dimensions DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1562 of 2895

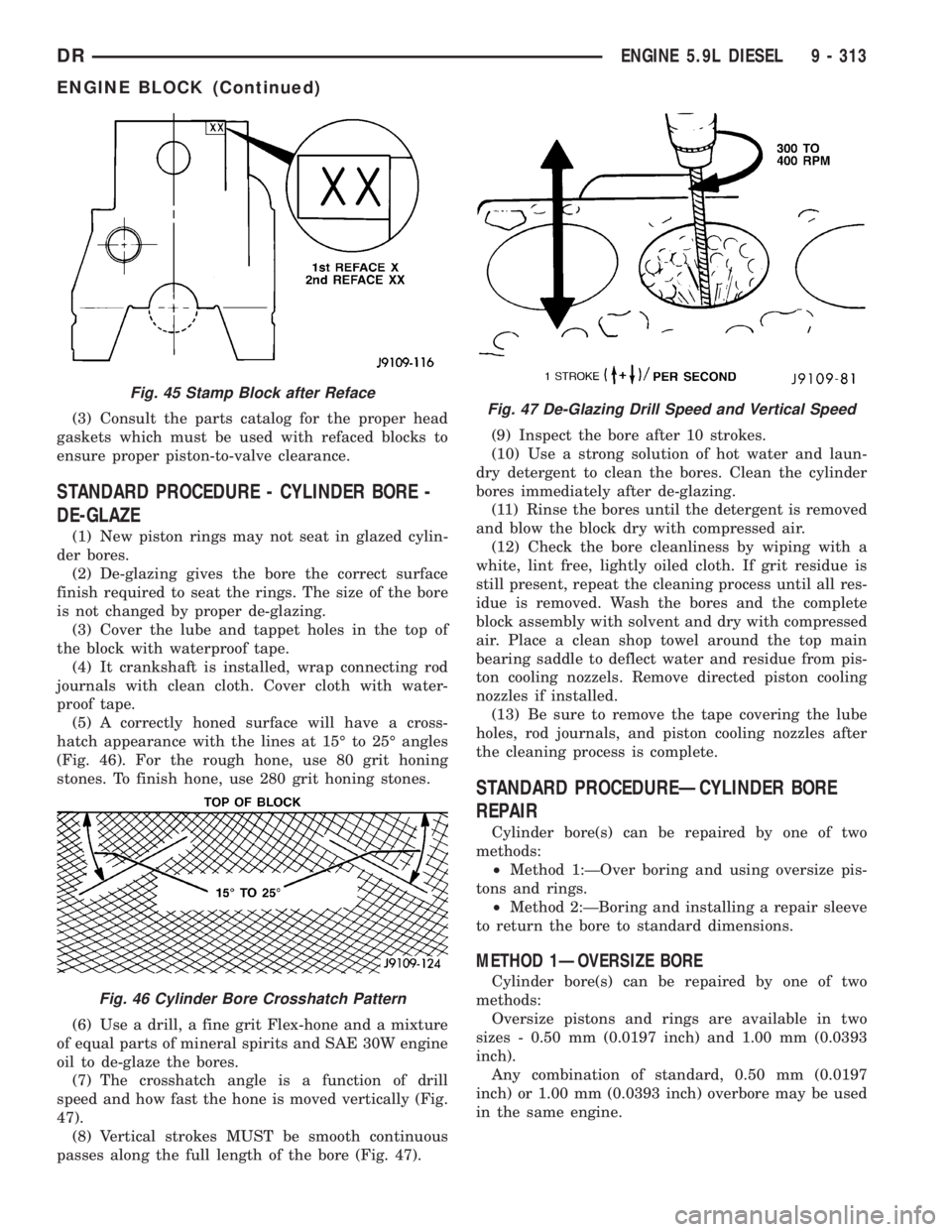

(3) Consult the parts catalog for the proper head

gaskets which must be used with refaced blocks to

ensure proper piston-to-valve clearance.

STANDARD PROCEDURE - CYLINDER BORE -

DE-GLAZE

(1) New piston rings may not seat in glazed cylin-

der bores.

(2) De-glazing gives the bore the correct surface

finish required to seat the rings. The size of the bore

is not changed by proper de-glazing.

(3) Cover the lube and tappet holes in the top of

the block with waterproof tape.

(4) It crankshaft is installed, wrap connecting rod

journals with clean cloth. Cover cloth with water-

proof tape.

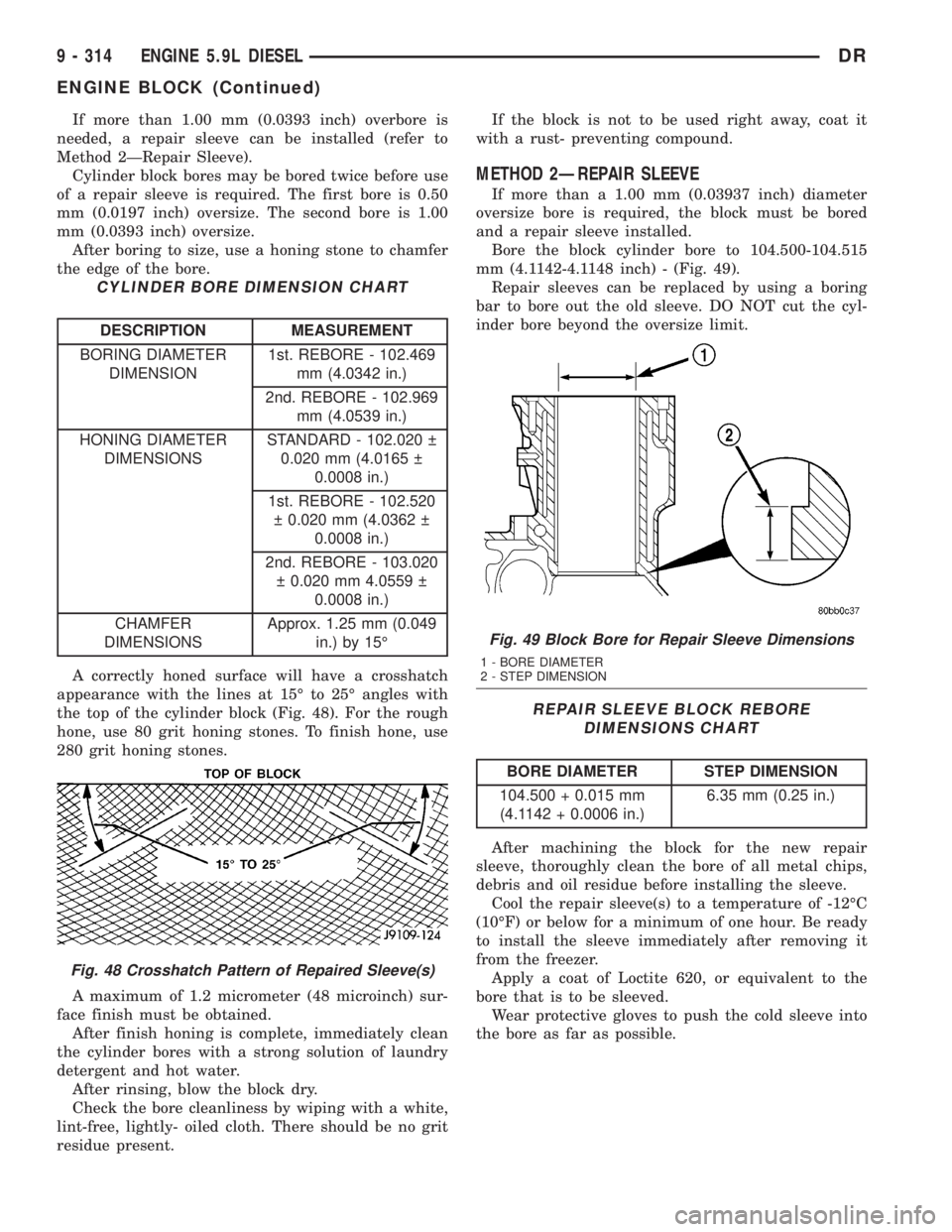

(5) A correctly honed surface will have a cross-

hatch appearance with the lines at 15É to 25É angles

(Fig. 46). For the rough hone, use 80 grit honing

stones. To finish hone, use 280 grit honing stones.

(6) Use a drill, a fine grit Flex-hone and a mixture

of equal parts of mineral spirits and SAE 30W engine

oil to de-glaze the bores.

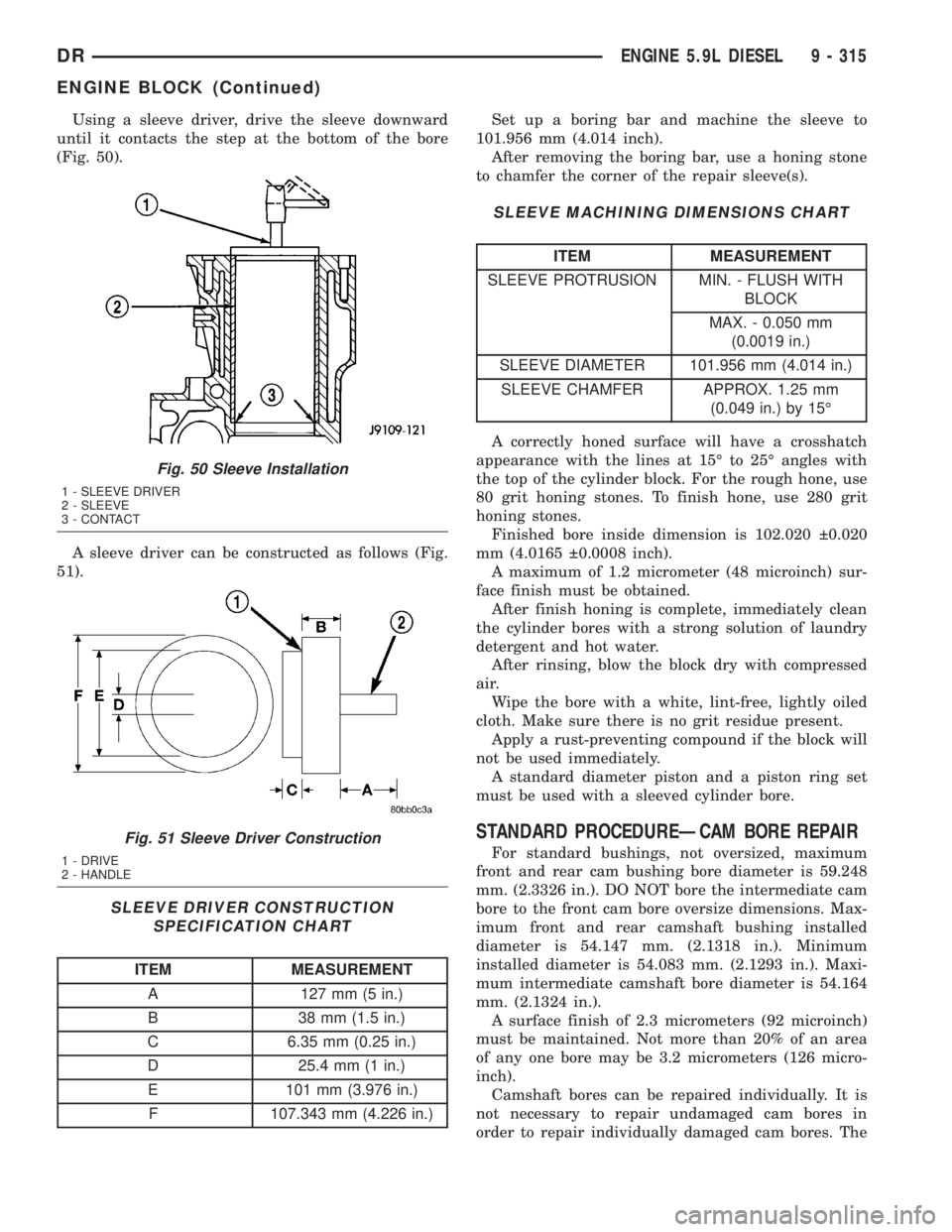

(7) The crosshatch angle is a function of drill

speed and how fast the hone is moved vertically (Fig.

47).

(8) Vertical strokes MUST be smooth continuous

passes along the full length of the bore (Fig. 47).(9) Inspect the bore after 10 strokes.

(10) Use a strong solution of hot water and laun-

dry detergent to clean the bores. Clean the cylinder

bores immediately after de-glazing.

(11) Rinse the bores until the detergent is removed

and blow the block dry with compressed air.

(12) Check the bore cleanliness by wiping with a

white, lint free, lightly oiled cloth. If grit residue is

still present, repeat the cleaning process until all res-

idue is removed. Wash the bores and the complete

block assembly with solvent and dry with compressed

air. Place a clean shop towel around the top main

bearing saddle to deflect water and residue from pis-

ton cooling nozzels. Remove directed piston cooling

nozzles if installed.

(13) Be sure to remove the tape covering the lube

holes, rod journals, and piston cooling nozzles after

the cleaning process is complete.

STANDARD PROCEDUREÐCYLINDER BORE

REPAIR

Cylinder bore(s) can be repaired by one of two

methods:

²Method 1:ÐOver boring and using oversize pis-

tons and rings.

²Method 2:ÐBoring and installing a repair sleeve

to return the bore to standard dimensions.

METHOD 1ÐOVERSIZE BORE

Cylinder bore(s) can be repaired by one of two

methods:

Oversize pistons and rings are available in two

sizes - 0.50 mm (0.0197 inch) and 1.00 mm (0.0393

inch).

Any combination of standard, 0.50 mm (0.0197

inch) or 1.00 mm (0.0393 inch) overbore may be used

in the same engine.

Fig. 45 Stamp Block after Reface

Fig. 46 Cylinder Bore Crosshatch Pattern

Fig. 47 De-Glazing Drill Speed and Vertical Speed

DRENGINE 5.9L DIESEL 9 - 313

ENGINE BLOCK (Continued)

Page 1563 of 2895

If more than 1.00 mm (0.0393 inch) overbore is

needed, a repair sleeve can be installed (refer to

Method 2ÐRepair Sleeve).

Cylinder block bores may be bored twice before use

of a repair sleeve is required. The first bore is 0.50

mm (0.0197 inch) oversize. The second bore is 1.00

mm (0.0393 inch) oversize.

After boring to size, use a honing stone to chamfer

the edge of the bore.

CYLINDER BORE DIMENSION CHART

DESCRIPTION MEASUREMENT

BORING DIAMETER

DIMENSION1st. REBORE - 102.469

mm (4.0342 in.)

2nd. REBORE - 102.969

mm (4.0539 in.)

HONING DIAMETER

DIMENSIONSSTANDARD - 102.020

0.020 mm (4.0165

0.0008 in.)

1st. REBORE - 102.520

0.020 mm (4.0362

0.0008 in.)

2nd. REBORE - 103.020

0.020 mm 4.0559

0.0008 in.)

CHAMFER

DIMENSIONSApprox. 1.25 mm (0.049

in.) by 15É

A correctly honed surface will have a crosshatch

appearance with the lines at 15É to 25É angles with

the top of the cylinder block (Fig. 48). For the rough

hone, use 80 grit honing stones. To finish hone, use

280 grit honing stones.

A maximum of 1.2 micrometer (48 microinch) sur-

face finish must be obtained.

After finish honing is complete, immediately clean

the cylinder bores with a strong solution of laundry

detergent and hot water.

After rinsing, blow the block dry.

Check the bore cleanliness by wiping with a white,

lint-free, lightly- oiled cloth. There should be no grit

residue present.If the block is not to be used right away, coat it

with a rust- preventing compound.

METHOD 2ÐREPAIR SLEEVE

If more than a 1.00 mm (0.03937 inch) diameter

oversize bore is required, the block must be bored

and a repair sleeve installed.

Bore the block cylinder bore to 104.500-104.515

mm (4.1142-4.1148 inch) - (Fig. 49).

Repair sleeves can be replaced by using a boring

bar to bore out the old sleeve. DO NOT cut the cyl-

inder bore beyond the oversize limit.

REPAIR SLEEVE BLOCK REBORE

DIMENSIONS CHART

BORE DIAMETER STEP DIMENSION

104.500 + 0.015 mm

(4.1142 + 0.0006 in.)6.35 mm (0.25 in.)

After machining the block for the new repair

sleeve, thoroughly clean the bore of all metal chips,

debris and oil residue before installing the sleeve.

Cool the repair sleeve(s) to a temperature of -12ÉC

(10ÉF) or below for a minimum of one hour. Be ready

to install the sleeve immediately after removing it

from the freezer.

Apply a coat of Loctite 620, or equivalent to the

bore that is to be sleeved.

Wear protective gloves to push the cold sleeve into

the bore as far as possible.

Fig. 48 Crosshatch Pattern of Repaired Sleeve(s)

Fig. 49 Block Bore for Repair Sleeve Dimensions

1 - BORE DIAMETER

2 - STEP DIMENSION

9 - 314 ENGINE 5.9L DIESELDR

ENGINE BLOCK (Continued)

Page 1564 of 2895

Using a sleeve driver, drive the sleeve downward

until it contacts the step at the bottom of the bore

(Fig. 50).

A sleeve driver can be constructed as follows (Fig.

51).

SLEEVE DRIVER CONSTRUCTION

SPECIFICATION CHART

ITEM MEASUREMENT

A 127 mm (5 in.)

B 38 mm (1.5 in.)

C 6.35 mm (0.25 in.)

D 25.4 mm (1 in.)

E 101 mm (3.976 in.)

F 107.343 mm (4.226 in.)Set up a boring bar and machine the sleeve to

101.956 mm (4.014 inch).

After removing the boring bar, use a honing stone

to chamfer the corner of the repair sleeve(s).

SLEEVE MACHINING DIMENSIONS CHART

ITEM MEASUREMENT

SLEEVE PROTRUSION MIN. - FLUSH WITH

BLOCK

MAX. - 0.050 mm

(0.0019 in.)

SLEEVE DIAMETER 101.956 mm (4.014 in.)

SLEEVE CHAMFER APPROX. 1.25 mm

(0.049 in.) by 15É

A correctly honed surface will have a crosshatch

appearance with the lines at 15É to 25É angles with

the top of the cylinder block. For the rough hone, use

80 grit honing stones. To finish hone, use 280 grit

honing stones.

Finished bore inside dimension is 102.020 0.020

mm (4.0165 0.0008 inch).

A maximum of 1.2 micrometer (48 microinch) sur-

face finish must be obtained.

After finish honing is complete, immediately clean

the cylinder bores with a strong solution of laundry

detergent and hot water.

After rinsing, blow the block dry with compressed

air.

Wipe the bore with a white, lint-free, lightly oiled

cloth. Make sure there is no grit residue present.

Apply a rust-preventing compound if the block will

not be used immediately.

A standard diameter piston and a piston ring set

must be used with a sleeved cylinder bore.

STANDARD PROCEDUREÐCAM BORE REPAIR

For standard bushings, not oversized, maximum

front and rear cam bushing bore diameter is 59.248

mm. (2.3326 in.). DO NOT bore the intermediate cam

bore to the front cam bore oversize dimensions. Max-

imum front and rear camshaft bushing installed

diameter is 54.147 mm. (2.1318 in.). Minimum

installed diameter is 54.083 mm. (2.1293 in.). Maxi-

mum intermediate camshaft bore diameter is 54.164

mm. (2.1324 in.).

A surface finish of 2.3 micrometers (92 microinch)

must be maintained. Not more than 20% of an area

of any one bore may be 3.2 micrometers (126 micro-

inch).

Camshaft bores can be repaired individually. It is

not necessary to repair undamaged cam bores in

order to repair individually damaged cam bores. The

Fig. 50 Sleeve Installation

1 - SLEEVE DRIVER

2 - SLEEVE

3 - CONTACT

Fig. 51 Sleeve Driver Construction

1 - DRIVE

2 - HANDLE

DRENGINE 5.9L DIESEL 9 - 315

ENGINE BLOCK (Continued)

Page 1567 of 2895

(b) Raise the dowel rod to bring the tappet to

the top of its travel, and wrap a rubber band

around the dowel rods (Fig. 57) to prevent the tap-

pets from dropping into the crankcase.

(c) Repeat this procedure for the remaining cyl-

inders.

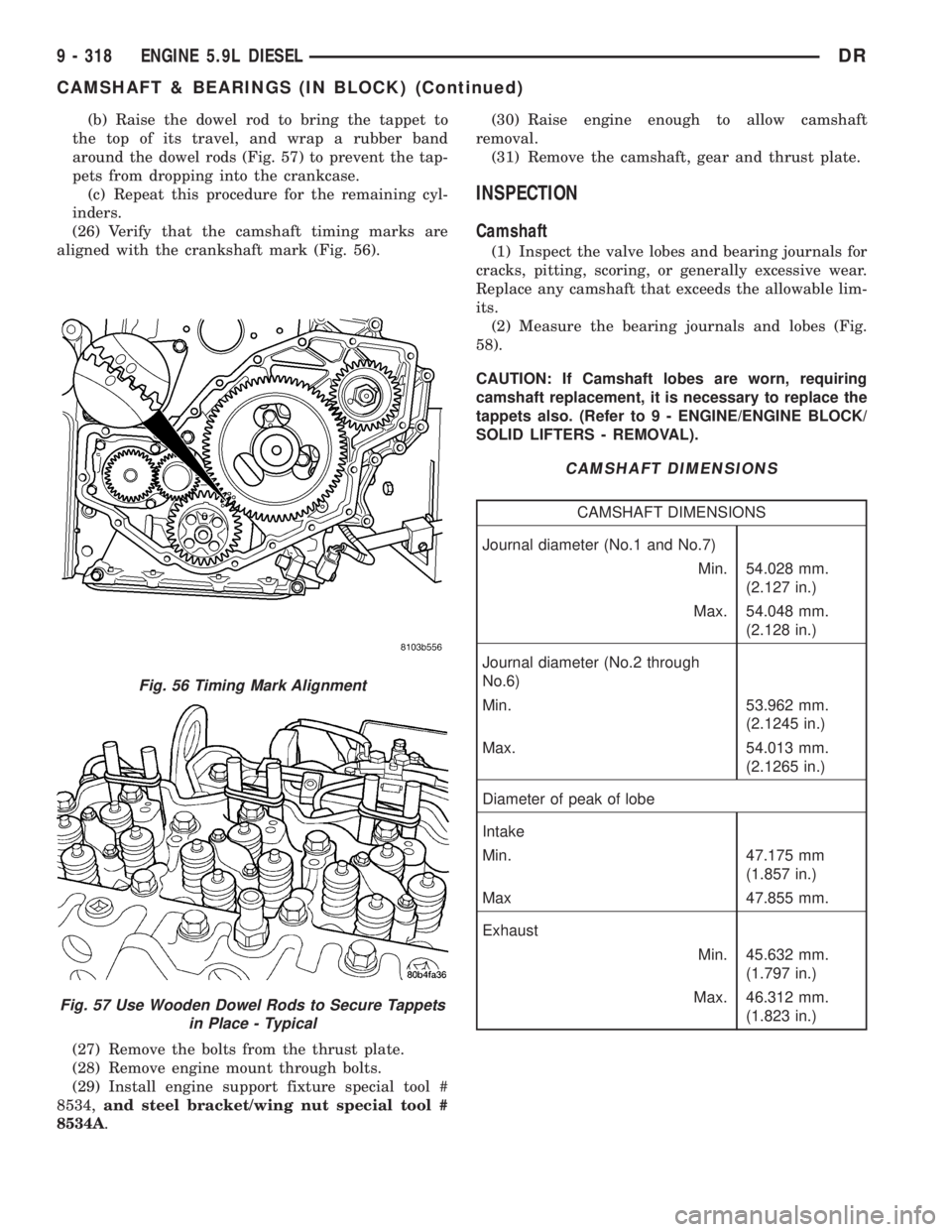

(26) Verify that the camshaft timing marks are

aligned with the crankshaft mark (Fig. 56).

(27) Remove the bolts from the thrust plate.

(28) Remove engine mount through bolts.

(29) Install engine support fixture special tool #

8534,and steel bracket/wing nut special tool #

8534A.(30) Raise engine enough to allow camshaft

removal.

(31) Remove the camshaft, gear and thrust plate.

INSPECTION

Camshaft

(1) Inspect the valve lobes and bearing journals for

cracks, pitting, scoring, or generally excessive wear.

Replace any camshaft that exceeds the allowable lim-

its.

(2) Measure the bearing journals and lobes (Fig.

58).

CAUTION: If Camshaft lobes are worn, requiring

camshaft replacement, it is necessary to replace the

tappets also. (Refer to 9 - ENGINE/ENGINE BLOCK/

SOLID LIFTERS - REMOVAL).

CAMSHAFT DIMENSIONS

CAMSHAFT DIMENSIONS

Journal diameter (No.1 and No.7)

Min. 54.028 mm.

(2.127 in.)

Max. 54.048 mm.

(2.128 in.)

Journal diameter (No.2 through

No.6)

Min. 53.962 mm.

(2.1245 in.)

Max. 54.013 mm.

(2.1265 in.)

Diameter of peak of lobe

Intake

Min. 47.175 mm

(1.857 in.)

Max 47.855 mm.

Exhaust

Min. 45.632 mm.

(1.797 in.)

Max. 46.312 mm.

(1.823 in.)

Fig. 56 Timing Mark Alignment

Fig. 57 Use Wooden Dowel Rods to Secure Tappets

in Place - Typical

9 - 318 ENGINE 5.9L DIESELDR

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1672 of 2895

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT AIR DAM

REMOVAL.............................2

INSTALLATION..........................2

FRONT BUMPER

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................3

INSTALLATION..........................3

REAR BUMPER

REMOVAL.............................4

INSTALLATION..........................4

FRAME

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY

FRONT FRAME RAIL TIP REPLACEMENT....4

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR.................12

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT.............15SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS . . . 17

SPECIFICATIONS - TORQUE............23

FRONT CROSSMEMBER

REMOVAL.............................23

INSTALLATION.........................23

FRONT SKID PLATE

REMOVAL.............................24

INSTALLATION.........................24

TRANSMISSION CROSSMEMBER

REMOVAL.............................24

INSTALLATION.........................25

TRAILER HITCH

REMOVAL.............................25

INSTALLATION.........................25

TRANSFER CASE SKID PLATE

REMOVAL.............................26

INSTALLATION.........................26

FRONT TOW HOOK ASSEMBLY

REMOVAL.............................26

INSTALLATION.........................26

BUMPERS

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

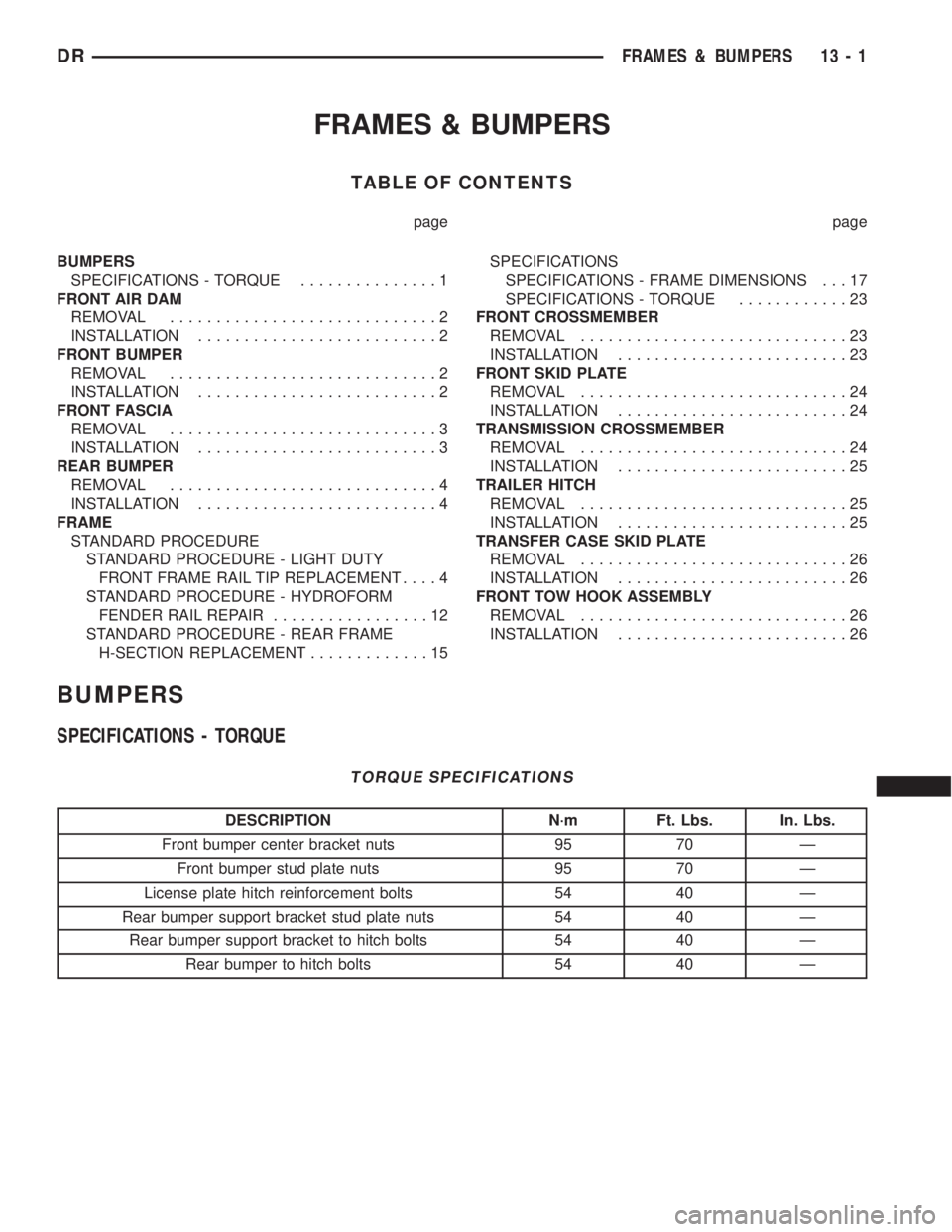

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper center bracket nuts 95 70 Ð

Front bumper stud plate nuts 95 70 Ð

License plate hitch reinforcement bolts 54 40 Ð

Rear bumper support bracket stud plate nuts 54 40 Ð

Rear bumper support bracket to hitch bolts 54 40 Ð

Rear bumper to hitch bolts 54 40 Ð

DRFRAMES & BUMPERS 13 - 1

Page 1677 of 2895

(11) Assemble the service sleeve. Refer to SER-

VICE SLEEVE ASSEMBLY at the end of this proce-

dure.

NOTE: Any burned surface coatings will need to be

removed from the sleeve prior to installation and

application of corrosion preventative coatings.

(12) Smooth and square the cut edges of the origi-

nal frame. (Fig. 7)

(13) Dress the cut edge of the existing frame in

preparation for the new rail tip.

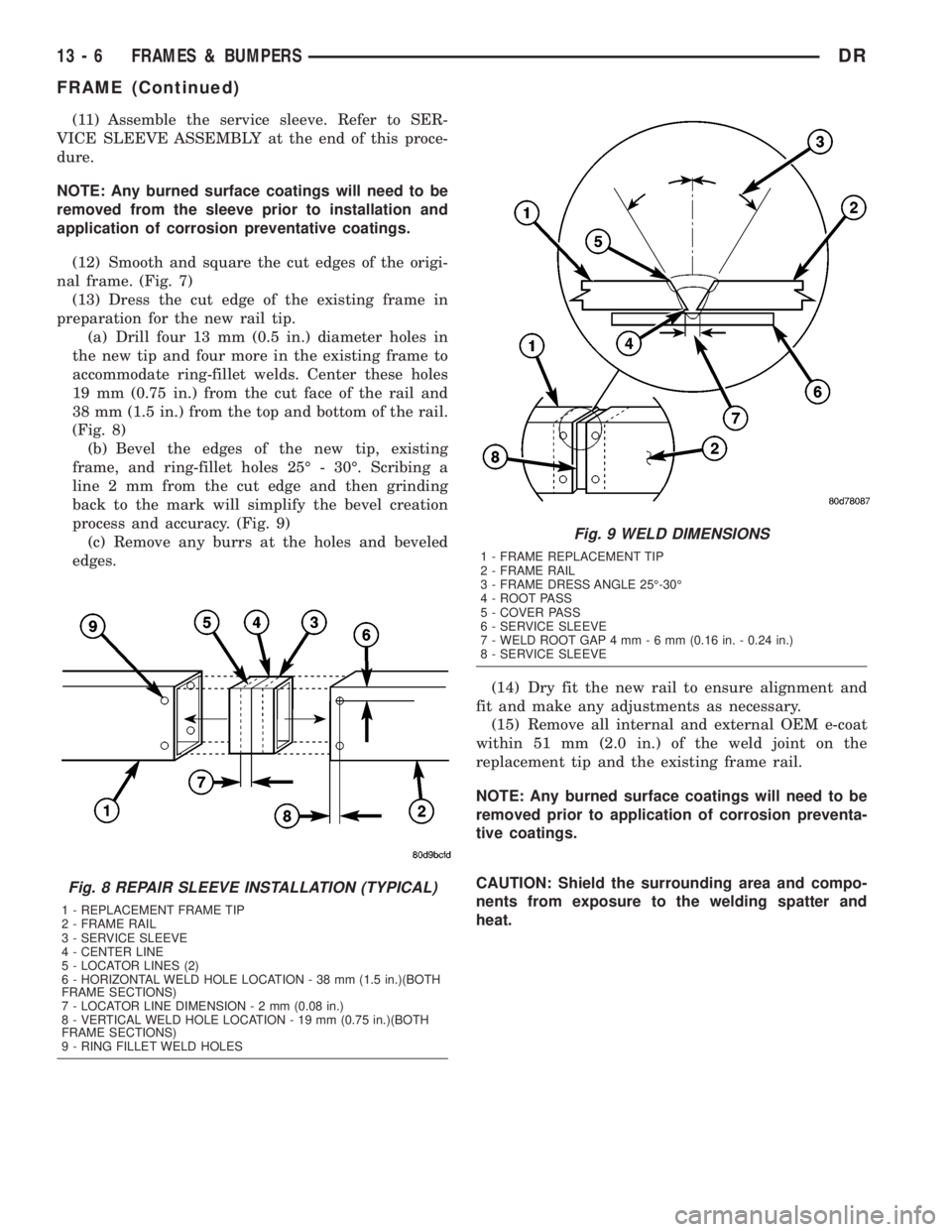

(a) Drill four 13 mm (0.5 in.) diameter holes in

the new tip and four more in the existing frame to

accommodate ring-fillet welds. Center these holes

19 mm (0.75 in.) from the cut face of the rail and

38 mm (1.5 in.) from the top and bottom of the rail.

(Fig. 8)

(b) Bevel the edges of the new tip, existing

frame, and ring-fillet holes 25É - 30É. Scribing a

line 2 mm from the cut edge and then grinding

back to the mark will simplify the bevel creation

process and accuracy. (Fig. 9)

(c) Remove any burrs at the holes and beveled

edges.

(14) Dry fit the new rail to ensure alignment and

fit and make any adjustments as necessary.

(15) Remove all internal and external OEM e-coat

within 51 mm (2.0 in.) of the weld joint on the

replacement tip and the existing frame rail.

NOTE: Any burned surface coatings will need to be

removed prior to application of corrosion preventa-

tive coatings.

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

Fig. 8 REPAIR SLEEVE INSTALLATION (TYPICAL)

1 - REPLACEMENT FRAME TIP

2 - FRAME RAIL

3 - SERVICE SLEEVE

4 - CENTER LINE

5 - LOCATOR LINES (2)

6 - HORIZONTAL WELD HOLE LOCATION - 38 mm (1.5 in.)(BOTH

FRAME SECTIONS)

7 - LOCATOR LINE DIMENSION-2mm(0.08 in.)

8 - VERTICAL WELD HOLE LOCATION - 19 mm (0.75 in.)(BOTH

FRAME SECTIONS)

9 - RING FILLET WELD HOLES

Fig. 9 WELD DIMENSIONS

1 - FRAME REPLACEMENT TIP

2 - FRAME RAIL

3 - FRAME DRESS ANGLE 25É-30É

4 - ROOT PASS

5 - COVER PASS

6 - SERVICE SLEEVE

7 - WELD ROOT GAP 4 mm-6mm(0.16 in. - 0.24 in.)

8 - SERVICE SLEEVE

13 - 6 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1680 of 2895

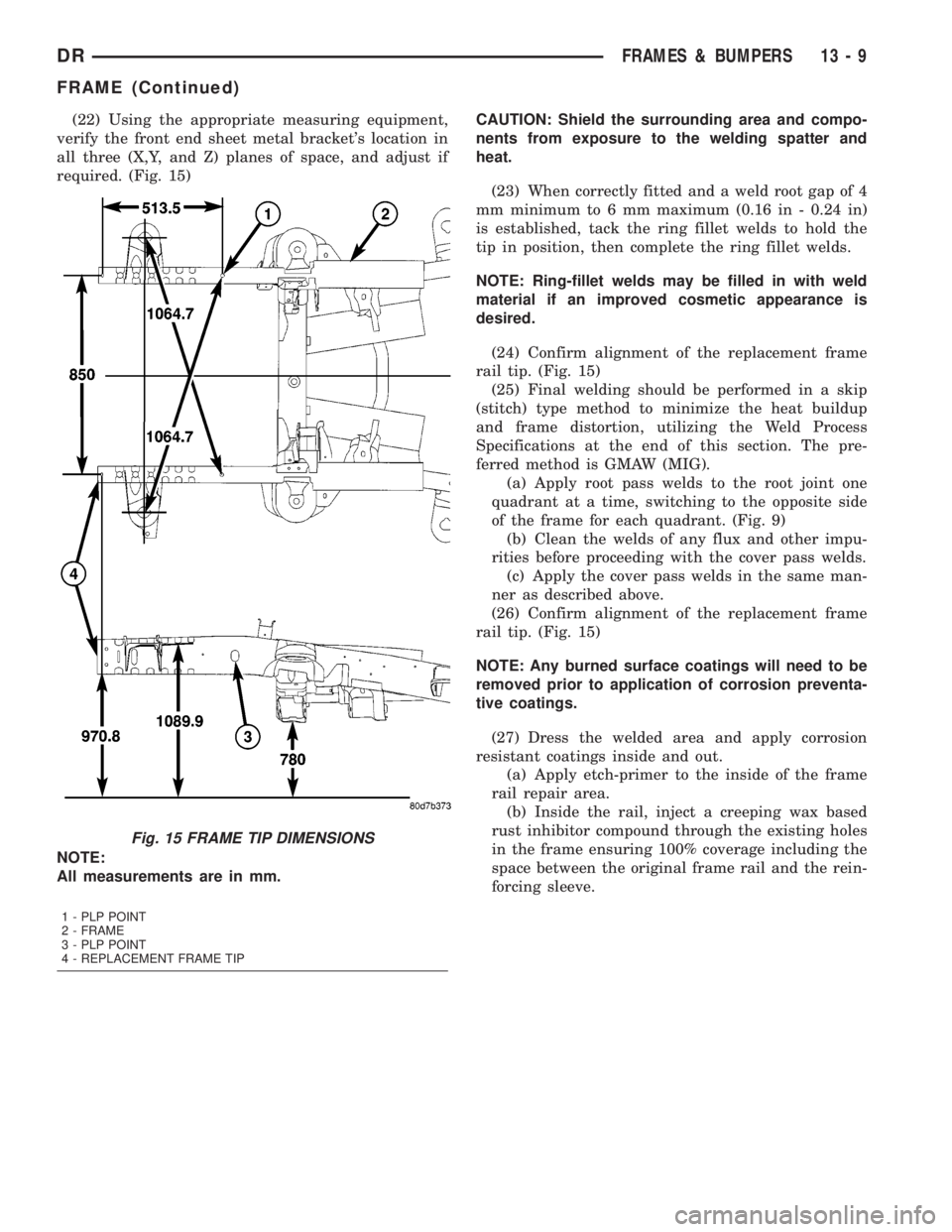

(22) Using the appropriate measuring equipment,

verify the front end sheet metal bracket's location in

all three (X,Y, and Z) planes of space, and adjust if

required. (Fig. 15)CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

(23) When correctly fitted and a weld root gap of 4

mm minimum to 6 mm maximum (0.16 in - 0.24 in)

is established, tack the ring fillet welds to hold the

tip in position, then complete the ring fillet welds.

NOTE: Ring-fillet welds may be filled in with weld

material if an improved cosmetic appearance is

desired.

(24) Confirm alignment of the replacement frame

rail tip. (Fig. 15)

(25) Final welding should be performed in a skip

(stitch) type method to minimize the heat buildup

and frame distortion, utilizing the Weld Process

Specifications at the end of this section. The pre-

ferred method is GMAW (MIG).

(a) Apply root pass welds to the root joint one

quadrant at a time, switching to the opposite side

of the frame for each quadrant. (Fig. 9)

(b) Clean the welds of any flux and other impu-

rities before proceeding with the cover pass welds.

(c) Apply the cover pass welds in the same man-

ner as described above.

(26) Confirm alignment of the replacement frame

rail tip. (Fig. 15)

NOTE: Any burned surface coatings will need to be

removed prior to application of corrosion preventa-

tive coatings.

(27) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Apply etch-primer to the inside of the frame

rail repair area.

(b) Inside the rail, inject a creeping wax based

rust inhibitor compound through the existing holes

in the frame ensuring 100% coverage including the

space between the original frame rail and the rein-

forcing sleeve.

Fig. 15 FRAME TIP DIMENSIONS

NOTE:

All measurements are in mm.

1 - PLP POINT

2 - FRAME

3 - PLP POINT

4 - REPLACEMENT FRAME TIP

DRFRAMES & BUMPERS 13 - 9

FRAME (Continued)

Page 1687 of 2895

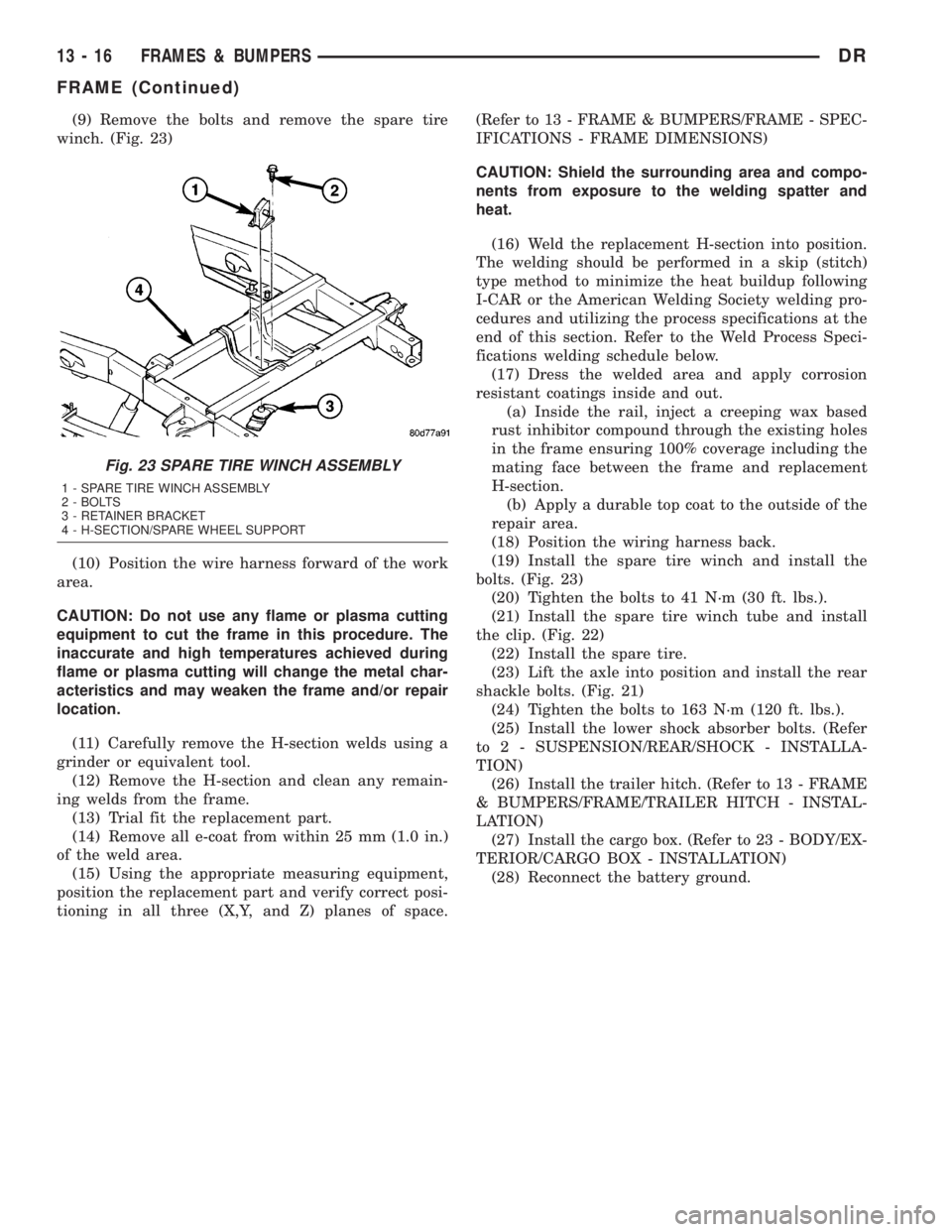

(9) Remove the bolts and remove the spare tire

winch. (Fig. 23)

(10) Position the wire harness forward of the work

area.

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. The

inaccurate and high temperatures achieved during

flame or plasma cutting will change the metal char-

acteristics and may weaken the frame and/or repair

location.

(11) Carefully remove the H-section welds using a

grinder or equivalent tool.

(12) Remove the H-section and clean any remain-

ing welds from the frame.

(13) Trial fit the replacement part.

(14) Remove all e-coat from within 25 mm (1.0 in.)

of the weld area.

(15) Using the appropriate measuring equipment,

position the replacement part and verify correct posi-

tioning in all three (X,Y, and Z) planes of space.(Refer to 13 - FRAME & BUMPERS/FRAME - SPEC-

IFICATIONS - FRAME DIMENSIONS)

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

(16) Weld the replacement H-section into position.

The welding should be performed in a skip (stitch)

type method to minimize the heat buildup following

I-CAR or the American Welding Society welding pro-

cedures and utilizing the process specifications at the

end of this section. Refer to the Weld Process Speci-

fications welding schedule below.

(17) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Inside the rail, inject a creeping wax based

rust inhibitor compound through the existing holes

in the frame ensuring 100% coverage including the

mating face between the frame and replacement

H-section.

(b) Apply a durable top coat to the outside of the

repair area.

(18) Position the wiring harness back.

(19) Install the spare tire winch and install the

bolts. (Fig. 23)

(20) Tighten the bolts to 41 N´m (30 ft. lbs.).

(21) Install the spare tire winch tube and install

the clip. (Fig. 22)

(22) Install the spare tire.

(23) Lift the axle into position and install the rear

shackle bolts. (Fig. 21)

(24) Tighten the bolts to 163 N´m (120 ft. lbs.).

(25) Install the lower shock absorber bolts. (Refer

to 2 - SUSPENSION/REAR/SHOCK - INSTALLA-

TION)

(26) Install the trailer hitch. (Refer to 13 - FRAME

& BUMPERS/FRAME/TRAILER HITCH - INSTAL-

LATION)

(27) Install the cargo box. (Refer to 23 - BODY/EX-

TERIOR/CARGO BOX - INSTALLATION)

(28) Reconnect the battery ground.

Fig. 23 SPARE TIRE WINCH ASSEMBLY

1 - SPARE TIRE WINCH ASSEMBLY

2 - BOLTS

3 - RETAINER BRACKET

4 - H-SECTION/SPARE WHEEL SUPPORT

13 - 16 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1688 of 2895

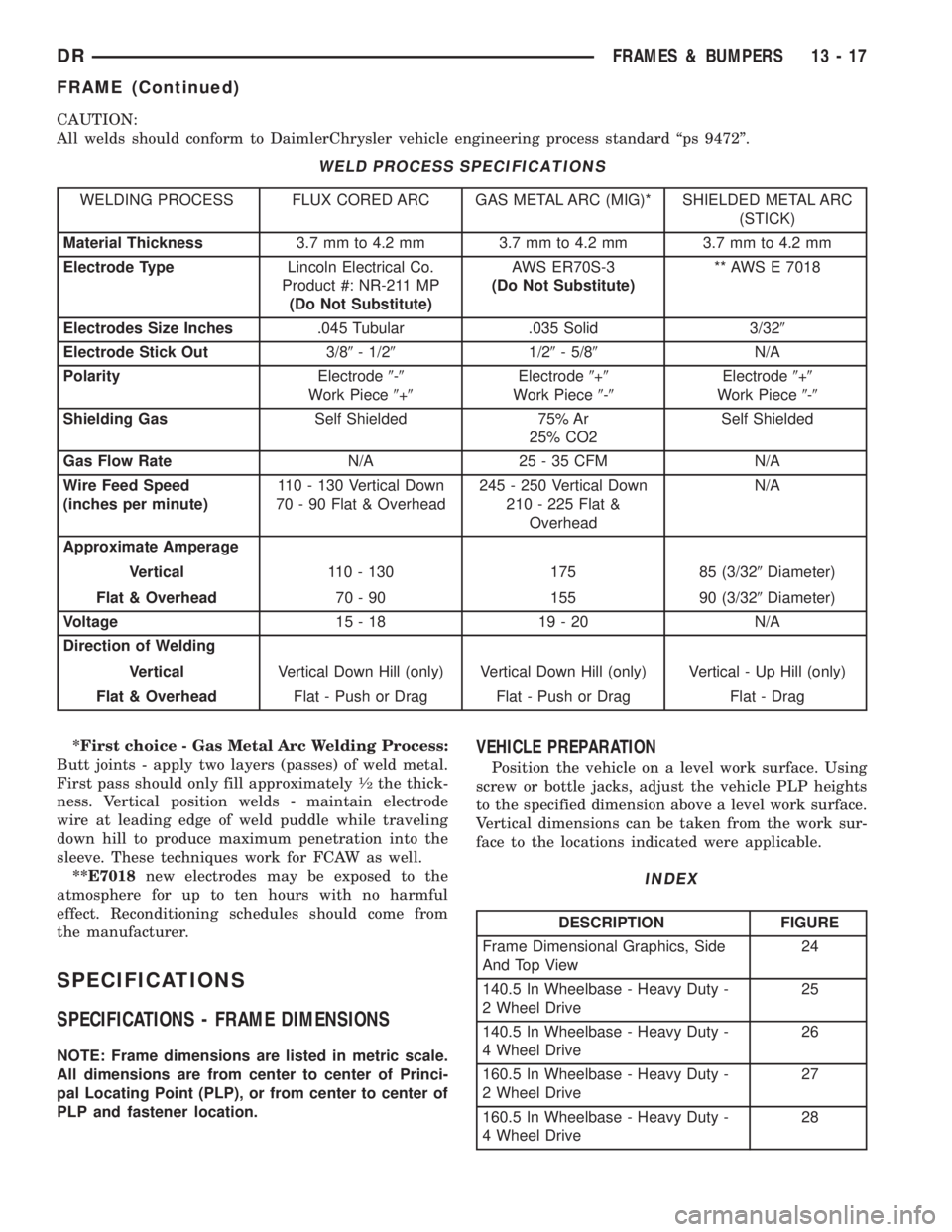

CAUTION:

All welds should conform to DaimlerChrysler vehicle engineering process standard ªps 9472º.

WELD PROCESS SPECIFICATIONS

WELDING PROCESS FLUX CORED ARC GAS METAL ARC (MIG)* SHIELDED METAL ARC

(STICK)

Material Thickness3.7 mm to 4.2 mm 3.7 mm to 4.2 mm 3.7 mm to 4.2 mm

Electrode TypeLincoln Electrical Co.

Product #: NR-211 MP

(Do Not Substitute)AWS ER70S-3

(Do Not Substitute)** AWS E 7018

Electrodes Size Inches.045 Tubular .035 Solid 3/329

Electrode Stick Out3/89- 1/291/29- 5/89N/A

PolarityElectrode9-9

Work Piece9+9Electrode9+9

Work Piece9-9Electrode9+9

Work Piece9-9

Shielding GasSelf Shielded 75% Ar

25% CO2Self Shielded

Gas Flow RateN/A 25 - 35 CFM N/A

Wire Feed Speed

(inches per minute)110 - 130 Vertical Down

70 - 90 Flat & Overhead245 - 250 Vertical Down

210 - 225 Flat &

OverheadN/A

Approximate Amperage

Vertical110 - 130 175 85 (3/329Diameter)

Flat & Overhead70 - 90 155 90 (3/329Diameter)

Voltage15-18 19-20 N/A

Direction of Welding

VerticalVertical Down Hill (only) Vertical Down Hill (only) Vertical - Up Hill (only)

Flat & OverheadFlat - Push or Drag Flat - Push or Drag Flat - Drag

*First choice - Gas Metal Arc Welding Process:

Butt joints - apply two layers (passes) of weld metal.

First pass should only fill approximately

1¤2the thick-

ness. Vertical position welds - maintain electrode

wire at leading edge of weld puddle while traveling

down hill to produce maximum penetration into the

sleeve. These techniques work for FCAW as well.

**E7018new electrodes may be exposed to the

atmosphere for up to ten hours with no harmful

effect. Reconditioning schedules should come from

the manufacturer.

SPECIFICATIONS

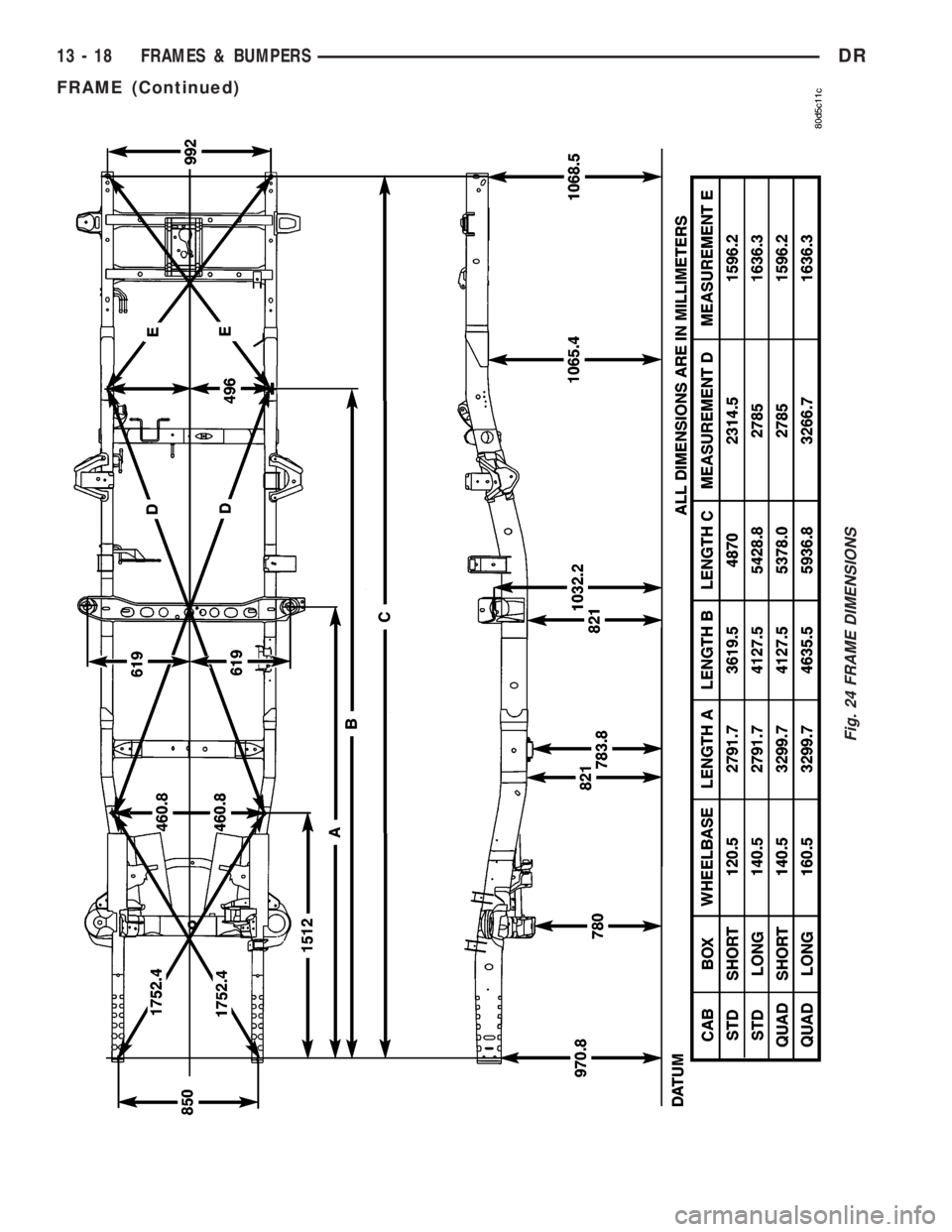

SPECIFICATIONS - FRAME DIMENSIONS

NOTE: Frame dimensions are listed in metric scale.

All dimensions are from center to center of Princi-

pal Locating Point (PLP), or from center to center of

PLP and fastener location.

VEHICLE PREPARATION

Position the vehicle on a level work surface. Using

screw or bottle jacks, adjust the vehicle PLP heights

to the specified dimension above a level work surface.

Vertical dimensions can be taken from the work sur-

face to the locations indicated were applicable.

INDEX

DESCRIPTION FIGURE

Frame Dimensional Graphics, Side

And Top View24

140.5 In Wheelbase - Heavy Duty -

2 Wheel Drive25

140.5 In Wheelbase - Heavy Duty -

4 Wheel Drive26

160.5 In Wheelbase - Heavy Duty -

2 Wheel Drive27

160.5 In Wheelbase - Heavy Duty -

4 Wheel Drive28

DRFRAMES & BUMPERS 13 - 17

FRAME (Continued)

Page 1689 of 2895

Fig. 24 FRAME DIMENSIONS

13 - 18 FRAMES & BUMPERSDR

FRAME (Continued)