DODGE RAM 2002 Service Repair Manual

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 201 of 2255

CAUTION: Do not blow the piston out of the bore

with sustained air pressure. This could result in a

cracked piston.

WARNING: NEVER ATTEMPT TO CATCH THE PIS-

TON AS IT LEAVES THE BORE. THIS COULD

RESULT IN PERSONAL INJURY.

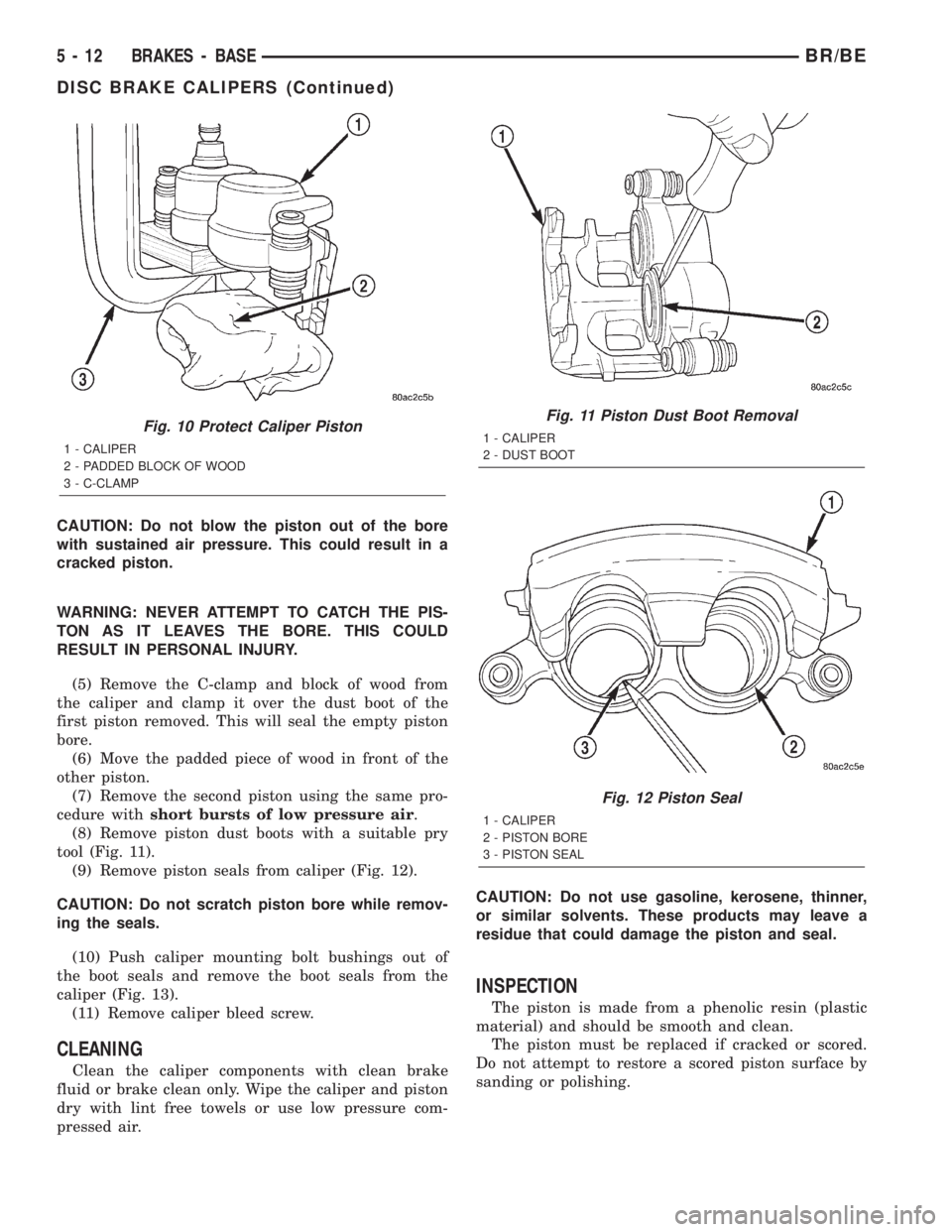

(5) Remove the C-clamp and block of wood from

the caliper and clamp it over the dust boot of the

first piston removed. This will seal the empty piston

bore.

(6) Move the padded piece of wood in front of the

other piston.

(7) Remove the second piston using the same pro-

cedure withshort bursts of low pressure air.

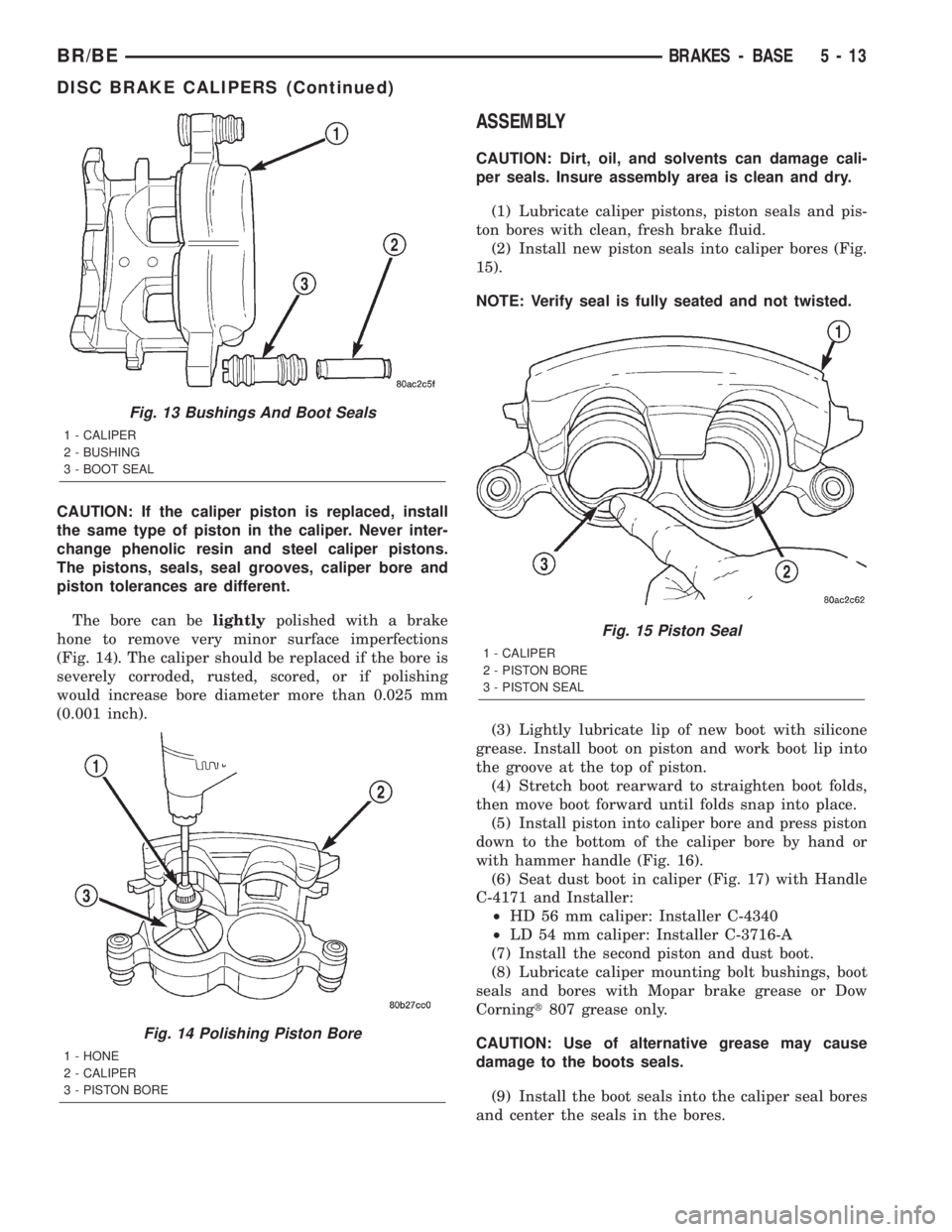

(8) Remove piston dust boots with a suitable pry

tool (Fig. 11).

(9) Remove piston seals from caliper (Fig. 12).

CAUTION: Do not scratch piston bore while remov-

ing the seals.

(10) Push caliper mounting bolt bushings out of

the boot seals and remove the boot seals from the

caliper (Fig. 13).

(11) Remove caliper bleed screw.

CLEANING

Clean the caliper components with clean brake

fluid or brake clean only. Wipe the caliper and piston

dry with lint free towels or use low pressure com-

pressed air.CAUTION: Do not use gasoline, kerosene, thinner,

or similar solvents. These products may leave a

residue that could damage the piston and seal.

INSPECTION

The piston is made from a phenolic resin (plastic

material) and should be smooth and clean.

The piston must be replaced if cracked or scored.

Do not attempt to restore a scored piston surface by

sanding or polishing.

Fig. 10 Protect Caliper Piston

1 - CALIPER

2 - PADDED BLOCK OF WOOD

3 - C-CLAMP

Fig. 11 Piston Dust Boot Removal

1 - CALIPER

2 - DUST BOOT

Fig. 12 Piston Seal

1 - CALIPER

2 - PISTON BORE

3 - PISTON SEAL

5 - 12 BRAKES - BASEBR/BE

DISC BRAKE CALIPERS (Continued)

Page 202 of 2255

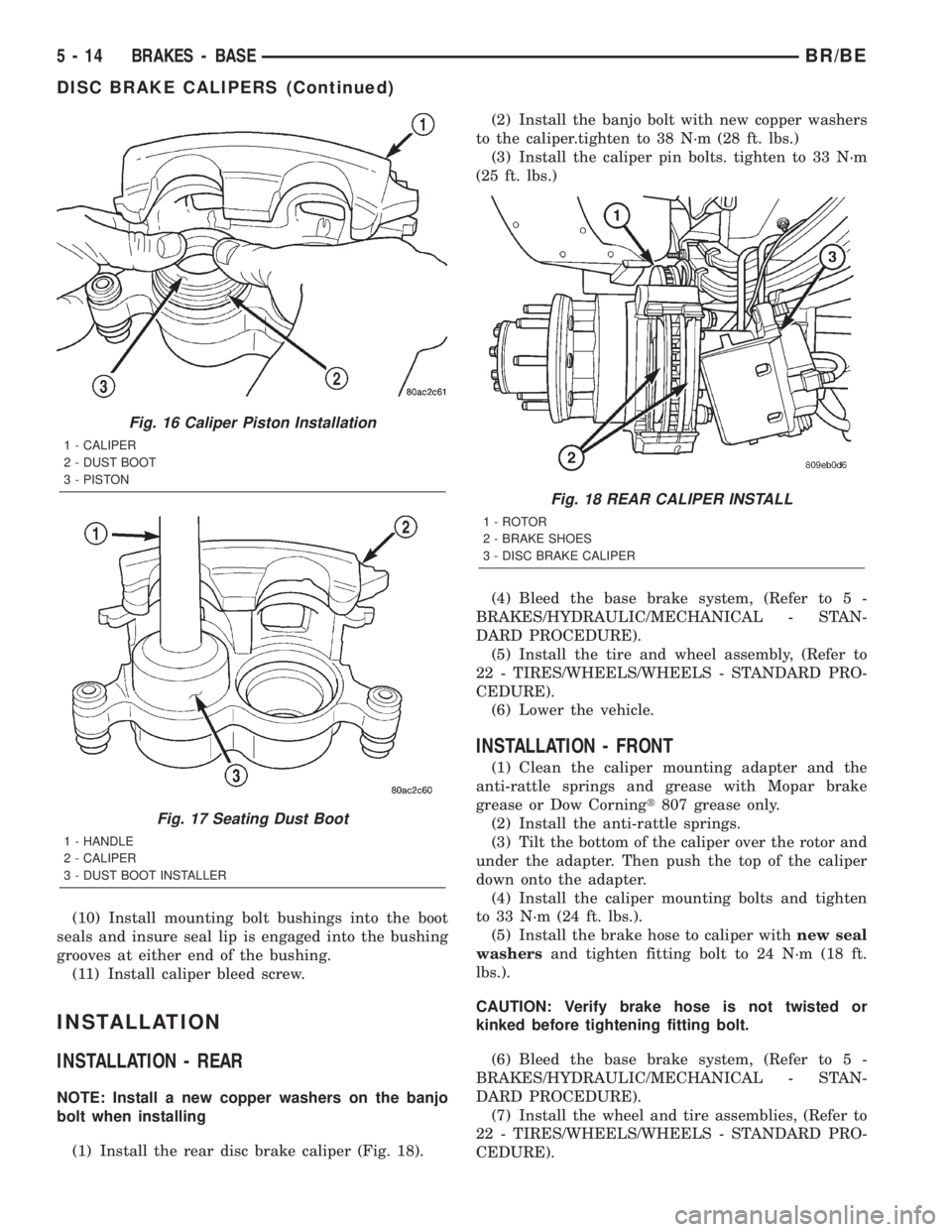

CAUTION: If the caliper piston is replaced, install

the same type of piston in the caliper. Never inter-

change phenolic resin and steel caliper pistons.

The pistons, seals, seal grooves, caliper bore and

piston tolerances are different.

The bore can belightlypolished with a brake

hone to remove very minor surface imperfections

(Fig. 14). The caliper should be replaced if the bore is

severely corroded, rusted, scored, or if polishing

would increase bore diameter more than 0.025 mm

(0.001 inch).

ASSEMBLY

CAUTION: Dirt, oil, and solvents can damage cali-

per seals. Insure assembly area is clean and dry.

(1) Lubricate caliper pistons, piston seals and pis-

ton bores with clean, fresh brake fluid.

(2) Install new piston seals into caliper bores (Fig.

15).

NOTE: Verify seal is fully seated and not twisted.

(3) Lightly lubricate lip of new boot with silicone

grease. Install boot on piston and work boot lip into

the groove at the top of piston.

(4) Stretch boot rearward to straighten boot folds,

then move boot forward until folds snap into place.

(5) Install piston into caliper bore and press piston

down to the bottom of the caliper bore by hand or

with hammer handle (Fig. 16).

(6) Seat dust boot in caliper (Fig. 17) with Handle

C-4171 and Installer:

²HD 56 mm caliper: Installer C-4340

²LD 54 mm caliper: Installer C-3716-A

(7) Install the second piston and dust boot.

(8) Lubricate caliper mounting bolt bushings, boot

seals and bores with Mopar brake grease or Dow

Corningt807 grease only.

CAUTION: Use of alternative grease may cause

damage to the boots seals.

(9) Install the boot seals into the caliper seal bores

and center the seals in the bores.

Fig. 13 Bushings And Boot Seals

1 - CALIPER

2 - BUSHING

3 - BOOT SEAL

Fig. 14 Polishing Piston Bore

1 - HONE

2 - CALIPER

3 - PISTON BORE

Fig. 15 Piston Seal

1 - CALIPER

2 - PISTON BORE

3 - PISTON SEAL

BR/BEBRAKES - BASE 5 - 13

DISC BRAKE CALIPERS (Continued)

Page 203 of 2255

(10) Install mounting bolt bushings into the boot

seals and insure seal lip is engaged into the bushing

grooves at either end of the bushing.

(11) Install caliper bleed screw.

INSTALLATION

INSTALLATION - REAR

NOTE: Install a new copper washers on the banjo

bolt when installing

(1) Install the rear disc brake caliper (Fig. 18).(2) Install the banjo bolt with new copper washers

to the caliper.tighten to 38 N´m (28 ft. lbs.)

(3) Install the caliper pin bolts. tighten to 33 N´m

(25 ft. lbs.)

(4) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(5) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(6) Lower the vehicle.

INSTALLATION - FRONT

(1) Clean the caliper mounting adapter and the

anti-rattle springs and grease with Mopar brake

grease or Dow Corningt807 grease only.

(2) Install the anti-rattle springs.

(3) Tilt the bottom of the caliper over the rotor and

under the adapter. Then push the top of the caliper

down onto the adapter.

(4) Install the caliper mounting bolts and tighten

to 33 N´m (24 ft. lbs.).

(5) Install the brake hose to caliper withnew seal

washersand tighten fitting bolt to 24 N´m (18 ft.

lbs.).

CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(6) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(7) Install the wheel and tire assemblies, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

Fig. 16 Caliper Piston Installation

1 - CALIPER

2 - DUST BOOT

3 - PISTON

Fig. 17 Seating Dust Boot

1 - HANDLE

2 - CALIPER

3 - DUST BOOT INSTALLER

Fig. 18 REAR CALIPER INSTALL

1 - ROTOR

2 - BRAKE SHOES

3 - DISC BRAKE CALIPER

5 - 14 BRAKES - BASEBR/BE

DISC BRAKE CALIPERS (Continued)

Page 204 of 2255

(8) Remove the supports and lower the vehicle.

(9) Verify a firm pedal before moving the vehicle.

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

STANDARD PROCEDURE - BRAKE FLUID

LEVEL

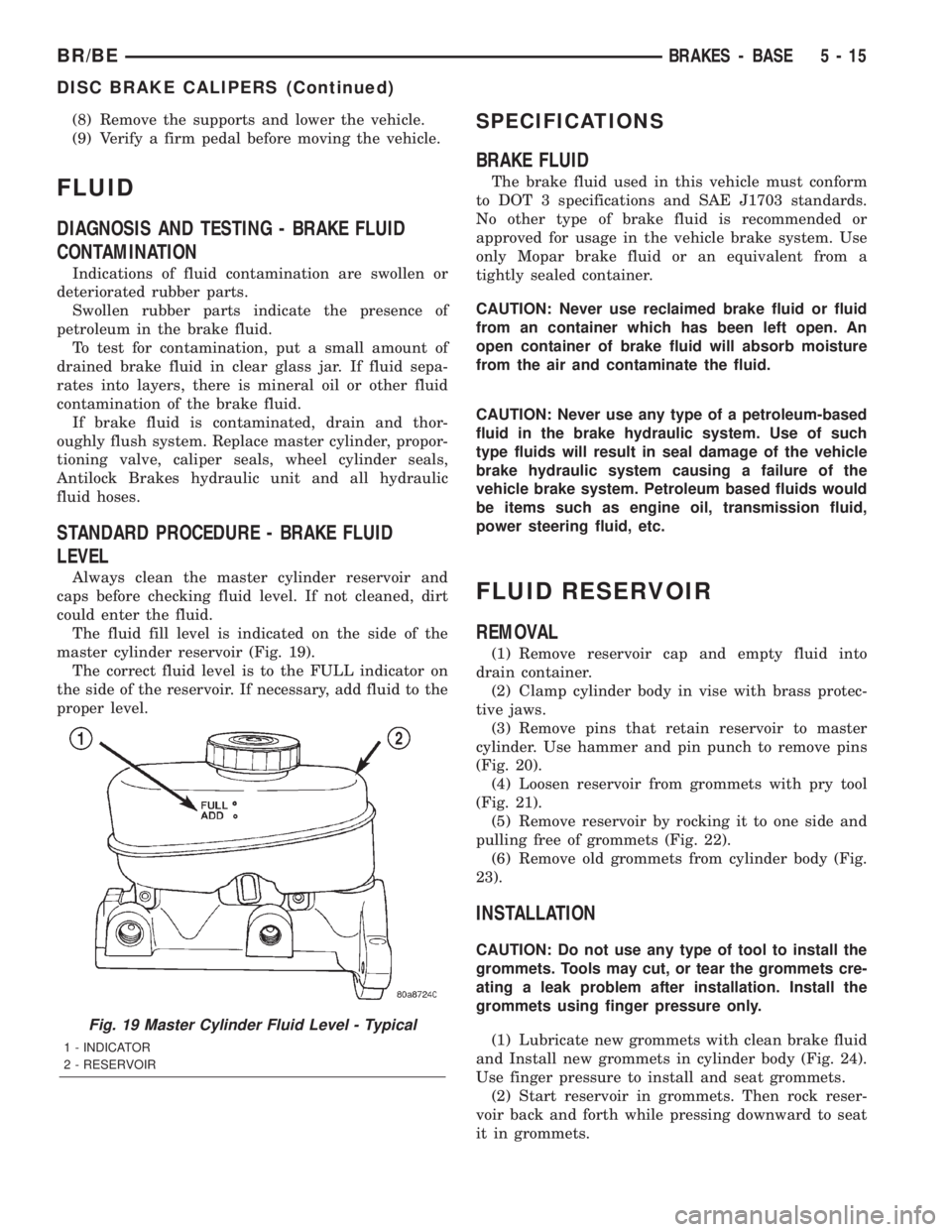

Always clean the master cylinder reservoir and

caps before checking fluid level. If not cleaned, dirt

could enter the fluid.

The fluid fill level is indicated on the side of the

master cylinder reservoir (Fig. 19).

The correct fluid level is to the FULL indicator on

the side of the reservoir. If necessary, add fluid to the

proper level.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

FLUID RESERVOIR

REMOVAL

(1) Remove reservoir cap and empty fluid into

drain container.

(2) Clamp cylinder body in vise with brass protec-

tive jaws.

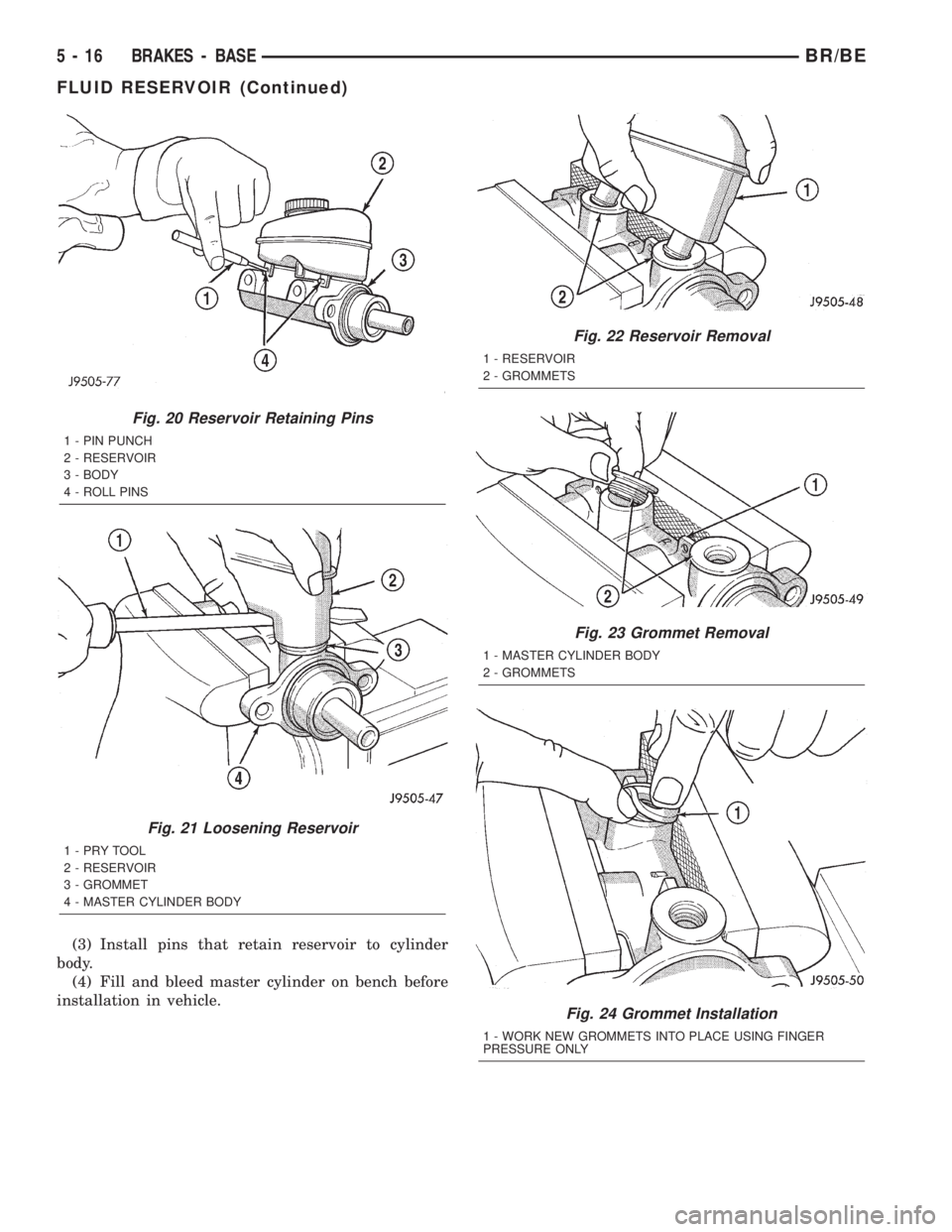

(3) Remove pins that retain reservoir to master

cylinder. Use hammer and pin punch to remove pins

(Fig. 20).

(4) Loosen reservoir from grommets with pry tool

(Fig. 21).

(5) Remove reservoir by rocking it to one side and

pulling free of grommets (Fig. 22).

(6) Remove old grommets from cylinder body (Fig.

23).

INSTALLATION

CAUTION: Do not use any type of tool to install the

grommets. Tools may cut, or tear the grommets cre-

ating a leak problem after installation. Install the

grommets using finger pressure only.

(1) Lubricate new grommets with clean brake fluid

and Install new grommets in cylinder body (Fig. 24).

Use finger pressure to install and seat grommets.

(2) Start reservoir in grommets. Then rock reser-

voir back and forth while pressing downward to seat

it in grommets.

Fig. 19 Master Cylinder Fluid Level - Typical

1 - INDICATOR

2 - RESERVOIR

BR/BEBRAKES - BASE 5 - 15

DISC BRAKE CALIPERS (Continued)

Page 205 of 2255

(3) Install pins that retain reservoir to cylinder

body.

(4) Fill and bleed master cylinder on bench before

installation in vehicle.

Fig. 20 Reservoir Retaining Pins

1 - PIN PUNCH

2 - RESERVOIR

3 - BODY

4 - ROLL PINS

Fig. 21 Loosening Reservoir

1-PRYTOOL

2 - RESERVOIR

3 - GROMMET

4 - MASTER CYLINDER BODY

Fig. 22 Reservoir Removal

1 - RESERVOIR

2 - GROMMETS

Fig. 23 Grommet Removal

1 - MASTER CYLINDER BODY

2 - GROMMETS

Fig. 24 Grommet Installation

1 - WORK NEW GROMMETS INTO PLACE USING FINGER

PRESSURE ONLY

5 - 16 BRAKES - BASEBR/BE

FLUID RESERVOIR (Continued)

Page 206 of 2255

PEDAL

DESCRIPTION

The brake booster is operated by a suspended type

brake pedal. The pedal pivots on a shaft located in a

mounting bracket attached to the dash panel. The

pedal shaft is supported by bushings in the pedal

and mounting bracket. The brake pedal is attached

to the booster push rod.

OPERATION

When the pedal is depressed, the primary booster

push rod is depressed which move the booster sec-

ondary rod. The booster secondary rod depress the

master cylinder piston.

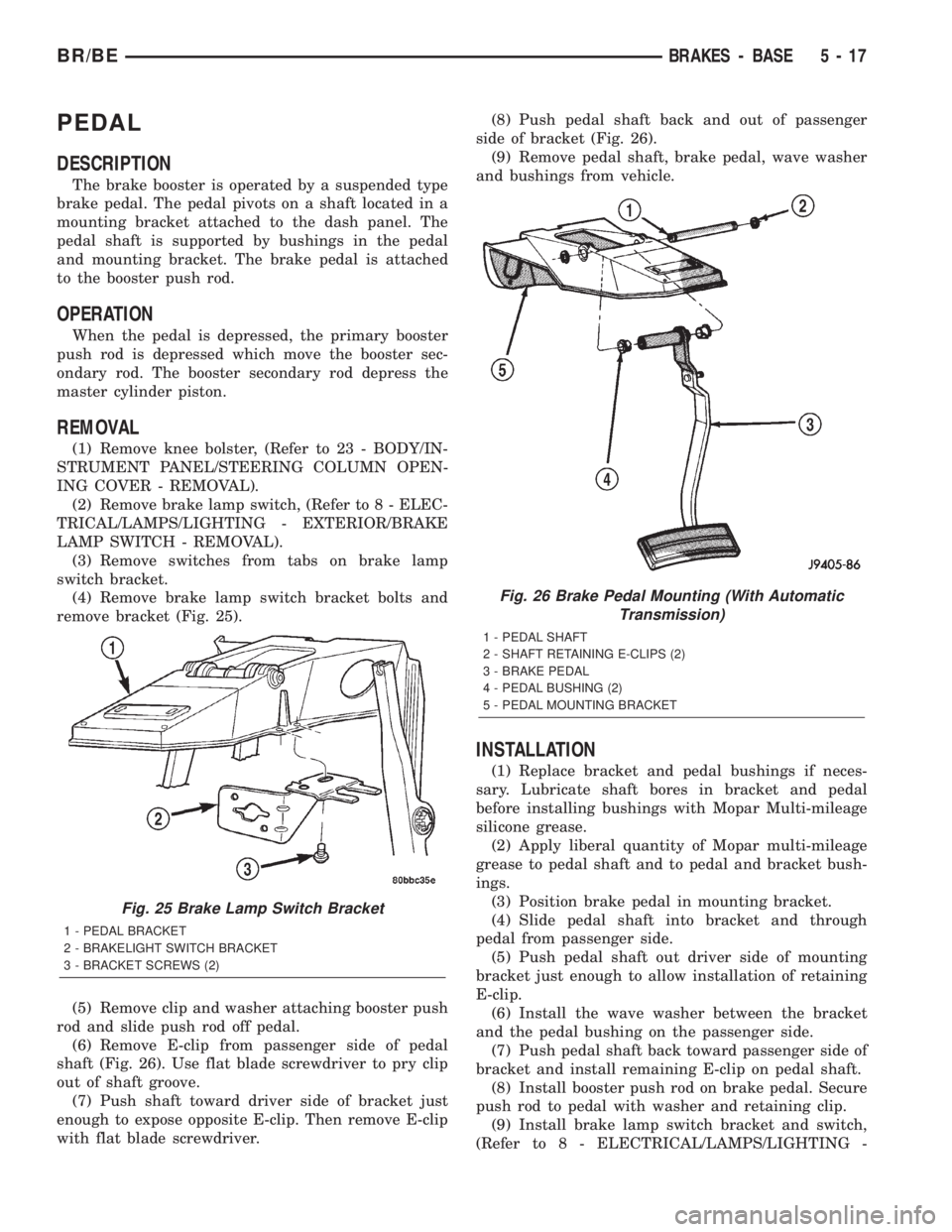

REMOVAL

(1) Remove knee bolster, (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(2) Remove brake lamp switch, (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL).

(3) Remove switches from tabs on brake lamp

switch bracket.

(4) Remove brake lamp switch bracket bolts and

remove bracket (Fig. 25).

(5) Remove clip and washer attaching booster push

rod and slide push rod off pedal.

(6) Remove E-clip from passenger side of pedal

shaft (Fig. 26). Use flat blade screwdriver to pry clip

out of shaft groove.

(7) Push shaft toward driver side of bracket just

enough to expose opposite E-clip. Then remove E-clip

with flat blade screwdriver.(8) Push pedal shaft back and out of passenger

side of bracket (Fig. 26).

(9) Remove pedal shaft, brake pedal, wave washer

and bushings from vehicle.

INSTALLATION

(1) Replace bracket and pedal bushings if neces-

sary. Lubricate shaft bores in bracket and pedal

before installing bushings with Mopar Multi-mileage

silicone grease.

(2) Apply liberal quantity of Mopar multi-mileage

grease to pedal shaft and to pedal and bracket bush-

ings.

(3) Position brake pedal in mounting bracket.

(4) Slide pedal shaft into bracket and through

pedal from passenger side.

(5) Push pedal shaft out driver side of mounting

bracket just enough to allow installation of retaining

E-clip.

(6) Install the wave washer between the bracket

and the pedal bushing on the passenger side.

(7) Push pedal shaft back toward passenger side of

bracket and install remaining E-clip on pedal shaft.

(8) Install booster push rod on brake pedal. Secure

push rod to pedal with washer and retaining clip.

(9) Install brake lamp switch bracket and switch,

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

Fig. 25 Brake Lamp Switch Bracket

1 - PEDAL BRACKET

2 - BRAKELIGHT SWITCH BRACKET

3 - BRACKET SCREWS (2)

Fig. 26 Brake Pedal Mounting (With Automatic

Transmission)

1 - PEDAL SHAFT

2 - SHAFT RETAINING E-CLIPS (2)

3 - BRAKE PEDAL

4 - PEDAL BUSHING (2)

5 - PEDAL MOUNTING BRACKET

BR/BEBRAKES - BASE 5 - 17

Page 207 of 2255

EXTERIOR/BRAKE LAMP SWITCH - INSTALLA-

TION).

(10) Install knee bolster, (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

POWER BRAKE BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER

The hydraulic booster uses hydraulic pressure from

the power steering pump. Before diagnosing a

booster problem, first verify the power steering pump

is operating properly. Perform the following checks.

²Check the power steering fluid level.

²Check the brake fluid level.

²Check all power steering hoses and lines for

leaks and restrictions.

²Check power steering pump pressure.

NOISES

The hydraulic booster unit will produce certain

characteristic booster noises. The noises may occur

when the brake pedal is used in a manner not asso-

ciated with normal braking or driving habits.

HISSING

A hissing noise may be noticed when above normal

brake pedal pressure is applied, 40 lbs. or above. The

noise will be more noticeable if the vehicle is not

moving. The noise will increase with the brake pedal

pressure and an increase of system operating temper-

ature.

CLUNK-CHATTER-CLICKING

A clunk-chatter-clicking may be noticed when the

brake pedal is released quickly, after above normal

brake pedal pressure is applied 50-100 lbs..

BOOSTER FUNCTION TEST

With the engine off depress the brake pedal several

times to discharge the accumulator. Then depress the

brake pedal using 40 lbs. of force and start the

engine. The brake pedal should fall and then push

back against your foot. This indicates the booster is

operating properly.

ACCUMULATOR LEAKDOWN

(1) Start the engine, apply the brakes and turn the

steering wheel from lock to lock. This will ensure the

accumulator is charged. Turn off the engine and let

the vehicle sit for one hour. After one hour there

should be at least two power assisted brake applica-

tion with the engine off. If the system does not retain

a charge the booster must be replaced.(2) With the engine off depress the brake pedal

several times to discharge the accumulator. Grasp

the accumulator and see if it wobbles or turns. If it

does the accumulator has lost a gas charge and the

booster must be replaced.

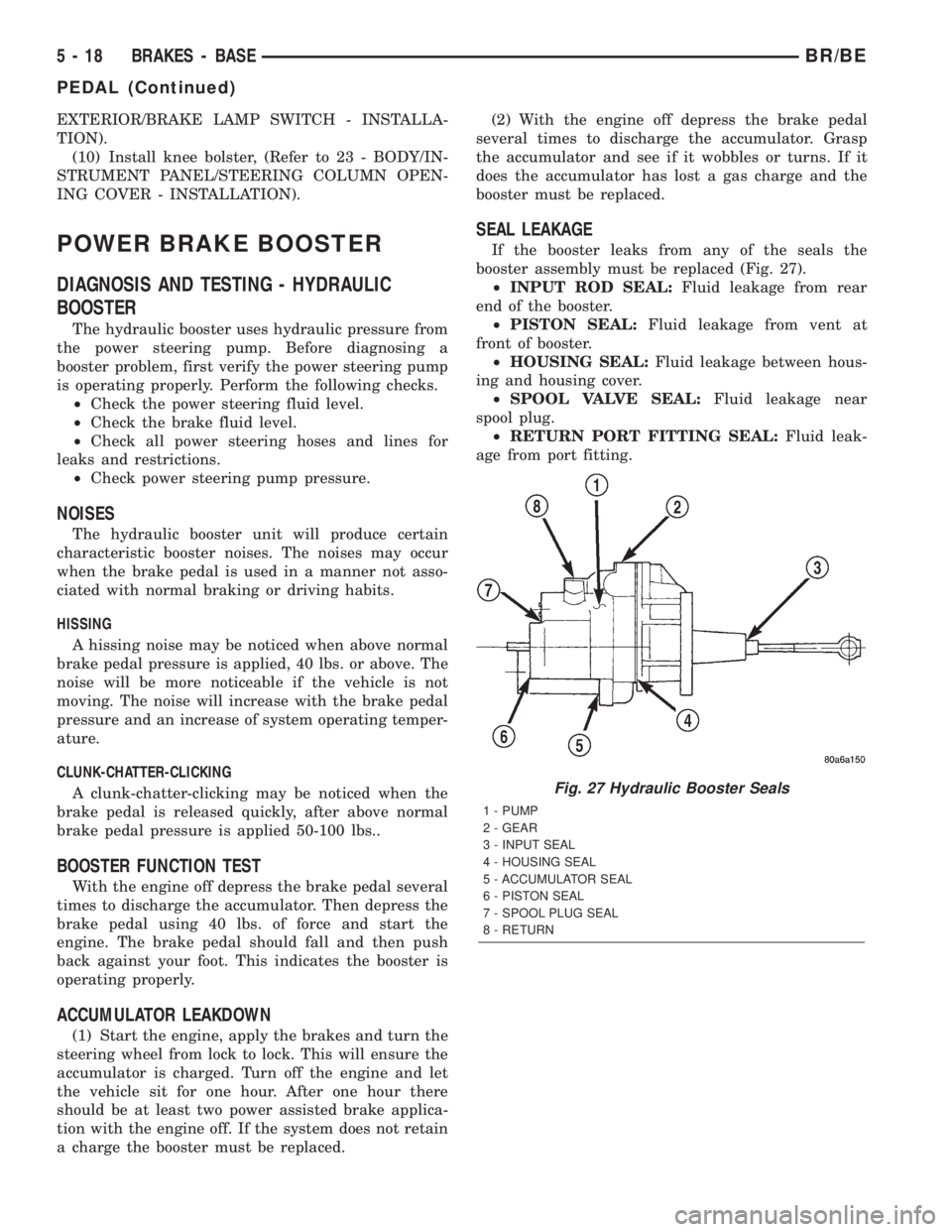

SEAL LEAKAGE

If the booster leaks from any of the seals the

booster assembly must be replaced (Fig. 27).

²INPUT ROD SEAL:Fluid leakage from rear

end of the booster.

²PISTON SEAL:Fluid leakage from vent at

front of booster.

²HOUSING SEAL:Fluid leakage between hous-

ing and housing cover.

²SPOOL VALVE SEAL:Fluid leakage near

spool plug.

²RETURN PORT FITTING SEAL:Fluid leak-

age from port fitting.

Fig. 27 Hydraulic Booster Seals

1 - PUMP

2 - GEAR

3 - INPUT SEAL

4 - HOUSING SEAL

5 - ACCUMULATOR SEAL

6 - PISTON SEAL

7 - SPOOL PLUG SEAL

8 - RETURN

5 - 18 BRAKES - BASEBR/BE

PEDAL (Continued)

Page 208 of 2255

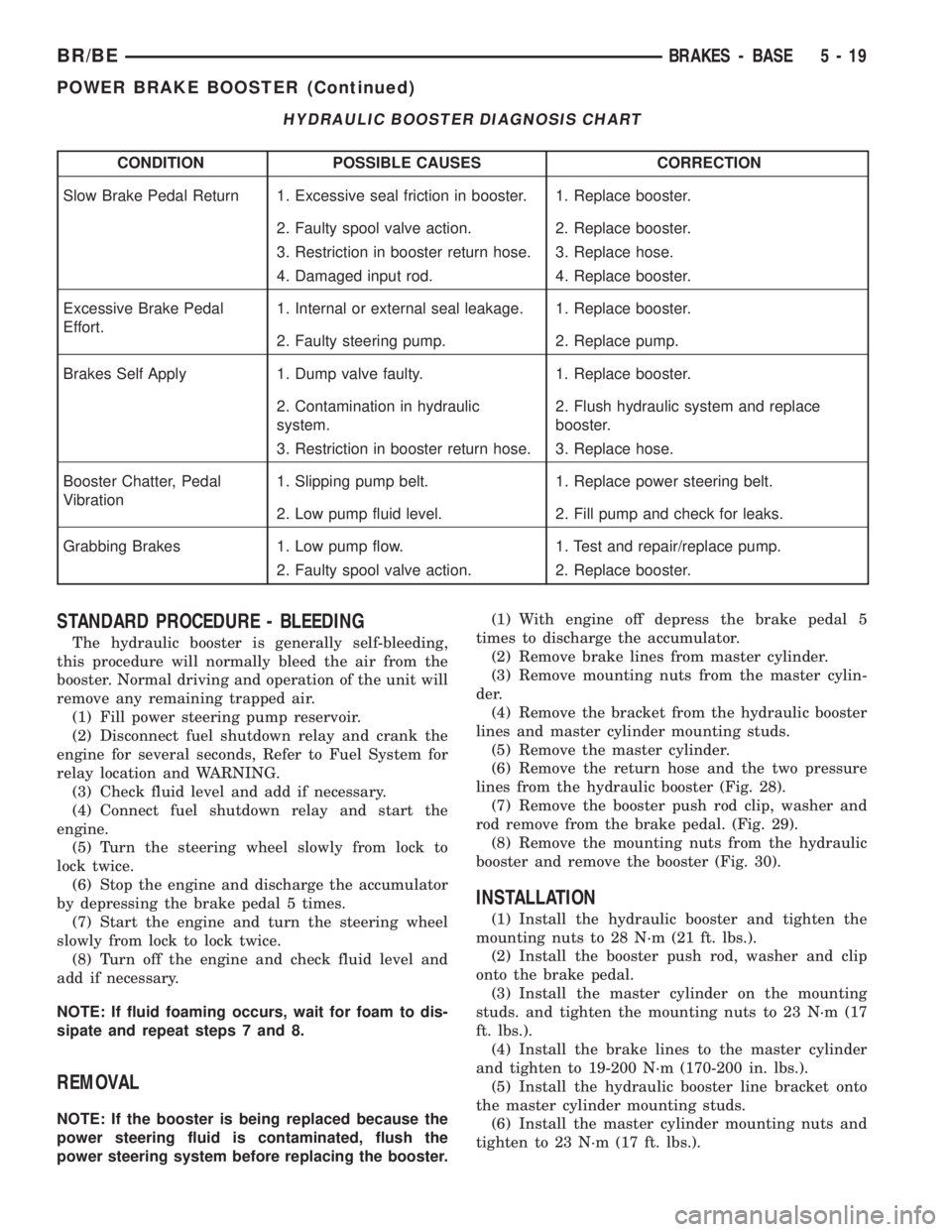

HYDRAULIC BOOSTER DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Slow Brake Pedal Return 1. Excessive seal friction in booster. 1. Replace booster.

2. Faulty spool valve action. 2. Replace booster.

3. Restriction in booster return hose. 3. Replace hose.

4. Damaged input rod. 4. Replace booster.

Excessive Brake Pedal

Effort.1. Internal or external seal leakage. 1. Replace booster.

2. Faulty steering pump. 2. Replace pump.

Brakes Self Apply 1. Dump valve faulty. 1. Replace booster.

2. Contamination in hydraulic

system.2. Flush hydraulic system and replace

booster.

3. Restriction in booster return hose. 3. Replace hose.

Booster Chatter, Pedal

Vibration1. Slipping pump belt. 1. Replace power steering belt.

2. Low pump fluid level. 2. Fill pump and check for leaks.

Grabbing Brakes 1. Low pump flow. 1. Test and repair/replace pump.

2. Faulty spool valve action. 2. Replace booster.

STANDARD PROCEDURE - BLEEDING

The hydraulic booster is generally self-bleeding,

this procedure will normally bleed the air from the

booster. Normal driving and operation of the unit will

remove any remaining trapped air.

(1) Fill power steering pump reservoir.

(2) Disconnect fuel shutdown relay and crank the

engine for several seconds, Refer to Fuel System for

relay location and WARNING.

(3) Check fluid level and add if necessary.

(4) Connect fuel shutdown relay and start the

engine.

(5) Turn the steering wheel slowly from lock to

lock twice.

(6) Stop the engine and discharge the accumulator

by depressing the brake pedal 5 times.

(7) Start the engine and turn the steering wheel

slowly from lock to lock twice.

(8) Turn off the engine and check fluid level and

add if necessary.

NOTE: If fluid foaming occurs, wait for foam to dis-

sipate and repeat steps 7 and 8.

REMOVAL

NOTE: If the booster is being replaced because the

power steering fluid is contaminated, flush the

power steering system before replacing the booster.(1) With engine off depress the brake pedal 5

times to discharge the accumulator.

(2) Remove brake lines from master cylinder.

(3) Remove mounting nuts from the master cylin-

der.

(4) Remove the bracket from the hydraulic booster

lines and master cylinder mounting studs.

(5) Remove the master cylinder.

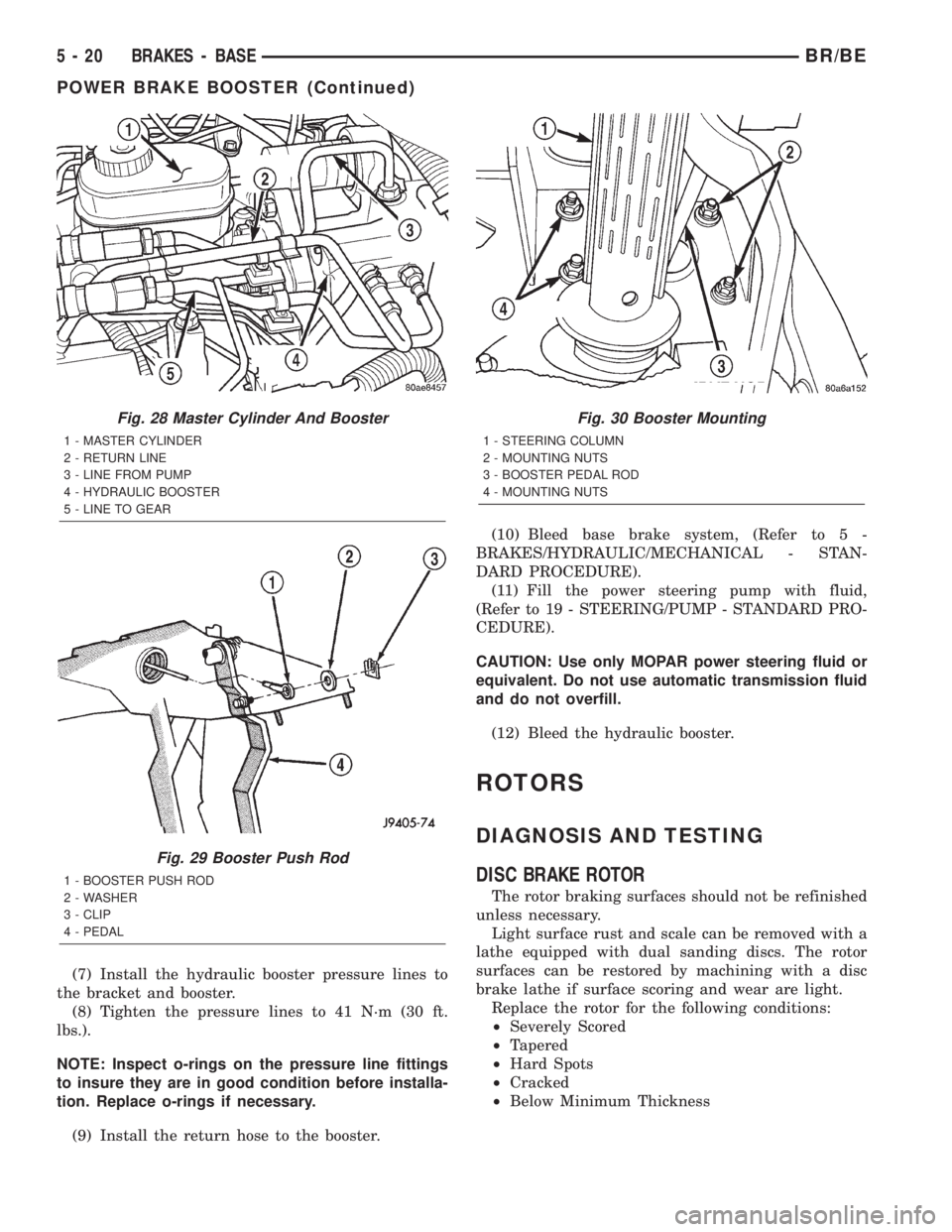

(6) Remove the return hose and the two pressure

lines from the hydraulic booster (Fig. 28).

(7) Remove the booster push rod clip, washer and

rod remove from the brake pedal. (Fig. 29).

(8) Remove the mounting nuts from the hydraulic

booster and remove the booster (Fig. 30).

INSTALLATION

(1) Install the hydraulic booster and tighten the

mounting nuts to 28 N´m (21 ft. lbs.).

(2) Install the booster push rod, washer and clip

onto the brake pedal.

(3) Install the master cylinder on the mounting

studs. and tighten the mounting nuts to 23 N´m (17

ft. lbs.).

(4) Install the brake lines to the master cylinder

and tighten to 19-200 N´m (170-200 in. lbs.).

(5) Install the hydraulic booster line bracket onto

the master cylinder mounting studs.

(6) Install the master cylinder mounting nuts and

tighten to 23 N´m (17 ft. lbs.).

BR/BEBRAKES - BASE 5 - 19

POWER BRAKE BOOSTER (Continued)

Page 209 of 2255

(7) Install the hydraulic booster pressure lines to

the bracket and booster.

(8) Tighten the pressure lines to 41 N´m (30 ft.

lbs.).

NOTE: Inspect o-rings on the pressure line fittings

to insure they are in good condition before installa-

tion. Replace o-rings if necessary.

(9) Install the return hose to the booster.(10) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(11) Fill the power steering pump with fluid,

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE).

CAUTION: Use only MOPAR power steering fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

(12) Bleed the hydraulic booster.

ROTORS

DIAGNOSIS AND TESTING

DISC BRAKE ROTOR

The rotor braking surfaces should not be refinished

unless necessary.

Light surface rust and scale can be removed with a

lathe equipped with dual sanding discs. The rotor

surfaces can be restored by machining with a disc

brake lathe if surface scoring and wear are light.

Replace the rotor for the following conditions:

²Severely Scored

²Tapered

²Hard Spots

²Cracked

²Below Minimum Thickness

Fig. 28 Master Cylinder And Booster

1 - MASTER CYLINDER

2 - RETURN LINE

3 - LINE FROM PUMP

4 - HYDRAULIC BOOSTER

5 - LINE TO GEAR

Fig. 29 Booster Push Rod

1 - BOOSTER PUSH ROD

2 - WASHER

3 - CLIP

4 - PEDAL

Fig. 30 Booster Mounting

1 - STEERING COLUMN

2 - MOUNTING NUTS

3 - BOOSTER PEDAL ROD

4 - MOUNTING NUTS

5 - 20 BRAKES - BASEBR/BE

POWER BRAKE BOOSTER (Continued)

Page 210 of 2255

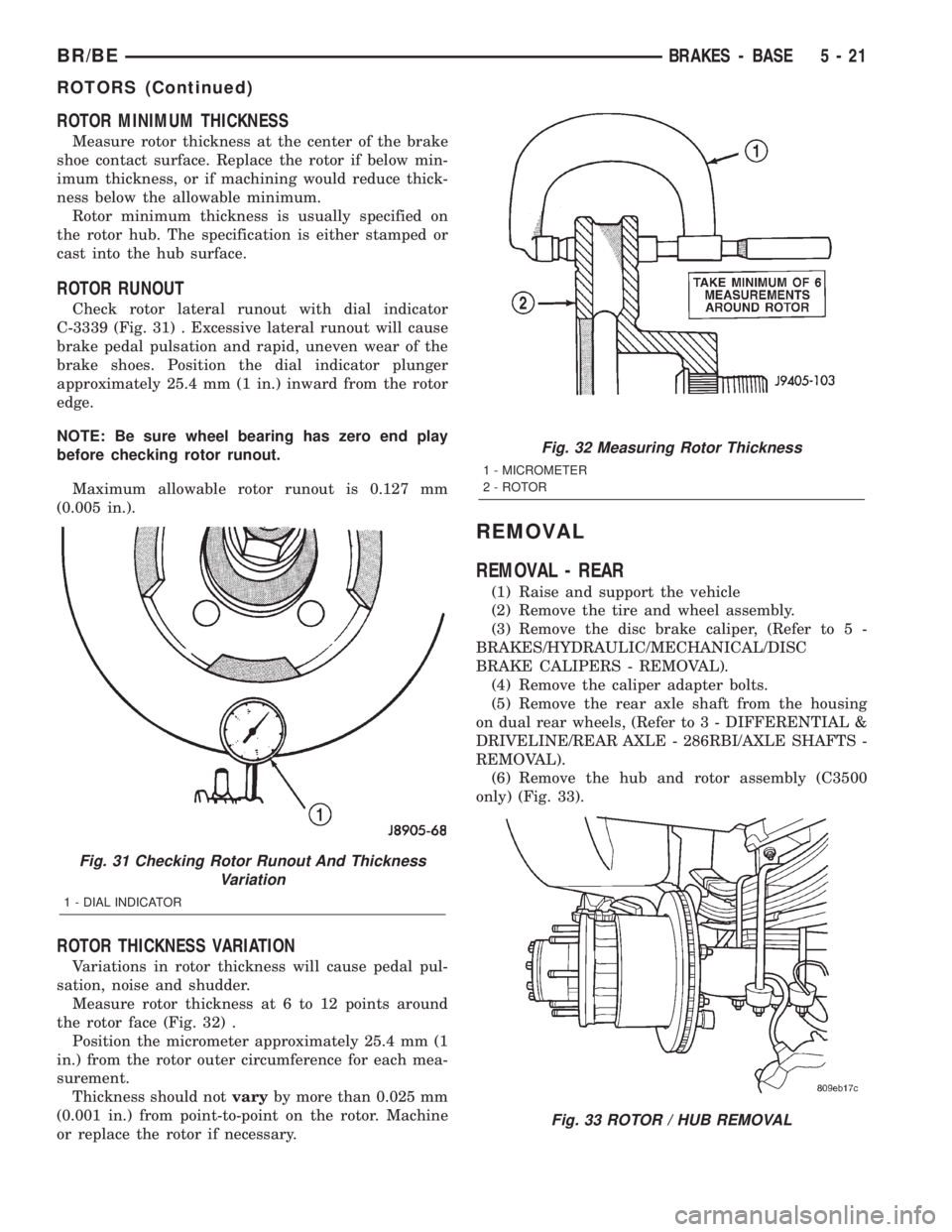

ROTOR MINIMUM THICKNESS

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if below min-

imum thickness, or if machining would reduce thick-

ness below the allowable minimum.

Rotor minimum thickness is usually specified on

the rotor hub. The specification is either stamped or

cast into the hub surface.

ROTOR RUNOUT

Check rotor lateral runout with dial indicator

C-3339 (Fig. 31) . Excessive lateral runout will cause

brake pedal pulsation and rapid, uneven wear of the

brake shoes. Position the dial indicator plunger

approximately 25.4 mm (1 in.) inward from the rotor

edge.

NOTE: Be sure wheel bearing has zero end play

before checking rotor runout.

Maximum allowable rotor runout is 0.127 mm

(0.005 in.).

ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pul-

sation, noise and shudder.

Measure rotor thickness at 6 to 12 points around

the rotor face (Fig. 32) .

Position the micrometer approximately 25.4 mm (1

in.) from the rotor outer circumference for each mea-

surement.

Thickness should notvaryby more than 0.025 mm

(0.001 in.) from point-to-point on the rotor. Machine

or replace the rotor if necessary.

REMOVAL

REMOVAL - REAR

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts.

(5) Remove the rear axle shaft from the housing

on dual rear wheels, (Refer to 3 - DIFFERENTIAL &

DRIVELINE/REAR AXLE - 286RBI/AXLE SHAFTS -

REMOVAL).

(6) Remove the hub and rotor assembly (C3500

only) (Fig. 33).

Fig. 31 Checking Rotor Runout And Thickness

Variation

1 - DIAL INDICATOR

Fig. 32 Measuring Rotor Thickness

1 - MICROMETER

2 - ROTOR

Fig. 33 ROTOR / HUB REMOVAL

BR/BEBRAKES - BASE 5 - 21

ROTORS (Continued)