ABS DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1403 of 2895

OIL PRESSURE SENSOR/

SWITCH

DESCRIPTION

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

DESCRIPTION

The 3±wire, electrical/mechanical engine oil pres-

sure sensor (sending unit) is located in an engine oil

pressure gallery.

OPERATION

OPERATION

The oil pressure sensor uses three circuits. They

are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²A signal to the PCM relating to engine oil pres-

sure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to the

instrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

OPERATION

The oil pressure sensor uses two circuits. They are:

²A signal to the PCM relating to engine oil pres-

sure

²A sensor ground through the PCM's sensor

return

The oil pressure sensor returns a voltage signal

back to the PCM relating to engine oil pressure. This

signal is then transferred (bussed) to the instrument

panel on a CCD bus circuit to operate the oil pres-

sure gauge and the check gauges lamp. Ground for

the sensor is provided by the PCM through a low-

noise sensor return.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle on hoist.

(3) Remove front splash shield.

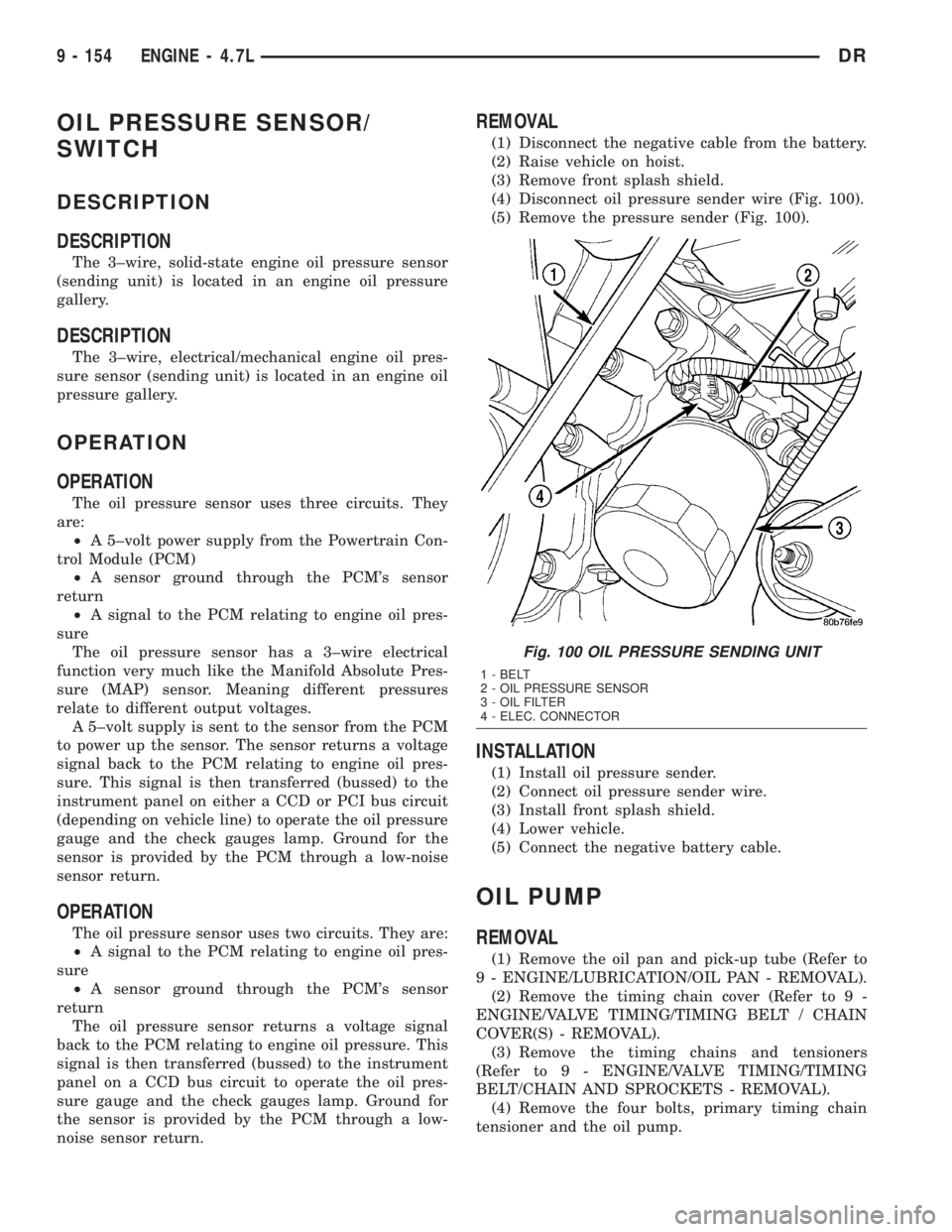

(4) Disconnect oil pressure sender wire (Fig. 100).

(5) Remove the pressure sender (Fig. 100).

INSTALLATION

(1) Install oil pressure sender.

(2) Connect oil pressure sender wire.

(3) Install front splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

OIL PUMP

REMOVAL

(1) Remove the oil pan and pick-up tube (Refer to

9 - ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(2) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(3) Remove the timing chains and tensioners

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

(4) Remove the four bolts, primary timing chain

tensioner and the oil pump.

Fig. 100 OIL PRESSURE SENDING UNIT

1 - BELT

2 - OIL PRESSURE SENSOR

3 - OIL FILTER

4 - ELEC. CONNECTOR

9 - 154 ENGINE - 4.7LDR

Page 1406 of 2895

INSTALLATION

(1) Position the oil pump onto the crankshaft and

install one oil pump retaining bolts.

(2) Position the primary timing chain tensioner

and install three retaining bolts.

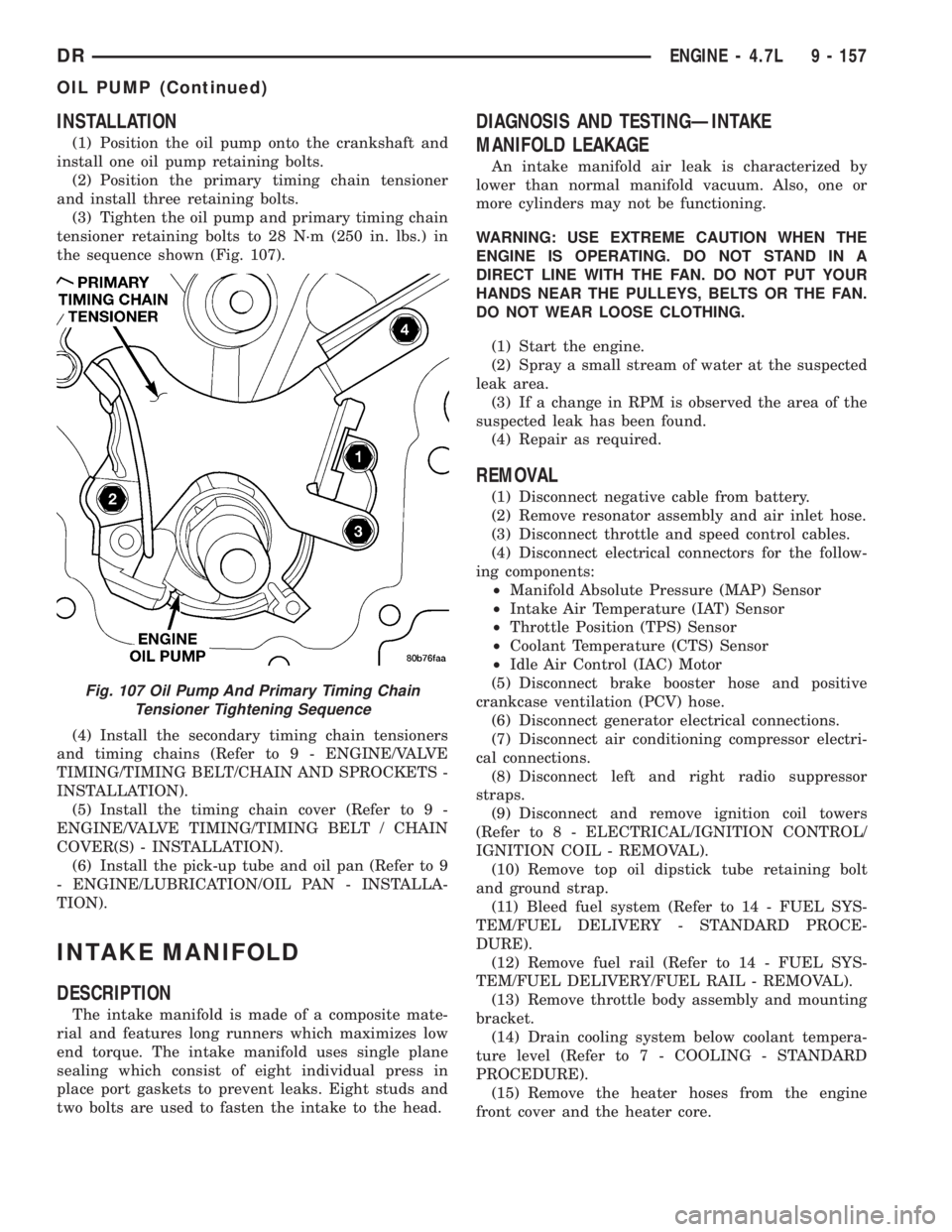

(3) Tighten the oil pump and primary timing chain

tensioner retaining bolts to 28 N´m (250 in. lbs.) in

the sequence shown (Fig. 107).

(4) Install the secondary timing chain tensioners

and timing chains (Refer to 9 - ENGINE/VALVE

TIMING/TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(5) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(6) Install the pick-up tube and oil pan (Refer to 9

- ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite mate-

rial and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks. Eight studs and

two bolts are used to fasten the intake to the head.

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect brake booster hose and positive

crankcase ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.

(8) Disconnect left and right radio suppressor

straps.

(9) Disconnect and remove ignition coil towers

(Refer to 8 - ELECTRICAL/IGNITION CONTROL/

IGNITION COIL - REMOVAL).

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

(11) Bleed fuel system (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY - STANDARD PROCE-

DURE).

(12) Remove fuel rail (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL RAIL - REMOVAL).

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(15) Remove the heater hoses from the engine

front cover and the heater core.

Fig. 107 Oil Pump And Primary Timing Chain

Tensioner Tightening Sequence

DRENGINE - 4.7L 9 - 157

OIL PUMP (Continued)

Page 1407 of 2895

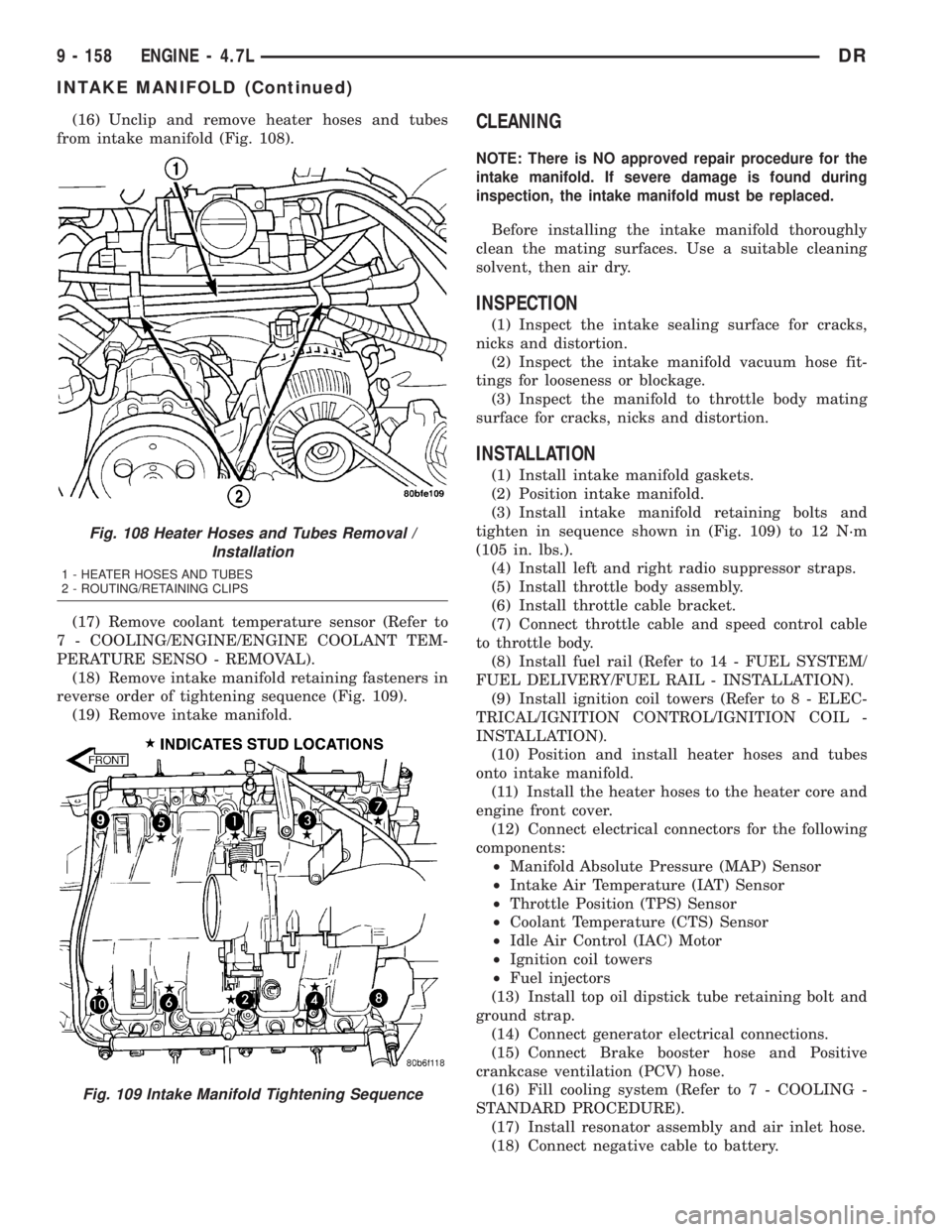

(16) Unclip and remove heater hoses and tubes

from intake manifold (Fig. 108).

(17) Remove coolant temperature sensor (Refer to

7 - COOLING/ENGINE/ENGINE COOLANT TEM-

PERATURE SENSO - REMOVAL).

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence (Fig. 109).

(19) Remove intake manifold.CLEANING

NOTE: There is NO approved repair procedure for the

intake manifold. If severe damage is found during

inspection, the intake manifold must be replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.

(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Position intake manifold.

(3) Install intake manifold retaining bolts and

tighten in sequence shown in (Fig. 109) to 12 N´m

(105 in. lbs.).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Install throttle cable bracket.

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install ignition coil towers (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

(10) Position and install heater hoses and tubes

onto intake manifold.

(11) Install the heater hoses to the heater core and

engine front cover.

(12) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(13) Install top oil dipstick tube retaining bolt and

ground strap.

(14) Connect generator electrical connections.

(15) Connect Brake booster hose and Positive

crankcase ventilation (PCV) hose.

(16) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(17) Install resonator assembly and air inlet hose.

(18) Connect negative cable to battery.

Fig. 108 Heater Hoses and Tubes Removal /

Installation

1 - HEATER HOSES AND TUBES

2 - ROUTING/RETAINING CLIPS

Fig. 109 Intake Manifold Tightening Sequence

9 - 158 ENGINE - 4.7LDR

INTAKE MANIFOLD (Continued)

Page 1443 of 2895

AIR INTAKE SYSTEM

REMOVAL

Filter Element Only

Housing removal is not necessary for element (fil-

ter) replacement.

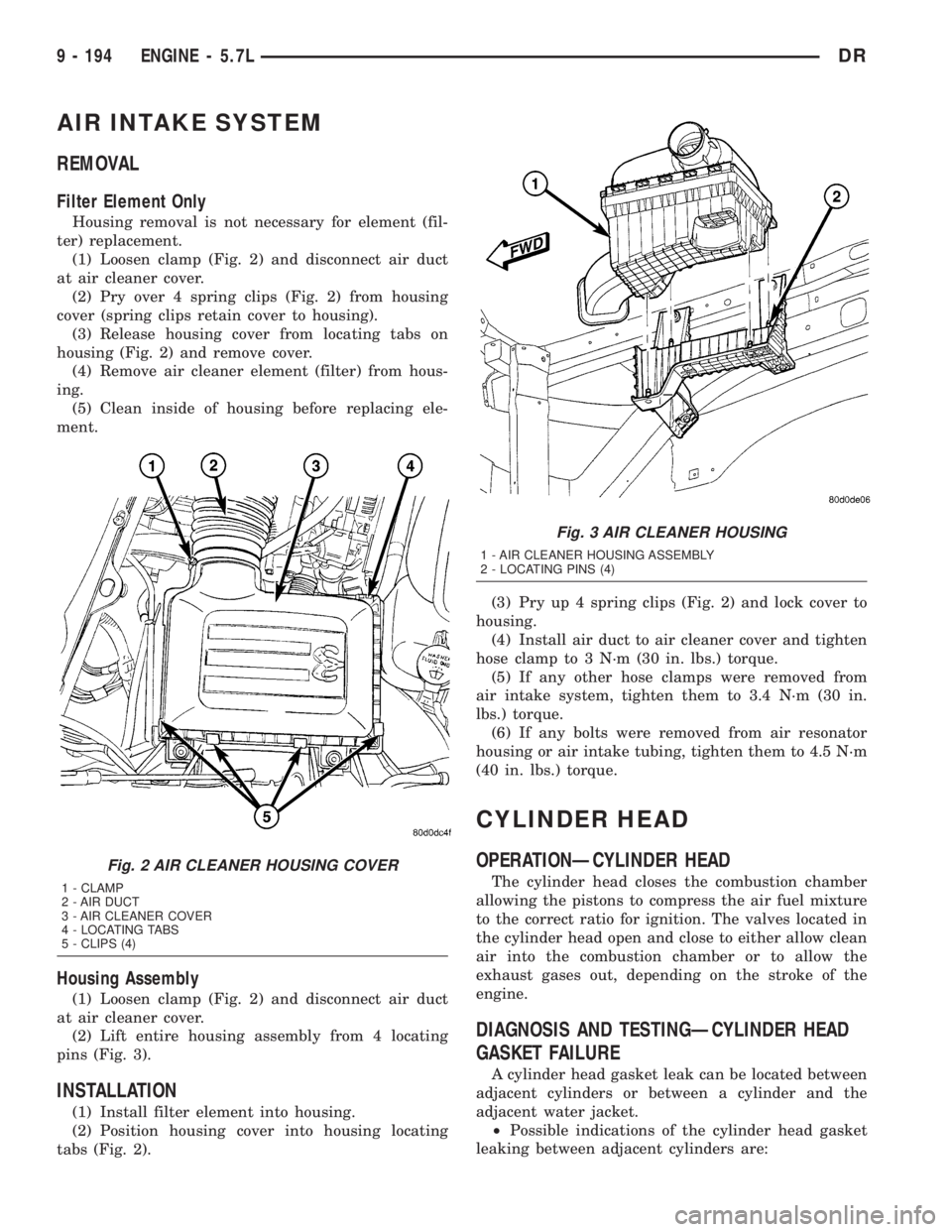

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 2) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 2) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

Housing Assembly

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Lift entire housing assembly from 4 locating

pins (Fig. 3).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 2).(3) Pry up 4 spring clips (Fig. 2) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture

to the correct ratio for ignition. The valves located in

the cylinder head open and close to either allow clean

air into the combustion chamber or to allow the

exhaust gases out, depending on the stroke of the

engine.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

Fig. 2 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 3 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

9 - 194 ENGINE - 5.7LDR

Page 1452 of 2895

MAIN BEARING SELECTION CHART - 5.7L

GRADE SIZE mm

(in.)FOR USE WITH

MARKING JOURNAL SIZE

A0.008 mm

U/S64.988±64.995 mm

(0.0004 in.)

U/S(2.5585± 2.5588in.)

BNOMINAL 64.996±65.004 mm

(2.5588±2.5592 in.)

C0.008 mm

O/S65.005±65.012 mm

(0.0004 in.)

O/S(2.5592±2.5595 in.)

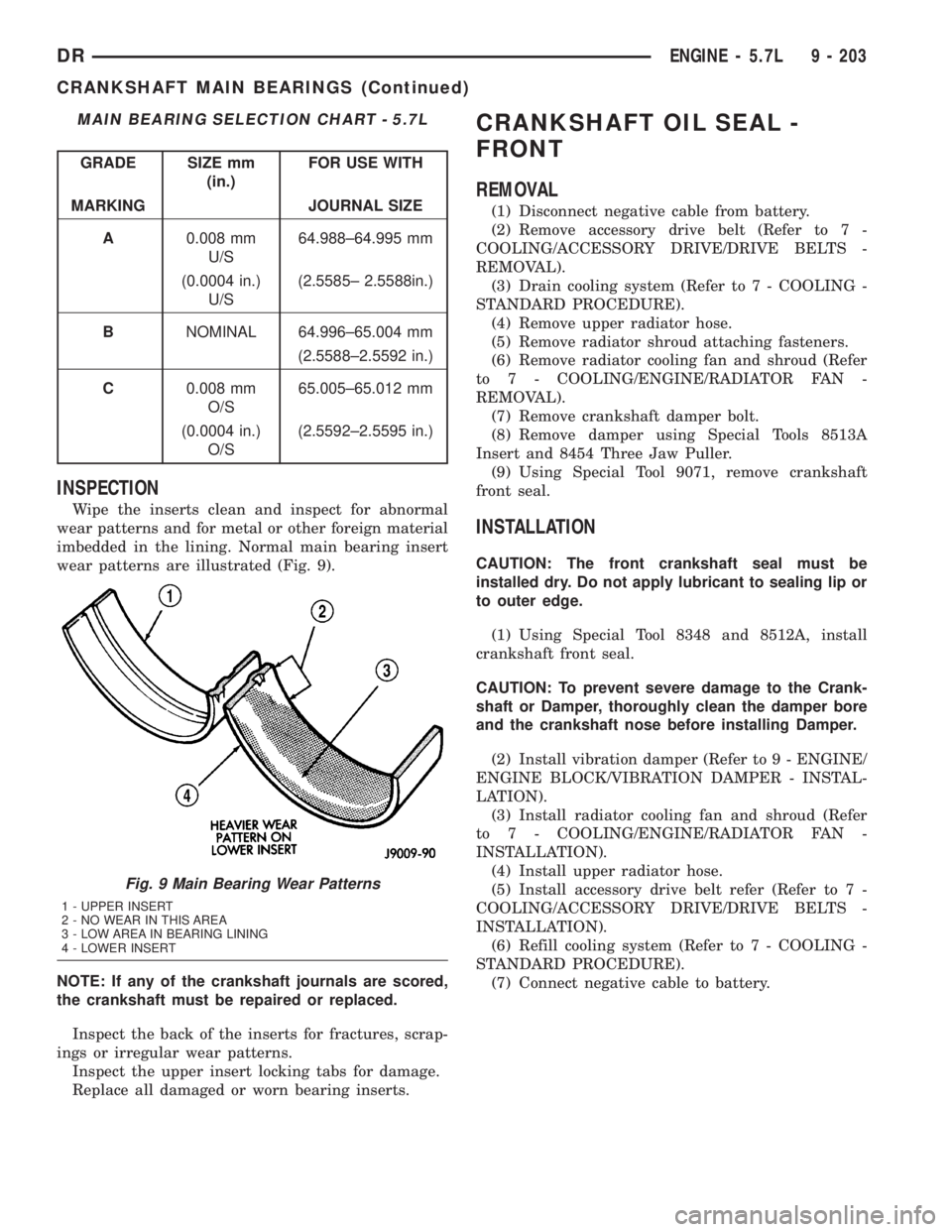

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 9).

NOTE: If any of the crankshaft journals are scored,

the crankshaft must be repaired or replaced.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(4) Remove upper radiator hose.

(5) Remove radiator shroud attaching fasteners.

(6) Remove radiator cooling fan and shroud (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(7) Remove crankshaft damper bolt.

(8) Remove damper using Special Tools 8513A

Insert and 8454 Three Jaw Puller.

(9) Using Special Tool 9071, remove crankshaft

front seal.

INSTALLATION

CAUTION: The front crankshaft seal must be

installed dry. Do not apply lubricant to sealing lip or

to outer edge.

(1) Using Special Tool 8348 and 8512A, install

crankshaft front seal.

CAUTION: To prevent severe damage to the Crank-

shaft or Damper, thoroughly clean the damper bore

and the crankshaft nose before installing Damper.

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(3) Install radiator cooling fan and shroud (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(4) Install upper radiator hose.

(5) Install accessory drive belt refer (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(6) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Connect negative cable to battery.

Fig. 9 Main Bearing Wear Patterns

1 - UPPER INSERT

2 - NO WEAR IN THIS AREA

3 - LOW AREA IN BEARING LINING

4 - LOWER INSERT

DRENGINE - 5.7L 9 - 203

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1468 of 2895

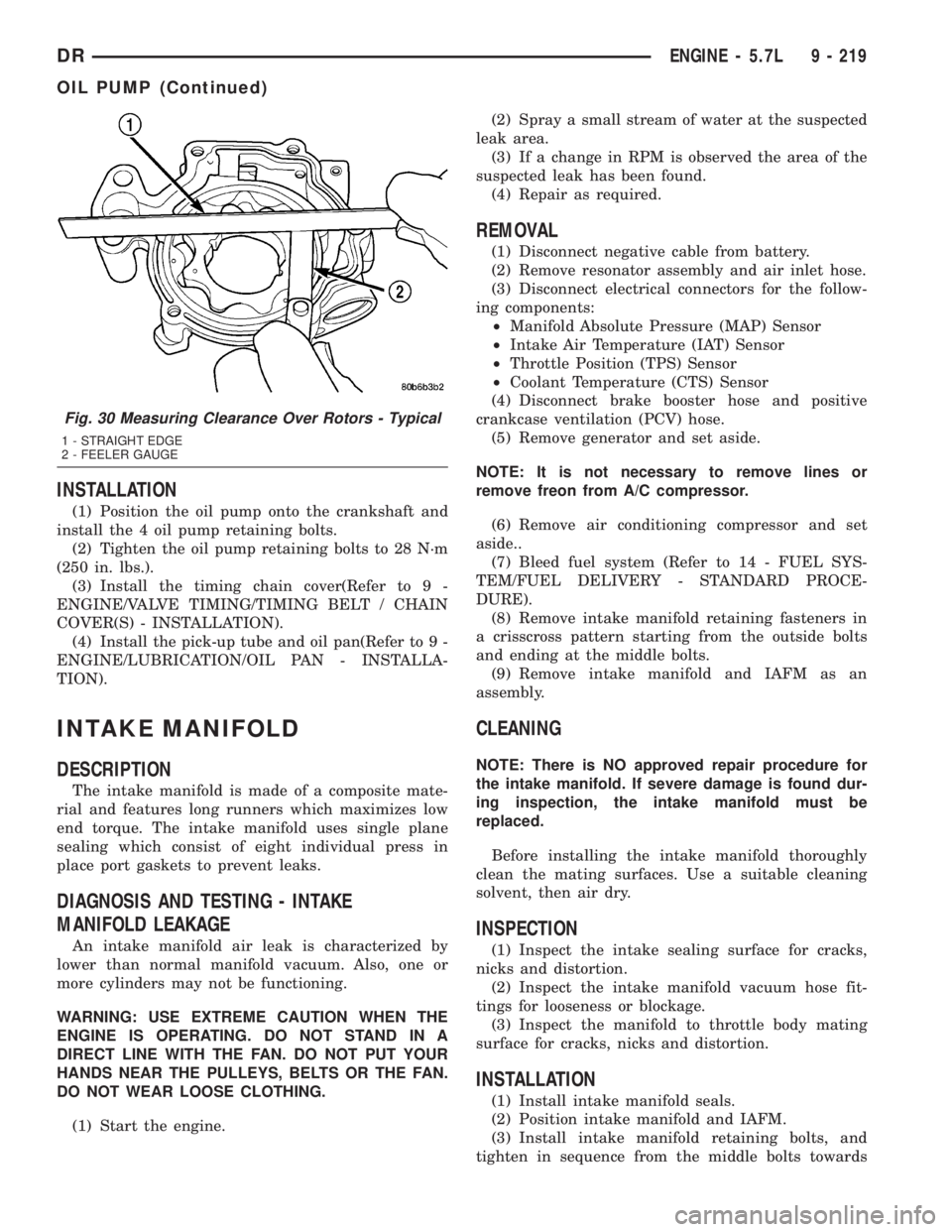

INSTALLATION

(1) Position the oil pump onto the crankshaft and

install the 4 oil pump retaining bolts.

(2) Tighten the oil pump retaining bolts to 28 N´m

(250 in. lbs.).

(3) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(4) Install the pick-up tube and oil pan(Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite mate-

rial and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect electrical connectors for the follow-

ing components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

(4) Disconnect brake booster hose and positive

crankcase ventilation (PCV) hose.

(5) Remove generator and set aside.

NOTE: It is not necessary to remove lines or

remove freon from A/C compressor.

(6) Remove air conditioning compressor and set

aside..

(7) Bleed fuel system (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY - STANDARD PROCE-

DURE).

(8) Remove intake manifold retaining fasteners in

a crisscross pattern starting from the outside bolts

and ending at the middle bolts.

(9) Remove intake manifold and IAFM as an

assembly.

CLEANING

NOTE: There is NO approved repair procedure for

the intake manifold. If severe damage is found dur-

ing inspection, the intake manifold must be

replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.

(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

INSTALLATION

(1) Install intake manifold seals.

(2) Position intake manifold and IAFM.

(3) Install intake manifold retaining bolts, and

tighten in sequence from the middle bolts towards

Fig. 30 Measuring Clearance Over Rotors - Typical

1 - STRAIGHT EDGE

2 - FEELER GAUGE

DRENGINE - 5.7L 9 - 219

OIL PUMP (Continued)

Page 1469 of 2895

the outside in a crisscross pattern. Torque fasteners

to 12 N´m (105 in. lbs.).

(4) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Install generator.

(6) Install A/C compressor.

(7) Connect Brake booster hose and Positive crank-

case ventilation (PCV) hose.

(8) Install resonator assembly and air inlet hose.

(9) Connect negative cable to battery.

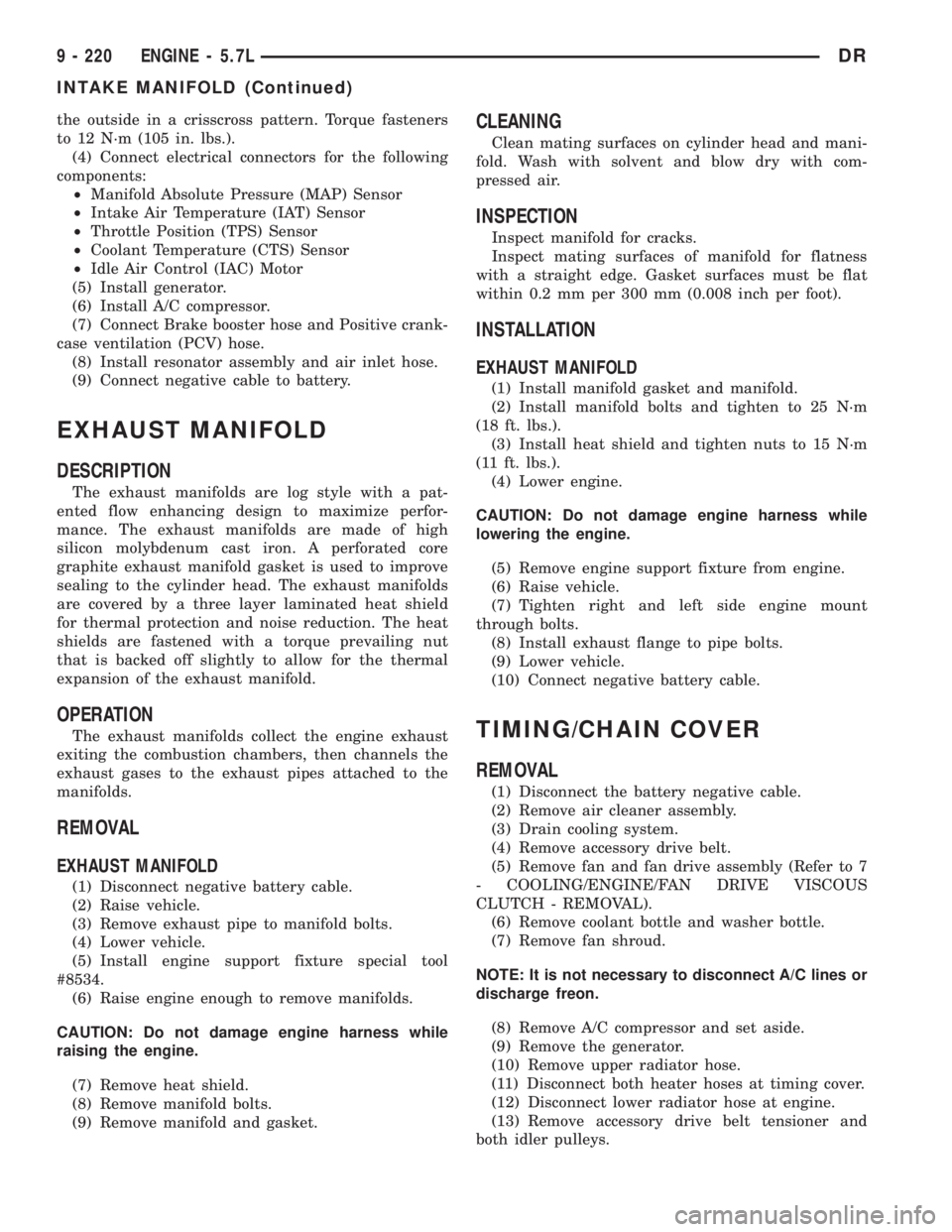

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

REMOVAL

EXHAUST MANIFOLD

(1) Disconnect negative battery cable.

(2) Raise vehicle.

(3) Remove exhaust pipe to manifold bolts.

(4) Lower vehicle.

(5) Install engine support fixture special tool

#8534.

(6) Raise engine enough to remove manifolds.

CAUTION: Do not damage engine harness while

raising the engine.

(7) Remove heat shield.

(8) Remove manifold bolts.

(9) Remove manifold and gasket.

CLEANING

Clean mating surfaces on cylinder head and mani-

fold. Wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

EXHAUST MANIFOLD

(1) Install manifold gasket and manifold.

(2) Install manifold bolts and tighten to 25 N´m

(18 ft. lbs.).

(3) Install heat shield and tighten nuts to 15 N´m

(11 ft. lbs.).

(4) Lower engine.

CAUTION: Do not damage engine harness while

lowering the engine.

(5) Remove engine support fixture from engine.

(6) Raise vehicle.

(7) Tighten right and left side engine mount

through bolts.

(8) Install exhaust flange to pipe bolts.

(9) Lower vehicle.

(10) Connect negative battery cable.

TIMING/CHAIN COVER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove air cleaner assembly.

(3) Drain cooling system.

(4) Remove accessory drive belt.

(5) Remove fan and fan drive assembly (Refer to 7

- COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

(6) Remove coolant bottle and washer bottle.

(7) Remove fan shroud.

NOTE: It is not necessary to disconnect A/C lines or

discharge freon.

(8) Remove A/C compressor and set aside.

(9) Remove the generator.

(10) Remove upper radiator hose.

(11) Disconnect both heater hoses at timing cover.

(12) Disconnect lower radiator hose at engine.

(13) Remove accessory drive belt tensioner and

both idler pulleys.

9 - 220 ENGINE - 5.7LDR

INTAKE MANIFOLD (Continued)

Page 1481 of 2895

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

9 - 232 ENGINE - 5.9LDR

ENGINE - 5.9L (Continued)

Page 1491 of 2895

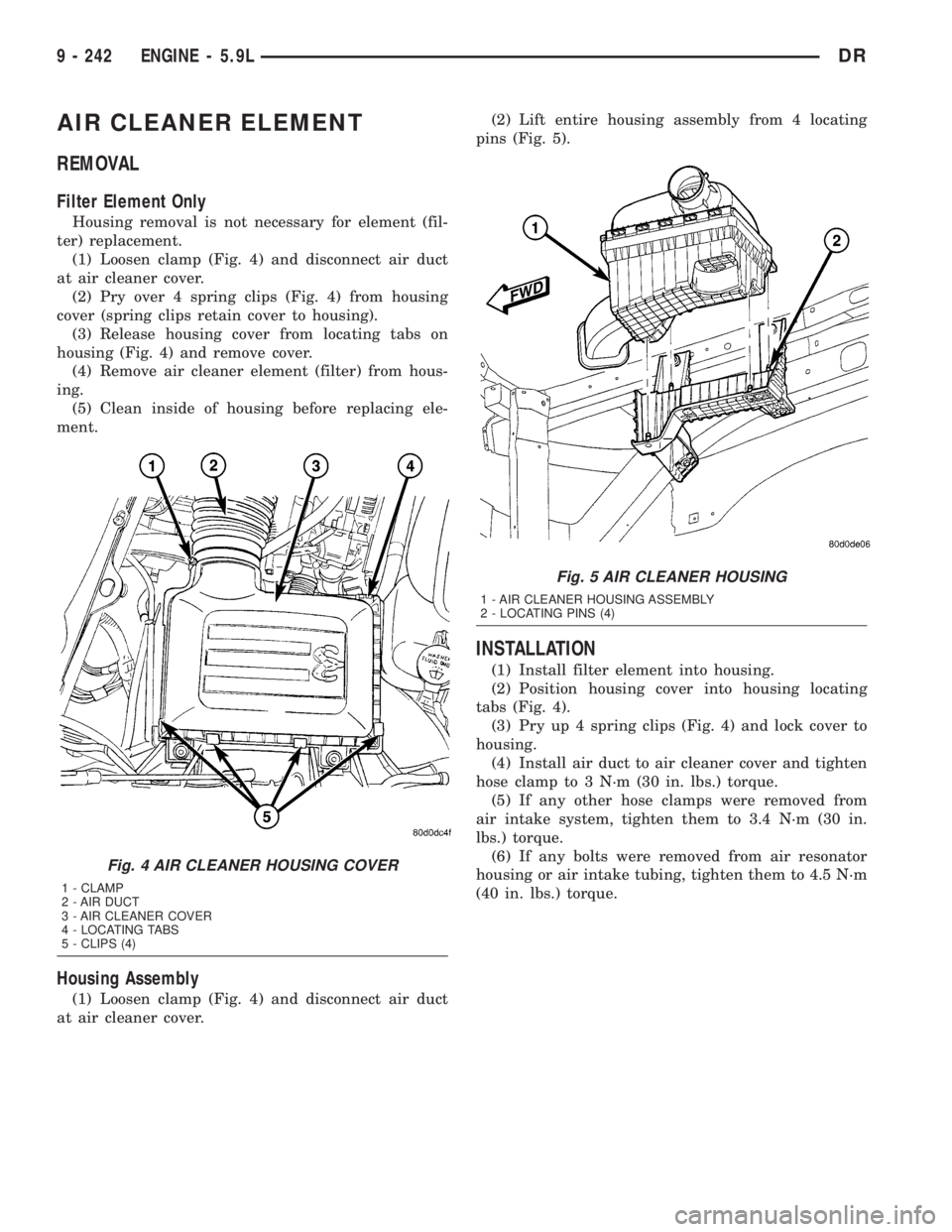

AIR CLEANER ELEMENT

REMOVAL

Filter Element Only

Housing removal is not necessary for element (fil-

ter) replacement.

(1) Loosen clamp (Fig. 4) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 4) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 4) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

Housing Assembly

(1) Loosen clamp (Fig. 4) and disconnect air duct

at air cleaner cover.(2) Lift entire housing assembly from 4 locating

pins (Fig. 5).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 4).

(3) Pry up 4 spring clips (Fig. 4) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

Fig. 4 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 5 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

9 - 242 ENGINE - 5.9LDR

Page 1524 of 2895

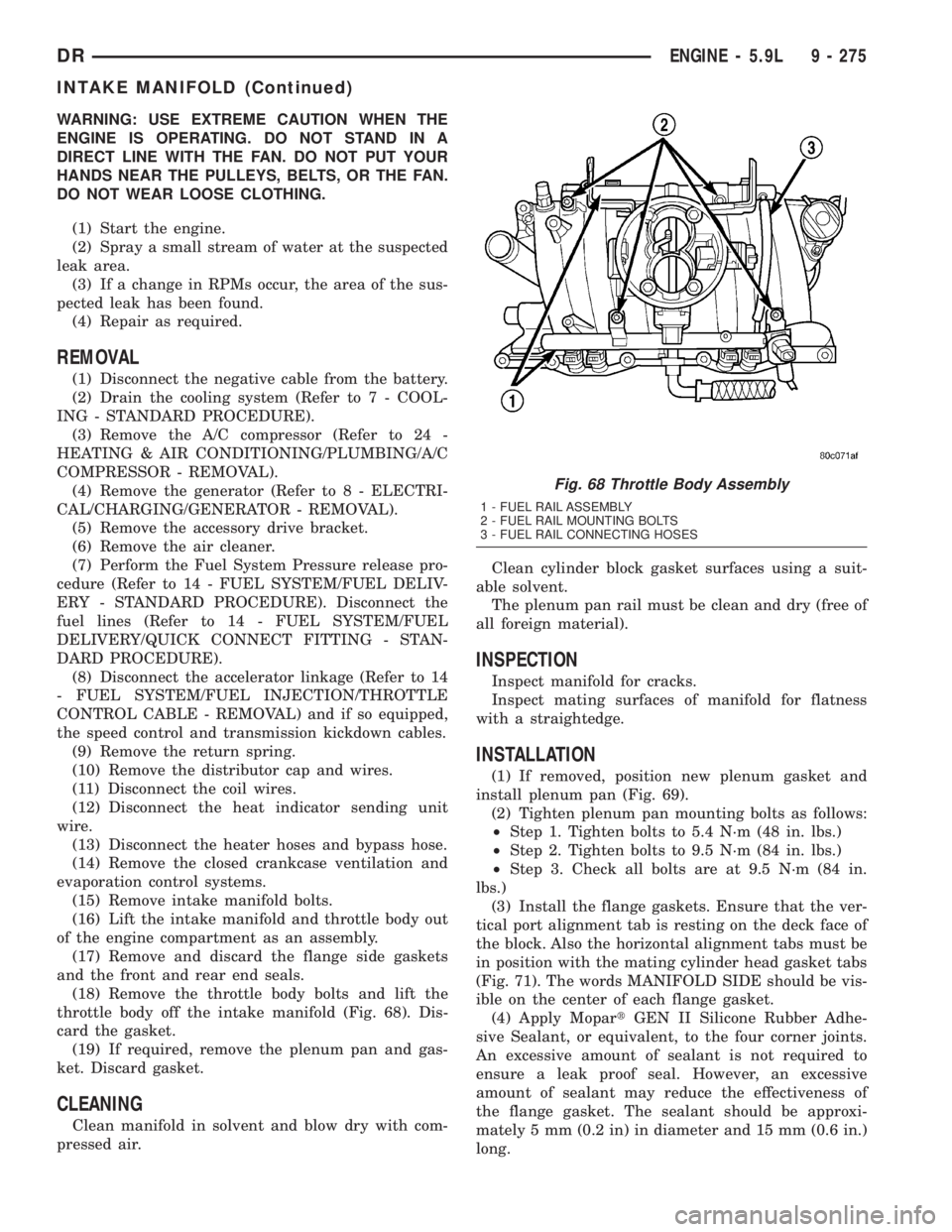

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPMs occur, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL).

(4) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner.

(7) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel lines (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect the accelerator linkage (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL) and if so equipped,

the speed control and transmission kickdown cables.

(9) Remove the return spring.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the heat indicator sending unit

wire.

(13) Disconnect the heater hoses and bypass hose.

(14) Remove the closed crankcase ventilation and

evaporation control systems.

(15) Remove intake manifold bolts.

(16) Lift the intake manifold and throttle body out

of the engine compartment as an assembly.

(17) Remove and discard the flange side gaskets

and the front and rear end seals.

(18) Remove the throttle body bolts and lift the

throttle body off the intake manifold (Fig. 68). Dis-

card the gasket.

(19) If required, remove the plenum pan and gas-

ket. Discard gasket.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.Clean cylinder block gasket surfaces using a suit-

able solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

(1) If removed, position new plenum gasket and

install plenum pan (Fig. 69).

(2) Tighten plenum pan mounting bolts as follows:

²Step 1. Tighten bolts to 5.4 N´m (48 in. lbs.)

²Step 2. Tighten bolts to 9.5 N´m (84 in. lbs.)

²Step 3. Check all bolts are at 9.5 N´m (84 in.

lbs.)

(3) Install the flange gaskets. Ensure that the ver-

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must be

in position with the mating cylinder head gasket tabs

(Fig. 71). The words MANIFOLD SIDE should be vis-

ible on the center of each flange gasket.

(4) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, to the four corner joints.

An excessive amount of sealant is not required to

ensure a leak proof seal. However, an excessive

amount of sealant may reduce the effectiveness of

the flange gasket. The sealant should be approxi-

mately 5 mm (0.2 in) in diameter and 15 mm (0.6 in.)

long.

Fig. 68 Throttle Body Assembly

1 - FUEL RAIL ASSEMBLY

2 - FUEL RAIL MOUNTING BOLTS

3 - FUEL RAIL CONNECTING HOSES

DRENGINE - 5.9L 9 - 275

INTAKE MANIFOLD (Continued)