ABS DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1177 of 2895

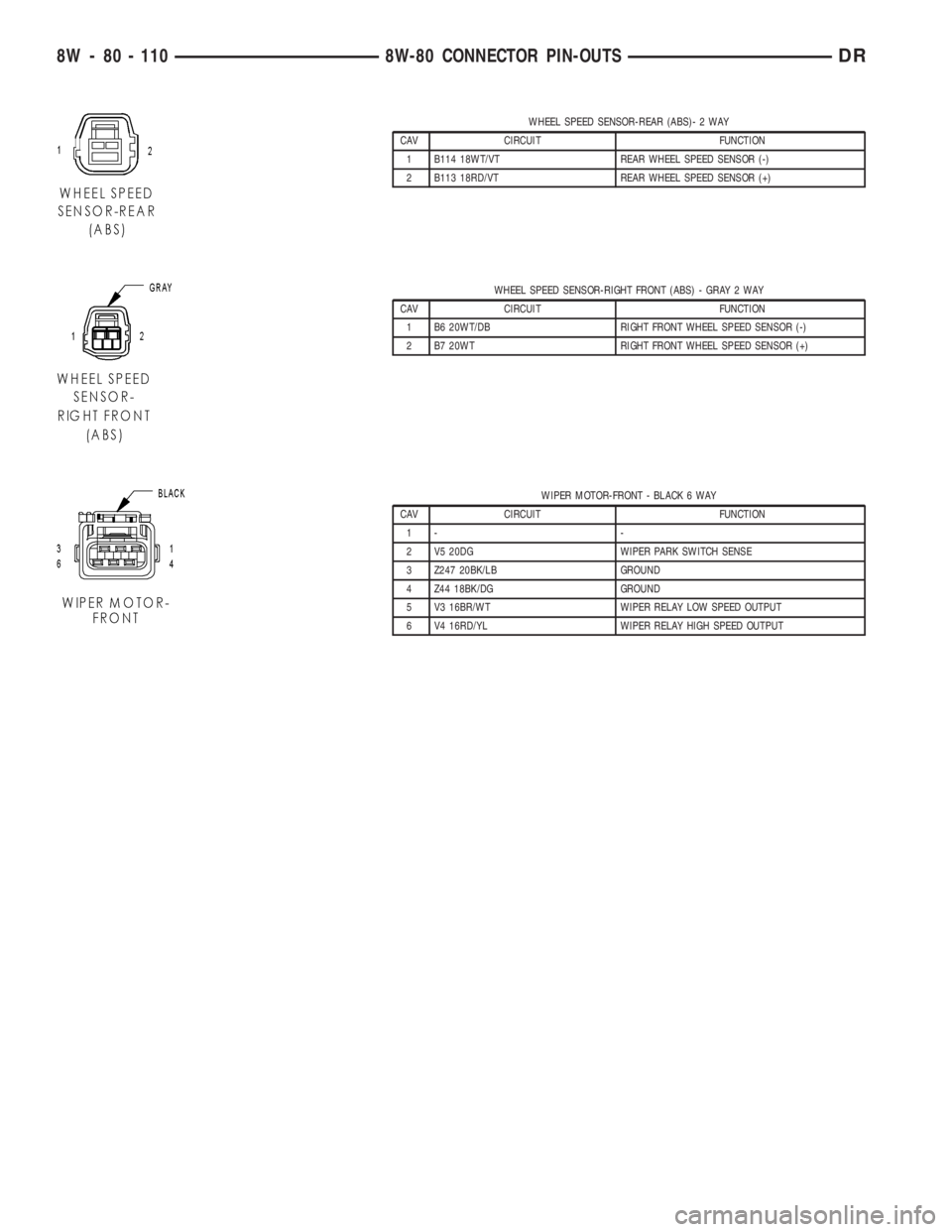

WHEEL SPEED SENSOR-REAR (ABS)- 2 WAY

CAV CIRCUIT FUNCTION

1 B114 18WT/VT REAR WHEEL SPEED SENSOR (-)

2 B113 18RD/VT REAR WHEEL SPEED SENSOR (+)

WHEEL SPEED SENSOR-RIGHT FRONT (ABS) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 B6 20WT/DB RIGHT FRONT WHEEL SPEED SENSOR (-)

2 B7 20WT RIGHT FRONT WHEEL SPEED SENSOR (+)

WIPER MOTOR-FRONT - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1- -

2 V5 20DG WIPER PARK SWITCH SENSE

3 Z247 20BK/LB GROUND

4 Z44 18BK/DG GROUND

5 V3 16BR/WT WIPER RELAY LOW SPEED OUTPUT

6 V4 16RD/YL WIPER RELAY HIGH SPEED OUTPUT

8W - 80 - 110 8W-80 CONNECTOR PIN-OUTSDR

Page 1180 of 2895

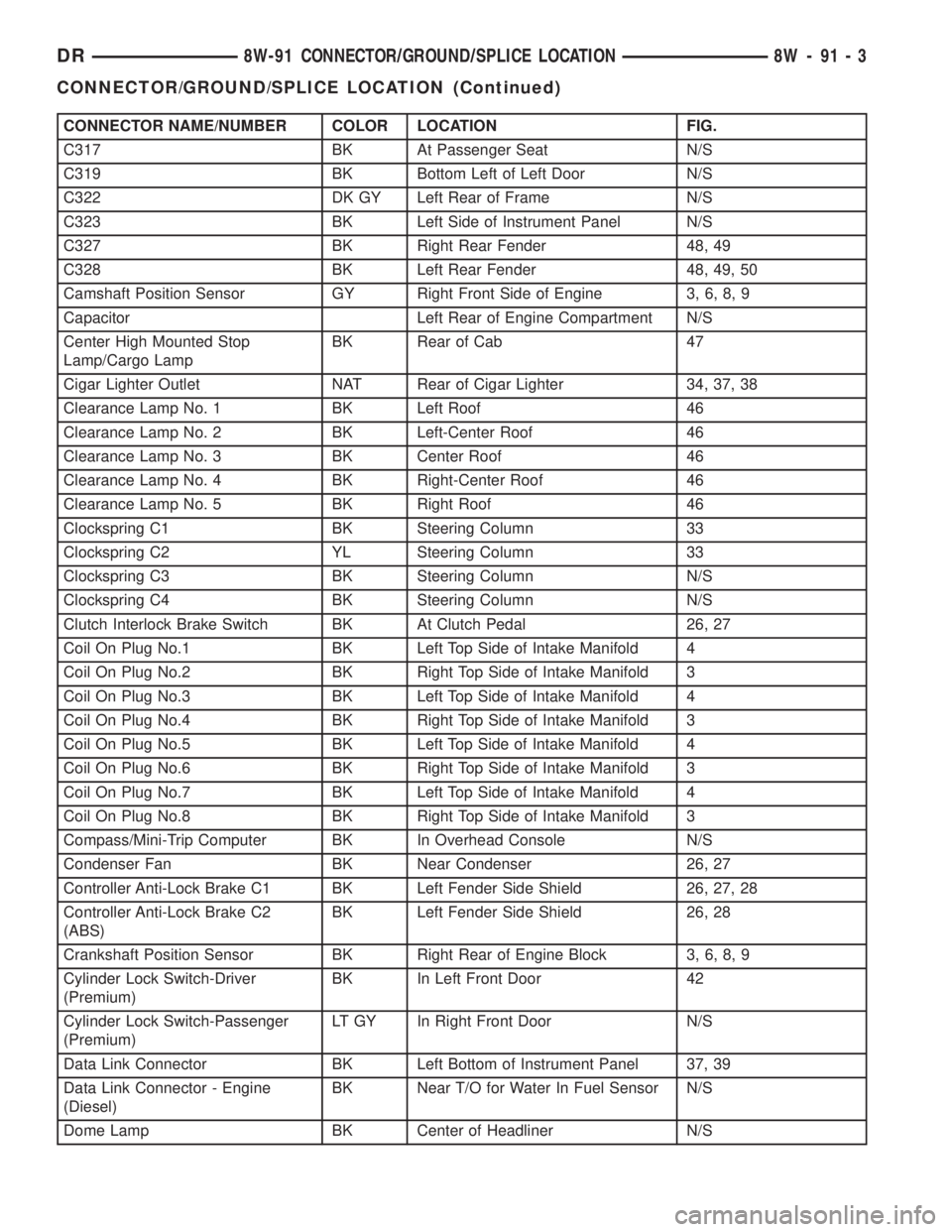

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C317 BK At Passenger Seat N/S

C319 BK Bottom Left of Left Door N/S

C322 DK GY Left Rear of Frame N/S

C323 BK Left Side of Instrument Panel N/S

C327 BK Right Rear Fender 48, 49

C328 BK Left Rear Fender 48, 49, 50

Camshaft Position Sensor GY Right Front Side of Engine 3, 6, 8, 9

Capacitor Left Rear of Engine Compartment N/S

Center High Mounted Stop

Lamp/Cargo LampBK Rear of Cab 47

Cigar Lighter Outlet NAT Rear of Cigar Lighter 34, 37, 38

Clearance Lamp No. 1 BK Left Roof 46

Clearance Lamp No. 2 BK Left-Center Roof 46

Clearance Lamp No. 3 BK Center Roof 46

Clearance Lamp No. 4 BK Right-Center Roof 46

Clearance Lamp No. 5 BK Right Roof 46

Clockspring C1 BK Steering Column 33

Clockspring C2 YL Steering Column 33

Clockspring C3 BK Steering Column N/S

Clockspring C4 BK Steering Column N/S

Clutch Interlock Brake Switch BK At Clutch Pedal 26, 27

Coil On Plug No.1 BK Left Top Side of Intake Manifold 4

Coil On Plug No.2 BK Right Top Side of Intake Manifold 3

Coil On Plug No.3 BK Left Top Side of Intake Manifold 4

Coil On Plug No.4 BK Right Top Side of Intake Manifold 3

Coil On Plug No.5 BK Left Top Side of Intake Manifold 4

Coil On Plug No.6 BK Right Top Side of Intake Manifold 3

Coil On Plug No.7 BK Left Top Side of Intake Manifold 4

Coil On Plug No.8 BK Right Top Side of Intake Manifold 3

Compass/Mini-Trip Computer BK In Overhead Console N/S

Condenser Fan BK Near Condenser 26, 27

Controller Anti-Lock Brake C1 BK Left Fender Side Shield 26, 27, 28

Controller Anti-Lock Brake C2

(ABS)BK Left Fender Side Shield 26, 28

Crankshaft Position Sensor BK Right Rear of Engine Block 3, 6, 8, 9

Cylinder Lock Switch-Driver

(Premium)BK In Left Front Door 42

Cylinder Lock Switch-Passenger

(Premium)LT GY In Right Front Door N/S

Data Link Connector BK Left Bottom of Instrument Panel 37, 39

Data Link Connector - Engine

(Diesel)BK Near T/O for Water In Fuel Sensor N/S

Dome Lamp BK Center of Headliner N/S

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1182 of 2895

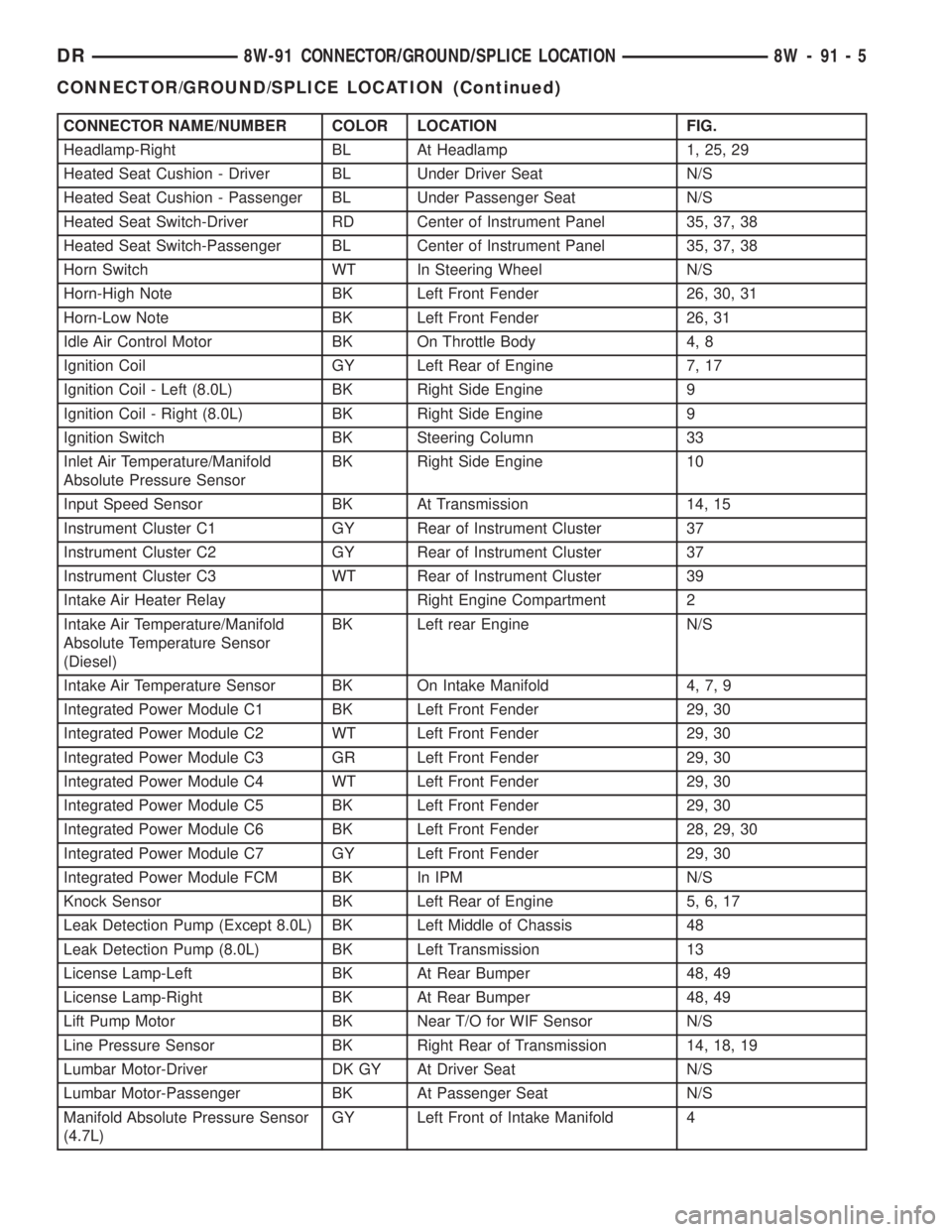

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Headlamp-Right BL At Headlamp 1, 25, 29

Heated Seat Cushion - Driver BL Under Driver Seat N/S

Heated Seat Cushion - Passenger BL Under Passenger Seat N/S

Heated Seat Switch-Driver RD Center of Instrument Panel 35, 37, 38

Heated Seat Switch-Passenger BL Center of Instrument Panel 35, 37, 38

Horn Switch WT In Steering Wheel N/S

Horn-High Note BK Left Front Fender 26, 30, 31

Horn-Low Note BK Left Front Fender 26, 31

Idle Air Control Motor BK On Throttle Body 4, 8

Ignition Coil GY Left Rear of Engine 7, 17

Ignition Coil - Left (8.0L) BK Right Side Engine 9

Ignition Coil - Right (8.0L) BK Right Side Engine 9

Ignition Switch BK Steering Column 33

Inlet Air Temperature/Manifold

Absolute Pressure SensorBK Right Side Engine 10

Input Speed Sensor BK At Transmission 14, 15

Instrument Cluster C1 GY Rear of Instrument Cluster 37

Instrument Cluster C2 GY Rear of Instrument Cluster 37

Instrument Cluster C3 WT Rear of Instrument Cluster 39

Intake Air Heater Relay Right Engine Compartment 2

Intake Air Temperature/Manifold

Absolute Temperature Sensor

(Diesel)BK Left rear Engine N/S

Intake Air Temperature Sensor BK On Intake Manifold 4, 7, 9

Integrated Power Module C1 BK Left Front Fender 29, 30

Integrated Power Module C2 WT Left Front Fender 29, 30

Integrated Power Module C3 GR Left Front Fender 29, 30

Integrated Power Module C4 WT Left Front Fender 29, 30

Integrated Power Module C5 BK Left Front Fender 29, 30

Integrated Power Module C6 BK Left Front Fender 28, 29, 30

Integrated Power Module C7 GY Left Front Fender 29, 30

Integrated Power Module FCM BK In IPM N/S

Knock Sensor BK Left Rear of Engine 5, 6, 17

Leak Detection Pump (Except 8.0L) BK Left Middle of Chassis 48

Leak Detection Pump (8.0L) BK Left Transmission 13

License Lamp-Left BK At Rear Bumper 48, 49

License Lamp-Right BK At Rear Bumper 48, 49

Lift Pump Motor BK Near T/O for WIF Sensor N/S

Line Pressure Sensor BK Right Rear of Transmission 14, 18, 19

Lumbar Motor-Driver DK GY At Driver Seat N/S

Lumbar Motor-Passenger BK At Passenger Seat N/S

Manifold Absolute Pressure Sensor

(4.7L)GY Left Front of Intake Manifold 4

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 5

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1183 of 2895

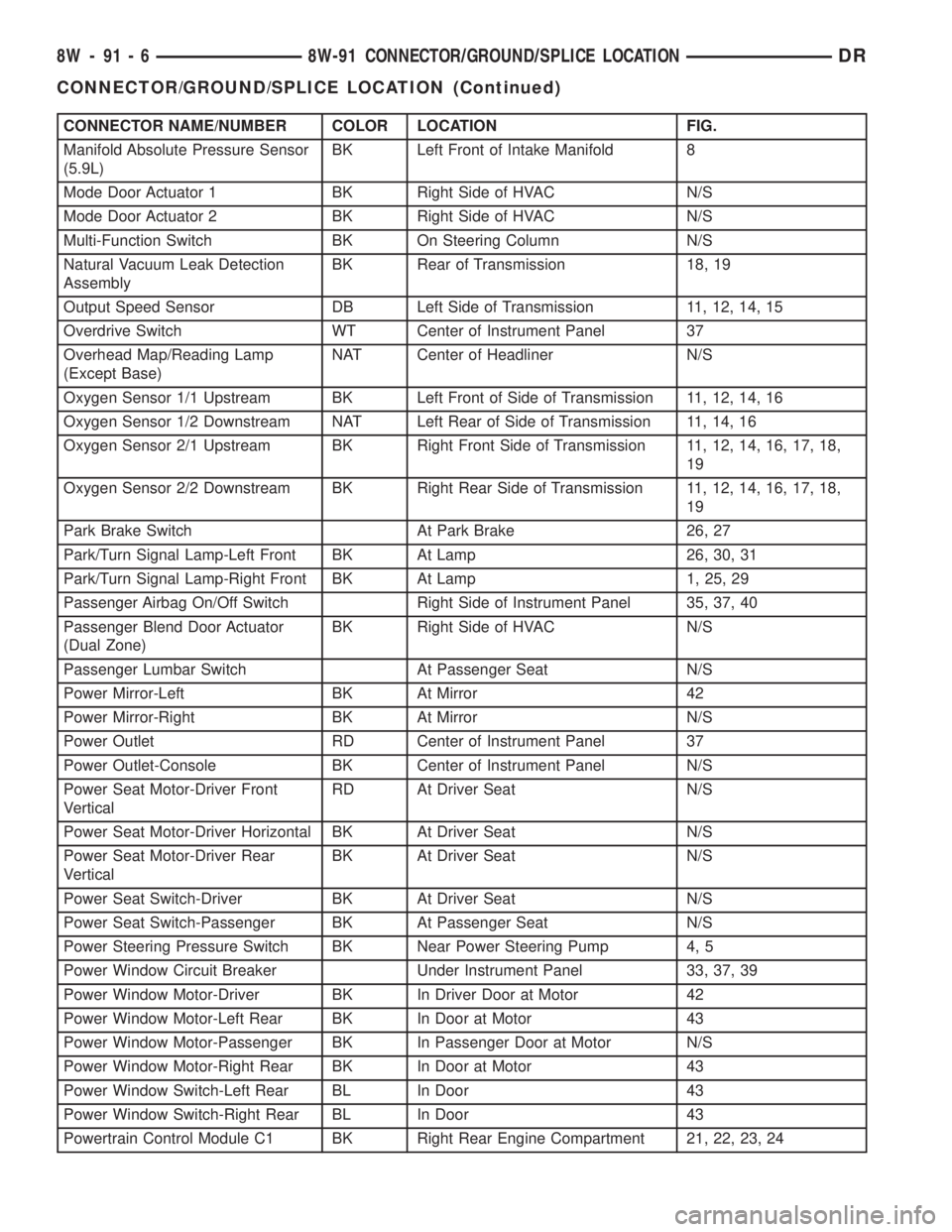

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Manifold Absolute Pressure Sensor

(5.9L)BK Left Front of Intake Manifold 8

Mode Door Actuator 1 BK Right Side of HVAC N/S

Mode Door Actuator 2 BK Right Side of HVAC N/S

Multi-Function Switch BK On Steering Column N/S

Natural Vacuum Leak Detection

AssemblyBK Rear of Transmission 18, 19

Output Speed Sensor DB Left Side of Transmission 11, 12, 14, 15

Overdrive Switch WT Center of Instrument Panel 37

Overhead Map/Reading Lamp

(Except Base)NAT Center of Headliner N/S

Oxygen Sensor 1/1 Upstream BK Left Front of Side of Transmission 11, 12, 14, 16

Oxygen Sensor 1/2 Downstream NAT Left Rear of Side of Transmission 11, 14, 16

Oxygen Sensor 2/1 Upstream BK Right Front Side of Transmission 11, 12, 14, 16, 17, 18,

19

Oxygen Sensor 2/2 Downstream BK Right Rear Side of Transmission 11, 12, 14, 16, 17, 18,

19

Park Brake Switch At Park Brake 26, 27

Park/Turn Signal Lamp-Left Front BK At Lamp 26, 30, 31

Park/Turn Signal Lamp-Right Front BK At Lamp 1, 25, 29

Passenger Airbag On/Off Switch Right Side of Instrument Panel 35, 37, 40

Passenger Blend Door Actuator

(Dual Zone)BK Right Side of HVAC N/S

Passenger Lumbar Switch At Passenger Seat N/S

Power Mirror-Left BK At Mirror 42

Power Mirror-Right BK At Mirror N/S

Power Outlet RD Center of Instrument Panel 37

Power Outlet-Console BK Center of Instrument Panel N/S

Power Seat Motor-Driver Front

VerticalRD At Driver Seat N/S

Power Seat Motor-Driver Horizontal BK At Driver Seat N/S

Power Seat Motor-Driver Rear

VerticalBK At Driver Seat N/S

Power Seat Switch-Driver BK At Driver Seat N/S

Power Seat Switch-Passenger BK At Passenger Seat N/S

Power Steering Pressure Switch BK Near Power Steering Pump 4, 5

Power Window Circuit Breaker Under Instrument Panel 33, 37, 39

Power Window Motor-Driver BK In Driver Door at Motor 42

Power Window Motor-Left Rear BK In Door at Motor 43

Power Window Motor-Passenger BK In Passenger Door at Motor N/S

Power Window Motor-Right Rear BK In Door at Motor 43

Power Window Switch-Left Rear BL In Door 43

Power Window Switch-Right Rear BL In Door 43

Powertrain Control Module C1 BK Right Rear Engine Compartment 21, 22, 23, 24

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1244 of 2895

tery and provides the primary means of circuit pro-

tection and power distribution for all vehicle

electrical systems. The front control module controls

power to some of these vehicle systems electrical and

electromechanical loads based on inputs received

from hard wired switch inputs and data received on

the PCI bus circuit (J1850).

For information on theIntegrated Power Mod-

ule Refer to the Power Distribution Sectionof

the service manual.

OPERATION

As messages are sent over the PCI bus circuit, the

front control module reads these messages and con-

trols power to some of the vehicles electrical systems

by completing the circuit to ground (low side driver)

or completing the circuit to 12 volt power (high side

driver). The following functions areControlledby

the Front Control Module:

²Headlamp Power with Voltage Regulation

²Windshield Wiper ªON/OFFº Relay Actuation

²Windshield Wiper ªHI/LOº Relay Actuation

²Windshield Washer Pump Motor

²Fog Lamp Relay Actuation

²Park Lamp Relay Actuation

²Horn Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection²Power Ground

²Ambient Temperature Sensing

²Ignition Switch Run

²Washer Fluid Level Switch

²Windshield Wiper Park Switch

²PCI Bus Circuit

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

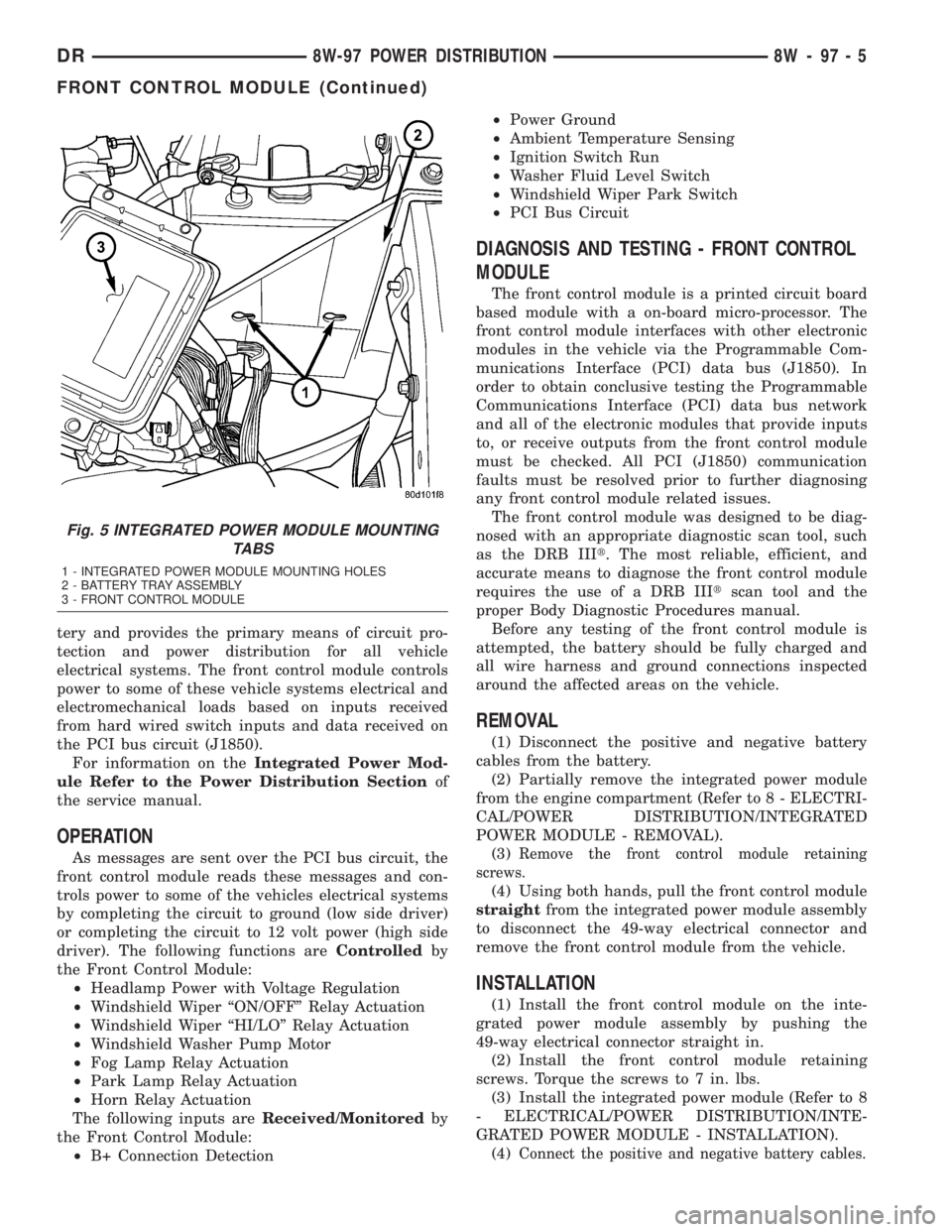

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3)

Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4)

Connect the positive and negative battery cables.

Fig. 5 INTEGRATED POWER MODULE MOUNTING

TABS

1 - INTEGRATED POWER MODULE MOUNTING HOLES

2 - BATTERY TRAY ASSEMBLY

3 - FRONT CONTROL MODULE

DR8W-97 POWER DISTRIBUTION 8W - 97 - 5

FRONT CONTROL MODULE (Continued)

Page 1245 of 2895

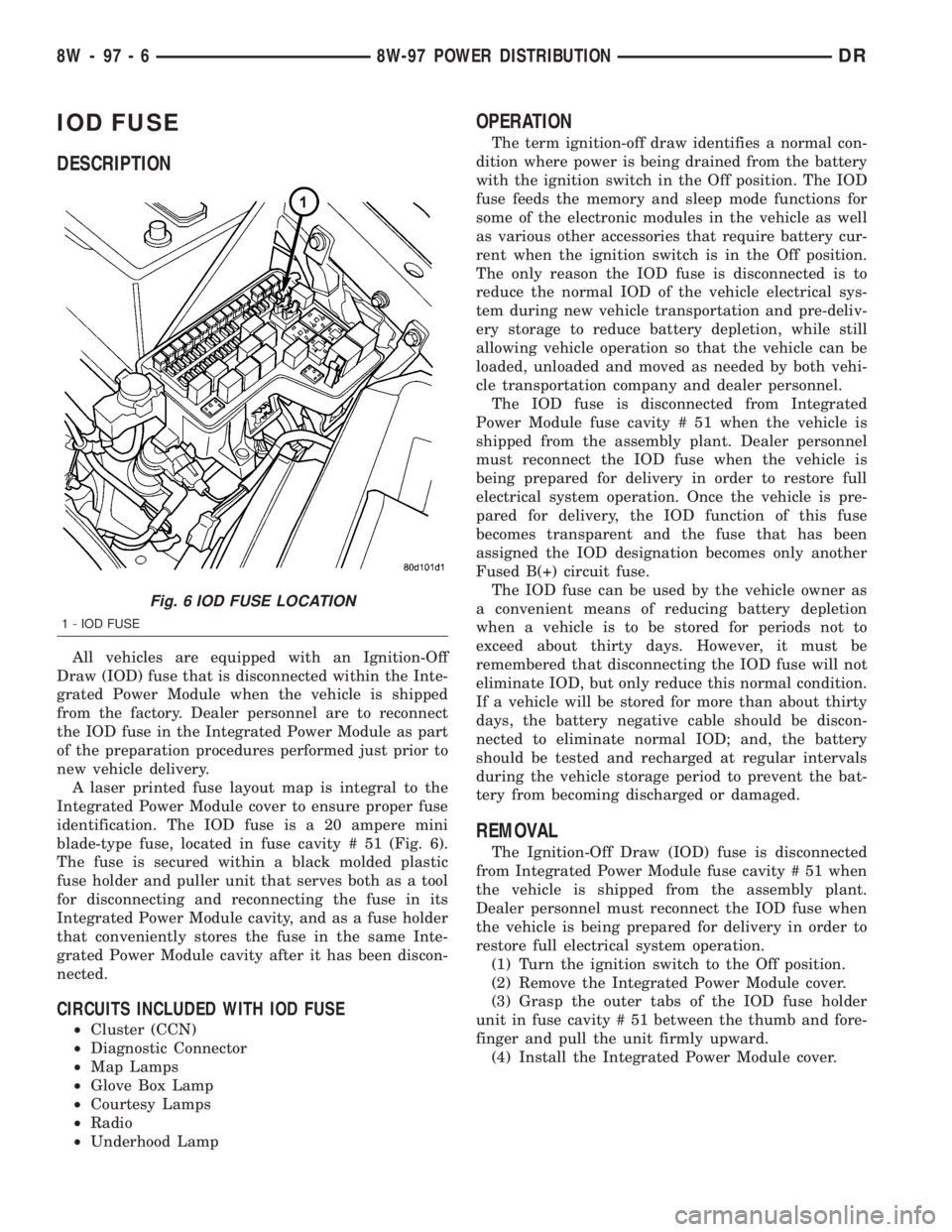

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is disconnected within the Inte-

grated Power Module when the vehicle is shipped

from the factory. Dealer personnel are to reconnect

the IOD fuse in the Integrated Power Module as part

of the preparation procedures performed just prior to

new vehicle delivery.

A laser printed fuse layout map is integral to the

Integrated Power Module cover to ensure proper fuse

identification. The IOD fuse is a 20 ampere mini

blade-type fuse, located in fuse cavity # 51 (Fig. 6).

The fuse is secured within a black molded plastic

fuse holder and puller unit that serves both as a tool

for disconnecting and reconnecting the fuse in its

Integrated Power Module cavity, and as a fuse holder

that conveniently stores the fuse in the same Inte-

grated Power Module cavity after it has been discon-

nected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cluster (CCN)

²Diagnostic Connector

²Map Lamps

²Glove Box Lamp

²Courtesy Lamps

²Radio

²Underhood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position.

The only reason the IOD fuse is disconnected is to

reduce the normal IOD of the vehicle electrical sys-

tem during new vehicle transportation and pre-deliv-

ery storage to reduce battery depletion, while still

allowing vehicle operation so that the vehicle can be

loaded, unloaded and moved as needed by both vehi-

cle transportation company and dealer personnel.

The IOD fuse is disconnected from Integrated

Power Module fuse cavity # 51 when the vehicle is

shipped from the assembly plant. Dealer personnel

must reconnect the IOD fuse when the vehicle is

being prepared for delivery in order to restore full

electrical system operation. Once the vehicle is pre-

pared for delivery, the IOD function of this fuse

becomes transparent and the fuse that has been

assigned the IOD designation becomes only another

Fused B(+) circuit fuse.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that disconnecting the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged.

REMOVAL

The Ignition-Off Draw (IOD) fuse is disconnected

from Integrated Power Module fuse cavity # 51 when

the vehicle is shipped from the assembly plant.

Dealer personnel must reconnect the IOD fuse when

the vehicle is being prepared for delivery in order to

restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) Remove the Integrated Power Module cover.

(3) Grasp the outer tabs of the IOD fuse holder

unit in fuse cavity # 51 between the thumb and fore-

finger and pull the unit firmly upward.

(4) Install the Integrated Power Module cover.

Fig. 6 IOD FUSE LOCATION

1 - IOD FUSE

8W - 97 - 6 8W-97 POWER DISTRIBUTIONDR

Page 1258 of 2895

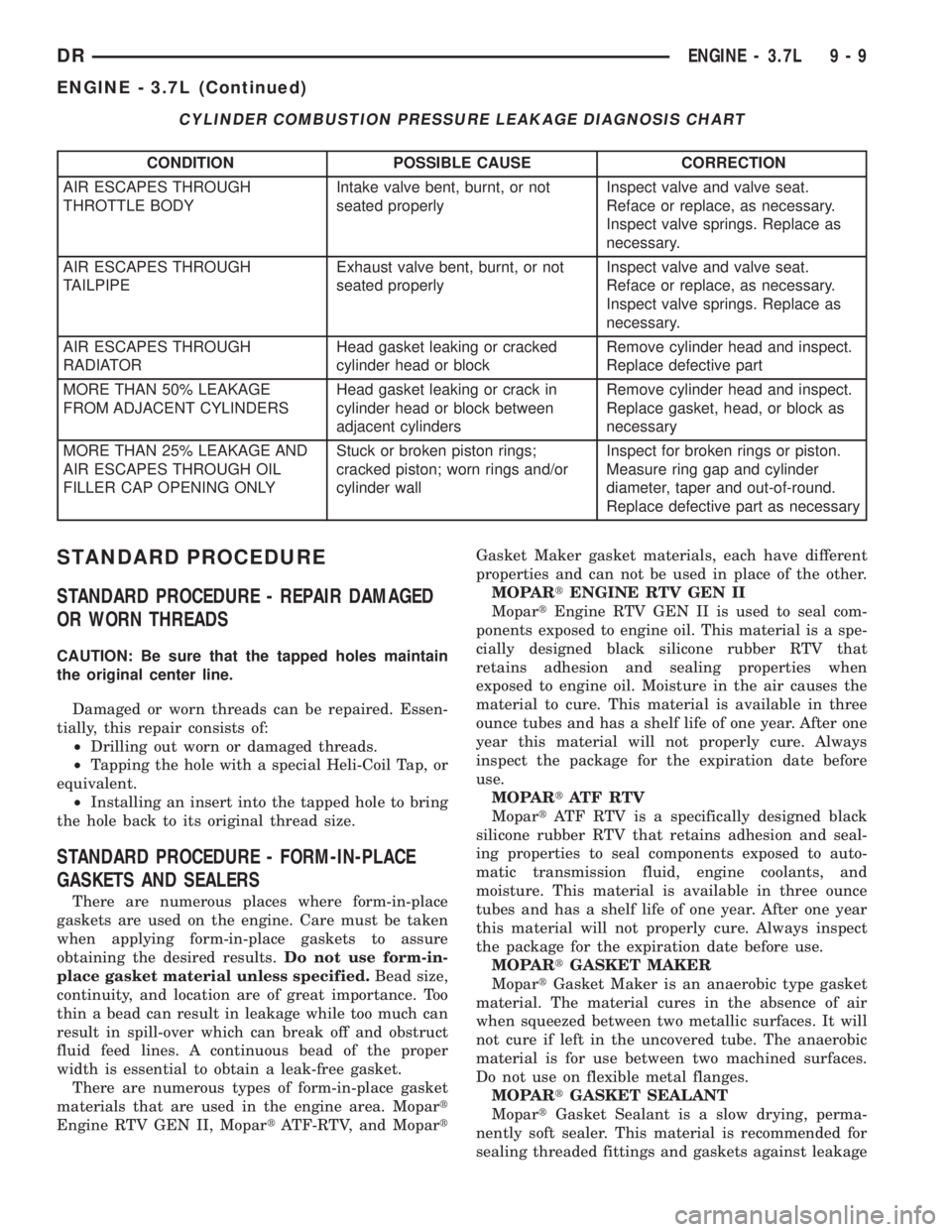

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and MopartGasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

DRENGINE - 3.7L 9 - 9

ENGINE - 3.7L (Continued)

Page 1260 of 2895

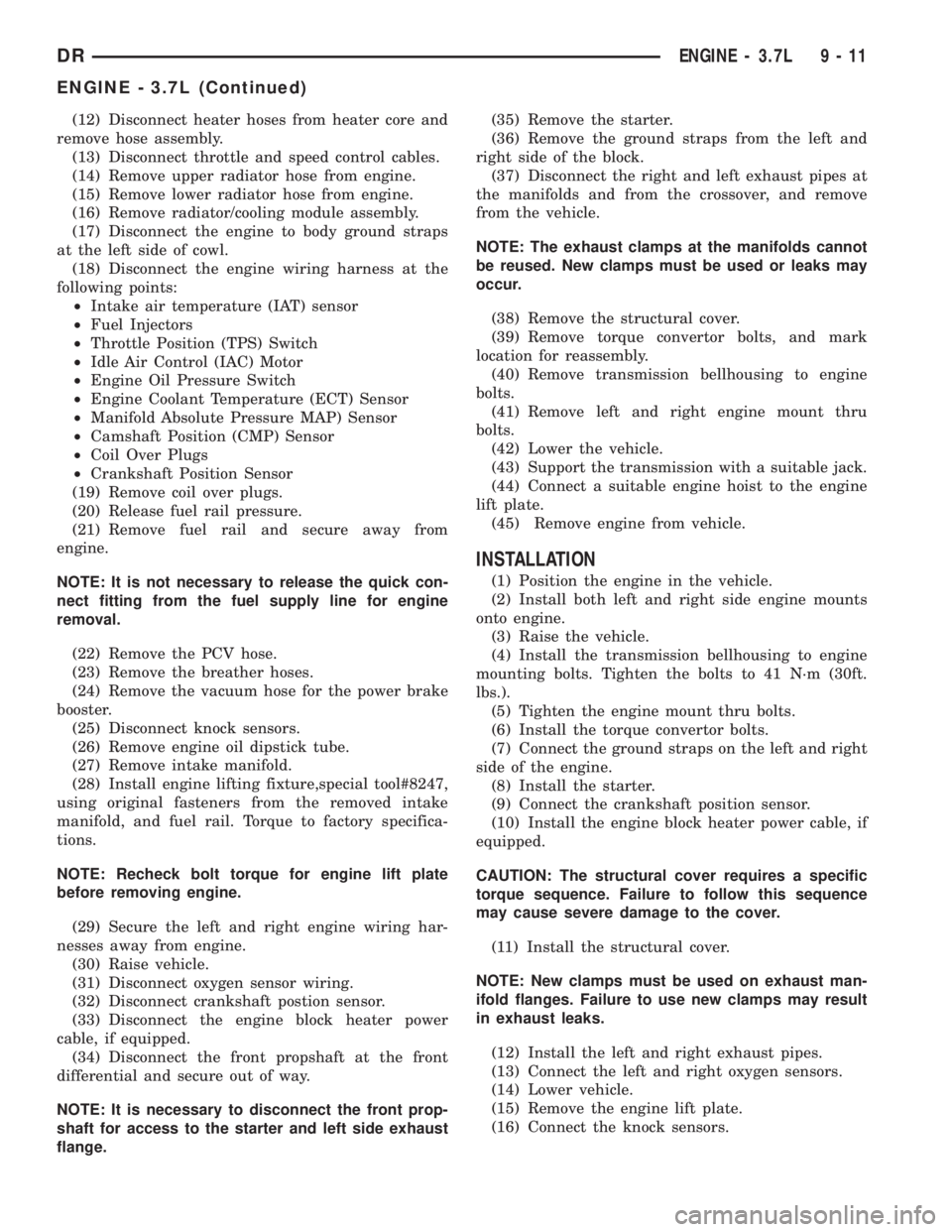

(12) Disconnect heater hoses from heater core and

remove hose assembly.

(13) Disconnect throttle and speed control cables.

(14) Remove upper radiator hose from engine.

(15) Remove lower radiator hose from engine.

(16) Remove radiator/cooling module assembly.

(17) Disconnect the engine to body ground straps

at the left side of cowl.

(18) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(19) Remove coil over plugs.

(20) Release fuel rail pressure.

(21) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(22) Remove the PCV hose.

(23) Remove the breather hoses.

(24) Remove the vacuum hose for the power brake

booster.

(25) Disconnect knock sensors.

(26) Remove engine oil dipstick tube.

(27) Remove intake manifold.

(28) Install engine lifting fixture,special tool#8247,

using original fasteners from the removed intake

manifold, and fuel rail. Torque to factory specifica-

tions.

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(29) Secure the left and right engine wiring har-

nesses away from engine.

(30) Raise vehicle.

(31) Disconnect oxygen sensor wiring.

(32) Disconnect crankshaft postion sensor.

(33) Disconnect the engine block heater power

cable, if equipped.

(34) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.(35) Remove the starter.

(36) Remove the ground straps from the left and

right side of the block.

(37) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

(38) Remove the structural cover.

(39) Remove torque convertor bolts, and mark

location for reassembly.

(40) Remove transmission bellhousing to engine

bolts.

(41) Remove left and right engine mount thru

bolts.

(42) Lower the vehicle.

(43) Support the transmission with a suitable jack.

(44) Connect a suitable engine hoist to the engine

lift plate.

(45) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.

(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

DRENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1261 of 2895

(17) Connect the engine to body ground straps at

the left side of the cowl.

(18) Install the intake manifold.

(19) Install the engine oil dipstick tube.

(20) Install the power brake booster vacuum hose.

(21) Install the breather hoses.

(22) Install the PCV hose.

(23) Install the fuel rail.

(24) Install the coil over plugs.

(25) Connect the engine wiring harness at the fol-

lowing points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(26) Reinstall the radiator/cooling module assem-

bly.

(27) Connect lower radiator hose.

(28) Connect upper radiator hose.

(29) Connect throttle and speed control cables.

(30) Install the heater hose assembly.

(31) Install coolant recovery bottle.

(32) Install the power steering pump.

(33) Install the generator.

(34) Install the A/C compressor.

(35) Install the drive belt.

(36) Install the fan shroud with the viscous fan

assembly.

(37) Install the radiator core support bracket.

(38) Install the air cleaner assembly.

(39) Refill the engine cooling system.

(40) Recharge the air conditioning.

(41) Install the hood.

(42) Check and fill engine oil.

(43) Connect the battery negative cable.

(44) Start the engine and check for leaks.SPECIFICATIONS

SPECIFICATIONS ± 3.7L ENGINE

DESCRIPTION SPECIFICATION

Engine Type 90É SOHC V-6 12-Valve

Displacement 3.7 Liters / 3700 cc

226 ( Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 90.8 mm (3.40 in.)

Compression Ratio 9.1:1

Horsepower 210 BHP @ 5200 RPM

Torque 225 LB-FT @ 4200 RPM

Lead Cylinder #1 Left Bank

Firing Order 1-6-5-4-3-2

CYLINDER BLOCK

Cylinder Block Cast Iron

Bore Diameter 93.0 .0075 mm

(3.6619 0.0003 in.)

Out of Round (MAX) 0.076 mm (0.003 in.)

Taper (MAX) 0.051 mm (0.002 in.)

PISTONS

Material Aluminum Alloy

Diameter 92.975 mm (3.6605 in.)

Weight 367.5 grams (12.96 oz)

Ring Groove Diameter

No. 1 83.73 - 83.13 mm

(3.296 - 3.273 in.)

No. 2 82.833 - 83.033 mm

(3.261 - 3.310 in.)

No. 3 83.88 - 84.08 mm

(3.302 - 3.310 in.)

PISTON PINS

Type Floating

Clearance In Piston 0.006 - 0.015 mm

(0.0002 - 0.0005 in.)

Diameter 24.017 - 24.020 mm

(0.9455 - 0.9456 in.)

PISTON RINGS

Ring Gap

Top Compression Ring 0.20 - 0.36 mm

(0.0079 - 0.0142 in.)

9 - 12 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1269 of 2895

AIR CLEANER ELEMENT

REMOVAL

Filter Element Only

Housing removal is not necessary for element (fil-

ter) replacement.

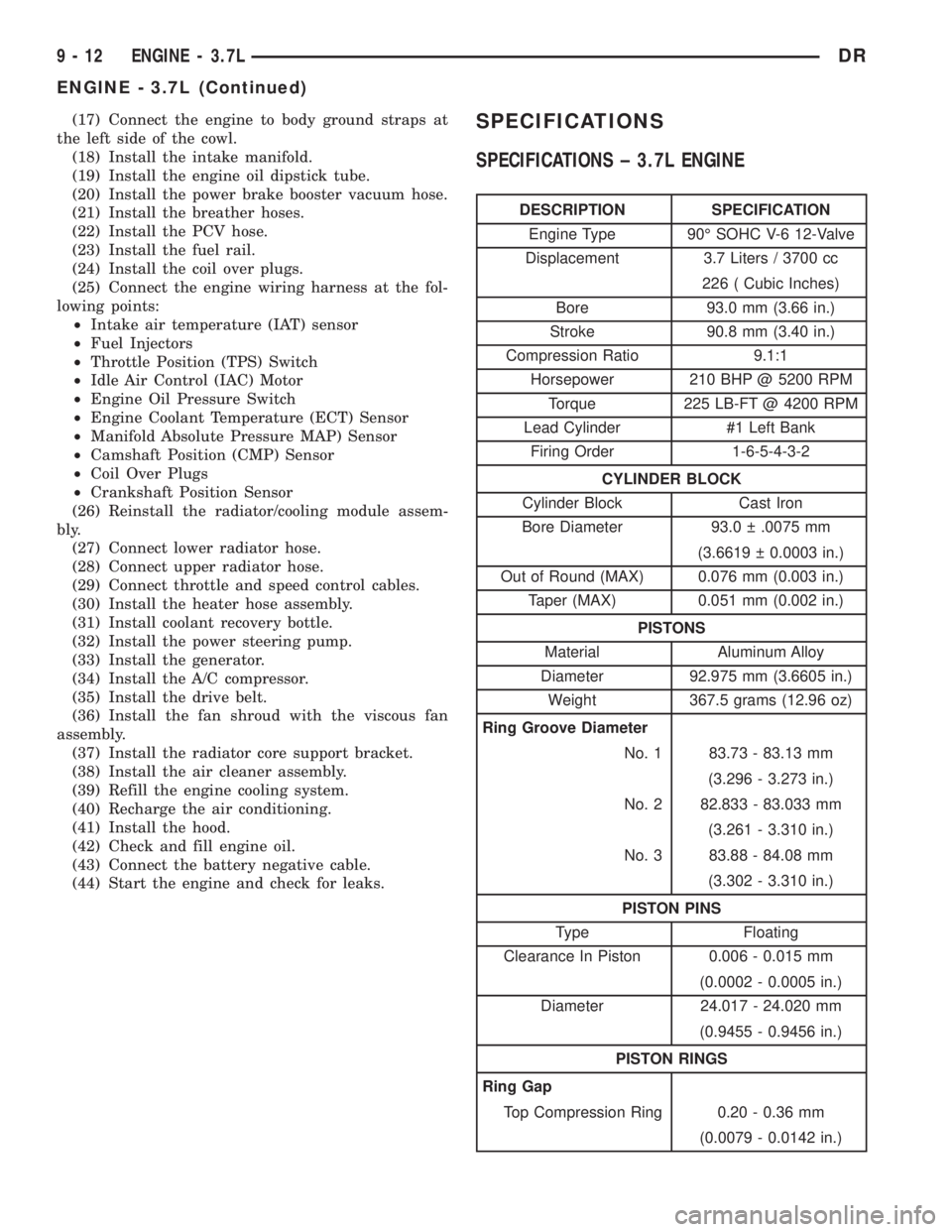

(1) Loosen clamp (Fig. 3) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 3) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 3) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

Housing Assembly

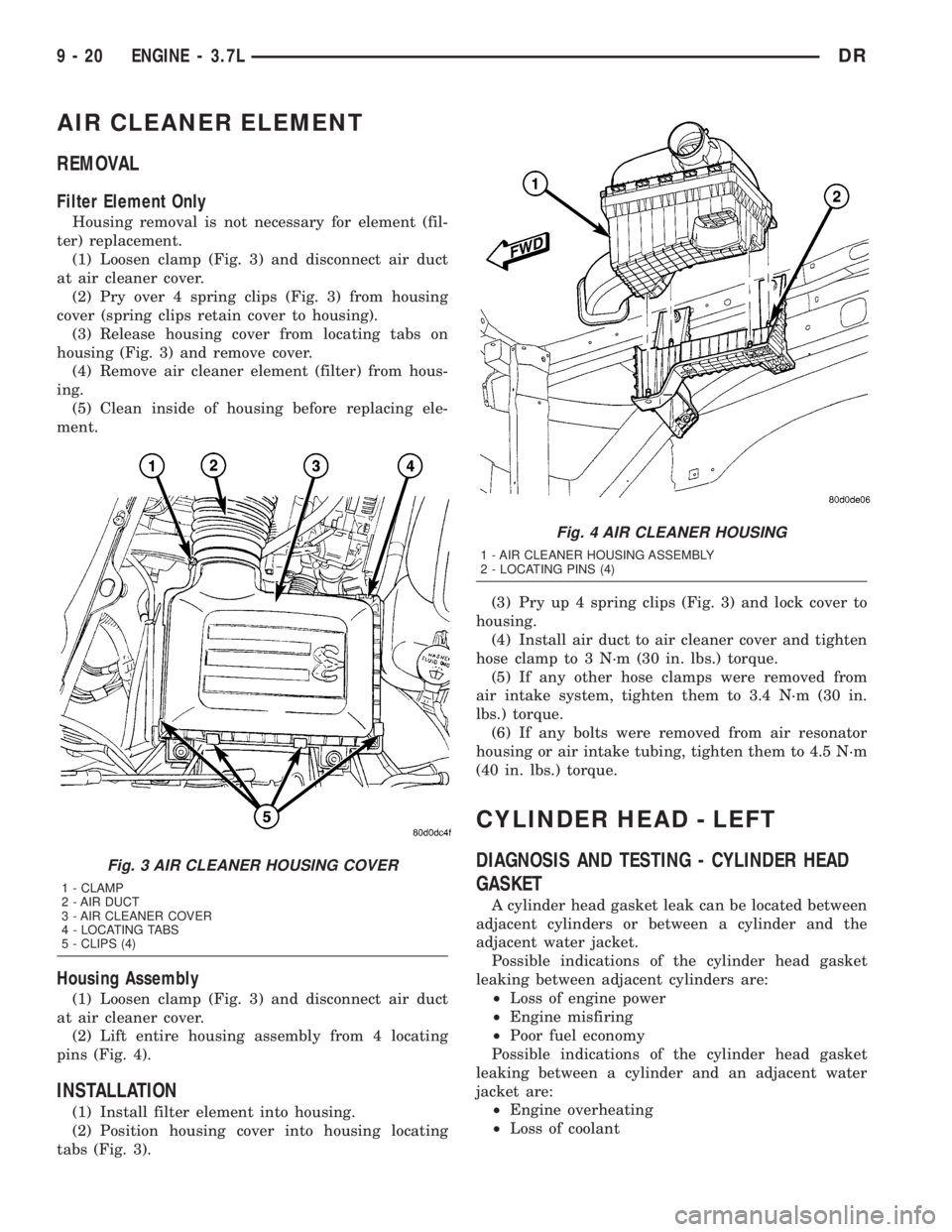

(1) Loosen clamp (Fig. 3) and disconnect air duct

at air cleaner cover.

(2) Lift entire housing assembly from 4 locating

pins (Fig. 4).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 3).(3) Pry up 4 spring clips (Fig. 3) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD - LEFT

DIAGNOSIS AND TESTING - CYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

Fig. 3 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 4 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

9 - 20 ENGINE - 3.7LDR