DODGE RAM 2002 Service Manual Online

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 81 of 2255

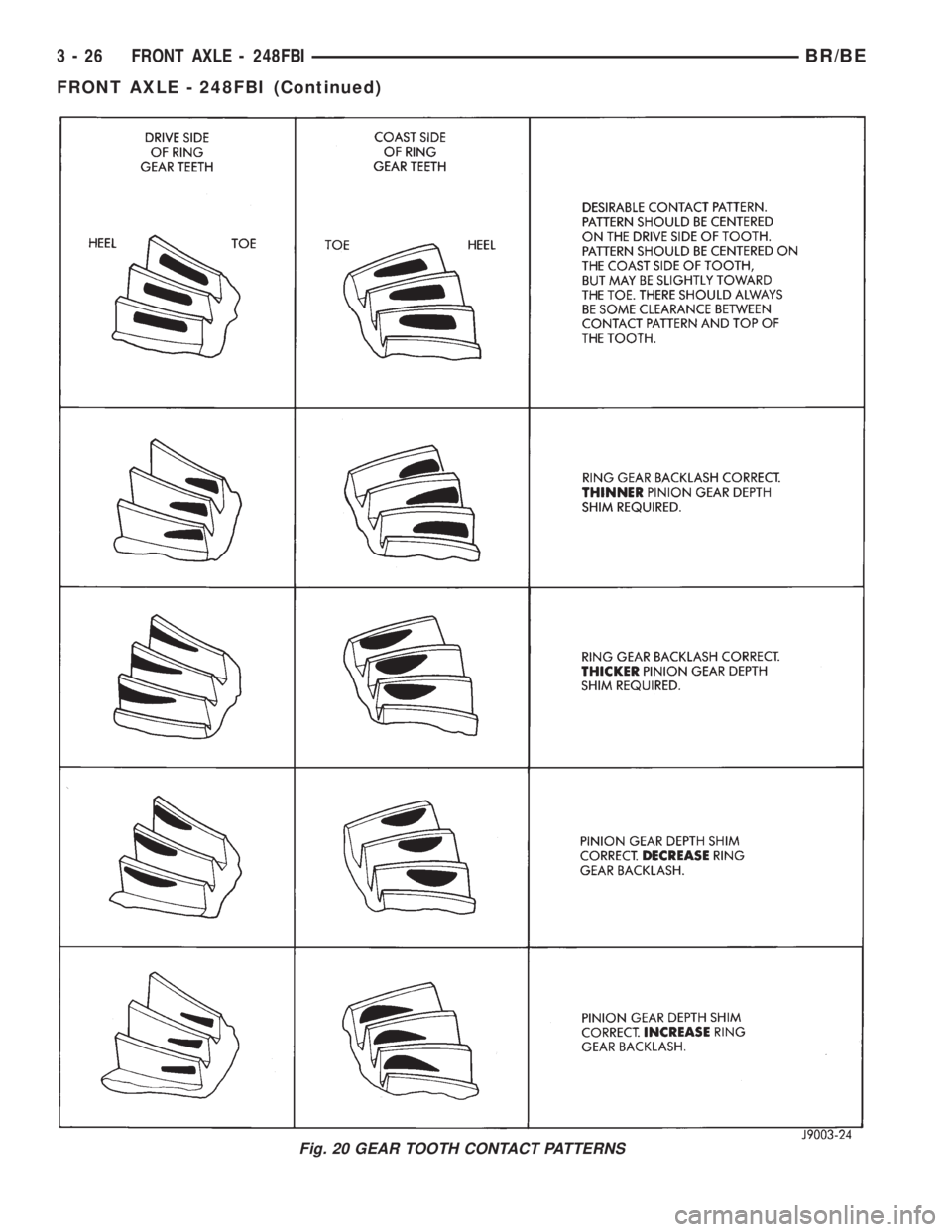

Fig. 20 GEAR TOOTH CONTACT PATTERNS

3 - 26 FRONT AXLE - 248FBIBR/BE

FRONT AXLE - 248FBI (Continued)

Page 82 of 2255

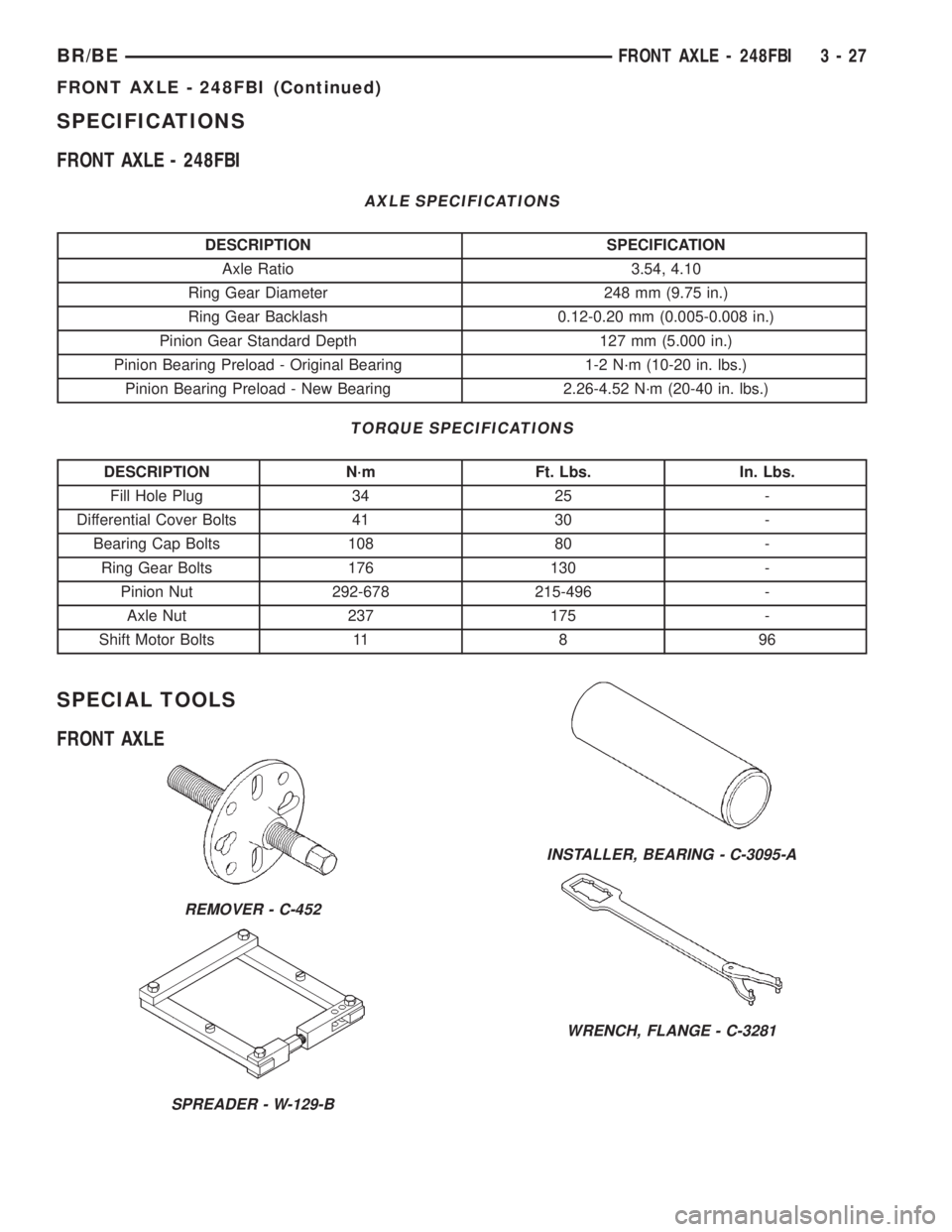

SPECIFICATIONS

FRONT AXLE - 248FBI

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.54, 4.10

Ring Gear Diameter 248 mm (9.75 in.)

Ring Gear Backlash 0.12-0.20 mm (0.005-0.008 in.)

Pinion Gear Standard Depth 127 mm (5.000 in.)

Pinion Bearing Preload - Original Bearing 1-2 N´m (10-20 in. lbs.)

Pinion Bearing Preload - New Bearing 2.26-4.52 N´m (20-40 in. lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fill Hole Plug 34 25 -

Differential Cover Bolts 41 30 -

Bearing Cap Bolts 108 80 -

Ring Gear Bolts 176 130 -

Pinion Nut 292-678 215-496 -

Axle Nut 237 175 -

Shift Motor Bolts 11 8 96

SPECIAL TOOLS

FRONT AXLE

REMOVER - C-452

SPREADER - W-129-B

INSTALLER, BEARING - C-3095-A

WRENCH, FLANGE - C-3281

BR/BEFRONT AXLE - 248FBI 3 - 27

FRONT AXLE - 248FBI (Continued)

Page 83 of 2255

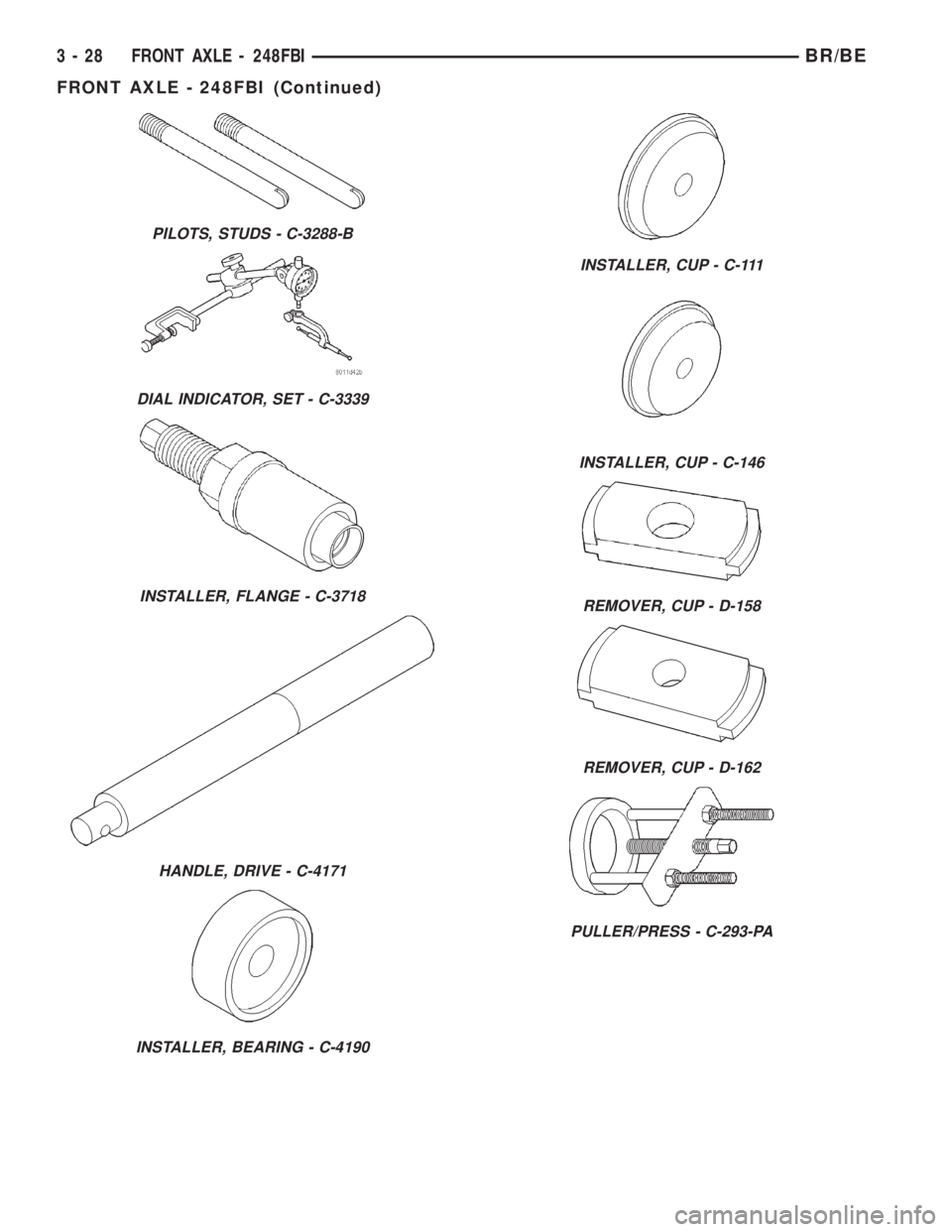

PILOTS, STUDS - C-3288-B

DIAL INDICATOR, SET - C-3339

INSTALLER, FLANGE - C-3718

HANDLE, DRIVE - C-4171

INSTALLER, BEARING - C-4190

INSTALLER, CUP - C-111

INSTALLER, CUP - C-146

REMOVER, CUP - D-158

REMOVER, CUP - D-162

PULLER/PRESS - C-293-PA

3 - 28 FRONT AXLE - 248FBIBR/BE

FRONT AXLE - 248FBI (Continued)

Page 84 of 2255

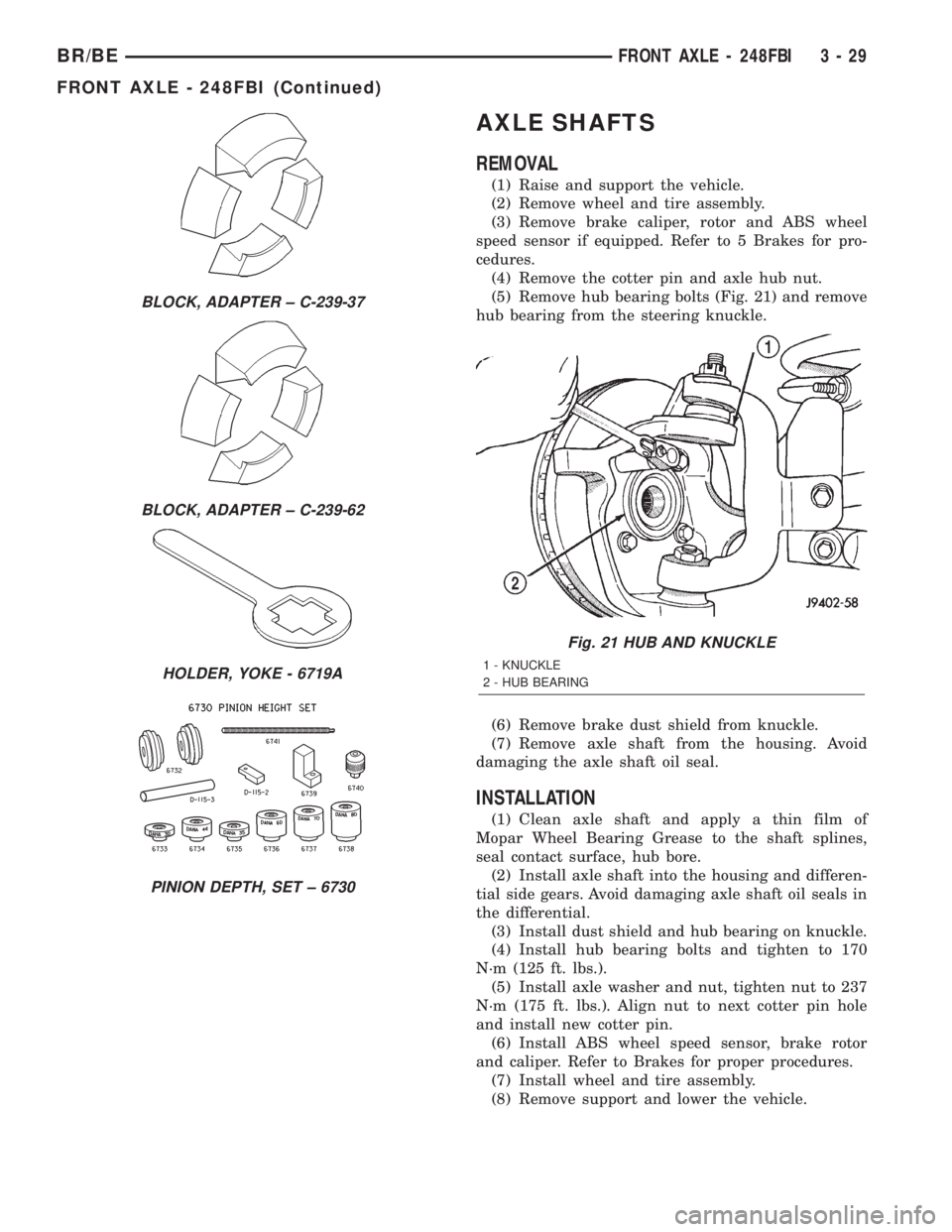

AXLE SHAFTS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assembly.

(3) Remove brake caliper, rotor and ABS wheel

speed sensor if equipped. Refer to 5 Brakes for pro-

cedures.

(4) Remove the cotter pin and axle hub nut.

(5) Remove hub bearing bolts (Fig. 21) and remove

hub bearing from the steering knuckle.

(6) Remove brake dust shield from knuckle.

(7) Remove axle shaft from the housing. Avoid

damaging the axle shaft oil seal.

INSTALLATION

(1) Clean axle shaft and apply a thin film of

Mopar Wheel Bearing Grease to the shaft splines,

seal contact surface, hub bore.

(2) Install axle shaft into the housing and differen-

tial side gears. Avoid damaging axle shaft oil seals in

the differential.

(3) Install dust shield and hub bearing on knuckle.

(4) Install hub bearing bolts and tighten to 170

N´m (125 ft. lbs.).

(5) Install axle washer and nut, tighten nut to 237

N´m (175 ft. lbs.). Align nut to next cotter pin hole

and install new cotter pin.

(6) Install ABS wheel speed sensor, brake rotor

and caliper. Refer to Brakes for proper procedures.

(7) Install wheel and tire assembly.

(8) Remove support and lower the vehicle.

BLOCK, ADAPTER ± C-239-37

BLOCK, ADAPTER ± C-239-62

HOLDER, YOKE - 6719A

PINION DEPTH, SET ± 6730

Fig. 21 HUB AND KNUCKLE

1 - KNUCKLE

2 - HUB BEARING

BR/BEFRONT AXLE - 248FBI 3 - 29

FRONT AXLE - 248FBI (Continued)

Page 85 of 2255

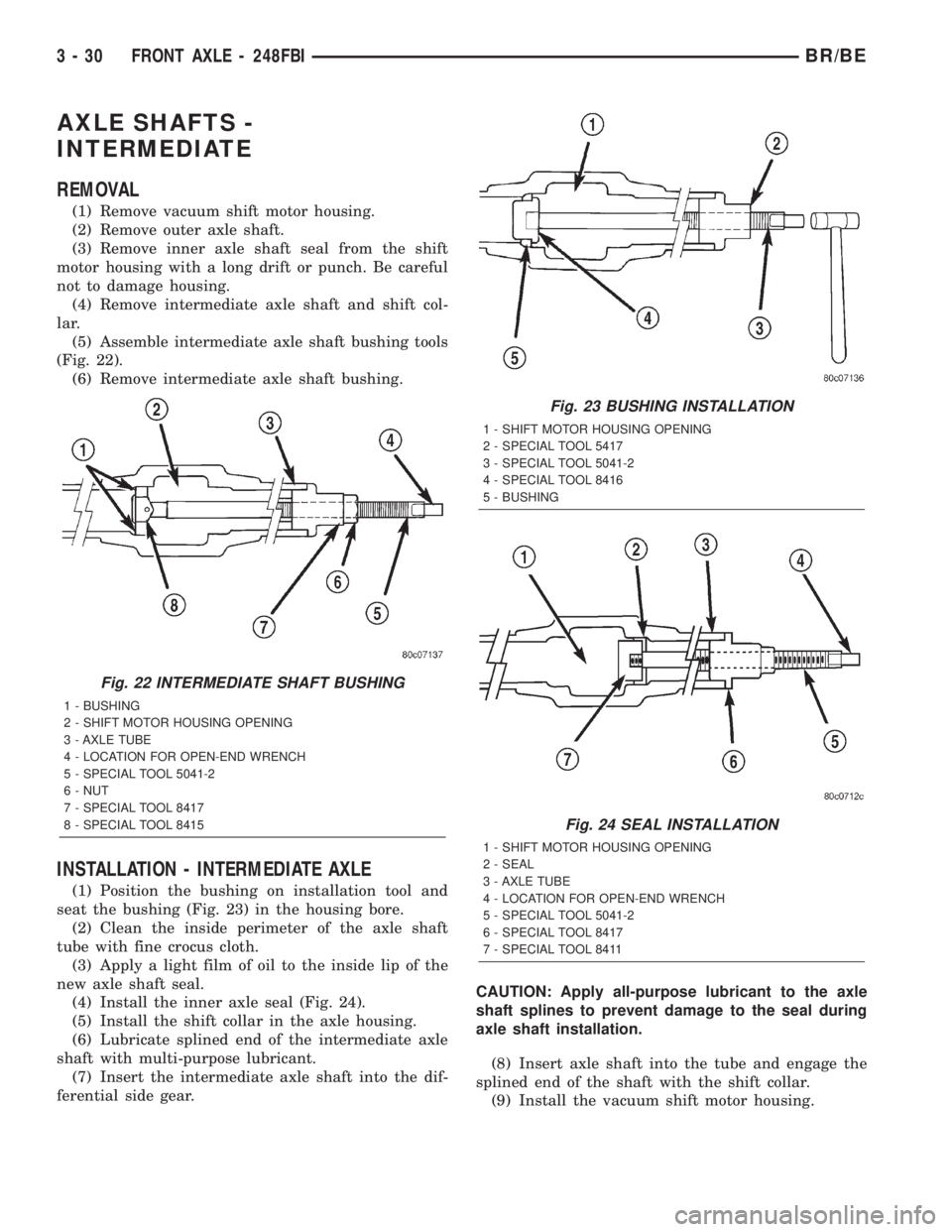

AXLE SHAFTS -

INTERMEDIATE

REMOVAL

(1) Remove vacuum shift motor housing.

(2) Remove outer axle shaft.

(3) Remove inner axle shaft seal from the shift

motor housing with a long drift or punch. Be careful

not to damage housing.

(4) Remove intermediate axle shaft and shift col-

lar.

(5) Assemble intermediate axle shaft bushing tools

(Fig. 22).

(6) Remove intermediate axle shaft bushing.

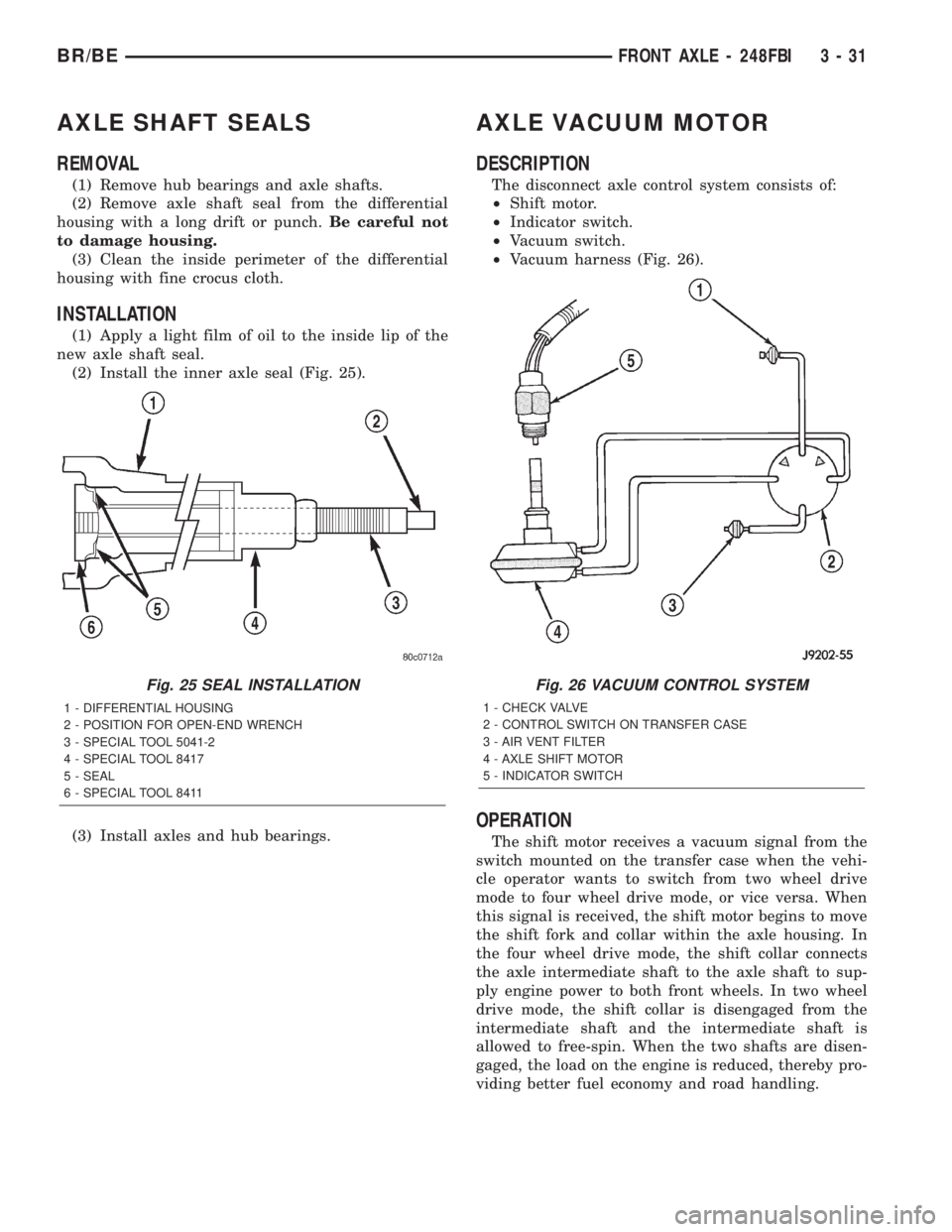

INSTALLATION - INTERMEDIATE AXLE

(1) Position the bushing on installation tool and

seat the bushing (Fig. 23) in the housing bore.

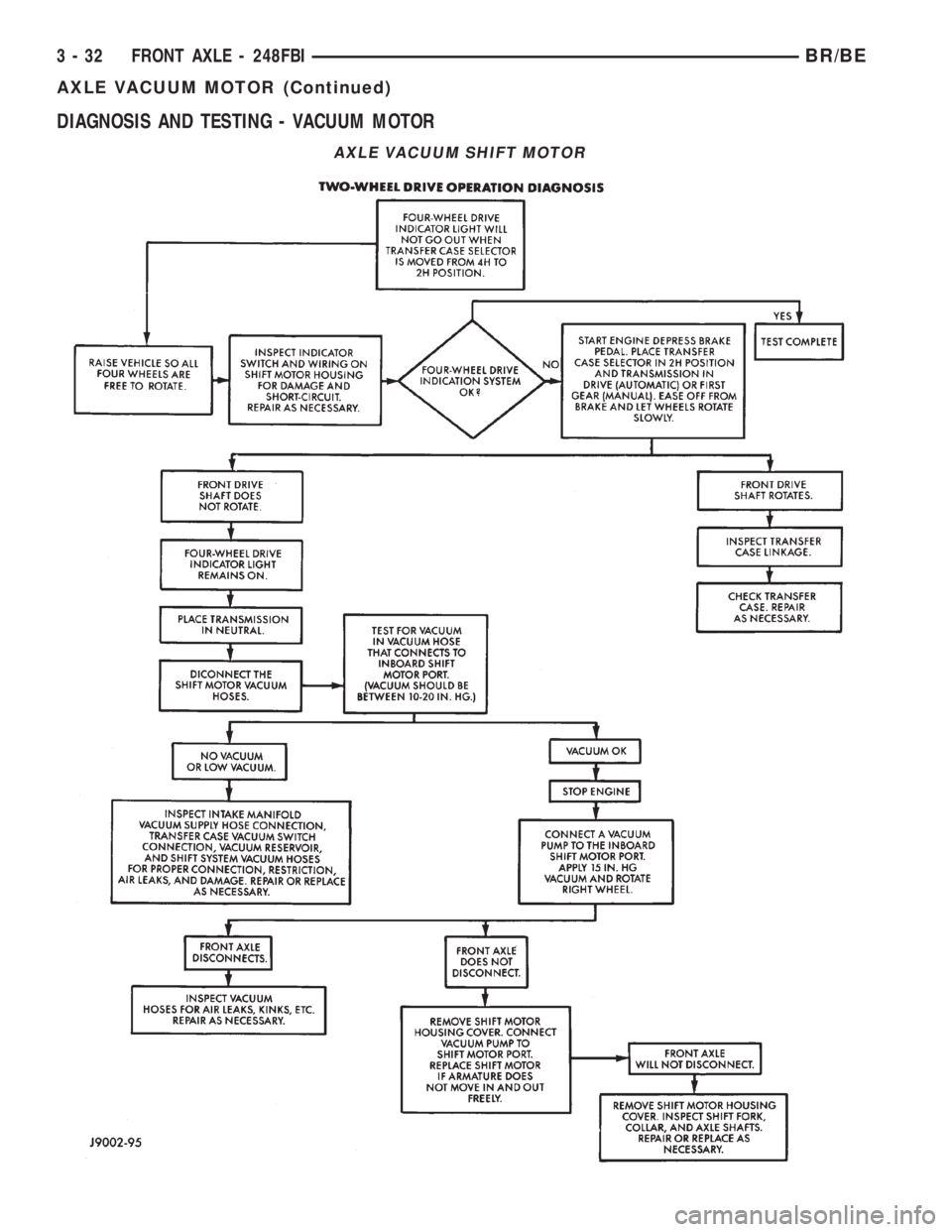

(2) Clean the inside perimeter of the axle shaft

tube with fine crocus cloth.

(3) Apply a light film of oil to the inside lip of the

new axle shaft seal.

(4) Install the inner axle seal (Fig. 24).

(5) Install the shift collar in the axle housing.

(6) Lubricate splined end of the intermediate axle

shaft with multi-purpose lubricant.

(7) Insert the intermediate axle shaft into the dif-

ferential side gear.CAUTION: Apply all-purpose lubricant to the axle

shaft splines to prevent damage to the seal during

axle shaft installation.

(8) Insert axle shaft into the tube and engage the

splined end of the shaft with the shift collar.

(9) Install the vacuum shift motor housing.

Fig. 22 INTERMEDIATE SHAFT BUSHING

1 - BUSHING

2 - SHIFT MOTOR HOUSING OPENING

3 - AXLE TUBE

4 - LOCATION FOR OPEN-END WRENCH

5 - SPECIAL TOOL 5041-2

6 - NUT

7 - SPECIAL TOOL 8417

8 - SPECIAL TOOL 8415

Fig. 23 BUSHING INSTALLATION

1 - SHIFT MOTOR HOUSING OPENING

2 - SPECIAL TOOL 5417

3 - SPECIAL TOOL 5041-2

4 - SPECIAL TOOL 8416

5 - BUSHING

Fig. 24 SEAL INSTALLATION

1 - SHIFT MOTOR HOUSING OPENING

2 - SEAL

3 - AXLE TUBE

4 - LOCATION FOR OPEN-END WRENCH

5 - SPECIAL TOOL 5041-2

6 - SPECIAL TOOL 8417

7 - SPECIAL TOOL 8411

3 - 30 FRONT AXLE - 248FBIBR/BE

Page 86 of 2255

AXLE SHAFT SEALS

REMOVAL

(1) Remove hub bearings and axle shafts.

(2) Remove axle shaft seal from the differential

housing with a long drift or punch.Be careful not

to damage housing.

(3) Clean the inside perimeter of the differential

housing with fine crocus cloth.

INSTALLATION

(1) Apply a light film of oil to the inside lip of the

new axle shaft seal.

(2) Install the inner axle seal (Fig. 25).

(3) Install axles and hub bearings.

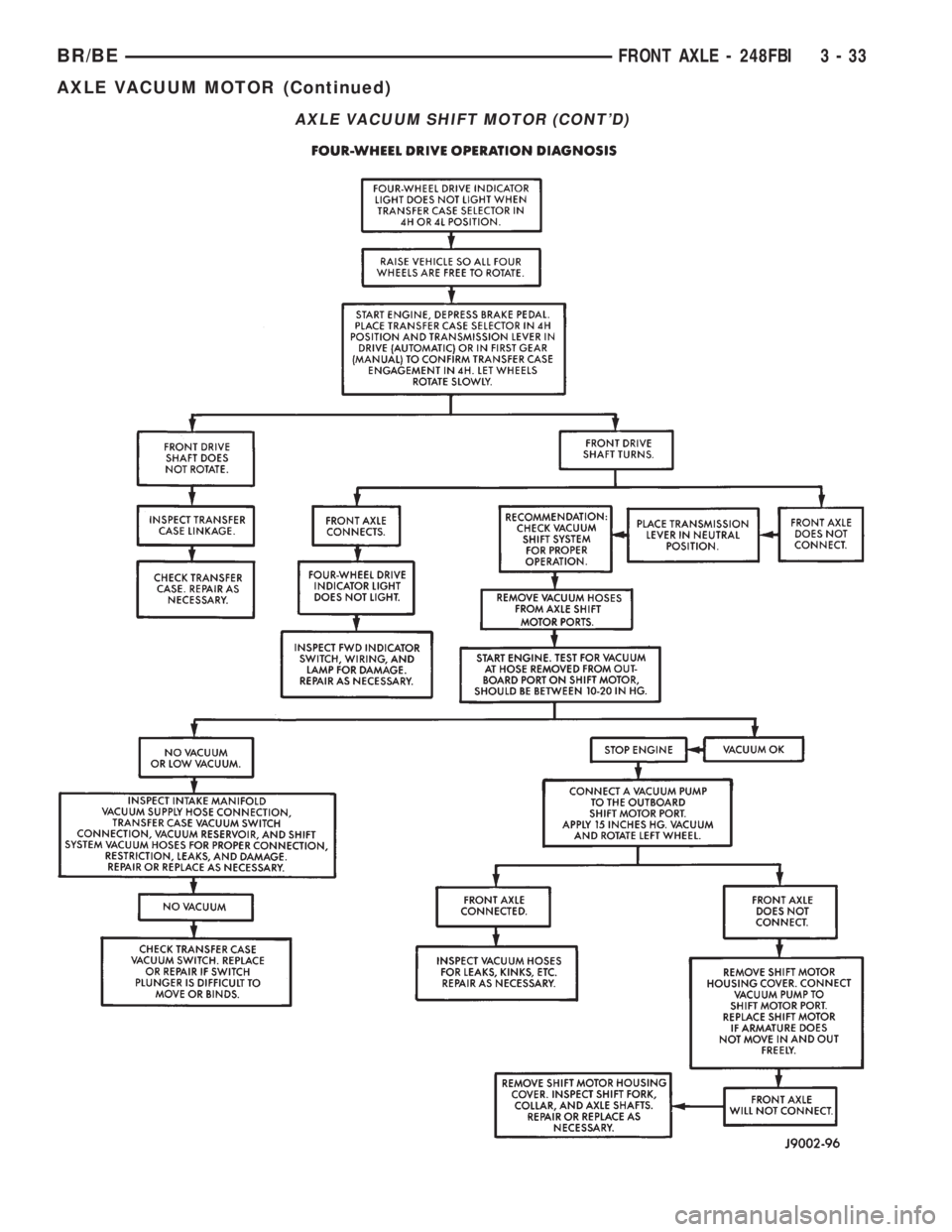

AXLE VACUUM MOTOR

DESCRIPTION

The disconnect axle control system consists of:

²Shift motor.

²Indicator switch.

²Vacuum switch.

²Vacuum harness (Fig. 26).

OPERATION

The shift motor receives a vacuum signal from the

switch mounted on the transfer case when the vehi-

cle operator wants to switch from two wheel drive

mode to four wheel drive mode, or vice versa. When

this signal is received, the shift motor begins to move

the shift fork and collar within the axle housing. In

the four wheel drive mode, the shift collar connects

the axle intermediate shaft to the axle shaft to sup-

ply engine power to both front wheels. In two wheel

drive mode, the shift collar is disengaged from the

intermediate shaft and the intermediate shaft is

allowed to free-spin. When the two shafts are disen-

gaged, the load on the engine is reduced, thereby pro-

viding better fuel economy and road handling.

Fig. 25 SEAL INSTALLATION

1 - DIFFERENTIAL HOUSING

2 - POSITION FOR OPEN-END WRENCH

3 - SPECIAL TOOL 5041-2

4 - SPECIAL TOOL 8417

5 - SEAL

6 - SPECIAL TOOL 8411

Fig. 26 VACUUM CONTROL SYSTEM

1 - CHECK VALVE

2 - CONTROL SWITCH ON TRANSFER CASE

3 - AIR VENT FILTER

4 - AXLE SHIFT MOTOR

5 - INDICATOR SWITCH

BR/BEFRONT AXLE - 248FBI 3 - 31

Page 87 of 2255

DIAGNOSIS AND TESTING - VACUUM MOTOR

AXLE VACUUM SHIFT MOTOR

3 - 32 FRONT AXLE - 248FBIBR/BE

AXLE VACUUM MOTOR (Continued)

Page 88 of 2255

AXLE VACUUM SHIFT MOTOR (CONT'D)

BR/BEFRONT AXLE - 248FBI 3 - 33

AXLE VACUUM MOTOR (Continued)

Page 89 of 2255

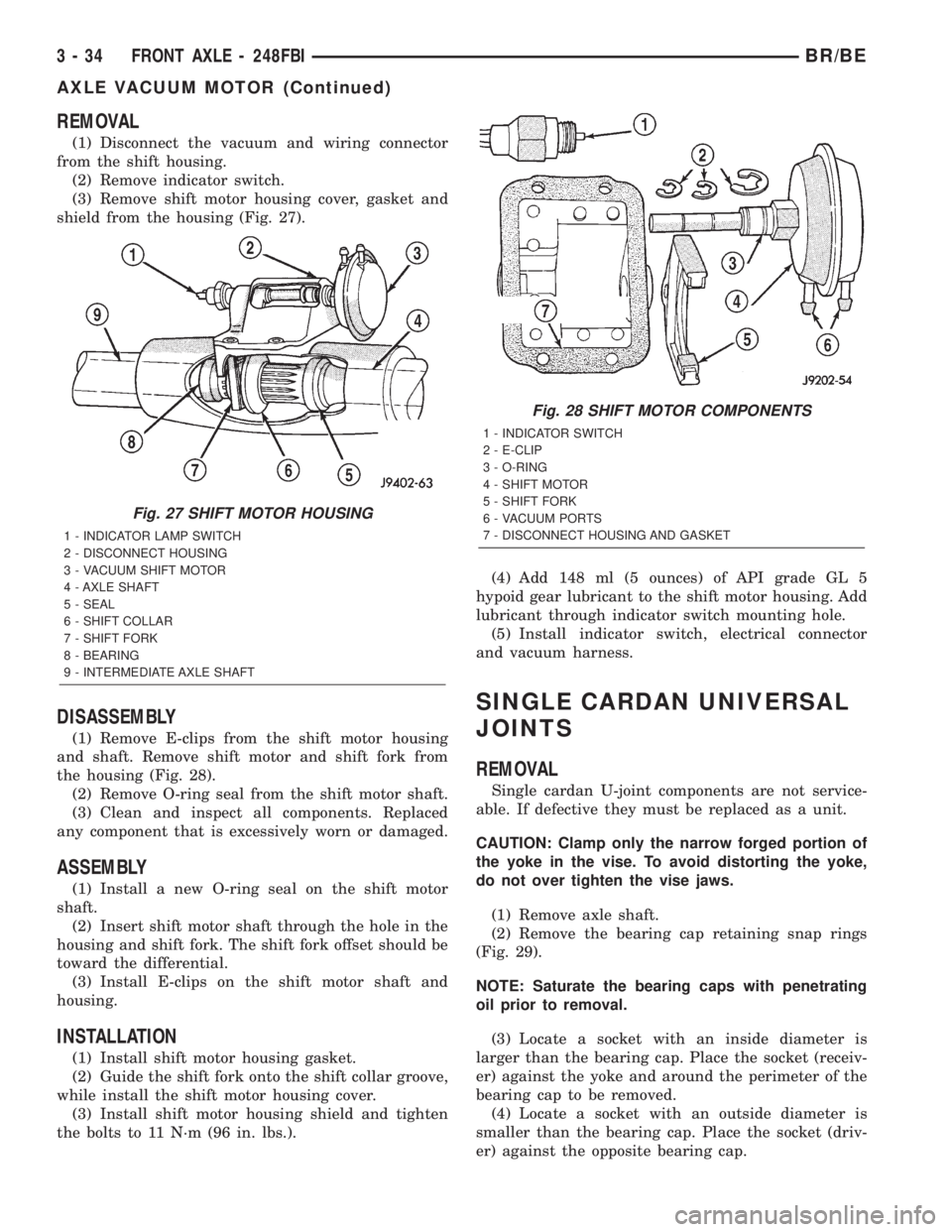

REMOVAL

(1) Disconnect the vacuum and wiring connector

from the shift housing.

(2) Remove indicator switch.

(3) Remove shift motor housing cover, gasket and

shield from the housing (Fig. 27).

DISASSEMBLY

(1) Remove E-clips from the shift motor housing

and shaft. Remove shift motor and shift fork from

the housing (Fig. 28).

(2) Remove O-ring seal from the shift motor shaft.

(3) Clean and inspect all components. Replaced

any component that is excessively worn or damaged.

ASSEMBLY

(1) Install a new O-ring seal on the shift motor

shaft.

(2) Insert shift motor shaft through the hole in the

housing and shift fork. The shift fork offset should be

toward the differential.

(3) Install E-clips on the shift motor shaft and

housing.

INSTALLATION

(1) Install shift motor housing gasket.

(2) Guide the shift fork onto the shift collar groove,

while install the shift motor housing cover.

(3) Install shift motor housing shield and tighten

the bolts to 11 N´m (96 in. lbs.).(4) Add 148 ml (5 ounces) of API grade GL 5

hypoid gear lubricant to the shift motor housing. Add

lubricant through indicator switch mounting hole.

(5) Install indicator switch, electrical connector

and vacuum harness.

SINGLE CARDAN UNIVERSAL

JOINTS

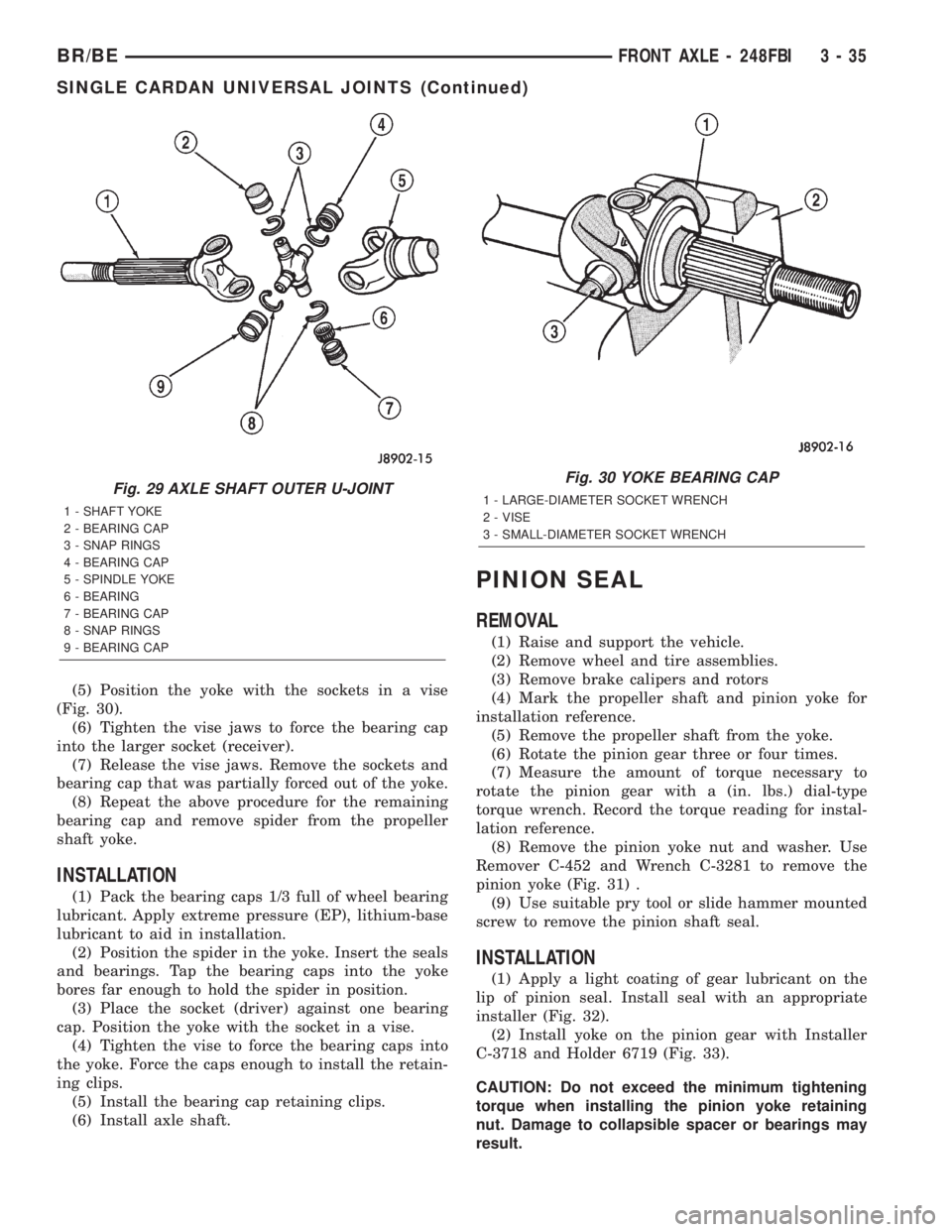

REMOVAL

Single cardan U-joint components are not service-

able. If defective they must be replaced as a unit.

CAUTION: Clamp only the narrow forged portion of

the yoke in the vise. To avoid distorting the yoke,

do not over tighten the vise jaws.

(1) Remove axle shaft.

(2) Remove the bearing cap retaining snap rings

(Fig. 29).

NOTE: Saturate the bearing caps with penetrating

oil prior to removal.

(3) Locate a socket with an inside diameter is

larger than the bearing cap. Place the socket (receiv-

er) against the yoke and around the perimeter of the

bearing cap to be removed.

(4) Locate a socket with an outside diameter is

smaller than the bearing cap. Place the socket (driv-

er) against the opposite bearing cap.

Fig. 27 SHIFT MOTOR HOUSING

1 - INDICATOR LAMP SWITCH

2 - DISCONNECT HOUSING

3 - VACUUM SHIFT MOTOR

4 - AXLE SHAFT

5 - SEAL

6 - SHIFT COLLAR

7 - SHIFT FORK

8 - BEARING

9 - INTERMEDIATE AXLE SHAFT

Fig. 28 SHIFT MOTOR COMPONENTS

1 - INDICATOR SWITCH

2 - E-CLIP

3 - O-RING

4 - SHIFT MOTOR

5 - SHIFT FORK

6 - VACUUM PORTS

7 - DISCONNECT HOUSING AND GASKET

3 - 34 FRONT AXLE - 248FBIBR/BE

AXLE VACUUM MOTOR (Continued)

Page 90 of 2255

(5) Position the yoke with the sockets in a vise

(Fig. 30).

(6) Tighten the vise jaws to force the bearing cap

into the larger socket (receiver).

(7) Release the vise jaws. Remove the sockets and

bearing cap that was partially forced out of the yoke.

(8) Repeat the above procedure for the remaining

bearing cap and remove spider from the propeller

shaft yoke.

INSTALLATION

(1) Pack the bearing caps 1/3 full of wheel bearing

lubricant. Apply extreme pressure (EP), lithium-base

lubricant to aid in installation.

(2) Position the spider in the yoke. Insert the seals

and bearings. Tap the bearing caps into the yoke

bores far enough to hold the spider in position.

(3) Place the socket (driver) against one bearing

cap. Position the yoke with the socket in a vise.

(4) Tighten the vise to force the bearing caps into

the yoke. Force the caps enough to install the retain-

ing clips.

(5) Install the bearing cap retaining clips.

(6) Install axle shaft.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove brake calipers and rotors

(4) Mark the propeller shaft and pinion yoke for

installation reference.

(5) Remove the propeller shaft from the yoke.

(6) Rotate the pinion gear three or four times.

(7) Measure the amount of torque necessary to

rotate the pinion gear with a (in. lbs.) dial-type

torque wrench. Record the torque reading for instal-

lation reference.

(8) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 31) .

(9) Use suitable pry tool or slide hammer mounted

screw to remove the pinion shaft seal.

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with an appropriate

installer (Fig. 32).

(2) Install yoke on the pinion gear with Installer

C-3718 and Holder 6719 (Fig. 33).

CAUTION: Do not exceed the minimum tightening

torque when installing the pinion yoke retaining

nut. Damage to collapsible spacer or bearings may

result.

Fig. 29 AXLE SHAFT OUTER U-JOINT

1 - SHAFT YOKE

2 - BEARING CAP

3 - SNAP RINGS

4 - BEARING CAP

5 - SPINDLE YOKE

6 - BEARING

7 - BEARING CAP

8 - SNAP RINGS

9 - BEARING CAP

Fig. 30 YOKE BEARING CAP

1 - LARGE-DIAMETER SOCKET WRENCH

2 - VISE

3 - SMALL-DIAMETER SOCKET WRENCH

BR/BEFRONT AXLE - 248FBI 3 - 35

SINGLE CARDAN UNIVERSAL JOINTS (Continued)