heating DODGE RAM 2002 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 445 of 2255

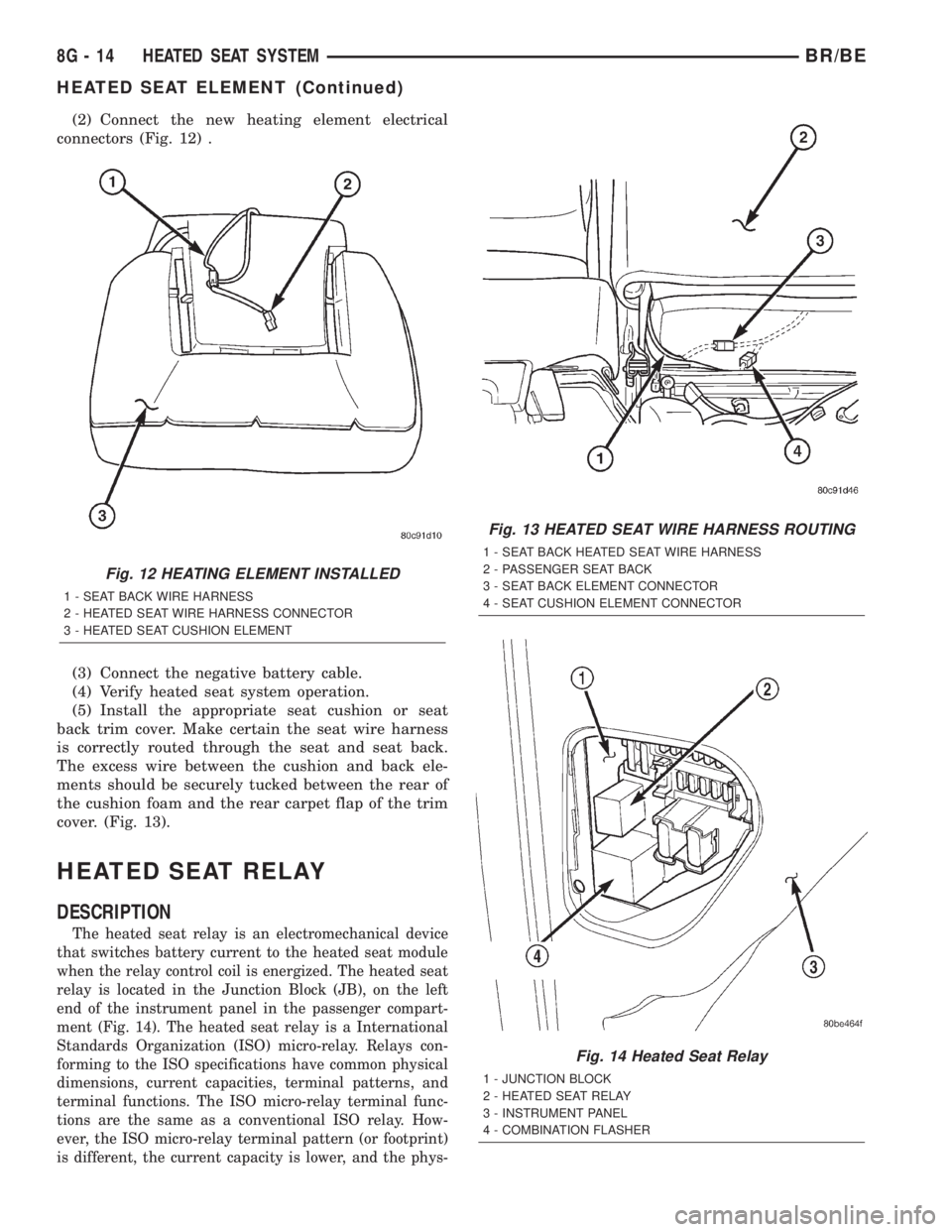

(2) Connect the new heating element electrical

connectors (Fig. 12) .

(3) Connect the negative battery cable.

(4) Verify heated seat system operation.

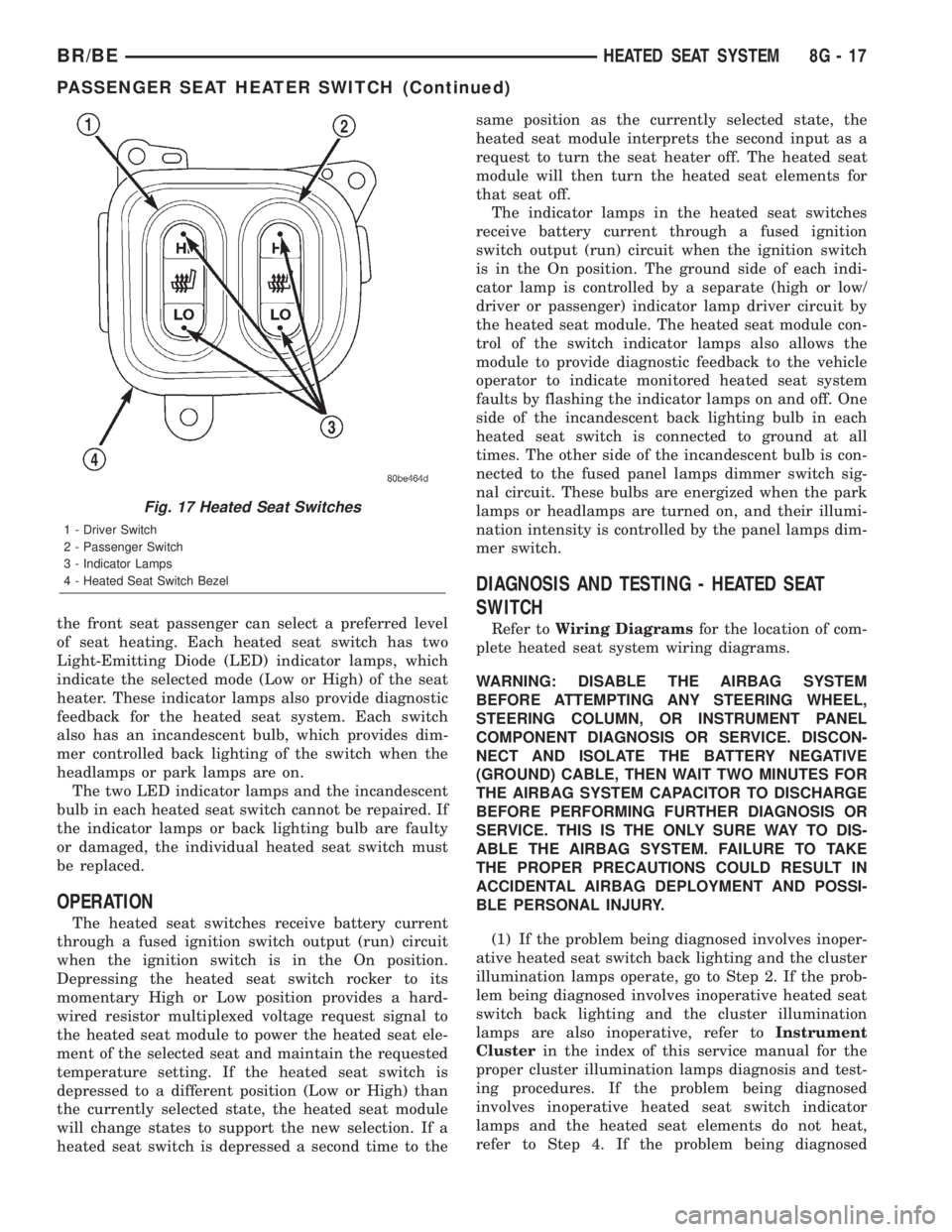

(5) Install the appropriate seat cushion or seat

back trim cover. Make certain the seat wire harness

is correctly routed through the seat and seat back.

The excess wire between the cushion and back ele-

ments should be securely tucked between the rear of

the cushion foam and the rear carpet flap of the trim

cover. (Fig. 13).

HEATED SEAT RELAY

DESCRIPTION

The heated seat relay is an electromechanical device

that switches battery current to the heated seat module

when the relay control coil is energized. The heated seat

relay is located in the Junction Block (JB), on the left

end of the instrument panel in the passenger compart-

ment (Fig. 14). The heated seat relay is a International

Standards Organization (ISO) micro-relay. Relays con-

forming to the ISO specifications have common physical

dimensions, current capacities, terminal patterns, and

terminal functions. The ISO micro-relay terminal func-

tions are the same as a conventional ISO relay. How-

ever, the ISO micro-relay terminal pattern (or footprint)

is different, the current capacity is lower, and the phys-

Fig. 12 HEATING ELEMENT INSTALLED

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

Fig. 13 HEATED SEAT WIRE HARNESS ROUTING

1 - SEAT BACK HEATED SEAT WIRE HARNESS

2 - PASSENGER SEAT BACK

3 - SEAT BACK ELEMENT CONNECTOR

4 - SEAT CUSHION ELEMENT CONNECTOR

Fig. 14 Heated Seat Relay

1 - JUNCTION BLOCK

2 - HEATED SEAT RELAY

3 - INSTRUMENT PANEL

4 - COMBINATION FLASHER

8G - 14 HEATED SEAT SYSTEMBR/BE

HEATED SEAT ELEMENT (Continued)

Page 448 of 2255

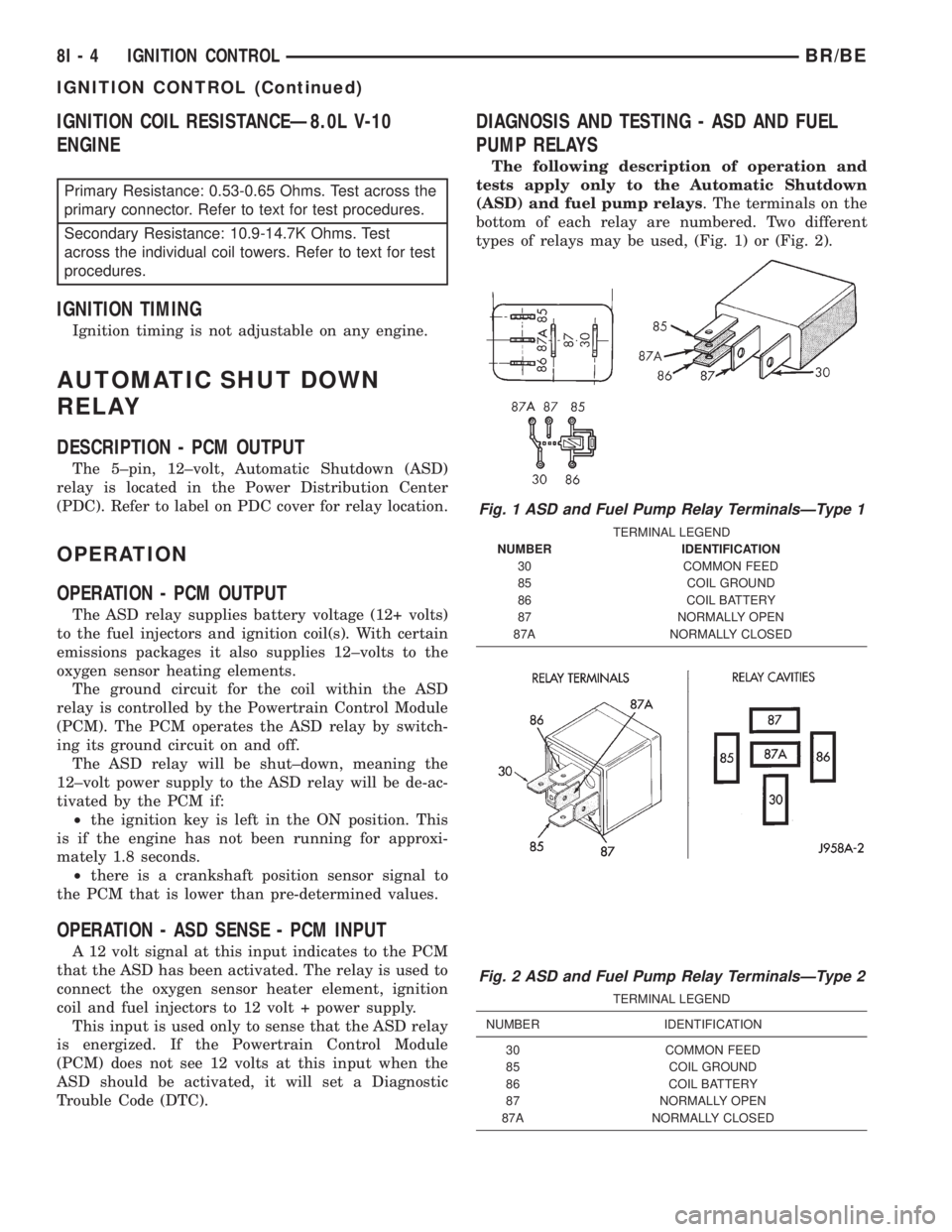

the front seat passenger can select a preferred level

of seat heating. Each heated seat switch has two

Light-Emitting Diode (LED) indicator lamps, which

indicate the selected mode (Low or High) of the seat

heater. These indicator lamps also provide diagnostic

feedback for the heated seat system. Each switch

also has an incandescent bulb, which provides dim-

mer controlled back lighting of the switch when the

headlamps or park lamps are on.

The two LED indicator lamps and the incandescent

bulb in each heated seat switch cannot be repaired. If

the indicator lamps or back lighting bulb are faulty

or damaged, the individual heated seat switch must

be replaced.

OPERATION

The heated seat switches receive battery current

through a fused ignition switch output (run) circuit

when the ignition switch is in the On position.

Depressing the heated seat switch rocker to its

momentary High or Low position provides a hard-

wired resistor multiplexed voltage request signal to

the heated seat module to power the heated seat ele-

ment of the selected seat and maintain the requested

temperature setting. If the heated seat switch is

depressed to a different position (Low or High) than

the currently selected state, the heated seat module

will change states to support the new selection. If a

heated seat switch is depressed a second time to thesame position as the currently selected state, the

heated seat module interprets the second input as a

request to turn the seat heater off. The heated seat

module will then turn the heated seat elements for

that seat off.

The indicator lamps in the heated seat switches

receive battery current through a fused ignition

switch output (run) circuit when the ignition switch

is in the On position. The ground side of each indi-

cator lamp is controlled by a separate (high or low/

driver or passenger) indicator lamp driver circuit by

the heated seat module. The heated seat module con-

trol of the switch indicator lamps also allows the

module to provide diagnostic feedback to the vehicle

operator to indicate monitored heated seat system

faults by flashing the indicator lamps on and off. One

side of the incandescent back lighting bulb in each

heated seat switch is connected to ground at all

times. The other side of the incandescent bulb is con-

nected to the fused panel lamps dimmer switch sig-

nal circuit. These bulbs are energized when the park

lamps or headlamps are turned on, and their illumi-

nation intensity is controlled by the panel lamps dim-

mer switch.

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH

Refer toWiring Diagramsfor the location of com-

plete heated seat system wiring diagrams.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) If the problem being diagnosed involves inoper-

ative heated seat switch back lighting and the cluster

illumination lamps operate, go to Step 2. If the prob-

lem being diagnosed involves inoperative heated seat

switch back lighting and the cluster illumination

lamps are also inoperative, refer toInstrument

Clusterin the index of this service manual for the

proper cluster illumination lamps diagnosis and test-

ing procedures. If the problem being diagnosed

involves inoperative heated seat switch indicator

lamps and the heated seat elements do not heat,

refer to Step 4. If the problem being diagnosed

Fig. 17 Heated Seat Switches

1 - Driver Switch

2 - Passenger Switch

3 - Indicator Lamps

4 - Heated Seat Switch Bezel

BR/BEHEATED SEAT SYSTEM 8G - 17

PASSENGER SEAT HEATER SWITCH (Continued)

Page 461 of 2255

IGNITION COIL RESISTANCEÐ8.0L V-10

ENGINE

Primary Resistance: 0.53-0.65 Ohms. Test across the

primary connector. Refer to text for test procedures.

Secondary Resistance: 10.9-14.7K Ohms. Test

across the individual coil towers. Refer to text for test

procedures.

IGNITION TIMING

Ignition timing is not adjustable on any engine.

AUTOMATIC SHUT DOWN

RELAY

DESCRIPTION - PCM OUTPUT

The 5±pin, 12±volt, Automatic Shutdown (ASD)

relay is located in the Power Distribution Center

(PDC). Refer to label on PDC cover for relay location.

OPERATION

OPERATION - PCM OUTPUT

The ASD relay supplies battery voltage (12+ volts)

to the fuel injectors and ignition coil(s). With certain

emissions packages it also supplies 12±volts to the

oxygen sensor heating elements.

The ground circuit for the coil within the ASD

relay is controlled by the Powertrain Control Module

(PCM). The PCM operates the ASD relay by switch-

ing its ground circuit on and off.

The ASD relay will be shut±down, meaning the

12±volt power supply to the ASD relay will be de-ac-

tivated by the PCM if:

²the ignition key is left in the ON position. This

is if the engine has not been running for approxi-

mately 1.8 seconds.

²there is a crankshaft position sensor signal to

the PCM that is lower than pre-determined values.

OPERATION - ASD SENSE - PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The relay is used to

connect the oxygen sensor heater element, ignition

coil and fuel injectors to 12 volt + power supply.

This input is used only to sense that the ASD relay

is energized. If the Powertrain Control Module

(PCM) does not see 12 volts at this input when the

ASD should be activated, it will set a Diagnostic

Trouble Code (DTC).

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS

The following description of operation and

tests apply only to the Automatic Shutdown

(ASD) and fuel pump relays. The terminals on the

bottom of each relay are numbered. Two different

types of relays may be used, (Fig. 1) or (Fig. 2).

Fig. 1 ASD and Fuel Pump Relay TerminalsÐType 1

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 2 ASD and Fuel Pump Relay TerminalsÐType 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8I - 4 IGNITION CONTROLBR/BE

IGNITION CONTROL (Continued)

Page 475 of 2255

cause of oil entry into that particular combustion

chamber.

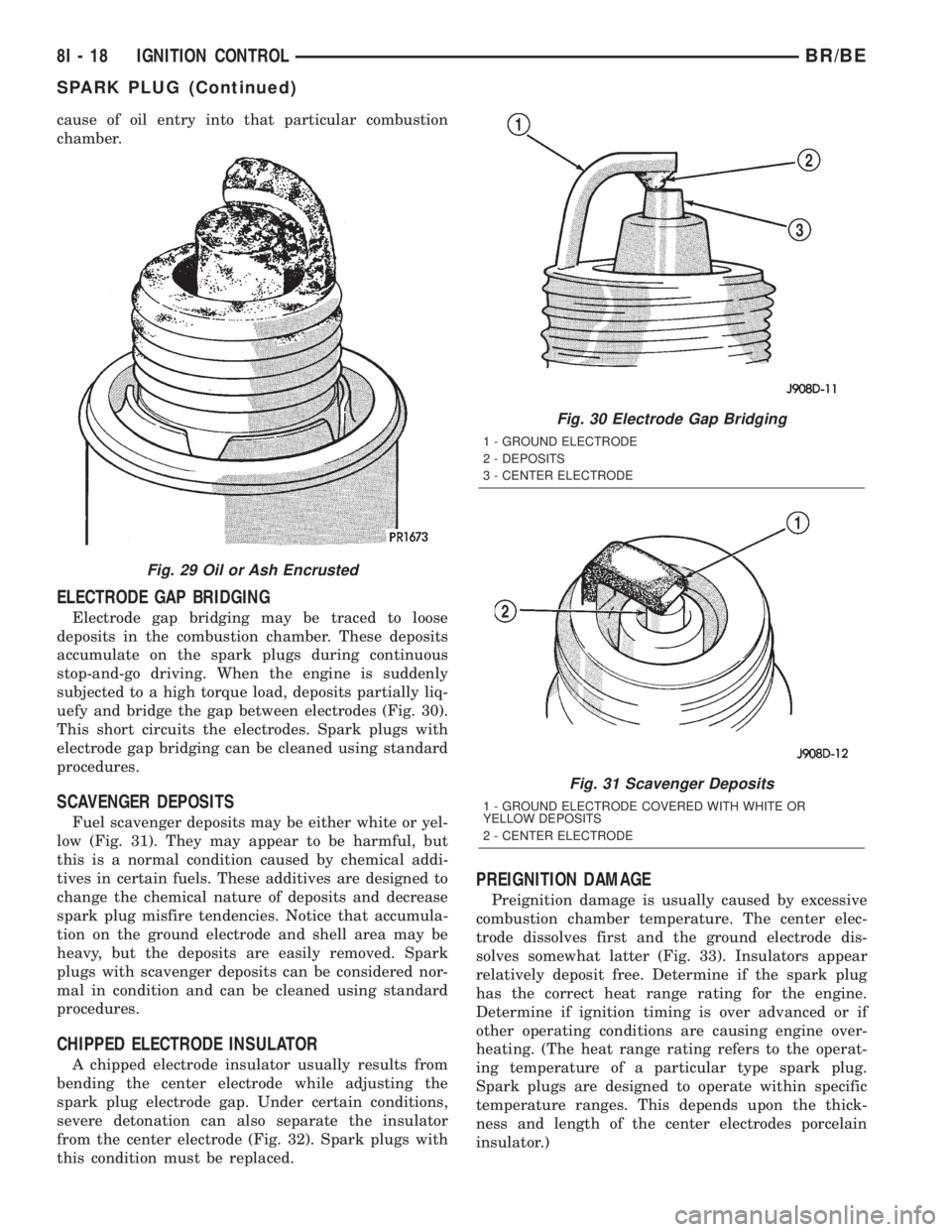

ELECTRODE GAP BRIDGING

Electrode gap bridging may be traced to loose

deposits in the combustion chamber. These deposits

accumulate on the spark plugs during continuous

stop-and-go driving. When the engine is suddenly

subjected to a high torque load, deposits partially liq-

uefy and bridge the gap between electrodes (Fig. 30).

This short circuits the electrodes. Spark plugs with

electrode gap bridging can be cleaned using standard

procedures.

SCAVENGER DEPOSITS

Fuel scavenger deposits may be either white or yel-

low (Fig. 31). They may appear to be harmful, but

this is a normal condition caused by chemical addi-

tives in certain fuels. These additives are designed to

change the chemical nature of deposits and decrease

spark plug misfire tendencies. Notice that accumula-

tion on the ground electrode and shell area may be

heavy, but the deposits are easily removed. Spark

plugs with scavenger deposits can be considered nor-

mal in condition and can be cleaned using standard

procedures.

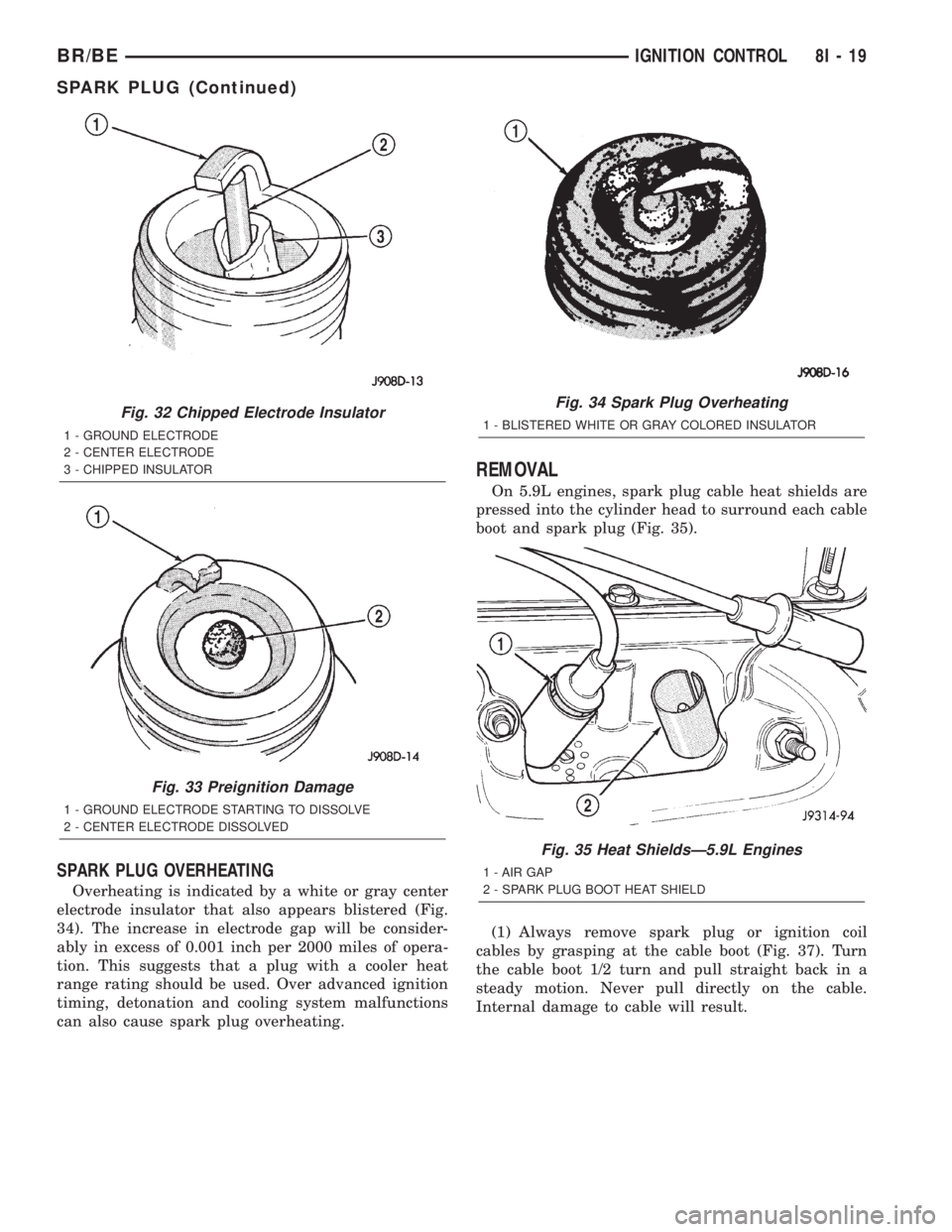

CHIPPED ELECTRODE INSULATOR

A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation can also separate the insulator

from the center electrode (Fig. 32). Spark plugs with

this condition must be replaced.

PREIGNITION DAMAGE

Preignition damage is usually caused by excessive

combustion chamber temperature. The center elec-

trode dissolves first and the ground electrode dis-

solves somewhat latter (Fig. 33). Insulators appear

relatively deposit free. Determine if the spark plug

has the correct heat range rating for the engine.

Determine if ignition timing is over advanced or if

other operating conditions are causing engine over-

heating. (The heat range rating refers to the operat-

ing temperature of a particular type spark plug.

Spark plugs are designed to operate within specific

temperature ranges. This depends upon the thick-

ness and length of the center electrodes porcelain

insulator.)

Fig. 29 Oil or Ash Encrusted

Fig. 30 Electrode Gap Bridging

1 - GROUND ELECTRODE

2 - DEPOSITS

3 - CENTER ELECTRODE

Fig. 31 Scavenger Deposits

1 - GROUND ELECTRODE COVERED WITH WHITE OR

YELLOW DEPOSITS

2 - CENTER ELECTRODE

8I - 18 IGNITION CONTROLBR/BE

SPARK PLUG (Continued)

Page 476 of 2255

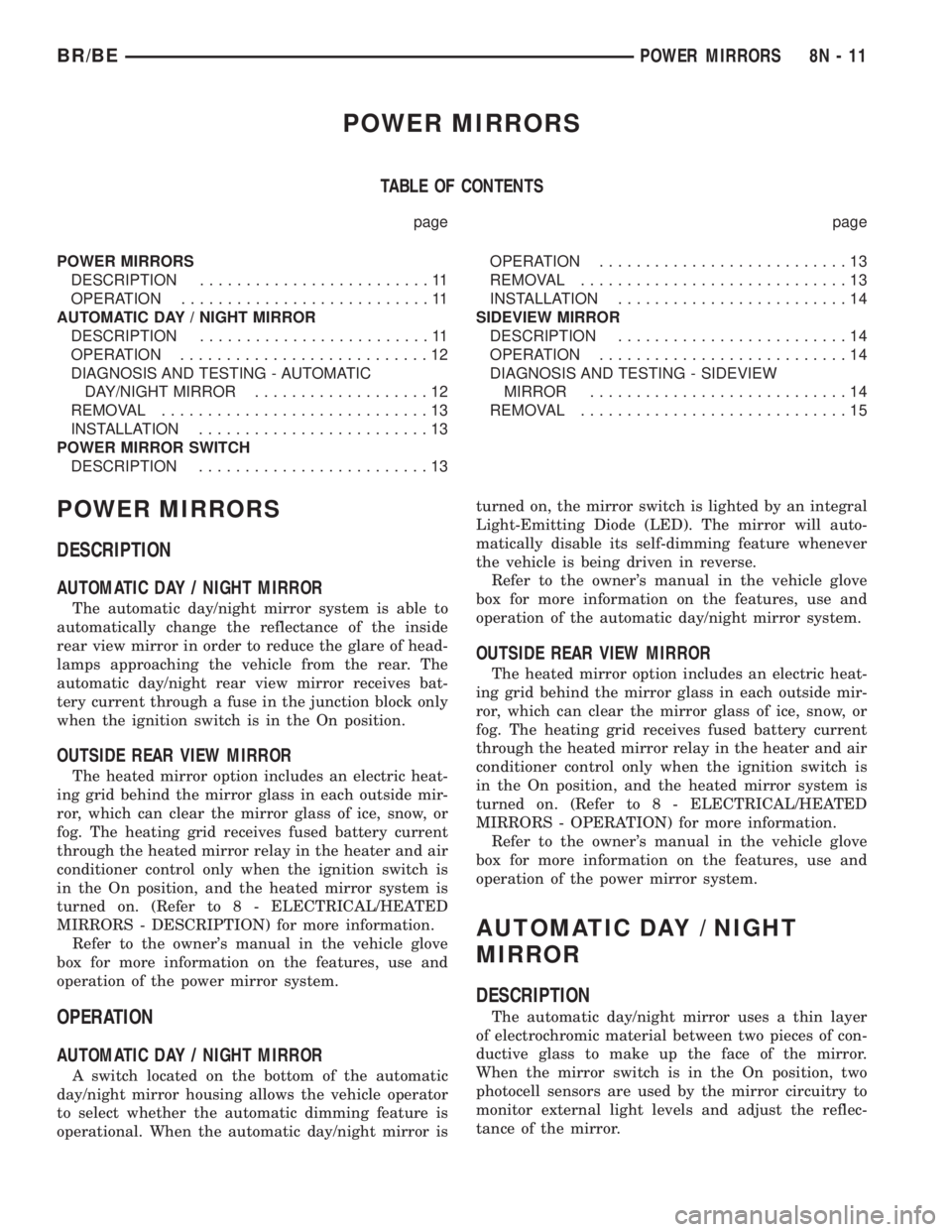

SPARK PLUG OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

34). The increase in electrode gap will be consider-

ably in excess of 0.001 inch per 2000 miles of opera-

tion. This suggests that a plug with a cooler heat

range rating should be used. Over advanced ignition

timing, detonation and cooling system malfunctions

can also cause spark plug overheating.

REMOVAL

On 5.9L engines, spark plug cable heat shields are

pressed into the cylinder head to surround each cable

boot and spark plug (Fig. 35).

(1) Always remove spark plug or ignition coil

cables by grasping at the cable boot (Fig. 37). Turn

the cable boot 1/2 turn and pull straight back in a

steady motion. Never pull directly on the cable.

Internal damage to cable will result.

Fig. 32 Chipped Electrode Insulator

1 - GROUND ELECTRODE

2 - CENTER ELECTRODE

3 - CHIPPED INSULATOR

Fig. 33 Preignition Damage

1 - GROUND ELECTRODE STARTING TO DISSOLVE

2 - CENTER ELECTRODE DISSOLVED

Fig. 34 Spark Plug Overheating

1 - BLISTERED WHITE OR GRAY COLORED INSULATOR

Fig. 35 Heat ShieldsÐ5.9L Engines

1 - AIR GAP

2 - SPARK PLUG BOOT HEAT SHIELD

BR/BEIGNITION CONTROL 8I - 19

SPARK PLUG (Continued)

Page 578 of 2255

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION.........................11

OPERATION...........................11

AUTOMATIC DAY / NIGHT MIRROR

DESCRIPTION.........................11

OPERATION...........................12

DIAGNOSIS AND TESTING - AUTOMATIC

DAY/NIGHT MIRROR...................12

REMOVAL.............................13

INSTALLATION.........................13

POWER MIRROR SWITCH

DESCRIPTION.........................13OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................14

SIDEVIEW MIRROR

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - SIDEVIEW

MIRROR............................14

REMOVAL.............................15

POWER MIRRORS

DESCRIPTION

AUTOMATIC DAY / NIGHT MIRROR

The automatic day/night mirror system is able to

automatically change the reflectance of the inside

rear view mirror in order to reduce the glare of head-

lamps approaching the vehicle from the rear. The

automatic day/night rear view mirror receives bat-

tery current through a fuse in the junction block only

when the ignition switch is in the On position.

OUTSIDE REAR VIEW MIRROR

The heated mirror option includes an electric heat-

ing grid behind the mirror glass in each outside mir-

ror, which can clear the mirror glass of ice, snow, or

fog. The heating grid receives fused battery current

through the heated mirror relay in the heater and air

conditioner control only when the ignition switch is

in the On position, and the heated mirror system is

turned on. (Refer to 8 - ELECTRICAL/HEATED

MIRRORS - DESCRIPTION) for more information.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the power mirror system.

OPERATION

AUTOMATIC DAY / NIGHT MIRROR

A switch located on the bottom of the automatic

day/night mirror housing allows the vehicle operator

to select whether the automatic dimming feature is

operational. When the automatic day/night mirror isturned on, the mirror switch is lighted by an integral

Light-Emitting Diode (LED). The mirror will auto-

matically disable its self-dimming feature whenever

the vehicle is being driven in reverse.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the automatic day/night mirror system.

OUTSIDE REAR VIEW MIRROR

The heated mirror option includes an electric heat-

ing grid behind the mirror glass in each outside mir-

ror, which can clear the mirror glass of ice, snow, or

fog. The heating grid receives fused battery current

through the heated mirror relay in the heater and air

conditioner control only when the ignition switch is

in the On position, and the heated mirror system is

turned on. (Refer to 8 - ELECTRICAL/HEATED

MIRRORS - OPERATION) for more information.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the power mirror system.

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

The automatic day/night mirror uses a thin layer

of electrochromic material between two pieces of con-

ductive glass to make up the face of the mirror.

When the mirror switch is in the On position, two

photocell sensors are used by the mirror circuitry to

monitor external light levels and adjust the reflec-

tance of the mirror.

BR/BEPOWER MIRRORS 8N - 11

Page 581 of 2255

INSTALLATION

(1) Insert the power mirror switch to the back of

the door trim panel.

(2) Connect the power mirror switch to the har-

ness connector.

(3) Install the trim panel to the inside of the

driver side door. (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION).

(4) Install the nut that secures the power mirror

switch to the driver side front door.

(5) Push the control knob on to the power mirror

switch.

(6) Connect the battery negative cable.

SIDEVIEW MIRROR

DESCRIPTION

Each power mirror head contains two electric

motors, two drive mechanisms, and the mirror glass.

One motor and drive controls mirror up-and-down

movement, and the other controls right-and-left

movement.

OPERATION

The power mirrors in vehicles equipped with the

available heated mirror system option also include an

electric heating grid located behind the mirror glass.

This heating grid is energized by the heated mirror

relay in the heater and air conditioner control only

when the ignition switch is in the On position, and

the heated mirror system is turned on. (Refer to 8 -

ELECTRICAL/HEATED MIRRORS - DESCRIP-

TION) for more information.

The power mirror assembly cannot be repaired. If

any component of the power mirror unit is faulty or

damaged, the entire assembly must be replaced.

DIAGNOSIS AND TESTING - SIDEVIEW

MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuses in the Power Distribution Cen-

ter (PDC) and the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).(2) Check for battery voltage at the fuse in the

junction block. If OK, go to Step 3. If not OK, repair

the open circuit to the PDC as required.

(3) Disconnect and isolate the battery negative

cable. Remove the driver side door trim panel and

unplug the wire harness connector from the power

mirror switch. Connect the battery negative cable.

Check for battery voltage at the fused B(+) circuit

cavity in the door wire harness half of the power mir-

ror switch wire harness connector. If OK, go to Step

4. If not OK, repair the open circuit to the junction

block as required.

(4) Disconnect and isolate the battery negative

cable. Check for continuity between the ground cir-

cuit cavity in the door wire harness half of the power

mirror switch wire harness connector and a good

ground. There should be continuity. If OK, go to Step

5. If not OK, repair the circuit to ground as required.

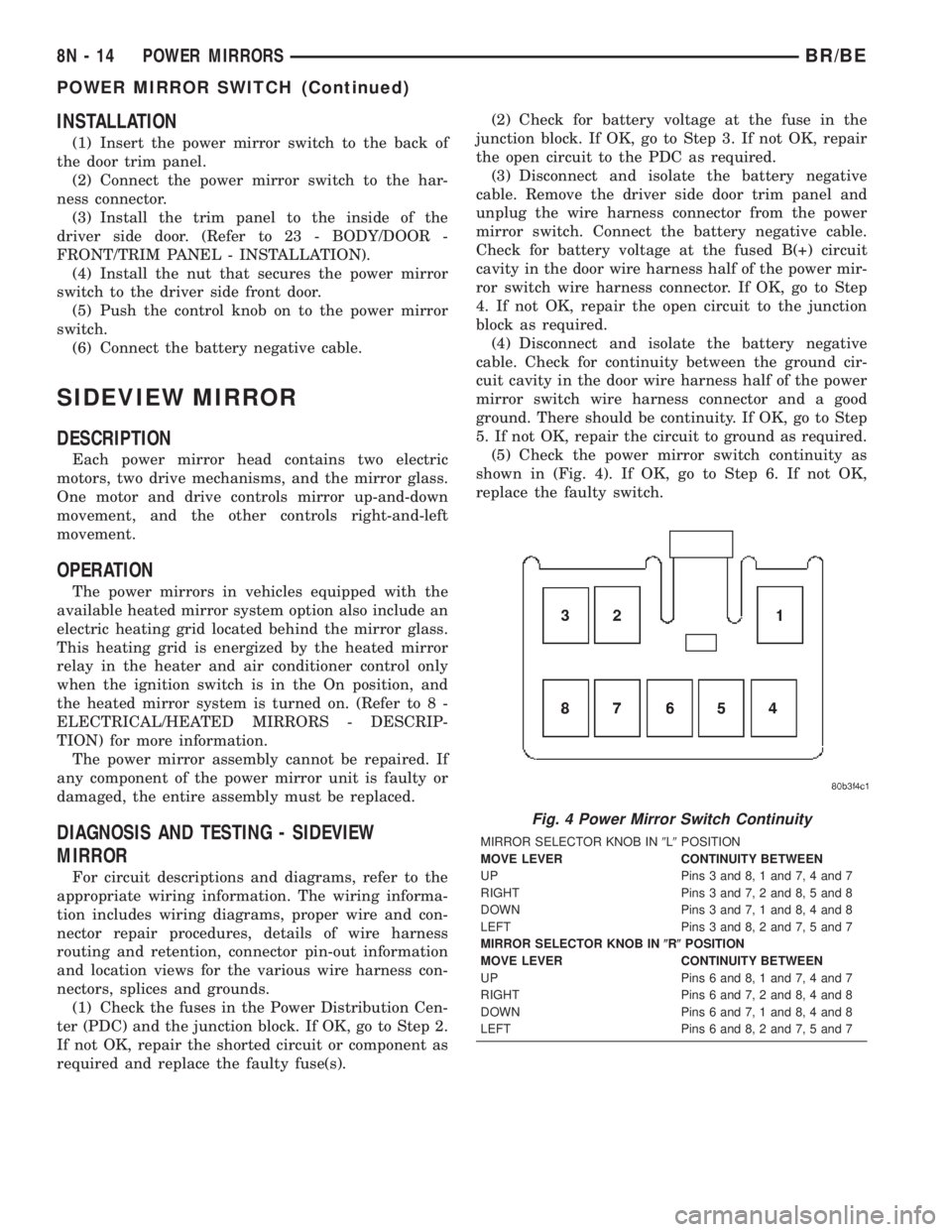

(5) Check the power mirror switch continuity as

shown in (Fig. 4). If OK, go to Step 6. If not OK,

replace the faulty switch.

Fig. 4 Power Mirror Switch Continuity

MIRROR SELECTOR KNOB IN9L9POSITION

MOVE LEVER CONTINUITY BETWEEN

UP Pins 3 and 8, 1 and 7, 4 and 7

RIGHT Pins 3 and 7, 2 and 8, 5 and 8

DOWN Pins 3 and 7, 1 and 8, 4 and 8

LEFT Pins 3 and 8, 2 and 7, 5 and 7

MIRROR SELECTOR KNOB IN(R(POSITION

MOVE LEVER CONTINUITY BETWEEN

UP Pins 6 and 8, 1 and 7, 4 and 7

RIGHT Pins 6 and 7, 2 and 8, 4 and 8

DOWN Pins 6 and 7, 1 and 8, 4 and 8

LEFT Pins 6 and 8, 2 and 7, 5 and 7

8N - 14 POWER MIRRORSBR/BE

POWER MIRROR SWITCH (Continued)

Page 614 of 2255

PASSENGER AIRBAG

DESCRIPTION

The rearward facing surface of the passenger air-

bag door above the glove box is the most visible part

of the passenger airbag. The airbag used in this

model is a Next Generation-type that complies with

revised federal airbag standards to deploy with less

force than those used in some prior models. The pas-

senger airbag is located in the instrument panel in

front of the front seat passenger seating position,

where it is secured to the instrument panel. Con-

cealed beneath the passenger airbag door are the

folded airbag cushion, the airbag retainer or housing,

and the airbag inflator. The airbag inflator is a

hybrid-type unit that is secured to and sealed within

the stamped steel airbag housing along with the

folded airbag cushion. The airbag housing stamping

also includes the two mounting brackets, one front

and one rear. The front bracket is secured beneath

the instrument panel top cover with screws to the

instrument panel structural support. The rear

bracket is secured with screws to the upper glove box

opening reinforcement. A yellow connector on the end

of a short, two-wire pigtail harness connects the pas-

senger airbag inflator to the vehicle electrical system.

The molded plastic passenger airbag door has pre-

determined breakout lines concealed beneath its dec-

orative cover. The lower edge of the passenger airbag

door is secured to the airbag housing, and includes

the two passenger side panel outlets. The sides and

upper edges are secured to the instrument panel top

cover with five molded tabs that are each fit with a

small metal retainer. The five retainers are snapped

into five slotted receptacles located around the sides

and top of the airbag door opening in the instrument

panel top cover. Following a passenger airbag deploy-

ment, the passenger airbag and airbag door unit

must be replaced. The passenger airbag cannot be

repaired, and must be replaced if faulty or in any

way damaged. The passenger airbag door is serviced

only as a unit with the passenger airbag, and

includes the two passenger side heating and air con-

ditioning panel outlet housings and barrels.

OPERATION

The passenger airbag is deployed by an electrical

signal generated by the Airbag Control Module

(ACM) through the passenger airbag line 1 and line 2

(or squib) circuits. The hybrid-type inflator assembly

includes a small canister of highly compressed argon

gas. When the ACM sends the proper electrical signal

to the airbag inflator, the electrical energy generates

enough heat to ignite chemical pellets within the

inflator. Once ignited, these chemical pellets burn

rapidly and produce the pressure necessary to rup-ture a containment disk in the argon gas canister.

The inflator and argon gas canister are sealed to the

airbag cushion so that all of the released argon gas is

directed into the airbag cushion, causing the cushion

to inflate. As the cushion inflates, the passenger air-

bag door will split at the breakout lines and the door

will pivot out of the way. Following an airbag deploy-

ment, the airbag cushion quickly deflates by venting

the argon gas through the porous fabric material

used on each end panel of the airbag cushion.

Some of the chemicals used to create the pressure

to burst the argon gas containment disk are consid-

ered hazardous in their solid state, before they are

burned, but they are securely sealed within the air-

bag inflator. However, the gas that is produced when

the chemicals are burned is harmless. A small

amount of residue from the burned chemicals may

cause some temporary discomfort if it contacts the

skin, eyes, or breathing passages. If skin or eye irri-

tation is noticed, rinse the affected area with plenty

of cool, clean water. If breathing passages are irri-

tated, move to another area where there is plenty of

clean, fresh air to breath. If the irritation is not alle-

viated by these actions, contact a physician immedi-

ately.

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

WARNING: WHEN REMOVING A DEPLOYED AIR-

BAG, RUBBER GLOVES, EYE PROTECTION, AND A

LONG-SLEEVED SHIRT SHOULD BE WORN. THERE

MAY BE DEPOSITS ON THE AIRBAG UNIT AND

OTHER INTERIOR SURFACES. IN LARGE DOSES,

THESE DEPOSITS MAY CAUSE IRRITATION TO THE

SKIN AND EYES.

(1) Disconnect and isolate the battery negative

cable. If either of the airbags has not been deployed,

wait two minutes for the system capacitor to dis-

charge before further service.

BR/BERESTRAINTS 8O - 21

Page 626 of 2255

Once the speed control has been disengaged,

depressing the RES/ACCEL switch (when speed is

greater than 30 mph) restores the vehicle to the tar-

get speed that was stored in the ECM.

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the RES/AC-

CEL switch. The new target speed is stored in the

ECM when the RES/ACCEL is released. The ECM

also has a9tap-up9feature in which vehicle speed

increases at a rate of approximately 2 mph for each

momentary switch activation of the RES/ACCEL

switch.

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - VACUUM SUPPLY

TEST

Gas Powered Engines

On gasoline powered engines: actual engine vac-

uum, a vacuum reservoir, a one-way check valve and

vacuum lines are used to supply vacuum to the speed

control servo.

(1) Disconnect vacuum hose at speed control servo

and install a vacuum gauge into the disconnected

hose.

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury.

(3) If vacuum is less than ten inches of mercury,

determine source of leak. Check vacuum line to

engine for leaks. Also check actual engine intake

manifold vacuum. If manifold vacuum does not meet

this requirement, check for poor engine performance

and repair as necessary.

(4) If vacuum line to engine is not leaking, check

for leak at vacuum reservoir. To locate and gain

access to reservoir, refer to Vacuum Reservoir Remov-

al/Installation in this group. Disconnect vacuum line

at reservoir and connect a hand-operated vacuum

pump to reservoir fitting. Apply vacuum. Reservoir

vacuum should not bleed off. If vacuum is being lost,

replace reservoir.

(5) Verify operation of one-way check valve and

check it for leaks.

(a) Locate one-way check valve. The valve is

located in vacuum line between vacuum reservoirand engine vacuum source. Disconnect vacuum

hoses (lines) at each end of valve.

(b) Connect a hand-operated vacuum pump to

reservoir end of check valve. Apply vacuum. Vac-

uum should not bleed off. If vacuum is being lost,

replace one-way check valve.

(c) Connect a hand-operated vacuum pump to

vacuum source end of check valve. Apply vacuum.

Vacuum should flow through valve. If vacuum is

not flowing, replace one-way check valve. Seal the

fitting at opposite end of valve with a finger and

apply vacuum. If vacuum will not hold, diaphragm

within check valve has ruptured. Replace valve.

Diesel Engines With Automatic Trans.

On diesel powered engines equipped with an auto-

matic transmission: an engine driven vacuum pump,

a one-way check valve and vacuum lines are used to

supply vacuum to the speed control servo. A vacuum

reservoir is not used.

(1) Disconnect vacuum hose at speed control servo

and install a vacuum gauge into the disconnected

hose.

(2) Start engine and observe gauge at idle. For

vacuum testing and vacuum specifications, refer to

Vacuum Pump OutputÐDiesel Engine in 9, Engines.

(3) If vacuum pump output is OK, determine other

source of leak. Check all vacuum lines to: speed con-

trol servo, engine vacuum pump and heating/air con-

ditioning system for leaks.

(4) Verify operation of one-way check valve and

check it for leaks.

(a) Locate one-way check valve. The valve is

located in vacuum line between speed control servo

and engine vacuum pump. Disconnect vacuum

hoses (lines) at each end of valve.

(b) Connect a hand-operated vacuum pump to

reservoir end of check valve. Apply vacuum. Vac-

uum should not bleed off. If vacuum is being lost,

replace one-way check valve.

(c) Connect a hand-operated vacuum pump to

vacuum source end of check valve. Apply vacuum.

Vacuum should flow through valve. If vacuum is

not flowing, replace one-way check valve. Seal the

fitting at opposite end of valve with a finger and

apply vacuum. If vacuum will not hold, diaphragm

within check valve has ruptured. Replace valve.

Diesel Engine With Manual Trans.

Vacuum is not used for any part of the speed con-

trol system if equipped with a diesel engine and a

manual transmission.

BR/BESPEED CONTROL 8P - 3

SPEED CONTROL (Continued)

Page 637 of 2255

INSTALLATION

(1) Install electrical connector to switch.

(2) Install switch and mounting screws.

(3) Tighten screws to 3 N´m (26 in. lbs. +/± 2 in.

lbs.) torque.

(4) Install airbag module. Refer to 8, Restraint

Systems for procedures.

(5) Connect negative battery cable(s).

VACUUM RESERVOIR

DESCRIPTION

Gasoline Powered Engines :A vacuum reservoir

is used to supply the vacuum needed to maintain

proper speed control operation when engine vacuum

drops, such as in climbing a grade while driving. A

one-way check valve is used in the vacuum line

between the reservoir and the vacuum source. This

check valve is used to trap engine vacuum in the res-

ervoir. On certain vehicle applications, this reservoir

is shared with the heating/air-conditioning system.

The vacuum reservoir cannot be repaired and must

be replaced if faulty.

Diesel Powered Engines With Auto. Trans. :A

vacuum reservoir is not used if equipped with a die-

sel powered engine. Instead, an engine driven pump

(vacuum pump) is used to supply vacuum for speed

control operation. This vacuum pump is used with

the diesel engine only if it is equipped with an auto-

matic transmission. Refer to Vacuum Pump in 9,

Engines for information.

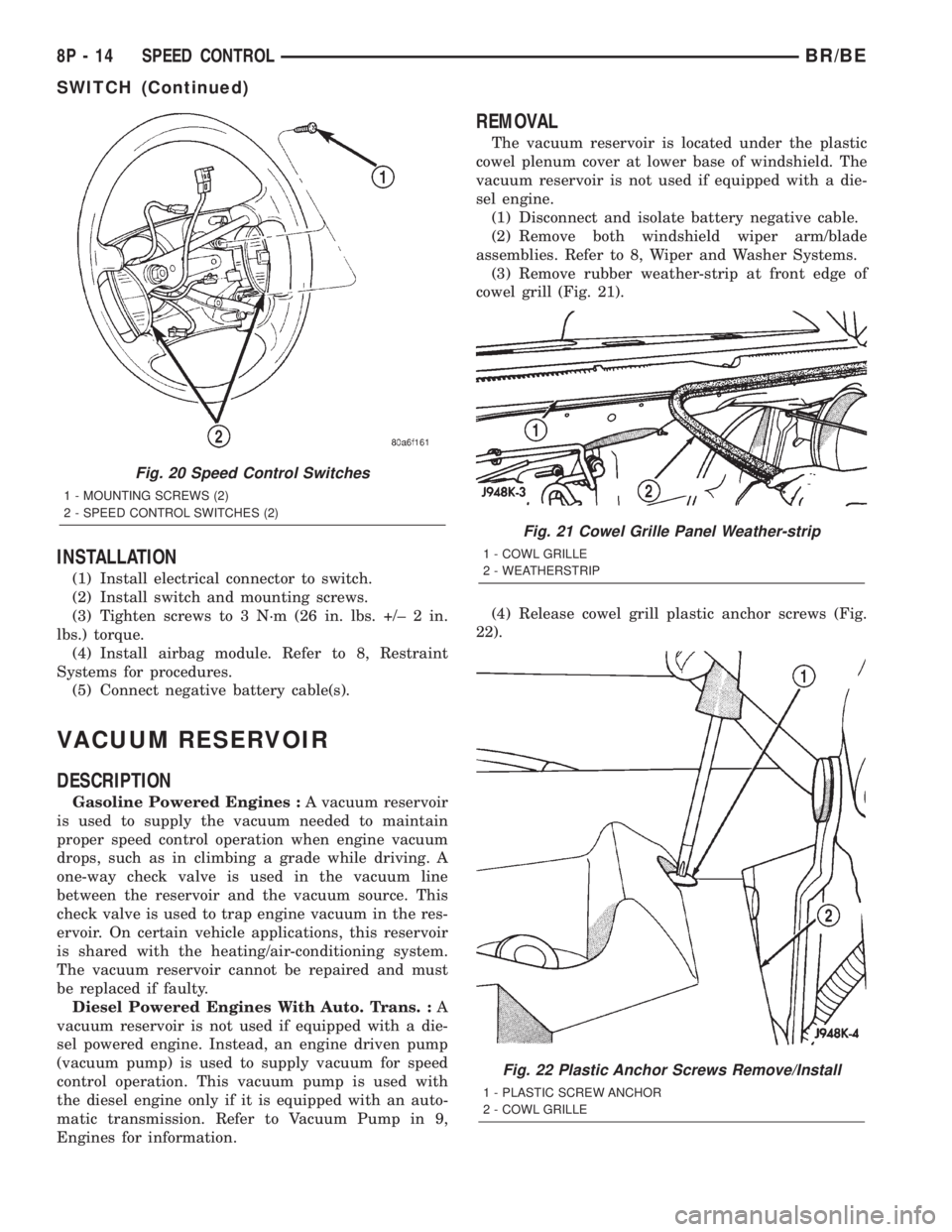

REMOVAL

The vacuum reservoir is located under the plastic

cowel plenum cover at lower base of windshield. The

vacuum reservoir is not used if equipped with a die-

sel engine.

(1) Disconnect and isolate battery negative cable.

(2) Remove both windshield wiper arm/blade

assemblies. Refer to 8, Wiper and Washer Systems.

(3) Remove rubber weather-strip at front edge of

cowel grill (Fig. 21).

(4) Release cowel grill plastic anchor screws (Fig.

22).

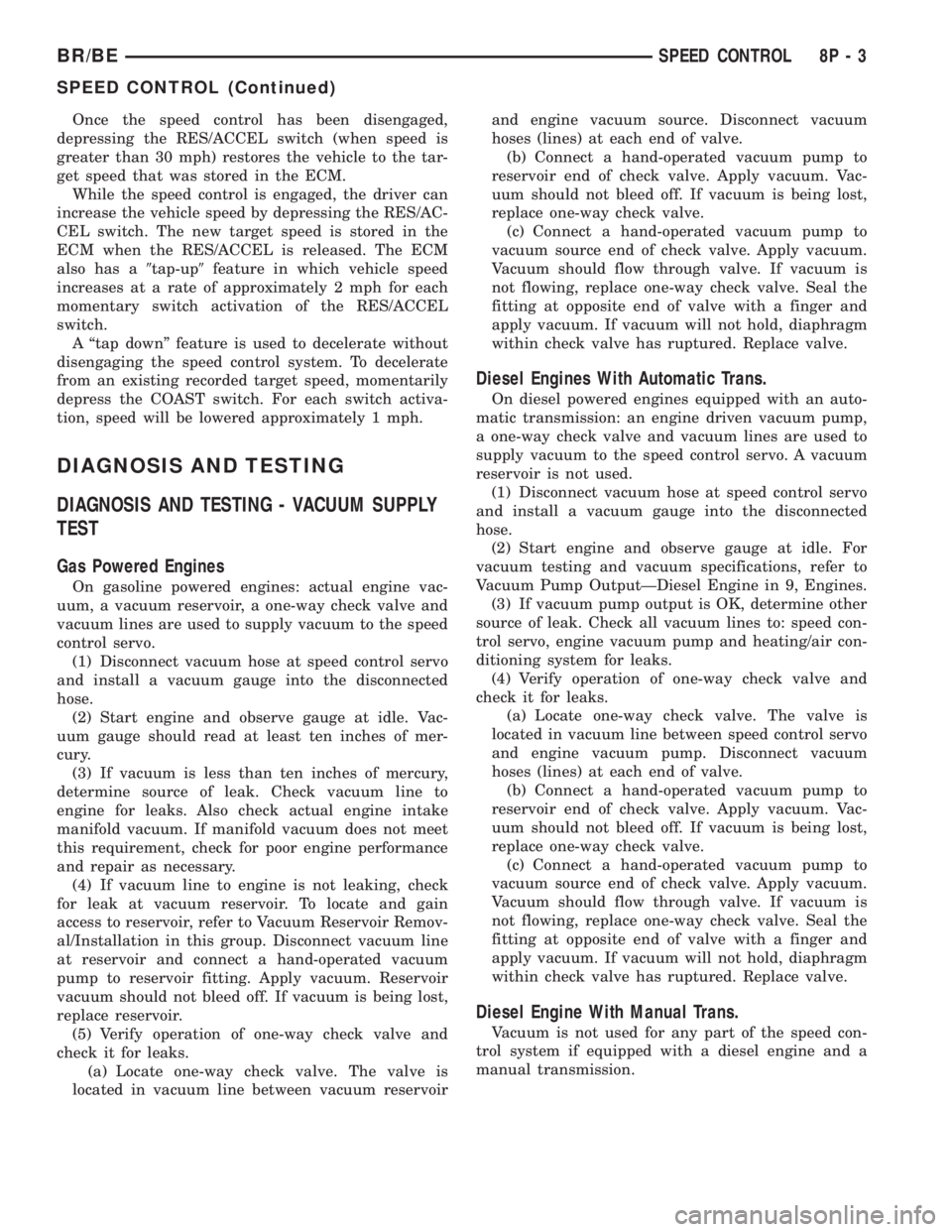

Fig. 20 Speed Control Switches

1 - MOUNTING SCREWS (2)

2 - SPEED CONTROL SWITCHES (2)

Fig. 21 Cowel Grille Panel Weather-strip

1 - COWL GRILLE

2 - WEATHERSTRIP

Fig. 22 Plastic Anchor Screws Remove/Install

1 - PLASTIC SCREW ANCHOR

2 - COWL GRILLE

8P - 14 SPEED CONTROLBR/BE

SWITCH (Continued)