radiator DODGE RAM SRT-10 2006 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3430 of 5267

FLUID AND FILTER

DIAGNOSIS AND TESTING

EFFECTS OF INCORRECT FLUID LEVEL

Alowfluidlevelallowsthepumptotakeinairalongwiththefluid.Airinthe fluid will cause fluid pressures to be

low and develop slower than normal. If the transmission is overfilled, thegears churn the fluid into foam. This aer-

ates the fluid and causing the same conditions occurring with a low level. In either case, air bubbles cause fluid

overheating, oxidation, and varnish buildup which interferes with valveand clutch operation. Foaming also causes

fluid expansion which can result in fluid overflow from the transmission vent or fill tube. Fluid overflow can easily be

mistaken for a leak if inspection is not careful.

CAUSES OF BURNT FLUID

Burnt, discolored fluid is a result of overheating which has three primarycauses.

1. Internal clutch slippage, usually caused by low line pressure, inadequate clutch apply pressure, or clutch seal

failure.

2. A result of restricted fluid flow through the main and/or auxiliary cooler. This condition is usually the result of a

faulty or improperly installed drainback valve, a damaged oil cooler, or severe restrictions in the coolers and lines

caused by debris or kinked lines.

3. Heavy duty operation with a vehicle not properly equipped for this type of operation. Trailer towing or similar high

load operation will overheat the transmission fluid if the vehicle is improperly equipped. Such vehicles should

have an auxiliary transmission fluid cooler, a heavy duty cooling system,and the engine/axle ratio combination

needed to handle heavy loads.

FLUID CONTAMINATION

Transmission fluid contamination is generally a result of:

adding incorrect fluid

failure to clean dipstick and fill tube when checking level

engine coolant entering the fluid

internal failure that generates debris

overheat that generates sludge (fluid breakdown)

failure to replace contaminated converter after repair

The use of non-recommended fluids can result in transmission failure. Theusual results are erratic shifts, slippage,

abnormal wear and eventual failure due to fluid breakdown and sludge formation. Avoid this condition by using rec-

ommended fluids only.

The dipstick cap and fill tube should be wiped clean before checking fluid level. Dirt, grease and other foreign mate-

rial on the cap and tube could fall into the tube if not removed beforehand. Take the time to wipe the cap and tube

clean before withdrawing the dipstick.

Engine coolant in the transmission fluid is generally caused by a cooler malfunction. The only remedy is to replace

the radiator as the cooler in the radiator is not a serviceable part. If coolant has circulated through the transmission,

an overhaul is necessary.

The torque converter should also be replaced whenever a failure generatessludge and debris. This is necessary

because normal converter flushing procedures will not remove all contaminants.

STANDARD PROCEDURE

FLUID LEVEL CHECK

Low fluid level can cause a variety of conditions because it allows the pumpto take in air along with the fluid. As

in any hydraulic system, air bubbles make the fluid spongy, therefore, pressures will be low and build up slowly.

Improper filling can also raise the fluid level too high. When the transmssion has too much fluid, the geartrain

churns up foam and cause the same conditions which occur with a low fluid level.

Page 3874 of 5267

FLUID AND FILTER

DIAGNOSIS AND TESTING

EFFECTS OF INCORRECT FLUID LEVEL

Alowfluidlevelallowsthepumptotakeinairalongwiththefluid.Airinthe fluid will cause fluid pressures to be

low and develop slower than normal. If the transmission is overfilled, thegears churn the fluid into foam. This aer-

ates the fluid and causing the same conditions occurring with a low level. In either case, air bubbles cause fluid

overheating, oxidation, and varnish buildup which interferes with valveand clutch operation. Foaming also causes

fluid expansion which can result in fluid overflow from the transmission vent or fill tube. Fluid overflow can easily be

mistaken for a leak if inspection is not careful.

CAUSES OF BURNT FLUID

Burnt, discolored fluid is a result of overheating which has two primary causes.

1. A result of restricted fluid flow through the main and/or auxiliary cooler. This condition is usually the result of a

faulty or improperly installed drainback valve, a damaged oil cooler, or severe restrictions in the coolers and lines

caused by debris or kinked lines.

2. Heavy duty operation with a vehicle not properly equipped for this type of operation. Trailer towing or similar high

load operation will overheat the transmission fluid if the vehicle is improperly equipped. Such vehicles should

have an auxiliary transmission fluid cooler, a heavy duty cooling system,and the engine/axle ratio combination

needed to handle heavy loads.

FLUID CONTAMINATION

Transmission fluid contamination is generally a result of:

adding incorrect fluid

failure to clean dipstick and fill tube when checking level

engine coolant entering the fluid

internal failure that generates debris

overheat that generates sludge (fluid breakdown)

failure to replace contaminated converter after repair

The use of non-recommended fluids can result in transmission failure. Theusual results are erratic shifts, slippage,

abnormal wear and eventual failure due to fluid breakdown and sludge formation. Avoid this condition by using rec-

ommended fluids only.

The dipstick cap and fill tube should be wiped clean before checking fluid level. Dirt, grease and other foreign mate-

rial on the cap and tube could fall into the tube if not removed beforehand. Take the time to wipe the cap and tube

clean before withdrawing the dipstick.

Engine coolant in the transmission fluid is generally caused by a cooler malfunction. The only remedy is to replace

the radiator as the cooler in the radiator is not a serviceable part. If coolant has circulated through the transmission,

an overhaul is necessary.

The torque converter should also be replaced whenever a failure generatessludge and debris. This is necessary

because normal converter flushing procedures will not remove all contaminants.

STANDARD PROCEDURE

FLUID LEVEL CHECK

Low fluid level can cause a variety of conditions because it allows the pumpto take in air along with the fluid. As

in any hydraulic system, air bubbles make the fluid spongy, therefore, pressures will be low and build up slowly.

Improper filling can also raise the fluid level too high. When the transmssion has too much fluid, the geartrain

churns up foam and cause the same conditions which occur with a low fluid level.

In either case, air bubbles can cause overheating and/or fluid oxidation,and varnishing. This can interfere with nor-

mal valve, clutch, and accumulator operation. Foaming can also result in fluid escaping from the transmission vent

where it may be mistaken for a leak.

Page 3959 of 5267

VALVE-TORQUE CONVERTER DRAINBACK

DESCRIPTION

GAS ENGINES

The drainback valve is located in the transmission cooler outlet (pressure) line.

DIESEL ENGINE

The converter drainback check valve is located in the in the TOC pressure - supply line, between the engine

mounted TOC and the air to oil TOC.

OPERATION

GAS ENGINES

The valve prevents fluid from draining from the converter into the cooler and lines when the vehicle is shut down for

lengthy periods. Production valves have a hose nipple at one end, while theopposite end is threaded for a flare

fitting. All valves have an arrow (or similar mark) to indicate direction of flow through the valve.

DIESEL ENGINE

The valve prevents fluid from draining from the converter into the cooler and lines when the vehicle is shut down for

lengthy periods. Production valves have pipe thread on one end, while the opposite end is threaded for a flare

fitting, and are threaded into the oil cooler mounted on the side of the engine. All valves have an arrow (or similar

mark) to indicate direction of flow through the valve.

STANDARD PROCEDURE

GAS ENGINES

The converter drainback check valve is located in the cooler outlet (pressure) line near the radiator tank. The valve

prevents fluid drainback when the vehicle is parked for lengthy periods. The valve check ball is spring loaded and

has an opening pressure of approximately 2 psi.

The valve is serviced as an assembly; it is not repairable. Do not clean the valve if restricted, or contaminated by

sludge, or debris. If the valve fails, or if a transmission malfunction occurs that generates significant amounts of

sludge and/or clutch particles and metal shavings, the valve must be replaced.

If the valve is restricted, installed backwards, or in the wrong line, it will cause an transmission overheating condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way flow device. It must be properly orientedintermsofflowdirec-

tion for the cooler to function properly. The valve must be installed in thepressure line. Otherwise flow will

be blocked and would cause an transmission overheating condition and eventual transmission failure.

DIESEL ENGINE

The converter drainback check valve is located in the in the TOC pressure - supply line, between the engine

mounted transmission oil cooler and the air to oil transmission oil cooler. The valve prevents fluid drainback when

the vehicle is parked for lengthy periods. The valve check ball is spring loaded and has an opening pressure of

approximately 2 psi.

The valve is serviced as an assembly; it is not repairable. Do not clean the valve if restricted, or contaminated by

sludge, or debris. If the valve fails, or if a transmission malfunction occurs that generates significant amounts of

sludge and/or clutch particles and metal shavings, the valve must be replaced.

If the valve is restricted, installed backwards, or in the wrong line, it will cause an transmission overheating condition

and possible transmission failure.

Page 4352 of 5267

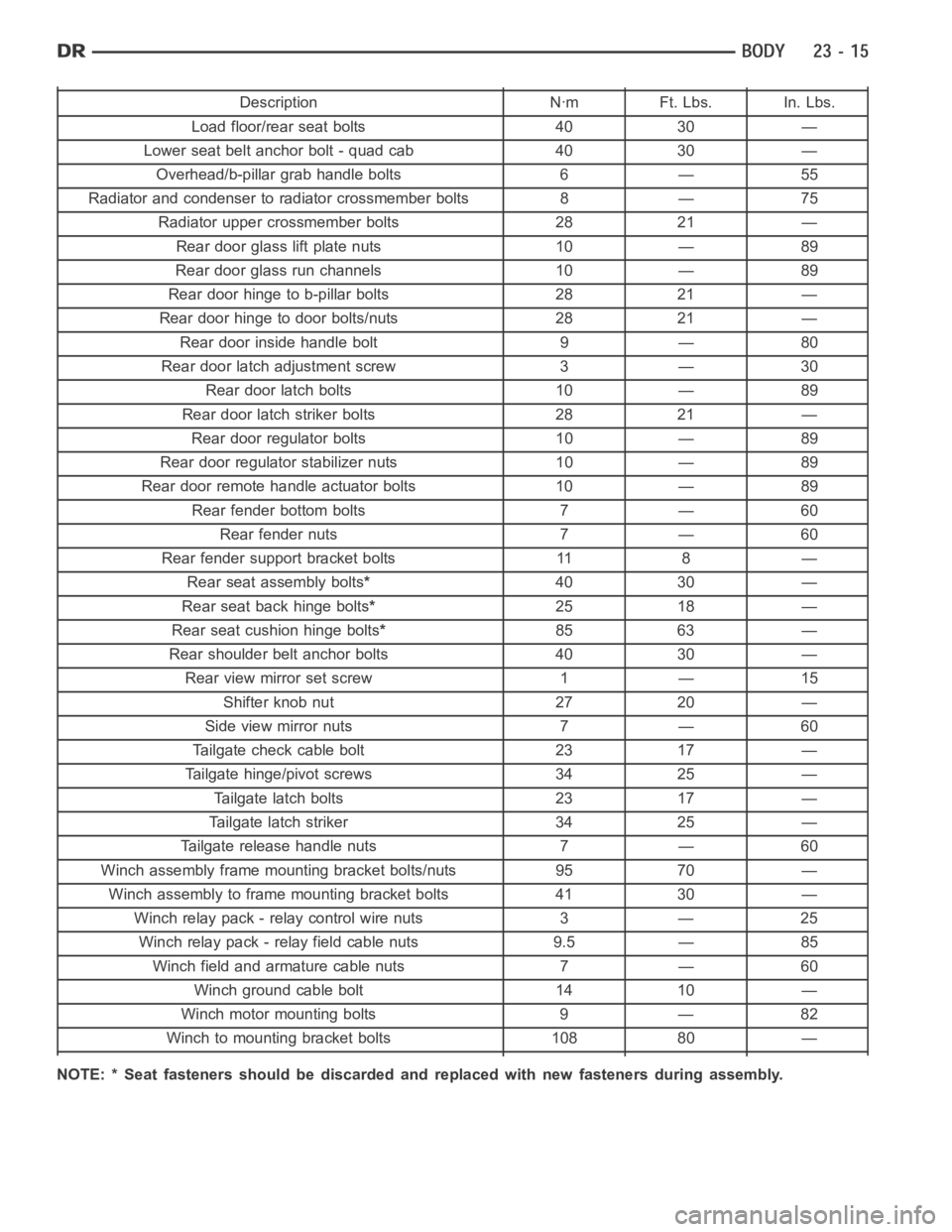

Description Nꞏm Ft. Lbs. In. Lbs.

Load floor/rear seat bolts 40 30 —

Lower seat belt anchor bolt - quad cab 40 30 —

Overhead/b-pillar grab handle bolts 6 — 55

Radiator and condenser to radiator crossmember bolts 8 — 75

Radiator upper crossmember bolts 28 21 —

Rear door glass lift plate nuts 10 — 89

Rear door glass run channels 10 — 89

Rear door hinge to b-pillar bolts 28 21 —

Rear door hinge to door bolts/nuts 28 21 —

Rear door inside handle bolt 9 — 80

Rear door latch adjustment screw 3 — 30

Rear door latch bolts 10 — 89

Rear door latch striker bolts 28 21 —

Rear door regulator bolts 10 — 89

Rear door regulatorstabilizer nuts 10 — 89

Rear door remote handle actuator bolts 10 — 89

Rear fender bottom bolts 7 — 60

Rear fender nuts 7 — 60

Rear fender support bracket bolts 11 8 —

Rear seat assembly bolts*40 30 —

Rear seat back hinge bolts*25 18 —

Rear seat cushion hinge bolts*85 63 —

Rear shoulder belt anchor bolts 40 30 —

Rear view mirror set screw 1 — 15

Shifter knob nut 27 20 —

Side view mirror nuts 7 — 60

Tailgate check cable bolt 23 17 —

Tailgate hinge/pivot screws 34 25 —

Tailgate latch bolts 23 17 —

Tailgate latch striker 34 25 —

Tailgate release handle nuts 7 — 60

Winch assembly frame mounting bracket bolts/nuts 95 70 —

Winch assembly to frame mounting bracket bolts 41 30 —

Winch relay pack - relay control wire nuts 3 — 25

Winch relay pack - relay field cable nuts 9.5 — 85

Winch field and armature cable nuts 7 — 60

Winch ground cable bolt 14 10 —

Winch motor mounting bolts 9 — 82

Winch to mounting bracket bolts 108 80 —

NOTE: * Seat fasteners should be discarded and replaced with new fastenersduring assembly.

Page 4423 of 5267

page page

BODY ISOLATORS

REMOVAL .................................... 87

INSTALLATION ............................... 87

BODY SIDE MOLDINGS

REMOVAL .................................... 88

INSTALLATION ............................... 88

CARGO BOX

REMOVAL .................................... 89

INSTALLATION ............................... 89

CARGO BOX - TIE DOWN

REMOVAL .................................... 91

INSTALLATION ............................... 91

COWL GRILLE

REMOVAL .................................... 92

INSTALLATION ............................... 92

EXTERIOR NAME PLATES

REMOVAL .................................... 93

INSTALLATION ............................... 94

FRONT FENDER

REMOVAL .................................... 95

INSTALLATION ............................... 95

FUEL FILL DOOR

REMOVAL .................................... 96

INSTALLATION ............................... 96

GRILLE

REMOVAL .................................... 97

INSTALLATION ............................... 97

GRILLE FRAME

REMOVAL .................................... 98

INSTALLATION ............................... 98

REAR FENDER-QUAD CAB MODELS

REMOVAL .................................... 99

INSTALLATION .............................. 100

SIDE VIEW MIRROR

REMOVAL ................................... 103

INSTALLATION .............................. 103

SIDE VIEW MIRROR GLASS

REMOVAL ................................... 104INSTALLATION .............................. 105

UPPER RADIATOR CROSSMEMBER

REMOVAL ................................... 107

INSTALLATION .............................. 107

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL ................................... 109

INSTALLATION .............................. 109

REAR WHEELHOUSE SPLASH SHIELD

REMOVAL ................................... 110

INSTALLATION .............................. 110

BELLY PAN-SRT-10

REMOVAL ................................... 111

INSTALLATION ............................... 111

CLADDING-BODY SIDE - BOX - SRT-10

REMOVAL ................................... 112

INSTALLATION .............................. 113

CLADDING-BODY SIDE - CAB - SRT-10

REMOVAL ................................... 115

INSTALLATION .............................. 115

CLADDING-BODY SIDE - DOOR - SRT-10

REMOVAL ................................... 117

INSTALLATION .............................. 117

CLADDING-BODY SIDE - FENDER SRT-10

REMOVAL ................................... 119

INSTALLATION .............................. 119

SPOILER - SRT-10

REMOVAL

WITHOUT CARGO BOX COVER ............ 120

WITH CARGO BOX COVER ................ 120

INSTALLATION

WITHOUT CARGO BOX COVER ............ 121

WITH CARGO BOX COVER ................ 121

FLARE MOLDING-FRONT WHEEL OPENING

REMOVAL ................................... 122

INSTALLATION .............................. 123

FLARE MOLDING-REAR WHEEL OPENING

REMOVAL ................................... 124

INSTALLATION .............................. 125

Page 4444 of 5267

UPPER RADIATOR CROSSMEMBER

REMOVAL

1. Remove the hood latch from the upper radiator

crossmember (3) and position the latch out of the

way(Referto23-BODY/HOOD/LATCH-

REMOVAL).

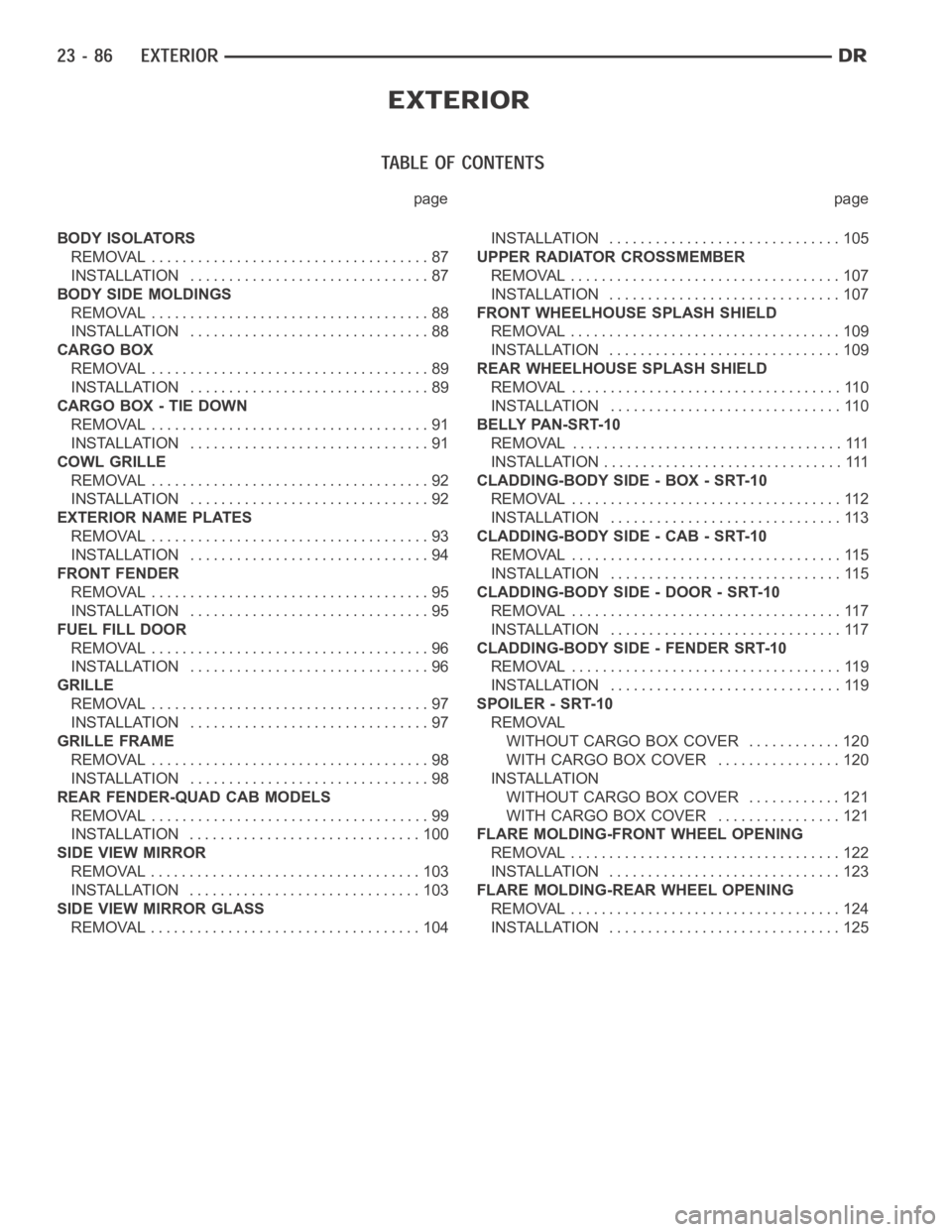

2. Remove the bolts (1 and 2) that secure the A/C

condenser and the radiator to the upper radiator

crossmember.

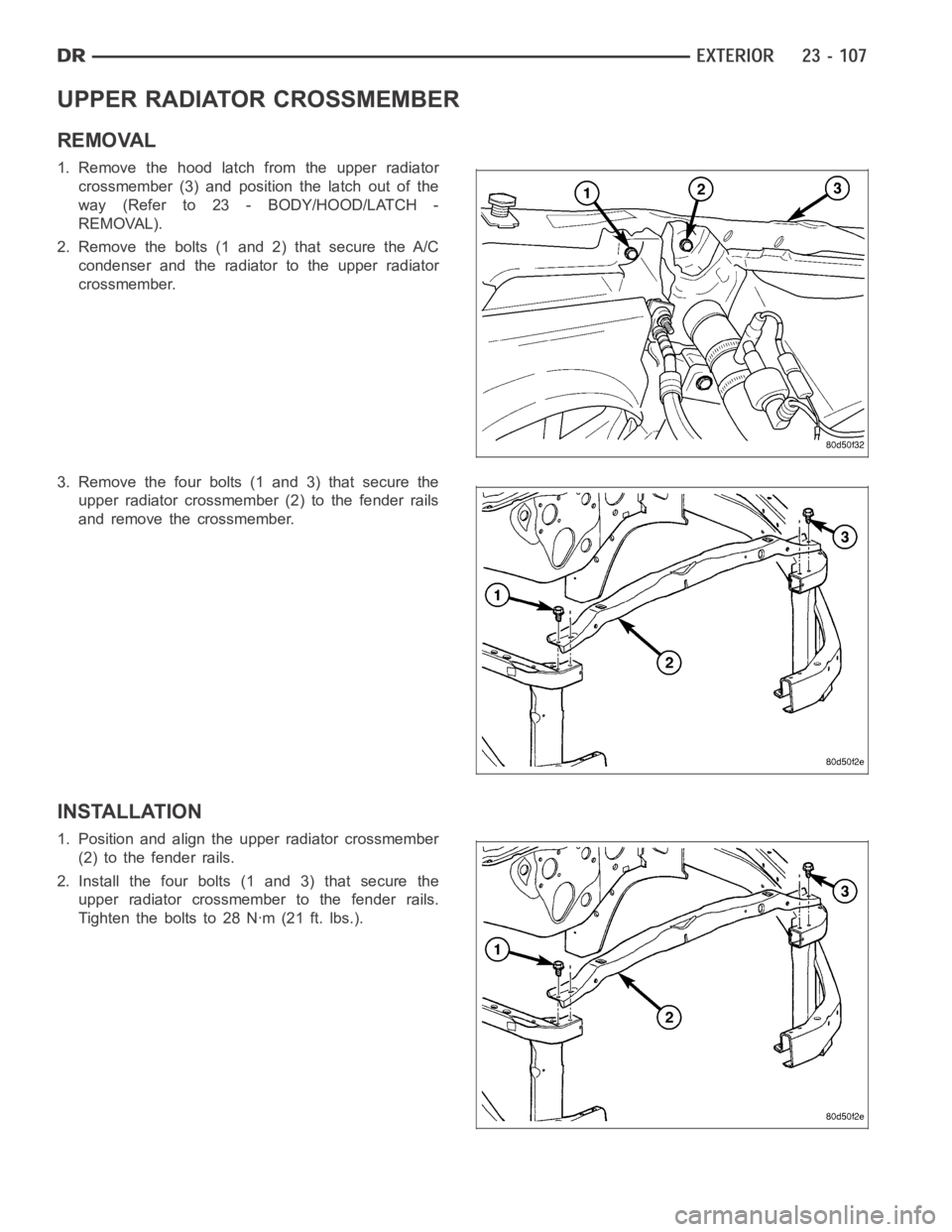

3. Remove the four bolts (1 and 3) that secure the

upper radiator crossmember (2) to the fender rails

and remove the crossmember.

INSTALLATION

1. Position and align the upper radiator crossmember

(2) to the fender rails.

2. Install the four bolts (1 and 3) that secure the

upper radiator crossmember to the fender rails.

Tighten the bolts to 28 Nꞏm (21 ft. lbs.).

Page 4445 of 5267

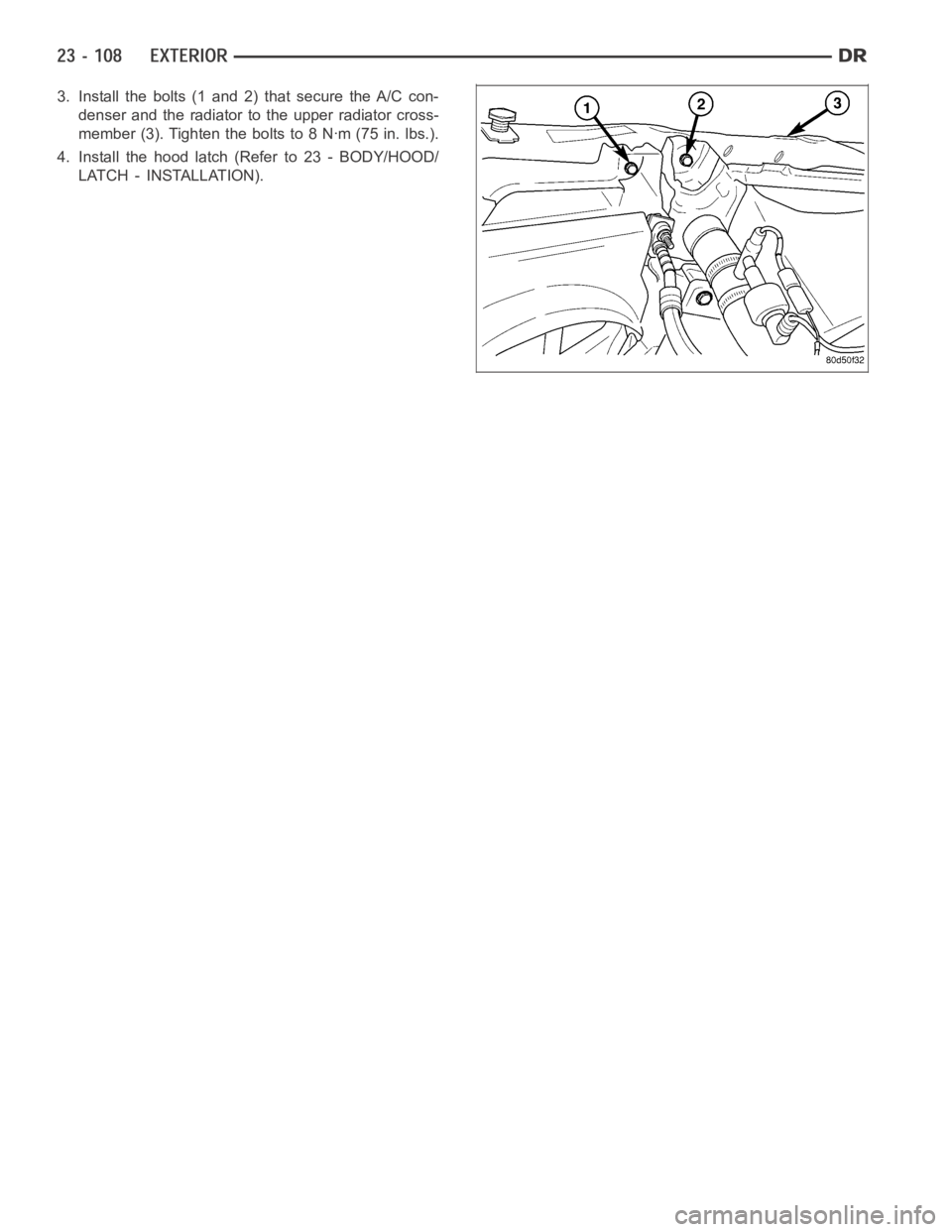

3. Install the bolts (1 and 2) that secure the A/C con-

denser and the radiator to the upper radiator cross-

member (3). Tighten the bolts to 8 Nꞏm (75 in. lbs.).

4. Install the hood latch (Refer to 23 - BODY/HOOD/

LATCH - INSTALLATION).

Page 4470 of 5267

LATCH

REMOVAL

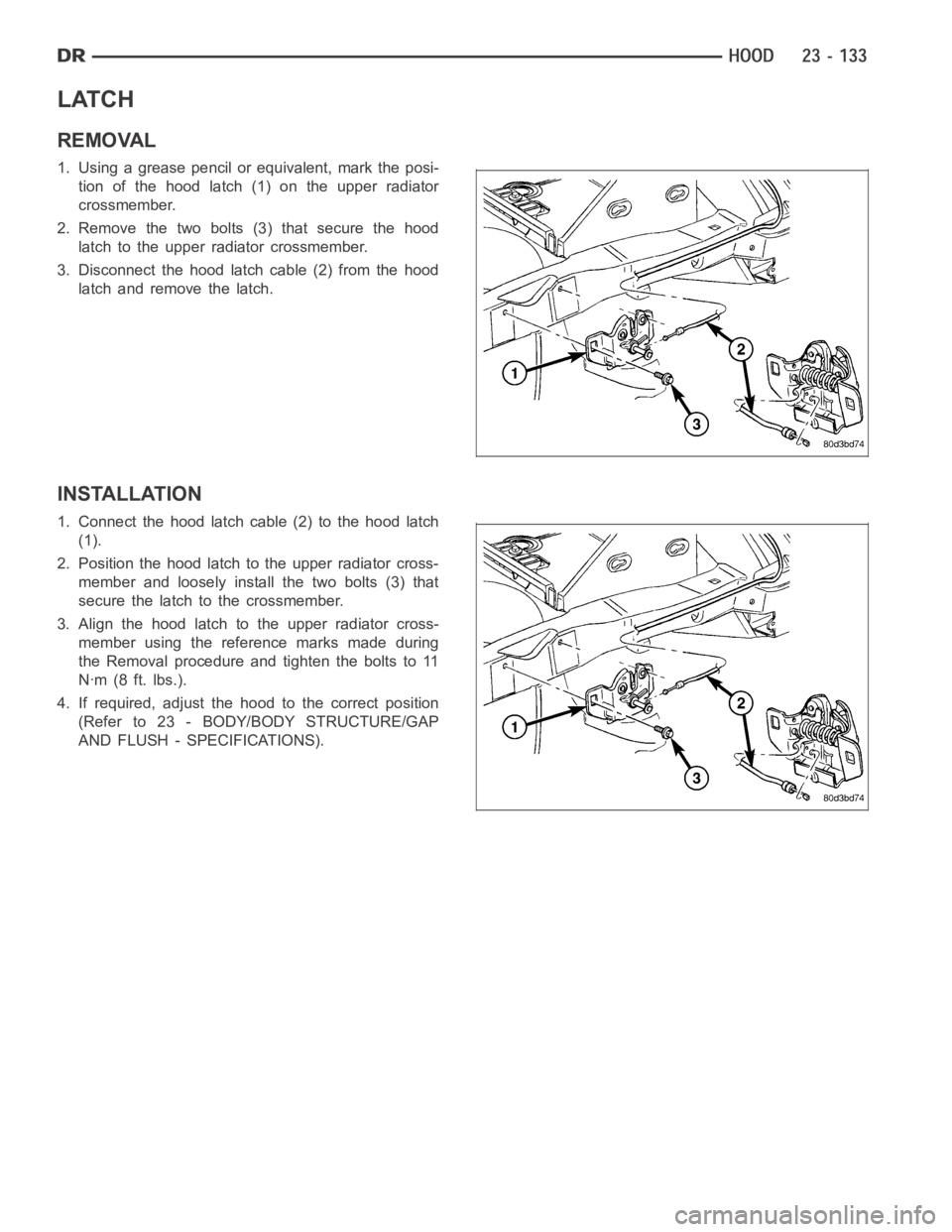

1. Using a grease pencil or equivalent, mark the posi-

tion of the hood latch (1) on the upper radiator

crossmember.

2. Remove the two bolts (3) that secure the hood

latch to the upper radiator crossmember.

3. Disconnect the hood latch cable (2) from the hood

latch and remove the latch.

INSTALLATION

1. Connect the hood latch cable (2) to the hood latch

(1).

2. Position the hood latch to the upper radiator cross-

member and loosely install the two bolts (3) that

secure the latch to the crossmember.

3. Align the hood latch to the upper radiator cross-

member using the reference marks made during

the Removal procedure and tighten the bolts to 11

Nꞏm (8 ft. lbs.).

4. If required, adjust the hood to the correct position

(Refer to 23 - BODY/BODY STRUCTURE/GAP

AND FLUSH - SPECIFICATIONS).

Page 4471 of 5267

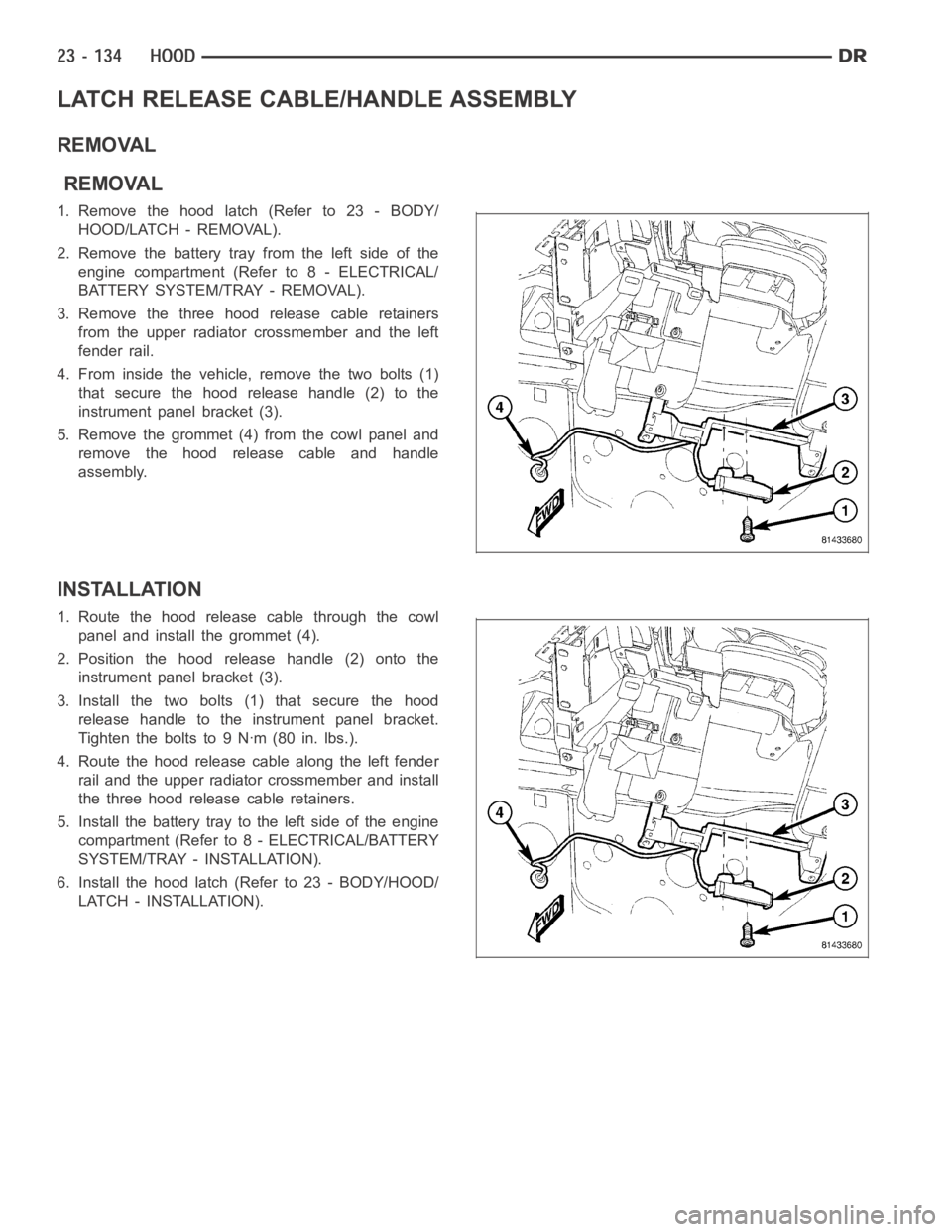

LATCH RELEASE CABLE/HANDLE ASSEMBLY

REMOVAL

REMOVAL

1.Removethehoodlatch(Referto23-BODY/

HOOD/LATCH - REMOVAL).

2. Remove the battery tray from the left side of the

engine compartment (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/TRAY - REMOVAL).

3. Remove the three hood release cable retainers

from the upper radiator crossmember and the left

fender rail.

4. From inside the vehicle, remove the two bolts (1)

that secure the hood release handle (2) to the

instrument panel bracket (3).

5. Remove the grommet (4) from the cowl panel and

remove the hood release cable and handle

assembly.

INSTALLATION

1. Route the hood release cable through the cowl

panel and install the grommet (4).

2. Position the hood release handle (2) onto the

instrument panel bracket (3).

3. Install the two bolts (1) that secure the hood

release handle to the instrument panel bracket.

Tightentheboltsto9Nꞏm(80in.lbs.).

4. Route the hood release cable along the left fender

rail and the upper radiator crossmember and install

the three hood release cable retainers.

5. Install the battery tray to the left side of the engine

compartment (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/TRAY - INSTALLATION).

6. Install the hood latch (Refer to 23 - BODY/HOOD/

LATCH - INSTALLATION).

Page 4732 of 5267

WELD LOCATIONS

SPECIFICATIONS

INDEX

DESCRIPTION FIGURE

FENDER BRACE, CLOSURE TUBE AND FRAME MOUNTING BRACKET TO FRONT

FENDER SUPPORT, FRONT FENDER AND RADIATOR TUBE46

STEERING COLUMN SUPPORT, CONNECTOR WIRING BRACKET AND WELD NUTS

TO LOWER PLENUM PANEL47

WIPER ATTACHING WELD NUTS AND VACUUM RESERVOIR ATTACHING STUDS TO

COWL PAR PANEL48

DASH PANEL TO FRONT FLOOR PAN 49

DASH PANEL TO LOWER PLENUM PANEL 50

LOWER PLENUM PANEL TO COWL BACK PANEL 51

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET, AND WELD NUTS TO COWL SIDE PANEL - LEFT SIDE52

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PA N E L - L E F T S I D E53

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET AND WELD NUTS TO COWL SIDE PANEL - RIGHT SIDE54

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - RIGHT SIDE55

REINFORCEMENT AND HEADLAMP MOUNTING PANEL TO OUTER FENDER PANEL 56

SEAT MOUNTING FRONT BRACKETS TO SEAT MOUNTING FRONT CROSSMEMBER

TO FRONT FLOOR PAN57

AIR BAG MODULE BRACKET SHIFTER MOUNTING PLATE AND REAR FLOOR PANEL

TO FRONT FLOOR PAN58

RIGHT TO LEFT REAR FLOOR CROSSMEMBER AND RIGHT TO LEFT SEAT

MOUNTING CROSSMEMBER59

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL60

SEAT MOUNTING FRONT CROSSMEMBER TO FRONT FLOOR PAN TO UNDERBODY

SUPPORT61

FRONT SEAT MOUNTING CROSSMEMBERS TO FRONT SEAT MOUNTING BRACKET

TO FRONT FLOOR PAN62

REAR FLOOR CROSSMEMBERS TO REAR FLOOR PAN 63

FLOOR SILL TO FRONT SEAT MOUNTING CROSSMEMBER, FRONT AND REAR

FLOOR PAN64

AIR BAG MODULE BRACKET, SHIFTER MOUNTING PLATE AND FRONT SEAT

MOUNTING CROSSMEMBER TO FRONT FLOOR PAN65

REAR SEAT MIDDLE MOUNTING PLATE TO REAR FLOOR PAN TO FRONT FLOOR

PA N66

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL67

LEFT REAR CROSSMEMBER TO RIGHT REAR CROSSMEMBER TO REAR FLOOR

PA N68

STORAGE BIN TO RIGHT AND LEFT REAR FLOOR CROSSMEMBER TO REAR

FLOOR PAN69