DODGE RAM 2002 Service Manual PDF

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 61 of 2255

SPECIFICATIONS

PROPELLER SHAFT

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Center Bearing Bolts 68 50 -

Front Shaft Flange Yoke 88 65 -

Front Shaft Axle Yoke 19 14 -

Rear Shaft Axle Yoke 29 22 -

SPECIAL TOOLS

PROPELLER SHAFT

PROPELLER SHAFT - FRONT

REMOVAL

(1) Shift the transmission and transfer case to

their neutral positions.(2) Raise and support vehicle and remove skid

plate, if equipped.

(3) Mark a line across the companion flange at the

transfer case and propeller shaft flange yoke for

installation reference.

(4) Mark a line across the propeller shaft yoke and

the pinion shaft yoke for installation reference.

(5) Remove the universal joint strap bolts at the

pinion shaft yoke (Fig. 9).

(6) Remove the bolts holding the propeller shaft to

the transfer case companion flange.

(7) Remove the propeller shaft.

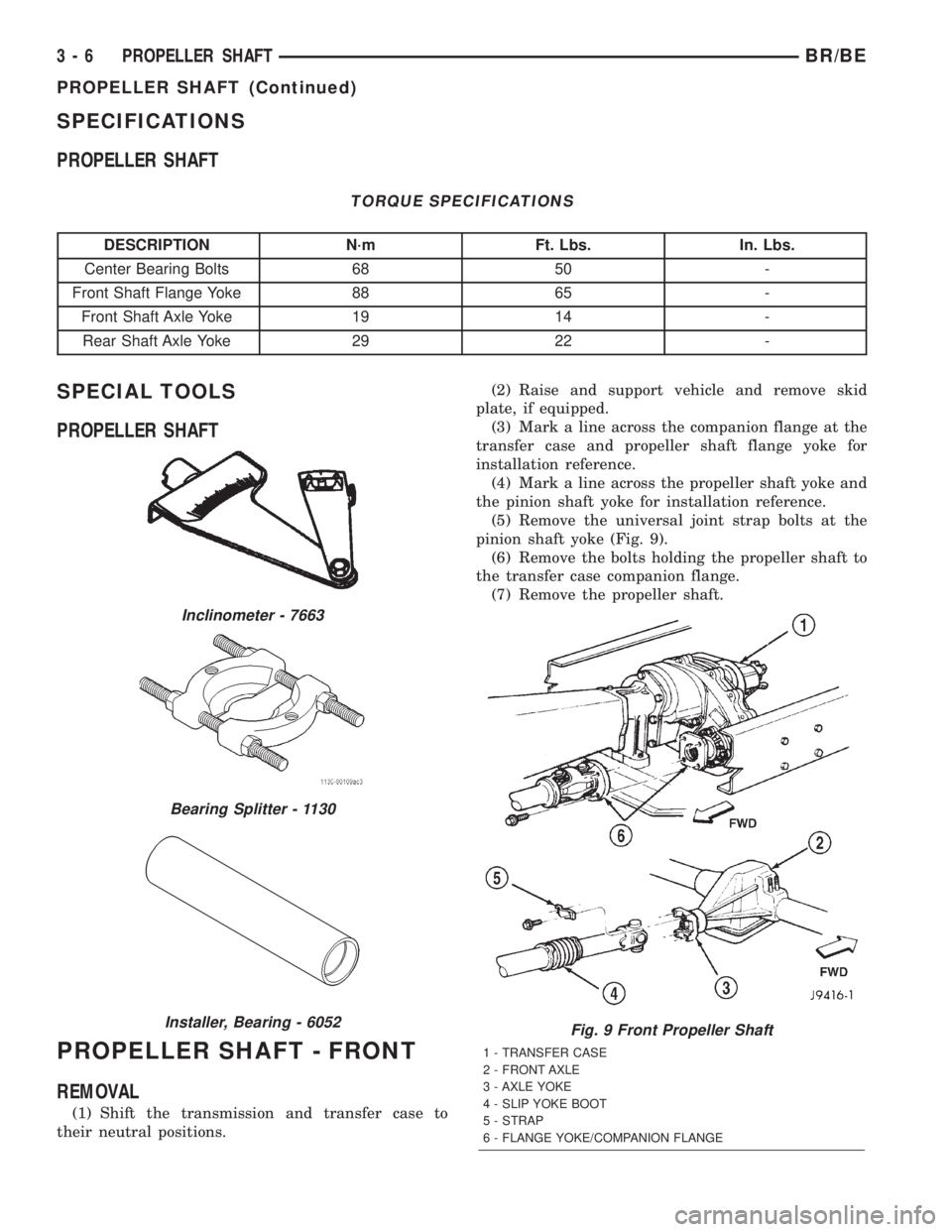

Inclinometer - 7663

Bearing Splitter - 1130

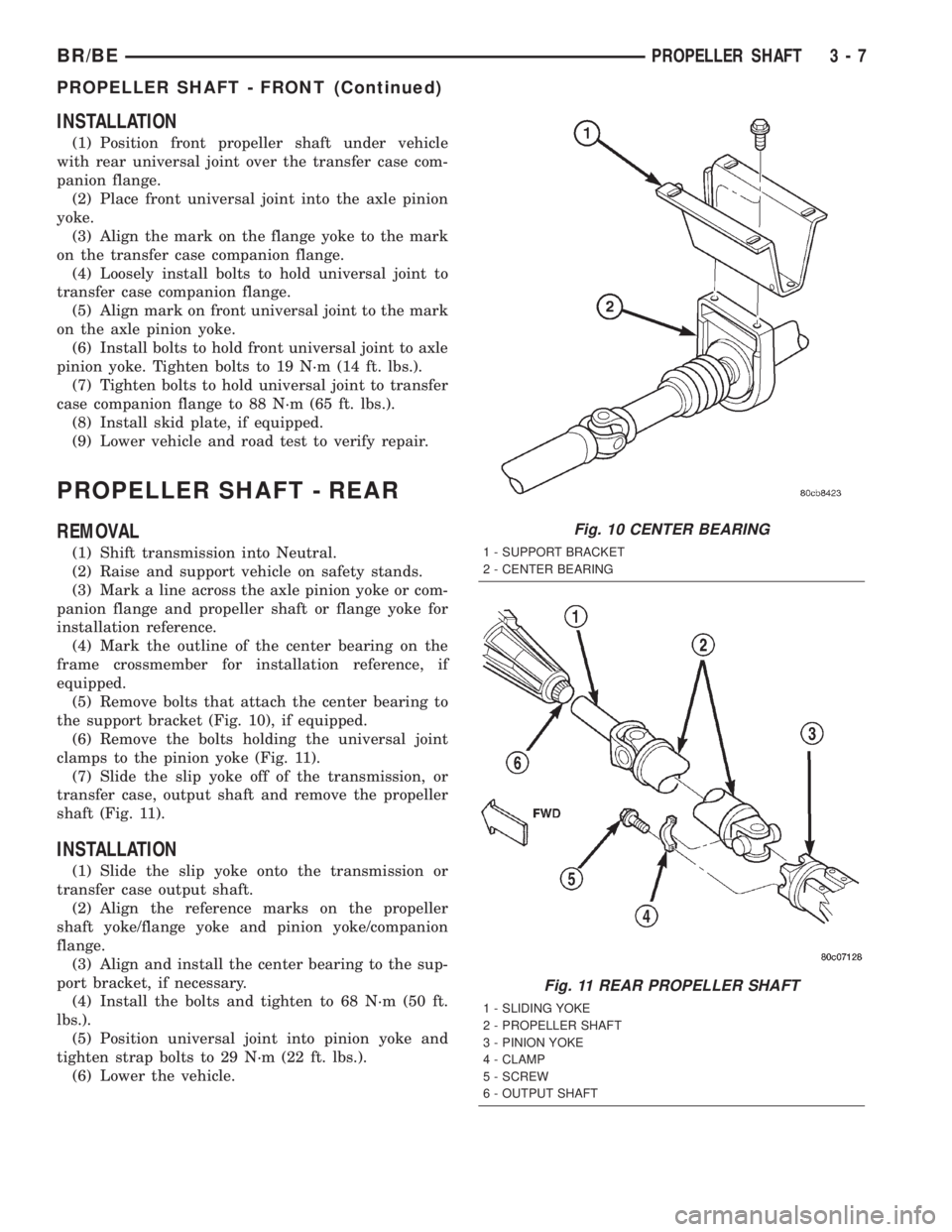

Installer, Bearing - 6052Fig. 9 Front Propeller Shaft

1 - TRANSFER CASE

2 - FRONT AXLE

3 - AXLE YOKE

4 - SLIP YOKE BOOT

5 - STRAP

6 - FLANGE YOKE/COMPANION FLANGE

3 - 6 PROPELLER SHAFTBR/BE

PROPELLER SHAFT (Continued)

Page 62 of 2255

INSTALLATION

(1) Position front propeller shaft under vehicle

with rear universal joint over the transfer case com-

panion flange.

(2) Place front universal joint into the axle pinion

yoke.

(3) Align the mark on the flange yoke to the mark

on the transfer case companion flange.

(4) Loosely install bolts to hold universal joint to

transfer case companion flange.

(5) Align mark on front universal joint to the mark

on the axle pinion yoke.

(6) Install bolts to hold front universal joint to axle

pinion yoke. Tighten bolts to 19 N´m (14 ft. lbs.).

(7) Tighten bolts to hold universal joint to transfer

case companion flange to 88 N´m (65 ft. lbs.).

(8) Install skid plate, if equipped.

(9) Lower vehicle and road test to verify repair.

PROPELLER SHAFT - REAR

REMOVAL

(1) Shift transmission into Neutral.

(2) Raise and support vehicle on safety stands.

(3) Mark a line across the axle pinion yoke or com-

panion flange and propeller shaft or flange yoke for

installation reference.

(4) Mark the outline of the center bearing on the

frame crossmember for installation reference, if

equipped.

(5) Remove bolts that attach the center bearing to

the support bracket (Fig. 10), if equipped.

(6) Remove the bolts holding the universal joint

clamps to the pinion yoke (Fig. 11).

(7) Slide the slip yoke off of the transmission, or

transfer case, output shaft and remove the propeller

shaft (Fig. 11).

INSTALLATION

(1) Slide the slip yoke onto the transmission or

transfer case output shaft.

(2) Align the reference marks on the propeller

shaft yoke/flange yoke and pinion yoke/companion

flange.

(3) Align and install the center bearing to the sup-

port bracket, if necessary.

(4) Install the bolts and tighten to 68 N´m (50 ft.

lbs.).

(5) Position universal joint into pinion yoke and

tighten strap bolts to 29 N´m (22 ft. lbs.).

(6) Lower the vehicle.

Fig. 10 CENTER BEARING

1 - SUPPORT BRACKET

2 - CENTER BEARING

Fig. 11 REAR PROPELLER SHAFT

1 - SLIDING YOKE

2 - PROPELLER SHAFT

3 - PINION YOKE

4 - CLAMP

5 - SCREW

6 - OUTPUT SHAFT

BR/BEPROPELLER SHAFT 3 - 7

PROPELLER SHAFT - FRONT (Continued)

Page 63 of 2255

CENTER BEARING

REMOVAL

(1) Remove rear propeller shaft.

(2) Remove slip joint boot clamp and separate the

two half-shafts.

(3) Use hammer and punch to tap slinger away

from shaft to provide room for bearing splitter.

(4) Position Bearing Splitter Tool 1130 between

slinger and shaft.

CAUTION: Do not damage shaft spline during

removal of center bearing.

(5)

Set shaft in press and press bearing off the shaft.

INSTALLATION

NOTE: Two types of center bearings are used and

are not interchangeable. Install the same type as

the vehicle was built with.

(1) Install new slinger on shaft and drive into posi-

tion with appropriate installer tool.

(2) Install new center bearing on shaft with Bear-

ing Installer Tool 6052. Drive on shaft with hammer

until bearing is seated.

(3) Clean shaft splines and apply a coat of multi-

purpose grease.

(4) Align master splines and slide front and rear

half-shafts together. Reposition slip yoke boot and

install new clamp.

(5) Install propeller shaft in vehicle.

ADJUSTMENTS

ADJUSTMENT - CENTER BEARING

Launch shudder is a vibration that occurs at first

acceleration from a stop. Shudder vibration usually

peaks at the engines highest torque output. Shudder is

a symptom associated with vehicles using a two-piece

propeller shaft. To decrease shudder, lower the center

bearing in 1/8 inch increments. Use shim stock or fab-

ricated plates. Plate stock must be used to maintain

compression of the rubber insulator around the bearing.

Do not use washers. Replace the original bolts with the

appropriate increased length bolts.

SINGLE CARDAN UNIVERSAL

JOINTS

DISASSEMBLY

Individual components of cardan universal joints

are not serviceable. If worn or leaking, they must be

replaced as an assembly.

(1) Remove the propeller shaft.

(2) With a soft drift, tap the outside of the bearing

cap assembly to loosen snap ring.

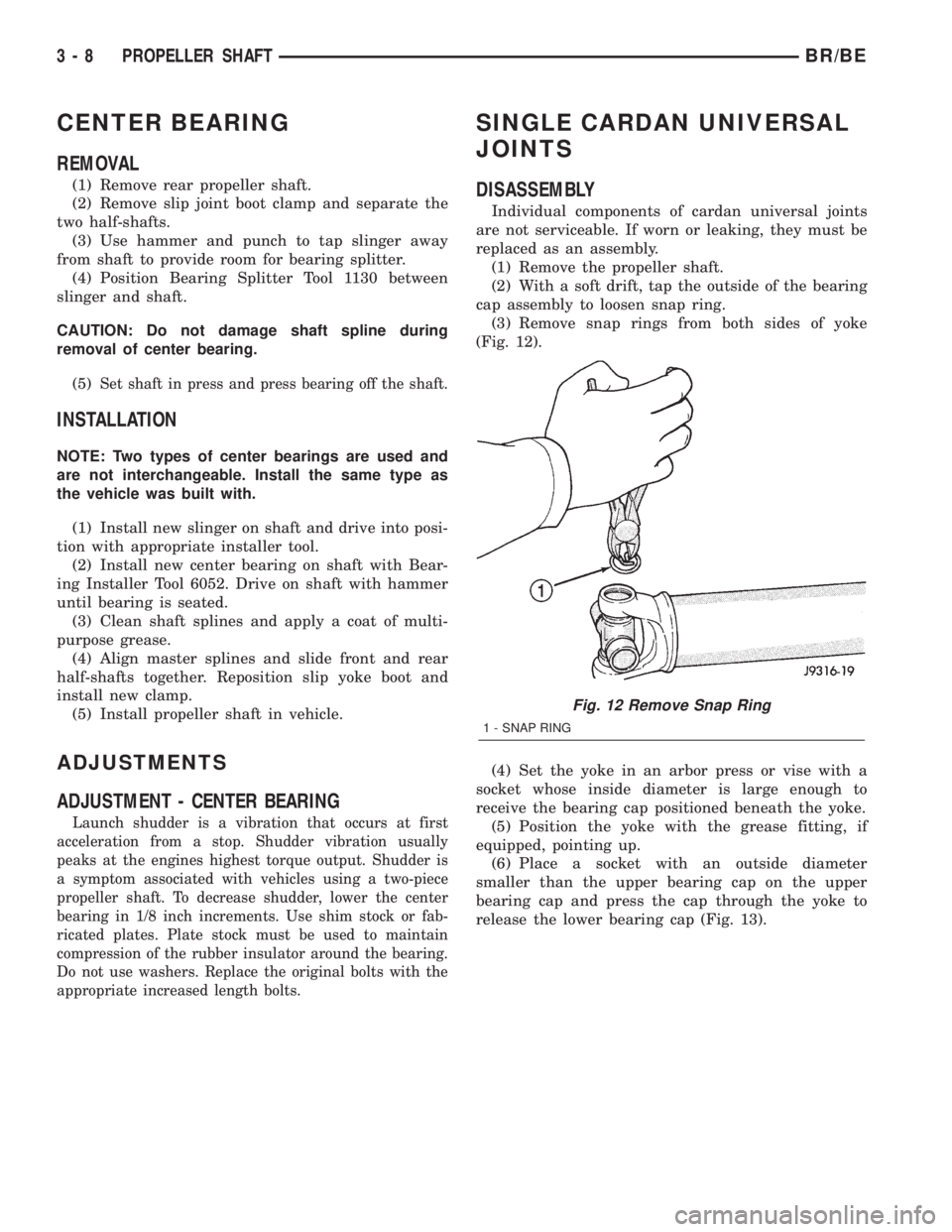

(3) Remove snap rings from both sides of yoke

(Fig. 12).

(4) Set the yoke in an arbor press or vise with a

socket whose inside diameter is large enough to

receive the bearing cap positioned beneath the yoke.

(5) Position the yoke with the grease fitting, if

equipped, pointing up.

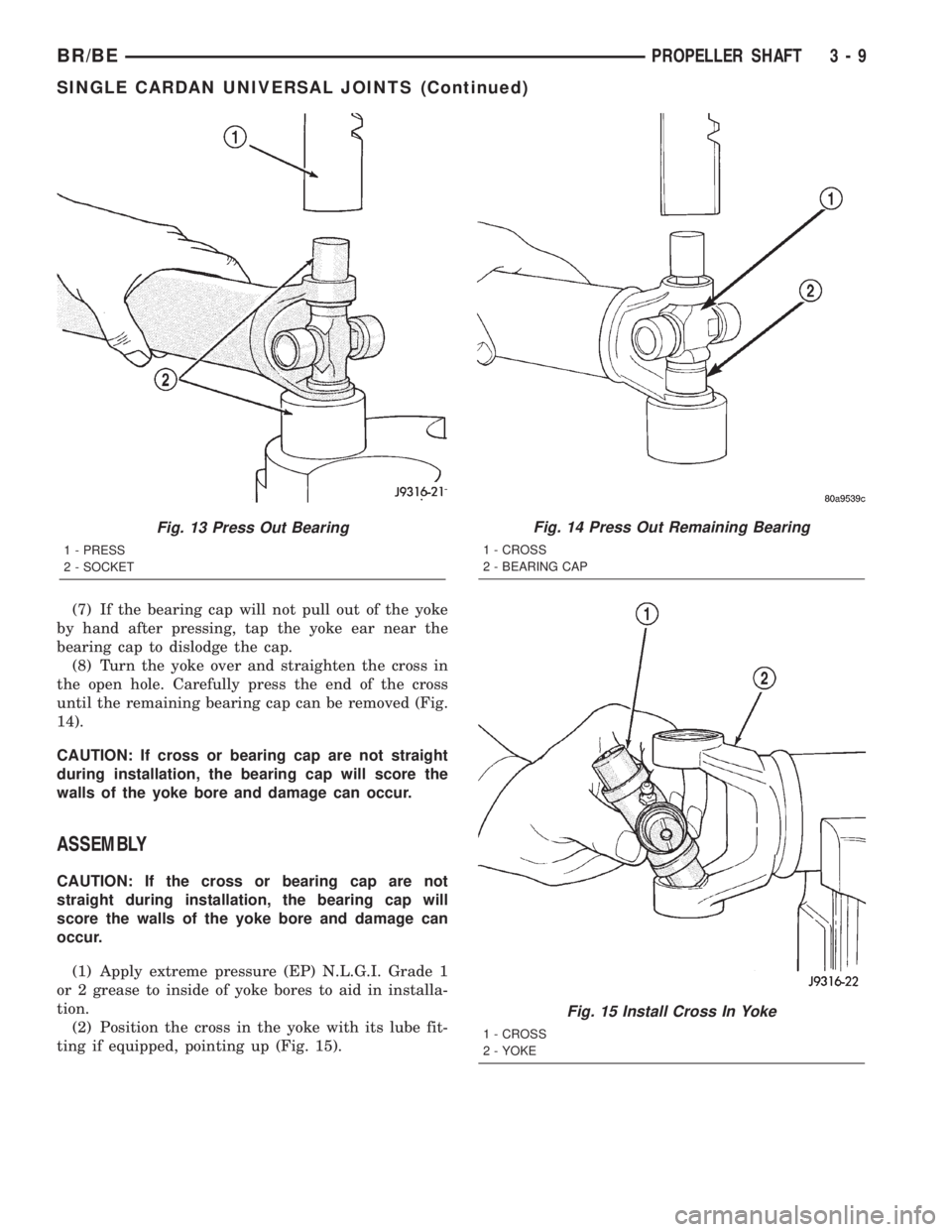

(6) Place a socket with an outside diameter

smaller than the upper bearing cap on the upper

bearing cap and press the cap through the yoke to

release the lower bearing cap (Fig. 13).

Fig. 12 Remove Snap Ring

1 - SNAP RING

3 - 8 PROPELLER SHAFTBR/BE

Page 64 of 2255

(7) If the bearing cap will not pull out of the yoke

by hand after pressing, tap the yoke ear near the

bearing cap to dislodge the cap.

(8) Turn the yoke over and straighten the cross in

the open hole. Carefully press the end of the cross

until the remaining bearing cap can be removed (Fig.

14).

CAUTION: If cross or bearing cap are not straight

during installation, the bearing cap will score the

walls of the yoke bore and damage can occur.

ASSEMBLY

CAUTION: If the cross or bearing cap are not

straight during installation, the bearing cap will

score the walls of the yoke bore and damage can

occur.

(1) Apply extreme pressure (EP) N.L.G.I. Grade 1

or 2 grease to inside of yoke bores to aid in installa-

tion.

(2) Position the cross in the yoke with its lube fit-

ting if equipped, pointing up (Fig. 15).

Fig. 13 Press Out Bearing

1 - PRESS

2 - SOCKET

Fig. 14 Press Out Remaining Bearing

1 - CROSS

2 - BEARING CAP

Fig. 15 Install Cross In Yoke

1 - CROSS

2 - YOKE

BR/BEPROPELLER SHAFT 3 - 9

SINGLE CARDAN UNIVERSAL JOINTS (Continued)

Page 65 of 2255

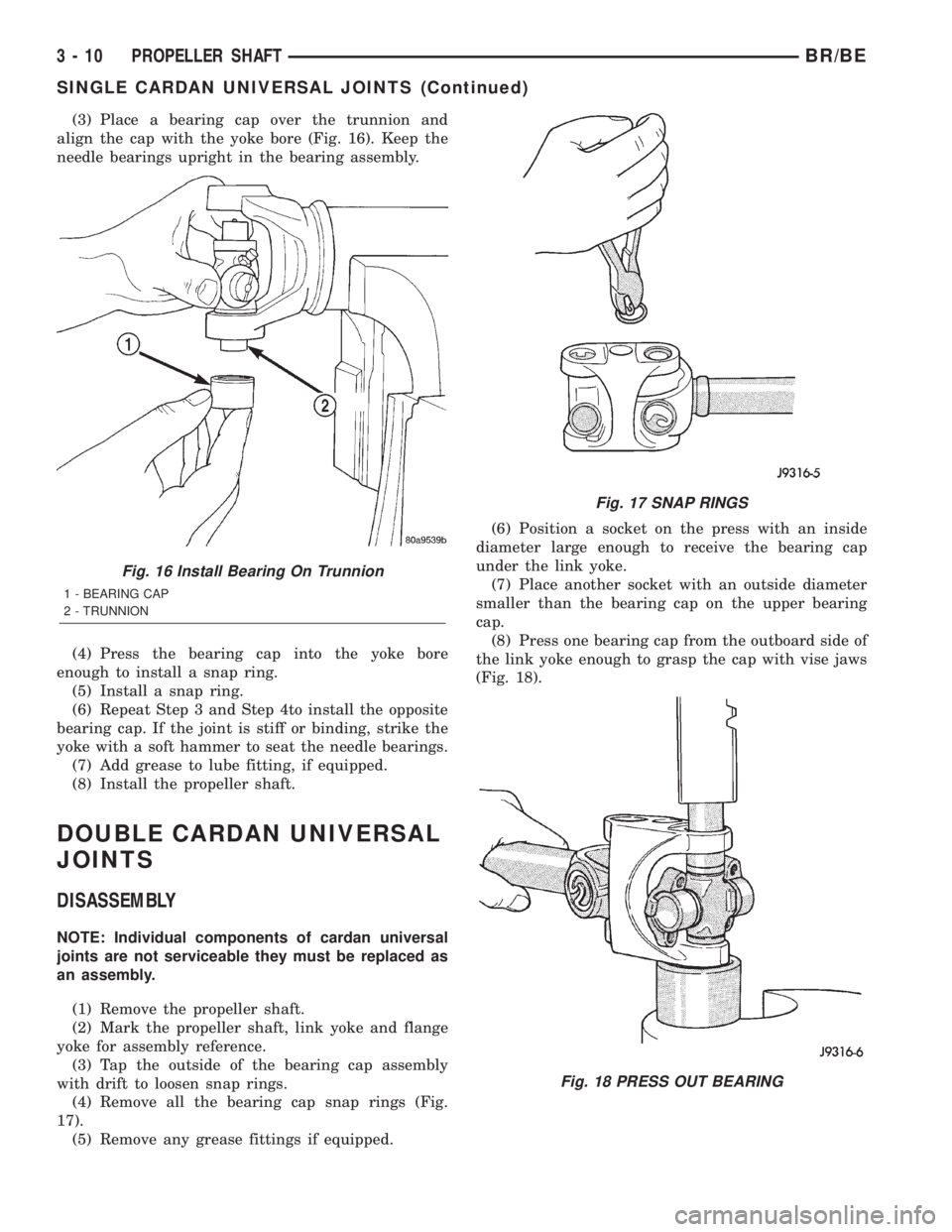

(3) Place a bearing cap over the trunnion and

align the cap with the yoke bore (Fig. 16). Keep the

needle bearings upright in the bearing assembly.

(4) Press the bearing cap into the yoke bore

enough to install a snap ring.

(5) Install a snap ring.

(6) Repeat Step 3 and Step 4to install the opposite

bearing cap. If the joint is stiff or binding, strike the

yoke with a soft hammer to seat the needle bearings.

(7) Add grease to lube fitting, if equipped.

(8) Install the propeller shaft.

DOUBLE CARDAN UNIVERSAL

JOINTS

DISASSEMBLY

NOTE: Individual components of cardan universal

joints are not serviceable they must be replaced as

an assembly.

(1) Remove the propeller shaft.

(2) Mark the propeller shaft, link yoke and flange

yoke for assembly reference.

(3) Tap the outside of the bearing cap assembly

with drift to loosen snap rings.

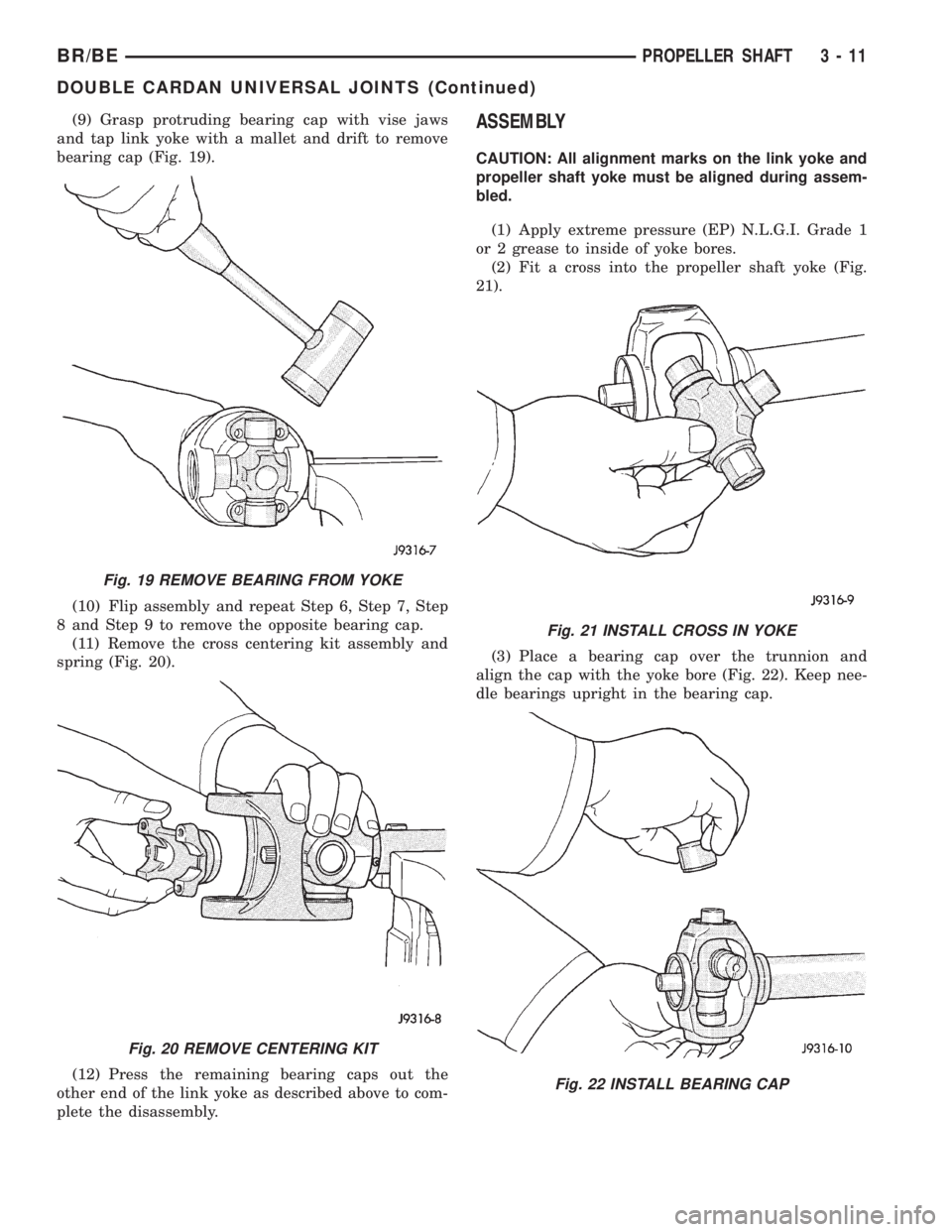

(4) Remove all the bearing cap snap rings (Fig.

17).

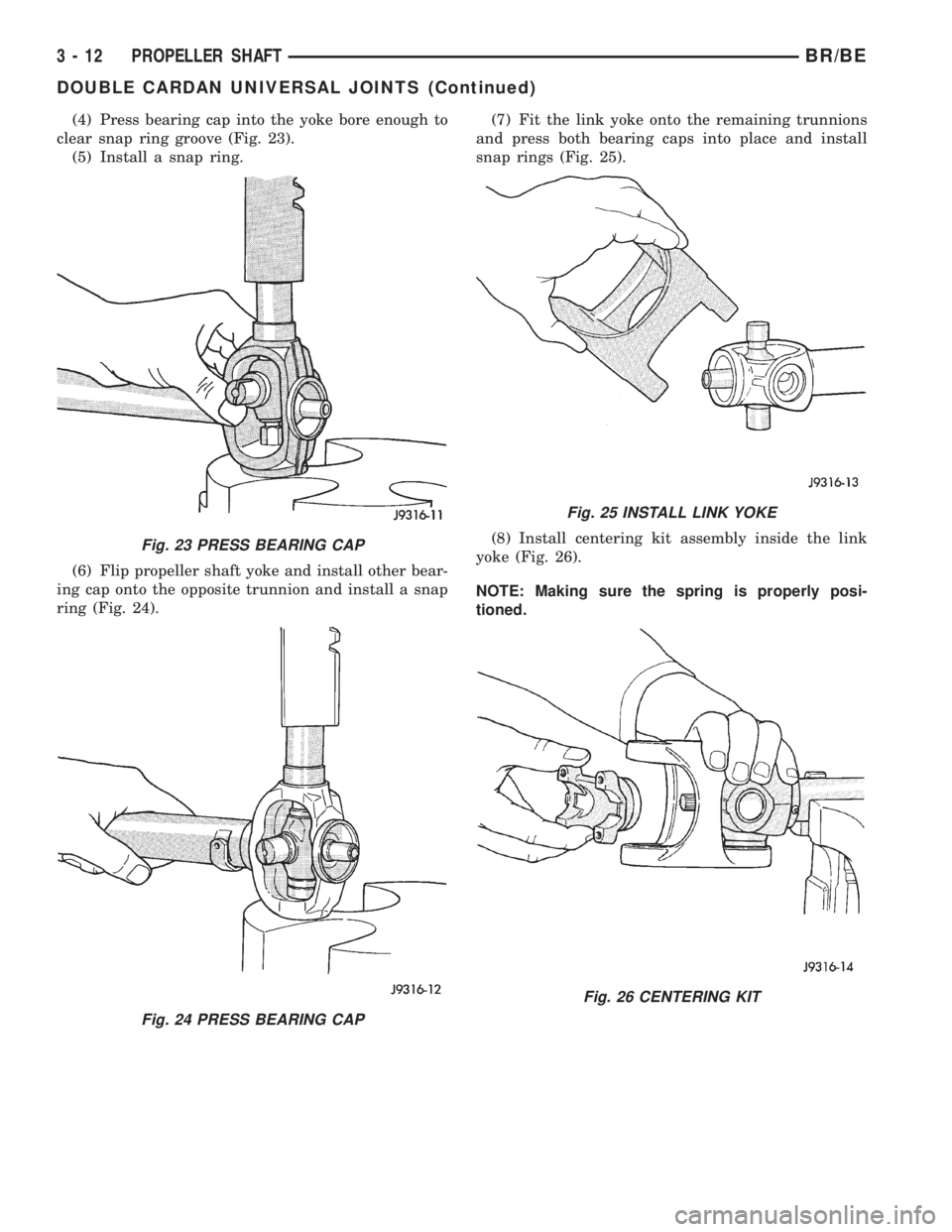

(5) Remove any grease fittings if equipped.(6) Position a socket on the press with an inside

diameter large enough to receive the bearing cap

under the link yoke.

(7) Place another socket with an outside diameter

smaller than the bearing cap on the upper bearing

cap.

(8) Press one bearing cap from the outboard side of

the link yoke enough to grasp the cap with vise jaws

(Fig. 18).

Fig. 16 Install Bearing On Trunnion

1 - BEARING CAP

2 - TRUNNION

Fig. 17 SNAP RINGS

Fig. 18 PRESS OUT BEARING

3 - 10 PROPELLER SHAFTBR/BE

SINGLE CARDAN UNIVERSAL JOINTS (Continued)

Page 66 of 2255

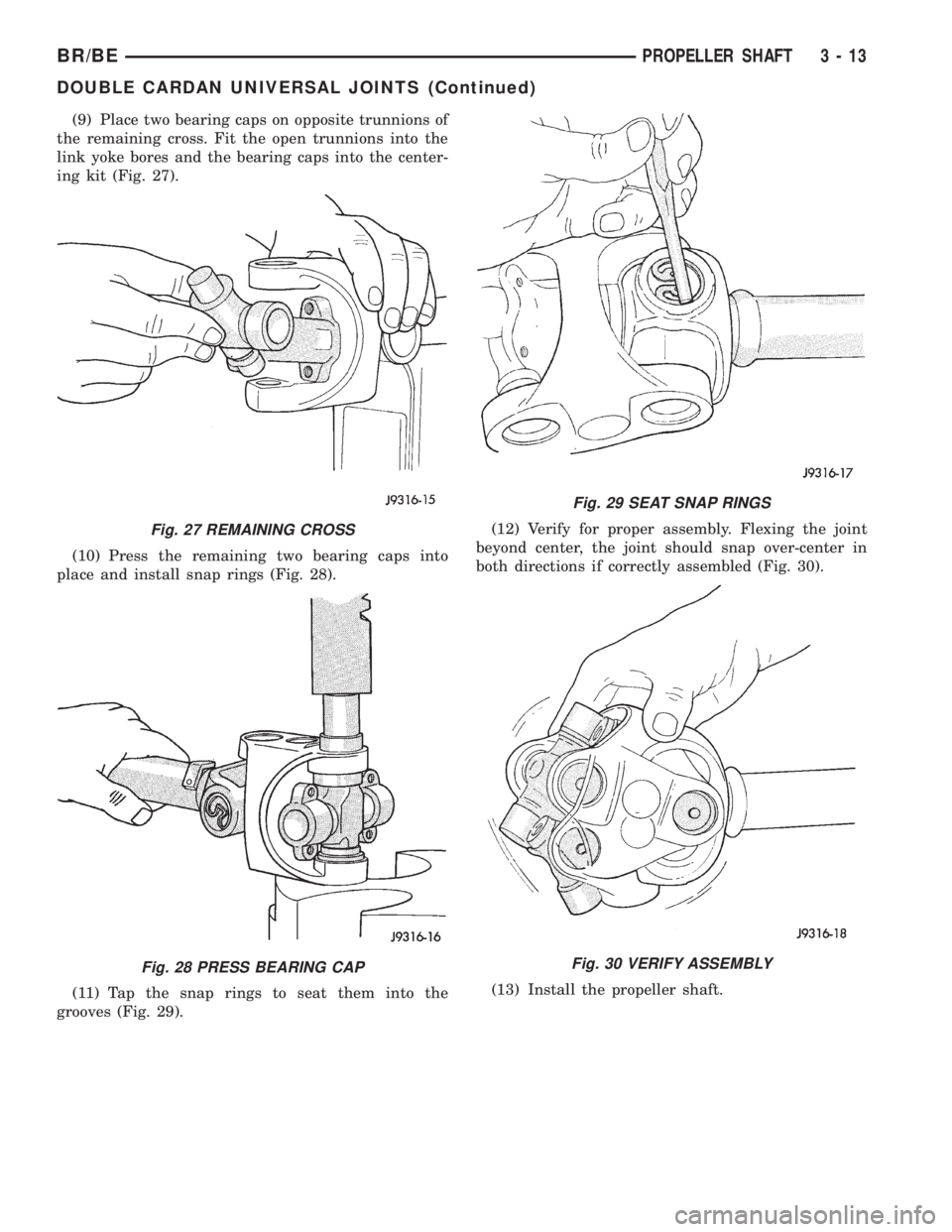

(9) Grasp protruding bearing cap with vise jaws

and tap link yoke with a mallet and drift to remove

bearing cap (Fig. 19).

(10) Flip assembly and repeat Step 6, Step 7, Step

8 and Step 9 to remove the opposite bearing cap.

(11) Remove the cross centering kit assembly and

spring (Fig. 20).

(12) Press the remaining bearing caps out the

other end of the link yoke as described above to com-

plete the disassembly.ASSEMBLY

CAUTION: All alignment marks on the link yoke and

propeller shaft yoke must be aligned during assem-

bled.

(1) Apply extreme pressure (EP) N.L.G.I. Grade 1

or 2 grease to inside of yoke bores.

(2) Fit a cross into the propeller shaft yoke (Fig.

21).

(3) Place a bearing cap over the trunnion and

align the cap with the yoke bore (Fig. 22). Keep nee-

dle bearings upright in the bearing cap.

Fig. 19 REMOVE BEARING FROM YOKE

Fig. 20 REMOVE CENTERING KIT

Fig. 21 INSTALL CROSS IN YOKE

Fig. 22 INSTALL BEARING CAP

BR/BEPROPELLER SHAFT 3 - 11

DOUBLE CARDAN UNIVERSAL JOINTS (Continued)

Page 67 of 2255

(4) Press bearing cap into the yoke bore enough to

clear snap ring groove (Fig. 23).

(5) Install a snap ring.

(6) Flip propeller shaft yoke and install other bear-

ing cap onto the opposite trunnion and install a snap

ring (Fig. 24).(7) Fit the link yoke onto the remaining trunnions

and press both bearing caps into place and install

snap rings (Fig. 25).

(8) Install centering kit assembly inside the link

yoke (Fig. 26).

NOTE: Making sure the spring is properly posi-

tioned.

Fig. 23 PRESS BEARING CAP

Fig. 24 PRESS BEARING CAP

Fig. 25 INSTALL LINK YOKE

Fig. 26 CENTERING KIT

3 - 12 PROPELLER SHAFTBR/BE

DOUBLE CARDAN UNIVERSAL JOINTS (Continued)

Page 68 of 2255

(9) Place two bearing caps on opposite trunnions of

the remaining cross. Fit the open trunnions into the

link yoke bores and the bearing caps into the center-

ing kit (Fig. 27).

(10) Press the remaining two bearing caps into

place and install snap rings (Fig. 28).

(11) Tap the snap rings to seat them into the

grooves (Fig. 29).(12) Verify for proper assembly. Flexing the joint

beyond center, the joint should snap over-center in

both directions if correctly assembled (Fig. 30).

(13) Install the propeller shaft.

Fig. 27 REMAINING CROSS

Fig. 28 PRESS BEARING CAP

Fig. 29 SEAT SNAP RINGS

Fig. 30 VERIFY ASSEMBLY

BR/BEPROPELLER SHAFT 3 - 13

DOUBLE CARDAN UNIVERSAL JOINTS (Continued)

Page 69 of 2255

FRONT AXLE - 248FBI

TABLE OF CONTENTS

page page

FRONT AXLE - 248FBI

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - AXLE..........15

REMOVAL.............................18

INSTALLATION.........................18

ADJUSTMENTS........................19

SPECIFICATIONS

FRONT AXLE - 248FBI.................27

SPECIAL TOOLS

FRONT AXLE........................27

AXLE SHAFTS

REMOVAL.............................29

INSTALLATION.........................29

AXLE SHAFTS - INTERMEDIATE

REMOVAL.............................30

INSTALLATION - INTERMEDIATE AXLE......30

AXLE SHAFT SEALS

REMOVAL.............................31

INSTALLATION.........................31

AXLE VACUUM MOTOR

DESCRIPTION.........................31

OPERATION...........................31DIAGNOSIS AND TESTING - VACUUM MOTOR . 32

REMOVAL.............................34

DISASSEMBLY.........................34

ASSEMBLY............................34

INSTALLATION.........................34

SINGLE CARDAN UNIVERSAL JOINTS

REMOVAL.............................34

INSTALLATION.........................35

PINION SEAL

REMOVAL.............................35

INSTALLATION.........................35

DIFFERENTIAL

REMOVAL.............................37

DISASSEMBLY.........................38

ASSEMBLY............................38

INSTALLATION.........................39

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................40

INSTALLATION.........................41

PINION GEAR/RING GEAR

REMOVAL.............................41

INSTALLATION.........................43

FRONT AXLE - 248FBI

DESCRIPTION

The Front Beam-design Iron (FBI) axle consists of a

cast iron center casting differential housing with axle

shaft tubes extending from each side. The tubes are

pressed into the differential housing and welded. The

axles is equipped with semi-floating axle shafts, mean-

ing that loads are supported by the hub bearings.

The differential case is a one-piece design. Differ-

ential bearing preload and ring gear backlash is

adjusted by the use of shims located between the dif-

ferential bearing cones and case. Pinion bearing pre-load is set and maintained by the use of a collapsible

spacer. The stamped steel cover provides a means for

inspection and servicing the differential.

OPERATION

The axle receives power from the transfer case

through the front propeller shaft. The front propeller

shaft is connected to the pinion gear which rotates

the differential through the gear mesh with the ring

gear bolted to the differential case. The engine power

is transmitted to the axle shafts through the pinion

mate and side gears. The side gears are splined to

the axle shafts.

3 - 14 FRONT AXLE - 248FBIBR/BE

Page 70 of 2255

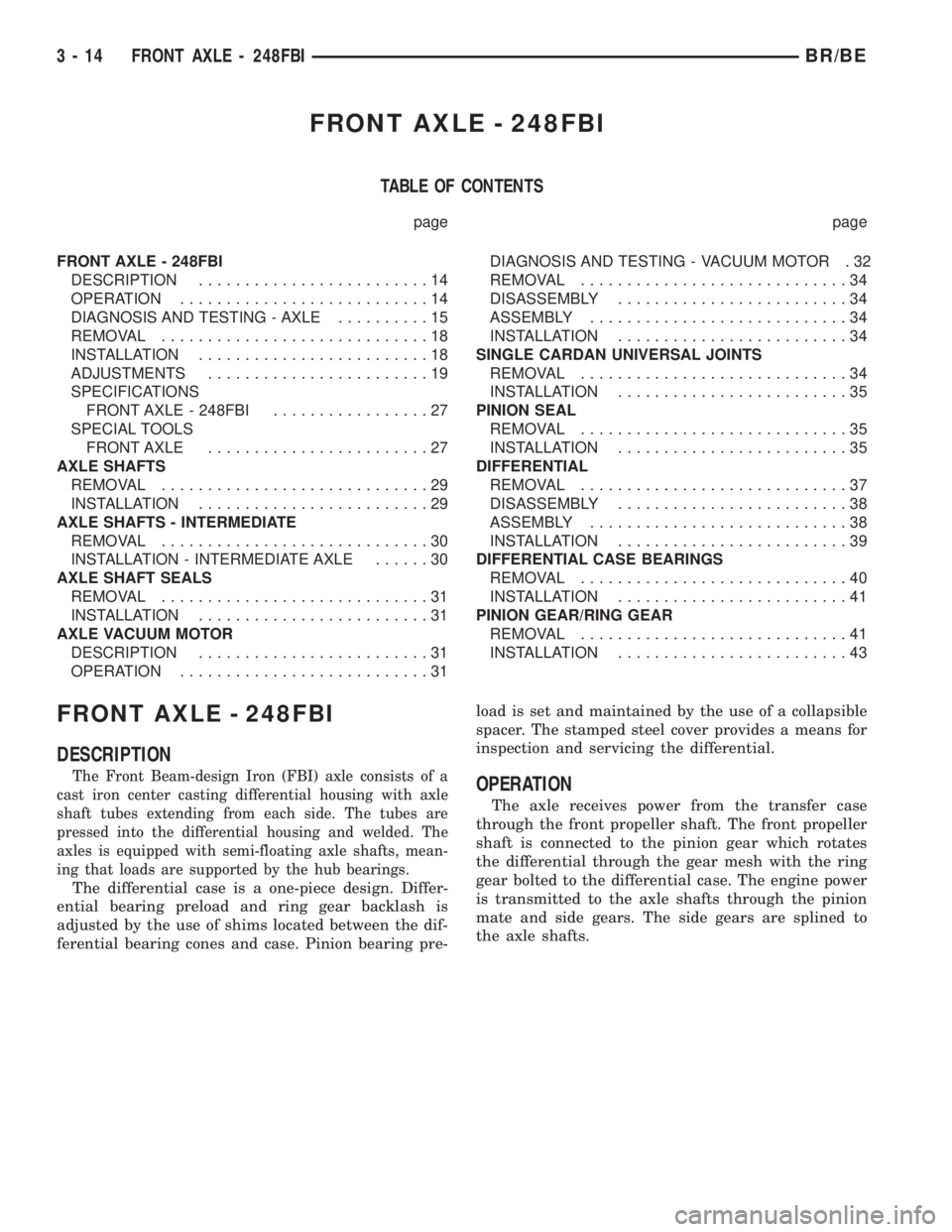

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 1).

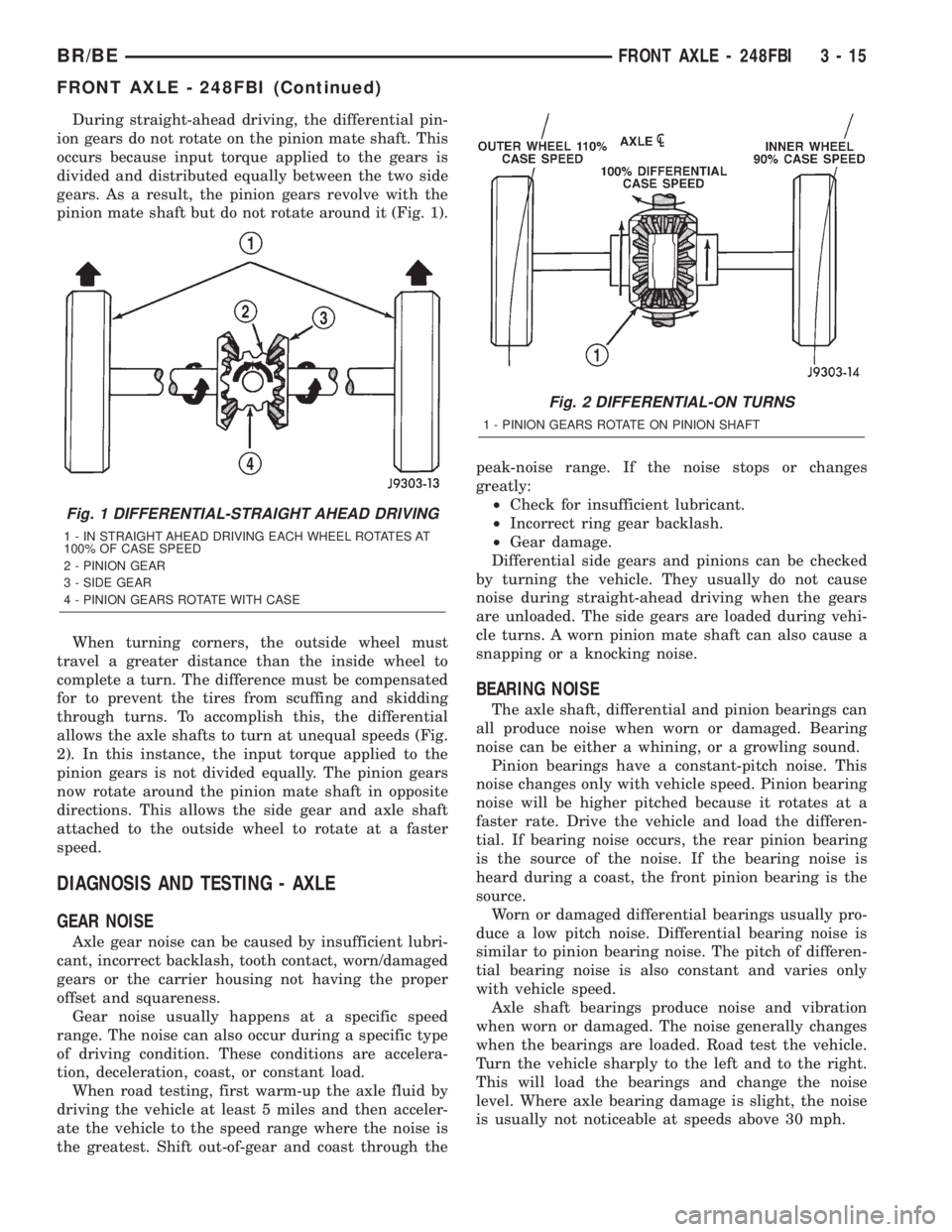

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. The difference must be compensated

for to prevent the tires from scuffing and skidding

through turns. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

2). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

DIAGNOSIS AND TESTING - AXLE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through thepeak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

Fig. 1 DIFFERENTIAL-STRAIGHT AHEAD DRIVING

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

Fig. 2 DIFFERENTIAL-ON TURNS

1 - PINION GEARS ROTATE ON PINION SHAFT

BR/BEFRONT AXLE - 248FBI 3 - 15

FRONT AXLE - 248FBI (Continued)