ECU DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 107 of 2255

Note the etched number on the face of the pinion

gear head (±1, ±2, 0, +1, +2, etc.). The numbers rep-

resent thousands of an inch deviation from the stan-

dard. If the number is negative, add that value to therequired thickness of the depth shims. If the number

is positive, subtract that value from the thickness of

the depth shim. If the number is 0 no change is nec-

essary.

PINION GEAR DEPTH VARIANCE

Original Pinion

Gear Depth

VarianceReplacement Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

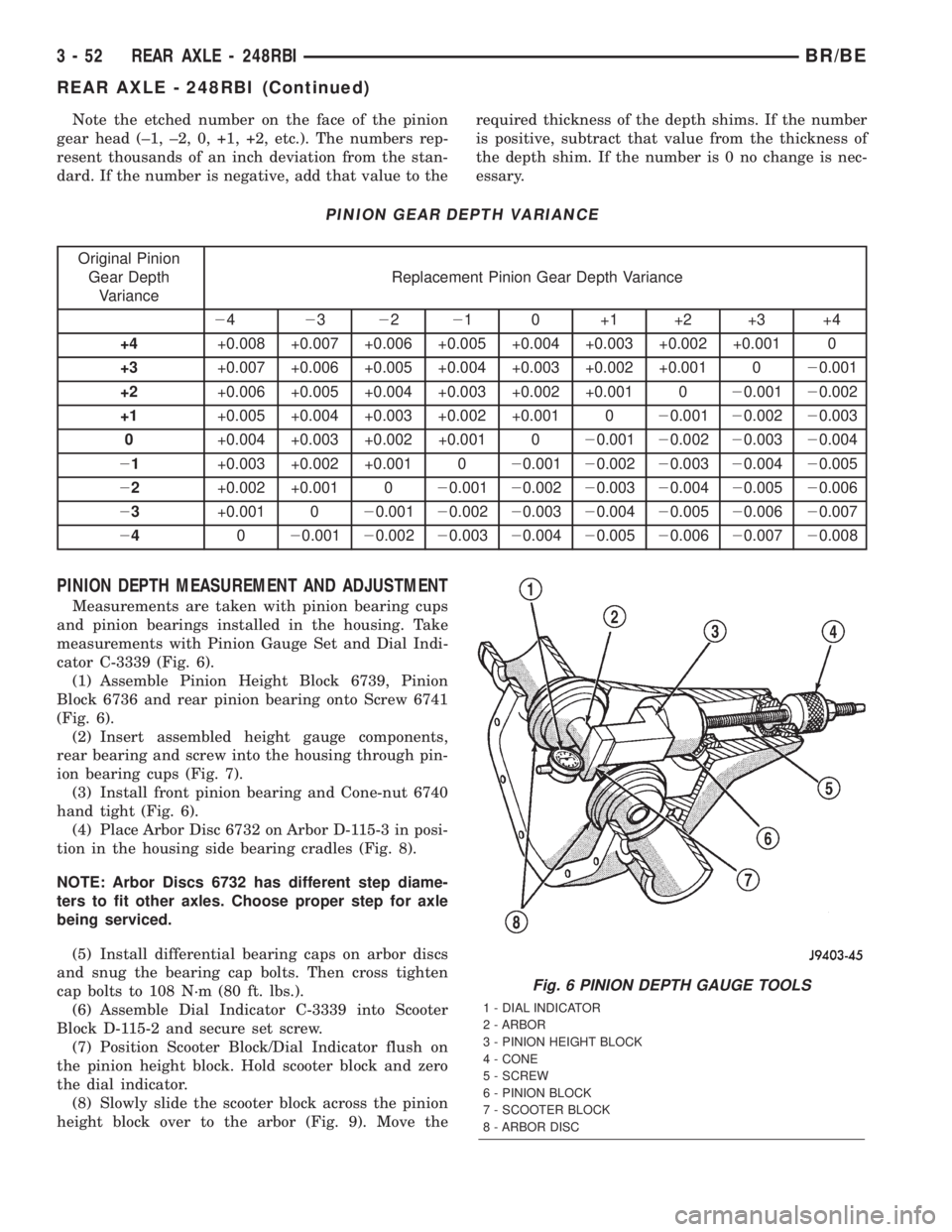

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 6).

(1) Assemble Pinion Height Block 6739, Pinion

Block 6736 and rear pinion bearing onto Screw 6741

(Fig. 6).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 7).

(3) Install front pinion bearing and Cone-nut 6740

hand tight (Fig. 6).

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 8).

NOTE: Arbor Discs 6732 has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 108 N´m (80 ft. lbs.).

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move the

Fig. 6 PINION DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

3 - 52 REAR AXLE - 248RBIBR/BE

REAR AXLE - 248RBI (Continued)

Page 125 of 2255

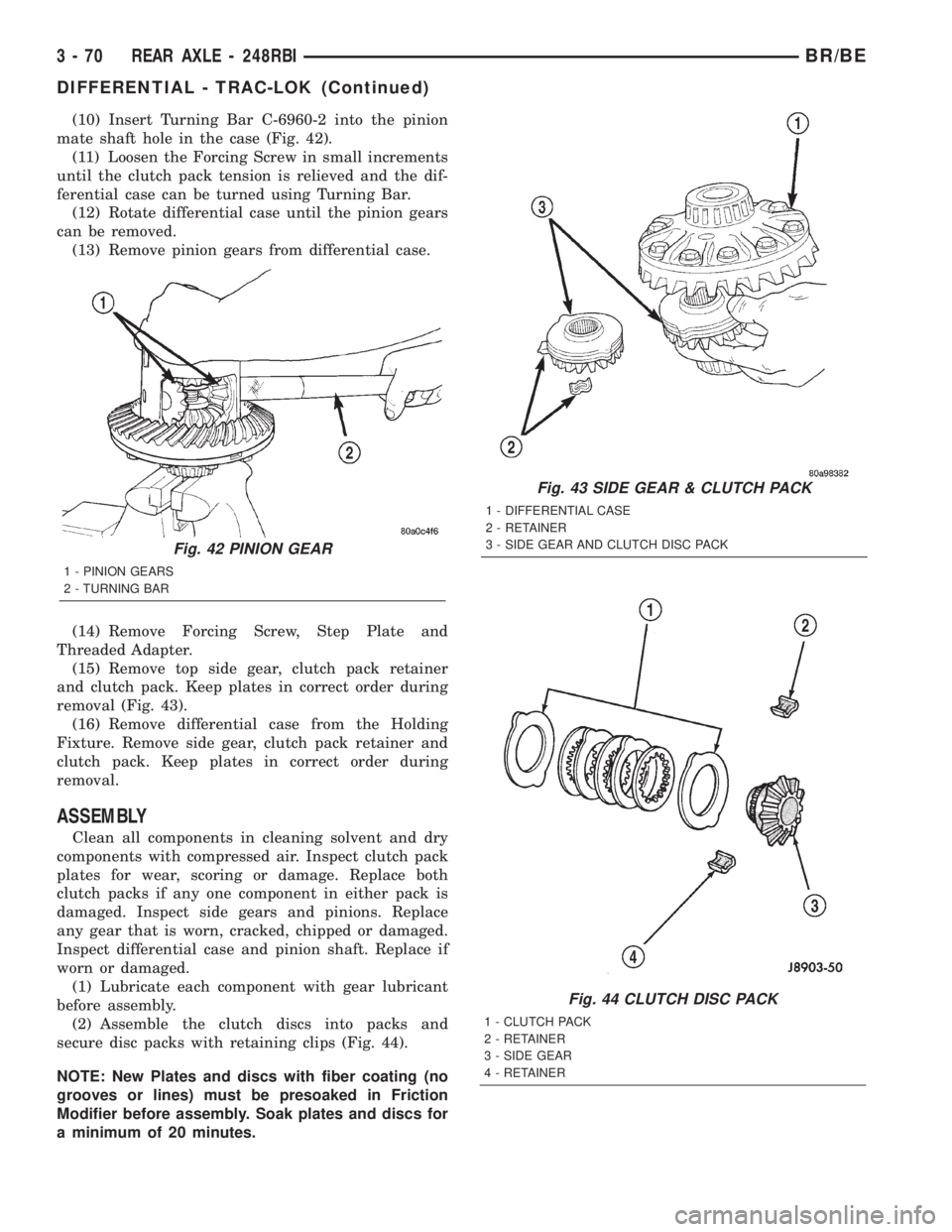

(10) Insert Turning Bar C-6960-2 into the pinion

mate shaft hole in the case (Fig. 42).

(11) Loosen the Forcing Screw in small increments

until the clutch pack tension is relieved and the dif-

ferential case can be turned using Turning Bar.

(12) Rotate differential case until the pinion gears

can be removed.

(13) Remove pinion gears from differential case.

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

(15) Remove top side gear, clutch pack retainer

and clutch pack. Keep plates in correct order during

removal (Fig. 43).

(16) Remove differential case from the Holding

Fixture. Remove side gear, clutch pack retainer and

clutch pack. Keep plates in correct order during

removal.

ASSEMBLY

Clean all components in cleaning solvent and dry

components with compressed air. Inspect clutch pack

plates for wear, scoring or damage. Replace both

clutch packs if any one component in either pack is

damaged. Inspect side gears and pinions. Replace

any gear that is worn, cracked, chipped or damaged.

Inspect differential case and pinion shaft. Replace if

worn or damaged.

(1) Lubricate each component with gear lubricant

before assembly.

(2) Assemble the clutch discs into packs and

secure disc packs with retaining clips (Fig. 44).

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.

Fig. 43 SIDE GEAR & CLUTCH PACK

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

Fig. 44 CLUTCH DISC PACK

1 - CLUTCH PACK

2 - RETAINER

3 - SIDE GEAR

4 - RETAINER

Fig. 42 PINION GEAR

1 - PINION GEARS

2 - TURNING BAR

3 - 70 REAR AXLE - 248RBIBR/BE

DIFFERENTIAL - TRAC-LOK (Continued)

Page 137 of 2255

Condition Possible Causes Correction

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct fluid

type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct fluid

type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion contact

pattern. Adjust backlash or pinion

depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched ring

gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued tot

he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position an axle lift under the axle and secure

it to the axle.

(3) Remove the wheels and tires.

(4) Remove RWAL sensor from the differential

housing, if necessary.

(5) Remove brake hose from the axle junction

block.

(6) Disconnect parking brake cables and cable

brackets.

(7) Remove vent hose from the axle shaft tube.(8) Mark propeller shaft and yoke for installation

alignment reference.

(9) Remove propeller shaft.

(10) Remove shock absorbers from the axle brack-

ets.

(11) Remove spring clamps and spring brackets.

(12) Remove axle from the vehicle.

INSTALLATION

(1) Raise axle with lift and align to the leaf spring

centering bolts.

(2) Install spring clamps and spring brackets.

3 - 82 REAR AXLE - 267RBIBR/BE

REAR AXLE - 267RBI (Continued)

Page 140 of 2255

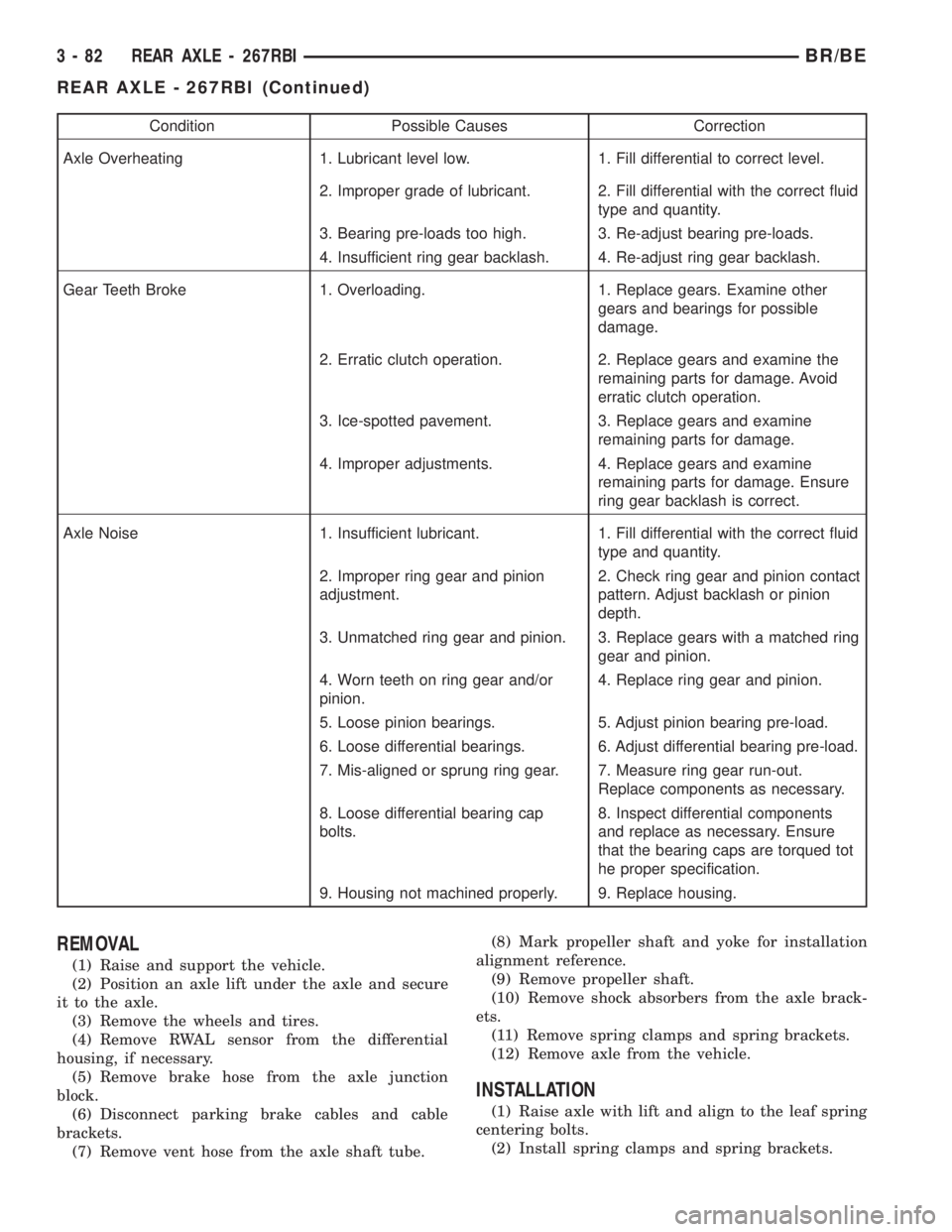

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 108 N´m (80 ft. lbs.).

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

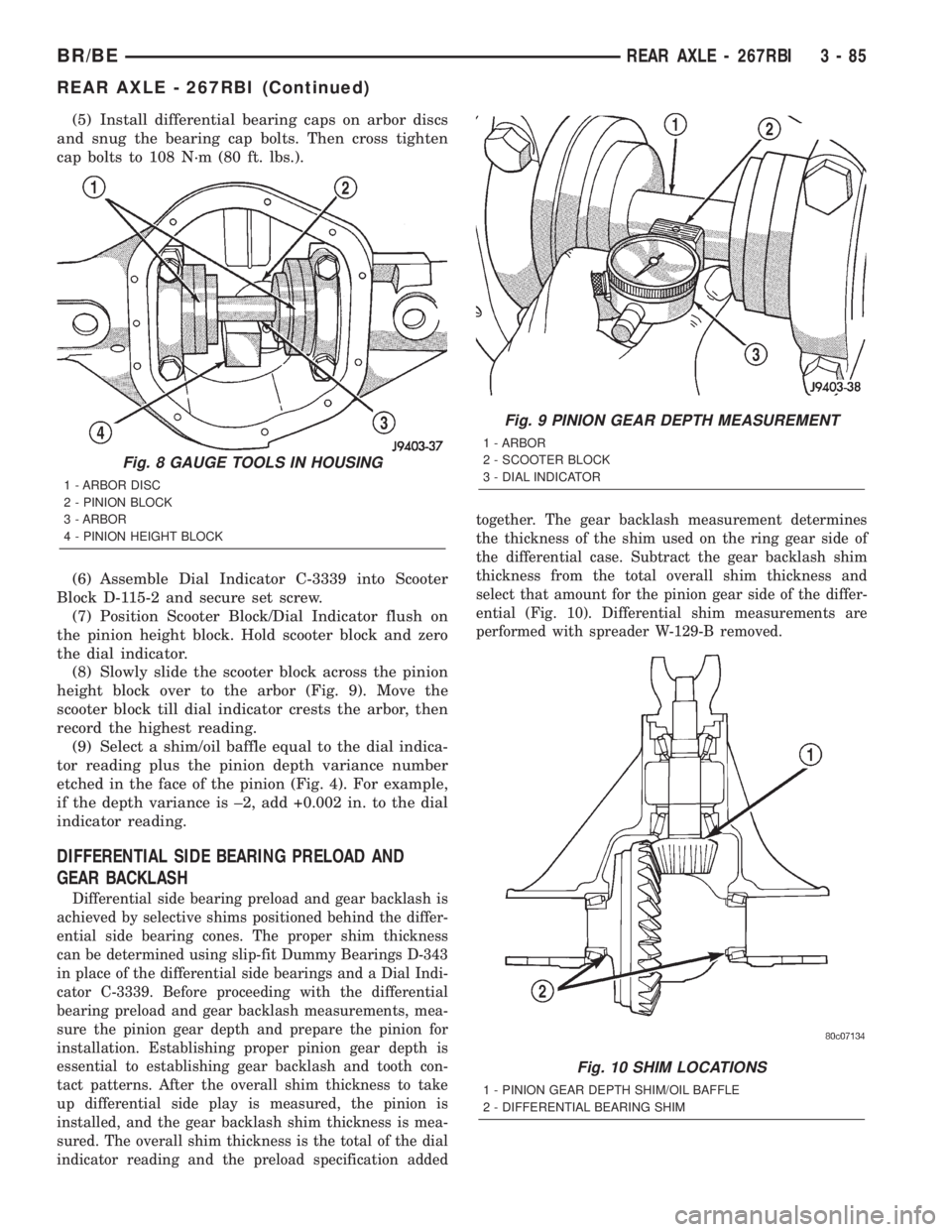

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim/oil baffle equal to the dial indica-

tor reading plus the pinion depth variance number

etched in the face of the pinion (Fig. 4). For example,

if the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

DIFFERENTIAL SIDE BEARING PRELOAD AND

GEAR BACKLASH

Differential side bearing preload and gear backlash is

achieved by selective shims positioned behind the differ-

ential side bearing cones. The proper shim thickness

can be determined using slip-fit Dummy Bearings D-343

in place of the differential side bearings and a Dial Indi-

cator C-3339. Before proceeding with the differential

bearing preload and gear backlash measurements, mea-

sure the pinion gear depth and prepare the pinion for

installation. Establishing proper pinion gear depth is

essential to establishing gear backlash and tooth con-

tact patterns. After the overall shim thickness to take

up differential side play is measured, the pinion is

installed, and the gear backlash shim thickness is mea-

sured. The overall shim thickness is the total of the dial

indicator reading and the preload specification addedtogether. The gear backlash measurement determines

the thickness of the shim used on the ring gear side of

the differential case. Subtract the gear backlash shim

thickness from the total overall shim thickness and

select that amount for the pinion gear side of the differ-

ential (Fig. 10). Differential shim measurements are

performed with spreader W-129-B removed.

Fig. 8 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 9 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 10 SHIM LOCATIONS

1 - PINION GEAR DEPTH SHIM/OIL BAFFLE

2 - DIFFERENTIAL BEARING SHIM

BR/BEREAR AXLE - 267RBI 3 - 85

REAR AXLE - 267RBI (Continued)

Page 167 of 2255

REMOVAL

(1) Raise and support the vehicle.

(2) Position a suitable lifting device under the

axle.

(3) Secure axle to device.

(4) Remove the wheels and tires.

(5) Remove the RWAL sensor from the differential

housing, if necessary.

(6) Disconnect the brake hose at the axle junction

block.

(7) Disconnect the parking brake cables and cable

brackets.

(8)

Disconnect the vent hose from the axle shaft tube.

(9) Mark the propeller shaft and companion flange

for installation alignment reference.

(10) Remove propeller shaft.

(11) Disconnect shock absorbers from axle.

(12)

Remove the spring clamps and spring brackets.

(13) Separate the axle from the vehicle.

INSTALLATION

(1) Raise the axle with lifting device and align to

the leaf spring centering bolts.

(2) Install the spring clamps and spring brackets.

(3) Install the shock absorbers.

(4) Install the RWAL sensor to the differential

housing, if necessary

(5) Install the parking brake cables and cable

brackets.

(6)

Install the brake hose to the axle junction block.

(7) Install axle vent hose.

(8) Install the propeller shaft with reference marks

aligned.

(9) Install the wheels and tires.

(10) Add gear lubricant, if necessary. Refer to

Specifications for lubricant requirements.

(11) Remove lifting device from axle and lower the

vehicle.

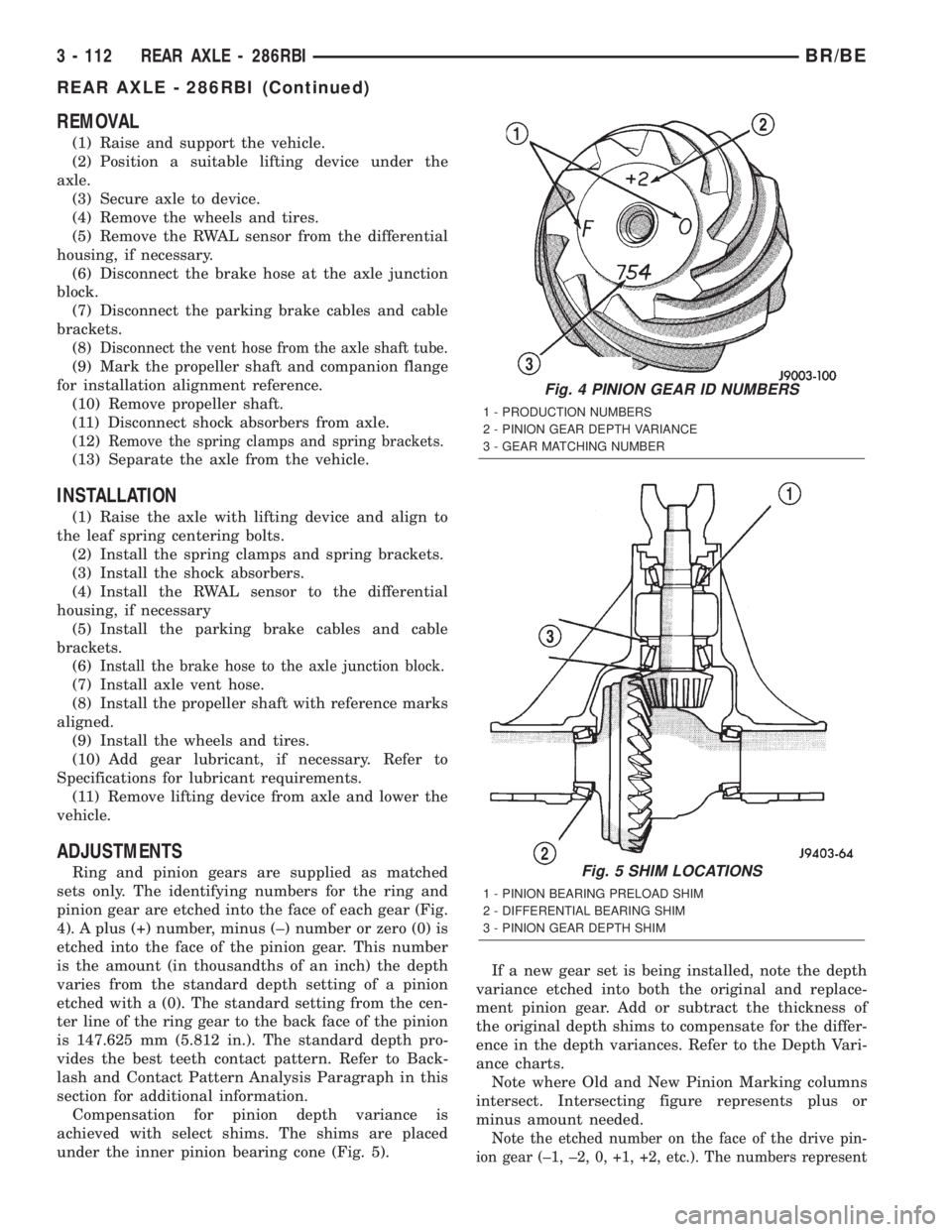

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets only. The identifying numbers for the ring and

pinion gear are etched into the face of each gear (Fig.

4). A plus (+) number, minus (±) number or zero (0) is

etched into the face of the pinion gear. This number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

etched with a (0). The standard setting from the cen-

ter line of the ring gear to the back face of the pinion

is 147.625 mm (5.812 in.). The standard depth pro-

vides the best teeth contact pattern. Refer to Back-

lash and Contact Pattern Analysis Paragraph in this

section for additional information.

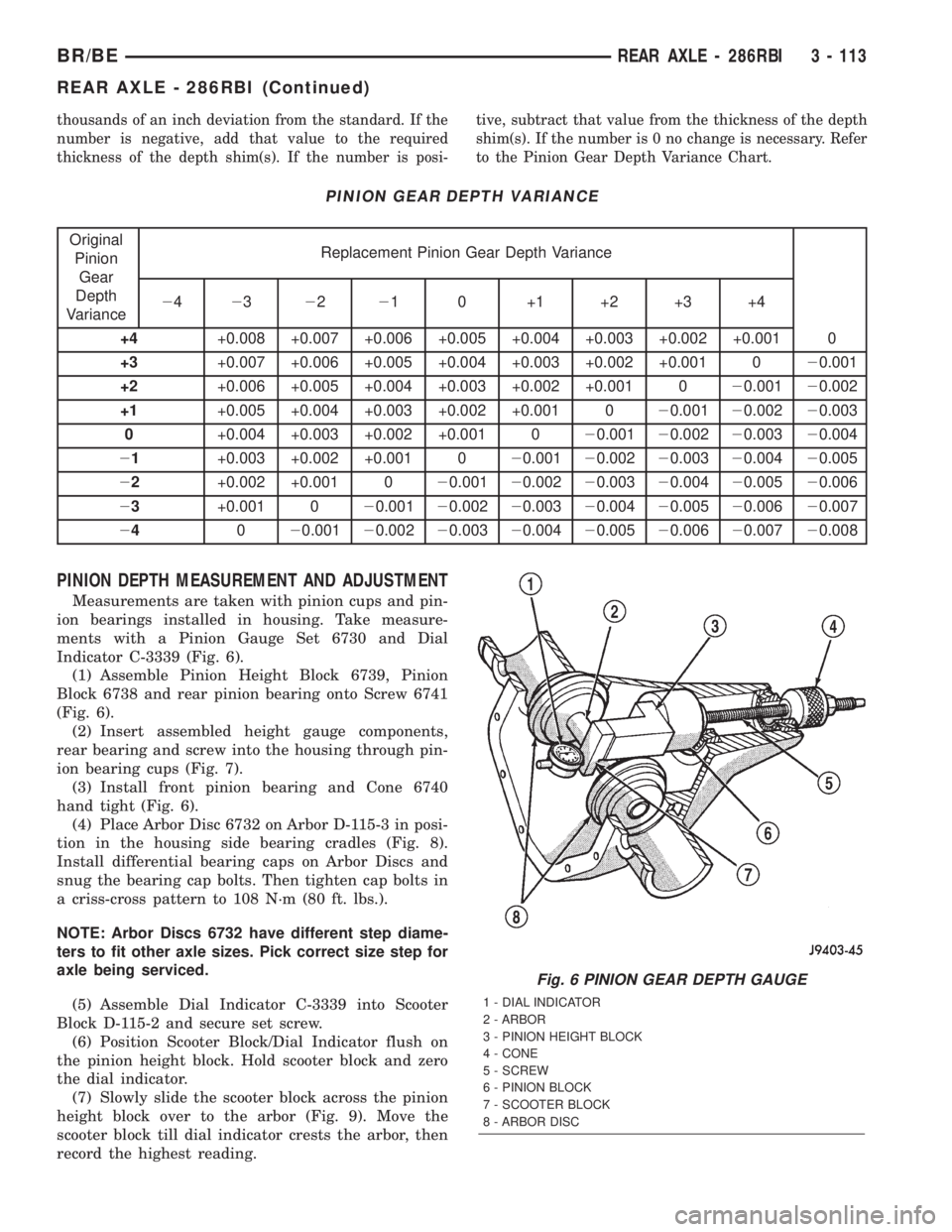

Compensation for pinion depth variance is

achieved with select shims. The shims are placed

under the inner pinion bearing cone (Fig. 5).If a new gear set is being installed, note the depth

variance etched into both the original and replace-

ment pinion gear. Add or subtract the thickness of

the original depth shims to compensate for the differ-

ence in the depth variances. Refer to the Depth Vari-

ance charts.

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or

minus amount needed.

Note the etched number on the face of the drive pin-

ion gear (±1, ±2, 0, +1, +2, etc.). The numbers represent

Fig. 4 PINION GEAR ID NUMBERS

1 - PRODUCTION NUMBERS

2 - PINION GEAR DEPTH VARIANCE

3 - GEAR MATCHING NUMBER

Fig. 5 SHIM LOCATIONS

1 - PINION BEARING PRELOAD SHIM

2 - DIFFERENTIAL BEARING SHIM

3 - PINION GEAR DEPTH SHIM

3 - 112 REAR AXLE - 286RBIBR/BE

REAR AXLE - 286RBI (Continued)

Page 168 of 2255

thousands of an inch deviation from the standard. If the

number is negative, add that value to the required

thickness of the depth shim(s). If the number is posi-tive, subtract that value from the thickness of the depth

shim(s). If the number is 0 no change is necessary. Refer

to the Pinion Gear Depth Variance Chart.

PINION GEAR DEPTH VARIANCE

Original

Pinion

Gear

Depth

VarianceReplacement Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion cups and pin-

ion bearings installed in housing. Take measure-

ments with a Pinion Gauge Set 6730 and Dial

Indicator C-3339 (Fig. 6).

(1) Assemble Pinion Height Block 6739, Pinion

Block 6738 and rear pinion bearing onto Screw 6741

(Fig. 6).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 7).

(3) Install front pinion bearing and Cone 6740

hand tight (Fig. 6).

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 8).

Install differential bearing caps on Arbor Discs and

snug the bearing cap bolts. Then tighten cap bolts in

a criss-cross pattern to 108 N´m (80 ft. lbs.).

NOTE: Arbor Discs 6732 have different step diame-

ters to fit other axle sizes. Pick correct size step for

axle being serviced.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(7) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

Fig. 6 PINION GEAR DEPTH GAUGE

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

BR/BEREAR AXLE - 286RBI 3 - 113

REAR AXLE - 286RBI (Continued)

Page 178 of 2255

AXLE SHAFTS

REMOVAL

(1) Remove the axle shaft flange bolts.

(2) Slide the axle shaft out from the axle tube.

INSTALLATION

(1) Clean the gasket contact surface area on the

flange with an appropriate solvent. Install a new

flange gasket and slide the axle shaft into the tube.

(2) Install the bolts and tighten to 129 N´m (95 ft.

lbs.).

AXLE BEARINGS

REMOVAL

(1) Remove wheel and tire assembly.

(2) Remove brake drum.

(3) Remove the axle shaft.

(4) Remove the lock wedge and adjustment nut.

Remove adjustment nut with Socket DD-1241-JD.

(5) Remove the hub assembly. The outer axle bear-

ing will slide out as the hub is being removed.

(6) Drive grease seal and inner bearing out of the

hub with Installer 5064 and Handle C-4171.

(7) Remove bearing cups from the hub with a

brass drift and a hammer.

INSTALLATION

(1) Thoroughly clean both axle bearings and inte-

rior of the hub with an appropriate cleaning solvent.

(2) Install bearing cups with Installer 8153 and

Handle C-4171.

(3) Pack inner and outer bearings with Mopar

wheel bearing grease or equivalent

(4) Apply lubricant to surface area of the bearing

cup.

(5) Install inner axle bearing in the hub.

(6) Install anewbearing grease seal with

Installer 8152 and Handle C-4171.

(7) Inspect bearing and seal contact surfaces on

the axle tube spindle for burrs and/or roughness.

Remove all the rough contact surfaces from the axle

spindle.

CAUTION: Do not let grease seal contact the axle

tube threads during installation.

(8) Carefully slide the hub onto the axle.

(9) Install outer axle bearing.

(10) Install hub bearing adjustment nut with

Socket DD-1241±JD.

(11) Tighten adjustment nut to 163-190 N´m (120-

140 ft. lbs.) while rotating the wheel.(12) Loosen adjustment nut 1/8 of-a-turn to pro-

vide 0.001-inch to 0.010-inch wheel bearing end play.

(13) Tap the locking wedge into the spindle key-

way and adjustment nut.

NOTE: Locate locking wedge in a new position in

the adjustment nut.

(14) Install axle shaft and brake drum.

(15) Install wheel and tire assembly.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the universal joint, pinion yoke, and pin-

ion shaft for installation reference.

(3) Disconnect the propeller shaft from the pinion

yoke. Secure the propeller shaft in an upright posi-

tion to prevent damage to the rear universal joint.

(4) Remove wheel and tire assemblies.

(5) Remove brake calipers to prevent any drag.

The drag may cause a false bearing preload torque

measurement.

(6) Rotate pinion yoke three or four times.

(7) Record the amount of torque necessary to

rotate the pinion gear with an inch pound dial-type

torque wrench.

(8) Hold the yoke with Holder 6719A and remove

the pinion shaft nut and washer.

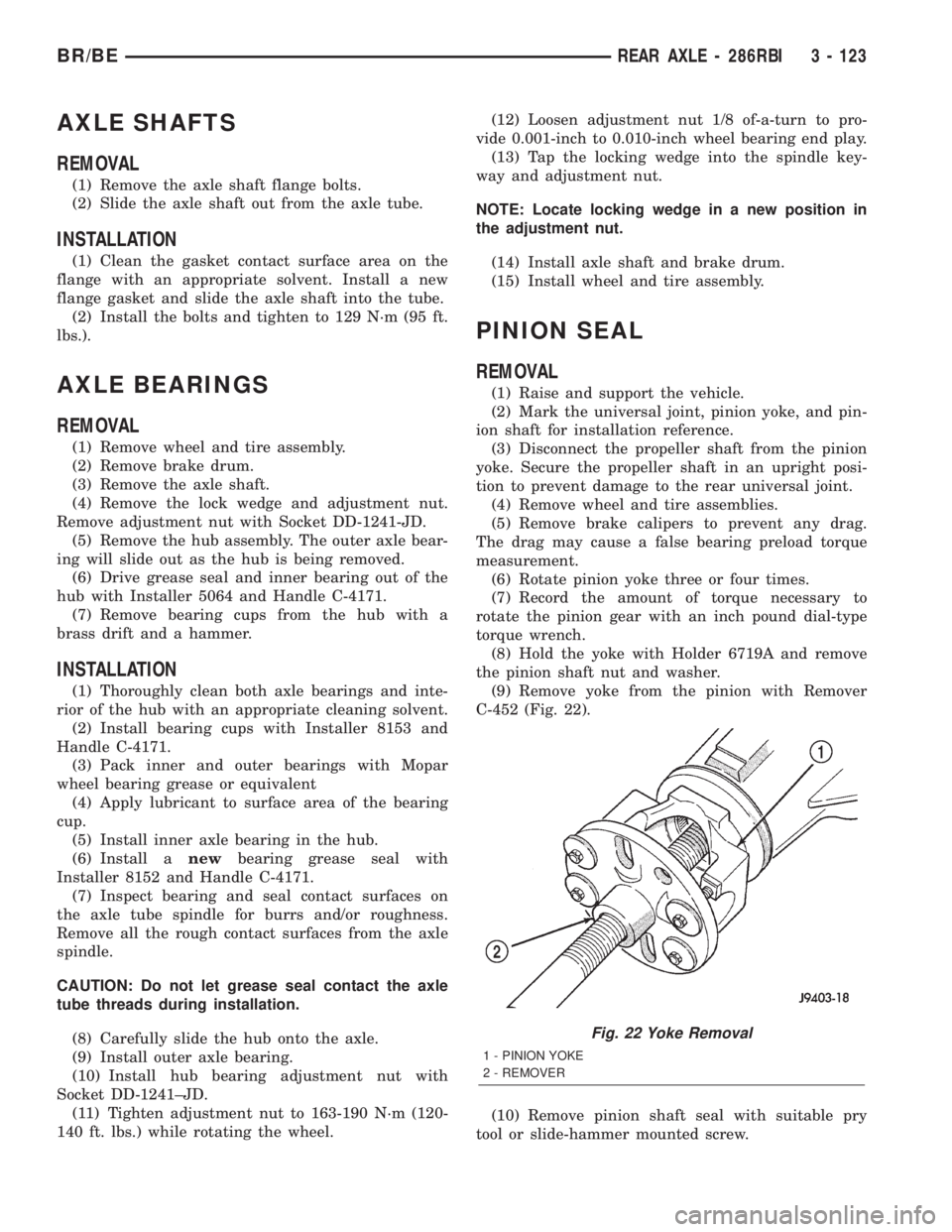

(9) Remove yoke from the pinion with Remover

C-452 (Fig. 22).

(10) Remove pinion shaft seal with suitable pry

tool or slide-hammer mounted screw.

Fig. 22 Yoke Removal

1 - PINION YOKE

2 - REMOVER

BR/BEREAR AXLE - 286RBI 3 - 123

Page 196 of 2255

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and/or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or wheel cylinders, worn seals, driv-

ing through deep water puddles, or lining that has

become covered with grease and grit during repair.

Contaminated lining should be replaced to avoid fur-

ther brake problems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation. A

tire with internal damage such as a severe bruise,

cut, or ply separation can cause pull and vibration.

BRAKE NOISES

Some brake noise is common with rear drum

brakes and on some disc brakes during the first few

stops after a vehicle has been parked overnight or

stored. This is primarily due to the formation of trace

corrosion (light rust) on metal surfaces. This light

corrosion is typically cleared from the metal surfaces

after a few brake applications causing the noise to

subside.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake shoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors and drums can become so scored that replace-

ment is necessary.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causes

of chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.THUMP/CLUNK NOISE

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. However,

calipers that bind on the slide surfaces can generate

a thump or clunk noise. In addition, worn out,

improperly adjusted, or improperly assembled rear

brake shoes can also produce a thump noise.

STANDARD PROCEDURE

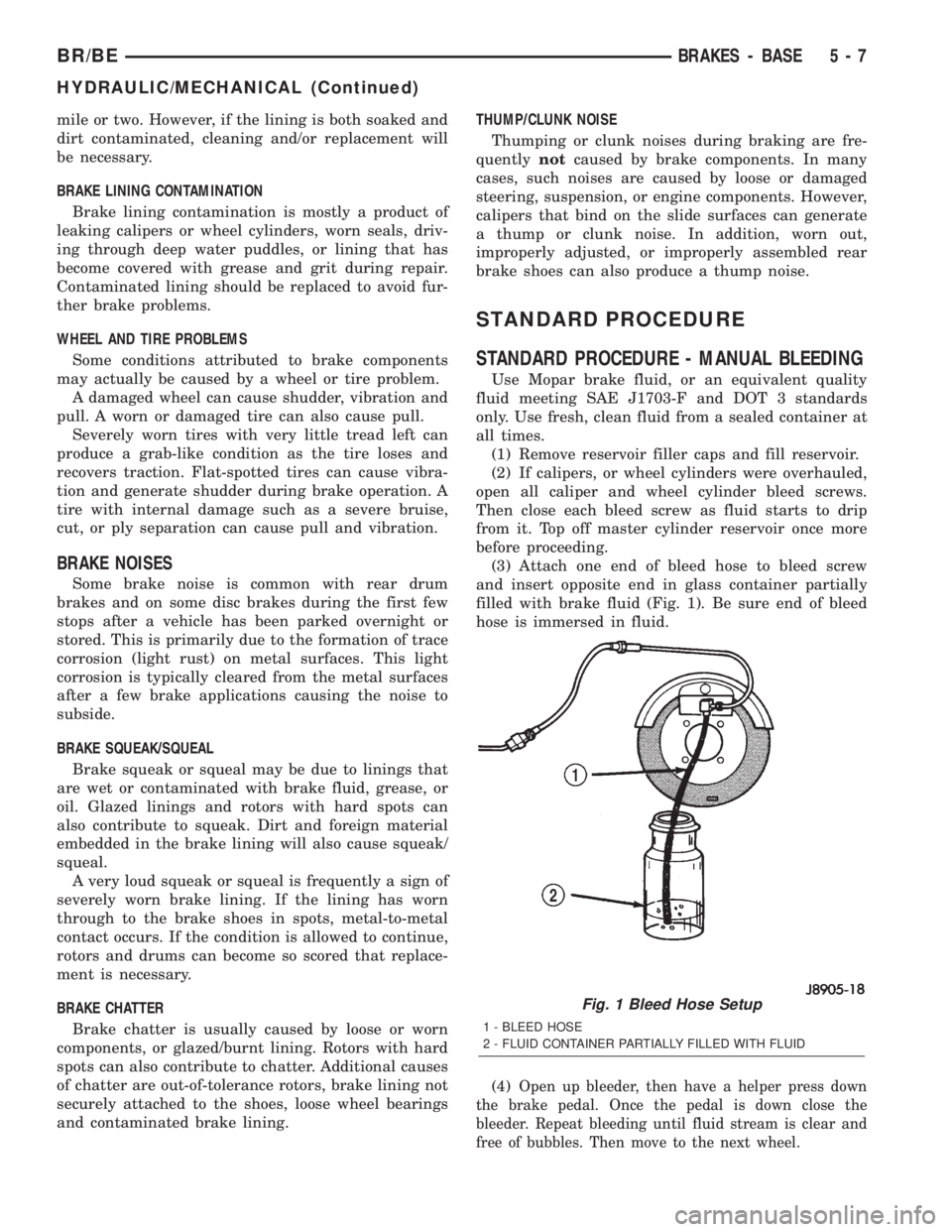

STANDARD PROCEDURE - MANUAL BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

(1) Remove reservoir filler caps and fill reservoir.

(2) If calipers, or wheel cylinders were overhauled,

open all caliper and wheel cylinder bleed screws.

Then close each bleed screw as fluid starts to drip

from it. Top off master cylinder reservoir once more

before proceeding.

(3) Attach one end of bleed hose to bleed screw

and insert opposite end in glass container partially

filled with brake fluid (Fig. 1). Be sure end of bleed

hose is immersed in fluid.

(4)

Open up bleeder, then have a helper press down

the brake pedal. Once the pedal is down close the

bleeder. Repeat bleeding until fluid stream is clear and

free of bubbles. Then move to the next wheel.

Fig. 1 Bleed Hose Setup

1 - BLEED HOSE

2 - FLUID CONTAINER PARTIALLY FILLED WITH FLUID

BR/BEBRAKES - BASE 5 - 7

HYDRAULIC/MECHANICAL (Continued)

Page 199 of 2255

(3) Connect the pressure differential switch wire

connector.

(4) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

DISC BRAKE CALIPERS

DESCRIPTION

The caliper is a one-piece casting. The piston bores

are located in the inboard side. A square-cut piston

seal is located in a machined groove in the cylinder

bore.

The caliper pistons dust boot prevents dirt, water

and road splash from entering the piston bore. The

boot is seated in a groove machined at the outer end

of the caliper piston. The boot retaining flange is

seated in a counterbore machined in the outer end of

the caliper piston bore.

Ventilated disc brake rotors are used for all appli-

cations. The rotors are serviceable and can be

machined to restore surface finish when necessary.

OPERATION

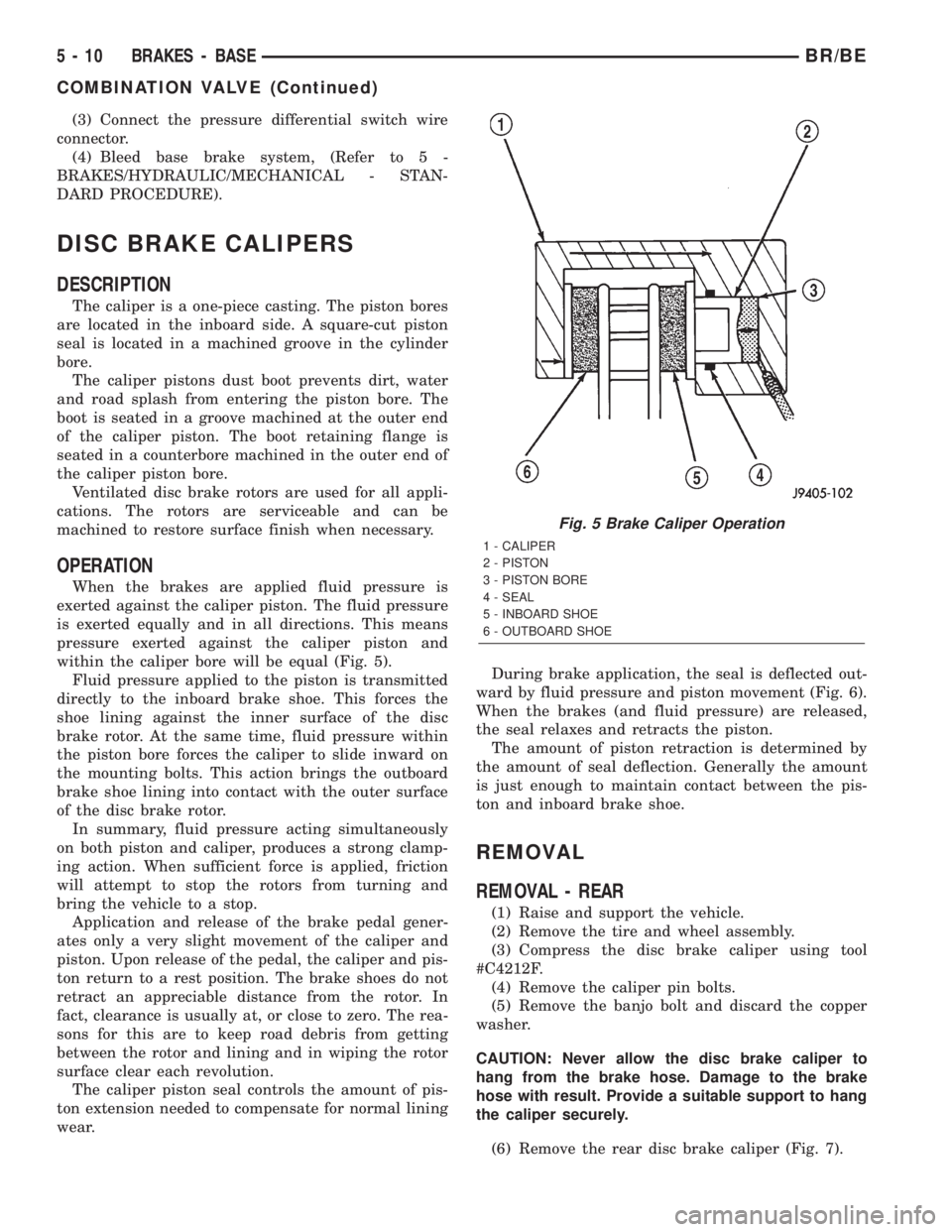

When the brakes are applied fluid pressure is

exerted against the caliper piston. The fluid pressure

is exerted equally and in all directions. This means

pressure exerted against the caliper piston and

within the caliper bore will be equal (Fig. 5).

Fluid pressure applied to the piston is transmitted

directly to the inboard brake shoe. This forces the

shoe lining against the inner surface of the disc

brake rotor. At the same time, fluid pressure within

the piston bore forces the caliper to slide inward on

the mounting bolts. This action brings the outboard

brake shoe lining into contact with the outer surface

of the disc brake rotor.

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamp-

ing action. When sufficient force is applied, friction

will attempt to stop the rotors from turning and

bring the vehicle to a stop.

Application and release of the brake pedal gener-

ates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and pis-

ton return to a rest position. The brake shoes do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The rea-

sons for this are to keep road debris from getting

between the rotor and lining and in wiping the rotor

surface clear each revolution.

The caliper piston seal controls the amount of pis-

ton extension needed to compensate for normal lining

wear.During brake application, the seal is deflected out-

ward by fluid pressure and piston movement (Fig. 6).

When the brakes (and fluid pressure) are released,

the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

the amount of seal deflection. Generally the amount

is just enough to maintain contact between the pis-

ton and inboard brake shoe.

REMOVAL

REMOVAL - REAR

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Compress the disc brake caliper using tool

#C4212F.

(4) Remove the caliper pin bolts.

(5) Remove the banjo bolt and discard the copper

washer.

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose with result. Provide a suitable support to hang

the caliper securely.

(6) Remove the rear disc brake caliper (Fig. 7).

Fig. 5 Brake Caliper Operation

1 - CALIPER

2 - PISTON

3 - PISTON BORE

4 - SEAL

5 - INBOARD SHOE

6 - OUTBOARD SHOE

5 - 10 BRAKES - BASEBR/BE

COMBINATION VALVE (Continued)

Page 206 of 2255

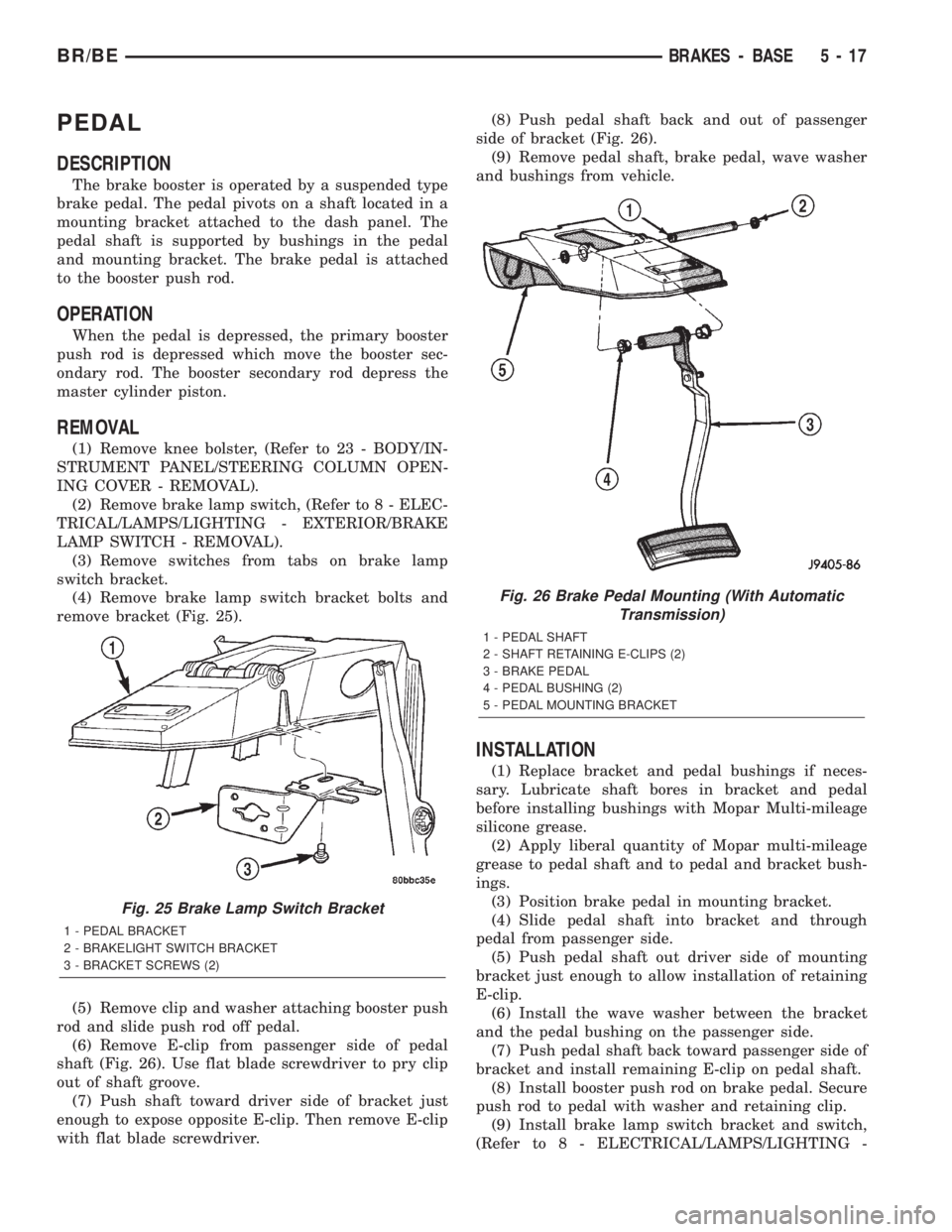

PEDAL

DESCRIPTION

The brake booster is operated by a suspended type

brake pedal. The pedal pivots on a shaft located in a

mounting bracket attached to the dash panel. The

pedal shaft is supported by bushings in the pedal

and mounting bracket. The brake pedal is attached

to the booster push rod.

OPERATION

When the pedal is depressed, the primary booster

push rod is depressed which move the booster sec-

ondary rod. The booster secondary rod depress the

master cylinder piston.

REMOVAL

(1) Remove knee bolster, (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(2) Remove brake lamp switch, (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL).

(3) Remove switches from tabs on brake lamp

switch bracket.

(4) Remove brake lamp switch bracket bolts and

remove bracket (Fig. 25).

(5) Remove clip and washer attaching booster push

rod and slide push rod off pedal.

(6) Remove E-clip from passenger side of pedal

shaft (Fig. 26). Use flat blade screwdriver to pry clip

out of shaft groove.

(7) Push shaft toward driver side of bracket just

enough to expose opposite E-clip. Then remove E-clip

with flat blade screwdriver.(8) Push pedal shaft back and out of passenger

side of bracket (Fig. 26).

(9) Remove pedal shaft, brake pedal, wave washer

and bushings from vehicle.

INSTALLATION

(1) Replace bracket and pedal bushings if neces-

sary. Lubricate shaft bores in bracket and pedal

before installing bushings with Mopar Multi-mileage

silicone grease.

(2) Apply liberal quantity of Mopar multi-mileage

grease to pedal shaft and to pedal and bracket bush-

ings.

(3) Position brake pedal in mounting bracket.

(4) Slide pedal shaft into bracket and through

pedal from passenger side.

(5) Push pedal shaft out driver side of mounting

bracket just enough to allow installation of retaining

E-clip.

(6) Install the wave washer between the bracket

and the pedal bushing on the passenger side.

(7) Push pedal shaft back toward passenger side of

bracket and install remaining E-clip on pedal shaft.

(8) Install booster push rod on brake pedal. Secure

push rod to pedal with washer and retaining clip.

(9) Install brake lamp switch bracket and switch,

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

Fig. 25 Brake Lamp Switch Bracket

1 - PEDAL BRACKET

2 - BRAKELIGHT SWITCH BRACKET

3 - BRACKET SCREWS (2)

Fig. 26 Brake Pedal Mounting (With Automatic

Transmission)

1 - PEDAL SHAFT

2 - SHAFT RETAINING E-CLIPS (2)

3 - BRAKE PEDAL

4 - PEDAL BUSHING (2)

5 - PEDAL MOUNTING BRACKET

BR/BEBRAKES - BASE 5 - 17