reset DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3536 of 5267

4.CHECK IF THE DTC IS CURRENT

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 5

No>>

Go To 9

5.PERFORM TCC SYSTEM TEST

With the scan tool, perform the TCC System Test.

Follow the instructions on the screen.

Did the engine stall?

Ye s>>

Go To 6

No>>

Go To 7

6.PERFORM GOV AND 3-4 SHIFT VALVE SYSTEM TEST

With the scan tool, perform the Gov and 3-4 Shift Valve System Test.

Follow the instructions on the screen.

Did the engine stall?

Ye s>>

Go To 8

No>>

Go To 7

7.CHECK THE COOLER OUT PRESSURE

Turn the ignition off to the lock position.

Connect a pressure gauge to the transmission cooler out port with a “T” connector. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - DIAGNOSIS AND TESTING)

Start the engine, with the scan tool, perform the TCC System Test.

Did the cooler out pressure on the gauge increase when the TCC was actuated?

Ye s>>

Remove the transmission oil pump and inspect the reaction shaft, input shaft and input shaft seals for

damage or wear and repair or replace as necessary. Replace the Torque Convertor.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Remove the Valve Body and inspect for an internal blockage or an internal leak in the TCC hydraulic

circuit. Repair as necessary. (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO M AT I C - 4 8 R E / VA LV E

BODY - REMOVAL)

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Page 3539 of 5267

Theory of Operation

The Torque Converter Clutch (TCC) solenoid is used to engage the TCC which improves fuel economy.

When Monitored:

Continuously with the ignition on.

Set Condition:

This DTC will set if the voltage detected by the PCM for the Torque ConverterClutch SolenoidControl circuit

is different than the expected voltage. Note: To clear this DTC it is necessarytodrivethevehicleatasus-

tained speed which would allow the TCC and/or Overdrive Clutch to operate.

Possible Causes

TRANSMISSION CONTROL OUTPUT DTCS PRESENT

(F941) FUSED IGNITION SWITCH OUTPUT CIRCUIT (RUN-START) OPEN

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT OPEN

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT SHORT TO GROUND

(T75) TCC SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T75) TCC SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

TOTALLY INTEGRATED POWER MODULE (TIPM)

TORQUE CONVERTER CLUTCH SOLENOID

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THERE ANY TRANSMISSION CONTROL DTCS PRESENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Are there any TIPM TCM Power Control Circuit DTCs also present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom(s). (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 48RE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 3

No>>

Go To 11

Page 3546 of 5267

Theory of Operation

The Governor Pressure Solenoid is used to control governor pressure. Governor pressure is used to shift between

first, second, and third gear.

When Monitored:

Continuously with the ignition on.

Set Condition:

This DTC will set if the PCM monitored voltage detected on the Governor Pressure Solenoid Control circuit is

different than the expected voltage. Note: To clear this DTC, it is necessary to drive the vehicle at a sustained

speed which would allow the TCC and/or Overdrive Clutch to operate.

Possible Causes

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT OPEN

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT SHORT TO GROUND

(T118) GOVERNOR PRESSURE SOLENOID CONTROL CIRCUIT OPEN

(T118) GOVERNOR PRESSURE SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T118) GOVERNOR PRESSURE SOLENOID CONTROL CIRCUIT SHORT TO VOLTAGE

(T118) GOVERNOR PRESSURE SOLENOID CONTROL CIRCUIT SHORT TO ANOTHER CIRCUIT

GOVERNOR PRESSURE SOLENOID

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THERE ANY TRANSMISSION CONTROL DTCS PRESENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Are there any TIPM TCM Power Control Circuit DTCs also present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 3

No>>

Go To 12

Page 3549 of 5267

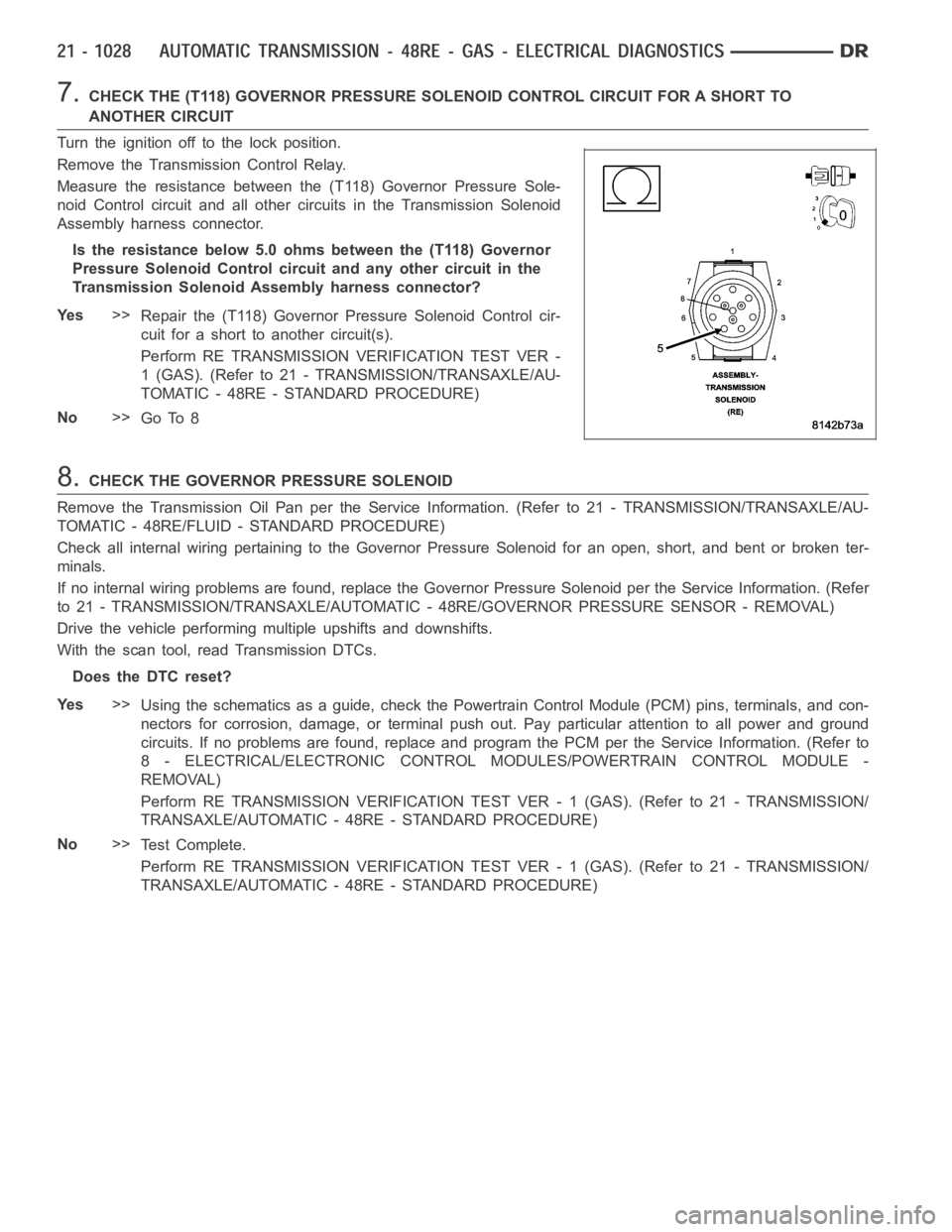

7.CHECK THE (T118) GOVERNOR PRESSURE SOLENOID CONTROL CIRCUIT FOR A SHORT TO

ANOTHER CIRCUIT

Turn the ignition off to the lock position.

Remove the Transmission Control Relay.

Measure the resistance between the (T118) Governor Pressure Sole-

noid Control circuit and all other circuits in the Transmission Solenoid

Assembly harness connector.

Is the resistance below 5.0 ohms between the (T118) Governor

Pressure Solenoid Control circuit and any other circuit in the

Transmission Solenoid Assembly harness connector?

Ye s>>

Repair the (T118) Governor Pressure Solenoid Control cir-

cuit for a short to another circuit(s).

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 8

8.CHECK THE GOVERNOR PRESSURE SOLENOID

Remove the Transmission Oil Pan per the Service Information. (Refer to 21 -TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE/FLUID - STANDARD PROCEDURE)

Check all internal wiring pertaining to the Governor Pressure Solenoid for an open, short, and bent or broken ter-

minals.

If no internal wiring problems are found, replace the Governor Pressure Solenoid per the Service Information. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 48RE/GOVERNOR PRESSURE SENSOR - REMOVAL)

Drive the vehicle performing multiple upshifts and downshifts.

With the scan tool, read Transmission DTCs.

Does the DTC reset?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)pins, terminals, and con-

nectors for corrosion, damage, or terminal push out. Pay particular attention to all power and ground

circuits. If no problems are found, replace and program the PCM per the Service Information. (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/POWERTRAIN CONTROL MODULE -

REMOVAL)

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Page 3557 of 5267

2.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 3

No>>

Go To 12

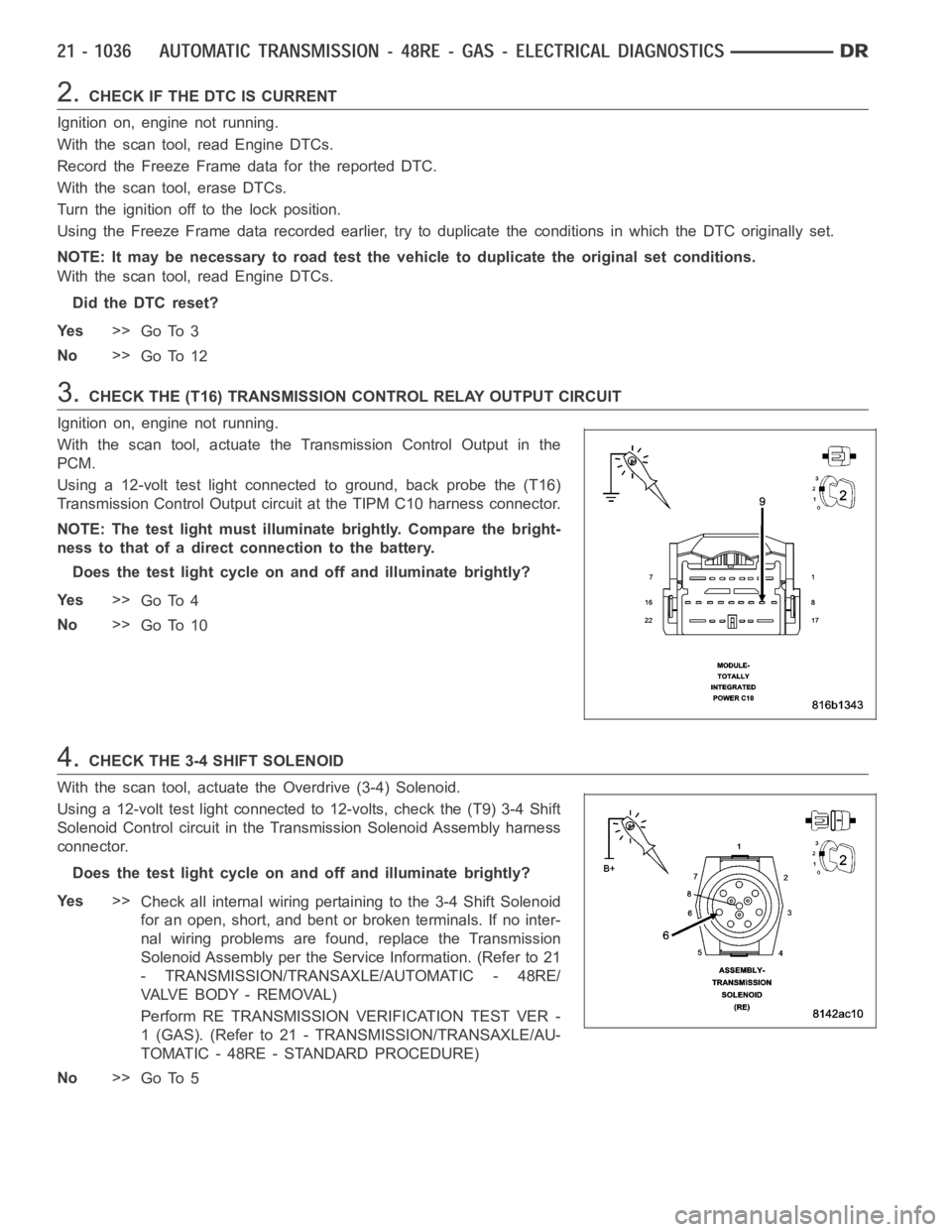

3.CHECK THE (T16) TRANSMISSION CONTROL RELAY OUTPUT CIRCUIT

Ignition on, engine not running.

With the scan tool, actuate the Transmission Control Output in the

PCM.

Using a 12-volt test light connected to ground, back probe the (T16)

Transmission Control Output circuit at the TIPM C10 harness connector.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light cycle on and off and illuminate brightly?

Ye s>>

Go To 4

No>>

Go To 10

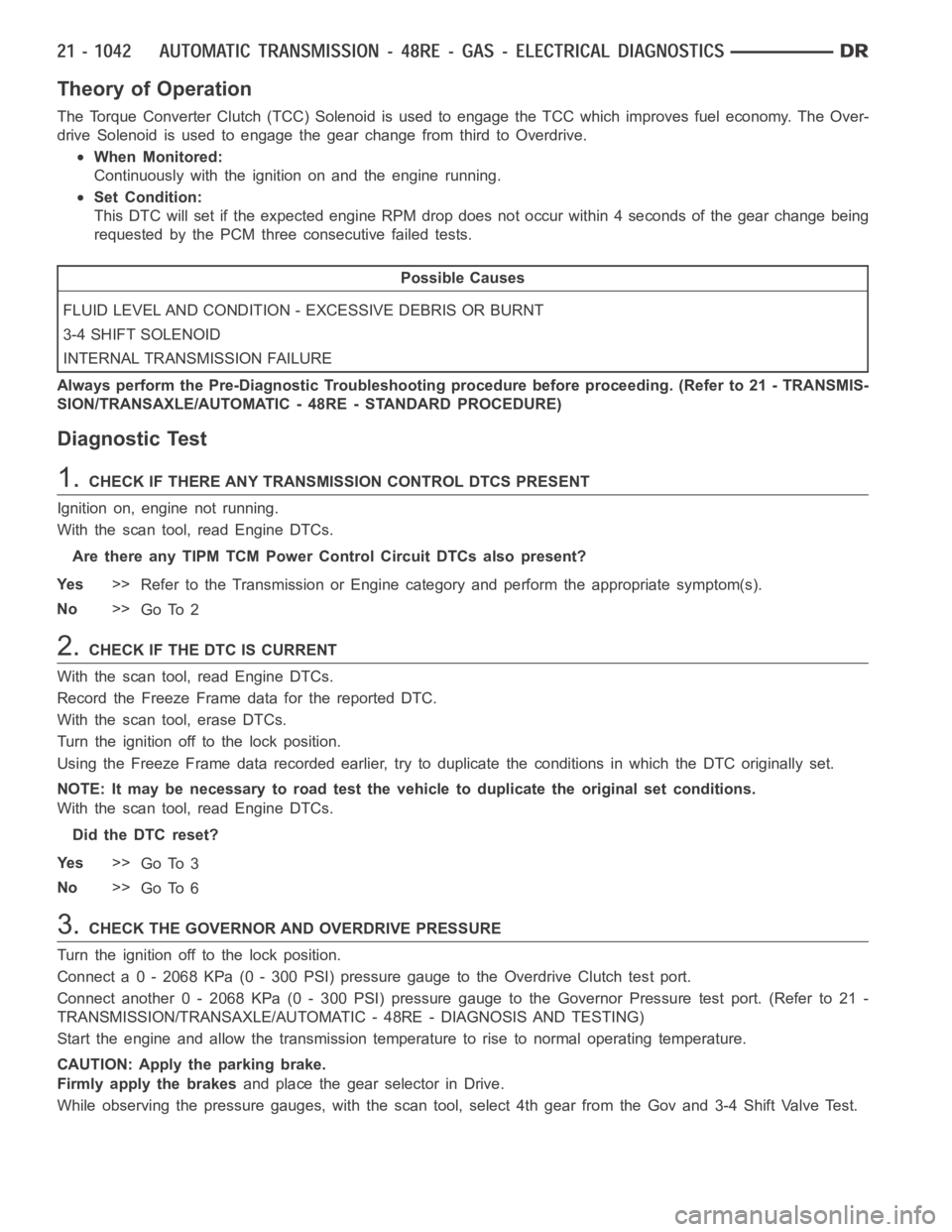

4.CHECK THE 3-4 SHIFT SOLENOID

With the scan tool, actuate the Overdrive (3-4) Solenoid.

Using a 12-volt test light connected to 12-volts, check the (T9) 3-4 Shift

Solenoid Control circuit in the Transmission Solenoid Assembly harness

connector.

Does the test light cycle on and off and illuminate brightly?

Ye s>>

Check all internal wiring pertaining to the 3-4 Shift Solenoid

for an open, short, and bent or broken terminals. If no inter-

nal wiring problems are found, replace the Transmission

Solenoid Assembly per the Service Information. (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC - 48RE/

VA LV E B O D Y - R E M O VA L )

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 5

Page 3563 of 5267

Theory of Operation

The Torque Converter Clutch (TCC) Solenoid is used to engage the TCC which improves fuel economy. The Over-

drive Solenoid is used to engage the gear change from third to Overdrive.

When Monitored:

Continuously with the ignition on and the engine running.

Set Condition:

This DTC will set if the expected engine RPM drop does not occur within 4 seconds of the gear change being

requested by the PCM three consecutive failed tests.

Possible Causes

FLUID LEVEL AND CONDITION - EXCESSIVE DEBRIS OR BURNT

3-4 SHIFT SOLENOID

INTERNAL TRANSMISSION FAILURE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THERE ANY TRANSMISSION CONTROL DTCS PRESENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Are there any TIPM TCM Power Control Circuit DTCs also present?

Ye s>>

Refer to the Transmission or Engine category and perform the appropriate symptom(s).

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 3

No>>

Go To 6

3.CHECK THE GOVERNOR AND OVERDRIVE PRESSURE

Turn the ignition off to the lock position.

Connect a 0 - 2068 KPa (0 - 300 PSI) pressure gauge to the Overdrive Clutch test port.

Connect another 0 - 2068 KPa (0 - 300 PSI) pressure gauge to the Governor Pressure test port. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 48RE - DIAGNOSIS AND TESTING)

Start the engine and allow the transmission temperature to rise to normal operating temperature.

CAUTION: Apply the parking brake.

Firmly apply the brakesand place the gear selector in Drive.

While observing the pressure gauges, with the scan tool, select 4th gear from the Gov and 3-4 Shift Valve Test.

Page 3573 of 5267

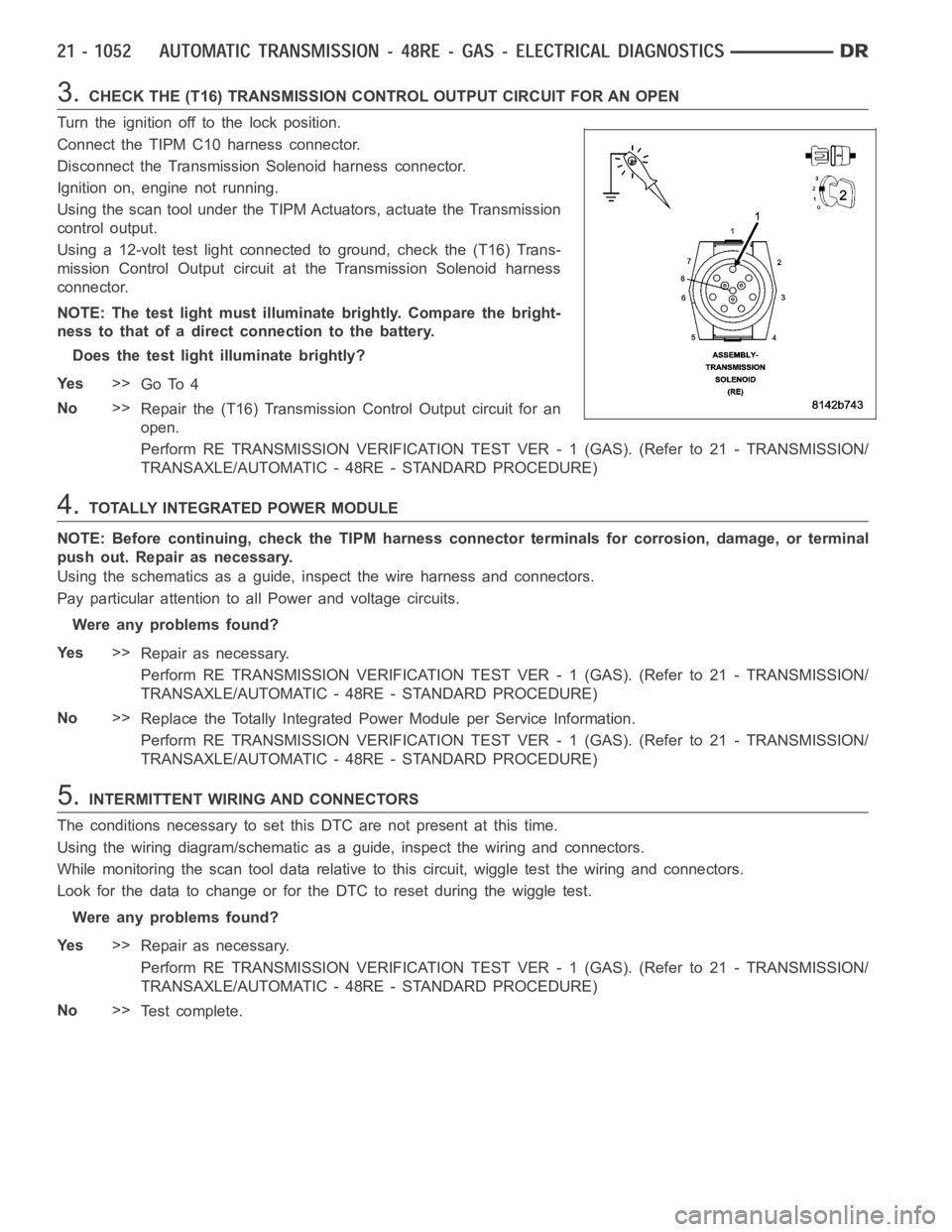

3.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Connect the TIPM C10 harness connector.

Disconnect the Transmission Solenoid harness connector.

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the Transmission

control output.

Using a 12-volt test light connected to ground, check the (T16) Trans-

mission Control Output circuit at the Transmission Solenoid harness

connector.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Go To 4

No>>

Repair the (T16) Transmission Control Output circuit for an

open.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

4.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3576 of 5267

3.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3579 of 5267

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3585 of 5267

3.CHECK IF THE DTC IS CURRENT

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 4

No>>

Go To 14

4.VERIFY THE TOW/ HAUL OVERDRIVE FEATURE

NOTE: The transmission fluid temperature must be above 0.0° C (32° F) before proceeding.

With the scan tool, build a custom display using: Engine RPM, Output Shaft Speed, TCC Solenoid, O/D Solenoid

and TPS.

NOTE: This display will monitor the operation of the components.

Start the engine, turn off Overdrive or Tow Haul and test drive the vehicle.

Attain a steady speed of 88.5 Km/h or 55 MPH with a minimum of 1.15 volts throttle opening for 20 seconds.

NOTE: Check the Shift pattern as the vehicle upshifts to speeds of 88.5 Km/hor 55 MPH.

Is the Engine RPM within 60 RPM of the Output Shaft Speed RPM?

Ye s>>

Go To 10

No>>

Go To 5

5.CHECK IF THE OUTPUT SPEED IS GREATER THAN ENGINE RPM

In the previous test, is the Output Shaft Speed greater than Engine RPM?

Ye s>>

Go To 6

No>>

Go To 10

6.CALCULATE EXPECTED ENGINE RPM

With the scan tool, build a custom display using: Engine RPM, Output Shaft Speed, TCC Solenoid, O/D Solenoid

and TPS.

NOTE: This display will monitor the operation of the components.

Start the engine, turn off Overdrive or Tow Haul and test drive the vehicle.

Attain a steady speed of 88.5 Km/h or 55 MPH with a minimum of 1.15 volts throttle opening for 20 seconds.

With the scan tool, verify the 3-4 Solenoid (O/D) Solenoid is on and the TCC solenoid is locked

NOTE: Use this formula, Output Shaft Speed x 0.69 = expected Engine RPM.

Did the Engine RPM drop to 0.69 of the Output Shaft Speed RPM?

Ye s>>

Go To 10

No>>

Go To 7