DODGE RAM 2002 Service Repair Manual

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 441 of 2255

(6) From the back of the heated seat switch bezel,

gently push the heated seat switch out through the

front of the bezel.

INSTALLATION

Both heated seat switches and the heated seat

switch bezel are available individually for service

replacement.

NOTE: When installing the heated seat switches, be

certain they are installed in the proper mounting

holes of the heated seat switch bezel. Note that the

driver side and passenger side switches are identi-

cal in appearance except for the keyway in the con-

nector receptacle on the backs of the switches. The

driver side switch has the keyway located near the

bottom of the connector receptacle and should be

installed in the left mounting hole of the heated

seat switch bezel. The passenger side switch has

the keyway located near the top of the connector

receptacle and should be installed in the right

mounting hole of the heated seat switch bezel.

(1) From the front of the heated seat switch bezel,

align the back of the heated seat switch with the

proper mounting hole in the heated seat switch bezel

and gently push the switch into the bezel until it

snaps into place.

(2) Position the heated seat switch bezel and both

switches to the instrument panel as a unit.

(3) Reconnect the two instrument panel wire har-

ness connectors to the connector receptacles on the

backs of the heated seat switches.(4) Position the heated seat switch bezel and both

switches in the instrument panel mounting hole as a

unit.

(5) Install and tighten the three screws that secure

the heated seat switch bezel to the instrument panel.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(6) Install the cluster bezel onto the instrument

panel. Refer toCluster Bezelin the index of this

service manual for the location of the proper cluster

bezel installation procedures.

(7) Reconnect the battery negative cable.

HEATED SEAT ELEMENT

DESCRIPTION

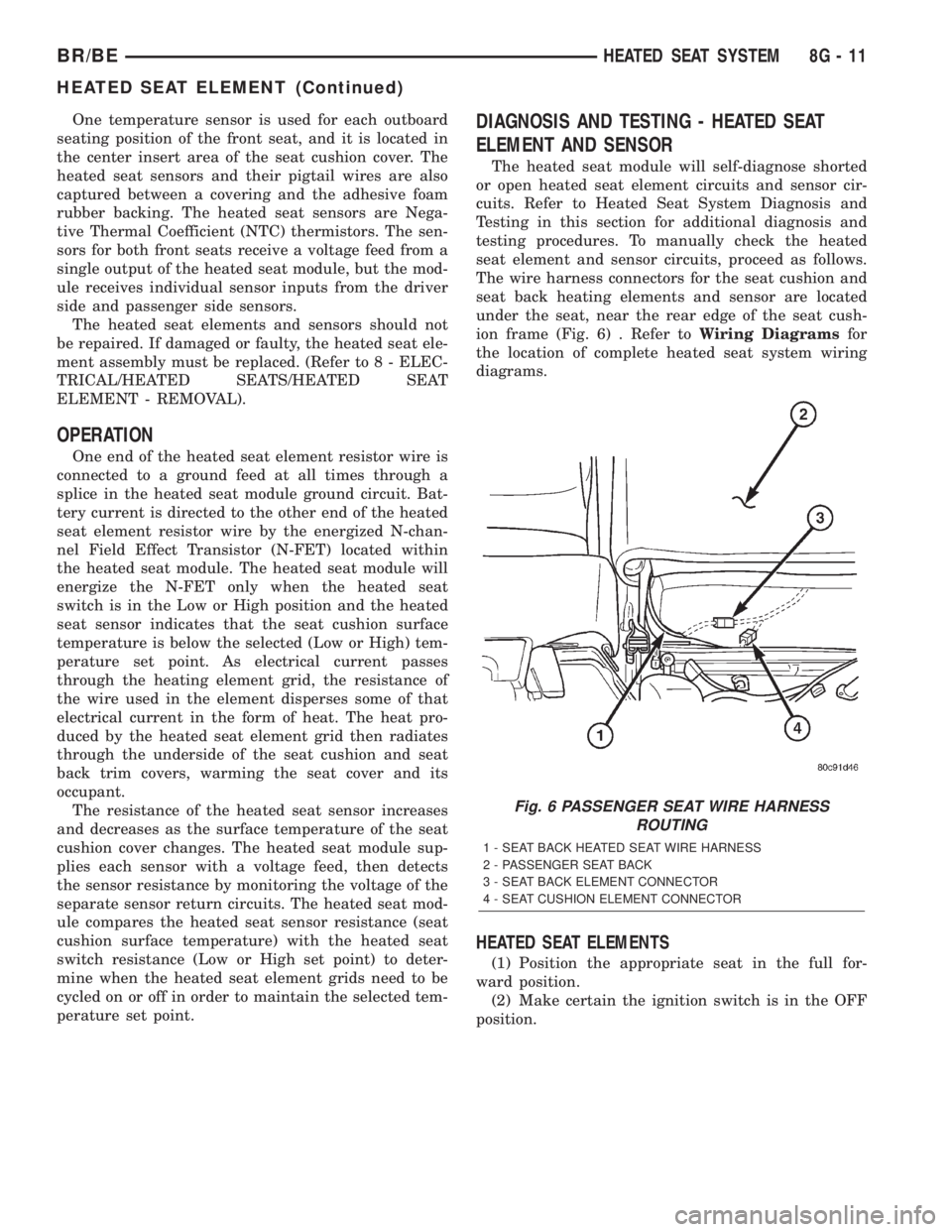

Vehicles equipped with the optional heated seat

system have two sets of electrically operated heating

element grids located in each front seat, one set for

the seat cushion and the other set for the seat back.

Each of the heated seat element grids consists of a

single length of resistor wire that is routed in a zig-

zag pattern and captured between a covering and the

adhesive foam rubber backing. Short pigtail wires

with connectors (Fig. 5) are soldered to each end of

each resistor wire element grid, which connect all of

the element grids for each seating position to each

other in series with the heated seat module through

the seat wire harness.

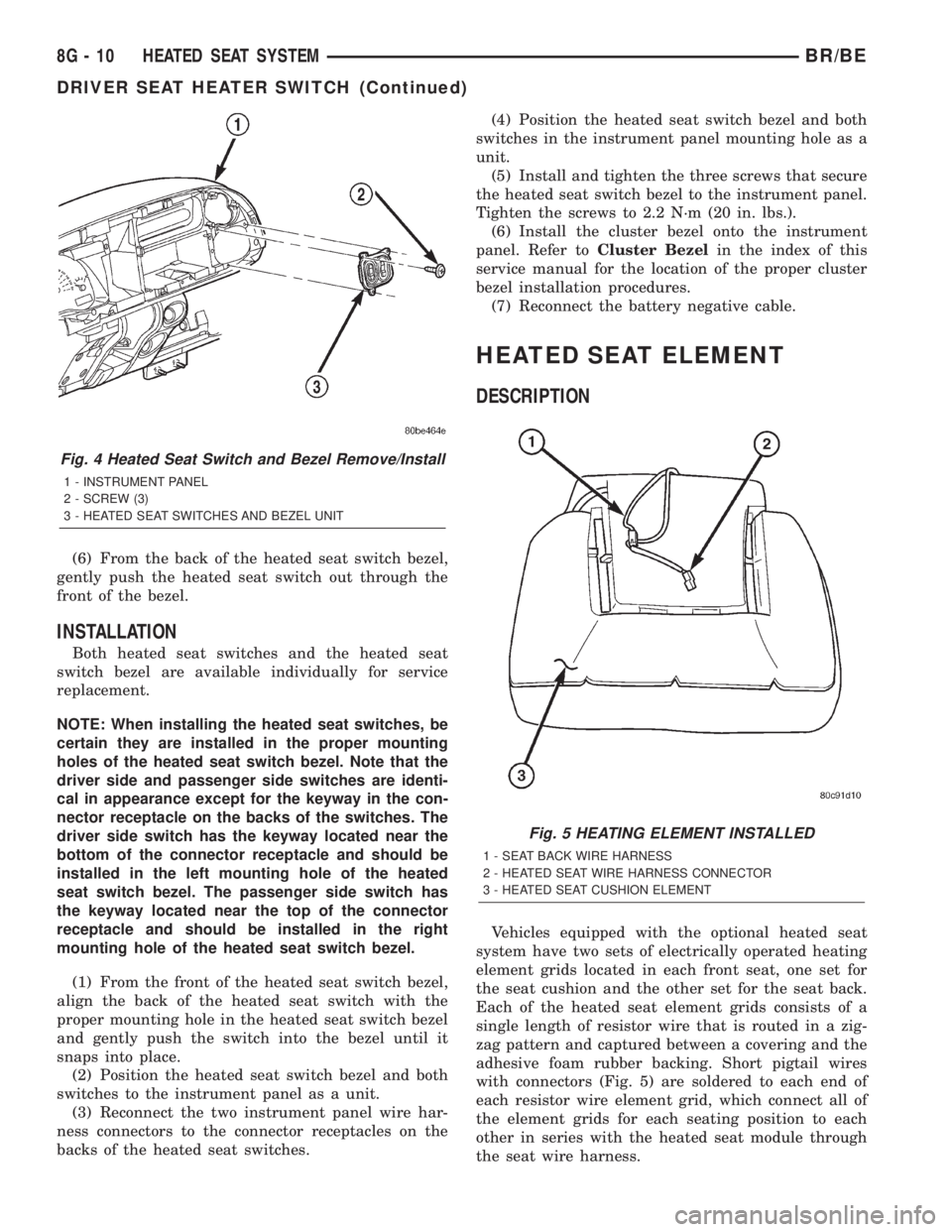

Fig. 4 Heated Seat Switch and Bezel Remove/Install

1 - INSTRUMENT PANEL

2 - SCREW (3)

3 - HEATED SEAT SWITCHES AND BEZEL UNIT

Fig. 5 HEATING ELEMENT INSTALLED

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

8G - 10 HEATED SEAT SYSTEMBR/BE

DRIVER SEAT HEATER SWITCH (Continued)

Page 442 of 2255

One temperature sensor is used for each outboard

seating position of the front seat, and it is located in

the center insert area of the seat cushion cover. The

heated seat sensors and their pigtail wires are also

captured between a covering and the adhesive foam

rubber backing. The heated seat sensors are Nega-

tive Thermal Coefficient (NTC) thermistors. The sen-

sors for both front seats receive a voltage feed from a

single output of the heated seat module, but the mod-

ule receives individual sensor inputs from the driver

side and passenger side sensors.

The heated seat elements and sensors should not

be repaired. If damaged or faulty, the heated seat ele-

ment assembly must be replaced. (Refer to 8 - ELEC-

TRICAL/HEATED SEATS/HEATED SEAT

ELEMENT - REMOVAL).

OPERATION

One end of the heated seat element resistor wire is

connected to a ground feed at all times through a

splice in the heated seat module ground circuit. Bat-

tery current is directed to the other end of the heated

seat element resistor wire by the energized N-chan-

nel Field Effect Transistor (N-FET) located within

the heated seat module. The heated seat module will

energize the N-FET only when the heated seat

switch is in the Low or High position and the heated

seat sensor indicates that the seat cushion surface

temperature is below the selected (Low or High) tem-

perature set point. As electrical current passes

through the heating element grid, the resistance of

the wire used in the element disperses some of that

electrical current in the form of heat. The heat pro-

duced by the heated seat element grid then radiates

through the underside of the seat cushion and seat

back trim covers, warming the seat cover and its

occupant.

The resistance of the heated seat sensor increases

and decreases as the surface temperature of the seat

cushion cover changes. The heated seat module sup-

plies each sensor with a voltage feed, then detects

the sensor resistance by monitoring the voltage of the

separate sensor return circuits. The heated seat mod-

ule compares the heated seat sensor resistance (seat

cushion surface temperature) with the heated seat

switch resistance (Low or High set point) to deter-

mine when the heated seat element grids need to be

cycled on or off in order to maintain the selected tem-

perature set point.

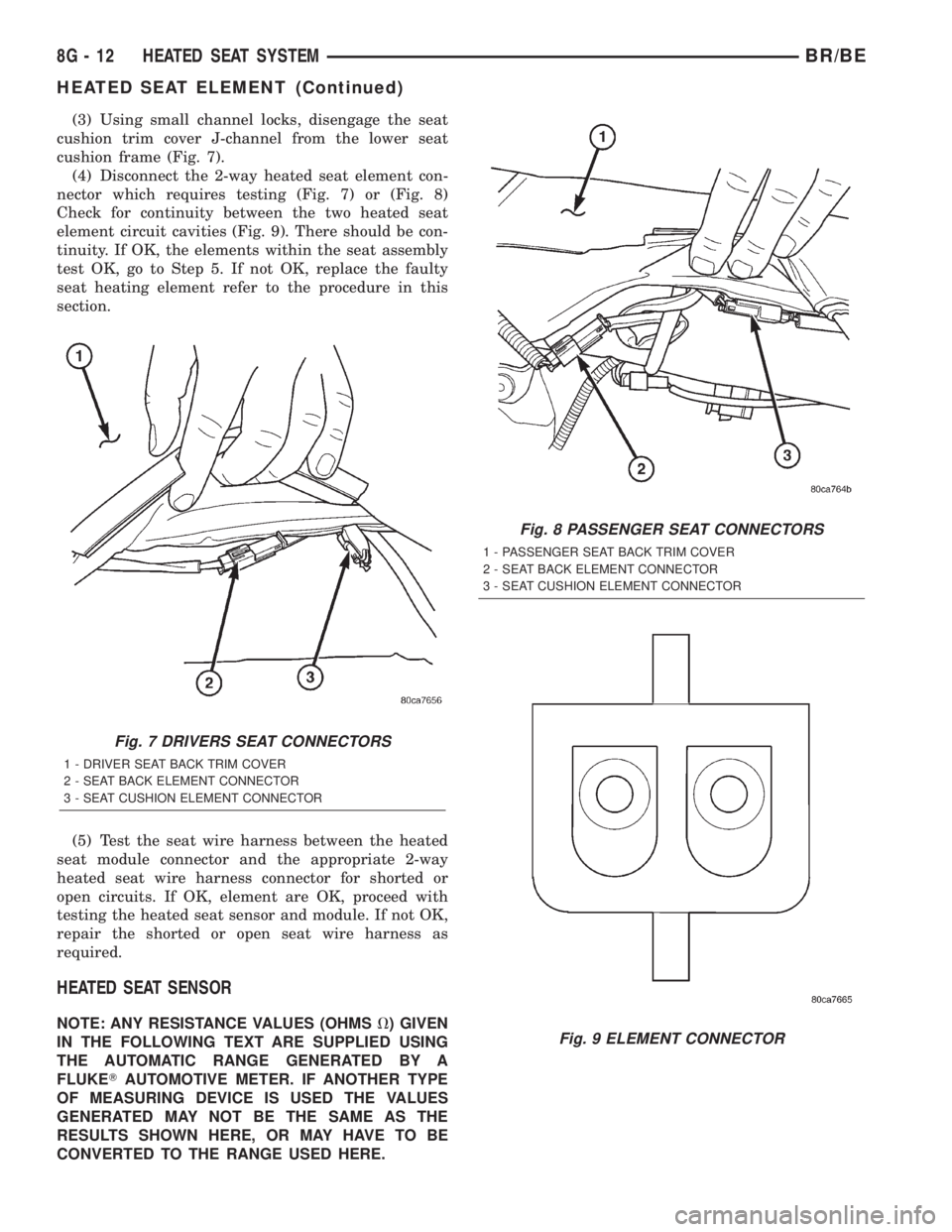

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT AND SENSOR

The heated seat module will self-diagnose shorted

or open heated seat element circuits and sensor cir-

cuits. Refer to Heated Seat System Diagnosis and

Testing in this section for additional diagnosis and

testing procedures. To manually check the heated

seat element and sensor circuits, proceed as follows.

The wire harness connectors for the seat cushion and

seat back heating elements and sensor are located

under the seat, near the rear edge of the seat cush-

ion frame (Fig. 6) . Refer toWiring Diagramsfor

the location of complete heated seat system wiring

diagrams.

HEATED SEAT ELEMENTS

(1) Position the appropriate seat in the full for-

ward position.

(2) Make certain the ignition switch is in the OFF

position.

Fig. 6 PASSENGER SEAT WIRE HARNESS

ROUTING

1 - SEAT BACK HEATED SEAT WIRE HARNESS

2 - PASSENGER SEAT BACK

3 - SEAT BACK ELEMENT CONNECTOR

4 - SEAT CUSHION ELEMENT CONNECTOR

BR/BEHEATED SEAT SYSTEM 8G - 11

HEATED SEAT ELEMENT (Continued)

Page 443 of 2255

(3) Using small channel locks, disengage the seat

cushion trim cover J-channel from the lower seat

cushion frame (Fig. 7).

(4) Disconnect the 2-way heated seat element con-

nector which requires testing (Fig. 7) or (Fig. 8)

Check for continuity between the two heated seat

element circuit cavities (Fig. 9). There should be con-

tinuity. If OK, the elements within the seat assembly

test OK, go to Step 5. If not OK, replace the faulty

seat heating element refer to the procedure in this

section.

(5) Test the seat wire harness between the heated

seat module connector and the appropriate 2-way

heated seat wire harness connector for shorted or

open circuits. If OK, element are OK, proceed with

testing the heated seat sensor and module. If not OK,

repair the shorted or open seat wire harness as

required.

HEATED SEAT SENSOR

NOTE: ANY RESISTANCE VALUES (OHMSV) GIVEN

IN THE FOLLOWING TEXT ARE SUPPLIED USING

THE AUTOMATIC RANGE GENERATED BY A

FLUKETAUTOMOTIVE METER. IF ANOTHER TYPE

OF MEASURING DEVICE IS USED THE VALUES

GENERATED MAY NOT BE THE SAME AS THE

RESULTS SHOWN HERE, OR MAY HAVE TO BE

CONVERTED TO THE RANGE USED HERE.

Fig. 7 DRIVERS SEAT CONNECTORS

1 - DRIVER SEAT BACK TRIM COVER

2 - SEAT BACK ELEMENT CONNECTOR

3 - SEAT CUSHION ELEMENT CONNECTOR

Fig. 8 PASSENGER SEAT CONNECTORS

1 - PASSENGER SEAT BACK TRIM COVER

2 - SEAT BACK ELEMENT CONNECTOR

3 - SEAT CUSHION ELEMENT CONNECTOR

Fig. 9 ELEMENT CONNECTOR

8G - 12 HEATED SEAT SYSTEMBR/BE

HEATED SEAT ELEMENT (Continued)

Page 444 of 2255

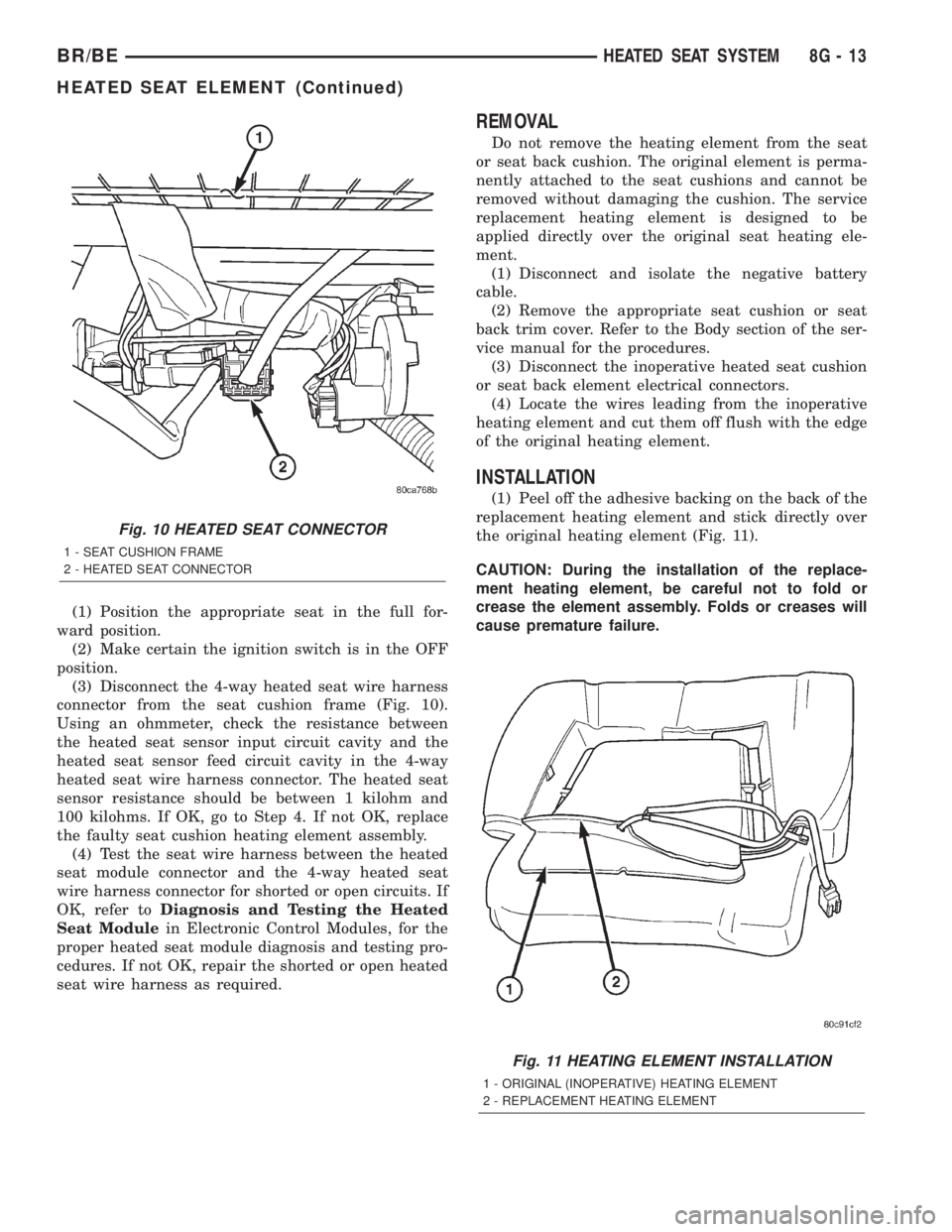

(1) Position the appropriate seat in the full for-

ward position.

(2) Make certain the ignition switch is in the OFF

position.

(3) Disconnect the 4-way heated seat wire harness

connector from the seat cushion frame (Fig. 10).

Using an ohmmeter, check the resistance between

the heated seat sensor input circuit cavity and the

heated seat sensor feed circuit cavity in the 4-way

heated seat wire harness connector. The heated seat

sensor resistance should be between 1 kilohm and

100 kilohms. If OK, go to Step 4. If not OK, replace

the faulty seat cushion heating element assembly.

(4) Test the seat wire harness between the heated

seat module connector and the 4-way heated seat

wire harness connector for shorted or open circuits. If

OK, refer toDiagnosis and Testing the Heated

Seat Modulein Electronic Control Modules, for the

proper heated seat module diagnosis and testing pro-

cedures. If not OK, repair the shorted or open heated

seat wire harness as required.

REMOVAL

Do not remove the heating element from the seat

or seat back cushion. The original element is perma-

nently attached to the seat cushions and cannot be

removed without damaging the cushion. The service

replacement heating element is designed to be

applied directly over the original seat heating ele-

ment.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate seat cushion or seat

back trim cover. Refer to the Body section of the ser-

vice manual for the procedures.

(3) Disconnect the inoperative heated seat cushion

or seat back element electrical connectors.

(4) Locate the wires leading from the inoperative

heating element and cut them off flush with the edge

of the original heating element.

INSTALLATION

(1) Peel off the adhesive backing on the back of the

replacement heating element and stick directly over

the original heating element (Fig. 11).

CAUTION: During the installation of the replace-

ment heating element, be careful not to fold or

crease the element assembly. Folds or creases will

cause premature failure.

Fig. 10 HEATED SEAT CONNECTOR

1 - SEAT CUSHION FRAME

2 - HEATED SEAT CONNECTOR

Fig. 11 HEATING ELEMENT INSTALLATION

1 - ORIGINAL (INOPERATIVE) HEATING ELEMENT

2 - REPLACEMENT HEATING ELEMENT

BR/BEHEATED SEAT SYSTEM 8G - 13

HEATED SEAT ELEMENT (Continued)

Page 445 of 2255

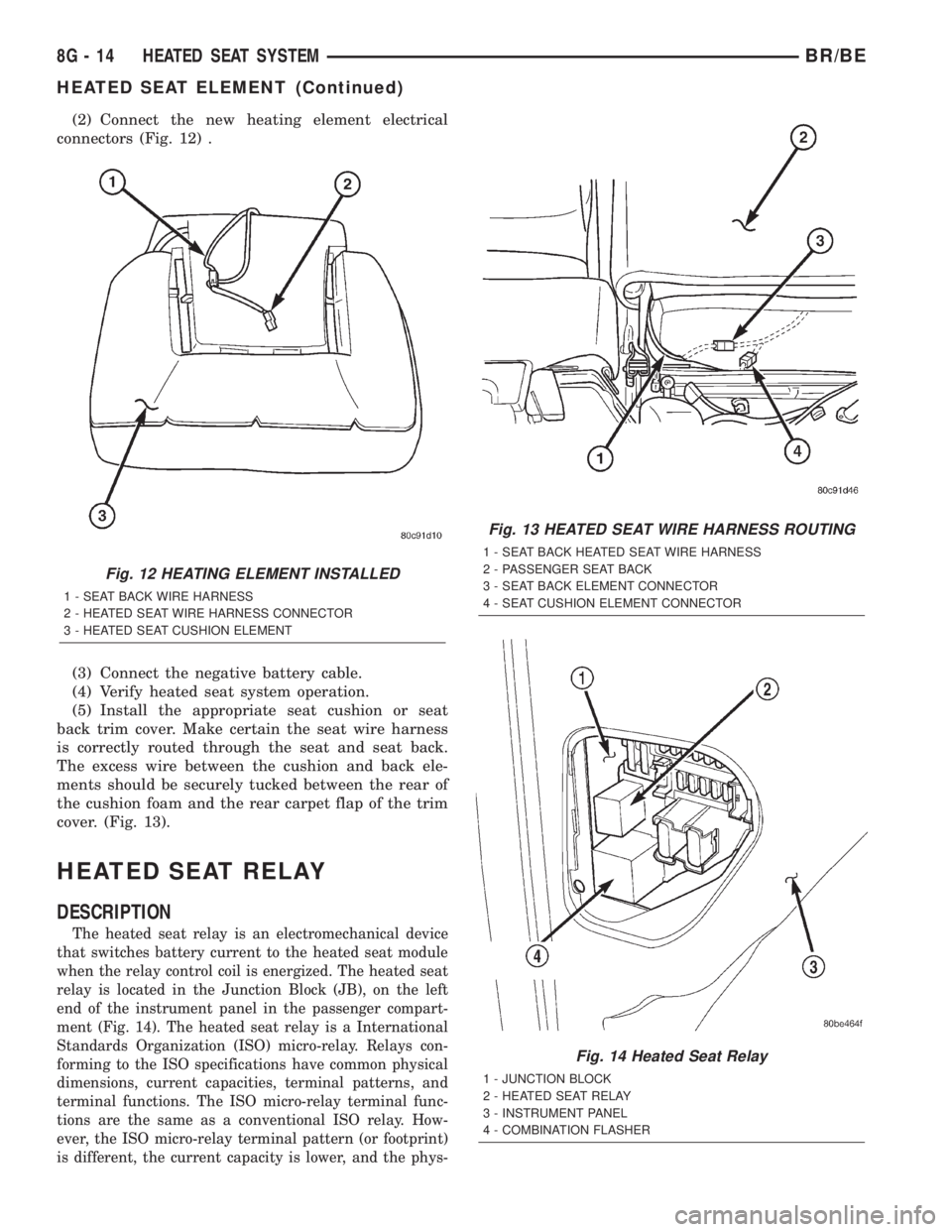

(2) Connect the new heating element electrical

connectors (Fig. 12) .

(3) Connect the negative battery cable.

(4) Verify heated seat system operation.

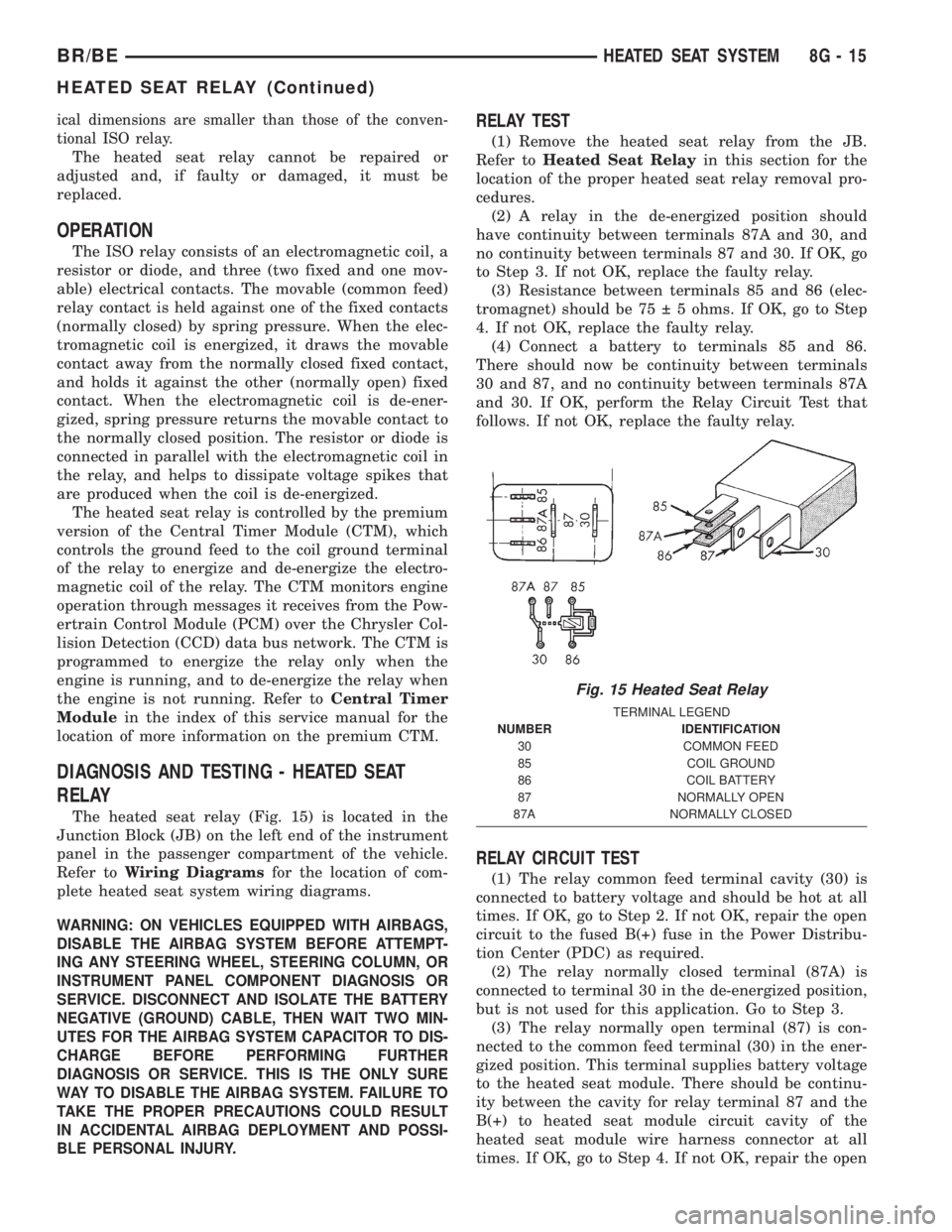

(5) Install the appropriate seat cushion or seat

back trim cover. Make certain the seat wire harness

is correctly routed through the seat and seat back.

The excess wire between the cushion and back ele-

ments should be securely tucked between the rear of

the cushion foam and the rear carpet flap of the trim

cover. (Fig. 13).

HEATED SEAT RELAY

DESCRIPTION

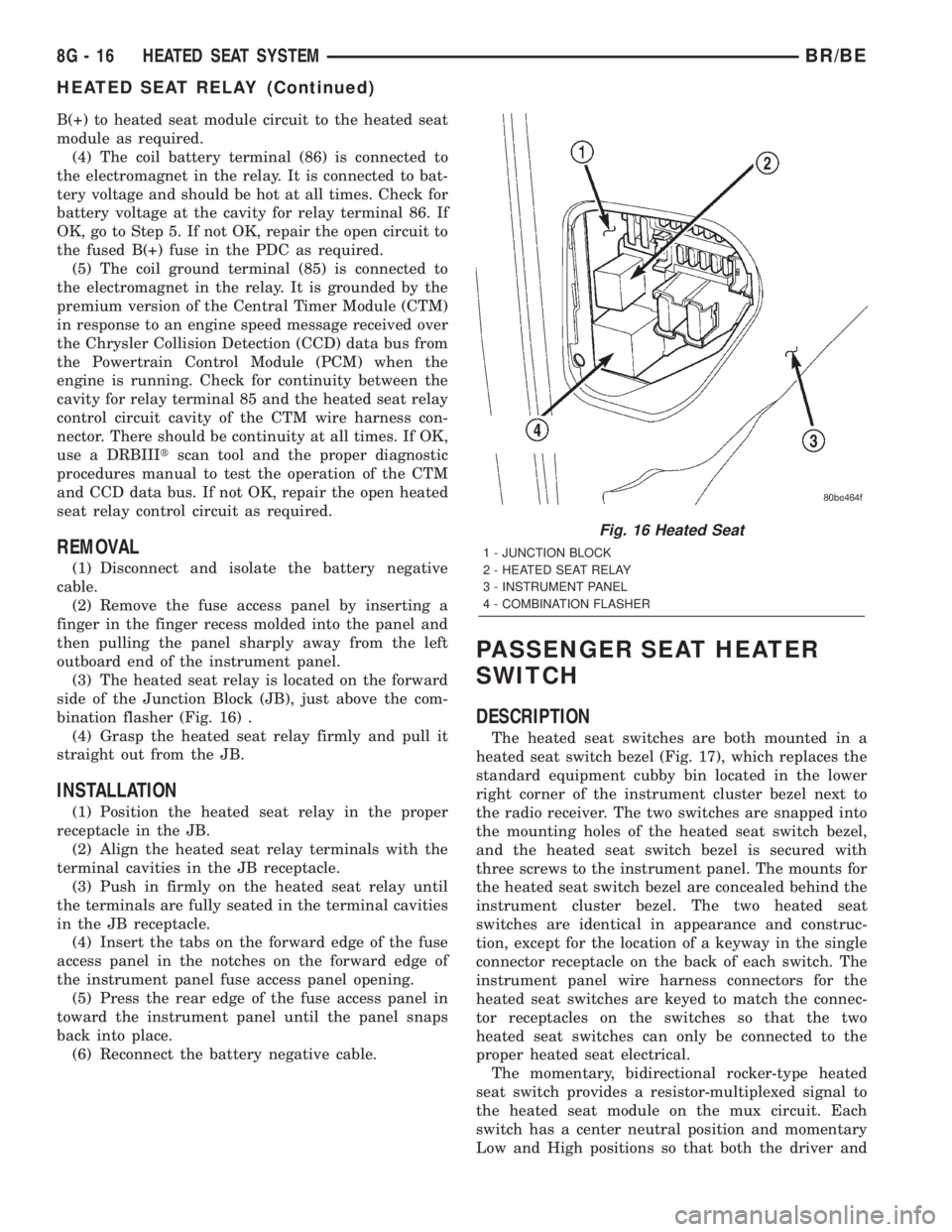

The heated seat relay is an electromechanical device

that switches battery current to the heated seat module

when the relay control coil is energized. The heated seat

relay is located in the Junction Block (JB), on the left

end of the instrument panel in the passenger compart-

ment (Fig. 14). The heated seat relay is a International

Standards Organization (ISO) micro-relay. Relays con-

forming to the ISO specifications have common physical

dimensions, current capacities, terminal patterns, and

terminal functions. The ISO micro-relay terminal func-

tions are the same as a conventional ISO relay. How-

ever, the ISO micro-relay terminal pattern (or footprint)

is different, the current capacity is lower, and the phys-

Fig. 12 HEATING ELEMENT INSTALLED

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

Fig. 13 HEATED SEAT WIRE HARNESS ROUTING

1 - SEAT BACK HEATED SEAT WIRE HARNESS

2 - PASSENGER SEAT BACK

3 - SEAT BACK ELEMENT CONNECTOR

4 - SEAT CUSHION ELEMENT CONNECTOR

Fig. 14 Heated Seat Relay

1 - JUNCTION BLOCK

2 - HEATED SEAT RELAY

3 - INSTRUMENT PANEL

4 - COMBINATION FLASHER

8G - 14 HEATED SEAT SYSTEMBR/BE

HEATED SEAT ELEMENT (Continued)

Page 446 of 2255

ical dimensions are smaller than those of the conven-

tional ISO relay.

The heated seat relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact. When the electromagnetic coil is de-ener-

gized, spring pressure returns the movable contact to

the normally closed position. The resistor or diode is

connected in parallel with the electromagnetic coil in

the relay, and helps to dissipate voltage spikes that

are produced when the coil is de-energized.

The heated seat relay is controlled by the premium

version of the Central Timer Module (CTM), which

controls the ground feed to the coil ground terminal

of the relay to energize and de-energize the electro-

magnetic coil of the relay. The CTM monitors engine

operation through messages it receives from the Pow-

ertrain Control Module (PCM) over the Chrysler Col-

lision Detection (CCD) data bus network. The CTM is

programmed to energize the relay only when the

engine is running, and to de-energize the relay when

the engine is not running. Refer toCentral Timer

Modulein the index of this service manual for the

location of more information on the premium CTM.

DIAGNOSIS AND TESTING - HEATED SEAT

RELAY

The heated seat relay (Fig. 15) is located in the

Junction Block (JB) on the left end of the instrument

panel in the passenger compartment of the vehicle.

Refer toWiring Diagramsfor the location of com-

plete heated seat system wiring diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO MIN-

UTES FOR THE AIRBAG SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

RELAY TEST

(1) Remove the heated seat relay from the JB.

Refer toHeated Seat Relayin this section for the

location of the proper heated seat relay removal pro-

cedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fused B(+) fuse in the Power Distribu-

tion Center (PDC) as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the heated seat module. There should be continu-

ity between the cavity for relay terminal 87 and the

B(+) to heated seat module circuit cavity of the

heated seat module wire harness connector at all

times. If OK, go to Step 4. If not OK, repair the open

Fig. 15 Heated Seat Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

BR/BEHEATED SEAT SYSTEM 8G - 15

HEATED SEAT RELAY (Continued)

Page 447 of 2255

B(+) to heated seat module circuit to the heated seat

module as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is connected to bat-

tery voltage and should be hot at all times. Check for

battery voltage at the cavity for relay terminal 86. If

OK, go to Step 5. If not OK, repair the open circuit to

the fused B(+) fuse in the PDC as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded by the

premium version of the Central Timer Module (CTM)

in response to an engine speed message received over

the Chrysler Collision Detection (CCD) data bus from

the Powertrain Control Module (PCM) when the

engine is running. Check for continuity between the

cavity for relay terminal 85 and the heated seat relay

control circuit cavity of the CTM wire harness con-

nector. There should be continuity at all times. If OK,

use a DRBIIItscan tool and the proper diagnostic

procedures manual to test the operation of the CTM

and CCD data bus. If not OK, repair the open heated

seat relay control circuit as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access panel by inserting a

finger in the finger recess molded into the panel and

then pulling the panel sharply away from the left

outboard end of the instrument panel.

(3) The heated seat relay is located on the forward

side of the Junction Block (JB), just above the com-

bination flasher (Fig. 16) .

(4) Grasp the heated seat relay firmly and pull it

straight out from the JB.

INSTALLATION

(1) Position the heated seat relay in the proper

receptacle in the JB.

(2) Align the heated seat relay terminals with the

terminal cavities in the JB receptacle.

(3) Push in firmly on the heated seat relay until

the terminals are fully seated in the terminal cavities

in the JB receptacle.

(4) Insert the tabs on the forward edge of the fuse

access panel in the notches on the forward edge of

the instrument panel fuse access panel opening.

(5) Press the rear edge of the fuse access panel in

toward the instrument panel until the panel snaps

back into place.

(6) Reconnect the battery negative cable.

PASSENGER SEAT HEATER

SWITCH

DESCRIPTION

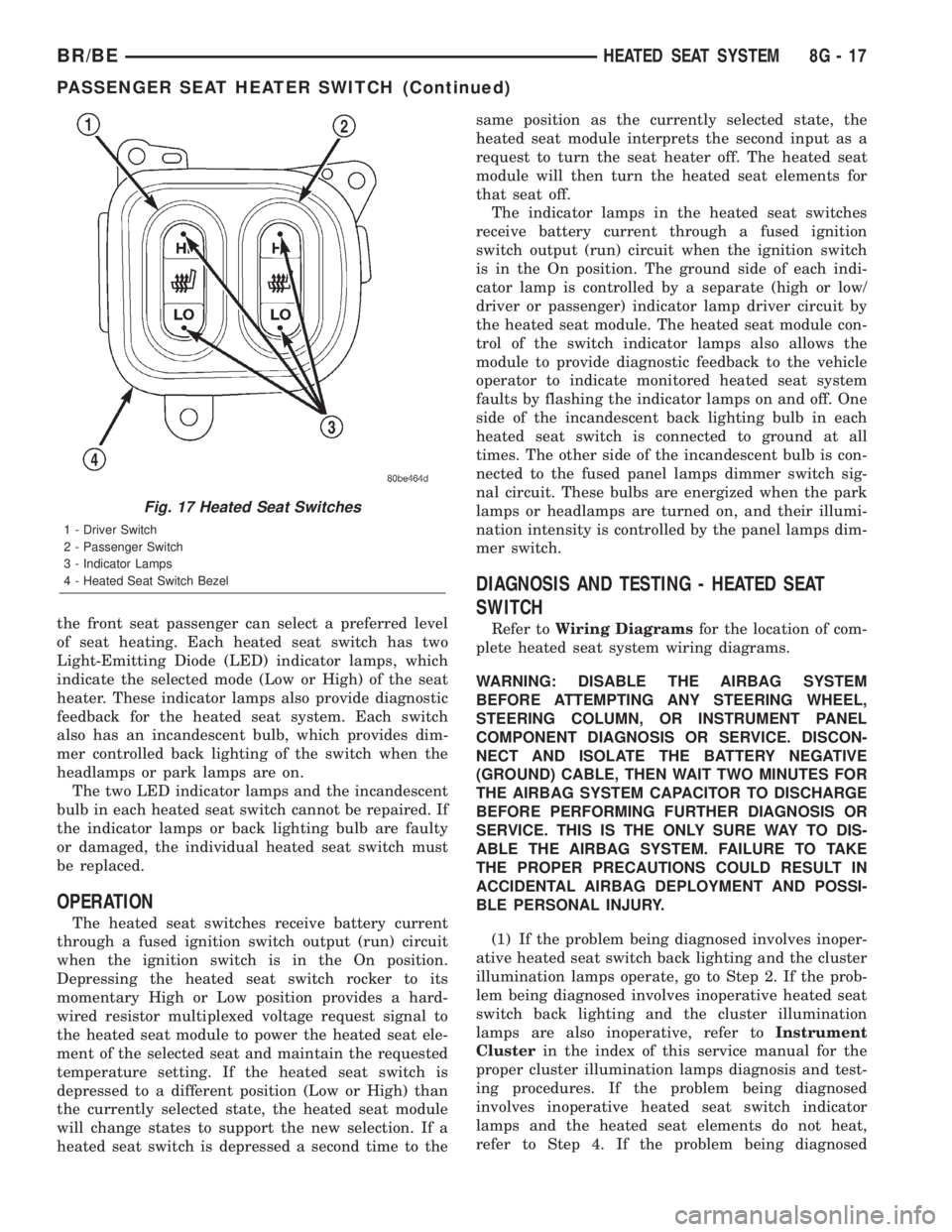

The heated seat switches are both mounted in a

heated seat switch bezel (Fig. 17), which replaces the

standard equipment cubby bin located in the lower

right corner of the instrument cluster bezel next to

the radio receiver. The two switches are snapped into

the mounting holes of the heated seat switch bezel,

and the heated seat switch bezel is secured with

three screws to the instrument panel. The mounts for

the heated seat switch bezel are concealed behind the

instrument cluster bezel. The two heated seat

switches are identical in appearance and construc-

tion, except for the location of a keyway in the single

connector receptacle on the back of each switch. The

instrument panel wire harness connectors for the

heated seat switches are keyed to match the connec-

tor receptacles on the switches so that the two

heated seat switches can only be connected to the

proper heated seat electrical.

The momentary, bidirectional rocker-type heated

seat switch provides a resistor-multiplexed signal to

the heated seat module on the mux circuit. Each

switch has a center neutral position and momentary

Low and High positions so that both the driver and

Fig. 16 Heated Seat

1 - JUNCTION BLOCK

2 - HEATED SEAT RELAY

3 - INSTRUMENT PANEL

4 - COMBINATION FLASHER

8G - 16 HEATED SEAT SYSTEMBR/BE

HEATED SEAT RELAY (Continued)

Page 448 of 2255

the front seat passenger can select a preferred level

of seat heating. Each heated seat switch has two

Light-Emitting Diode (LED) indicator lamps, which

indicate the selected mode (Low or High) of the seat

heater. These indicator lamps also provide diagnostic

feedback for the heated seat system. Each switch

also has an incandescent bulb, which provides dim-

mer controlled back lighting of the switch when the

headlamps or park lamps are on.

The two LED indicator lamps and the incandescent

bulb in each heated seat switch cannot be repaired. If

the indicator lamps or back lighting bulb are faulty

or damaged, the individual heated seat switch must

be replaced.

OPERATION

The heated seat switches receive battery current

through a fused ignition switch output (run) circuit

when the ignition switch is in the On position.

Depressing the heated seat switch rocker to its

momentary High or Low position provides a hard-

wired resistor multiplexed voltage request signal to

the heated seat module to power the heated seat ele-

ment of the selected seat and maintain the requested

temperature setting. If the heated seat switch is

depressed to a different position (Low or High) than

the currently selected state, the heated seat module

will change states to support the new selection. If a

heated seat switch is depressed a second time to thesame position as the currently selected state, the

heated seat module interprets the second input as a

request to turn the seat heater off. The heated seat

module will then turn the heated seat elements for

that seat off.

The indicator lamps in the heated seat switches

receive battery current through a fused ignition

switch output (run) circuit when the ignition switch

is in the On position. The ground side of each indi-

cator lamp is controlled by a separate (high or low/

driver or passenger) indicator lamp driver circuit by

the heated seat module. The heated seat module con-

trol of the switch indicator lamps also allows the

module to provide diagnostic feedback to the vehicle

operator to indicate monitored heated seat system

faults by flashing the indicator lamps on and off. One

side of the incandescent back lighting bulb in each

heated seat switch is connected to ground at all

times. The other side of the incandescent bulb is con-

nected to the fused panel lamps dimmer switch sig-

nal circuit. These bulbs are energized when the park

lamps or headlamps are turned on, and their illumi-

nation intensity is controlled by the panel lamps dim-

mer switch.

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH

Refer toWiring Diagramsfor the location of com-

plete heated seat system wiring diagrams.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) If the problem being diagnosed involves inoper-

ative heated seat switch back lighting and the cluster

illumination lamps operate, go to Step 2. If the prob-

lem being diagnosed involves inoperative heated seat

switch back lighting and the cluster illumination

lamps are also inoperative, refer toInstrument

Clusterin the index of this service manual for the

proper cluster illumination lamps diagnosis and test-

ing procedures. If the problem being diagnosed

involves inoperative heated seat switch indicator

lamps and the heated seat elements do not heat,

refer to Step 4. If the problem being diagnosed

Fig. 17 Heated Seat Switches

1 - Driver Switch

2 - Passenger Switch

3 - Indicator Lamps

4 - Heated Seat Switch Bezel

BR/BEHEATED SEAT SYSTEM 8G - 17

PASSENGER SEAT HEATER SWITCH (Continued)

Page 449 of 2255

involves inoperative heated seat switch indicator

lamps and the heated seat elements do heat, go to

Step 8. If the problem being diagnosed involves a

heated seat switch indicator lamp that remains illu-

minated after the heated seat has been turned Off,

refer toHeated Seat Modulein Electronic Control

Modules for the location of the proper heated seat

module diagnosis and testing procedures. Also refer

to the Body Diagnostic Manual for additional diagno-

sis and testing procedures.

(2) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the instru-

ment panel wire harness connector from the connec-

tor receptacle on the back of the heated seat switch

to be tested. Check for continuity between the ground

circuit cavity of the instrument panel wire harness

connector for the heated seat switch and a good

ground. There should be continuity. If OK, go to Step

3. If not OK, repair the open ground circuit to ground

as required.

(3) Reconnect the battery negative cable. Turn the

park lamps on with the headlamp switch. Rotate the

panel lamps dimmer thumbwheel on the headlamp

switch upward to just before the interior lamps

detent. Check for battery voltage at the fused panel

lamps dimmer switch signal circuit cavity of the

instrument panel wire harness connector for the

heated seat switch. If OK, replace the faulty heated

seat switch. If not OK, repair the open fused panel

lamps dimmer switch signal circuit to the fuse in the

Junction Block (JB) as required.

(4) Check the fused ignition switch output (run)

fuse in the Junction Block (JB). If OK, go to Step 5.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(5) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the JB. If OK, go to Step 6. If

not OK, repair the open fused ignition switch output

(run) circuit to the ignition switch as required.

(6) Disconnect and isolate the battery negative

cable. Remove the heated seat switch and bezel unit

from the instrument panel. Disconnect the instru-

ment panel wire harness connector from the connec-

tor receptacle on the back of the heated seat switch

to be tested. Reconnect the battery negative cable.

Turn the ignition switch to the On position. Check

for battery voltage at the fused ignition switch out-

put (run) circuit cavity of the instrument panel wire

harness connector for the heated seat switch. If OK,

go to Step 7. If not OK, repair the open fused ignition

switch output (run) circuit to the JB fuse as required.

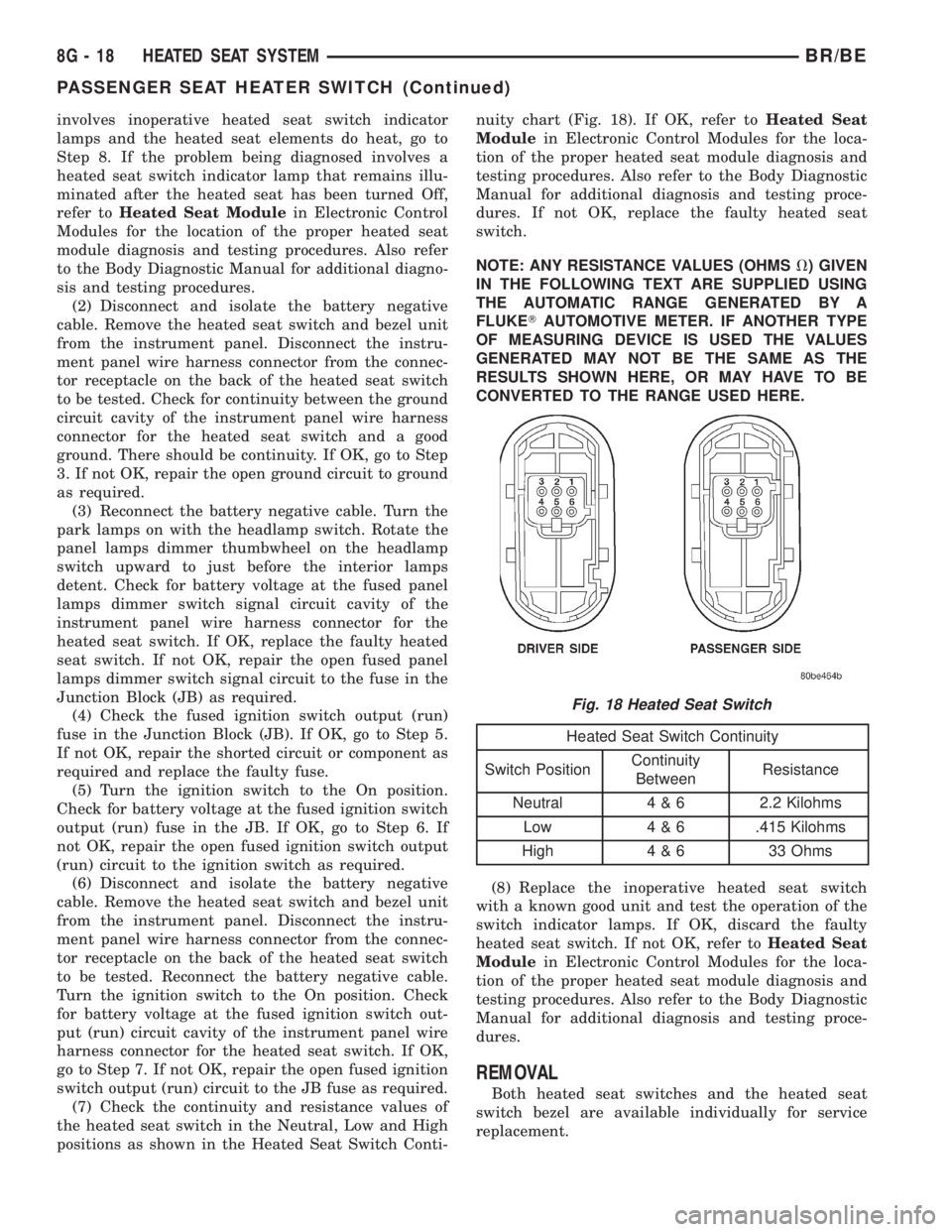

(7) Check the continuity and resistance values of

the heated seat switch in the Neutral, Low and High

positions as shown in the Heated Seat Switch Conti-nuity chart (Fig. 18). If OK, refer toHeated Seat

Modulein Electronic Control Modules for the loca-

tion of the proper heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures. If not OK, replace the faulty heated seat

switch.

NOTE: ANY RESISTANCE VALUES (OHMSV) GIVEN

IN THE FOLLOWING TEXT ARE SUPPLIED USING

THE AUTOMATIC RANGE GENERATED BY A

FLUKETAUTOMOTIVE METER. IF ANOTHER TYPE

OF MEASURING DEVICE IS USED THE VALUES

GENERATED MAY NOT BE THE SAME AS THE

RESULTS SHOWN HERE, OR MAY HAVE TO BE

CONVERTED TO THE RANGE USED HERE.

Heated Seat Switch Continuity

Switch PositionContinuity

BetweenResistance

Neutral 4 & 6 2.2 Kilohms

Low 4 & 6 .415 Kilohms

High 4 & 6 33 Ohms

(8) Replace the inoperative heated seat switch

with a known good unit and test the operation of the

switch indicator lamps. If OK, discard the faulty

heated seat switch. If not OK, refer toHeated Seat

Modulein Electronic Control Modules for the loca-

tion of the proper heated seat module diagnosis and

testing procedures. Also refer to the Body Diagnostic

Manual for additional diagnosis and testing proce-

dures.

REMOVAL

Both heated seat switches and the heated seat

switch bezel are available individually for service

replacement.

Fig. 18 Heated Seat Switch

8G - 18 HEATED SEAT SYSTEMBR/BE

PASSENGER SEAT HEATER SWITCH (Continued)

Page 450 of 2255

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel. Refer toCluster Bezelin the index of this

service manual for the location of the proper cluster

bezel removal procedures.

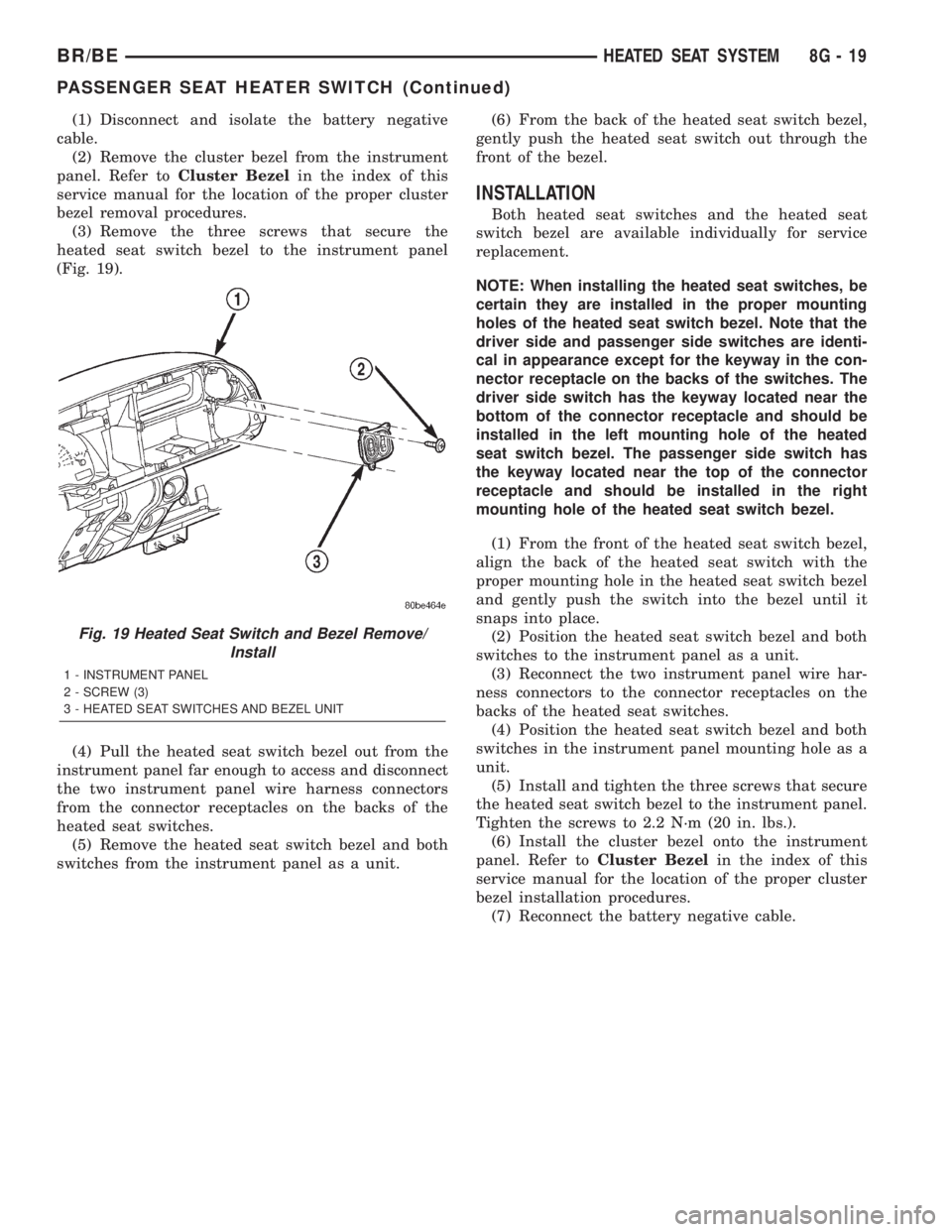

(3) Remove the three screws that secure the

heated seat switch bezel to the instrument panel

(Fig. 19).

(4) Pull the heated seat switch bezel out from the

instrument panel far enough to access and disconnect

the two instrument panel wire harness connectors

from the connector receptacles on the backs of the

heated seat switches.

(5) Remove the heated seat switch bezel and both

switches from the instrument panel as a unit.(6) From the back of the heated seat switch bezel,

gently push the heated seat switch out through the

front of the bezel.

INSTALLATION

Both heated seat switches and the heated seat

switch bezel are available individually for service

replacement.

NOTE: When installing the heated seat switches, be

certain they are installed in the proper mounting

holes of the heated seat switch bezel. Note that the

driver side and passenger side switches are identi-

cal in appearance except for the keyway in the con-

nector receptacle on the backs of the switches. The

driver side switch has the keyway located near the

bottom of the connector receptacle and should be

installed in the left mounting hole of the heated

seat switch bezel. The passenger side switch has

the keyway located near the top of the connector

receptacle and should be installed in the right

mounting hole of the heated seat switch bezel.

(1) From the front of the heated seat switch bezel,

align the back of the heated seat switch with the

proper mounting hole in the heated seat switch bezel

and gently push the switch into the bezel until it

snaps into place.

(2) Position the heated seat switch bezel and both

switches to the instrument panel as a unit.

(3) Reconnect the two instrument panel wire har-

ness connectors to the connector receptacles on the

backs of the heated seat switches.

(4) Position the heated seat switch bezel and both

switches in the instrument panel mounting hole as a

unit.

(5) Install and tighten the three screws that secure

the heated seat switch bezel to the instrument panel.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(6) Install the cluster bezel onto the instrument

panel. Refer toCluster Bezelin the index of this

service manual for the location of the proper cluster

bezel installation procedures.

(7) Reconnect the battery negative cable.

Fig. 19 Heated Seat Switch and Bezel Remove/

Install

1 - INSTRUMENT PANEL

2 - SCREW (3)

3 - HEATED SEAT SWITCHES AND BEZEL UNIT

BR/BEHEATED SEAT SYSTEM 8G - 19

PASSENGER SEAT HEATER SWITCH (Continued)