DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1631 of 2895

(13) Install the rocker arms (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - INSTALLATION).

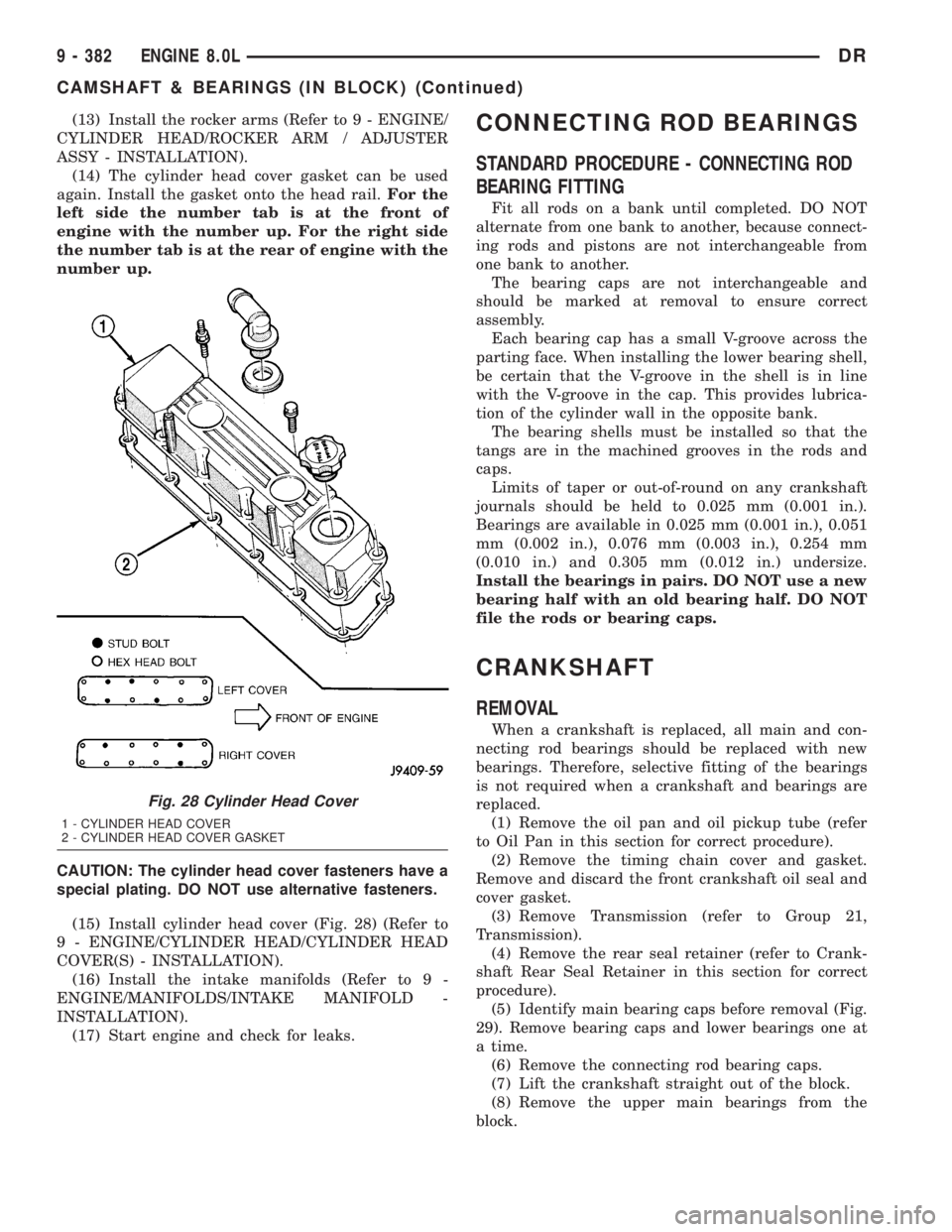

(14) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

CAUTION: The cylinder head cover fasteners have a

special plating. DO NOT use alternative fasteners.

(15) Install cylinder head cover (Fig. 28) (Refer to

9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(16) Install the intake manifolds (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Start engine and check for leaks.CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING ROD

BEARING FITTING

Fit all rods on a bank until completed. DO NOT

alternate from one bank to another, because connect-

ing rods and pistons are not interchangeable from

one bank to another.

The bearing caps are not interchangeable and

should be marked at removal to ensure correct

assembly.

Each bearing cap has a small V-groove across the

parting face. When installing the lower bearing shell,

be certain that the V-groove in the shell is in line

with the V-groove in the cap. This provides lubrica-

tion of the cylinder wall in the opposite bank.

The bearing shells must be installed so that the

tangs are in the machined grooves in the rods and

caps.

Limits of taper or out-of-round on any crankshaft

journals should be held to 0.025 mm (0.001 in.).

Bearings are available in 0.025 mm (0.001 in.), 0.051

mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm

(0.010 in.) and 0.305 mm (0.012 in.) undersize.

Install the bearings in pairs. DO NOT use a new

bearing half with an old bearing half. DO NOT

file the rods or bearing caps.

CRANKSHAFT

REMOVAL

When a crankshaft is replaced, all main and con-

necting rod bearings should be replaced with new

bearings. Therefore, selective fitting of the bearings

is not required when a crankshaft and bearings are

replaced.

(1) Remove the oil pan and oil pickup tube (refer

to Oil Pan in this section for correct procedure).

(2) Remove the timing chain cover and gasket.

Remove and discard the front crankshaft oil seal and

cover gasket.

(3) Remove Transmission (refer to Group 21,

Transmission).

(4) Remove the rear seal retainer (refer to Crank-

shaft Rear Seal Retainer in this section for correct

procedure).

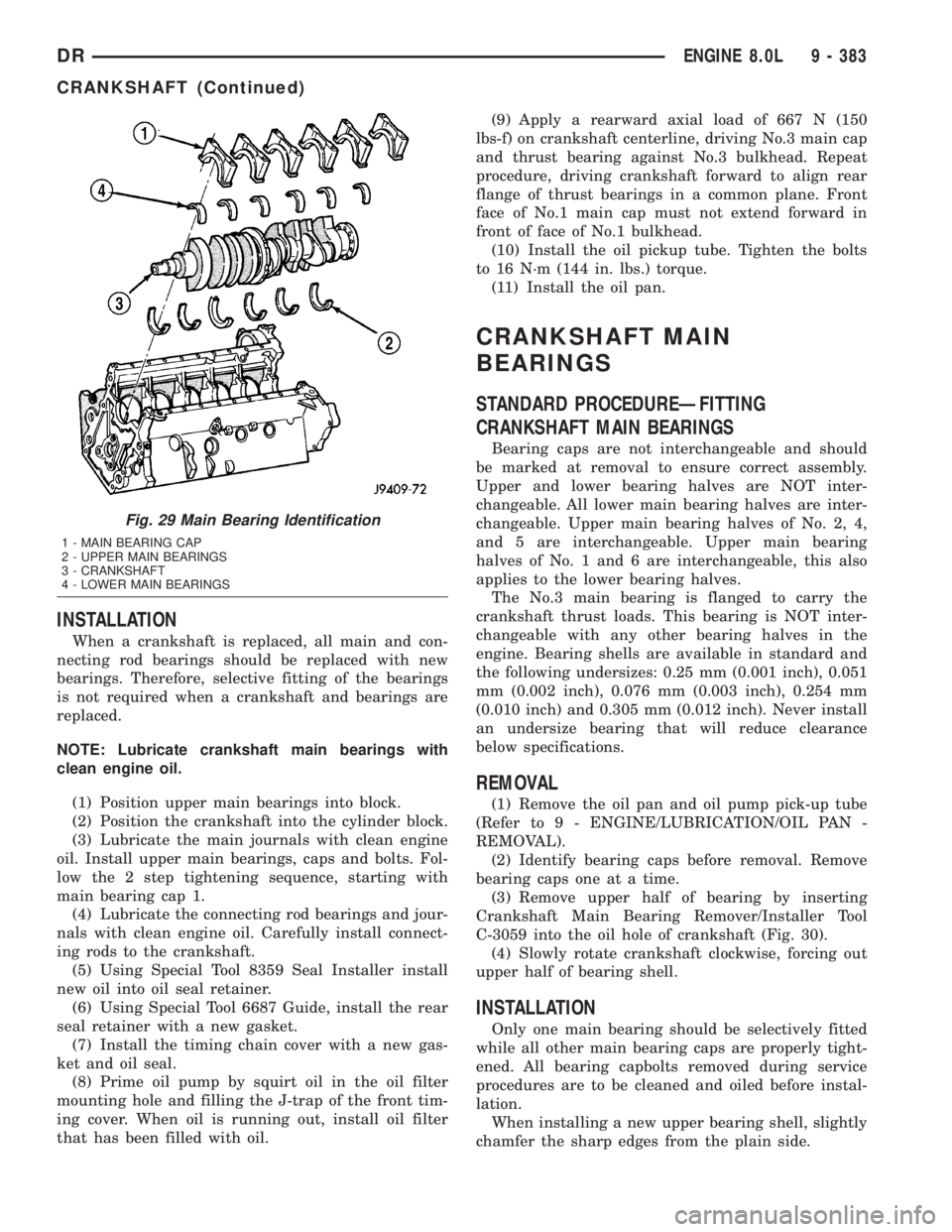

(5) Identify main bearing caps before removal (Fig.

29). Remove bearing caps and lower bearings one at

a time.

(6) Remove the connecting rod bearing caps.

(7) Lift the crankshaft straight out of the block.

(8) Remove the upper main bearings from the

block.

Fig. 28 Cylinder Head Cover

1 - CYLINDER HEAD COVER

2 - CYLINDER HEAD COVER GASKET

9 - 382 ENGINE 8.0LDR

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1632 of 2895

INSTALLATION

When a crankshaft is replaced, all main and con-

necting rod bearings should be replaced with new

bearings. Therefore, selective fitting of the bearings

is not required when a crankshaft and bearings are

replaced.

NOTE: Lubricate crankshaft main bearings with

clean engine oil.

(1) Position upper main bearings into block.

(2) Position the crankshaft into the cylinder block.

(3) Lubricate the main journals with clean engine

oil. Install upper main bearings, caps and bolts. Fol-

low the 2 step tightening sequence, starting with

main bearing cap 1.

(4) Lubricate the connecting rod bearings and jour-

nals with clean engine oil. Carefully install connect-

ing rods to the crankshaft.

(5) Using Special Tool 8359 Seal Installer install

new oil into oil seal retainer.

(6) Using Special Tool 6687 Guide, install the rear

seal retainer with a new gasket.

(7) Install the timing chain cover with a new gas-

ket and oil seal.

(8) Prime oil pump by squirt oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.(9) Apply a rearward axial load of 667 N (150

lbs-f) on crankshaft centerline, driving No.3 main cap

and thrust bearing against No.3 bulkhead. Repeat

procedure, driving crankshaft forward to align rear

flange of thrust bearings in a common plane. Front

face of No.1 main cap must not extend forward in

front of face of No.1 bulkhead.

(10) Install the oil pickup tube. Tighten the bolts

to 16 N´m (144 in. lbs.) torque.

(11) Install the oil pan.

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐFITTING

CRANKSHAFT MAIN BEARINGS

Bearing caps are not interchangeable and should

be marked at removal to ensure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. All lower main bearing halves are inter-

changeable. Upper main bearing halves of No. 2, 4,

and 5 are interchangeable. Upper main bearing

halves of No. 1 and 6 are interchangeable, this also

applies to the lower bearing halves.

The No.3 main bearing is flanged to carry the

crankshaft thrust loads. This bearing is NOT inter-

changeable with any other bearing halves in the

engine. Bearing shells are available in standard and

the following undersizes: 0.25 mm (0.001 inch), 0.051

mm (0.002 inch), 0.076 mm (0.003 inch), 0.254 mm

(0.010 inch) and 0.305 mm (0.012 inch). Never install

an undersize bearing that will reduce clearance

below specifications.

REMOVAL

(1) Remove the oil pan and oil pump pick-up tube

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(2) Identify bearing caps before removal. Remove

bearing caps one at a time.

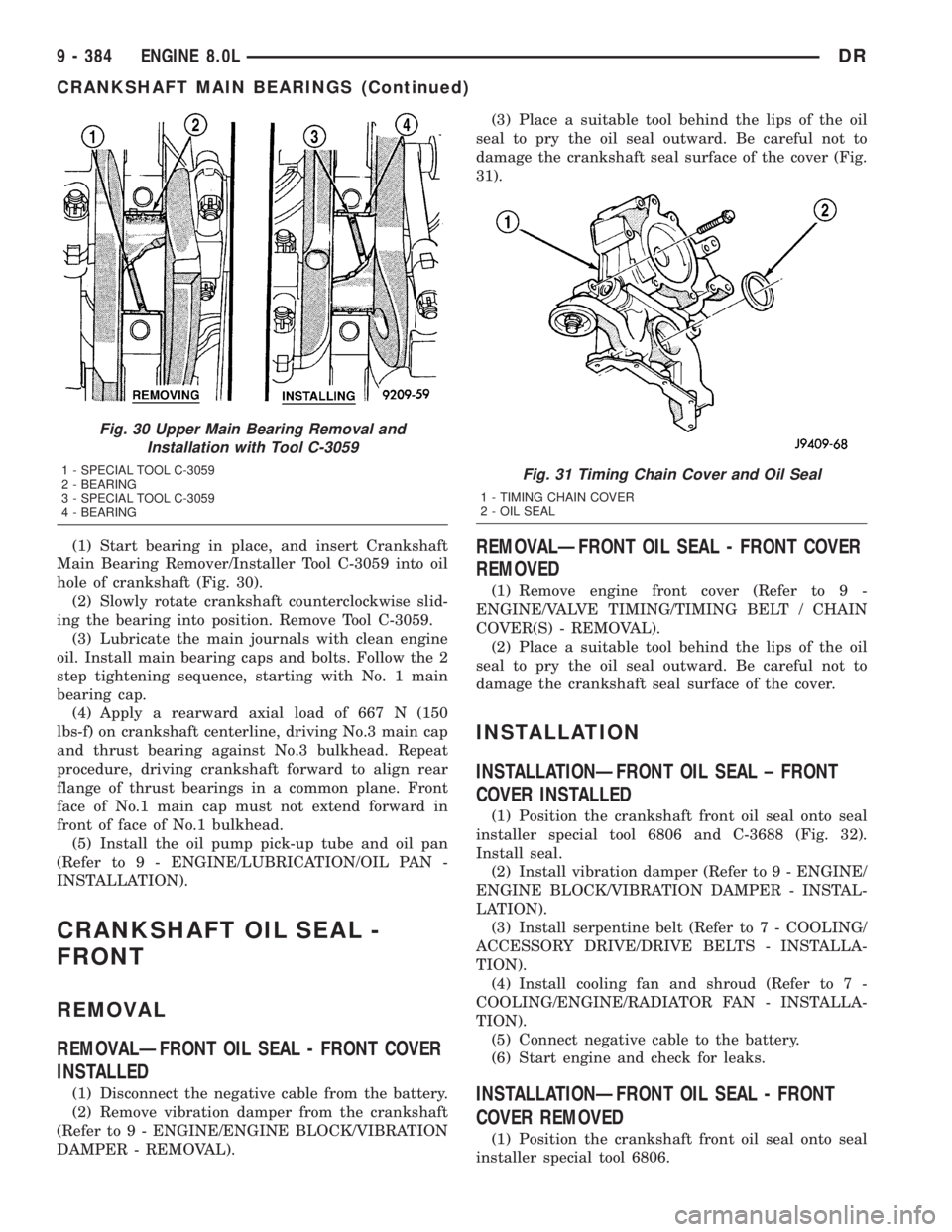

(3) Remove upper half of bearing by inserting

Crankshaft Main Bearing Remover/Installer Tool

C-3059 into the oil hole of crankshaft (Fig. 30).

(4) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

Only one main bearing should be selectively fitted

while all other main bearing caps are properly tight-

ened. All bearing capbolts removed during service

procedures are to be cleaned and oiled before instal-

lation.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

Fig. 29 Main Bearing Identification

1 - MAIN BEARING CAP

2 - UPPER MAIN BEARINGS

3 - CRANKSHAFT

4 - LOWER MAIN BEARINGS

DRENGINE 8.0L 9 - 383

CRANKSHAFT (Continued)

Page 1633 of 2895

(1) Start bearing in place, and insert Crankshaft

Main Bearing Remover/Installer Tool C-3059 into oil

hole of crankshaft (Fig. 30).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Tool C-3059.

(3) Lubricate the main journals with clean engine

oil. Install main bearing caps and bolts. Follow the 2

step tightening sequence, starting with No. 1 main

bearing cap.

(4) Apply a rearward axial load of 667 N (150

lbs-f) on crankshaft centerline, driving No.3 main cap

and thrust bearing against No.3 bulkhead. Repeat

procedure, driving crankshaft forward to align rear

flange of thrust bearings in a common plane. Front

face of No.1 main cap must not extend forward in

front of face of No.1 bulkhead.

(5) Install the oil pump pick-up tube and oil pan

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

INSTALLATION).

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

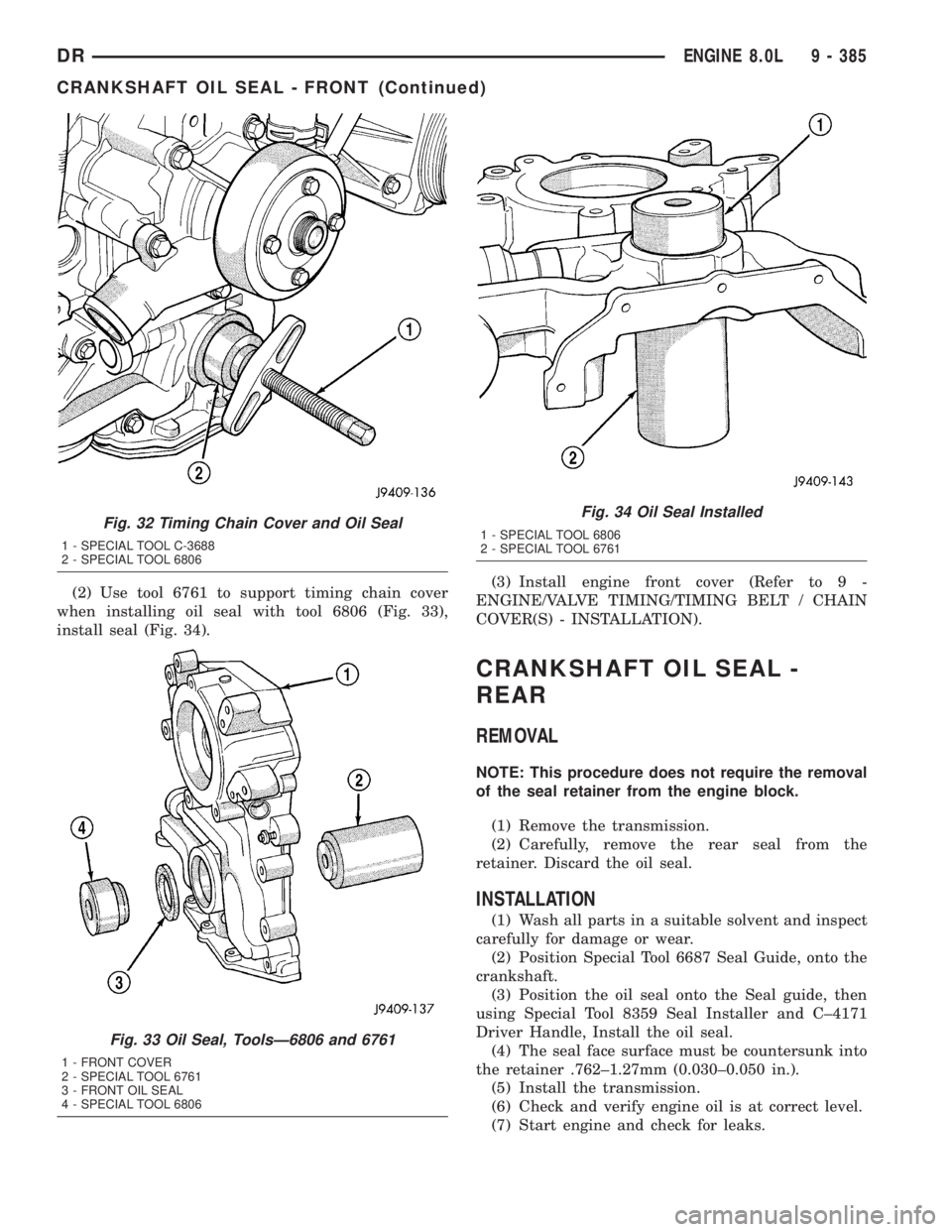

REMOVALÐFRONT OIL SEAL - FRONT COVER

INSTALLED

(1) Disconnect the negative cable from the battery.

(2) Remove vibration damper from the crankshaft

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).(3) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of the cover (Fig.

31).

REMOVALÐFRONT OIL SEAL - FRONT COVER

REMOVED

(1) Remove engine front cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(2) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of the cover.

INSTALLATION

INSTALLATIONÐFRONT OIL SEAL ± FRONT

COVER INSTALLED

(1) Position the crankshaft front oil seal onto seal

installer special tool 6806 and C-3688 (Fig. 32).

Install seal.

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(3) Install serpentine belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(4) Install cooling fan and shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(5) Connect negative cable to the battery.

(6) Start engine and check for leaks.

INSTALLATIONÐFRONT OIL SEAL - FRONT

COVER REMOVED

(1) Position the crankshaft front oil seal onto seal

installer special tool 6806.

Fig. 30 Upper Main Bearing Removal and

Installation with Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARINGFig. 31 Timing Chain Cover and Oil Seal

1 - TIMING CHAIN COVER

2 - OIL SEAL

9 - 384 ENGINE 8.0LDR

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1634 of 2895

(2) Use tool 6761 to support timing chain cover

when installing oil seal with tool 6806 (Fig. 33),

install seal (Fig. 34).(3) Install engine front cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

NOTE: This procedure does not require the removal

of the seal retainer from the engine block.

(1) Remove the transmission.

(2) Carefully, remove the rear seal from the

retainer. Discard the oil seal.

INSTALLATION

(1) Wash all parts in a suitable solvent and inspect

carefully for damage or wear.

(2) Position Special Tool 6687 Seal Guide, onto the

crankshaft.

(3) Position the oil seal onto the Seal guide, then

using Special Tool 8359 Seal Installer and C±4171

Driver Handle, Install the oil seal.

(4) The seal face surface must be countersunk into

the retainer .762±1.27mm (0.030±0.050 in.).

(5) Install the transmission.

(6) Check and verify engine oil is at correct level.

(7) Start engine and check for leaks.

Fig. 32 Timing Chain Cover and Oil Seal

1 - SPECIAL TOOL C-3688

2 - SPECIAL TOOL 6806

Fig. 33 Oil Seal, ToolsÐ6806 and 6761

1 - FRONT COVER

2 - SPECIAL TOOL 6761

3 - FRONT OIL SEAL

4 - SPECIAL TOOL 6806

Fig. 34 Oil Seal Installed

1 - SPECIAL TOOL 6806

2 - SPECIAL TOOL 6761

DRENGINE 8.0L 9 - 385

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1635 of 2895

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the transmission.

(3) Remove the drive plate / flywheel.

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(5) Remove the rear oil seal retainer mounting

bolts.

(6) Carefully remove the retainer from the engine

block.

INSTALLATION

(1) Throughly clean all gasket resdue from the

engine block.

(2) Use extream care and clean all gasket resdue

from the retainer.

(3) Apply a small amount of MopartSilicone Rub-

ber Adhesive Sealant to the retainer gasket. Position

the gasket onto the retainer.

(4) Position Special Tool 6687 Seal Guide onto the

crankshaft.

(5) Position the retainer and seal over the guide

and onto the engine block.

(6) Install the retainer mounting bolts. Tighten the

bolts to 22 N´m (16 ft. lbs.).

(7) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(8) Install the drive plate / flywheel.

(9) Install the transmission.

(10) Check and verify engine oil level.

(11) Start engine and check for leaks.

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTINGÐHYDRAULIC

TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at

the pressure sending-unit. The pressure should be

between 207-552 kPa (30-80 psi) at 3,000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick. The oil level in the pan

should never be above the FULL mark or below the

ADD OIL mark on dipstick. Either of these two con-

ditions could be responsible for noisy tappets.

OIL LEVEL

HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the

engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the

hydraulic tappets by the oil pump causing them to

lose length and allow valves to seat noisily.

LOW

Low oil level may allow oil pump to take in air.

When air is fed to the tappets, they lose length,

which allows valves to seat noisily. Any leaks on

intake side of oil pump through which air can be

drawn will create the same tappet action. Check the

lubrication system from the intake strainer to the

pump cover, including the relief valve retainer cap.

When tappet noise is due to aeration, it may be

intermittent or constant, and usually more than one

tappet will be noisy. When oil level and leaks have

been corrected, operate the engine at fast idle. Run

engine for a sufficient time to allow all of the air

inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger, or by the

plunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click is

caused by a tappet check valve not seating, or by for-

eign particles wedged between the plunger and the

tappet body. This will cause the plunger to stick in

the down position. This heavy click will be accompa-

nied by excessive clearance between the valve stem

and rocker arm as valve closes. In either case, tappet

assembly should be removed for inspection and clean-

ing.

9 - 386 ENGINE 8.0LDR

Page 1636 of 2895

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

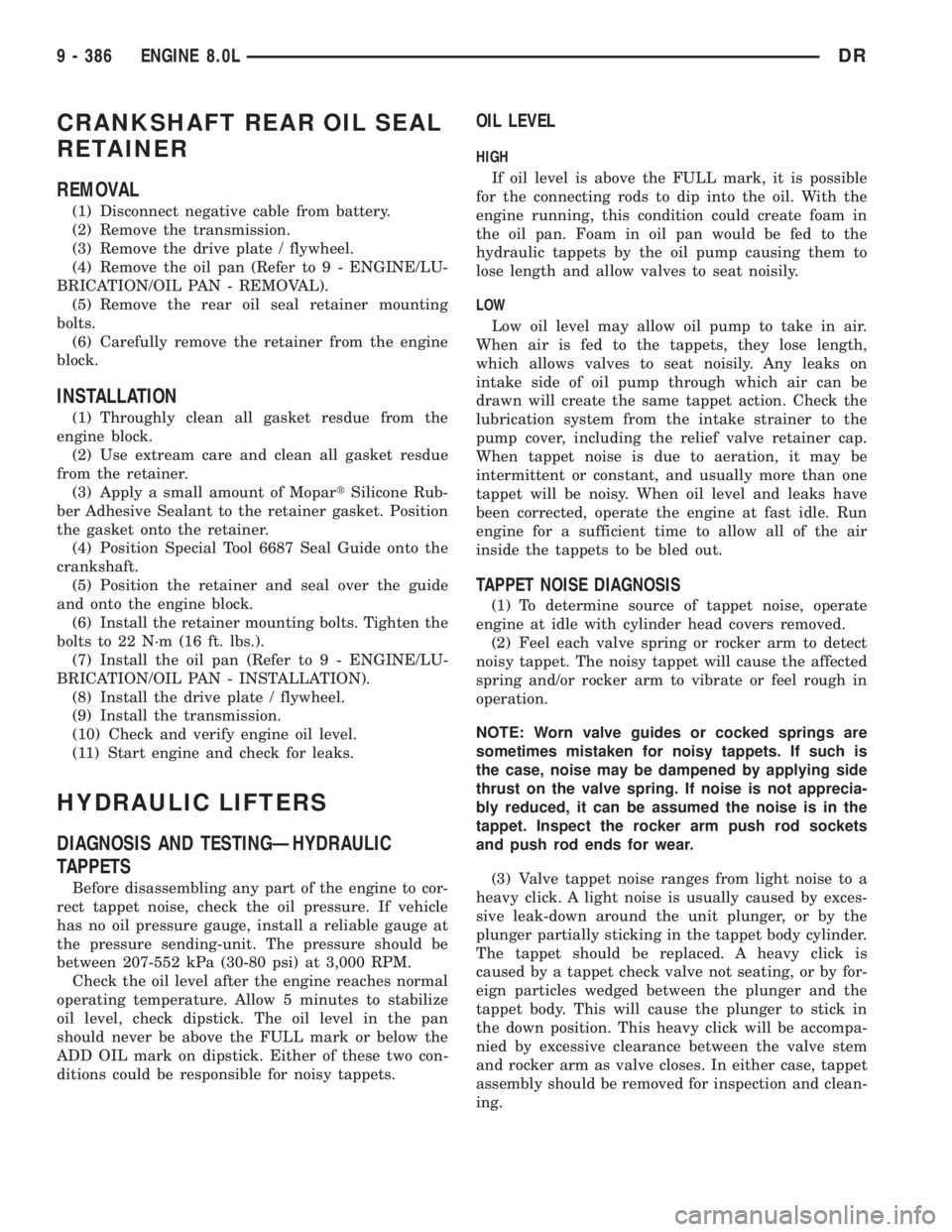

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 35).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the air cleaner.

(3) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(4) Remove rocker arm assembly and push rods

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL). Identify

push rods to ensure installation in original location.

(5) Remove upper and lower intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - REMOVAL).(6) Cut the cylinder head gasket for accessibility if

the end tappets are to be removed.

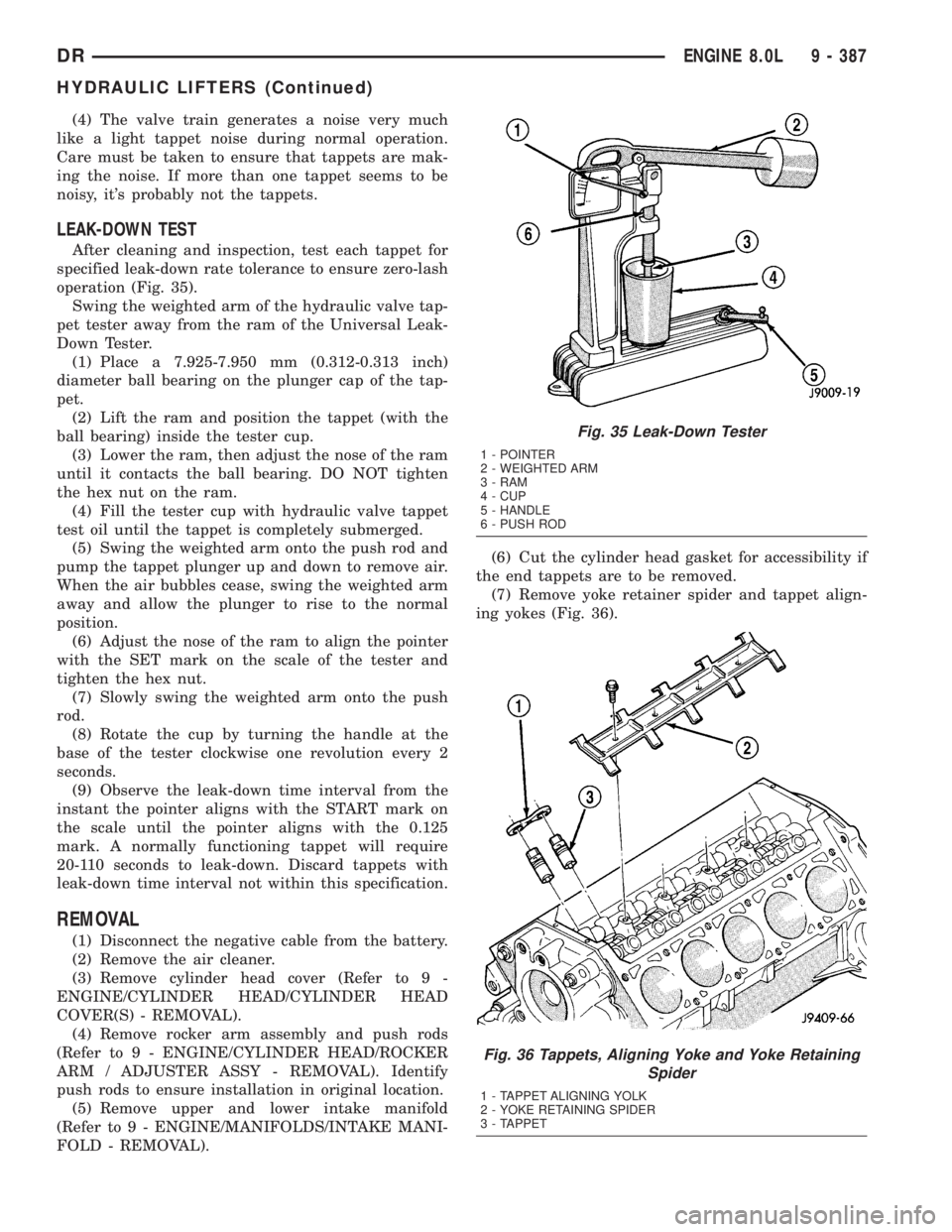

(7) Remove yoke retainer spider and tappet align-

ing yokes (Fig. 36).

Fig. 35 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

Fig. 36 Tappets, Aligning Yoke and Yoke Retaining

Spider

1 - TAPPET ALIGNING YOLK

2 - YOKE RETAINING SPIDER

3 - TAPPET

DRENGINE 8.0L 9 - 387

HYDRAULIC LIFTERS (Continued)

Page 1637 of 2895

(8) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed, identify tappets to

ensure installation in original location.

(9) If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore to

next oversize. Replace with oversize tappet.

(10) Check camshaft lobes for abnormal wear.

CLEANING

Clean tappet with a suitable solvent. Rinse in hot

water and blow dry with a clean shop rag or com-

pressed air.

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets in their original positions.

Ensure that the oil bleed hole (if so equipped)

faces forward.

(3) Install tappet aligning yokes. Position the yoke

retainer spider over the tappet aligning yokes (Fig.

36)Install the yoke retaining spider bolts and tighten

to 22 N´m (16 ft. lbs.) torque.

(4) Install the push rods in their original location.

(5) Install the rocker arms (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - INSTALLATION).

(6) Install lower and upper intake manifold (Refer

to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(7) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

(8) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(9) Install the air cleaner.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

(10) Connect the negative cable to the battery.

(11) Road test vehicle and check for leaks.

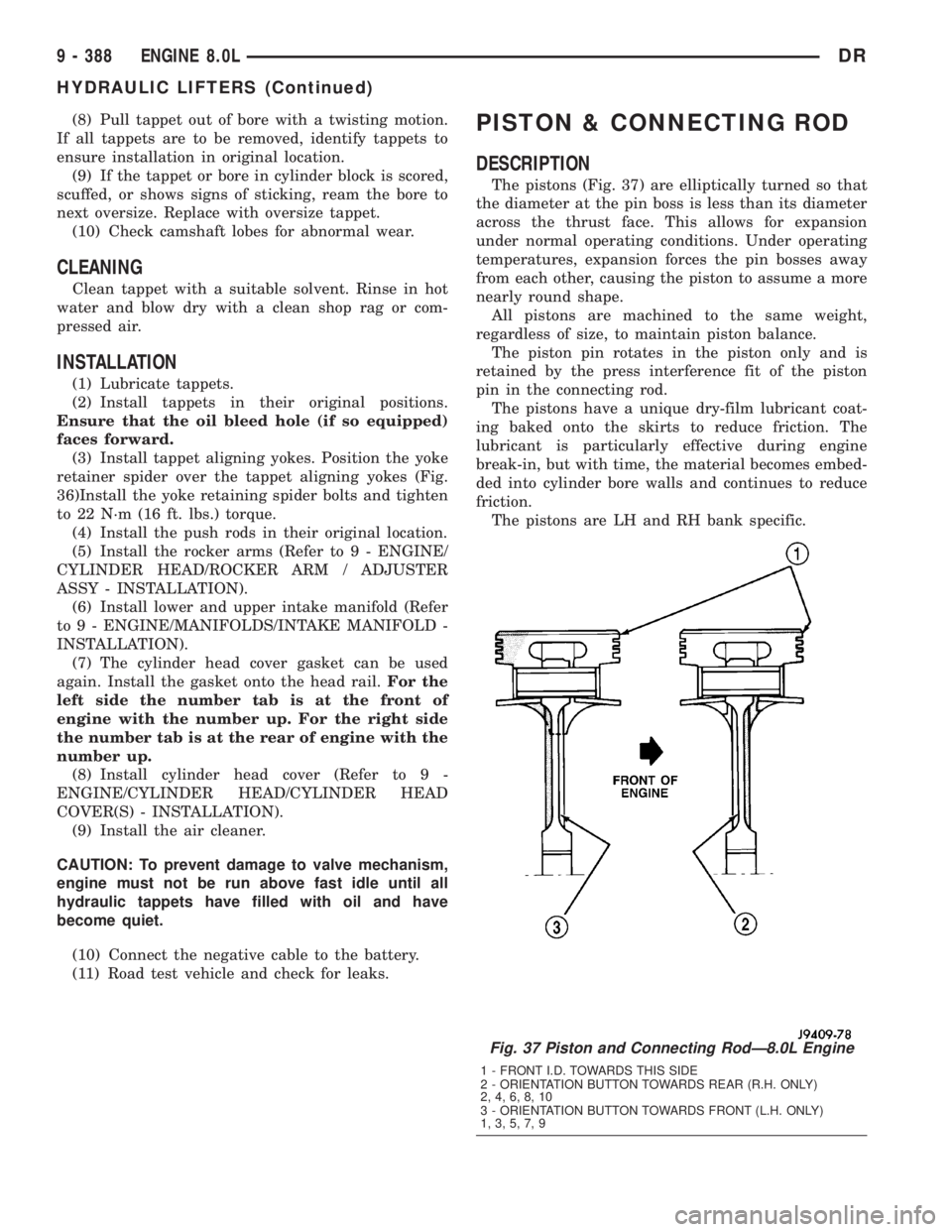

PISTON & CONNECTING ROD

DESCRIPTION

The pistons (Fig. 37) are elliptically turned so that

the diameter at the pin boss is less than its diameter

across the thrust face. This allows for expansion

under normal operating conditions. Under operating

temperatures, expansion forces the pin bosses away

from each other, causing the piston to assume a more

nearly round shape.

All pistons are machined to the same weight,

regardless of size, to maintain piston balance.

The piston pin rotates in the piston only and is

retained by the press interference fit of the piston

pin in the connecting rod.

The pistons have a unique dry-film lubricant coat-

ing baked onto the skirts to reduce friction. The

lubricant is particularly effective during engine

break-in, but with time, the material becomes embed-

ded into cylinder bore walls and continues to reduce

friction.

The pistons are LH and RH bank specific.

Fig. 37 Piston and Connecting RodÐ8.0L Engine

1 - FRONT I.D. TOWARDS THIS SIDE

2 - ORIENTATION BUTTON TOWARDS REAR (R.H. ONLY)

2, 4, 6, 8, 10

3 - ORIENTATION BUTTON TOWARDS FRONT (L.H. ONLY)

1, 3, 5, 7, 9

9 - 388 ENGINE 8.0LDR

HYDRAULIC LIFTERS (Continued)

Page 1638 of 2895

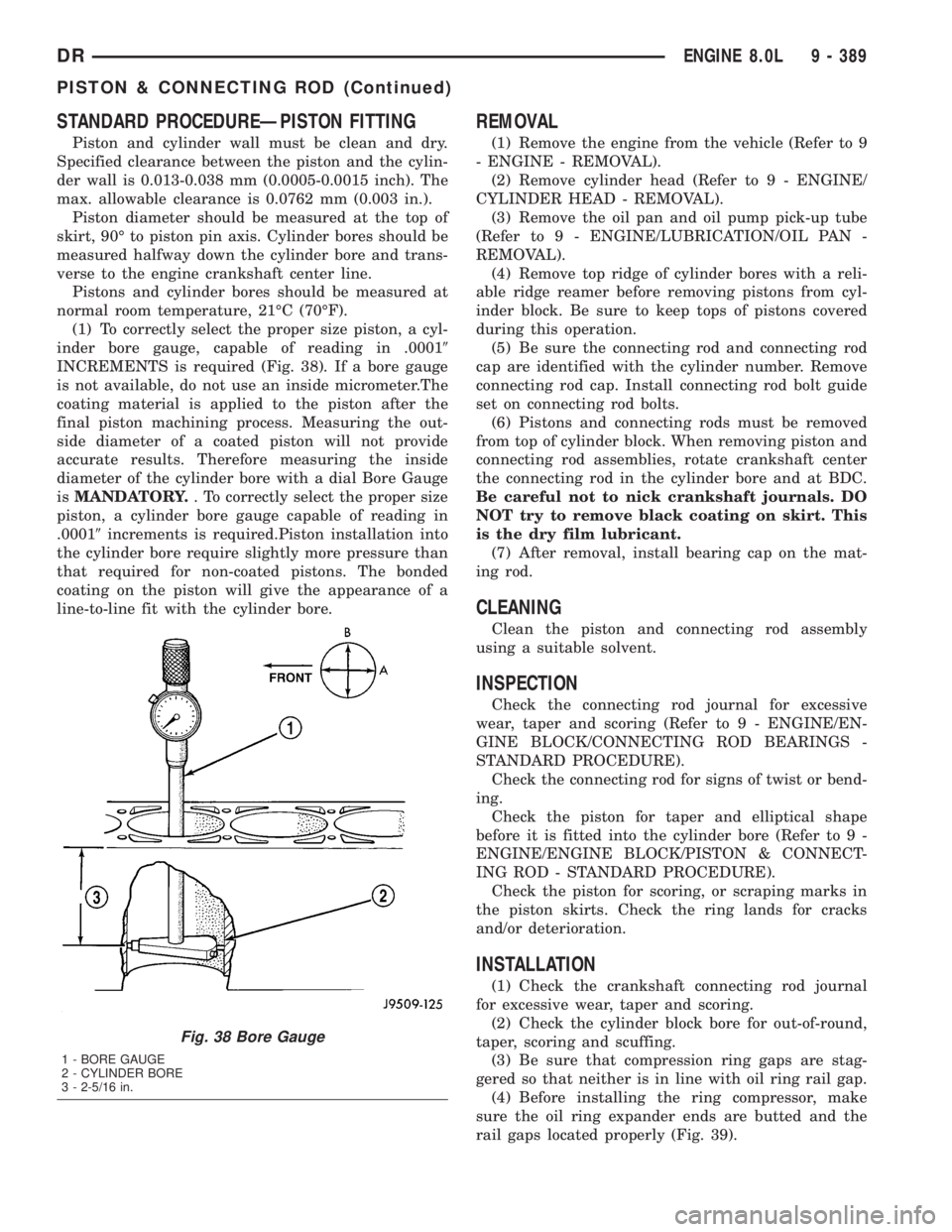

STANDARD PROCEDUREÐPISTON FITTING

Piston and cylinder wall must be clean and dry.

Specified clearance between the piston and the cylin-

der wall is 0.013-0.038 mm (0.0005-0.0015 inch). The

max. allowable clearance is 0.0762 mm (0.003 in.).

Piston diameter should be measured at the top of

skirt, 90É to piston pin axis. Cylinder bores should be

measured halfway down the cylinder bore and trans-

verse to the engine crankshaft center line.

Pistons and cylinder bores should be measured at

normal room temperature, 21ÉC (70ÉF).

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in .00019

INCREMENTS is required (Fig. 38). If a bore gauge

is not available, do not use an inside micrometer.The

coating material is applied to the piston after the

final piston machining process. Measuring the out-

side diameter of a coated piston will not provide

accurate results. Therefore measuring the inside

diameter of the cylinder bore with a dial Bore Gauge

isMANDATORY.. To correctly select the proper size

piston, a cylinder bore gauge capable of reading in

.00019increments is required.Piston installation into

the cylinder bore require slightly more pressure than

that required for non-coated pistons. The bonded

coating on the piston will give the appearance of a

line-to-line fit with the cylinder bore.

REMOVAL

(1) Remove the engine from the vehicle (Refer to 9

- ENGINE - REMOVAL).

(2) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan and oil pump pick-up tube

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block. Be sure to keep tops of pistons covered

during this operation.

(5) Be sure the connecting rod and connecting rod

cap are identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing piston and

connecting rod assemblies, rotate crankshaft center

the connecting rod in the cylinder bore and at BDC.

Be careful not to nick crankshaft journals. DO

NOT try to remove black coating on skirt. This

is the dry film lubricant.

(7) After removal, install bearing cap on the mat-

ing rod.

CLEANING

Clean the piston and connecting rod assembly

using a suitable solvent.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

(1) Check the crankshaft connecting rod journal

for excessive wear, taper and scoring.

(2) Check the cylinder block bore for out-of-round,

taper, scoring and scuffing.

(3) Be sure that compression ring gaps are stag-

gered so that neither is in line with oil ring rail gap.

(4) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

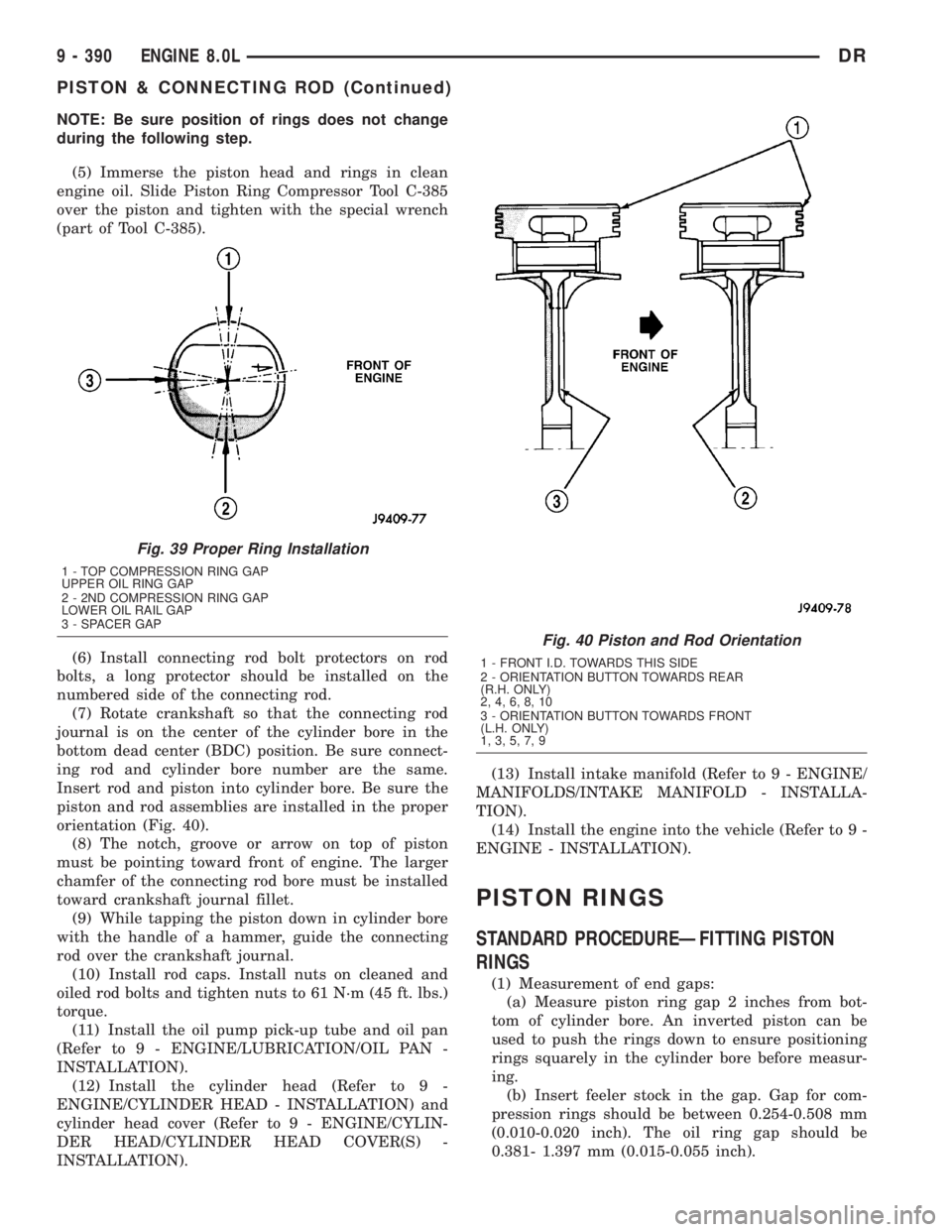

rail gaps located properly (Fig. 39).

Fig. 38 Bore Gauge

1 - BORE GAUGE

2 - CYLINDER BORE

3 - 2-5/16 in.

DRENGINE 8.0L 9 - 389

PISTON & CONNECTING ROD (Continued)

Page 1639 of 2895

NOTE: Be sure position of rings does not change

during the following step.

(5) Immerse the piston head and rings in clean

engine oil. Slide Piston Ring Compressor Tool C-385

over the piston and tighten with the special wrench

(part of Tool C-385).

(6) Install connecting rod bolt protectors on rod

bolts, a long protector should be installed on the

numbered side of the connecting rod.

(7) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore in the

bottom dead center (BDC) position. Be sure connect-

ing rod and cylinder bore number are the same.

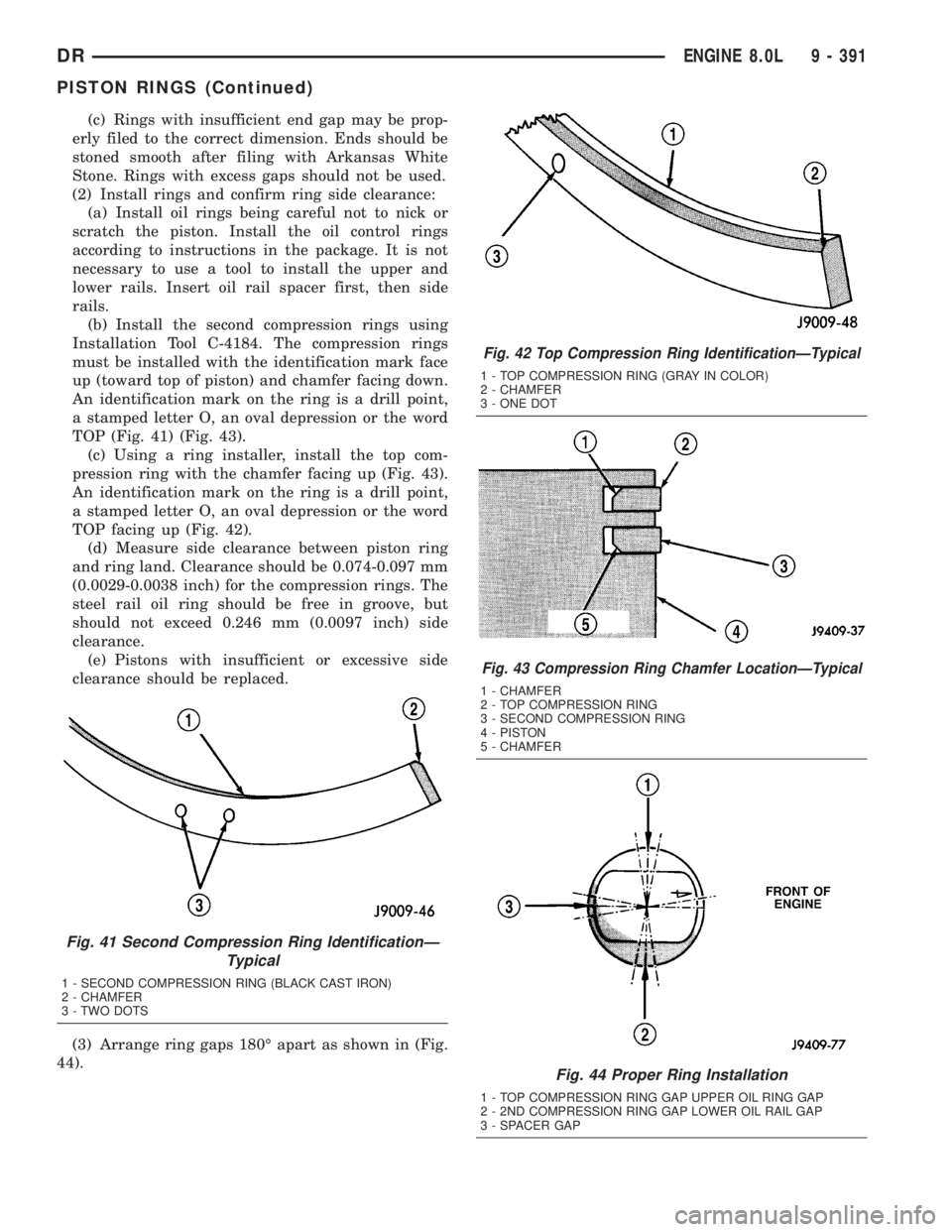

Insert rod and piston into cylinder bore. Be sure the

piston and rod assemblies are installed in the proper

orientation (Fig. 40).

(8) The notch, groove or arrow on top of piston

must be pointing toward front of engine. The larger

chamfer of the connecting rod bore must be installed

toward crankshaft journal fillet.

(9) While tapping the piston down in cylinder bore

with the handle of a hammer, guide the connecting

rod over the crankshaft journal.

(10) Install rod caps. Install nuts on cleaned and

oiled rod bolts and tighten nuts to 61 N´m (45 ft. lbs.)

torque.

(11) Install the oil pump pick-up tube and oil pan

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

INSTALLATION).

(12) Install the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION) and

cylinder head cover (Refer to 9 - ENGINE/CYLIN-

DER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).(13) Install intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

(14) Install the engine into the vehicle (Refer to 9 -

ENGINE - INSTALLATION).

PISTON RINGS

STANDARD PROCEDUREÐFITTING PISTON

RINGS

(1) Measurement of end gaps:

(a) Measure piston ring gap 2 inches from bot-

tom of cylinder bore. An inverted piston can be

used to push the rings down to ensure positioning

rings squarely in the cylinder bore before measur-

ing.

(b) Insert feeler stock in the gap. Gap for com-

pression rings should be between 0.254-0.508 mm

(0.010-0.020 inch). The oil ring gap should be

0.381- 1.397 mm (0.015-0.055 inch).

Fig. 39 Proper Ring Installation

1 - TOP COMPRESSION RING GAP

UPPER OIL RING GAP

2 - 2ND COMPRESSION RING GAP

LOWER OIL RAIL GAP

3 - SPACER GAP

Fig. 40 Piston and Rod Orientation

1 - FRONT I.D. TOWARDS THIS SIDE

2 - ORIENTATION BUTTON TOWARDS REAR

(R.H. ONLY)

2, 4, 6, 8, 10

3 - ORIENTATION BUTTON TOWARDS FRONT

(L.H. ONLY)

1, 3, 5, 7, 9

9 - 390 ENGINE 8.0LDR

PISTON & CONNECTING ROD (Continued)

Page 1640 of 2895

(c) Rings with insufficient end gap may be prop-

erly filed to the correct dimension. Ends should be

stoned smooth after filing with Arkansas White

Stone. Rings with excess gaps should not be used.

(2) Install rings and confirm ring side clearance:

(a) Install oil rings being careful not to nick or

scratch the piston. Install the oil control rings

according to instructions in the package. It is not

necessary to use a tool to install the upper and

lower rails. Insert oil rail spacer first, then side

rails.

(b) Install the second compression rings using

Installation Tool C-4184. The compression rings

must be installed with the identification mark face

up (toward top of piston) and chamfer facing down.

An identification mark on the ring is a drill point,

a stamped letter O, an oval depression or the word

TOP (Fig. 41) (Fig. 43).

(c) Using a ring installer, install the top com-

pression ring with the chamfer facing up (Fig. 43).

An identification mark on the ring is a drill point,

a stamped letter O, an oval depression or the word

TOP facing up (Fig. 42).

(d) Measure side clearance between piston ring

and ring land. Clearance should be 0.074-0.097 mm

(0.0029-0.0038 inch) for the compression rings. The

steel rail oil ring should be free in groove, but

should not exceed 0.246 mm (0.0097 inch) side

clearance.

(e) Pistons with insufficient or excessive side

clearance should be replaced.

(3) Arrange ring gaps 180É apart as shown in (Fig.

44).

Fig. 41 Second Compression Ring IdentificationÐ

Typical

1 - SECOND COMPRESSION RING (BLACK CAST IRON)

2 - CHAMFER

3 - TWO DOTS

Fig. 42 Top Compression Ring IdentificationÐTypical

1 - TOP COMPRESSION RING (GRAY IN COLOR)

2 - CHAMFER

3 - ONE DOT

Fig. 43 Compression Ring Chamfer LocationÐTypical

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

Fig. 44 Proper Ring Installation

1 - TOP COMPRESSION RING GAP UPPER OIL RING GAP

2 - 2ND COMPRESSION RING GAP LOWER OIL RAIL GAP

3 - SPACER GAP

DRENGINE 8.0L 9 - 391

PISTON RINGS (Continued)