PCM DODGE RAM 2002 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1343 of 2255

²Spark-advance programs

²Shift-point strategies (certain automatic trans-

missions only)

²Idle speed

²Decel fuel shutoff

The MAP sensor signal is provided from a single

piezoresistive element located in the center of a dia-

phragm. The element and diaphragm are both made

of silicone. As manifold pressure changes, the dia-

phragm moves causing the element to deflect, which

stresses the silicone. When silicone is exposed to

stress, its resistance changes. As manifold vacuum

increases, the MAP sensor input voltage decreases

proportionally. The sensor also contains electronics

that condition the signal and provide temperature

compensation.

The PCM recognizes a decrease in manifold pres-

sure by monitoring a decrease in voltage from the

reading stored in the barometric pressure memory

cell. The MAP sensor is a linear sensor; meaning as

pressure changes, voltage changes proportionately.

The range of voltage output from the sensor is usu-

ally between 4.6 volts at sea level to as low as 0.3

volts at 26 in. of Hg. Barometric pressure is the pres-

sure exerted by the atmosphere upon an object. At

sea level on a standard day, no storm, barometric

pressure is approximately 29.92 in Hg. For every 100

feet of altitude, barometric pressure drops .10 in. Hg.

If a storm goes through it can change barometric

pressure from what should be present for that alti-

tude. You should know what the average pressure

and corresponding barometric pressure is for your

area.

REMOVAL

REMOVAL - 5.9L

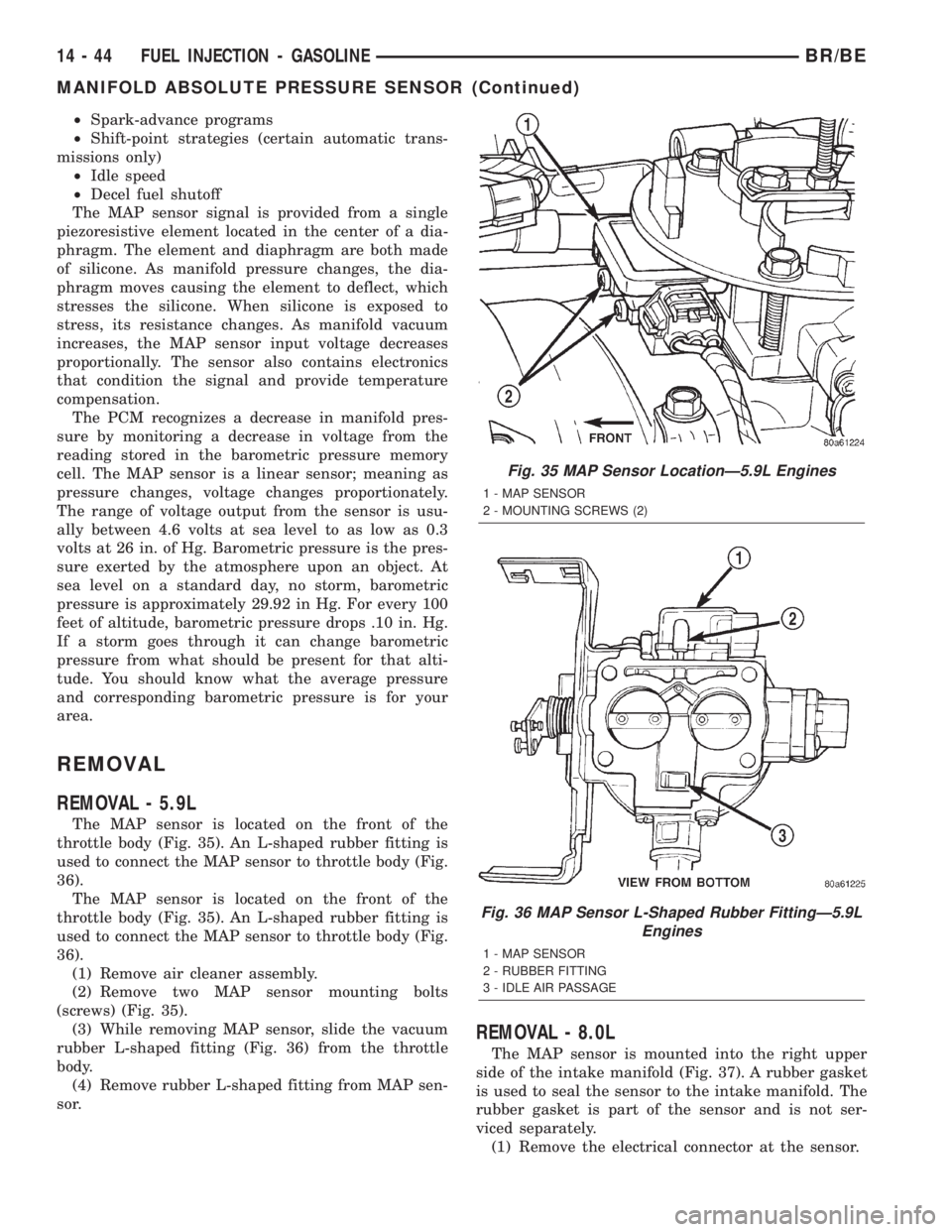

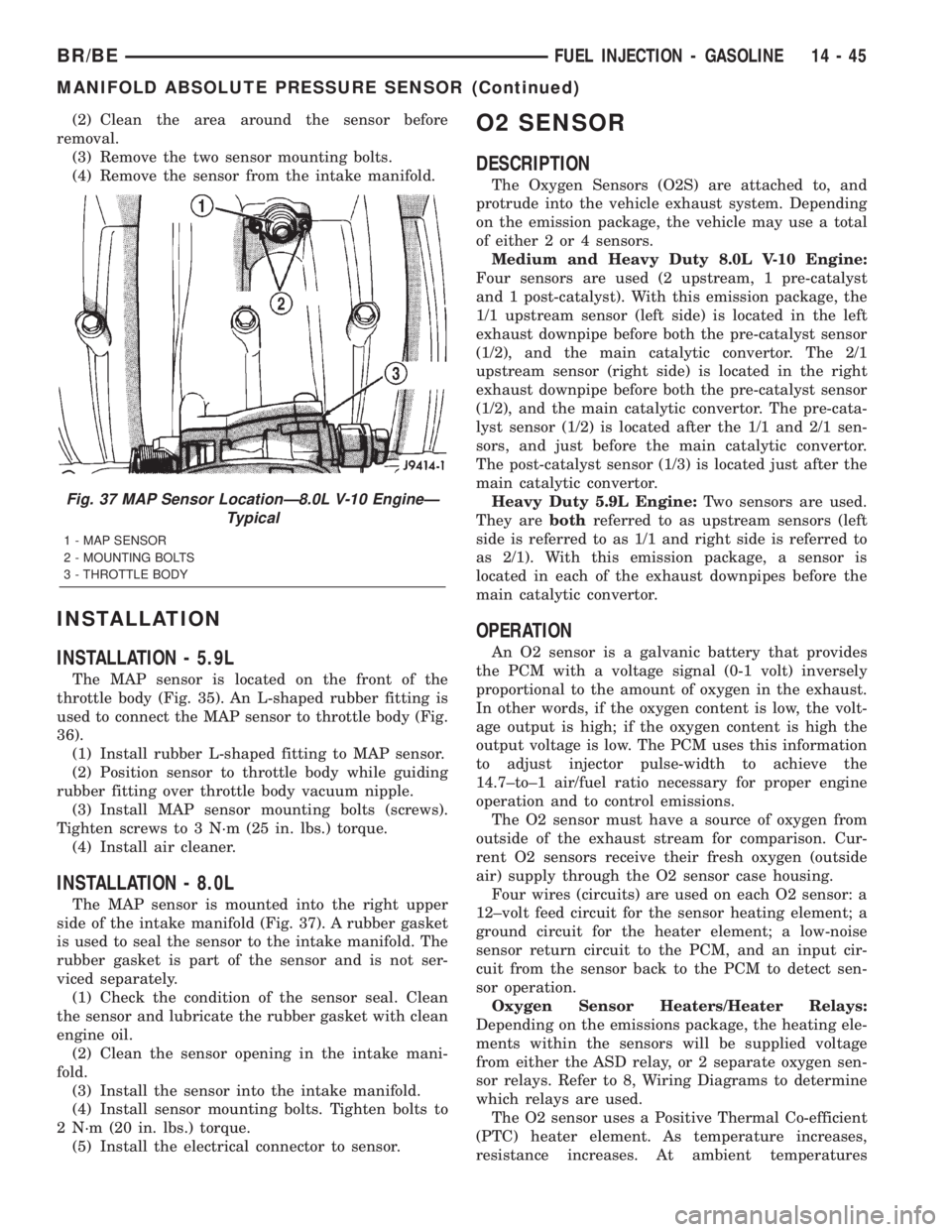

The MAP sensor is located on the front of the

throttle body (Fig. 35). An L-shaped rubber fitting is

used to connect the MAP sensor to throttle body (Fig.

36).

The MAP sensor is located on the front of the

throttle body (Fig. 35). An L-shaped rubber fitting is

used to connect the MAP sensor to throttle body (Fig.

36).

(1) Remove air cleaner assembly.

(2) Remove two MAP sensor mounting bolts

(screws) (Fig. 35).

(3) While removing MAP sensor, slide the vacuum

rubber L-shaped fitting (Fig. 36) from the throttle

body.

(4) Remove rubber L-shaped fitting from MAP sen-

sor.

REMOVAL - 8.0L

The MAP sensor is mounted into the right upper

side of the intake manifold (Fig. 37). A rubber gasket

is used to seal the sensor to the intake manifold. The

rubber gasket is part of the sensor and is not ser-

viced separately.

(1) Remove the electrical connector at the sensor.

Fig. 35 MAP Sensor LocationÐ5.9L Engines

1 - MAP SENSOR

2 - MOUNTING SCREWS (2)

Fig. 36 MAP Sensor L-Shaped Rubber FittingÐ5.9L

Engines

1 - MAP SENSOR

2 - RUBBER FITTING

3 - IDLE AIR PASSAGE

14 - 44 FUEL INJECTION - GASOLINEBR/BE

MANIFOLD ABSOLUTE PRESSURE SENSOR (Continued)

Page 1344 of 2255

(2) Clean the area around the sensor before

removal.

(3) Remove the two sensor mounting bolts.

(4) Remove the sensor from the intake manifold.

INSTALLATION

INSTALLATION - 5.9L

The MAP sensor is located on the front of the

throttle body (Fig. 35). An L-shaped rubber fitting is

used to connect the MAP sensor to throttle body (Fig.

36).

(1) Install rubber L-shaped fitting to MAP sensor.

(2) Position sensor to throttle body while guiding

rubber fitting over throttle body vacuum nipple.

(3) Install MAP sensor mounting bolts (screws).

Tighten screws to 3 N´m (25 in. lbs.) torque.

(4) Install air cleaner.

INSTALLATION - 8.0L

The MAP sensor is mounted into the right upper

side of the intake manifold (Fig. 37). A rubber gasket

is used to seal the sensor to the intake manifold. The

rubber gasket is part of the sensor and is not ser-

viced separately.

(1) Check the condition of the sensor seal. Clean

the sensor and lubricate the rubber gasket with clean

engine oil.

(2) Clean the sensor opening in the intake mani-

fold.

(3) Install the sensor into the intake manifold.

(4) Install sensor mounting bolts. Tighten bolts to

2 N´m (20 in. lbs.) torque.

(5) Install the electrical connector to sensor.

O2 SENSOR

DESCRIPTION

The Oxygen Sensors (O2S) are attached to, and

protrude into the vehicle exhaust system. Depending

on the emission package, the vehicle may use a total

of either 2 or 4 sensors.

Medium and Heavy Duty 8.0L V-10 Engine:

Four sensors are used (2 upstream, 1 pre-catalyst

and 1 post-catalyst). With this emission package, the

1/1 upstream sensor (left side) is located in the left

exhaust downpipe before both the pre-catalyst sensor

(1/2), and the main catalytic convertor. The 2/1

upstream sensor (right side) is located in the right

exhaust downpipe before both the pre-catalyst sensor

(1/2), and the main catalytic convertor. The pre-cata-

lyst sensor (1/2) is located after the 1/1 and 2/1 sen-

sors, and just before the main catalytic convertor.

The post-catalyst sensor (1/3) is located just after the

main catalytic convertor.

Heavy Duty 5.9L Engine:Two sensors are used.

They arebothreferred to as upstream sensors (left

side is referred to as 1/1 and right side is referred to

as 2/1). With this emission package, a sensor is

located in each of the exhaust downpipes before the

main catalytic convertor.

OPERATION

An O2 sensor is a galvanic battery that provides

the PCM with a voltage signal (0-1 volt) inversely

proportional to the amount of oxygen in the exhaust.

In other words, if the oxygen content is low, the volt-

age output is high; if the oxygen content is high the

output voltage is low. The PCM uses this information

to adjust injector pulse-width to achieve the

14.7±to±1 air/fuel ratio necessary for proper engine

operation and to control emissions.

The O2 sensor must have a source of oxygen from

outside of the exhaust stream for comparison. Cur-

rent O2 sensors receive their fresh oxygen (outside

air) supply through the O2 sensor case housing.

Four wires (circuits) are used on each O2 sensor: a

12±volt feed circuit for the sensor heating element; a

ground circuit for the heater element; a low-noise

sensor return circuit to the PCM, and an input cir-

cuit from the sensor back to the PCM to detect sen-

sor operation.

Oxygen Sensor Heaters/Heater Relays:

Depending on the emissions package, the heating ele-

ments within the sensors will be supplied voltage

from either the ASD relay, or 2 separate oxygen sen-

sor relays. Refer to 8, Wiring Diagrams to determine

which relays are used.

The O2 sensor uses a Positive Thermal Co-efficient

(PTC) heater element. As temperature increases,

resistance increases. At ambient temperatures

Fig. 37 MAP Sensor LocationÐ8.0L V-10 EngineÐ

Typical

1 - MAP SENSOR

2 - MOUNTING BOLTS

3 - THROTTLE BODY

BR/BEFUEL INJECTION - GASOLINE 14 - 45

MANIFOLD ABSOLUTE PRESSURE SENSOR (Continued)

Page 1345 of 2255

around 70ÉF, the resistance of the heating element is

approximately 4.5 ohms. As the sensor's temperature

increases, resistance in the heater element increases.

This allows the heater to maintain the optimum

operating temperature of approximately 930É-1100ÉF

(500É-600É C). Although the sensors operate the

same, there are physical differences, due to the envi-

ronment that they operate in, that keep them from

being interchangeable.

Maintaining correct sensor temperature at all

times allows the system to enter into closed loop

operation sooner. Also, it allows the system to remain

in closed loop operation during periods of extended

idle.

In Closed Loop operation, the PCM monitors cer-

tain O2 sensor input(s) along with other inputs, and

adjusts the injector pulse width accordingly. During

Open Loop operation, the PCM ignores the O2 sensor

input. The PCM adjusts injector pulse width based

on preprogrammed (fixed) values and inputs from

other sensors.

Upstream Sensors:Two upstream sensors are

used (1/1 and 2/1). The 1/1 sensor is the first sensor

to receive exhaust gases from the #1 cylinder. They

provide an input voltage to the PCM. The input tells

the PCM the oxygen content of the exhaust gas. The

PCM uses this information to fine tune fuel delivery

to maintain the correct oxygen content at the down-

stream oxygen sensors. The PCM will change the air/

fuel ratio until the upstream sensors input a voltage

that the PCM has determined will make the down-

stream sensors output (oxygen content) correct.

The upstream oxygen sensors also provide an input

to determine mini-catalyst efficiency. Main catalytic

convertor efficiency is not calculated with this pack-

age.

Downstream Sensors:Two downstream sensors

are used (1/2 and 2/2). The downstream sensors are

used to determine the correct air-fuel ratio. As the

oxygen content changes at the downstream sensor,

the PCM calculates how much air-fuel ratio change is

required. The PCM then looks at the upstream oxy-

gen sensor voltage, and changes fuel delivery until

the upstream sensor voltage changes enough to cor-

rect the downstream sensor voltage (oxygen content).

The downstream oxygen sensors also provide an

input to determine mini-catalyst efficiency. Main cat-

alytic convertor efficiency is not calculated with this

package.

Medium and Heavy Duty 8.0L V-10 Engine:

Four oxygen sensors are used (2 upstream, 1 pre-cat-

alyst and 1 post-catalyst). The upstream sensors (1/1

and 2/1) will fine-tune the air-fuel ratio through the

Powertrain Control Module (PCM). The pre-catalyst

(1/2) and post-catalyst (1/3) sensors will determine

catalytic convertor efficiency (efficiency of the maincatalytic convertor). This is also done through the

PCM.

Heavy Duty 5.9L Engine:Downstream sensors

are not used with this emissions package, meaning

catalytic convertor efficiency is not calculated with

this package. Two upstream sensors are used. The

left upstream sensor (1/1) will monitor cylinders 1, 3,

5 and 7. The right upstream sensor (2/1) will monitor

cylinders 2, 4, 6 and 8. The PCM monitors the oxy-

gen content of the sensors, and will fine-tune the air-

fuel ratio.

Engines equipped with either a downstream sen-

sor(s), or a post-catalytic sensor, will monitor cata-

lytic convertor efficiency. If efficiency is below

emission standards, the Malfunction Indicator Lamp

(MIL) will be illuminated and a Diagnostic Trouble

Code (DTC) will be set. Refer to Monitored Systems

in Emission Control Systems for additional informa-

tion.

REMOVAL

Never apply any type of grease to the oxygen

sensor electrical connector, or attempt any sol-

dering of the sensor wiring harness.

The O2S (oxygen sensors) are numbered 1/1, 1/2,

1/3, 2/1 and 2/2.

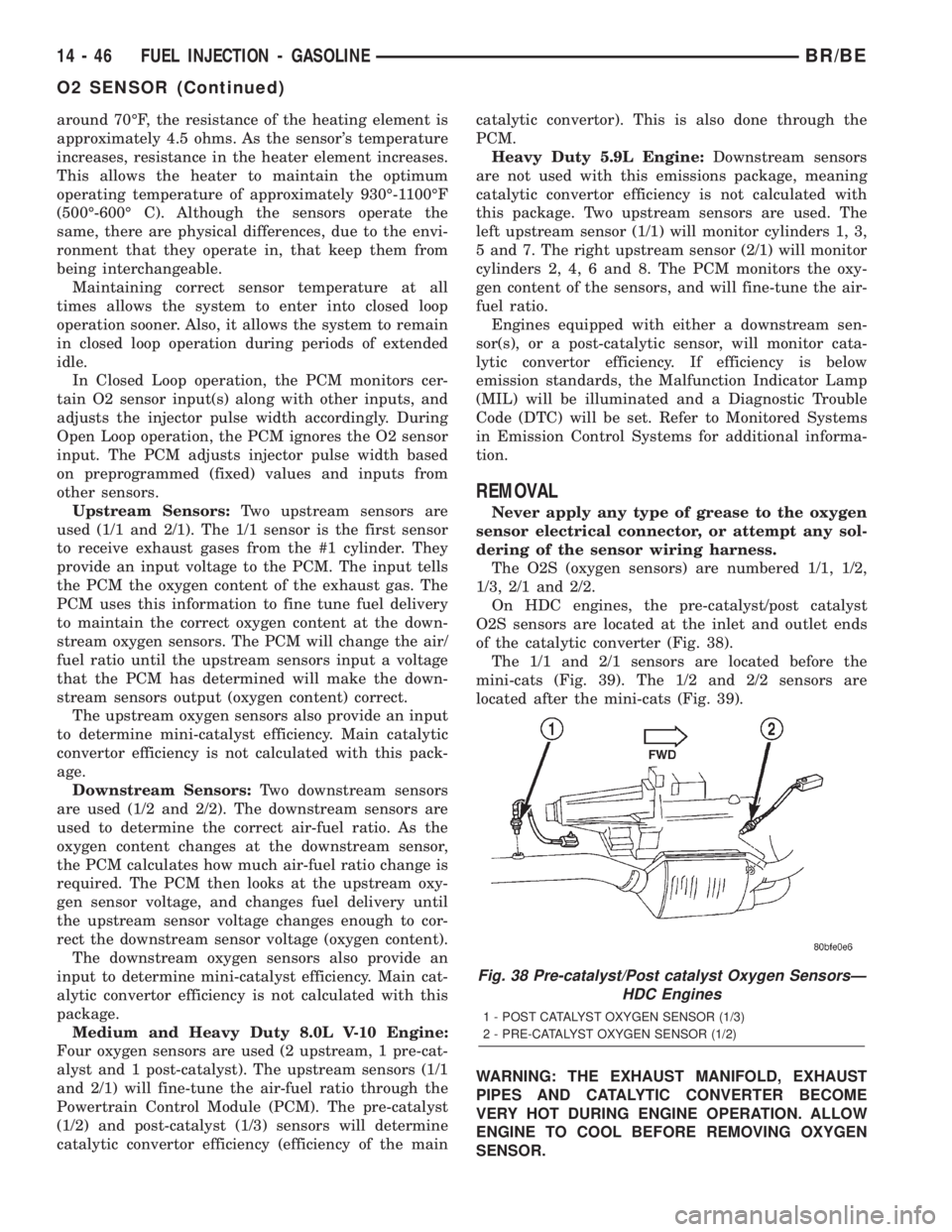

On HDC engines, the pre-catalyst/post catalyst

O2S sensors are located at the inlet and outlet ends

of the catalytic converter (Fig. 38).

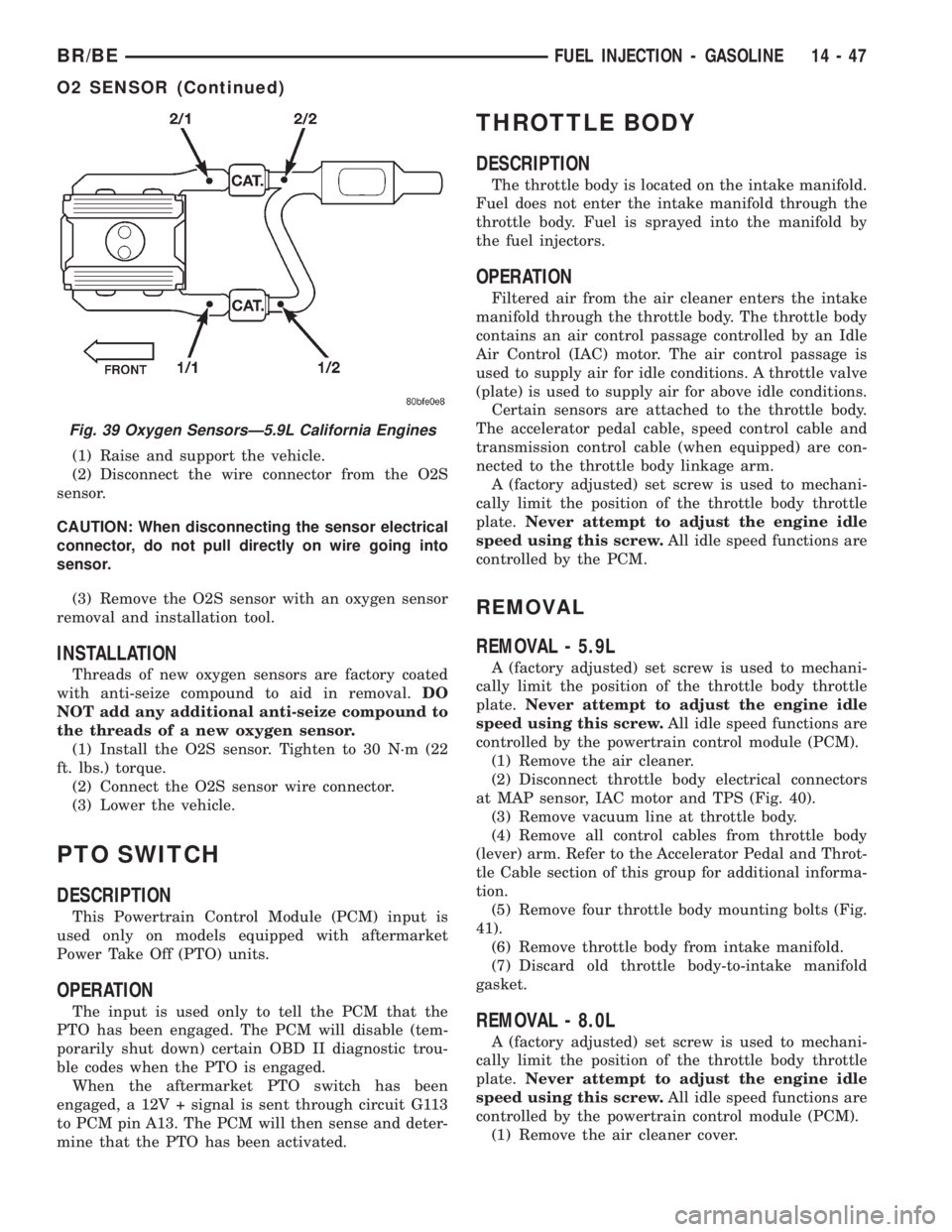

The 1/1 and 2/1 sensors are located before the

mini-cats (Fig. 39). The 1/2 and 2/2 sensors are

located after the mini-cats (Fig. 39).

WARNING: THE EXHAUST MANIFOLD, EXHAUST

PIPES AND CATALYTIC CONVERTER BECOME

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

Fig. 38 Pre-catalyst/Post catalyst Oxygen SensorsÐ

HDC Engines

1 - POST CATALYST OXYGEN SENSOR (1/3)

2 - PRE-CATALYST OXYGEN SENSOR (1/2)

14 - 46 FUEL INJECTION - GASOLINEBR/BE

O2 SENSOR (Continued)

Page 1346 of 2255

(1) Raise and support the vehicle.

(2) Disconnect the wire connector from the O2S

sensor.

CAUTION: When disconnecting the sensor electrical

connector, do not pull directly on wire going into

sensor.

(3) Remove the O2S sensor with an oxygen sensor

removal and installation tool.

INSTALLATION

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

the threads of a new oxygen sensor.

(1) Install the O2S sensor. Tighten to 30 N´m (22

ft. lbs.) torque.

(2) Connect the O2S sensor wire connector.

(3) Lower the vehicle.

PTO SWITCH

DESCRIPTION

This Powertrain Control Module (PCM) input is

used only on models equipped with aftermarket

Power Take Off (PTO) units.

OPERATION

The input is used only to tell the PCM that the

PTO has been engaged. The PCM will disable (tem-

porarily shut down) certain OBD II diagnostic trou-

ble codes when the PTO is engaged.

When the aftermarket PTO switch has been

engaged, a 12V + signal is sent through circuit G113

to PCM pin A13. The PCM will then sense and deter-

mine that the PTO has been activated.

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

REMOVAL - 5.9L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Remove the air cleaner.

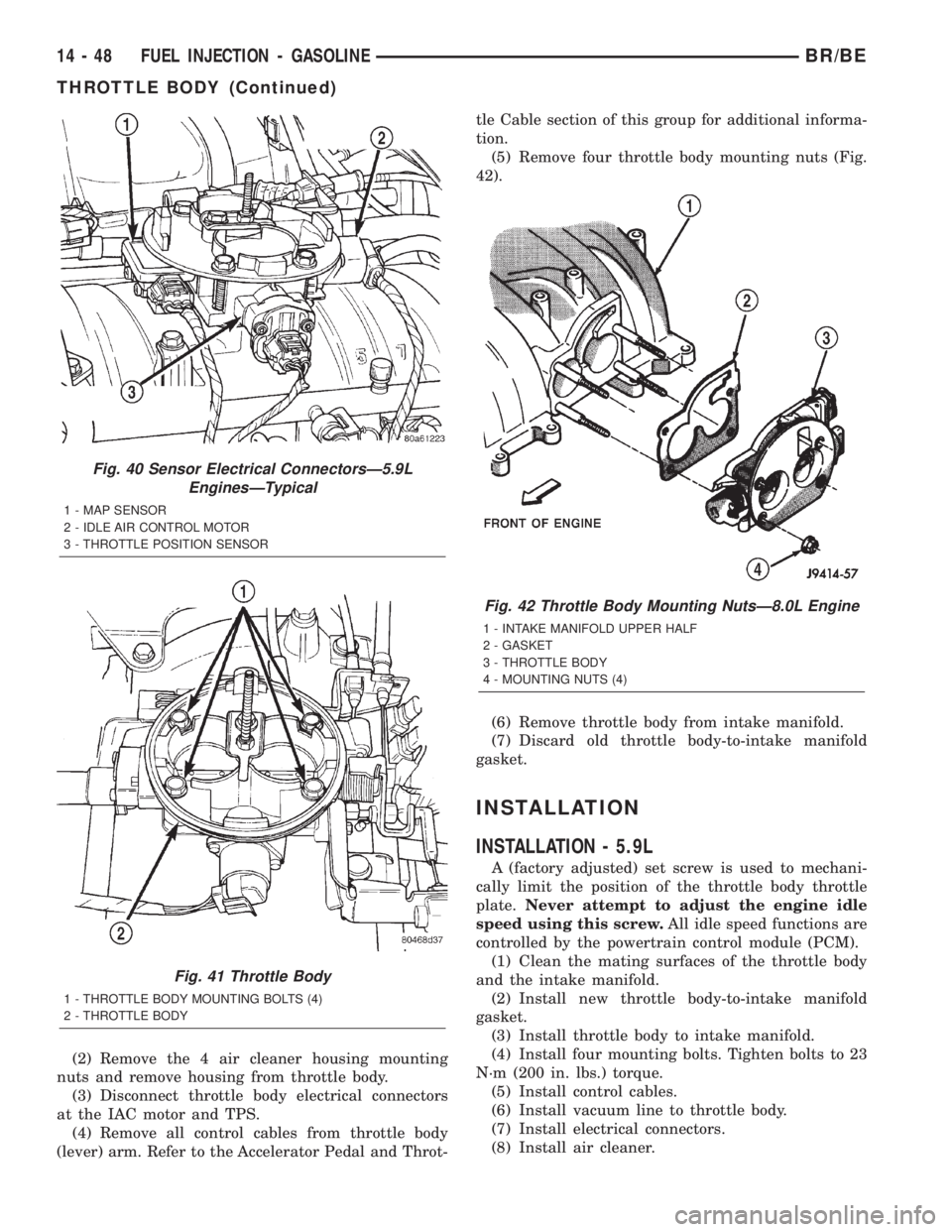

(2) Disconnect throttle body electrical connectors

at MAP sensor, IAC motor and TPS (Fig. 40).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section of this group for additional informa-

tion.

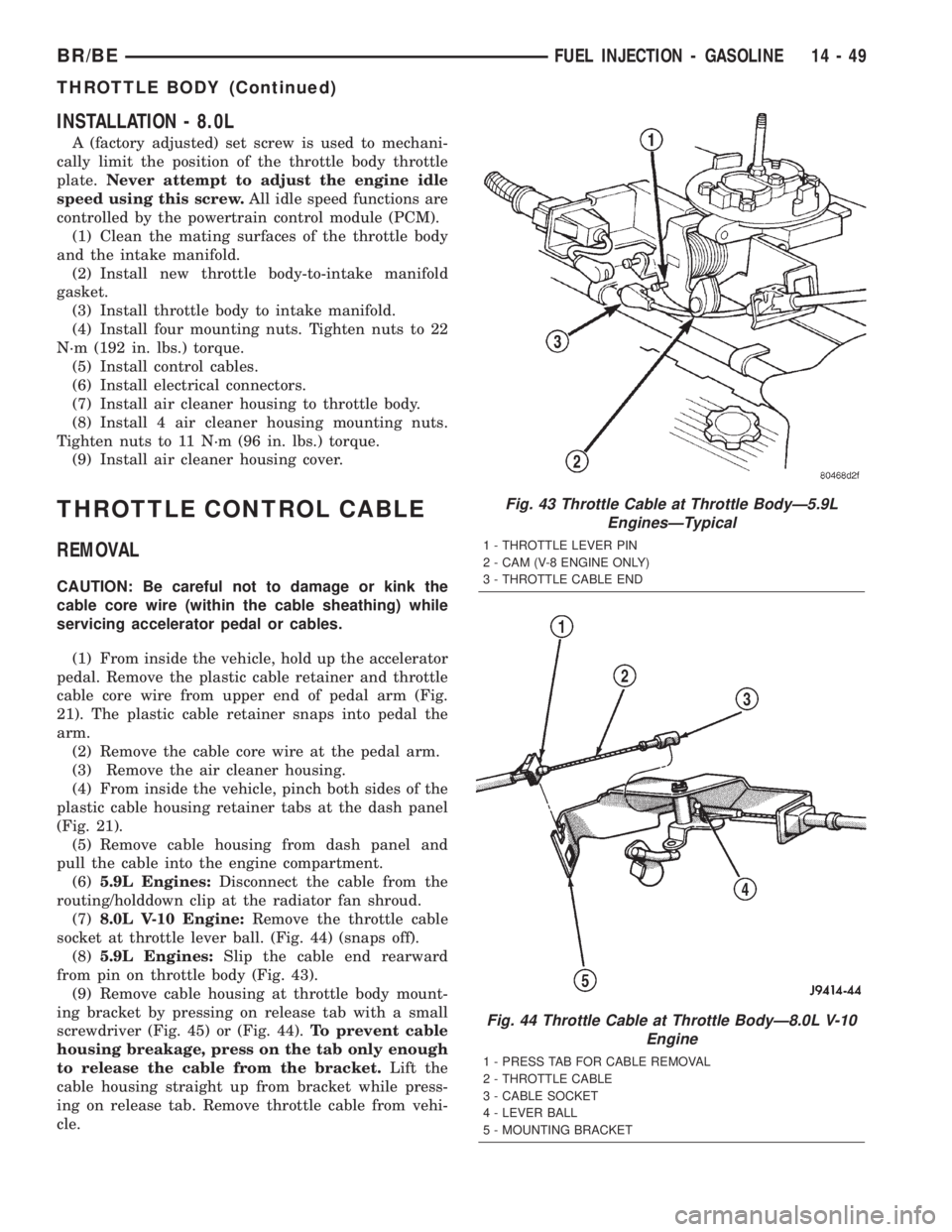

(5) Remove four throttle body mounting bolts (Fig.

41).

(6) Remove throttle body from intake manifold.

(7) Discard old throttle body-to-intake manifold

gasket.

REMOVAL - 8.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Remove the air cleaner cover.

Fig. 39 Oxygen SensorsÐ5.9L California Engines

BR/BEFUEL INJECTION - GASOLINE 14 - 47

O2 SENSOR (Continued)

Page 1347 of 2255

(2) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(3) Disconnect throttle body electrical connectors

at the IAC motor and TPS.

(4) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-tle Cable section of this group for additional informa-

tion.

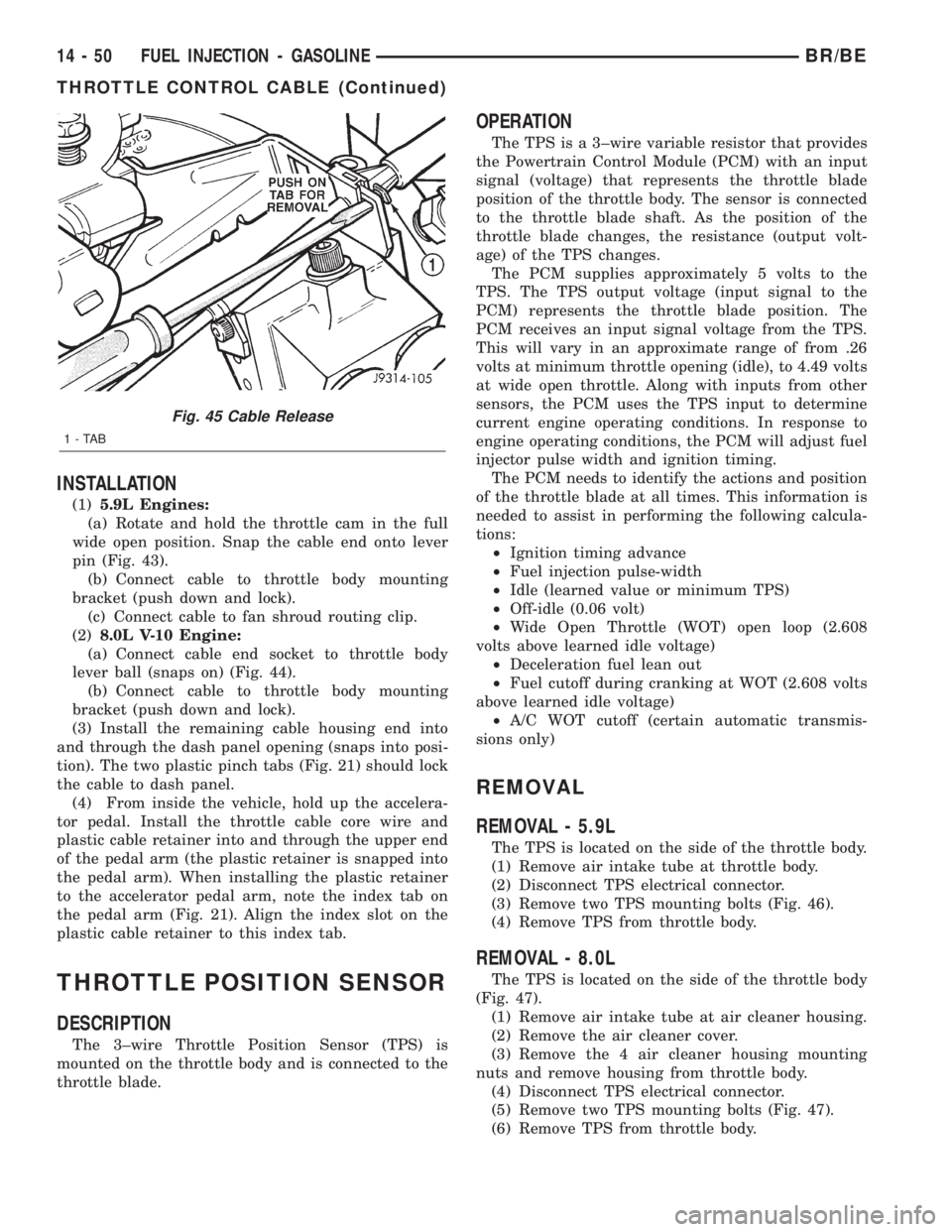

(5) Remove four throttle body mounting nuts (Fig.

42).

(6) Remove throttle body from intake manifold.

(7) Discard old throttle body-to-intake manifold

gasket.

INSTALLATION

INSTALLATION - 5.9L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Clean the mating surfaces of the throttle body

and the intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting bolts. Tighten bolts to 23

N´m (200 in. lbs.) torque.

(5) Install control cables.

(6) Install vacuum line to throttle body.

(7) Install electrical connectors.

(8) Install air cleaner.

Fig. 40 Sensor Electrical ConnectorsÐ5.9L

EnginesÐTypical

1 - MAP SENSOR

2 - IDLE AIR CONTROL MOTOR

3 - THROTTLE POSITION SENSOR

Fig. 41 Throttle Body

1 - THROTTLE BODY MOUNTING BOLTS (4)

2 - THROTTLE BODY

Fig. 42 Throttle Body Mounting NutsÐ8.0L Engine

1 - INTAKE MANIFOLD UPPER HALF

2 - GASKET

3 - THROTTLE BODY

4 - MOUNTING NUTS (4)

14 - 48 FUEL INJECTION - GASOLINEBR/BE

THROTTLE BODY (Continued)

Page 1348 of 2255

INSTALLATION - 8.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Clean the mating surfaces of the throttle body

and the intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting nuts. Tighten nuts to 22

N´m (192 in. lbs.) torque.

(5) Install control cables.

(6) Install electrical connectors.

(7) Install air cleaner housing to throttle body.

(8) Install 4 air cleaner housing mounting nuts.

Tighten nuts to 11 N´m (96 in. lbs.) torque.

(9) Install air cleaner housing cover.

THROTTLE CONTROL CABLE

REMOVAL

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or cables.

(1) From inside the vehicle, hold up the accelerator

pedal. Remove the plastic cable retainer and throttle

cable core wire from upper end of pedal arm (Fig.

21). The plastic cable retainer snaps into pedal the

arm.

(2) Remove the cable core wire at the pedal arm.

(3) Remove the air cleaner housing.

(4) From inside the vehicle, pinch both sides of the

plastic cable housing retainer tabs at the dash panel

(Fig. 21).

(5) Remove cable housing from dash panel and

pull the cable into the engine compartment.

(6)5.9L Engines:Disconnect the cable from the

routing/holddown clip at the radiator fan shroud.

(7)8.0L V-10 Engine:Remove the throttle cable

socket at throttle lever ball. (Fig. 44) (snaps off).

(8)5.9L Engines:Slip the cable end rearward

from pin on throttle body (Fig. 43).

(9) Remove cable housing at throttle body mount-

ing bracket by pressing on release tab with a small

screwdriver (Fig. 45) or (Fig. 44).To prevent cable

housing breakage, press on the tab only enough

to release the cable from the bracket.Lift the

cable housing straight up from bracket while press-

ing on release tab. Remove throttle cable from vehi-

cle.

Fig. 43 Throttle Cable at Throttle BodyÐ5.9L

EnginesÐTypical

1 - THROTTLE LEVER PIN

2 - CAM (V-8 ENGINE ONLY)

3 - THROTTLE CABLE END

Fig. 44 Throttle Cable at Throttle BodyÐ8.0L V-10

Engine

1 - PRESS TAB FOR CABLE REMOVAL

2 - THROTTLE CABLE

3 - CABLE SOCKET

4 - LEVER BALL

5 - MOUNTING BRACKET

BR/BEFUEL INJECTION - GASOLINE 14 - 49

THROTTLE BODY (Continued)

Page 1349 of 2255

INSTALLATION

(1)5.9L Engines:

(a) Rotate and hold the throttle cam in the full

wide open position. Snap the cable end onto lever

pin (Fig. 43).

(b) Connect cable to throttle body mounting

bracket (push down and lock).

(c) Connect cable to fan shroud routing clip.

(2)8.0L V-10 Engine:

(a) Connect cable end socket to throttle body

lever ball (snaps on) (Fig. 44).

(b) Connect cable to throttle body mounting

bracket (push down and lock).

(3) Install the remaining cable housing end into

and through the dash panel opening (snaps into posi-

tion). The two plastic pinch tabs (Fig. 21) should lock

the cable to dash panel.

(4) From inside the vehicle, hold up the accelera-

tor pedal. Install the throttle cable core wire and

plastic cable retainer into and through the upper end

of the pedal arm (the plastic retainer is snapped into

the pedal arm). When installing the plastic retainer

to the accelerator pedal arm, note the index tab on

the pedal arm (Fig. 21). Align the index slot on the

plastic cable retainer to this index tab.

THROTTLE POSITION SENSOR

DESCRIPTION

The 3±wire Throttle Position Sensor (TPS) is

mounted on the throttle body and is connected to the

throttle blade.

OPERATION

The TPS is a 3±wire variable resistor that provides

the Powertrain Control Module (PCM) with an input

signal (voltage) that represents the throttle blade

position of the throttle body. The sensor is connected

to the throttle blade shaft. As the position of the

throttle blade changes, the resistance (output volt-

age) of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS.

This will vary in an approximate range of from .26

volts at minimum throttle opening (idle), to 4.49 volts

at wide open throttle. Along with inputs from other

sensors, the PCM uses the TPS input to determine

current engine operating conditions. In response to

engine operating conditions, the PCM will adjust fuel

injector pulse width and ignition timing.

The PCM needs to identify the actions and position

of the throttle blade at all times. This information is

needed to assist in performing the following calcula-

tions:

²Ignition timing advance

²Fuel injection pulse-width

²Idle (learned value or minimum TPS)

²Off-idle (0.06 volt)

²Wide Open Throttle (WOT) open loop (2.608

volts above learned idle voltage)

²Deceleration fuel lean out

²Fuel cutoff during cranking at WOT (2.608 volts

above learned idle voltage)

²A/C WOT cutoff (certain automatic transmis-

sions only)

REMOVAL

REMOVAL - 5.9L

The TPS is located on the side of the throttle body.

(1) Remove air intake tube at throttle body.

(2) Disconnect TPS electrical connector.

(3) Remove two TPS mounting bolts (Fig. 46).

(4) Remove TPS from throttle body.

REMOVAL - 8.0L

The TPS is located on the side of the throttle body

(Fig. 47).

(1) Remove air intake tube at air cleaner housing.

(2) Remove the air cleaner cover.

(3) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(4) Disconnect TPS electrical connector.

(5) Remove two TPS mounting bolts (Fig. 47).

(6) Remove TPS from throttle body.

Fig. 45 Cable Release

1-TAB

14 - 50 FUEL INJECTION - GASOLINEBR/BE

THROTTLE CONTROL CABLE (Continued)

Page 1351 of 2255

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate the throttle control lever by

hand to check for any binding of the TPS.

(4) Connect TPS electrical connector to TPS.

(5) Install air cleaner housing to throttle body.

(6) Install 4 air cleaner housing mounting nuts.

Tighten nuts to 11 N´m (96 in. lbs.) torque.

(7) Install air cleaner housing cover.

(8) Install air intake tube to cover.

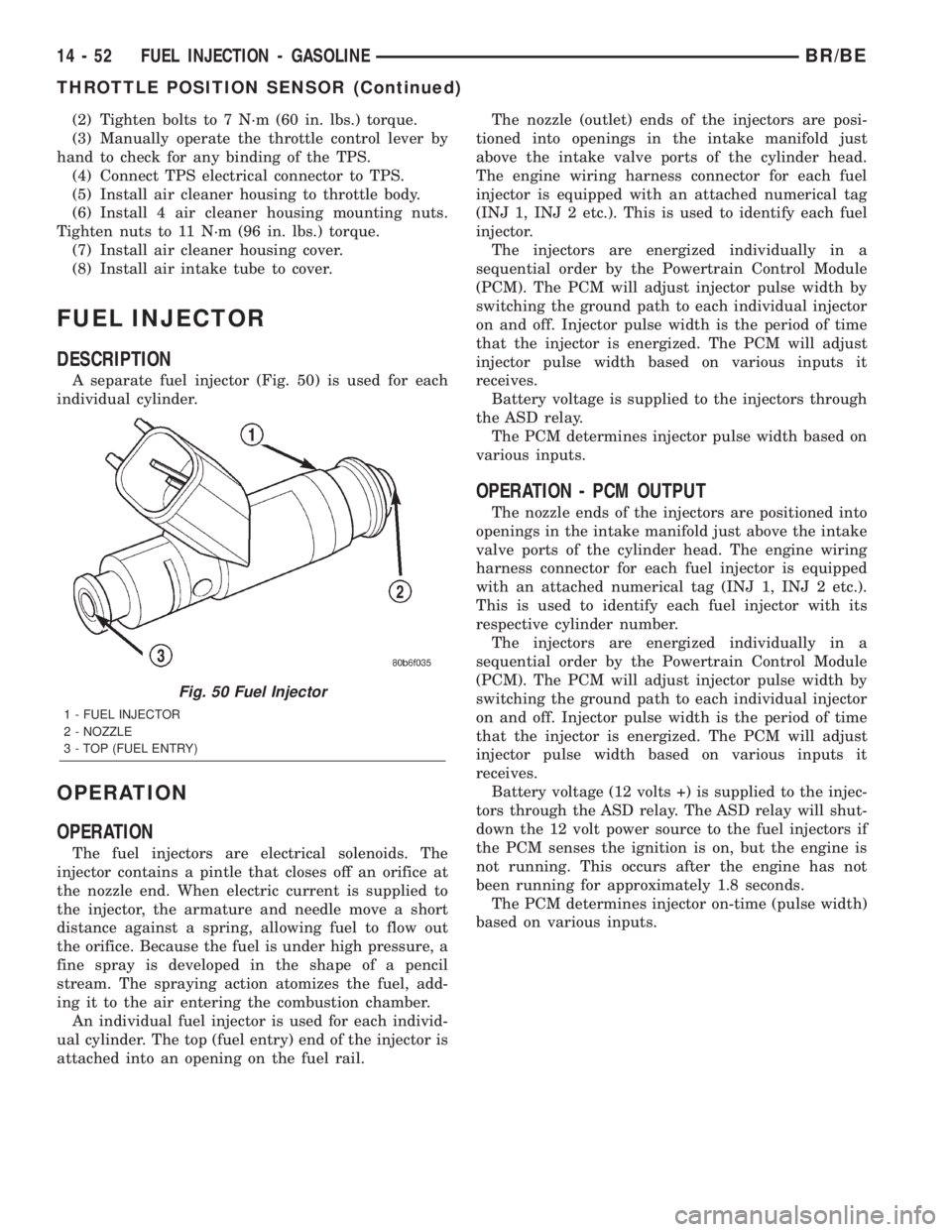

FUEL INJECTOR

DESCRIPTION

A separate fuel injector (Fig. 50) is used for each

individual cylinder.

OPERATION

OPERATION

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

An individual fuel injector is used for each individ-

ual cylinder. The top (fuel entry) end of the injector is

attached into an opening on the fuel rail.The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

Fig. 50 Fuel Injector

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

14 - 52 FUEL INJECTION - GASOLINEBR/BE

THROTTLE POSITION SENSOR (Continued)

Page 1354 of 2255

FUEL DELIVERY - DIESEL

DESCRIPTION

DESCRIPTION - DIESEL FUEL DELIVERY

SYSTEM

The fuel system on the Cummins 24 valveÐTurbo

Diesel Engine uses anelectronically controlled

fuel injection pump with three control modules.

Also refer to the Powertrain Control Module (PCM)

or Engine Control Module sections.

Some fuel system components are shown in (Fig.

1).

The fuel delivery system consists of the:

²Accelerator pedal

²Air cleaner housing/element

²Fuel drain manifold (passage)

²Fuel filter/water separator

²Fuel heater

²Fuel heater relay

²Fuel transfer (lift) pump

²Fuel injection pump

²Fuel injectors

²Fuel heater temperature sensor

²Fuel tank

²Fuel tank filler/vent tube assembly²Fuel tank filler tube cap

²Fuel tank module containing the rollover valve,

fuel gauge sending unit (fuel level sensor) and a sep-

arate fuel filter located at bottom of tank module

²Fuel tubes/lines/hoses

²High-pressure fuel injector lines

²In-tank fuel filter (at bottom of fuel tank mod-

ule)

²Low-pressure fuel supply lines

²Low-pressure fuel return line

²Overflow valve

²Quick-connect fittings

²Throttle cable

²Water draining

OPERATION

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 120,000 KPA (17,405

PSI). USE EXTREME CAUTION WHEN INSPECTING

FOR HIGH-PRESSURE FUEL LEAKS. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

BR/BEFUEL DELIVERY - DIESEL 14 - 55

Page 1365 of 2255

(d) Tighten sensor to 2±3 N´m (15±20 in. lbs.)

torque.

(e) Connect electrical connector to WIF sensor.

(f) Install fuel filter. Refer to previous steps.

(4)Fuel Heater Element:

(a) Do not install fuel filter until heater element

is installed.

(b) Position heater element into filter housing

(fingers downward). Lock fingers into housing.

(c) Install new o-ring to electrical connector

(where connector passes through filter housing).

Apply a light film of clean diesel oil to o-ring seal.

Press this connector into filter housing until it

snaps into heater element.

(d) Install temperature sensor housing and 2

mounting screws to fuel filter housing.

(e) Connect electrical connector.

(f) Install fuel filter. Refer to previous steps.

(5)Drain Valve:

(a) Install 2 new o-rings to valve and filter hous-

ing.

(b) Apply a light film of clean diesel oil to both

seals.

(c) Position valve to filter housing.

(d) Install 4 mounting screws and tighten to 3±5

N´m (30±40 in. lbs.) torque.

(e) Connect drain hose to drain valve.

(f) Install fuel filter. Refer to previous steps.

(6) Start engine and check for leaks.

FUEL HEATER

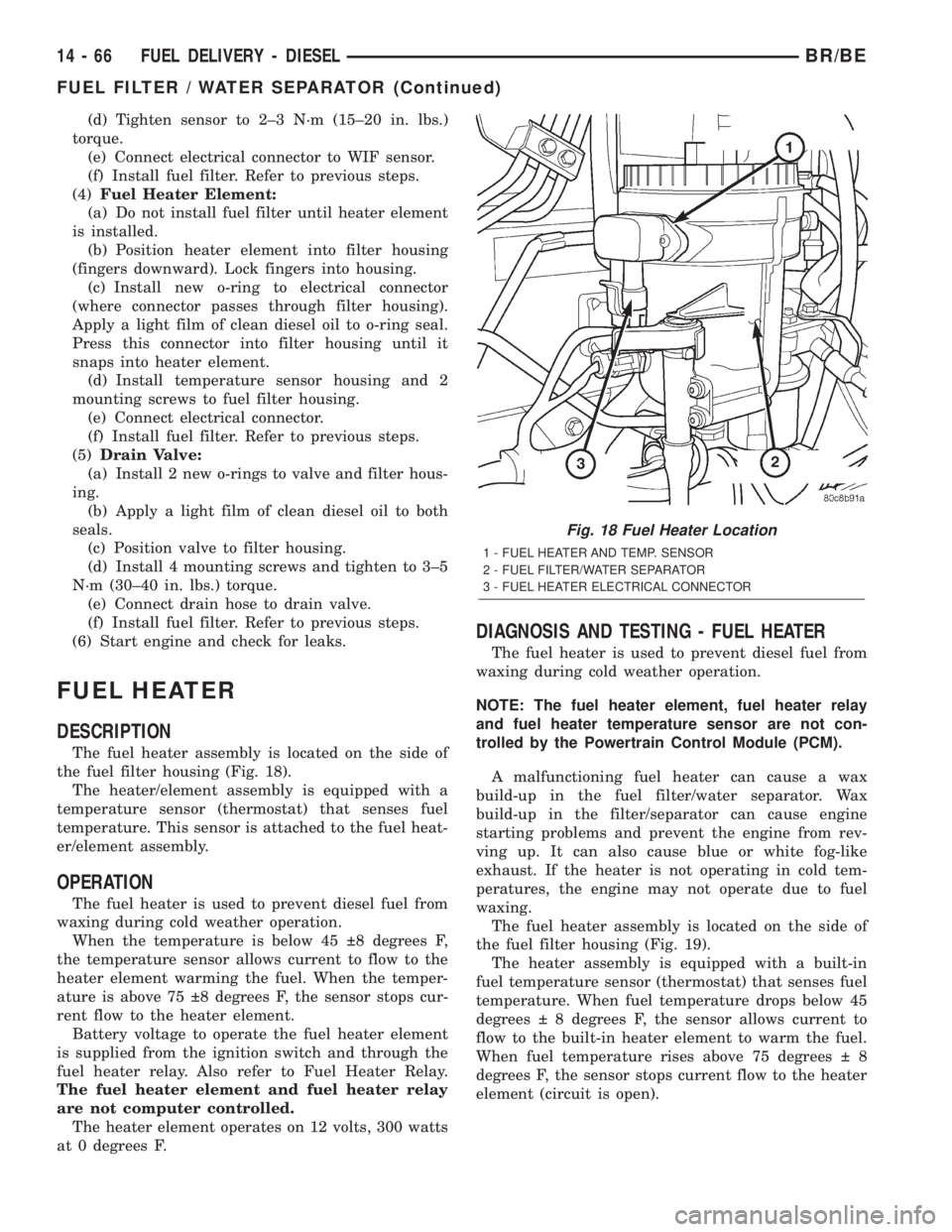

DESCRIPTION

The fuel heater assembly is located on the side of

the fuel filter housing (Fig. 18).

The heater/element assembly is equipped with a

temperature sensor (thermostat) that senses fuel

temperature. This sensor is attached to the fuel heat-

er/element assembly.

OPERATION

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

When the temperature is below 45 8 degrees F,

the temperature sensor allows current to flow to the

heater element warming the fuel. When the temper-

ature is above 75 8 degrees F, the sensor stops cur-

rent flow to the heater element.

Battery voltage to operate the fuel heater element

is supplied from the ignition switch and through the

fuel heater relay. Also refer to Fuel Heater Relay.

The fuel heater element and fuel heater relay

are not computer controlled.

The heater element operates on 12 volts, 300 watts

at 0 degrees F.

DIAGNOSIS AND TESTING - FUEL HEATER

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

NOTE: The fuel heater element, fuel heater relay

and fuel heater temperature sensor are not con-

trolled by the Powertrain Control Module (PCM).

A malfunctioning fuel heater can cause a wax

build-up in the fuel filter/water separator. Wax

build-up in the filter/separator can cause engine

starting problems and prevent the engine from rev-

ving up. It can also cause blue or white fog-like

exhaust. If the heater is not operating in cold tem-

peratures, the engine may not operate due to fuel

waxing.

The fuel heater assembly is located on the side of

the fuel filter housing (Fig. 19).

The heater assembly is equipped with a built-in

fuel temperature sensor (thermostat) that senses fuel

temperature. When fuel temperature drops below 45

degrees 8 degrees F, the sensor allows current to

flow to the built-in heater element to warm the fuel.

When fuel temperature rises above 75 degrees 8

degrees F, the sensor stops current flow to the heater

element (circuit is open).

Fig. 18 Fuel Heater Location

1 - FUEL HEATER AND TEMP. SENSOR

2 - FUEL FILTER/WATER SEPARATOR

3 - FUEL HEATER ELECTRICAL CONNECTOR

14 - 66 FUEL DELIVERY - DIESELBR/BE

FUEL FILTER / WATER SEPARATOR (Continued)