horn DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 546 of 2255

TURN SIGNAL CANCEL CAM

DESCRIPTION

The turn signal cancel cam is concealed within the

steering column below the steering wheel. The turn

signal cancel cam consists of two lobes that are inte-

gral to the lower surface of the clockspring rotor. The

clockspring mechanism provides turn signal cancella-

tion as well as a constant electrical connection

between the horn switch, driver airbag, speed control

switches, and remote radio switches on the steering

wheel and the instrument panel wire harness on the

steering column. The housing of the clockspring is

secured to the steering column and remains station-

ary. The rotor of the clockspring, including the turn

signal cancel cam lobes rotate with the steering

wheel.

The turn signal cancel cam is serviced as a unit

with the clockspring and cannot be repaired. If faulty

or damaged, the entire clockspring unit must be

replaced. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL).

OPERATION

The turn signal cancel cam has two lobes molded

into the lower surface of the clockspring rotor. When

the turn signals are activated by moving the multi-

function switch control stalk to a detent position, a

turn signal cancel actuator is extended from the

inside surface of the multi-function switch housing

toward the center of the steering column and the

turn signal cancel cam. When the steering wheel is

rotated during a turning maneuver, one of the two

turn signal cancel cam lobes will contact the turn sig-

nal cancel actuator. The cancel actuator latches

against the cancel cam rotation in the direction oppo-

site that which is signaled. In other words, if the left

turn signal detent is selected, the lobes of the cancel

cam will ratchet past the cancel actuator when the

steering wheel is rotated to the left, but will unlatch

the cancel actuator as the steering wheel rotates to

the right and returns to center, which will cancel the

turn signal event and release the control stalk from

the detent so it returns to the neutral Off position.

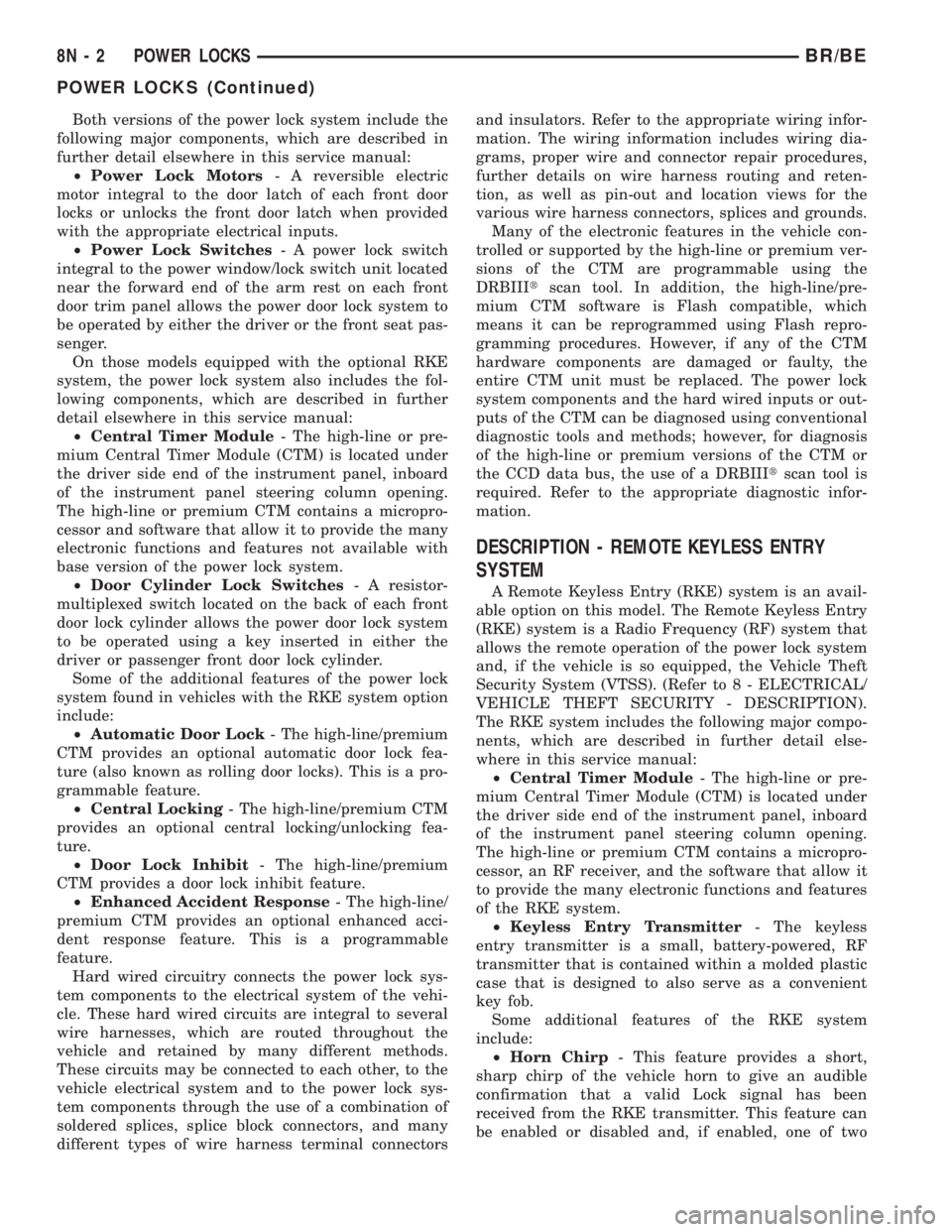

UNDERHOOD LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert a small flat blade in the access slot

between the lamp base and lamp lens.

(3) Pry the lamp lens upward and remove the

lamp lens (Fig. 31).

(4) Depress the bulb terminal inward (Fig. 32) to

release the bulb.

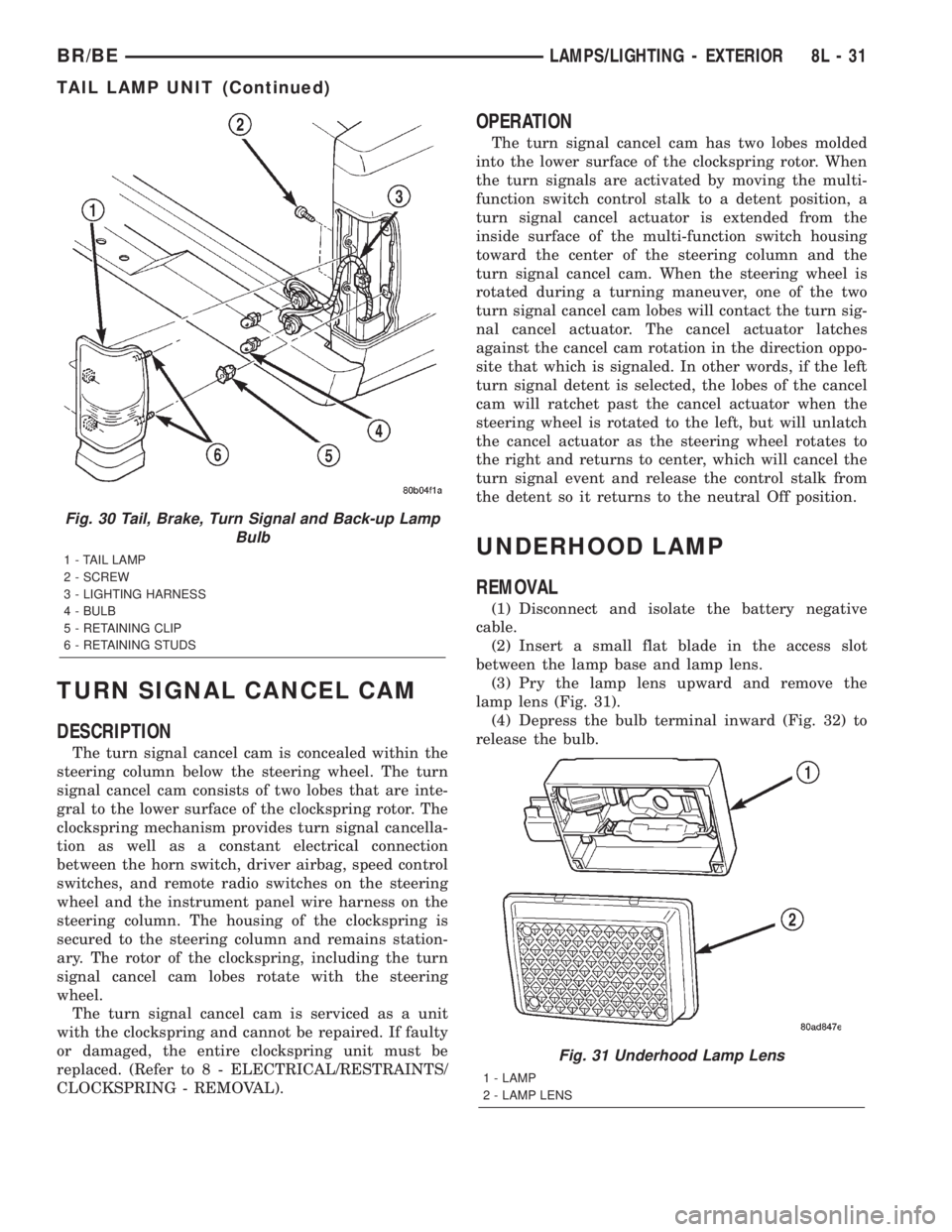

Fig. 30 Tail, Brake, Turn Signal and Back-up Lamp

Bulb

1 - TAIL LAMP

2 - SCREW

3 - LIGHTING HARNESS

4 - BULB

5 - RETAINING CLIP

6 - RETAINING STUDS

Fig. 31 Underhood Lamp Lens

1 - LAMP

2 - LAMP LENS

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 31

TAIL LAMP UNIT (Continued)

Page 569 of 2255

Both versions of the power lock system include the

following major components, which are described in

further detail elsewhere in this service manual:

²Power Lock Motors- A reversible electric

motor integral to the door latch of each front door

locks or unlocks the front door latch when provided

with the appropriate electrical inputs.

²Power Lock Switches- A power lock switch

integral to the power window/lock switch unit located

near the forward end of the arm rest on each front

door trim panel allows the power door lock system to

be operated by either the driver or the front seat pas-

senger.

On those models equipped with the optional RKE

system, the power lock system also includes the fol-

lowing components, which are described in further

detail elsewhere in this service manual:

²Central Timer Module- The high-line or pre-

mium Central Timer Module (CTM) is located under

the driver side end of the instrument panel, inboard

of the instrument panel steering column opening.

The high-line or premium CTM contains a micropro-

cessor and software that allow it to provide the many

electronic functions and features not available with

base version of the power lock system.

²Door Cylinder Lock Switches- A resistor-

multiplexed switch located on the back of each front

door lock cylinder allows the power door lock system

to be operated using a key inserted in either the

driver or passenger front door lock cylinder.

Some of the additional features of the power lock

system found in vehicles with the RKE system option

include:

²Automatic Door Lock- The high-line/premium

CTM provides an optional automatic door lock fea-

ture (also known as rolling door locks). This is a pro-

grammable feature.

²Central Locking- The high-line/premium CTM

provides an optional central locking/unlocking fea-

ture.

²Door Lock Inhibit- The high-line/premium

CTM provides a door lock inhibit feature.

²Enhanced Accident Response- The high-line/

premium CTM provides an optional enhanced acci-

dent response feature. This is a programmable

feature.

Hard wired circuitry connects the power lock sys-

tem components to the electrical system of the vehi-

cle. These hard wired circuits are integral to several

wire harnesses, which are routed throughout the

vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the power lock sys-

tem components through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectorsand insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

Many of the electronic features in the vehicle con-

trolled or supported by the high-line or premium ver-

sions of the CTM are programmable using the

DRBIIItscan tool. In addition, the high-line/pre-

mium CTM software is Flash compatible, which

means it can be reprogrammed using Flash repro-

gramming procedures. However, if any of the CTM

hardware components are damaged or faulty, the

entire CTM unit must be replaced. The power lock

system components and the hard wired inputs or out-

puts of the CTM can be diagnosed using conventional

diagnostic tools and methods; however, for diagnosis

of the high-line or premium versions of the CTM or

the CCD data bus, the use of a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

DESCRIPTION - REMOTE KEYLESS ENTRY

SYSTEM

A Remote Keyless Entry (RKE) system is an avail-

able option on this model. The Remote Keyless Entry

(RKE) system is a Radio Frequency (RF) system that

allows the remote operation of the power lock system

and, if the vehicle is so equipped, the Vehicle Theft

Security System (VTSS). (Refer to 8 - ELECTRICAL/

VEHICLE THEFT SECURITY - DESCRIPTION).

The RKE system includes the following major compo-

nents, which are described in further detail else-

where in this service manual:

²Central Timer Module- The high-line or pre-

mium Central Timer Module (CTM) is located under

the driver side end of the instrument panel, inboard

of the instrument panel steering column opening.

The high-line or premium CTM contains a micropro-

cessor, an RF receiver, and the software that allow it

to provide the many electronic functions and features

of the RKE system.

²Keyless Entry Transmitter- The keyless

entry transmitter is a small, battery-powered, RF

transmitter that is contained within a molded plastic

case that is designed to also serve as a convenient

key fob.

Some additional features of the RKE system

include:

²Horn Chirp- This feature provides a short,

sharp chirp of the vehicle horn to give an audible

confirmation that a valid Lock signal has been

received from the RKE transmitter. This feature can

be enabled or disabled and, if enabled, one of two

8N - 2 POWER LOCKSBR/BE

POWER LOCKS (Continued)

Page 570 of 2255

optional horn chirp durations (twenty or forty milli-

seconds) can also be selected.

²Illuminated Entry- This feature turns on the

courtesy lamps in the vehicle for a timed interval

(about thirty seconds) each time a valid Unlock sig-

nal has been received from the RKE transmitter.

²Panic Mode- This feature allows the vehicle

operator to cause the vehicle horn to pulse, the head-

lights to flash, and the courtesy lamps to illuminate

for about three minutes by depressing a Panic button

on the RKE transmitter. Pressing the Panic button a

second time will cancel the Panic mode. A vehicle

speed of about 24 kilometers-per-hour (15 miles-per-

hour) will also cancel the panic mode.

OPERATION

OPERATION - POWER LOCKS

All versions of the power lock system allow both

doors to be locked or unlocked electrically by operat-

ing the power lock switch on either front door trim

panel. On vehicles that are also equipped with the

optional Remote Keyless Entry (RKE) system, both

doors may also be locked or unlocked using a key in

either front door lock cylinder, or by using the RKE

transmitter. On vehicles with the RKE system, if cer-

tain features have been electronically enabled, the

locks may also be operated automatically by the

high-line or premium Central Timer Module (CTM)

based upon various other inputs. Those features and

their inputs are:

²Automatic Door Lock- If enabled, the high-

line/premium CTM will automatically lock the doors

when it receives a message from the Powertrain Con-

trol Module (PCM) indicating that the vehicle speed

is about 24 kilometers-per-hour (15 miles-per-hour)

or greater. The CTM also monitors the door ajar

switches, and will not activate the automatic door

lock feature until both doors have been closed for at

least five seconds. If this feature is enabled and a

door is opened after the vehicle is moving, the CTM

will also lock the doors five seconds after both doors

are closed.

²Central Locking- Vehicles equipped with a

high-line/premium CTM also have a resistor-multi-

plexed door cylinder lock switch mounted to the back

of the door lock cylinder within each front door. The

CTM continually monitors the input from these

switches to provide the central locking/unlocking fea-

ture. The CTM will automatically lock or unlock both

front doors when either front door is locked or

unlocked using a key.

²Door Lock Inhibit- The high-line/premium

CTM receives inputs from the key-in ignition switch,the headlamp switch, and the door ajar switches. The

logic within the CTM allows it to monitor these

inputs to provide a door lock inhibit feature. The

door lock inhibit feature prevents the power lock sys-

tem from being energized with a power lock switch

input if the driver door is open with the headlamps

on or the key still in the ignition switch. However,

the locks can still be operated with the manual door

lock button or with a key in the door lock cylinder,

and the power locks will still operate using the RKE

transmitter while the driver door is open with the

headlamps on or a key in the ignition.

²Enhanced Accident Response- If enabled,

the high-line/premium CTM provides an enhanced

accident response feature. This feature uses elec-

tronic message inputs received by the CTM from the

Airbag Control Module (ACM) to determine when an

airbag has been deployed. The CTM also monitors

the state of the power lock system and the vehicle

speed messages from the PCM in order to provide

this feature. If the airbag has been deployed and the

vehicle has stopped moving, the CTM will automati-

cally unlock the doors, prevent the doors from being

locked, and turn on the courtesy lamps inside the

vehicle. Of course, these responses are dependent

upon a functional battery and electrical circuitry fol-

lowing the impact.

All versions of the power lock system operate on

battery current received through a fused B(+) circuit

from a fuse in the Junction Block (JB) so that the

system remains functional, regardless of the ignition

switch position. Also, in both versions of the power

lock system, each power lock switch receives battery

current independent of the other. In vehicles with the

base version of the power lock system, the driver side

power lock switch receives ground through the body

wire harness. A single wire take out of the body wire

harness with an eyelet terminal connector is secured

by a ground screw to the lower left B-pillar (regular

cab, extended cab) or lower left quarter inner panel

(quad cab). The passenger side power lock switch

receives ground through the driver side power lock

switch in the base version of the power lock system.

The base version power lock switches direct the

appropriate battery current and ground feeds to the

power lock motors. In the power lock system for vehi-

cles with the RKE system, the power lock switches

direct a battery current Lock or Unlock request sig-

nal to the high-line or premium CTM, and the CTM

energizes internal relays to direct the appropriate

battery current and ground feeds to the power lock

motors.

BR/BEPOWER LOCKS 8N - 3

POWER LOCKS (Continued)

Page 571 of 2255

OPERATION - REMOTE KEYLESS ENTRY

SYSTEM

On vehicles with the Remote Keyless Entry (RKE)

system, the power locks can be operated remotely

using the RKE transmitter. If the vehicle is so

equipped, the RKE transmitter also arms and dis-

arms the factory-installed Vehicle Theft Security Sys-

tem (VTSS). Three small, recessed buttons on the

outside of the transmitter case labelled Lock, Unlock,

and Panic allow the user to choose the function that

is desired. The RKE transmitter then sends the

appropriate Radio Frequency (RF) signal. An RF

receiver that is integral to the high-line or premium

version of the Central Timer Module (CTM) receives

the transmitted signal, then uses its internal elec-

tronic programming to determine whether the

received signal is valid and what function has been

requested. If the signal is valid, the CTM provides

the programmed features.

Besides operating the power lock system and arm-

ing or disarming the VTSS, the RKE system also

controls the following features:

²Horn Chirp- If this feature is enabled, the

CTM provides a horn chirp by internally pulling the

control coil of the horn relay to ground through a

hard wired circuit output.

²Illuminated Entry- The CTM provides illumi-

nated entry by internally controlling the current flow

to the courtesy lamps in the vehicle through a hard

wired output circuit.

²Panic Mode- The CTM provides the horn pulse

and headlight flash by internally pulling the control

coils of the horn relay and headlamp relay to ground

through hard wired circuit outputs. The CTM con-

trols the current flow to the courtesy lamps in the

vehicle through a hard wired output circuit. The

CTM also monitors the vehicle speed through elec-

tronic messages it receives from the Powertrain Con-

trol Module (PCM) over the Chrysler Collision

Detection (CCD) data bus network.

The RKE system operates on battery current

received through a fused B(+) circuit from a fuse in

the Junction Block (JB) so that the system remains

functional, regardless of the ignition switch position.

The RKE system can retain the vehicle access codes

of up to four RKE transmitters. The transmitter

codes are retained in RKE system memory, even if

the battery is disconnected. If a transmitter is faulty

or is lost, new transmitter vehicle access codes can be

programmed into the system using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Many of the electronic features in the vehicle con-

trolled or supported by the high-line or premium ver-

sions of the CTM are programmable using the

DRBIIItscan tool. In addition, the high-line/pre-

mium CTM software is Flash compatible, whichmeans it can be reprogrammed using Flash repro-

gramming procedures. However, if any of the CTM

hardware components are damaged or faulty, the

entire CTM unit must be replaced. The hard wired

inputs or outputs of the CTM can be diagnosed using

conventional diagnostic tools and methods; however,

for diagnosis of the high-line or premium versions of

the CTM or the CCD data bus, the use of a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER LOCKS

The following tests provide a preliminary diagnosis

for the power lock system usedonlyon vehicles

equipped with a base version of the Central Timer

Module (CTM). These testsdo notapply to the diag-

nosis of the power lock system used on vehicles

equipped with the optional Remote Keyless Entry

(RKE) system, which includes a high-line or premium

CTM. (Refer to 8 - ELECTRICAL/POWER LOCKS -

DIAGNOSIS AND TESTING - POWER LOCK &

REMOTE KEYLESS ENTRY SYSTEM). Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

PRELIMINARY TESTS

To begin this test, note the system operation while

you actuate both the Lock and Unlock functions with

the power lock switches. Then, proceed as follows:

²If the entire power lock system fails to function

with both of the power lock switches, check the fused

B(+) fuse in the Junction Block (JB). If the fuse is

OK, check the ground circuit between the driver side

power lock switch and ground (G301). If the ground

circuit is OK, proceed to the diagnosis of the power

lock motors. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK MOTOR - DIAGNOSIS AND

TESTING).

²If the entire power lock system fails to function

with only one of the power lock switches, proceed to

diagnosis of the power lock switches. (Refer to 8 -

ELECTRICAL/POWER LOCKS/POWER LOCK

SWITCH - DIAGNOSIS AND TESTING).

²If only one power lock motor fails to operate

with both power lock switches, proceed to diagnosis

of the power lock motor. (Refer to 8 - ELECTRICAL/

POWER LOCKS/POWER LOCK MOTOR - DIAGNO-

SIS AND TESTING).

8N - 4 POWER LOCKSBR/BE

POWER LOCKS (Continued)

Page 572 of 2255

DIAGNOSIS AND TESTING - POWER LOCK &

REMOTE KEYLESS ENTRY SYSTEM

The following tests include a preliminary diagnosis

for the power lock system usedonlyon vehicles

equipped with the optional Remote Keyless Entry

(RKE) system, which includes a high-line or premium

Central Timer Module (CTM). These testsdo not

apply to the diagnosis of the power lock system on

vehicles equipped with a base version of the CTM.

(Refer to 8 - ELECTRICAL/POWER LOCKS - DIAG-

NOSIS AND TESTING - POWER LOCK SYSTEM).

These tests will help to diagnose the hard wired

components and circuits of the power lock system.

However, these tests may not prove conclusive in the

diagnosis of this system. In order to obtain conclusive

testing of the power lock and RKE system, the

Chrysler Collision Detection (CCD) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the power lock and RKE

system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the power lock and RKE system requires

the use of a DRBIIItscan tool. The DRBIIItscan

tool can provide confirmation that the CCD data bus

is functional, that all of the electronic modules are

sending and receiving the proper messages on the

CCD data bus, that the CTM is receiving the proper

hard wired inputs, and that the power lock motors

are being sent the proper hard wired outputs by the

CTM.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

PRELIMINARY TESTS

To begin this test, note the system operation while

you actuate both the Lock and Unlock functions with

the power lock switches, the door cylinder lock

switches, and the RKE transmitter. Then, proceed as

follows:

²If the entire power lock system fails to function

with the power lock switches, the door cylinder lock

switches, or the RKE transmitter, check the fused

B(+) fuse in the Junction Block (JB). If the fuse is

OK, proceed to the diagnosis of the power lock

motors. (Refer to 8 - ELECTRICAL/POWER LOCKS/

POWER LOCK MOTOR - DIAGNOSIS AND TEST-

ING).

²If the power lock system functions with both

power lock switches, and both door cylinder lock

switches, but not with the RKE transmitter, proceed

to the diagnosis of the transmitter. (Refer to 8 -

ELECTRICAL/POWER LOCKS/REMOTE KEYLESSENTRY TRANSMITTER - DIAGNOSIS AND TEST-

ING).

²If the entire power lock system functions with

the RKE transmitter, and both door cylinder lock

switches, but not with one or both of the power lock

switches, proceed to diagnosis of the power lock

switches. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK SWITCH - DIAGNOSIS AND

TESTING).

²If the entire power lock system functions with

the RKE transmitter, and both power lock switches,

but not with one or both of the door cylinder lock

switches, proceed to diagnosis of the door cylinder

lock switches. (Refer to 8 - ELECTRICAL/POWER

LOCKS/DOOR CYLINDER LOCK SWITCH - DIAG-

NOSIS AND TESTING).

²If one power lock motor fails to operate with

both of the power lock switches, both of the door cyl-

inder lock switches and/or the RKE transmitter, pro-

ceed to diagnosis of the power lock motor. (Refer to 8

- ELECTRICAL/POWER LOCKS/POWER LOCK

MOTOR - DIAGNOSIS AND TESTING).

If the problem being diagnosed is related to one or

more of the electronic features (automatic locks, door

lock inhibit, enhanced accident response, illuminated

entry, panic mode, or RKE horn chirp), further diag-

nosis should be performed using a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

A door cylinder lock switch is snapped onto the

back of the key lock cylinder inside each front door of

vehicles equipped with a high-line or premium Cen-

tral Timer Module (CTM). The door cylinder lock

switch is a resistor multiplexed momentary switch

that is hard wired in series between a body ground

and the CTM through the front door wire harness.

The door cylinder lock switches are driven by the key

lock cylinders and contain three internal resistors.

One resistor is used for the neutral switch position,

one for the Lock position, and one for the Unlock

position.

The door cylinder lock switches cannot be adjusted

or repaired and, if faulty or damaged, they must be

replaced.

OPERATION

The door cylinder lock switches are actuated by the

key lock cylinder when the key is inserted in the lock

cylinder and turned to the lock or unlock positions.

The door cylinder lock switch closes a path to ground

through one of three internal resistors for the Cen-

BR/BEPOWER LOCKS 8N - 5

POWER LOCKS (Continued)

Page 603 of 2255

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the child tether anchor (standard cab)

or child tether (club/quad cab) onto the cab back

panel (Fig. 7).

(2) Install and tighten the screw that secures the

child tether anchor (standard cab) or child tether

(club/quad cab) onto the cab back panel. Tighten the

screw to 13.5 N´m (120 in. lbs.).

(3) Reinstall the trim onto the inside of the cab

back panel. (Refer to 23 - BODY/INTERIOR/REAR

CLOSURE PANEL TRIM - INSTALLATION).

CLOCKSPRING

DESCRIPTION

The clockspring assembly is secured with two inte-

gral plastic latches onto the steering column lock

housing near the top of the steering column, behind

the steering wheel. The clockspring consists of a flat,

round molded plastic case with a stubby tail that

hangs below the steering column and contains a con-

nector receptacle and a long pigtail wire with connec-

tor that face toward the instrument panel. Within

the plastic housing is a spool-like molded plastic

rotor with a large exposed hub. The upper surface of

the rotor hub has a large center hole, two large flats,

two auto-locking tabs, and three short pigtail wires

with connectors that face toward the steering wheel.

The lower surface of the rotor hub has two integral

turn signal cancelling cam lobes. Within the plastic

case and wound around the rotor spool is a long rib-

bon-like tape that consists of several thin copper wire

leads sandwiched between two thin plastic mem-

branes. The outer end of the tape terminates at the

connector receptacle and pigtail wire that face the

instrument panel, while the inner end of the tape

terminates at the pigtail wires on the hub of the

clockspring rotor that face the steering wheel.

Service replacement clocksprings are shipped pre-

centered and with a piece of tape covering theengaged auto-locking tabs. The auto-locking tabs

secure the centered clockspring rotor to the clock-

spring case during shipment, but these tabs are auto-

matically disengaged once the clockspring is installed

on the steering column. (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - STANDARD PRO-

CEDURE - CLOCKSPRING CENTERING).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mounted

on or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,

and the remote radio switches if the vehicle is so

equipped. The clockspring case is positioned and

secured to the upper steering column lock housing by

two integral plastic latches. The connector receptacle

on the tail of the fixed clockspring housing connect

the clockspring to the vehicle electrical system

through a take out with connector from the instru-

ment panel wire harness. The lower clockspring pig-

tail on the tail of the clockspring housing connect the

clockspring driver airbag circuits to a separate take

out and connector of the instrument panel wire har-

ness located near the lower instrument panel rein-

forcement, below the steering column. The

clockspring rotor is movable and is keyed to the hub

of the steering wheel by two large flats that are

molded into the rotor hub. The two lobes on the

lower surface of the clockspring rotor hub contact a

turn signal cancel actuator of the multi-function

switch to provide automatic turn signal cancellation.

The pigtail wires on the upper surface of the clock-

spring connect the clockspring to the horn switch, the

two speed control switches, and the remote radio

switches on vehicles that are so equipped.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring must be centered when it is installed on

the steering column. Centering the clockspring

indexes the clockspring spool to the movable steering

components so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components and must be re-cen-

tered following completion of the service or the tape

8O - 10 RESTRAINTSBR/BE

CHILD TETHER (Continued)

Page 604 of 2255

may be damaged. Service replacement clocksprings

are shipped pre-centered and with the auto-locking

tabs engaged. A piece of tape covers the auto-locking

tabs to discourage tampering. These auto-locking

tabs should not be disengaged until the clockspring

has been installed on the steering column. If this

shipping tape is removed or damaged, or if the auto-

locking tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING).

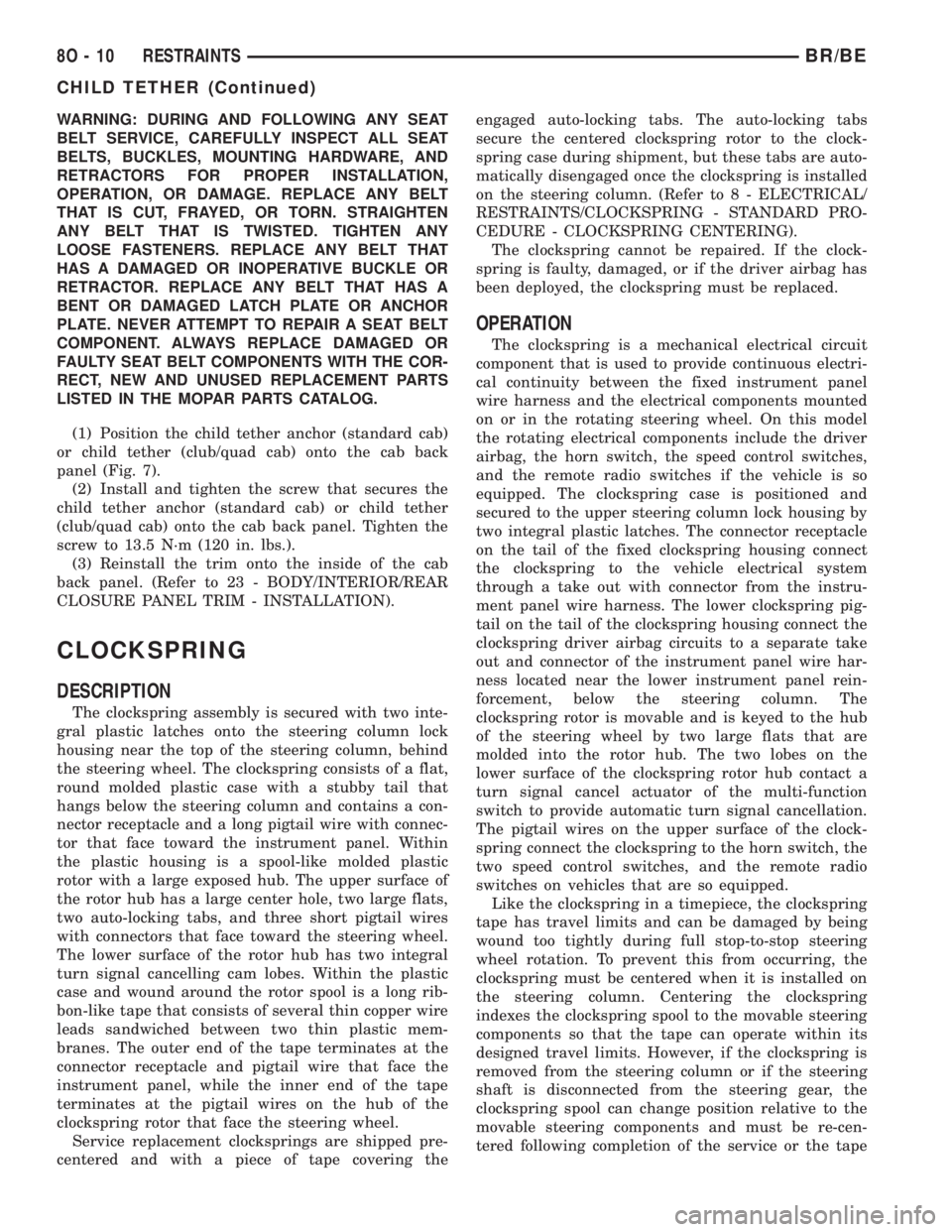

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

from the centered position, without damaging the

clockspring tape.

However, if the clockspring is removed for service

or if the steering column is disconnected from the

steering gear, the clockspring tape can change posi-

tion relative to the other steering components. The

clockspring must then be re-centered following com-

pletion of such service or the clockspring tape may be

damaged. Service replacement clocksprings are

shipped pre-centered and with the auto-locking tabs

engaged (raised). These auto-locking tabs should not

be disengaged until the clockspring has been

installed on the steering column. If the auto-locking

tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the clockspring from the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL).

(3) Depress the two plastic clockspring auto-lock-

ing tabs (Fig. 8).

(4) Keeping the auto-locking tabs depressed, rotate

the clockspring rotor clockwise to the end of its

travel.Do not apply excessive torque.

(5) From the end of the clockwise travel, rotate the

rotor about two and one-half turns counterclockwise,

then release the auto-locking tabs. The clockspring

pigtail wire for the horn switch should end up at the

top, and the pigtail wires for the airbag, optional

speed control switches, and optional remote radio

switches at the bottom. The clockspring is now cen-

tered.

(6) The front wheels should still be in the straight-

ahead position. Reinstall the clockspring onto the

steering column. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - INSTALLATION).

Fig. 8 Clockspring Auto-Locking Tabs

1 - AIRBAG MODULE WIRE

2 - SPEED CONTROL WIRING

3 - HORN WIRE

4 - CLOCKSPRING ASSEMBLY

5 - AUTO-LOCKING TABS

BR/BERESTRAINTS 8O - 11

CLOCKSPRING (Continued)

Page 607 of 2255

DRIVER AIRBAG

DESCRIPTION

The driver airbag protective trim cover is the most

visible part of the driver airbag. The airbag used in

this model is a Next Generation-type that complies

with revised federal airbag standards to deploy with

less force than those used in some prior models. The

driver airbag is located in the center of the steering

wheel, where it is secured with two screws to the

steering wheel armature. Concealed beneath the

driver airbag trim cover are the horn switch, the

folded airbag cushion, the airbag retainer or housing,

the airbag inflator, and the retainers that secure the

trim cover to the airbag housing. The resistive mem-

brane-type horn switch is secured with heat stakes to

the inside surface of the airbag trim cover, between

the trim cover and the folded airbag cushion. The air-

bag inflator is a conventional pyrotechnic-type unit

that is secured with nuts to four studs on the back of

the stamped metal airbag housing.

The driver airbag trim cover has locking blocks

molded into the back side of it that engage a lip

formed around the perimeter of the airbag housing.

Two stamped metal retainers then fit over the infla-

tor mounting studs on the back of the airbag housing

and tabs on the retainer are engaged in slots on the

inside of the trim cover, securely locking the cover

into place. One horn switch pigtail wire has an eyelet

terminal connector that is captured on the upper left

inflator mounting stud between the inflator and the

upper trim cover retainer. The connector insulator of

the other horn switch pigtail wire is routed between

the upper right inflator mounting stud and the infla-

tor, where it is captured by a small plastic retainer

that is pushed onto the stud. The driver airbag can-

not be repaired, and must be replaced if deployed or

in any way damaged. The driver airbag trim cover

and horn switch are available as a unit, and may be

disassembled from the driver airbag for service

replacement.

OPERATION

The driver airbag is deployed by an electrical sig-

nal generated by the Airbag Control Module (ACM)

through the driver airbag line 1 and line 2 (or squib)

circuits. When the ACM sends the proper electrical

signal to the airbag inflator, the electrical energy

generates enough heat to initiate a small pyrotechnic

charge which, in turn, ignites chemical pellets within

the inflator. Once ignited, these chemical pellets burn

rapidly and produce a large quantity of nitrogen gas.

The inflator is sealed to the back of the airbag hous-

ing and a diffuser in the inflator directs all of the

nitrogen gas into the airbag cushion, causing the

cushion to inflate. As the cushion inflates, the driverairbag trim cover will split at predetermined break-

out lines, then fold back out of the way along with

the horn switch. Following an airbag deployment, the

airbag cushion quickly deflates by venting the nitro-

gen gas towards the instrument panel through the

porous fabric material used on the steering wheel

side of the airbag cushion.

Some of the chemicals used to create the nitrogen

gas are considered hazardous in their solid state,

before they are burned, but they are securely sealed

within the airbag inflator. However, the nitrogen gas

that is produced when the chemicals are burned is

harmless. A small amount of residue from the burned

chemicals may cause some temporary discomfort if it

contacts the skin, eyes, or breathing passages. If skin

or eye irritation is noticed, rinse the affected area

with plenty of cool, clean water. If breathing pas-

sages are irritated, move to another area where there

is plenty of clean, fresh air to breath. If the irritation

is not alleviated by these actions, contact a physician.

REMOVAL

The following procedure is for replacement of a

faulty or damaged driver airbag. If the driver airbag

has been deployed, the clockspring and the steering

column assembly must also be replaced. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

REMOVAL) (Refer to 19 - STEERING/COLUMN -

REMOVAL).

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

WARNING: WHEN REMOVING A DEPLOYED AIR-

BAG, RUBBER GLOVES, EYE PROTECTION, AND A

LONG-SLEEVED SHIRT SHOULD BE WORN. THERE

MAY BE DEPOSITS ON THE AIRBAG CUSHION AND

OTHER INTERIOR SURFACES. IN LARGE DOSES,

THESE DEPOSITS MAY CAUSE IRRITATION TO THE

SKIN AND EYES.

(1) Disconnect and isolate the battery negative

cable. If either of the airbags has not been deployed,

wait two minutes for the system capacitor to dis-

charge before further service.

8O - 14 RESTRAINTSBR/BE

Page 608 of 2255

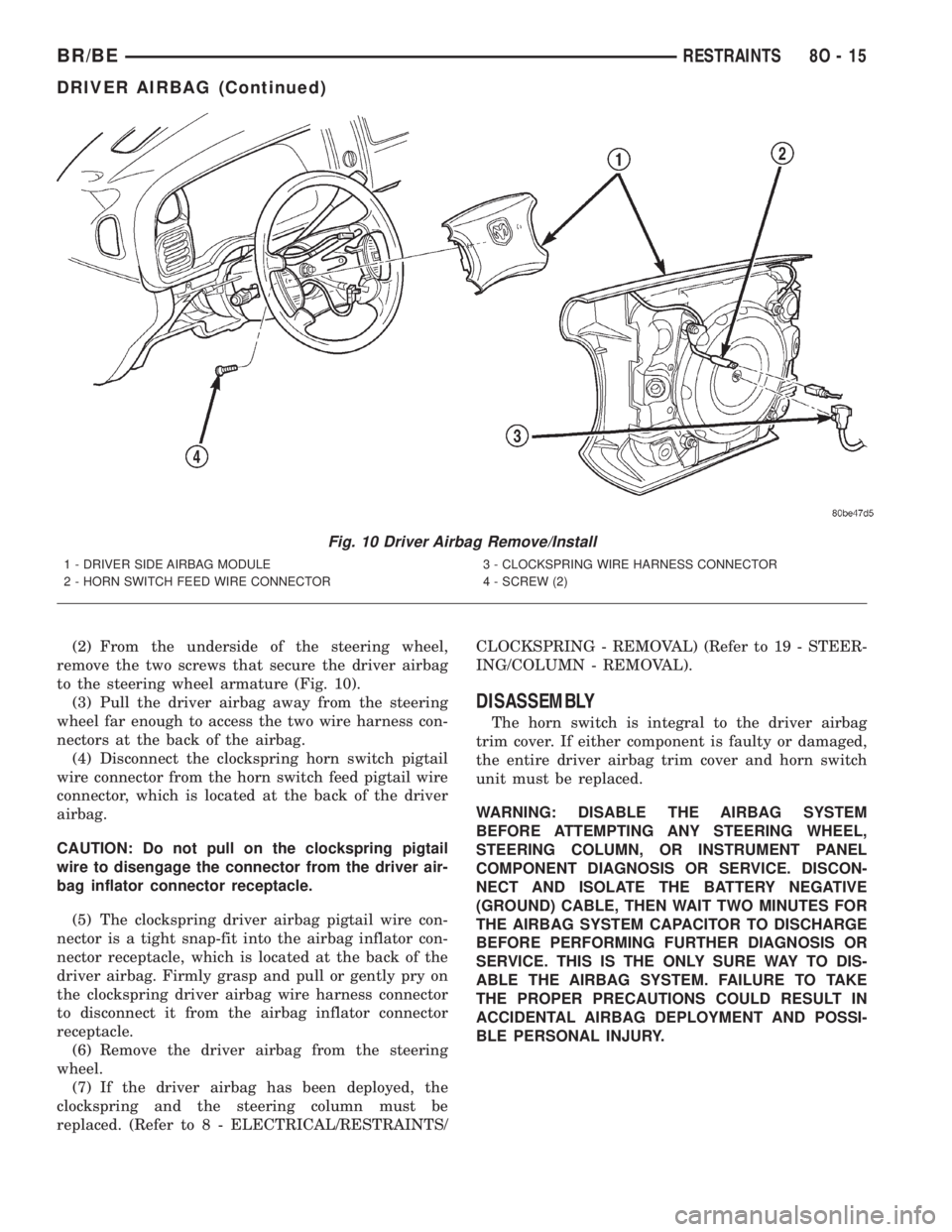

(2) From the underside of the steering wheel,

remove the two screws that secure the driver airbag

to the steering wheel armature (Fig. 10).

(3) Pull the driver airbag away from the steering

wheel far enough to access the two wire harness con-

nectors at the back of the airbag.

(4) Disconnect the clockspring horn switch pigtail

wire connector from the horn switch feed pigtail wire

connector, which is located at the back of the driver

airbag.

CAUTION: Do not pull on the clockspring pigtail

wire to disengage the connector from the driver air-

bag inflator connector receptacle.

(5) The clockspring driver airbag pigtail wire con-

nector is a tight snap-fit into the airbag inflator con-

nector receptacle, which is located at the back of the

driver airbag. Firmly grasp and pull or gently pry on

the clockspring driver airbag wire harness connector

to disconnect it from the airbag inflator connector

receptacle.

(6) Remove the driver airbag from the steering

wheel.

(7) If the driver airbag has been deployed, the

clockspring and the steering column must be

replaced. (Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING - REMOVAL) (Refer to 19 - STEER-

ING/COLUMN - REMOVAL).

DISASSEMBLY

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

the entire driver airbag trim cover and horn switch

unit must be replaced.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

Fig. 10 Driver Airbag Remove/Install

1 - DRIVER SIDE AIRBAG MODULE

2 - HORN SWITCH FEED WIRE CONNECTOR3 - CLOCKSPRING WIRE HARNESS CONNECTOR

4 - SCREW (2)

BR/BERESTRAINTS 8O - 15

DRIVER AIRBAG (Continued)

Page 609 of 2255

WARNING: THE HORN SWITCH IS INTEGRAL TO

THE DRIVER AIRBAG UNIT. SERVICE OF THIS UNIT

SHOULD BE PERFORMED ONLY BY

DAIMLERCHRYSLER-TRAINED AND AUTHORIZED

DEALER SERVICE TECHNICIANS. FAILURE TO

TAKE THE PROPER PRECAUTIONS OR TO FOL-

LOW THE PROPER PROCEDURES COULD RESULT

IN ACCIDENTAL, INCOMPLETE, OR IMPROPER AIR-

BAG DEPLOYMENT AND POSSIBLE OCCUPANT

INJURIES.

(1) Disconnect and isolate the battery negative

cable. If either of the airbags has not been deployed,

wait two minutes for the system capacitor to dis-

charge before further service.

(2) Remove the driver airbag from the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

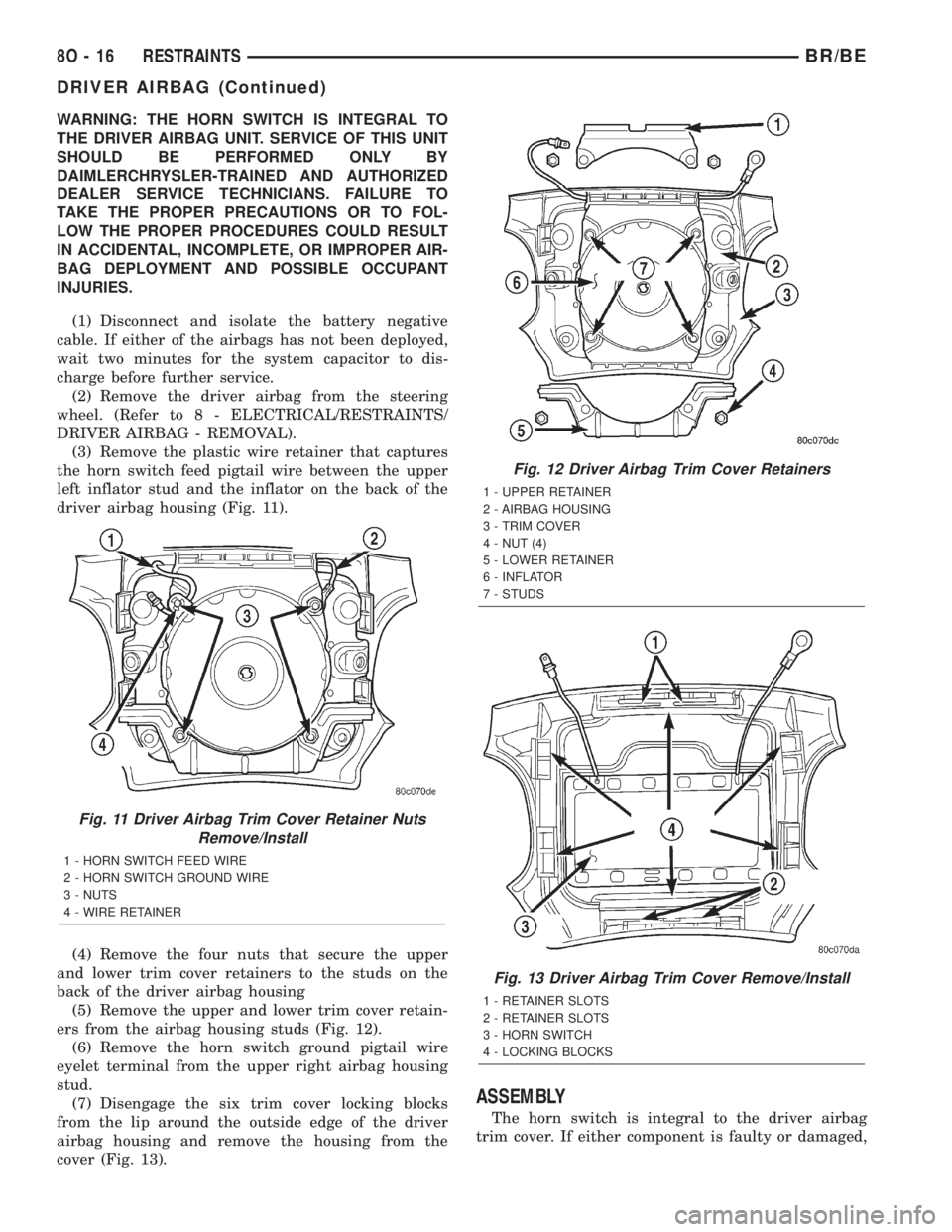

(3) Remove the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing (Fig. 11).

(4) Remove the four nuts that secure the upper

and lower trim cover retainers to the studs on the

back of the driver airbag housing

(5) Remove the upper and lower trim cover retain-

ers from the airbag housing studs (Fig. 12).

(6) Remove the horn switch ground pigtail wire

eyelet terminal from the upper right airbag housing

stud.

(7) Disengage the six trim cover locking blocks

from the lip around the outside edge of the driver

airbag housing and remove the housing from the

cover (Fig. 13).

ASSEMBLY

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

Fig. 11 Driver Airbag Trim Cover Retainer Nuts

Remove/Install

1 - HORN SWITCH FEED WIRE

2 - HORN SWITCH GROUND WIRE

3 - NUTS

4 - WIRE RETAINER

Fig. 12 Driver Airbag Trim Cover Retainers

1 - UPPER RETAINER

2 - AIRBAG HOUSING

3 - TRIM COVER

4 - NUT (4)

5 - LOWER RETAINER

6 - INFLATOR

7 - STUDS

Fig. 13 Driver Airbag Trim Cover Remove/Install

1 - RETAINER SLOTS

2 - RETAINER SLOTS

3 - HORN SWITCH

4 - LOCKING BLOCKS

8O - 16 RESTRAINTSBR/BE

DRIVER AIRBAG (Continued)