DODGE RAM 2002 Service Owners Manual

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 91 of 2255

(3) Install a new nut on the pinion gear. Tighten

the nut only enough to remove the shaft end play.

(4) Rotate the pinion shaft using an inch pound

torque wrench. Rotating torque should be equal to

the reading recorded during removal, plus an addi-

tional 0.56 N´m (5 in. lbs.) (Fig. 34).

(5) If the rotating torque is to low, use Holder 6719

to hold the pinion yoke (Fig. 35), and tighten the pin-

ion shaft nut in 6.8 N´m (5 ft. lbs.) until proper rotat-

ing torque is achieved.

(6) Align the installation reference marks and

attach the propeller shaft to the yoke.

(7) Check and add lubricant to axle, if necessary.

Refer to Lubricant Specifications in this section for

lubricant requirements.

(8) Install brake rotors and calipers.

(9) Install wheel and tire assemblies.

(10) Lower the vehicle.

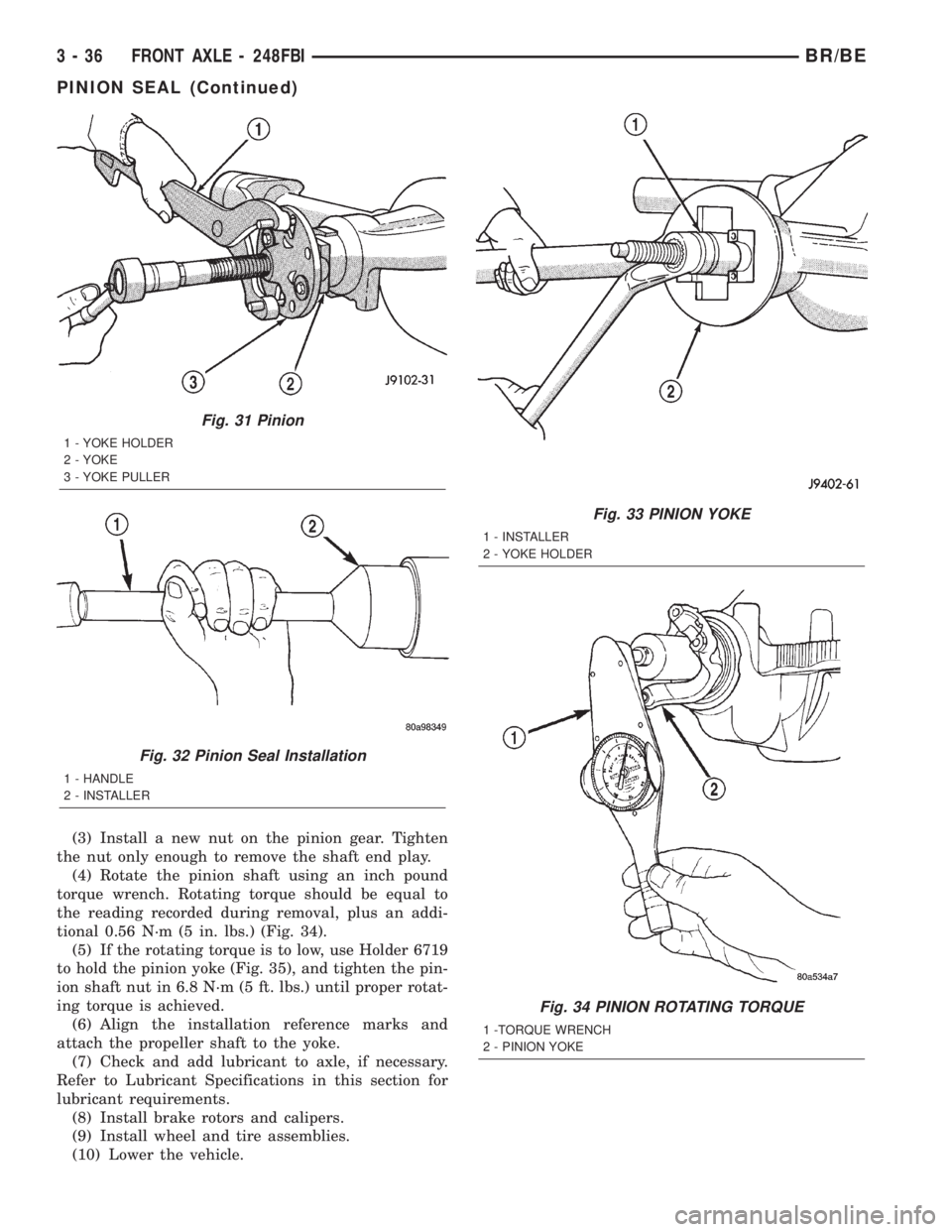

Fig. 31 Pinion

1 - YOKE HOLDER

2 - YOKE

3 - YOKE PULLER

Fig. 32 Pinion Seal Installation

1 - HANDLE

2 - INSTALLER

Fig. 33 PINION YOKE

1 - INSTALLER

2 - YOKE HOLDER

Fig. 34 PINION ROTATING TORQUE

1 -TORQUE WRENCH

2 - PINION YOKE

3 - 36 FRONT AXLE - 248FBIBR/BE

PINION SEAL (Continued)

Page 92 of 2255

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove lubricant fill hole plug from the differ-

ential housing cover.

(3) Remove differential housing cover and drain

the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove hub bearings and axle shafts.

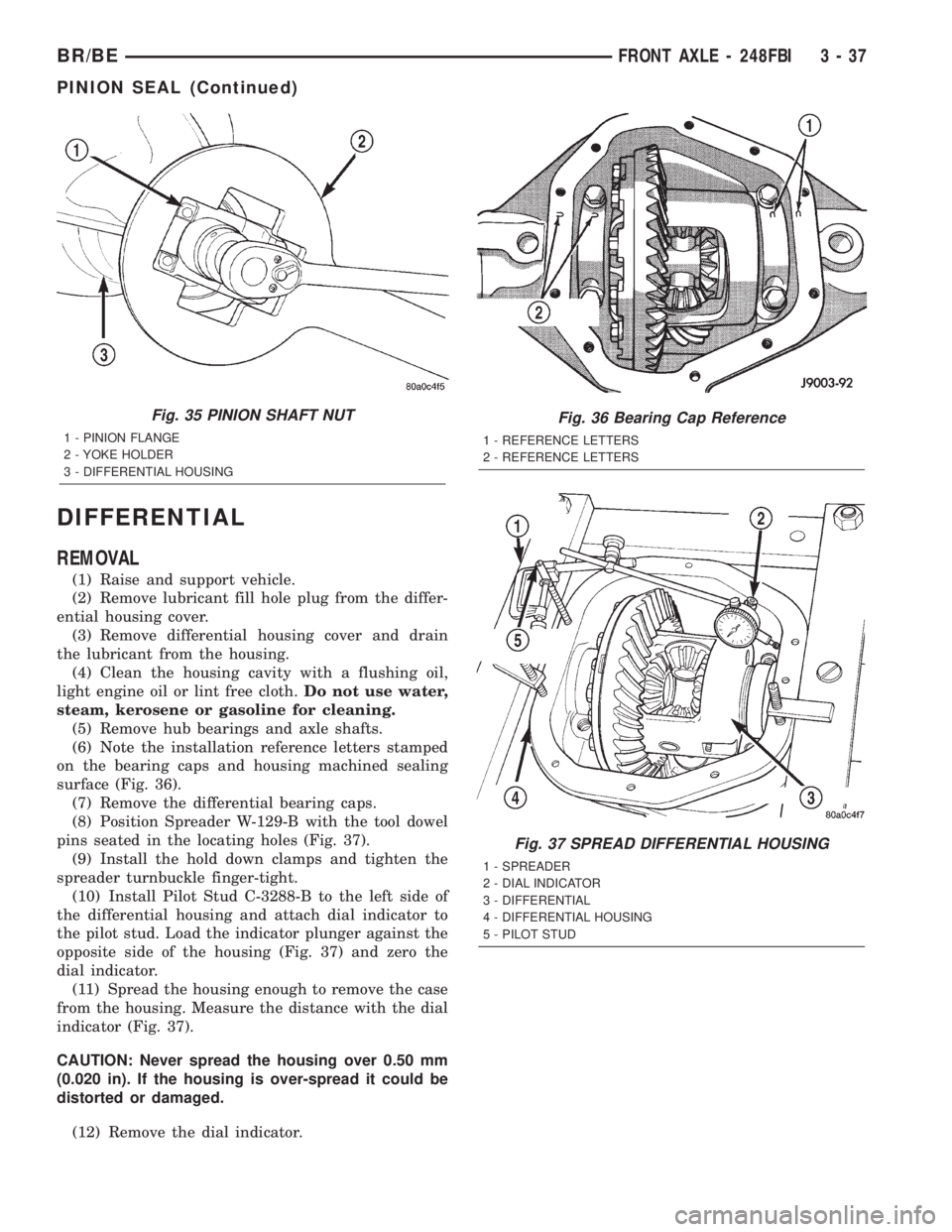

(6) Note the installation reference letters stamped

on the bearing caps and housing machined sealing

surface (Fig. 36).

(7) Remove the differential bearing caps.

(8) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 37).

(9) Install the hold down clamps and tighten the

spreader turnbuckle finger-tight.

(10) Install Pilot Stud C-3288-B to the left side of

the differential housing and attach dial indicator to

the pilot stud. Load the indicator plunger against the

opposite side of the housing (Fig. 37) and zero the

dial indicator.

(11) Spread the housing enough to remove the case

from the housing. Measure the distance with the dial

indicator (Fig. 37).

CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If the housing is over-spread it could be

distorted or damaged.

(12) Remove the dial indicator.

Fig. 35 PINION SHAFT NUT

1 - PINION FLANGE

2 - YOKE HOLDER

3 - DIFFERENTIAL HOUSING

Fig. 36 Bearing Cap Reference

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 37 SPREAD DIFFERENTIAL HOUSING

1 - SPREADER

2 - DIAL INDICATOR

3 - DIFFERENTIAL

4 - DIFFERENTIAL HOUSING

5 - PILOT STUD

BR/BEFRONT AXLE - 248FBI 3 - 37

PINION SEAL (Continued)

Page 93 of 2255

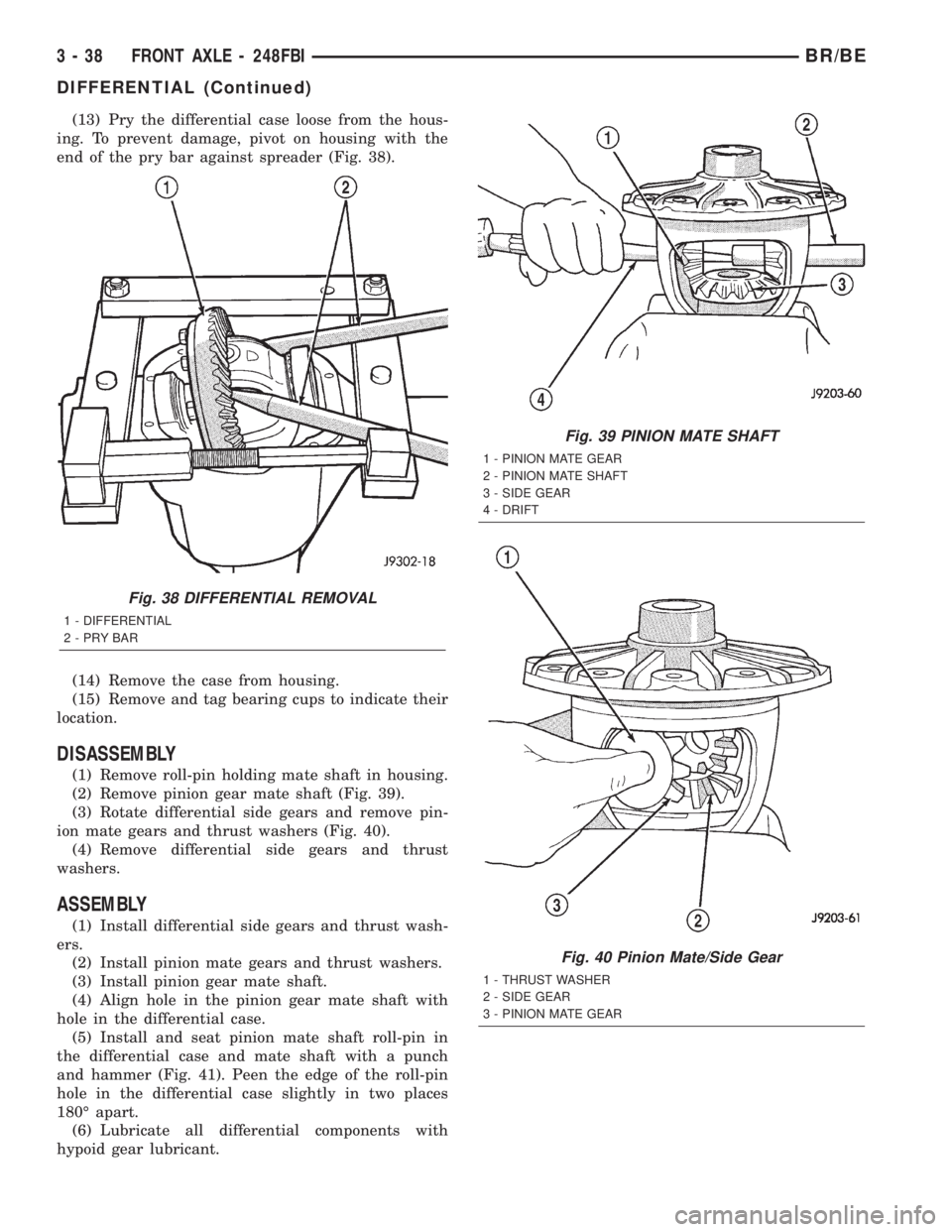

(13) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 38).

(14) Remove the case from housing.

(15) Remove and tag bearing cups to indicate their

location.

DISASSEMBLY

(1) Remove roll-pin holding mate shaft in housing.

(2) Remove pinion gear mate shaft (Fig. 39).

(3) Rotate differential side gears and remove pin-

ion mate gears and thrust washers (Fig. 40).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install pinion mate gears and thrust washers.

(3) Install pinion gear mate shaft.

(4) Align hole in the pinion gear mate shaft with

hole in the differential case.

(5) Install and seat pinion mate shaft roll-pin in

the differential case and mate shaft with a punch

and hammer (Fig. 41). Peen the edge of the roll-pin

hole in the differential case slightly in two places

180É apart.

(6) Lubricate all differential components with

hypoid gear lubricant.

Fig. 38 DIFFERENTIAL REMOVAL

1 - DIFFERENTIAL

2-PRYBAR

Fig. 39 PINION MATE SHAFT

1 - PINION MATE GEAR

2 - PINION MATE SHAFT

3 - SIDE GEAR

4 - DRIFT

Fig. 40 Pinion Mate/Side Gear

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEAR

3 - 38 FRONT AXLE - 248FBIBR/BE

DIFFERENTIAL (Continued)

Page 94 of 2255

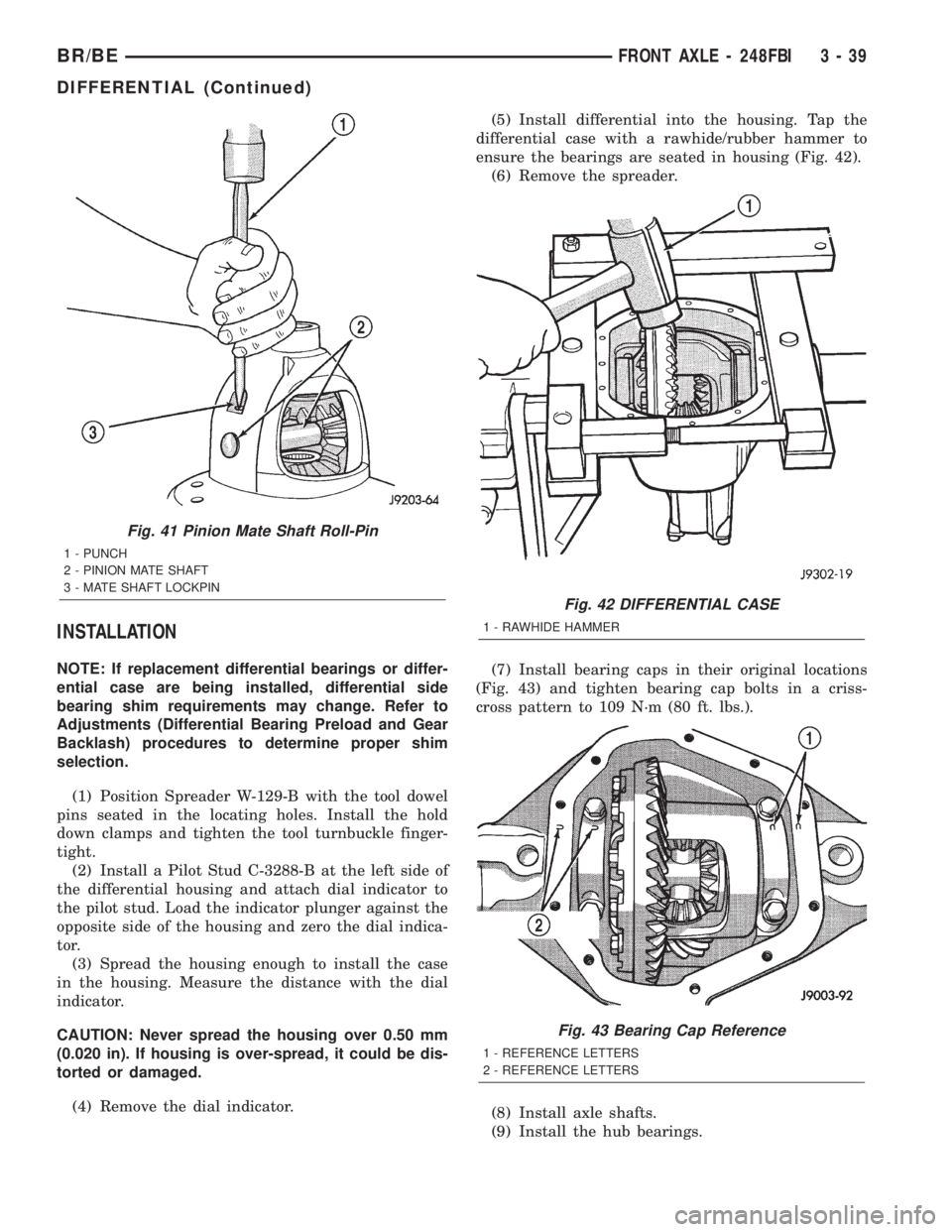

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer to

Adjustments (Differential Bearing Preload and Gear

Backlash) procedures to determine proper shim

selection.

(1) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes. Install the hold

down clamps and tighten the tool turnbuckle finger-

tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing and attach dial indicator to

the pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the dial indica-

tor.

(3) Spread the housing enough to install the case

in the housing. Measure the distance with the dial

indicator.

CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If housing is over-spread, it could be dis-

torted or damaged.

(4) Remove the dial indicator.(5) Install differential into the housing. Tap the

differential case with a rawhide/rubber hammer to

ensure the bearings are seated in housing (Fig. 42).

(6) Remove the spreader.

(7) Install bearing caps in their original locations

(Fig. 43) and tighten bearing cap bolts in a criss-

cross pattern to 109 N´m (80 ft. lbs.).

(8) Install axle shafts.

(9) Install the hub bearings.

Fig. 41 Pinion Mate Shaft Roll-Pin

1 - PUNCH

2 - PINION MATE SHAFT

3 - MATE SHAFT LOCKPIN

Fig. 42 DIFFERENTIAL CASE

1 - RAWHIDE HAMMER

Fig. 43 Bearing Cap Reference

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

BR/BEFRONT AXLE - 248FBI 3 - 39

DIFFERENTIAL (Continued)

Page 95 of 2255

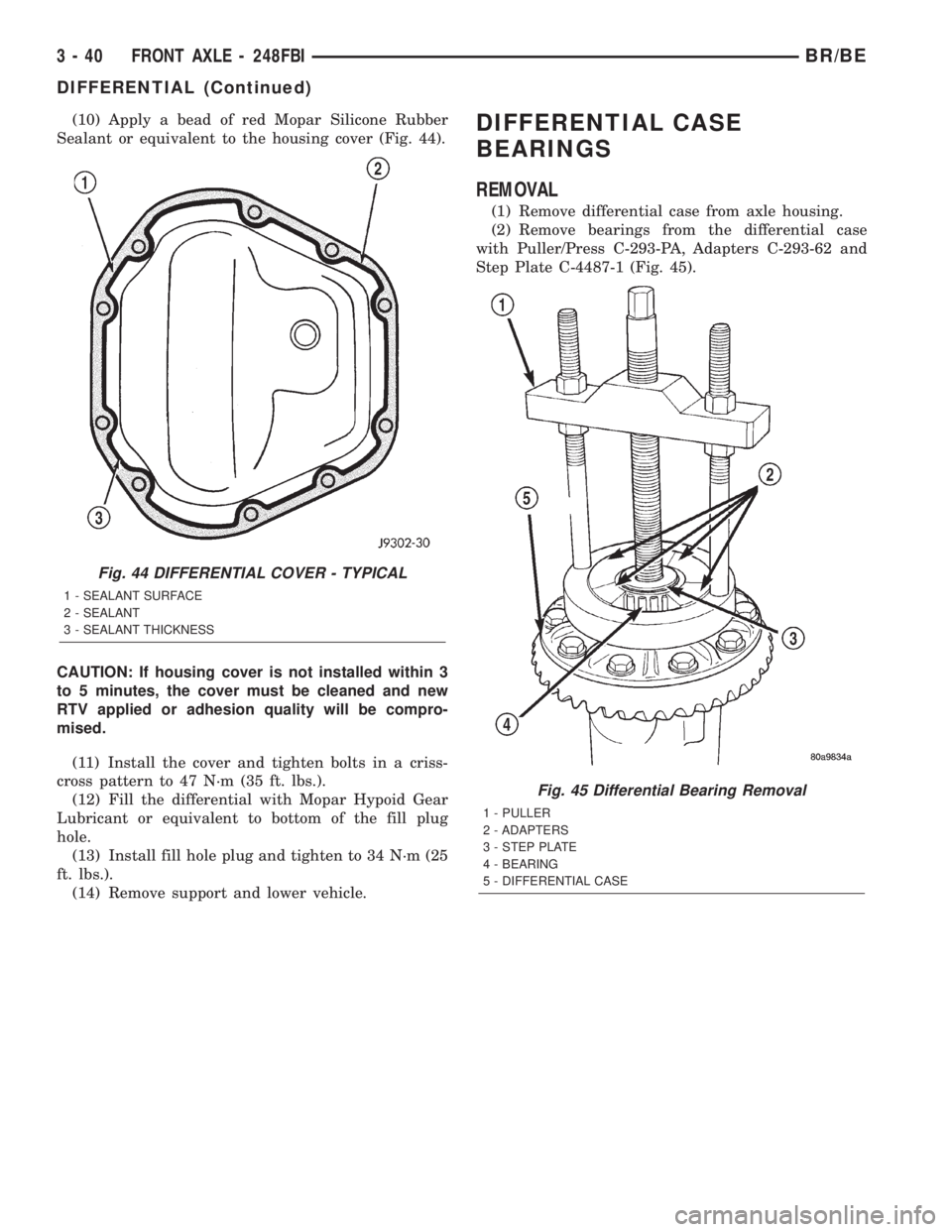

(10) Apply a bead of red Mopar Silicone Rubber

Sealant or equivalent to the housing cover (Fig. 44).

CAUTION: If housing cover is not installed within 3

to 5 minutes, the cover must be cleaned and new

RTV applied or adhesion quality will be compro-

mised.

(11) Install the cover and tighten bolts in a criss-

cross pattern to 47 N´m (35 ft. lbs.).

(12) Fill the differential with Mopar Hypoid Gear

Lubricant or equivalent to bottom of the fill plug

hole.

(13) Install fill hole plug and tighten to 34 N´m (25

ft. lbs.).

(14) Remove support and lower vehicle.DIFFERENTIAL CASE

BEARINGS

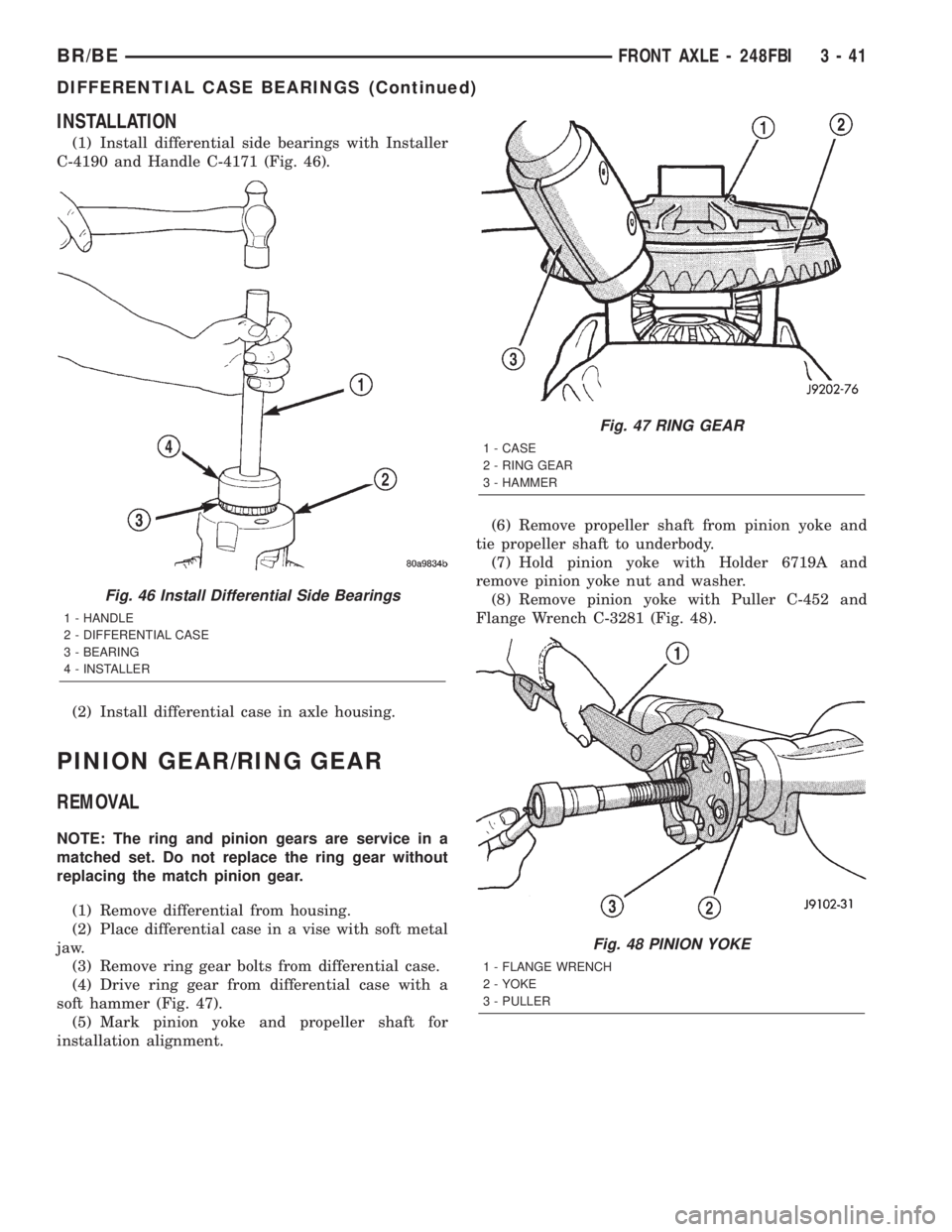

REMOVAL

(1) Remove differential case from axle housing.

(2) Remove bearings from the differential case

with Puller/Press C-293-PA, Adapters C-293-62 and

Step Plate C-4487-1 (Fig. 45).

Fig. 44 DIFFERENTIAL COVER - TYPICAL

1 - SEALANT SURFACE

2 - SEALANT

3 - SEALANT THICKNESS

Fig. 45 Differential Bearing Removal

1 - PULLER

2 - ADAPTERS

3 - STEP PLATE

4 - BEARING

5 - DIFFERENTIAL CASE

3 - 40 FRONT AXLE - 248FBIBR/BE

DIFFERENTIAL (Continued)

Page 96 of 2255

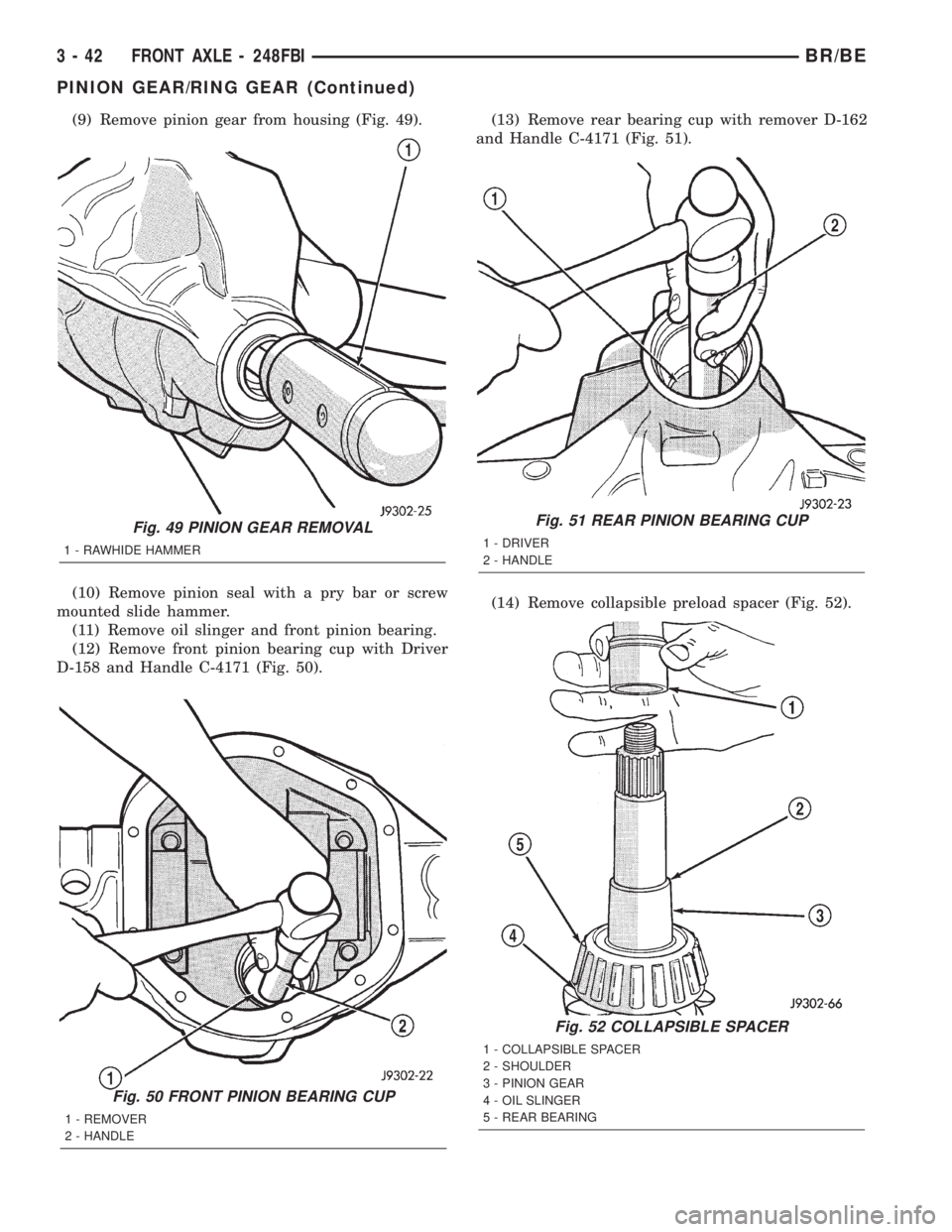

INSTALLATION

(1) Install differential side bearings with Installer

C-4190 and Handle C-4171 (Fig. 46).

(2) Install differential case in axle housing.

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring and pinion gears are service in a

matched set. Do not replace the ring gear without

replacing the match pinion gear.

(1) Remove differential from housing.

(2) Place differential case in a vise with soft metal

jaw.

(3) Remove ring gear bolts from differential case.

(4) Drive ring gear from differential case with a

soft hammer (Fig. 47).

(5) Mark pinion yoke and propeller shaft for

installation alignment.(6) Remove propeller shaft from pinion yoke and

tie propeller shaft to underbody.

(7) Hold pinion yoke with Holder 6719A and

remove pinion yoke nut and washer.

(8) Remove pinion yoke with Puller C-452 and

Flange Wrench C-3281 (Fig. 48).

Fig. 46 Install Differential Side Bearings

1 - HANDLE

2 - DIFFERENTIAL CASE

3 - BEARING

4 - INSTALLER

Fig. 47 RING GEAR

1 - CASE

2 - RING GEAR

3 - HAMMER

Fig. 48 PINION YOKE

1 - FLANGE WRENCH

2 - YOKE

3 - PULLER

BR/BEFRONT AXLE - 248FBI 3 - 41

DIFFERENTIAL CASE BEARINGS (Continued)

Page 97 of 2255

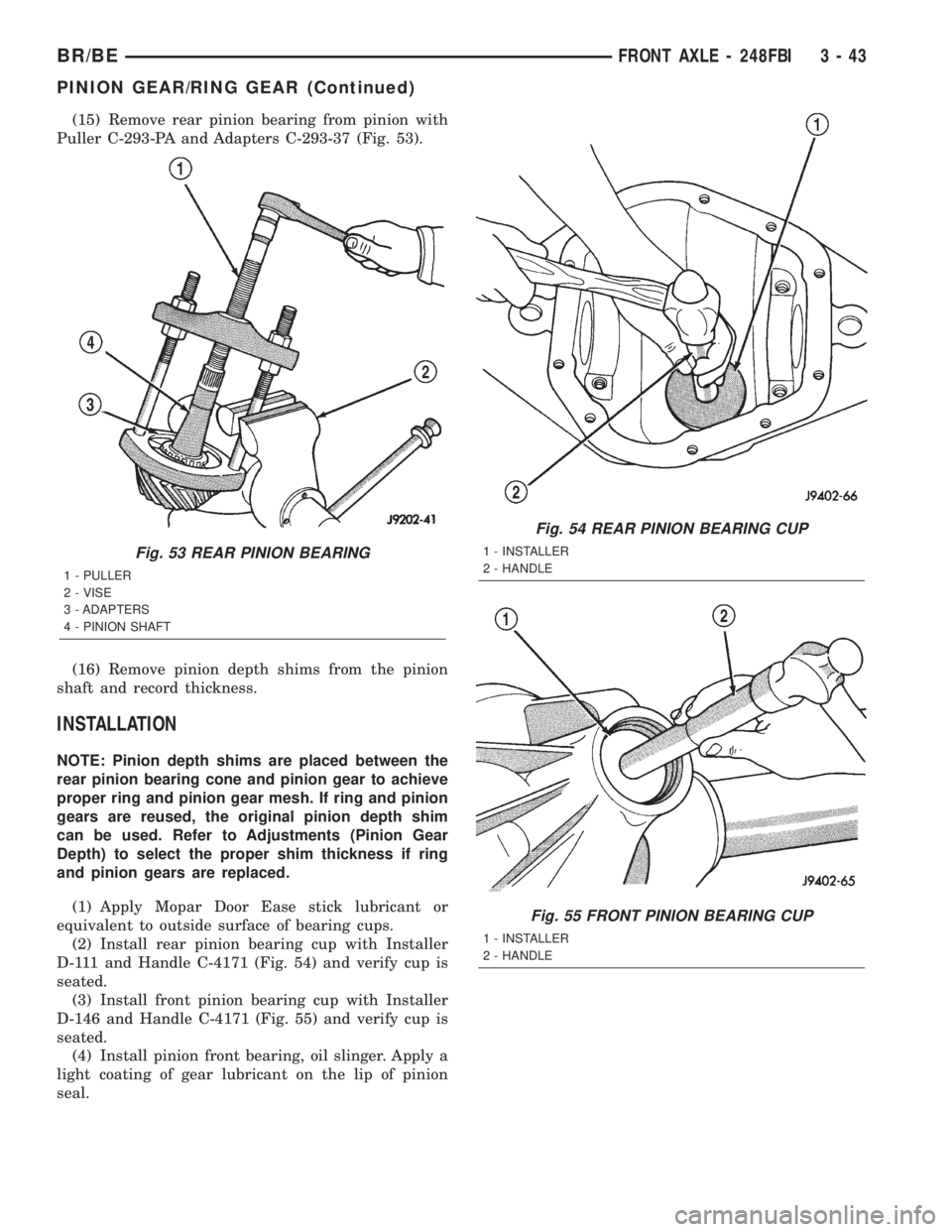

(9) Remove pinion gear from housing (Fig. 49).

(10) Remove pinion seal with a pry bar or screw

mounted slide hammer.

(11) Remove oil slinger and front pinion bearing.

(12) Remove front pinion bearing cup with Driver

D-158 and Handle C-4171 (Fig. 50).(13) Remove rear bearing cup with remover D-162

and Handle C-4171 (Fig. 51).

(14) Remove collapsible preload spacer (Fig. 52).

Fig. 50 FRONT PINION BEARING CUP

1 - REMOVER

2 - HANDLE

Fig. 49 PINION GEAR REMOVAL

1 - RAWHIDE HAMMER

Fig. 51 REAR PINION BEARING CUP

1 - DRIVER

2 - HANDLE

Fig. 52 COLLAPSIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION GEAR

4 - OIL SLINGER

5 - REAR BEARING

3 - 42 FRONT AXLE - 248FBIBR/BE

PINION GEAR/RING GEAR (Continued)

Page 98 of 2255

(15) Remove rear pinion bearing from pinion with

Puller C-293-PA and Adapters C-293-37 (Fig. 53).

(16) Remove pinion depth shims from the pinion

shaft and record thickness.

INSTALLATION

NOTE: Pinion depth shims are placed between the

rear pinion bearing cone and pinion gear to achieve

proper ring and pinion gear mesh. If ring and pinion

gears are reused, the original pinion depth shim

can be used. Refer to Adjustments (Pinion Gear

Depth) to select the proper shim thickness if ring

and pinion gears are replaced.

(1) Apply Mopar Door Ease stick lubricant or

equivalent to outside surface of bearing cups.

(2) Install rear pinion bearing cup with Installer

D-111 and Handle C-4171 (Fig. 54) and verify cup is

seated.

(3) Install front pinion bearing cup with Installer

D-146 and Handle C-4171 (Fig. 55) and verify cup is

seated.

(4) Install pinion front bearing, oil slinger. Apply a

light coating of gear lubricant on the lip of pinion

seal.

Fig. 53 REAR PINION BEARING

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - PINION SHAFT

Fig. 54 REAR PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 55 FRONT PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

BR/BEFRONT AXLE - 248FBI 3 - 43

PINION GEAR/RING GEAR (Continued)

Page 99 of 2255

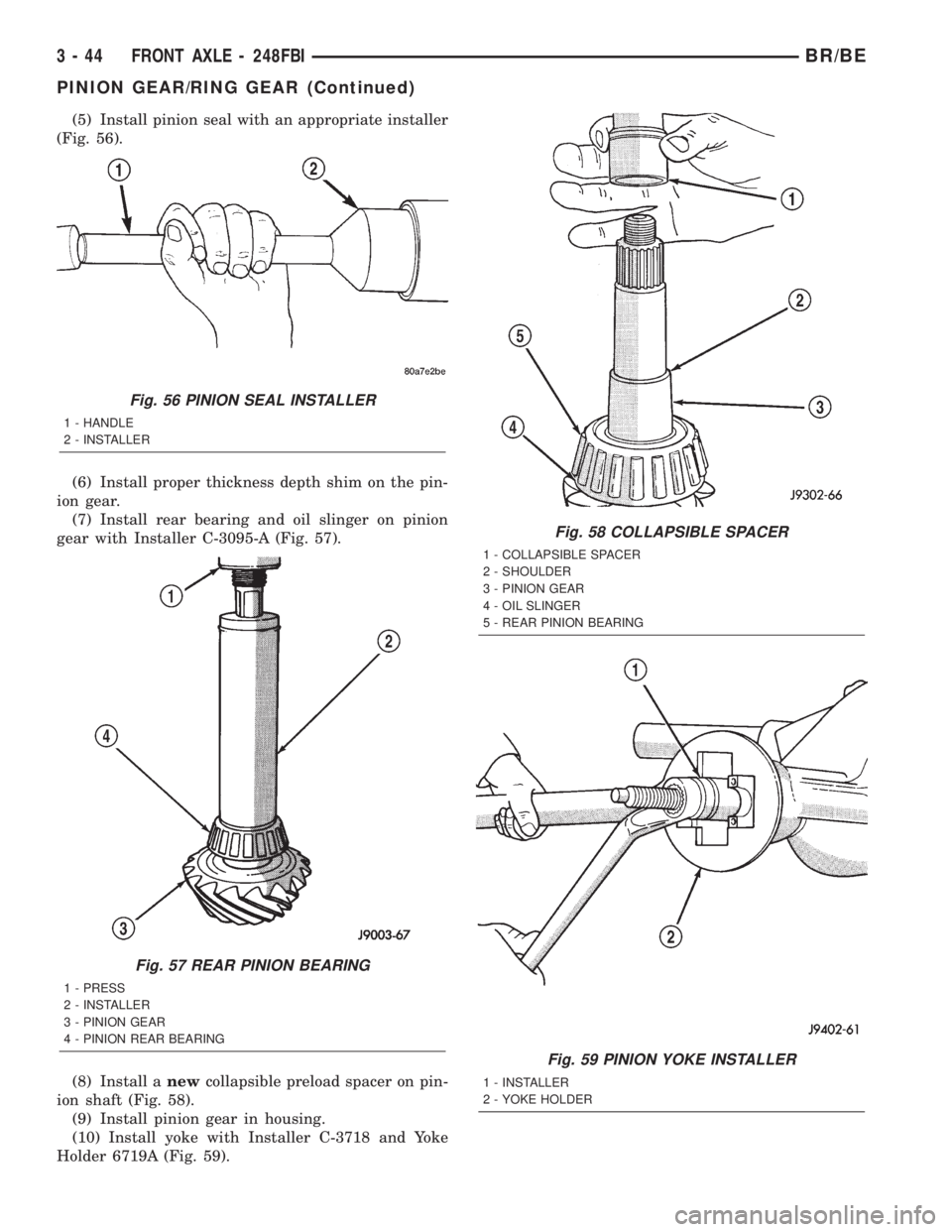

(5) Install pinion seal with an appropriate installer

(Fig. 56).

(6) Install proper thickness depth shim on the pin-

ion gear.

(7) Install rear bearing and oil slinger on pinion

gear with Installer C-3095-A (Fig. 57).

(8) Install anewcollapsible preload spacer on pin-

ion shaft (Fig. 58).

(9) Install pinion gear in housing.

(10) Install yoke with Installer C-3718 and Yoke

Holder 6719A (Fig. 59).

Fig. 56 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 57 REAR PINION BEARING

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - PINION REAR BEARING

Fig. 58 COLLAPSIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION GEAR

4 - OIL SLINGER

5 - REAR PINION BEARING

Fig. 59 PINION YOKE INSTALLER

1 - INSTALLER

2 - YOKE HOLDER

3 - 44 FRONT AXLE - 248FBIBR/BE

PINION GEAR/RING GEAR (Continued)

Page 100 of 2255

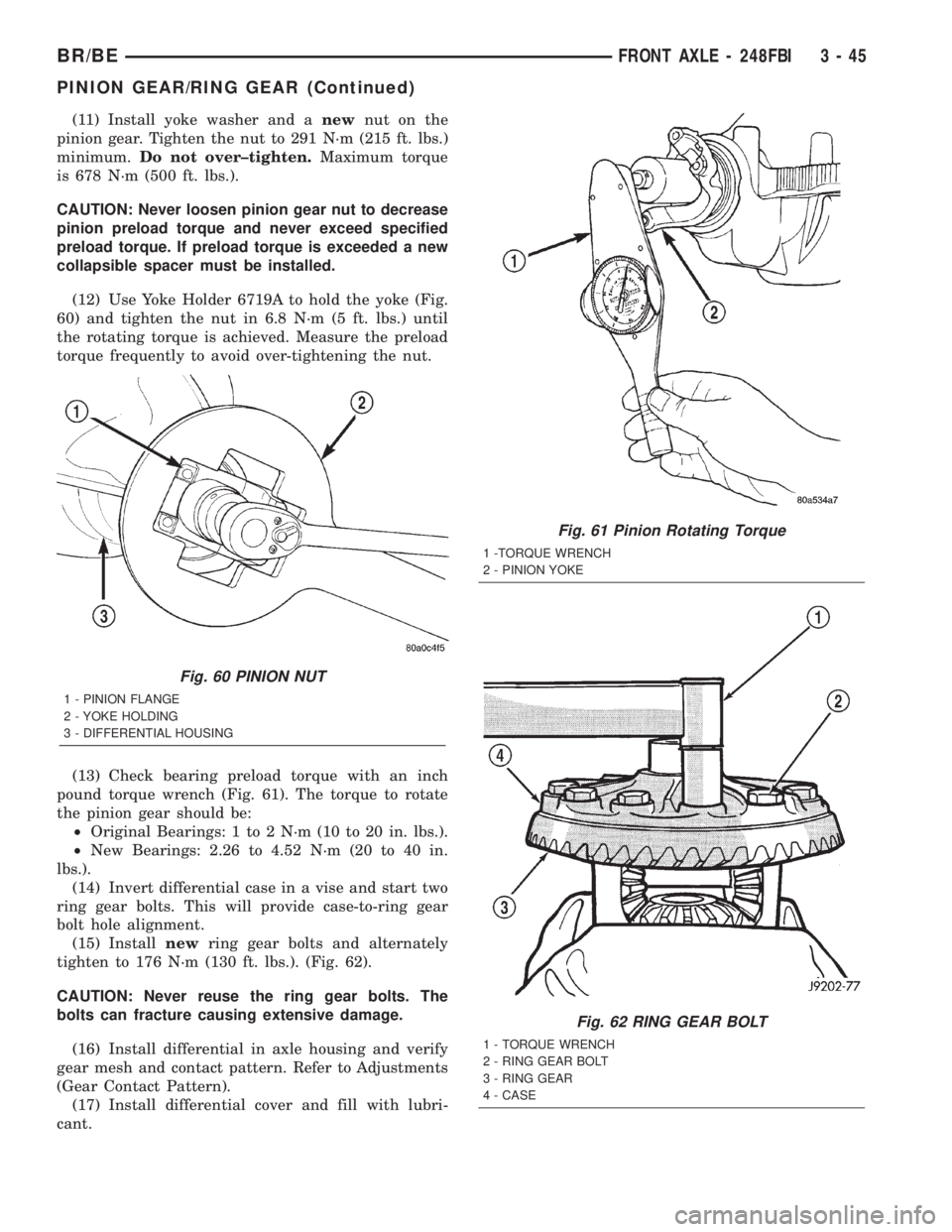

(11) Install yoke washer and anewnut on the

pinion gear. Tighten the nut to 291 N´m (215 ft. lbs.)

minimum.Do not over±tighten.Maximum torque

is 678 N´m (500 ft. lbs.).

CAUTION: Never loosen pinion gear nut to decrease

pinion preload torque and never exceed specified

preload torque. If preload torque is exceeded a new

collapsible spacer must be installed.

(12) Use Yoke Holder 6719A to hold the yoke (Fig.

60) and tighten the nut in 6.8 N´m (5 ft. lbs.) until

the rotating torque is achieved. Measure the preload

torque frequently to avoid over-tightening the nut.

(13) Check bearing preload torque with an inch

pound torque wrench (Fig. 61). The torque to rotate

the pinion gear should be:

²Original Bearings: 1 to 2 N´m (10 to 20 in. lbs.).

²New Bearings: 2.26 to 4.52 N´m (20 to 40 in.

lbs.).

(14) Invert differential case in a vise and start two

ring gear bolts. This will provide case-to-ring gear

bolt hole alignment.

(15) Installnewring gear bolts and alternately

tighten to 176 N´m (130 ft. lbs.). (Fig. 62).

CAUTION: Never reuse the ring gear bolts. The

bolts can fracture causing extensive damage.

(16) Install differential in axle housing and verify

gear mesh and contact pattern. Refer to Adjustments

(Gear Contact Pattern).

(17) Install differential cover and fill with lubri-

cant.

Fig. 60 PINION NUT

1 - PINION FLANGE

2 - YOKE HOLDING

3 - DIFFERENTIAL HOUSING

Fig. 61 Pinion Rotating Torque

1 -TORQUE WRENCH

2 - PINION YOKE

Fig. 62 RING GEAR BOLT

1 - TORQUE WRENCH

2 - RING GEAR BOLT

3 - RING GEAR

4 - CASE

BR/BEFRONT AXLE - 248FBI 3 - 45

PINION GEAR/RING GEAR (Continued)