ABS DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1525 of 2895

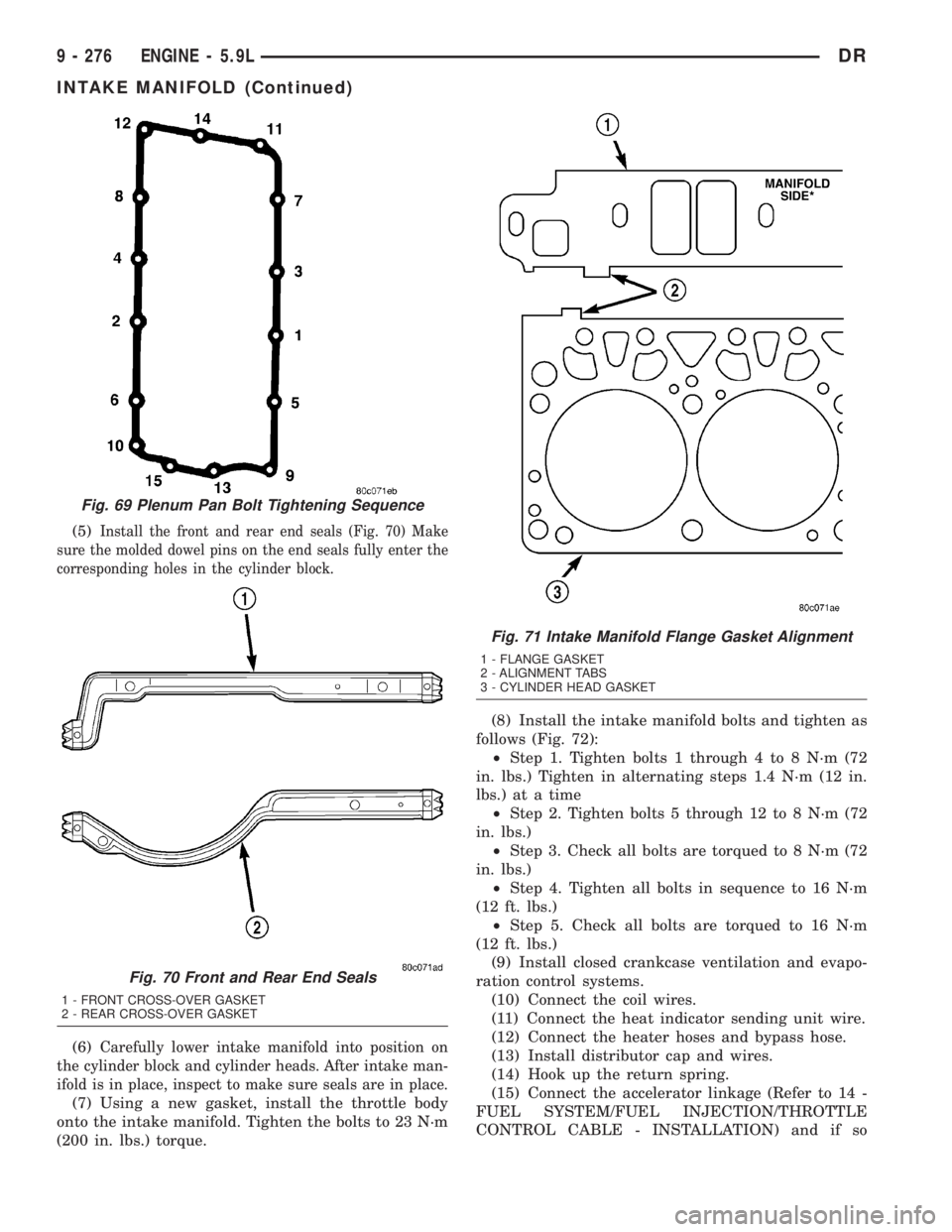

(5)Install the front and rear end seals (Fig. 70) Make

sure the molded dowel pins on the end seals fully enter the

corresponding holes in the cylinder block.

(6)Carefully lower intake manifold into position on

the cylinder block and cylinder heads. After intake man-

ifold is in place, inspect to make sure seals are in place.

(7) Using a new gasket, install the throttle body

onto the intake manifold. Tighten the bolts to 23 N´m

(200 in. lbs.) torque.(8) Install the intake manifold bolts and tighten as

follows (Fig. 72):

²Step 1. Tighten bolts 1 through 4 to 8 N´m (72

in. lbs.) Tighten in alternating steps 1.4 N´m (12 in.

lbs.) at a time

²Step 2. Tighten bolts 5 through 12 to 8 N´m (72

in. lbs.)

²Step 3. Check all bolts are torqued to 8 N´m (72

in. lbs.)

²Step 4. Tighten all bolts in sequence to 16 N´m

(12 ft. lbs.)

²Step 5. Check all bolts are torqued to 16 N´m

(12 ft. lbs.)

(9) Install closed crankcase ventilation and evapo-

ration control systems.

(10) Connect the coil wires.

(11) Connect the heat indicator sending unit wire.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Hook up the return spring.

(15) Connect the accelerator linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION) and if so

Fig. 69 Plenum Pan Bolt Tightening Sequence

Fig. 70 Front and Rear End Seals

1 - FRONT CROSS-OVER GASKET

2 - REAR CROSS-OVER GASKET

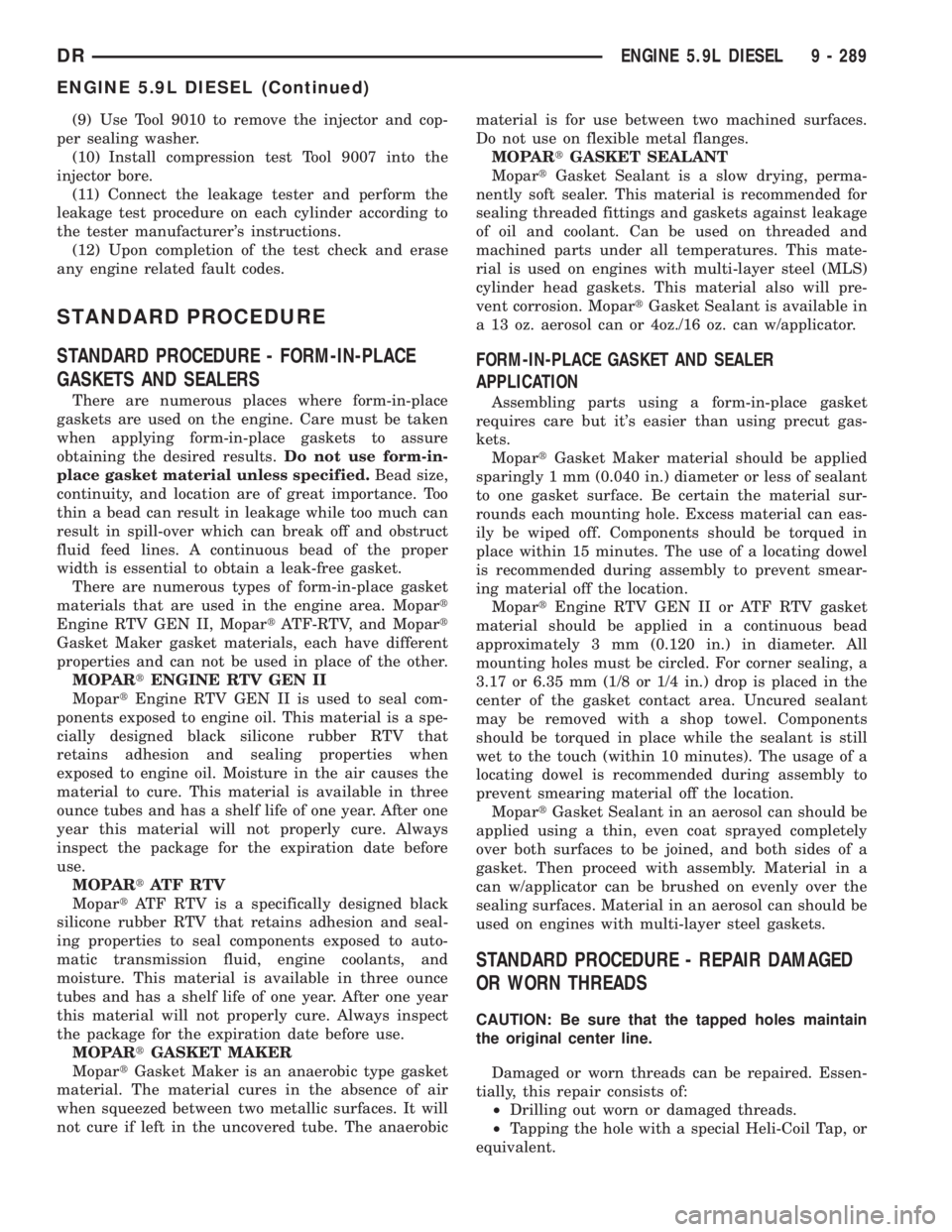

Fig. 71 Intake Manifold Flange Gasket Alignment

1 - FLANGE GASKET

2 - ALIGNMENT TABS

3 - CYLINDER HEAD GASKET

9 - 276 ENGINE - 5.9LDR

INTAKE MANIFOLD (Continued)

Page 1538 of 2895

(9) Use Tool 9010 to remove the injector and cop-

per sealing washer.

(10) Install compression test Tool 9007 into the

injector bore.

(11) Connect the leakage tester and perform the

leakage test procedure on each cylinder according to

the tester manufacturer's instructions.

(12) Upon completion of the test check and erase

any engine related fault codes.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobicmaterial is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

DRENGINE 5.9L DIESEL 9 - 289

ENGINE 5.9L DIESEL (Continued)

Page 1547 of 2895

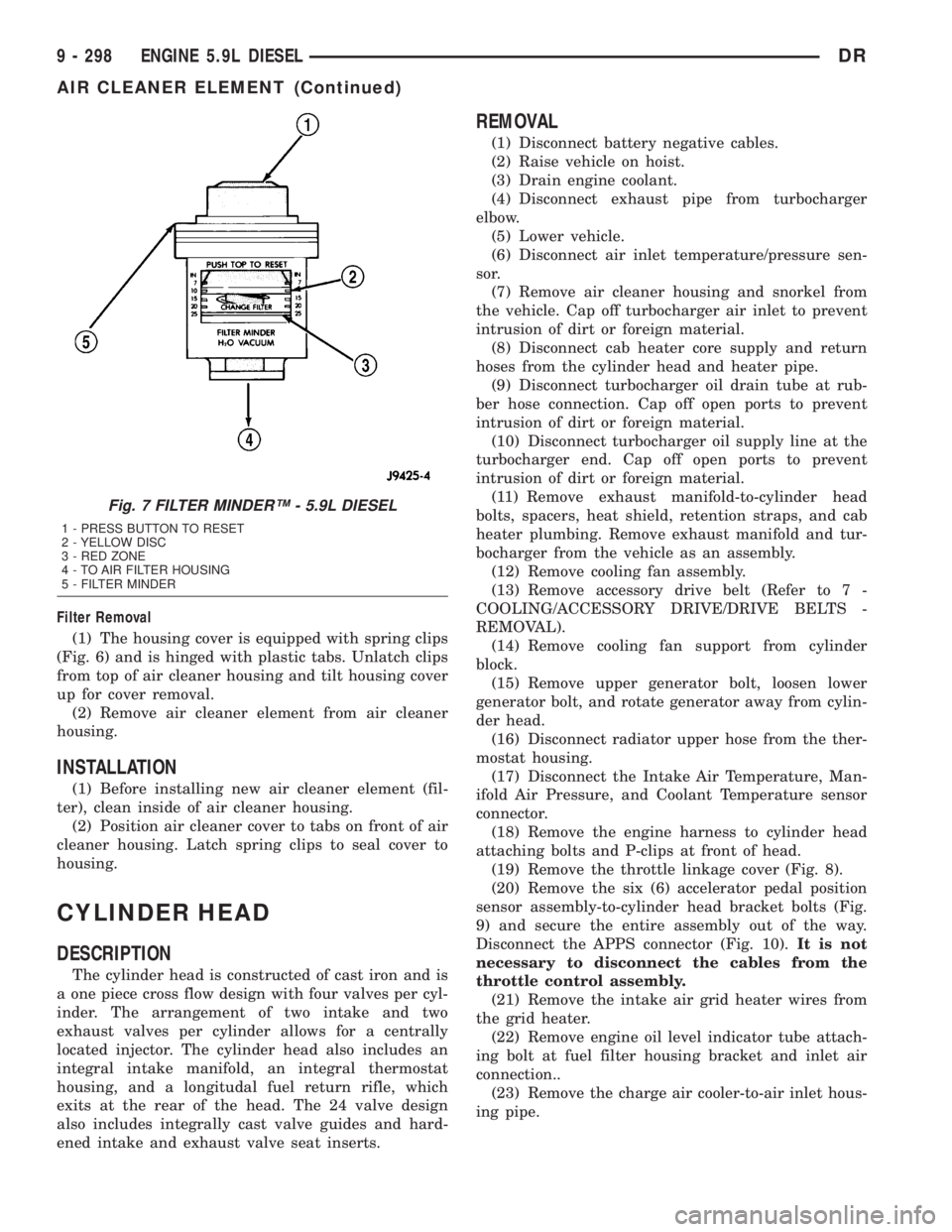

Filter Removal

(1) The housing cover is equipped with spring clips

(Fig. 6) and is hinged with plastic tabs. Unlatch clips

from top of air cleaner housing and tilt housing cover

up for cover removal.

(2) Remove air cleaner element from air cleaner

housing.

INSTALLATION

(1) Before installing new air cleaner element (fil-

ter), clean inside of air cleaner housing.

(2) Position air cleaner cover to tabs on front of air

cleaner housing. Latch spring clips to seal cover to

housing.

CYLINDER HEAD

DESCRIPTION

The cylinder head is constructed of cast iron and is

a one piece cross flow design with four valves per cyl-

inder. The arrangement of two intake and two

exhaust valves per cylinder allows for a centrally

located injector. The cylinder head also includes an

integral intake manifold, an integral thermostat

housing, and a longitudal fuel return rifle, which

exits at the rear of the head. The 24 valve design

also includes integrally cast valve guides and hard-

ened intake and exhaust valve seat inserts.

REMOVAL

(1) Disconnect battery negative cables.

(2) Raise vehicle on hoist.

(3) Drain engine coolant.

(4) Disconnect exhaust pipe from turbocharger

elbow.

(5) Lower vehicle.

(6) Disconnect air inlet temperature/pressure sen-

sor.

(7) Remove air cleaner housing and snorkel from

the vehicle. Cap off turbocharger air inlet to prevent

intrusion of dirt or foreign material.

(8) Disconnect cab heater core supply and return

hoses from the cylinder head and heater pipe.

(9) Disconnect turbocharger oil drain tube at rub-

ber hose connection. Cap off open ports to prevent

intrusion of dirt or foreign material.

(10) Disconnect turbocharger oil supply line at the

turbocharger end. Cap off open ports to prevent

intrusion of dirt or foreign material.

(11) Remove exhaust manifold-to-cylinder head

bolts, spacers, heat shield, retention straps, and cab

heater plumbing. Remove exhaust manifold and tur-

bocharger from the vehicle as an assembly.

(12) Remove cooling fan assembly.

(13) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(14) Remove cooling fan support from cylinder

block.

(15) Remove upper generator bolt, loosen lower

generator bolt, and rotate generator away from cylin-

der head.

(16) Disconnect radiator upper hose from the ther-

mostat housing.

(17) Disconnect the Intake Air Temperature, Man-

ifold Air Pressure, and Coolant Temperature sensor

connector.

(18) Remove the engine harness to cylinder head

attaching bolts and P-clips at front of head.

(19) Remove the throttle linkage cover (Fig. 8).

(20) Remove the six (6) accelerator pedal position

sensor assembly-to-cylinder head bracket bolts (Fig.

9) and secure the entire assembly out of the way.

Disconnect the APPS connector (Fig. 10).It is not

necessary to disconnect the cables from the

throttle control assembly.

(21) Remove the intake air grid heater wires from

the grid heater.

(22) Remove engine oil level indicator tube attach-

ing bolt at fuel filter housing bracket and inlet air

connection..

(23) Remove the charge air cooler-to-air inlet hous-

ing pipe.

Fig. 7 FILTER MINDERŸ - 5.9L DIESEL

1 - PRESS BUTTON TO RESET

2 - YELLOW DISC

3 - RED ZONE

4 - TO AIR FILTER HOUSING

5 - FILTER MINDER

9 - 298 ENGINE 5.9L DIESELDR

AIR CLEANER ELEMENT (Continued)

Page 1610 of 2895

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

REMOVAL

(1) Remove the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

DRENGINE 8.0L 9 - 361

ENGINE 8.0L (Continued)

Page 1619 of 2895

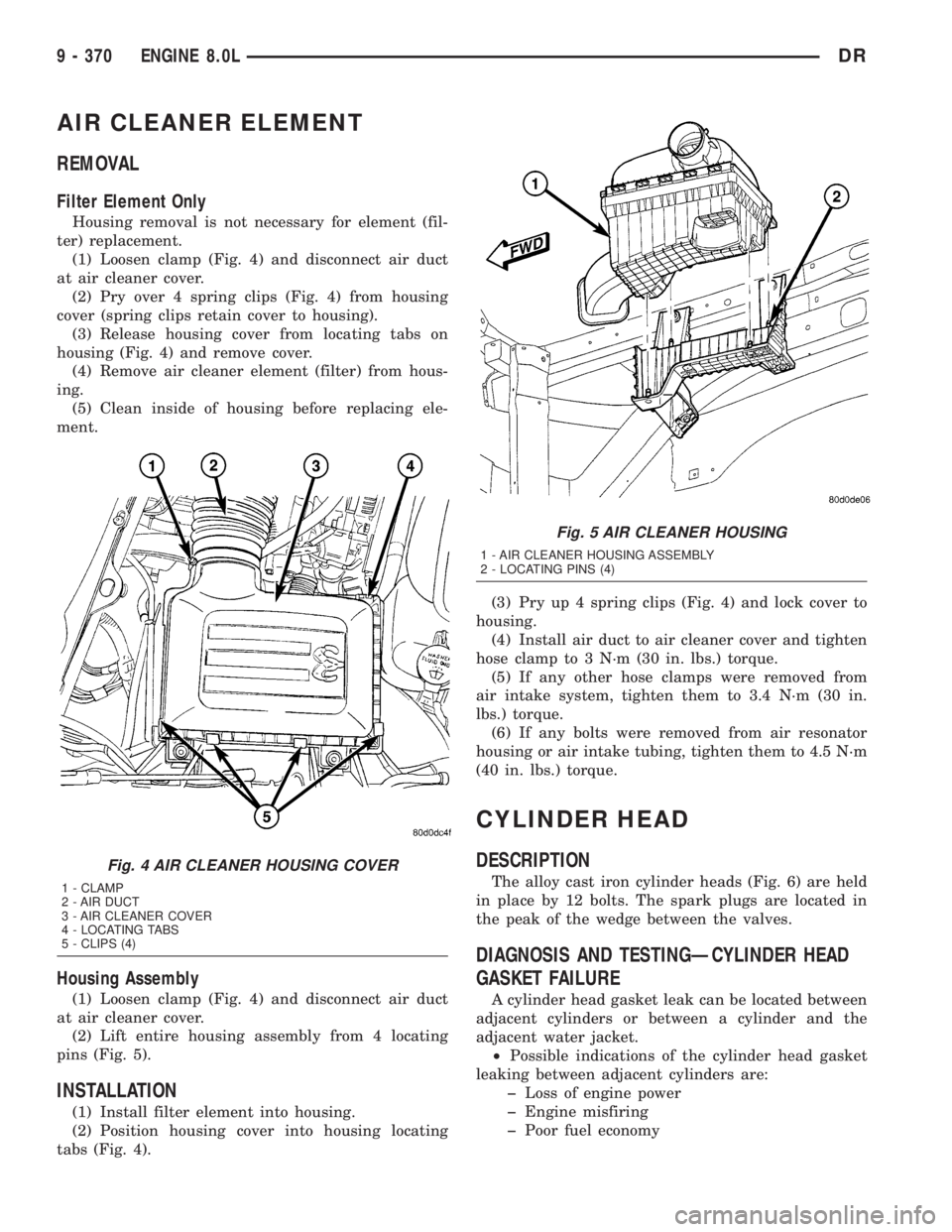

AIR CLEANER ELEMENT

REMOVAL

Filter Element Only

Housing removal is not necessary for element (fil-

ter) replacement.

(1) Loosen clamp (Fig. 4) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 4) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 4) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

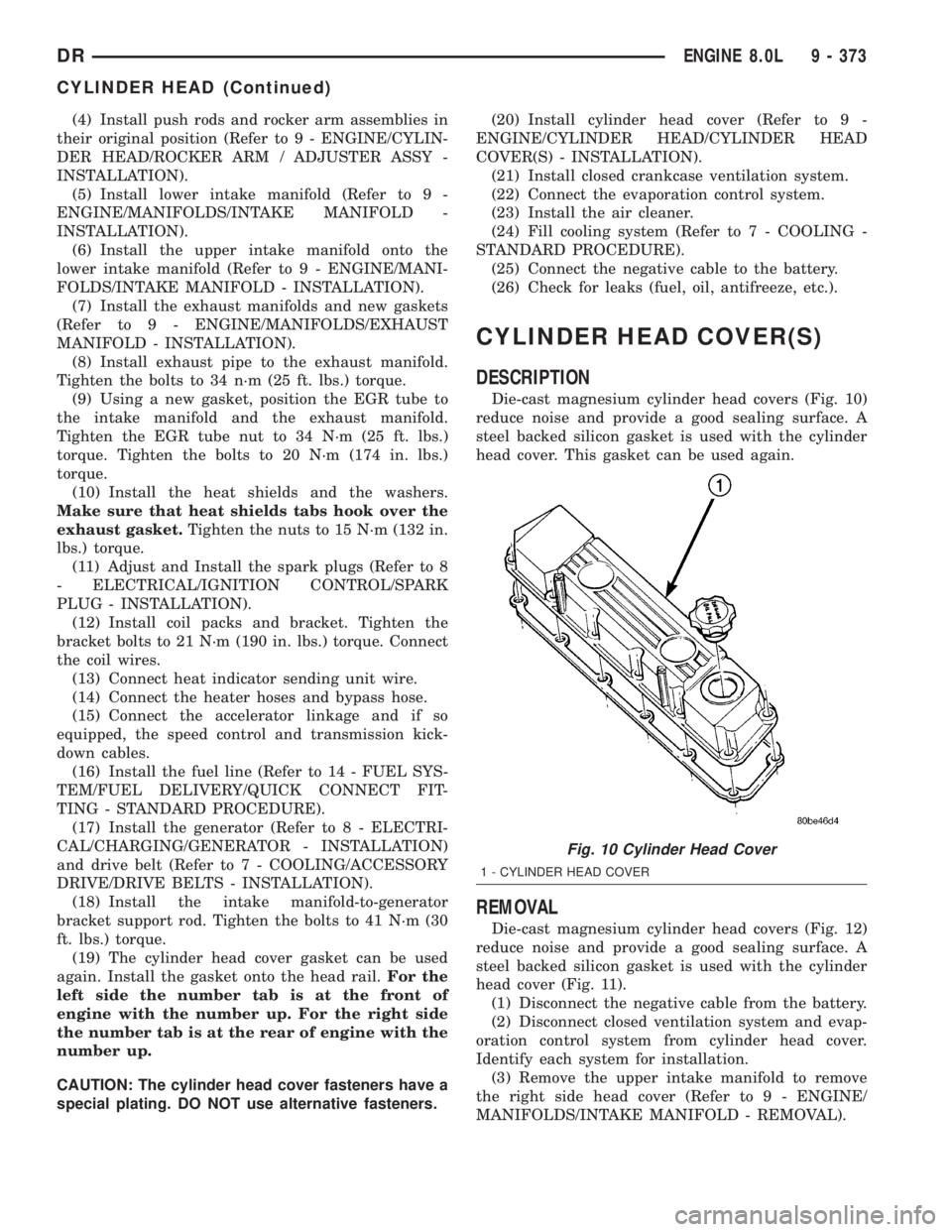

Housing Assembly

(1) Loosen clamp (Fig. 4) and disconnect air duct

at air cleaner cover.

(2) Lift entire housing assembly from 4 locating

pins (Fig. 5).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 4).(3) Pry up 4 spring clips (Fig. 4) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD

DESCRIPTION

The alloy cast iron cylinder heads (Fig. 6) are held

in place by 12 bolts. The spark plugs are located in

the peak of the wedge between the valves.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

þ Loss of engine power

þ Engine misfiring

þ Poor fuel economy

Fig. 4 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 5 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

9 - 370 ENGINE 8.0LDR

Page 1622 of 2895

(4) Install push rods and rocker arm assemblies in

their original position (Refer to 9 - ENGINE/CYLIN-

DER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

(5) Install lower intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(6) Install the upper intake manifold onto the

lower intake manifold (Refer to 9 - ENGINE/MANI-

FOLDS/INTAKE MANIFOLD - INSTALLATION).

(7) Install the exhaust manifolds and new gaskets

(Refer to 9 - ENGINE/MANIFOLDS/EXHAUST

MANIFOLD - INSTALLATION).

(8) Install exhaust pipe to the exhaust manifold.

Tighten the bolts to 34 n´m (25 ft. lbs.) torque.

(9) Using a new gasket, position the EGR tube to

the intake manifold and the exhaust manifold.

Tighten the EGR tube nut to 34 N´m (25 ft. lbs.)

torque. Tighten the bolts to 20 N´m (174 in. lbs.)

torque.

(10) Install the heat shields and the washers.

Make sure that heat shields tabs hook over the

exhaust gasket.Tighten the nuts to 15 N´m (132 in.

lbs.) torque.

(11) Adjust and Install the spark plugs (Refer to 8

- ELECTRICAL/IGNITION CONTROL/SPARK

PLUG - INSTALLATION).

(12) Install coil packs and bracket. Tighten the

bracket bolts to 21 N´m (190 in. lbs.) torque. Connect

the coil wires.

(13) Connect heat indicator sending unit wire.

(14) Connect the heater hoses and bypass hose.

(15) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(16) Install the fuel line (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(17) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION)

and drive belt (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - INSTALLATION).

(18) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts to 41 N´m (30

ft. lbs.) torque.

(19) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

CAUTION: The cylinder head cover fasteners have a

special plating. DO NOT use alternative fasteners.(20) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(21) Install closed crankcase ventilation system.

(22) Connect the evaporation control system.

(23) Install the air cleaner.

(24) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(25) Connect the negative cable to the battery.

(26) Check for leaks (fuel, oil, antifreeze, etc.).

CYLINDER HEAD COVER(S)

DESCRIPTION

Die-cast magnesium cylinder head covers (Fig. 10)

reduce noise and provide a good sealing surface. A

steel backed silicon gasket is used with the cylinder

head cover. This gasket can be used again.

REMOVAL

Die-cast magnesium cylinder head covers (Fig. 12)

reduce noise and provide a good sealing surface. A

steel backed silicon gasket is used with the cylinder

head cover (Fig. 11).

(1) Disconnect the negative cable from the battery.

(2) Disconnect closed ventilation system and evap-

oration control system from cylinder head cover.

Identify each system for installation.

(3) Remove the upper intake manifold to remove

the right side head cover (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

Fig. 10 Cylinder Head Cover

1 - CYLINDER HEAD COVER

DRENGINE 8.0L 9 - 373

CYLINDER HEAD (Continued)

Page 1653 of 2895

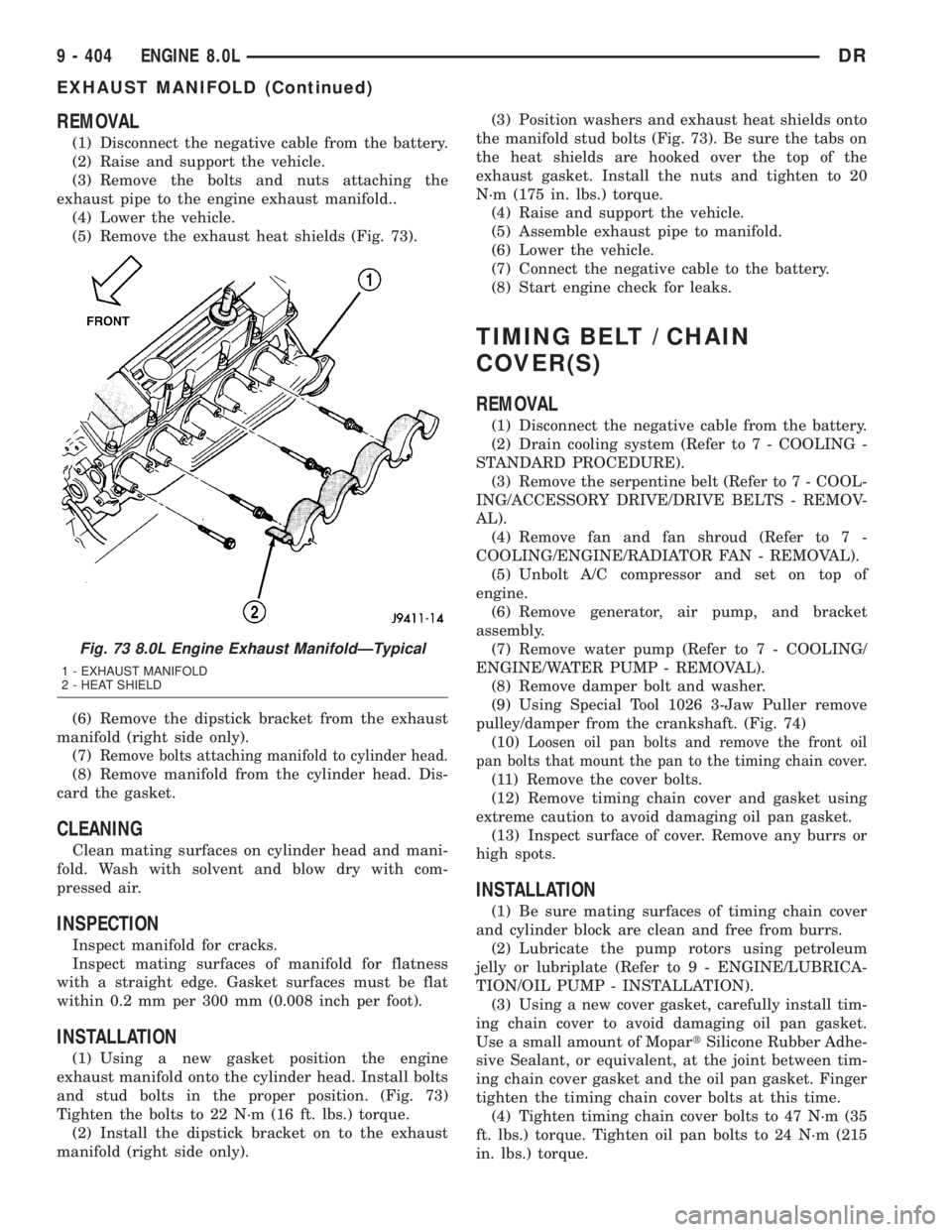

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold..

(4) Lower the vehicle.

(5) Remove the exhaust heat shields (Fig. 73).

(6) Remove the dipstick bracket from the exhaust

manifold (right side only).

(7)

Remove bolts attaching manifold to cylinder head.

(8) Remove manifold from the cylinder head. Dis-

card the gasket.

CLEANING

Clean mating surfaces on cylinder head and mani-

fold. Wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

(1) Using a new gasket position the engine

exhaust manifold onto the cylinder head. Install bolts

and stud bolts in the proper position. (Fig. 73)

Tighten the bolts to 22 N´m (16 ft. lbs.) torque.

(2) Install the dipstick bracket on to the exhaust

manifold (right side only).(3) Position washers and exhaust heat shields onto

the manifold stud bolts (Fig. 73). Be sure the tabs on

the heat shields are hooked over the top of the

exhaust gasket. Install the nuts and tighten to 20

N´m (175 in. lbs.) torque.

(4) Raise and support the vehicle.

(5) Assemble exhaust pipe to manifold.

(6) Lower the vehicle.

(7) Connect the negative cable to the battery.

(8) Start engine check for leaks.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(4) Remove fan and fan shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(5) Unbolt A/C compressor and set on top of

engine.

(6) Remove generator, air pump, and bracket

assembly.

(7) Remove water pump (Refer to 7 - COOLING/

ENGINE/WATER PUMP - REMOVAL).

(8) Remove damper bolt and washer.

(9) Using Special Tool 1026 3-Jaw Puller remove

pulley/damper from the crankshaft. (Fig. 74)

(10)

Loosen oil pan bolts and remove the front oil

pan bolts that mount the pan to the timing chain cover.

(11) Remove the cover bolts.

(12) Remove timing chain cover and gasket using

extreme caution to avoid damaging oil pan gasket.

(13) Inspect surface of cover. Remove any burrs or

high spots.

INSTALLATION

(1) Be sure mating surfaces of timing chain cover

and cylinder block are clean and free from burrs.

(2) Lubricate the pump rotors using petroleum

jelly or lubriplate (Refer to 9 - ENGINE/LUBRICA-

TION/OIL PUMP - INSTALLATION).

(3) Using a new cover gasket, carefully install tim-

ing chain cover to avoid damaging oil pan gasket.

Use a small amount of MopartSilicone Rubber Adhe-

sive Sealant, or equivalent, at the joint between tim-

ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.

(4) Tighten timing chain cover bolts to 47 N´m (35

ft. lbs.) torque. Tighten oil pan bolts to 24 N´m (215

in. lbs.) torque.

Fig. 73 8.0L Engine Exhaust ManifoldÐTypical

1 - EXHAUST MANIFOLD

2 - HEAT SHIELD

9 - 404 ENGINE 8.0LDR

EXHAUST MANIFOLD (Continued)

Page 1686 of 2895

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

²BEFORE PROCEEDING WITH FRAME REPAIR

INVOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

²DO NOT ALLOW OPEN FLAME OR HEAT AND

METAL SPATTER FROM ARC WELDING, TO CON-

TACT PLASTIC BODY PANELS. FIRE OR EXPLO-

SION CAN RESULT.

²WHEN WELDED FRAME COMPONENTS ARE

REPLACED, ENSURE COMPLETE PENETRATION

WELD IS ACHIEVED DURING INSTALLATION. IF

NOT, DANGEROUS OPERATING CONDITIONS CAN

RESULT.

²STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN

RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT SUPPORTED ON SAFETY

STANDS, PERSONAL INJURY CAN RESULT.

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect. Failure to use only pro-

duction fasteners or fasteners of equivalent hard-

ness can result in loosening or failure. Do not drill

holes in top or bottom frame rail flanges, frame rail

failure can result. When using heat to straighten

frame components do not exceed 566ÉC (1050ÉF),

metal fatigue can result.

CAUTION: This procedure is designed to replace

the H-section/spare tire support located at the rear

of the frame assembly. Prior to any cutting, the

vehicle must be mounted on the appropriate frame

repair equipment (ªframe rackº), checked with three

dimensional measuring equipment, and the neces-

sary pull corrections made. If damage remains in

the frame beyond the area covered by this service

part after the pull, the frame must be replaced in its

entirety.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cargo box. (Refer to 23 - BODY/EX-

TERIOR/CARGO BOX - REMOVAL)(3) Remove the trailer hitch. (Refer to 13 - FRAME

& BUMPERS/FRAME/TRAILER HITCH -

REMOVAL)

(4) Raise and support the frame so the tires are off

floor.

(5) Remove the shock absorbers. (Refer to 2 - SUS-

PENSION/REAR/SHOCK - REMOVAL)

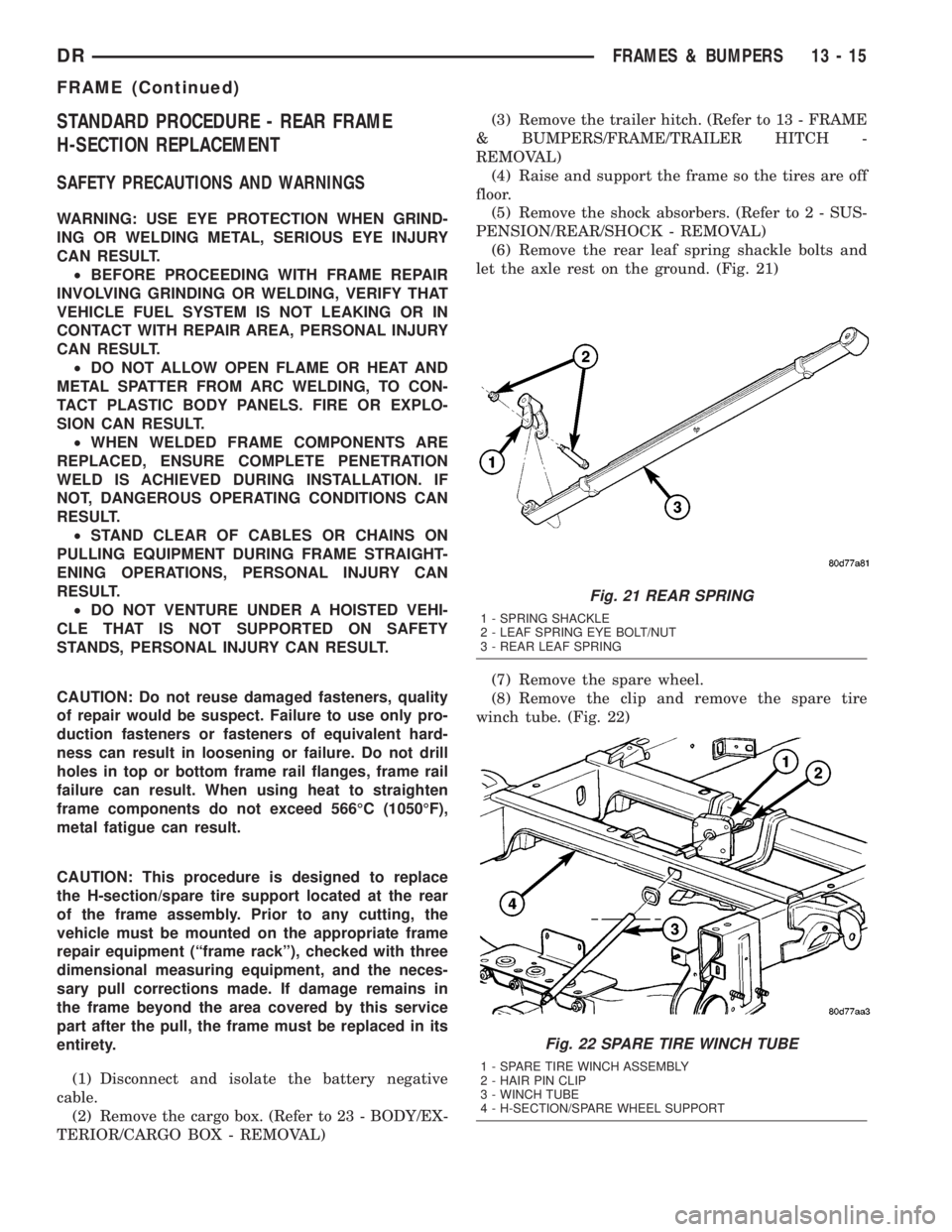

(6) Remove the rear leaf spring shackle bolts and

let the axle rest on the ground. (Fig. 21)

(7) Remove the spare wheel.

(8) Remove the clip and remove the spare tire

winch tube. (Fig. 22)

Fig. 21 REAR SPRING

1 - SPRING SHACKLE

2 - LEAF SPRING EYE BOLT/NUT

3 - REAR LEAF SPRING

Fig. 22 SPARE TIRE WINCH TUBE

1 - SPARE TIRE WINCH ASSEMBLY

2 - HAIR PIN CLIP

3 - WINCH TUBE

4 - H-SECTION/SPARE WHEEL SUPPORT

DRFRAMES & BUMPERS 13 - 15

FRAME (Continued)

Page 1687 of 2895

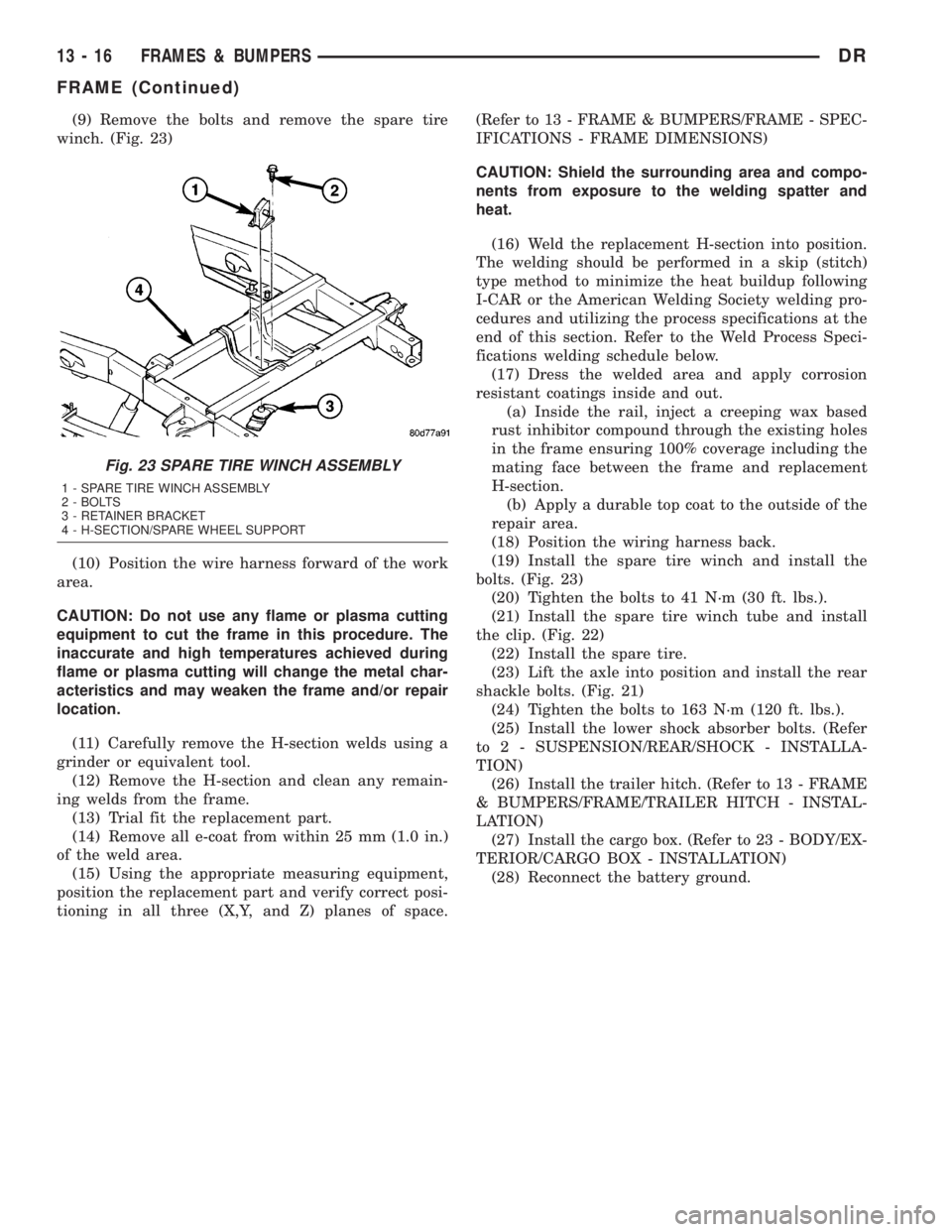

(9) Remove the bolts and remove the spare tire

winch. (Fig. 23)

(10) Position the wire harness forward of the work

area.

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. The

inaccurate and high temperatures achieved during

flame or plasma cutting will change the metal char-

acteristics and may weaken the frame and/or repair

location.

(11) Carefully remove the H-section welds using a

grinder or equivalent tool.

(12) Remove the H-section and clean any remain-

ing welds from the frame.

(13) Trial fit the replacement part.

(14) Remove all e-coat from within 25 mm (1.0 in.)

of the weld area.

(15) Using the appropriate measuring equipment,

position the replacement part and verify correct posi-

tioning in all three (X,Y, and Z) planes of space.(Refer to 13 - FRAME & BUMPERS/FRAME - SPEC-

IFICATIONS - FRAME DIMENSIONS)

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

(16) Weld the replacement H-section into position.

The welding should be performed in a skip (stitch)

type method to minimize the heat buildup following

I-CAR or the American Welding Society welding pro-

cedures and utilizing the process specifications at the

end of this section. Refer to the Weld Process Speci-

fications welding schedule below.

(17) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Inside the rail, inject a creeping wax based

rust inhibitor compound through the existing holes

in the frame ensuring 100% coverage including the

mating face between the frame and replacement

H-section.

(b) Apply a durable top coat to the outside of the

repair area.

(18) Position the wiring harness back.

(19) Install the spare tire winch and install the

bolts. (Fig. 23)

(20) Tighten the bolts to 41 N´m (30 ft. lbs.).

(21) Install the spare tire winch tube and install

the clip. (Fig. 22)

(22) Install the spare tire.

(23) Lift the axle into position and install the rear

shackle bolts. (Fig. 21)

(24) Tighten the bolts to 163 N´m (120 ft. lbs.).

(25) Install the lower shock absorber bolts. (Refer

to 2 - SUSPENSION/REAR/SHOCK - INSTALLA-

TION)

(26) Install the trailer hitch. (Refer to 13 - FRAME

& BUMPERS/FRAME/TRAILER HITCH - INSTAL-

LATION)

(27) Install the cargo box. (Refer to 23 - BODY/EX-

TERIOR/CARGO BOX - INSTALLATION)

(28) Reconnect the battery ground.

Fig. 23 SPARE TIRE WINCH ASSEMBLY

1 - SPARE TIRE WINCH ASSEMBLY

2 - BOLTS

3 - RETAINER BRACKET

4 - H-SECTION/SPARE WHEEL SUPPORT

13 - 16 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1695 of 2895

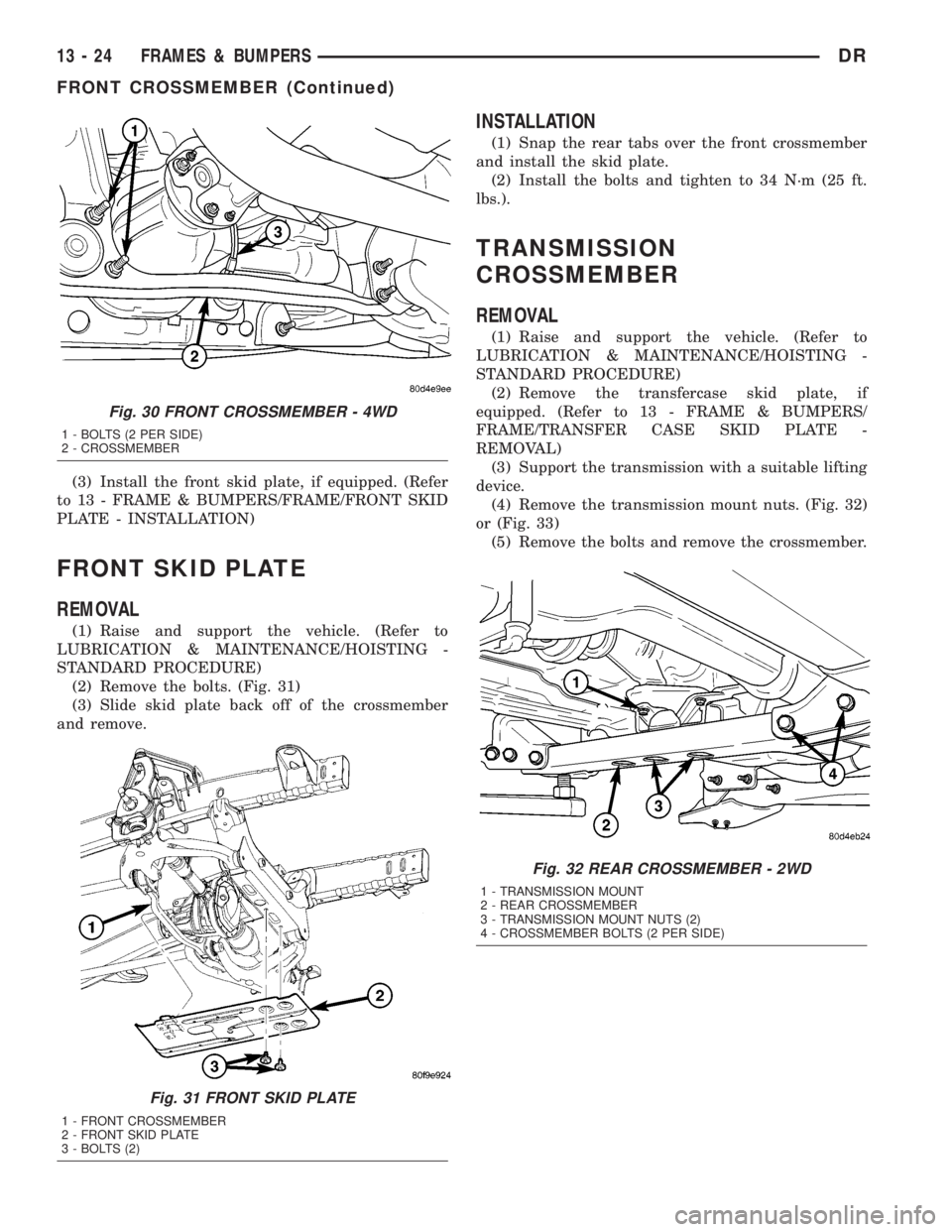

(3) Install the front skid plate, if equipped. (Refer

to 13 - FRAME & BUMPERS/FRAME/FRONT SKID

PLATE - INSTALLATION)

FRONT SKID PLATE

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the bolts. (Fig. 31)

(3) Slide skid plate back off of the crossmember

and remove.

INSTALLATION

(1) Snap the rear tabs over the front crossmember

and install the skid plate.

(2) Install the bolts and tighten to 34 N´m (25 ft.

lbs.).

TRANSMISSION

CROSSMEMBER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove the transfercase skid plate, if

equipped. (Refer to 13 - FRAME & BUMPERS/

FRAME/TRANSFER CASE SKID PLATE -

REMOVAL)

(3) Support the transmission with a suitable lifting

device.

(4) Remove the transmission mount nuts. (Fig. 32)

or (Fig. 33)

(5) Remove the bolts and remove the crossmember.

Fig. 30 FRONT CROSSMEMBER - 4WD

1 - BOLTS (2 PER SIDE)

2 - CROSSMEMBER

Fig. 31 FRONT SKID PLATE

1 - FRONT CROSSMEMBER

2 - FRONT SKID PLATE

3 - BOLTS (2)

Fig. 32 REAR CROSSMEMBER - 2WD

1 - TRANSMISSION MOUNT

2 - REAR CROSSMEMBER

3 - TRANSMISSION MOUNT NUTS (2)

4 - CROSSMEMBER BOLTS (2 PER SIDE)

13 - 24 FRAMES & BUMPERSDR

FRONT CROSSMEMBER (Continued)