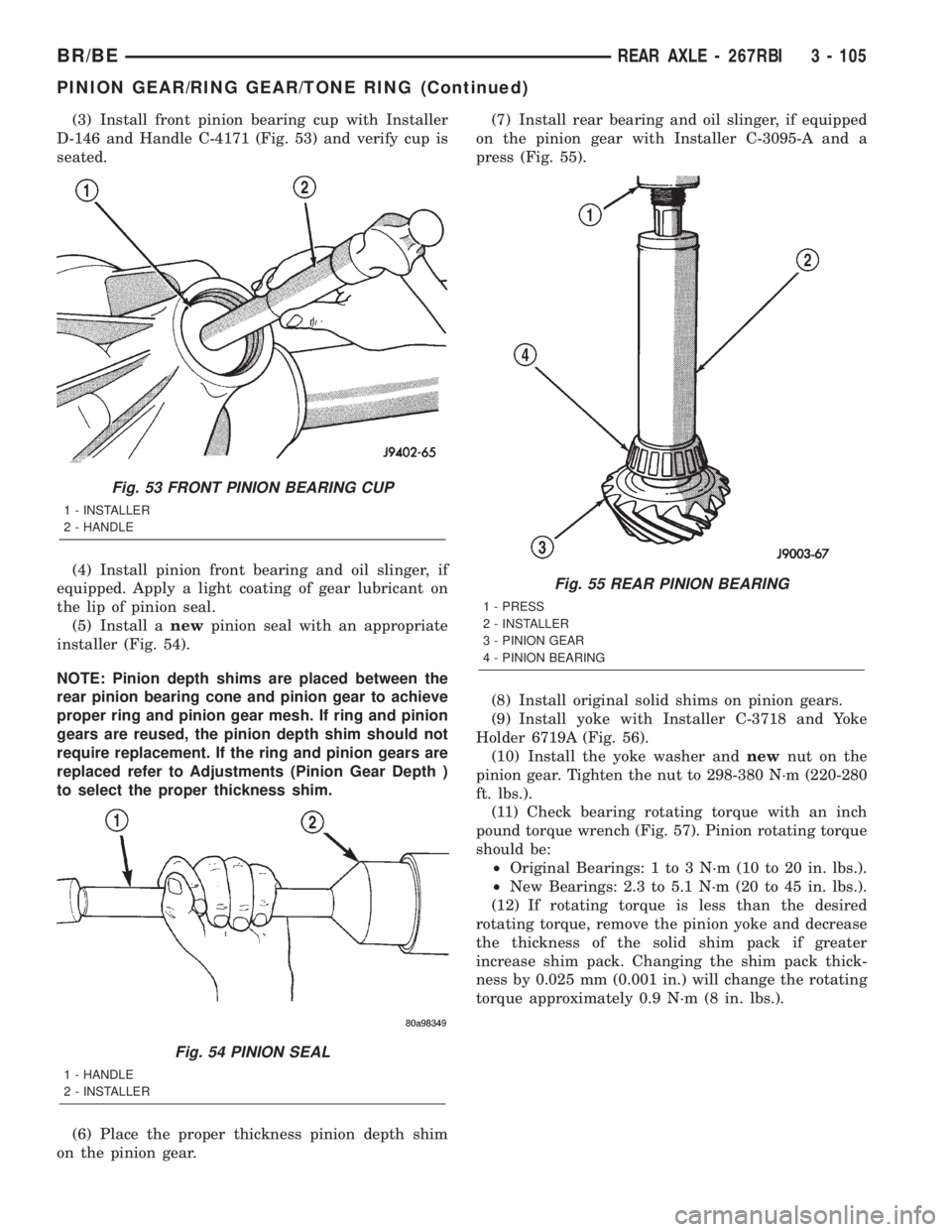

(3) Install front pinion bearing cup with Installer

D-146 and Handle C-4171 (Fig. 53) and verify cup is

seated.

(4) Install pinion front bearing and oil slinger, if

equipped. Apply a light coating of gear lubricant on

the lip of pinion seal.

(5) Install anewpinion seal with an appropriate

installer (Fig. 54).

NOTE: Pinion depth shims are placed between the

rear pinion bearing cone and pinion gear to achieve

proper ring and pinion gear mesh. If ring and pinion

gears are reused, the pinion depth shim should not

require replacement. If the ring and pinion gears are

replaced refer to Adjustments (Pinion Gear Depth )

to select the proper thickness shim.

(6) Place the proper thickness pinion depth shim

on the pinion gear.(7) Install rear bearing and oil slinger, if equipped

on the pinion gear with Installer C-3095-A and a

press (Fig. 55).

(8) Install original solid shims on pinion gears.

(9) Install yoke with Installer C-3718 and Yoke

Holder 6719A (Fig. 56).

(10) Install the yoke washer andnewnut on the

pinion gear. Tighten the nut to 298-380 N´m (220-280

ft. lbs.).

(11) Check bearing rotating torque with an inch

pound torque wrench (Fig. 57). Pinion rotating torque

should be:

²Original Bearings: 1 to 3 N´m (10 to 20 in. lbs.).

²New Bearings: 2.3 to 5.1 N´m (20 to 45 in. lbs.).

(12) If rotating torque is less than the desired

rotating torque, remove the pinion yoke and decrease

the thickness of the solid shim pack if greater

increase shim pack. Changing the shim pack thick-

ness by 0.025 mm (0.001 in.) will change the rotating

torque approximately 0.9 N´m (8 in. lbs.).

Fig. 53 FRONT PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 54 PINION SEAL

1 - HANDLE

2 - INSTALLER

Fig. 55 REAR PINION BEARING

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - PINION BEARING

BR/BEREAR AXLE - 267RBI 3 - 105

PINION GEAR/RING GEAR/TONE RING (Continued)