check engine DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1797 of 2895

DIAGNOSIS AND TESTING - POWER STEERING

FLOW AND PRESSURE

The following procedure is used to test the opera-

tion of the power steering system on the vehicle. This

test will provide the gallons per minute (GPM) or

flow rate of the power steering pump along with the

maximum relief pressure. Perform test any time a

power steering system problem is present. This test

will determine if the power steering pump or power

steering gear is not functioning properly. The follow-

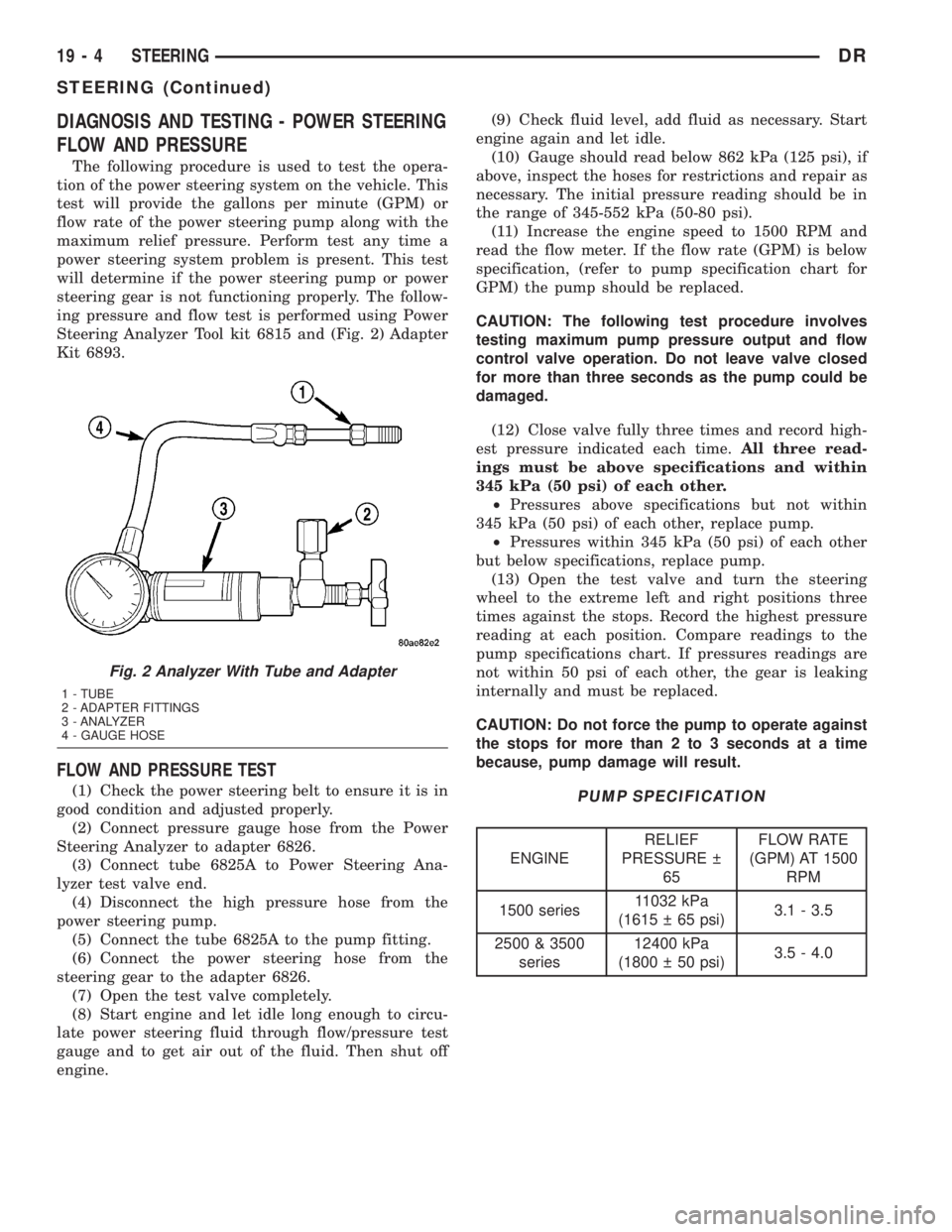

ing pressure and flow test is performed using Power

Steering Analyzer Tool kit 6815 and (Fig. 2) Adapter

Kit 6893.

FLOW AND PRESSURE TEST

(1) Check the power steering belt to ensure it is in

good condition and adjusted properly.

(2) Connect pressure gauge hose from the Power

Steering Analyzer to adapter 6826.

(3) Connect tube 6825A to Power Steering Ana-

lyzer test valve end.

(4) Disconnect the high pressure hose from the

power steering pump.

(5) Connect the tube 6825A to the pump fitting.

(6) Connect the power steering hose from the

steering gear to the adapter 6826.

(7) Open the test valve completely.

(8) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

gauge and to get air out of the fluid. Then shut off

engine.(9) Check fluid level, add fluid as necessary. Start

engine again and let idle.

(10) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure reading should be in

the range of 345-552 kPa (50-80 psi).

(11) Increase the engine speed to 1500 RPM and

read the flow meter. If the flow rate (GPM) is below

specification, (refer to pump specification chart for

GPM) the pump should be replaced.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than three seconds as the pump could be

damaged.

(12) Close valve fully three times and record high-

est pressure indicated each time.All three read-

ings must be above specifications and within

345 kPa (50 psi) of each other.

²Pressures above specifications but not within

345 kPa (50 psi) of each other, replace pump.

²Pressures within 345 kPa (50 psi) of each other

but below specifications, replace pump.

(13) Open the test valve and turn the steering

wheel to the extreme left and right positions three

times against the stops. Record the highest pressure

reading at each position. Compare readings to the

pump specifications chart. If pressures readings are

not within 50 psi of each other, the gear is leaking

internally and must be replaced.

CAUTION: Do not force the pump to operate against

the stops for more than 2 to 3 seconds at a time

because, pump damage will result.PUMP SPECIFICATION

ENGINERELIEF

PRESSURE

65FLOW RATE

(GPM) AT 1500

RPM

1500 series11032 kPa

(1615 65 psi)3.1 - 3.5

2500 & 3500

series12400 kPa

(1800 50 psi)3.5 - 4.0

Fig. 2 Analyzer With Tube and Adapter

1 - TUBE

2 - ADAPTER FITTINGS

3 - ANALYZER

4 - GAUGE HOSE

19 - 4 STEERINGDR

STEERING (Continued)

Page 1832 of 2895

DIAGNOSIS AND TESTING - PUMP LEAKAGE

The pump is serviced as an assembly and should

not be disassembled. The plastic pump reservoir and

the reservoir o-rings can be replaced.

Check for leaks in the following areas:

²Pump shaft seal behind the pulley

²Pump to reservoir O-ring

²Reservoir cap

²Pressure and return lines

²Flow control valve fitting

STANDARD PROCEDURE

STANDARD PROCEDURE - POWER STEERING

PUMP - INITIAL OPERATION

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: MOPARTATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature.(1) Turn steering wheel all the way to the left

(2) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes.

(3) Raise the front wheels off the ground.

(4) Slowly turn the steering wheel lock-to-lock 20

times with the engine off while checking the fluid

level.

NOTE: For vehicles with long return lines or oil

coolers turn wheel 40 times.

(5) Start the engine. With the engine idling main-

tain the fluid level.

(6) Lower the front wheels and let the engine idle

for two minutes.

(7) Turn the steering wheel in both direction and

verify power assist and quiet operation of the pump.

If the fluid is extremely foamy or milky looking,

allow the vehicle to stand a few minutes and repeat

the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

STANDARD PROCEDURE - FLUSHING POWER

STEERING SYSTEM

Flushing is required when the power steering/hy-

draulic booster system fluid has become contami-

nated. Contaminated fluid in the steering/booster

system can cause seal deterioration and affect steer-

ing gear/booster spool valve operation.

(1) Raise the front end of the vehicle off the

ground until the wheels are free to turn.

(2) Remove the return line from the pump.

NOTE: If vehicle is equipped with a hydraulic

booster remove both return lines from the pump.

(3) Plug the return line port/ports at the pump.

(4) Position the return line/lines into a large con-

tainer to catch the fluid.

(5) While an assistant is filling the pump reservoir

start the engine.

(6) With the engine running at idle turn the wheel

back and forth.

NOTE: Do not contact or hold the wheel against the

steering stops.

(7) Run a quart of fluid through the system then

stop the engine and install the return line/lines.

(8) Fill the system with fluid and perform Steering

Pump Initial Operation, (Refer to 19 - STEERING/

PUMP - STANDARD PROCEDURE).

(9) Start the engine and run it for fifteen minutes

then stop the engine.

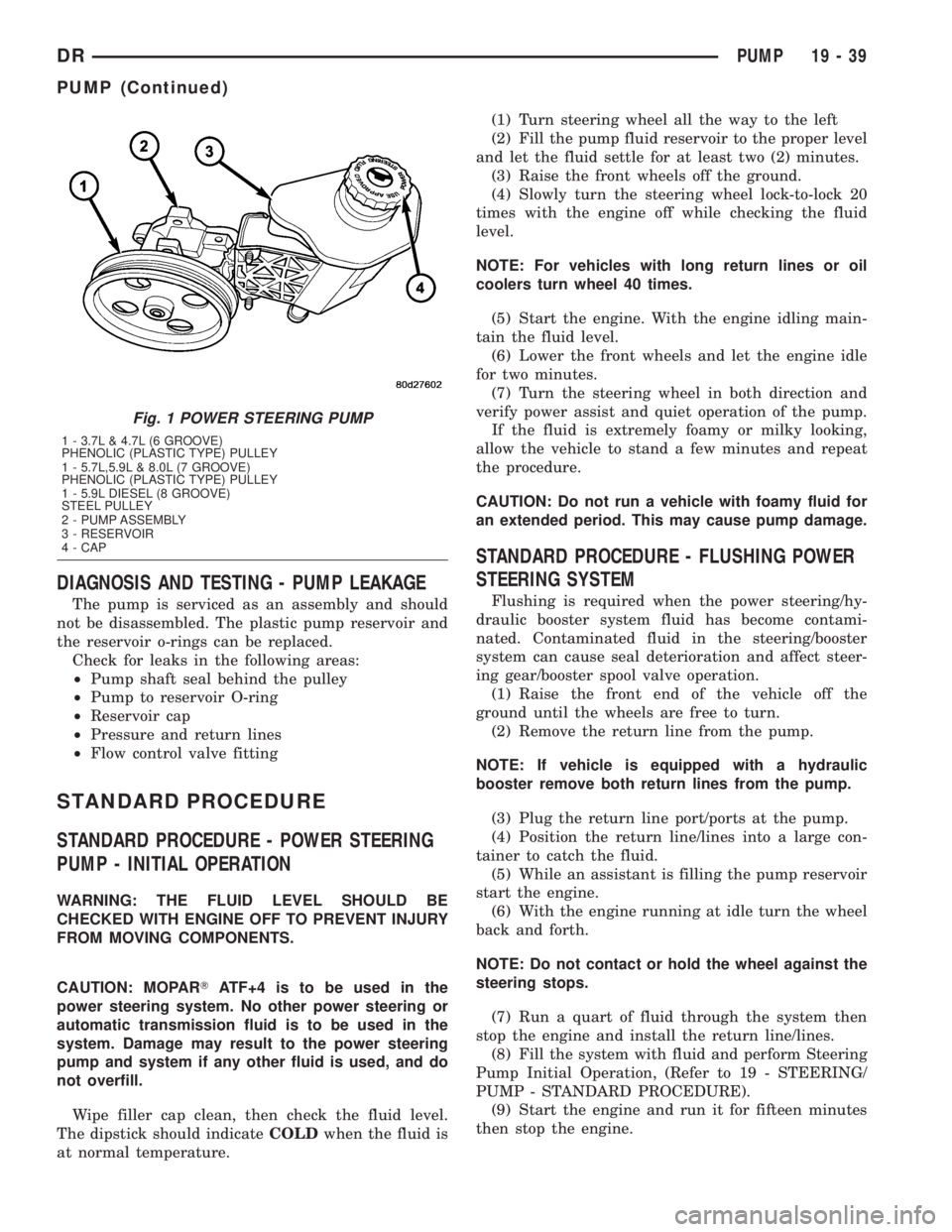

Fig. 1 POWER STEERING PUMP

1 - 3.7L & 4.7L (6 GROOVE)

PHENOLIC (PLASTIC TYPE) PULLEY

1 - 5.7L,5.9L & 8.0L (7 GROOVE)

PHENOLIC (PLASTIC TYPE) PULLEY

1 - 5.9L DIESEL (8 GROOVE)

STEEL PULLEY

2 - PUMP ASSEMBLY

3 - RESERVOIR

4 - CAP

DRPUMP 19 - 39

PUMP (Continued)

Page 1833 of 2895

(10) Remove the return line/lines from the pump

and plug the pump port/ports.

(11) Pour fresh fluid into the reservoir and check

the draining fluid for contamination. If the fluid is

still contaminated, then flush the system again.

(12) Install the return line/lines and perform

Steering Pump Initial Operation, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

REMOVAL

REMOVAL - GAS

(1) Drain and siphon the power steering fluid from

the reservoir.

(2) Remove the serpentine belt.

CAUTION: Do not remove the fitting on the pump

that the high pressure hose screws into. The fitting

may come loose unless it is backed up using

another wrench. If the fitting does come loose, it

must be retightened before continuing. (57 - 67Nm,

40 - 50 lbft) If this fitting comes out of the pump

body, the internal spring and valve parts will fall out

of the pump and they cannot be reinstalled prop-

erly. If this occurs the pump needs to be replaced

with a new pump.

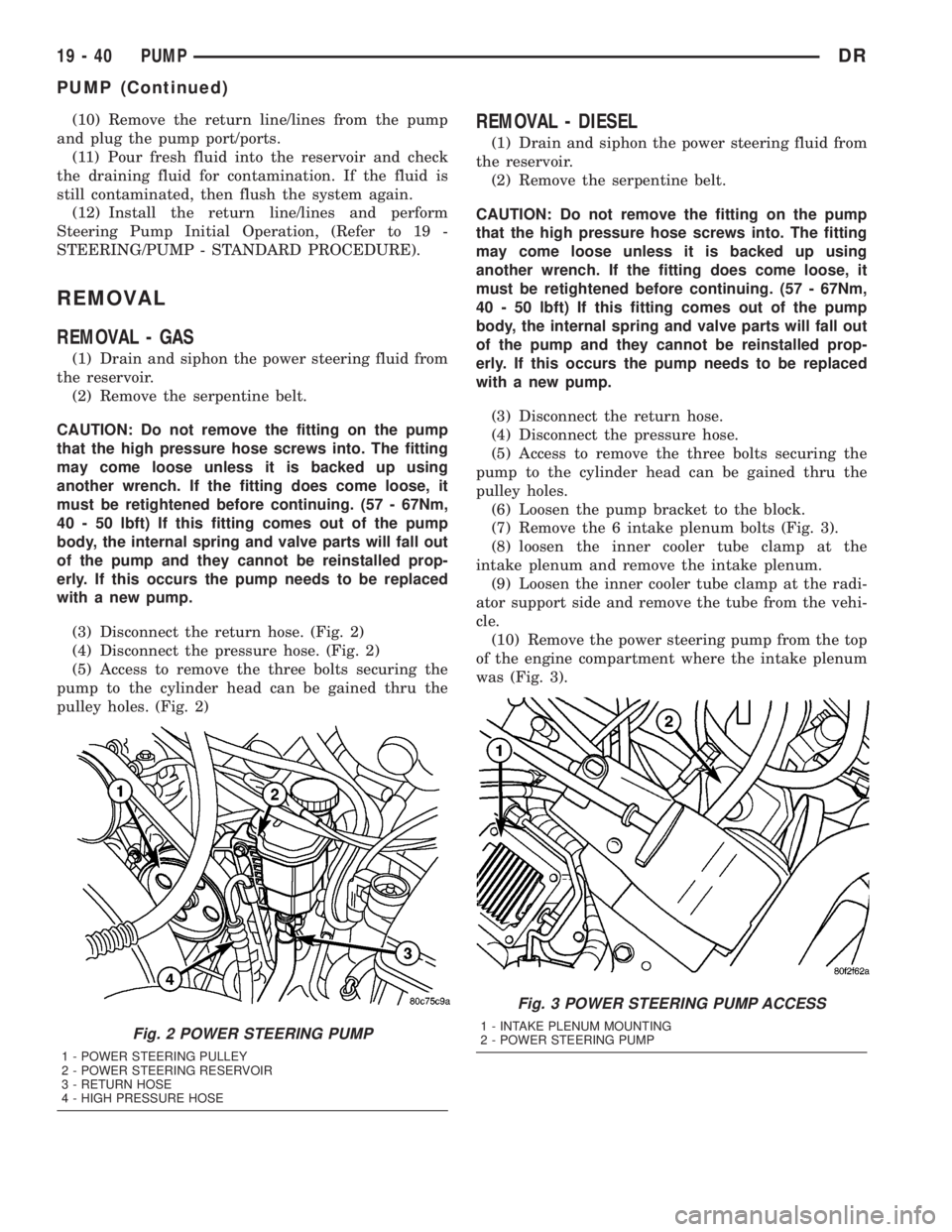

(3) Disconnect the return hose. (Fig. 2)

(4) Disconnect the pressure hose. (Fig. 2)

(5) Access to remove the three bolts securing the

pump to the cylinder head can be gained thru the

pulley holes. (Fig. 2)

REMOVAL - DIESEL

(1) Drain and siphon the power steering fluid from

the reservoir.

(2) Remove the serpentine belt.

CAUTION: Do not remove the fitting on the pump

that the high pressure hose screws into. The fitting

may come loose unless it is backed up using

another wrench. If the fitting does come loose, it

must be retightened before continuing. (57 - 67Nm,

40 - 50 lbft) If this fitting comes out of the pump

body, the internal spring and valve parts will fall out

of the pump and they cannot be reinstalled prop-

erly. If this occurs the pump needs to be replaced

with a new pump.

(3) Disconnect the return hose.

(4) Disconnect the pressure hose.

(5) Access to remove the three bolts securing the

pump to the cylinder head can be gained thru the

pulley holes.

(6) Loosen the pump bracket to the block.

(7) Remove the 6 intake plenum bolts (Fig. 3).

(8) loosen the inner cooler tube clamp at the

intake plenum and remove the intake plenum.

(9) Loosen the inner cooler tube clamp at the radi-

ator support side and remove the tube from the vehi-

cle.

(10) Remove the power steering pump from the top

of the engine compartment where the intake plenum

was (Fig. 3).

Fig. 2 POWER STEERING PUMP

1 - POWER STEERING PULLEY

2 - POWER STEERING RESERVOIR

3 - RETURN HOSE

4 - HIGH PRESSURE HOSE

Fig. 3 POWER STEERING PUMP ACCESS

1 - INTAKE PLENUM MOUNTING

2 - POWER STEERING PUMP

19 - 40 PUMPDR

PUMP (Continued)

Page 1835 of 2895

FLUID

DESCRIPTION

The recommended fluid for the power steering sys-

tem is MopartATF +4.

MopartATF+4, when new is red in color. The

ATF+4 is dyed red so it can be identified from other

fluids used in the vehicle such as engine oil or anti-

freeze. The red color is not permanent and is not an

indicator of fluid condition, As the vehicle is driven,

the ATF+4 will begin to look darker in color and may

eventually become brown.THIS IS NORMAL.

ATF+4 also has a unique odor that may change with

age. Consequently, odor and color cannot be used to

indicate the fluid condition or the need for a fluid

change.

STANDARD PROCEDURE - POWER STEERING

FLUID LEVEL CHECKING

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: MOPARTATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

The power steering fluid level can be viewed on the

dipstick attached to the filler cap. There are two

ranges listed on the dipstick, COLD and HOT. Before

opening power steering system, wipe the reservoir

filler cap free of dirt and debris. Remove the cap and

check the fluid level on its dipstick. When the fluid is

at normal ambient temperature, approximately 21ÉC

to 27ÉC (70ÉF to 80ÉF), the fluid level should read

between the minimum and maximum area of the cold

range. When the fluid is hot, fluid level is allowed to

read up to the highest end of the HOT range. Only

add fluid when the vehicle is cold.

Use only MopartATF+4Do not overfill the

power steering system.

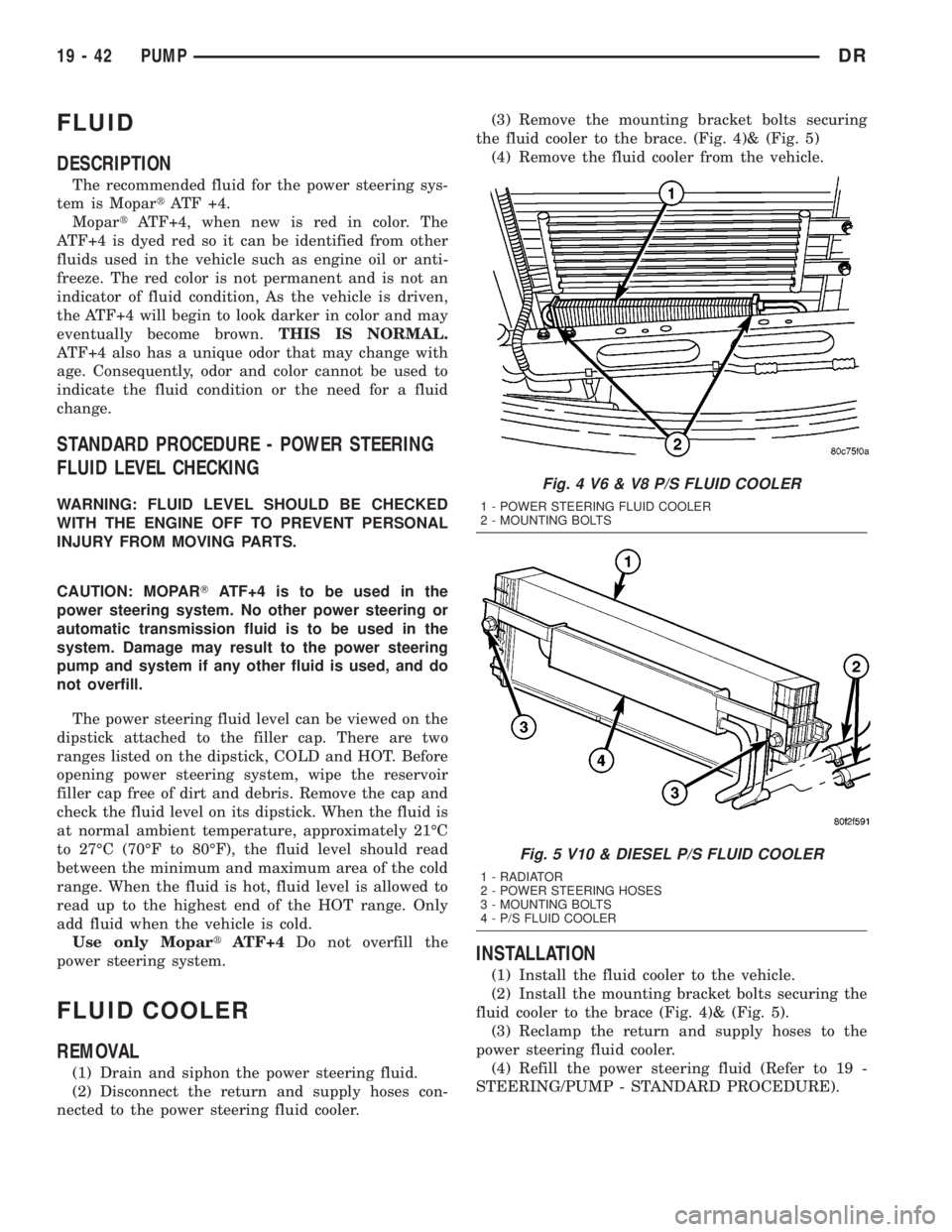

FLUID COOLER

REMOVAL

(1) Drain and siphon the power steering fluid.

(2) Disconnect the return and supply hoses con-

nected to the power steering fluid cooler.(3) Remove the mounting bracket bolts securing

the fluid cooler to the brace. (Fig. 4)& (Fig. 5)

(4) Remove the fluid cooler from the vehicle.

INSTALLATION

(1) Install the fluid cooler to the vehicle.

(2) Install the mounting bracket bolts securing the

fluid cooler to the brace (Fig. 4)& (Fig. 5).

(3) Reclamp the return and supply hoses to the

power steering fluid cooler.

(4) Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

Fig. 4 V6 & V8 P/S FLUID COOLER

1 - POWER STEERING FLUID COOLER

2 - MOUNTING BOLTS

Fig. 5 V10 & DIESEL P/S FLUID COOLER

1 - RADIATOR

2 - POWER STEERING HOSES

3 - MOUNTING BOLTS

4 - P/S FLUID COOLER

19 - 42 PUMPDR

Page 1838 of 2895

POWER STEERING PRESSURE

SWITCH

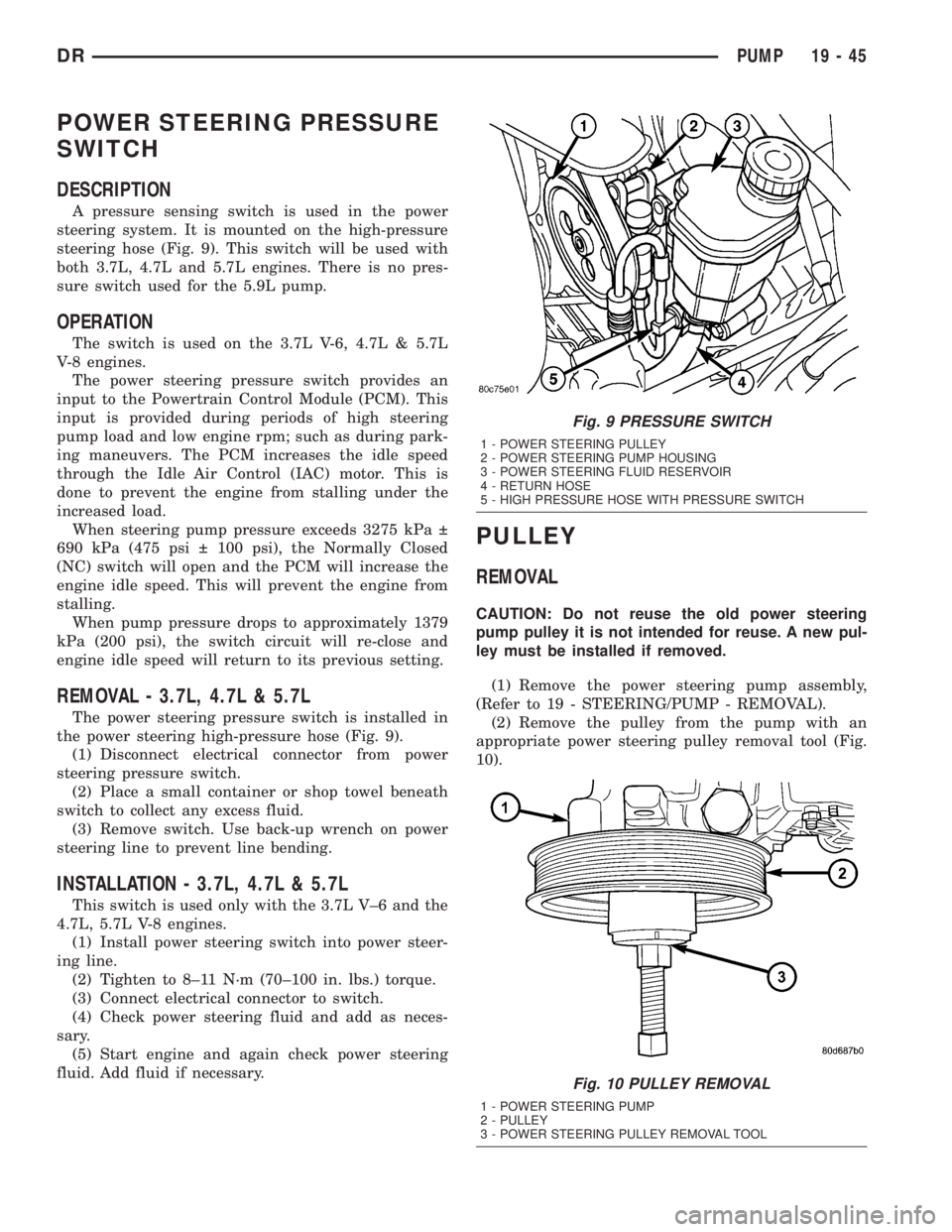

DESCRIPTION

A pressure sensing switch is used in the power

steering system. It is mounted on the high-pressure

steering hose (Fig. 9). This switch will be used with

both 3.7L, 4.7L and 5.7L engines. There is no pres-

sure switch used for the 5.9L pump.

OPERATION

The switch is used on the 3.7L V-6, 4.7L & 5.7L

V-8 engines.

The power steering pressure switch provides an

input to the Powertrain Control Module (PCM). This

input is provided during periods of high steering

pump load and low engine rpm; such as during park-

ing maneuvers. The PCM increases the idle speed

through the Idle Air Control (IAC) motor. This is

done to prevent the engine from stalling under the

increased load.

When steering pump pressure exceeds 3275 kPa

690 kPa (475 psi 100 psi), the Normally Closed

(NC) switch will open and the PCM will increase the

engine idle speed. This will prevent the engine from

stalling.

When pump pressure drops to approximately 1379

kPa (200 psi), the switch circuit will re-close and

engine idle speed will return to its previous setting.

REMOVAL - 3.7L, 4.7L & 5.7L

The power steering pressure switch is installed in

the power steering high-pressure hose (Fig. 9).

(1) Disconnect electrical connector from power

steering pressure switch.

(2) Place a small container or shop towel beneath

switch to collect any excess fluid.

(3) Remove switch. Use back-up wrench on power

steering line to prevent line bending.

INSTALLATION - 3.7L, 4.7L & 5.7L

This switch is used only with the 3.7L V±6 and the

4.7L, 5.7L V-8 engines.

(1) Install power steering switch into power steer-

ing line.

(2) Tighten to 8±11 N´m (70±100 in. lbs.) torque.

(3) Connect electrical connector to switch.

(4) Check power steering fluid and add as neces-

sary.

(5) Start engine and again check power steering

fluid. Add fluid if necessary.

PULLEY

REMOVAL

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new pul-

ley must be installed if removed.

(1) Remove the power steering pump assembly,

(Refer to 19 - STEERING/PUMP - REMOVAL).

(2) Remove the pulley from the pump with an

appropriate power steering pulley removal tool (Fig.

10).

Fig. 9 PRESSURE SWITCH

1 - POWER STEERING PULLEY

2 - POWER STEERING PUMP HOUSING

3 - POWER STEERING FLUID RESERVOIR

4 - RETURN HOSE

5 - HIGH PRESSURE HOSE WITH PRESSURE SWITCH

Fig. 10 PULLEY REMOVAL

1 - POWER STEERING PUMP

2 - PULLEY

3 - POWER STEERING PULLEY REMOVAL TOOL

DRPUMP 19 - 45

Page 1877 of 2895

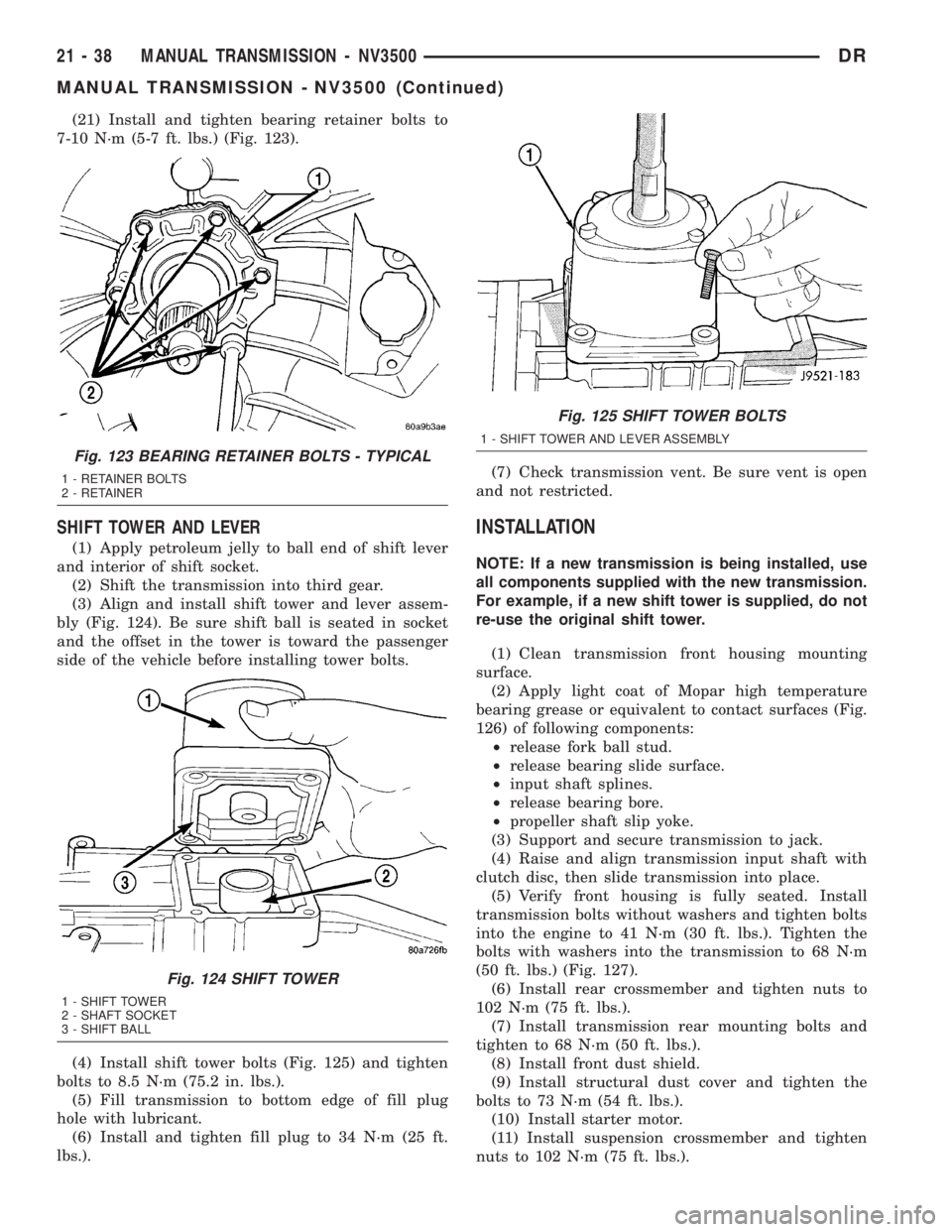

(21) Install and tighten bearing retainer bolts to

7-10 N´m (5-7 ft. lbs.) (Fig. 123).

SHIFT TOWER AND LEVER

(1) Apply petroleum jelly to ball end of shift lever

and interior of shift socket.

(2) Shift the transmission into third gear.

(3) Align and install shift tower and lever assem-

bly (Fig. 124). Be sure shift ball is seated in socket

and the offset in the tower is toward the passenger

side of the vehicle before installing tower bolts.

(4) Install shift tower bolts (Fig. 125) and tighten

bolts to 8.5 N´m (75.2 in. lbs.).

(5) Fill transmission to bottom edge of fill plug

hole with lubricant.

(6) Install and tighten fill plug to 34 N´m (25 ft.

lbs.).(7) Check transmission vent. Be sure vent is open

and not restricted.

INSTALLATION

NOTE: If a new transmission is being installed, use

all components supplied with the new transmission.

For example, if a new shift tower is supplied, do not

re-use the original shift tower.

(1) Clean transmission front housing mounting

surface.

(2) Apply light coat of Mopar high temperature

bearing grease or equivalent to contact surfaces (Fig.

126) of following components:

²release fork ball stud.

²release bearing slide surface.

²input shaft splines.

²release bearing bore.

²propeller shaft slip yoke.

(3) Support and secure transmission to jack.

(4) Raise and align transmission input shaft with

clutch disc, then slide transmission into place.

(5) Verify front housing is fully seated. Install

transmission bolts without washers and tighten bolts

into the engine to 41 N´m (30 ft. lbs.). Tighten the

bolts with washers into the transmission to 68 N´m

(50 ft. lbs.) (Fig. 127).

(6) Install rear crossmember and tighten nuts to

102 N´m (75 ft. lbs.).

(7) Install transmission rear mounting bolts and

tighten to 68 N´m (50 ft. lbs.).

(8) Install front dust shield.

(9) Install structural dust cover and tighten the

bolts to 73 N´m (54 ft. lbs.).

(10) Install starter motor.

(11) Install suspension crossmember and tighten

nuts to 102 N´m (75 ft. lbs.).

Fig. 123 BEARING RETAINER BOLTS - TYPICAL

1 - RETAINER BOLTS

2 - RETAINER

Fig. 124 SHIFT TOWER

1 - SHIFT TOWER

2 - SHAFT SOCKET

3 - SHIFT BALL

Fig. 125 SHIFT TOWER BOLTS

1 - SHIFT TOWER AND LEVER ASSEMBLY

21 - 38 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1917 of 2895

²release fork ball stud.

²propeller shaft slip yoke.

(2) Apply sealer to threads of bottom PTO cover

bolt and install bolt in case.

(3) Mount transmission on jack and position trans-

mission under vehicle.

(4) Raise transmission until input shaft is centered

in release bearing and clutch disc hub.

(5) Move transmission forward and start input

shaft in release bearing, clutch disc and pilot bush-

ing.

(6) Work transmission forward until seated against

clutch housing. Do not allow transmission to remain

unsupported after input shaft has entered clutch

disc.

(7) Install transmission bolts and tighten to 108

N´m (80 ft. lbs.).

(8) Install transmission mount on transmission or

rear crossmember.

(9) Install rear crossmember.

(10) Remove transmission jack and engine support

fixture.

(11) Position transmission harness wires in clips

on shift cover.

(12) Install clutch slave cylinder and install slave

cylinder shield, if equipped.

(13) Connect speed sensor and backup light switch

wires.

TWO WHEEL DRIVE

(1) Fill transmission with recommended lubricant.

Correct fill level is bottom edge of fill plug hole.

(2) Align and install propeller shaft.

(3) Lower vehicle.

(4) Clean the mating surfaces of shift tower, isola-

tor plate and shift cover with suitable wax and

grease remover.

(5) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the shift cover. Do not over

apply sealant.

(6) Install the isolator plate onto the shift cover,

metal side down.

(7) Install the shift tower onto the isolator plate.

No sealant is necessary between the shift tower and

the isolator plate.

(8) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(9) Install the bolts to hold the shift tower to the

isolator plate and the shift cover. Tighten the shift

tower bolts to 10.2-11.25 N´m (7.5-8.3 ft. lbs.).

(10) Install the shift lever extension onto the shift

tower and lever assembly.

(11) Install shift boot and bezel.

(12) Connect battery negative cable.

FOUR WHEEL DRIVE

(1) Install transfer case shift mechanism on trans-

mission.

(2) Install transfer case on transmission jack.

Secure transfer case to jack with safety chains.

(3) Raise jack and align transfer case input gear

with transmission mainshaft.

(4) Move transfer case forward and seat it on

adapter.

(5) Install transfer case nuts and tighten to:

²If 3/8 studs 41-47 N´m (30-35 ft. lbs.).

²If 5/16 studs 30-41 N´m (22-30 ft. lbs.).

(6) Install transfer case shift mechanism to side of

transfer case.

(7) Connect transfer case shift lever to range lever

on transfer case.

(8) Align and connect propeller shafts.

(9) Fill transmission with required lubricant.

Check lubricant level in transfer case and add lubri-

cant if necessary.

(10) Install transfer case skid plate, if equipped

and crossmember. Tighten attaching bolts/nuts to 41

N´m (30 ft. lbs.).

(11) Install exhaust system components.

(12) Lower vehicle.

(13) Clean the mating surfaces of shift tower, iso-

lator plate and shift cover with suitable wax and

grease remover.

(14) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the shift cover. Do not over

apply sealant.

(15) Install the isolator plate onto the shift cover,

metal side down.

(16) Install the shift tower onto the isolator plate.

No sealant is necessary between the shift tower and

the isolator plate.

(17) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(18) Install the bolts to hold the shift tower to the

isolator plate and the shift cover. Tighten the shift

tower bolts to 10.2-11.25 N´m (7.5-8.3 ft. lbs.).

(19) Install the shift lever extension onto the shift

tower and lever assembly.

(20) Install shift lever boot and bezel.

(21) Connect battery negative cable.

21 - 78 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1959 of 2895

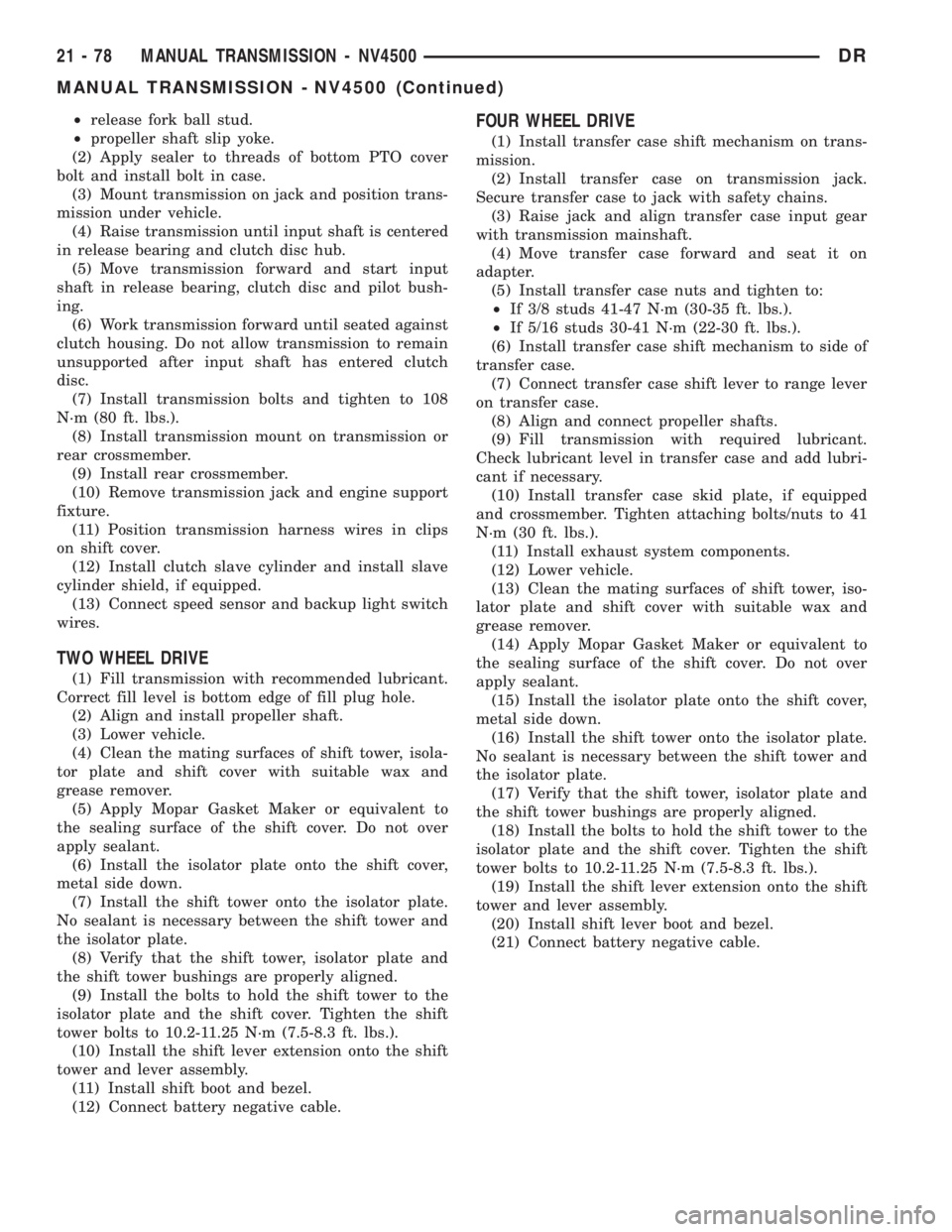

(14) Use Installer to install the reverse counter-

shaft bearing race into the extension/adapter hous-

ing.

(15) Install back-up lamp switch into the exten-

sion/adapter housing and tighten to 28 N´m (20

ft.lbs.).

(16) Install crossover cam into the extension/

adapter housing.

(17) Install bolt to hold the crossover cam to the

extension/adapter housing (Fig. 94).

(18) Install crossover detent plunger, spring and

plug into the extension/adapter housing. Tighten the

plug to 47.5 N´m (35 ft.lbs.) (Fig. 95).

(19) Apply sealer to the surface of the transmis-

sion case.(20) Install extension/adapter housing onto the

transmission case.

(21) Install bolts to hold the extension/adapter

housing onto the transmission gear case. Tighten

bolts to 48 N´m (35 ft.lbs.).

(22) Install shift rail blocker bolt and tighten bolt

to 55 N´m (41 ft.lbs.).

(23) Install primary shift rail detent plunger,

spring and plug into the transmission case. Tighten

detent plug to 47.5 N´m (35 ft.lbs.).

(24) Install shift tower onto the transmission case

and tighten bolts to 9 N´m (7 ft.lbs.).

INSTALLATION

NOTE: If installing a new transmission, use all com-

ponents supplied with the transmission. If a new

shift tower is supplied with the new transmission,

do not re-use the original shift tower.

(1) Apply a light coat of Mopar high temperature

bearing grease or equivalent to contact surfaces of

following components:

²input shaft splines.

²release bearing slide surface of front retainer.

²release bearing bore.

²release fork.

²release fork ball stud.

²propeller shaft slip yoke.

(2) Apply sealer to threads of bottom PTO cover

bolt and install bolt in case.

(3) Mount transmission on jack and position trans-

mission under vehicle.

(4) Raise transmission until input shaft is centered

in clutch disc hub.

(5) Move transmission forward and start input

shaft in clutch disc and pilot bushing/bearing.

(6) Work transmission forward until seated against

engine block. Do not allow transmission to remain

unsupported after input shaft has entered clutch

disc.

(7) Install and tighten transmission-to-engine

block bolts.

(8) Install clutch slave cylinder.

(9) Connect backup light switch wires.

(10) Position transmission harness wires in clips

on transmission.

(11) Install transmission mount on transmission or

rear crossmember.

(12) Install rear crossmember.

(13) Remove transmission jack and engine support

fixture.

(14) Fill transmission with required lubricant (Fig.

96). Check lubricant level in transfer case if

equipped.

Fig. 94 CROSSOVER CAM BOLT

1 - CROSSOVER CAM

2 - BOLT

3 - EXTENSION HOUSING

Fig. 95 CROSSOVER CAM DETENT PLUG

1 - DETENT PLUG

2 - EXTENSION HOUSING

21 - 120 MANUAL TRANSMISSION - NV5600DR

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1978 of 2895

FOURTH GEAR POWERFLOW

Fourth gear overdrive range is electronically con-

trolled and hydraulically activated. Various sensor

inputs are supplied to the powertrain control module

to operate the overdrive solenoid on the valve body.

The solenoid contains a check ball that opens and

closes a vent port in the 3-4 shift valve feed passage.

The overdrive solenoid (and check ball) are not ener-

gized in first, second, third, or reverse gear. The vent

port remains open, diverting line pressure from the

2-3 shift valve away from the 3-4 shift valve. The

overdrive control switch must be in the ON position

to transmit overdrive status to the PCM. A 3-4

upshift occurs only when the overdrive solenoid is

energized by the PCM. The PCM energizes the over-

drive solenoid during the 3-4 upshift. This causes the

solenoid check ball to close the vent port allowing

line pressure from the 2-3 shift valve to act directly

on the 3-4 upshift valve. Line pressure on the 3-4

shift valve overcomes valve spring pressure moving

the valve to the upshift position. This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston. Line pressure through the timing

valve moves the overdrive piston into contact with

the overdrive clutch. The direct clutch is disengaged

before the overdrive clutch is engaged. The boost

valve provides increased fluid apply pressure to the

overdrive clutch during 3-4 upshifts, and when accel-

erating in fourth gear. The 3-4 accumulator cushions

overdrive clutch engagement to smooth 3-4 upshifts.

The accumulator is charged at the same time as

apply pressure acts against the overdrive piston.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

Automatic transmission problems can be a result of

poor engine performance, incorrect fluid level, incor-

rect linkage or cable adjustment, band or hydraulic

control pressure adjustments, hydraulic system mal-

functions or electrical/mechanical component mal-

functions. Begin diagnosis by checking the easily

accessible items such as: fluid level and condition,

linkage adjustments and electrical connections. A

road test will determine if further diagnosis is neces-

sary.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate proce-

dure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVEABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust throttle and gearshift linkage if com-

plaint was based on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(6) Perform air-pressure test to check clutch-band

operation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2) Check for broken or disconnected gearshift or

throttle linkage.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged drive plate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that diagnostic trouble

codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, band or overrunning clutch problems. If the

condition is advanced, an overhaul will be necessary

to restore normal operation.

A slipping clutch or band can often be determined

by comparing which internal units are applied in the

various gear ranges. The Clutch and Band Applica-

tion chart provides a basis for analyzing road test

results.

DRAUTOMATIC TRANSMISSION - 46RE 21 - 139

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1980 of 2895

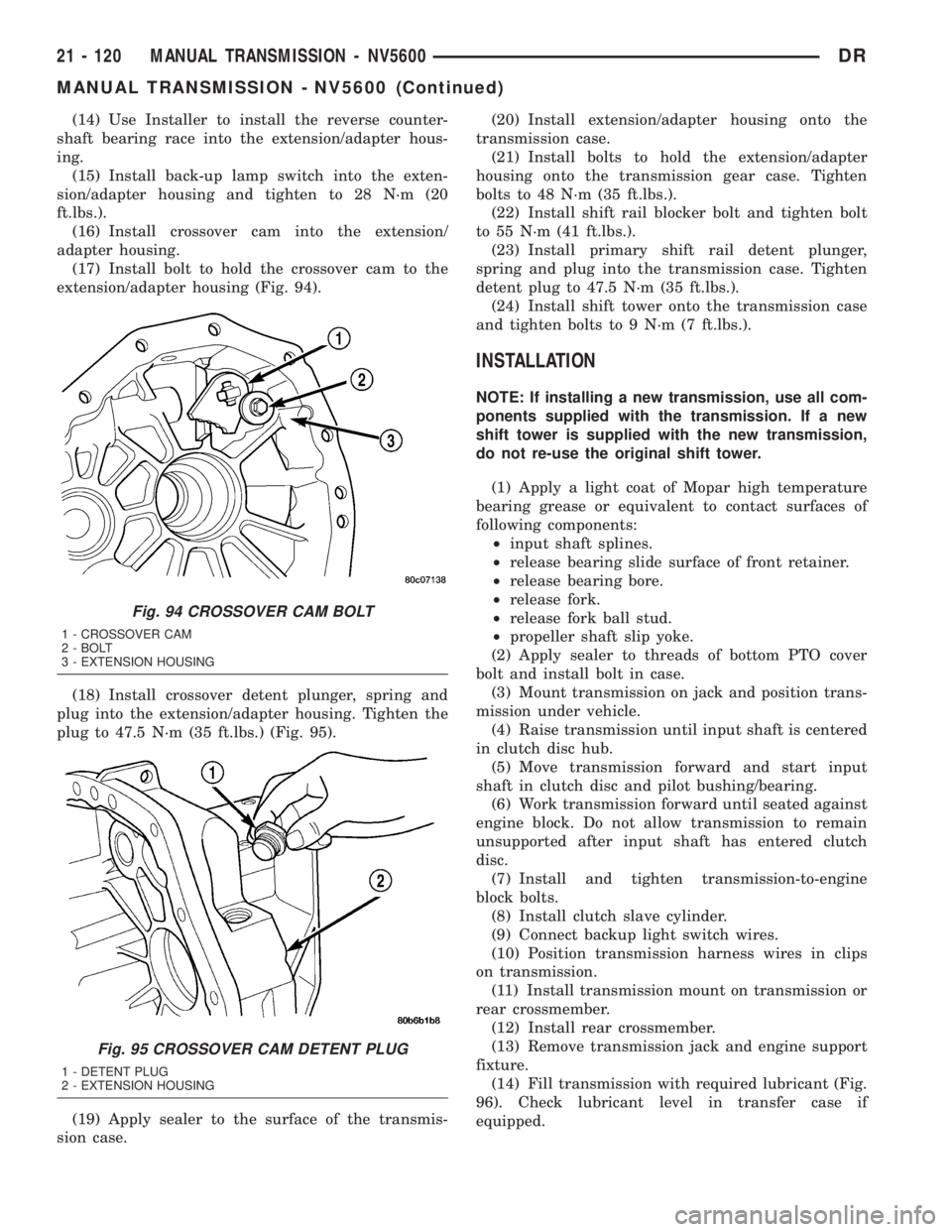

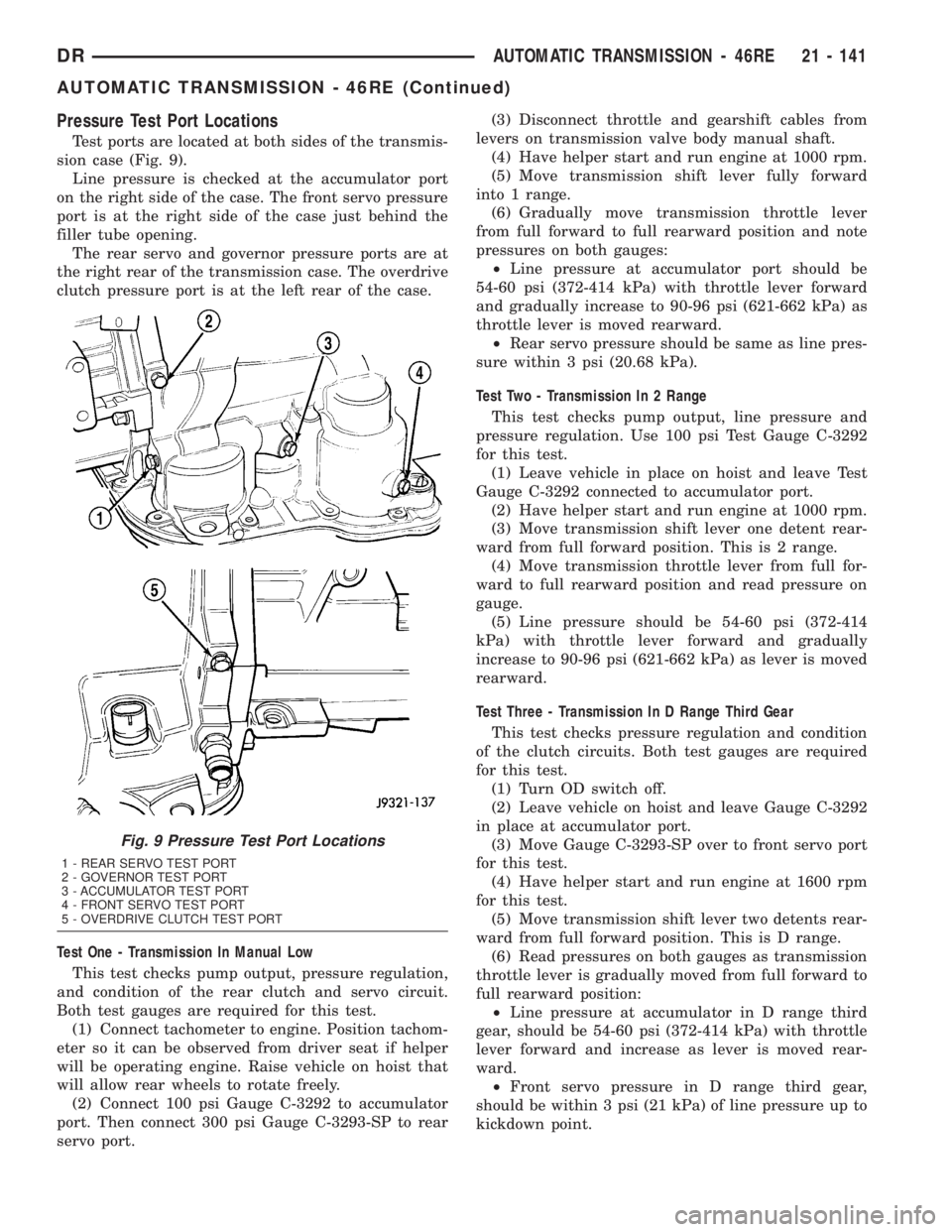

Pressure Test Port Locations

Test ports are located at both sides of the transmis-

sion case (Fig. 9).

Line pressure is checked at the accumulator port

on the right side of the case. The front servo pressure

port is at the right side of the case just behind the

filler tube opening.

The rear servo and governor pressure ports are at

the right rear of the transmission case. The overdrive

clutch pressure port is at the left rear of the case.

Test One - Transmission In Manual Low

This test checks pump output, pressure regulation,

and condition of the rear clutch and servo circuit.

Both test gauges are required for this test.

(1) Connect tachometer to engine. Position tachom-

eter so it can be observed from driver seat if helper

will be operating engine. Raise vehicle on hoist that

will allow rear wheels to rotate freely.

(2) Connect 100 psi Gauge C-3292 to accumulator

port. Then connect 300 psi Gauge C-3293-SP to rear

servo port.(3) Disconnect throttle and gearshift cables from

levers on transmission valve body manual shaft.

(4) Have helper start and run engine at 1000 rpm.

(5) Move transmission shift lever fully forward

into 1 range.

(6) Gradually move transmission throttle lever

from full forward to full rearward position and note

pressures on both gauges:

²Line pressure at accumulator port should be

54-60 psi (372-414 kPa) with throttle lever forward

and gradually increase to 90-96 psi (621-662 kPa) as

throttle lever is moved rearward.

²Rear servo pressure should be same as line pres-

sure within 3 psi (20.68 kPa).

Test Two - Transmission In 2 Range

This test checks pump output, line pressure and

pressure regulation. Use 100 psi Test Gauge C-3292

for this test.

(1) Leave vehicle in place on hoist and leave Test

Gauge C-3292 connected to accumulator port.

(2) Have helper start and run engine at 1000 rpm.

(3) Move transmission shift lever one detent rear-

ward from full forward position. This is 2 range.

(4) Move transmission throttle lever from full for-

ward to full rearward position and read pressure on

gauge.

(5) Line pressure should be 54-60 psi (372-414

kPa) with throttle lever forward and gradually

increase to 90-96 psi (621-662 kPa) as lever is moved

rearward.

Test Three - Transmission In D Range Third Gear

This test checks pressure regulation and condition

of the clutch circuits. Both test gauges are required

for this test.

(1) Turn OD switch off.

(2) Leave vehicle on hoist and leave Gauge C-3292

in place at accumulator port.

(3) Move Gauge C-3293-SP over to front servo port

for this test.

(4) Have helper start and run engine at 1600 rpm

for this test.

(5) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(6) Read pressures on both gauges as transmission

throttle lever is gradually moved from full forward to

full rearward position:

²Line pressure at accumulator in D range third

gear, should be 54-60 psi (372-414 kPa) with throttle

lever forward and increase as lever is moved rear-

ward.

²Front servo pressure in D range third gear,

should be within 3 psi (21 kPa) of line pressure up to

kickdown point.

Fig. 9 Pressure Test Port Locations

1 - REAR SERVO TEST PORT

2 - GOVERNOR TEST PORT

3 - ACCUMULATOR TEST PORT

4 - FRONT SERVO TEST PORT

5 - OVERDRIVE CLUTCH TEST PORT

DRAUTOMATIC TRANSMISSION - 46RE 21 - 141

AUTOMATIC TRANSMISSION - 46RE (Continued)