torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1923 of 5267

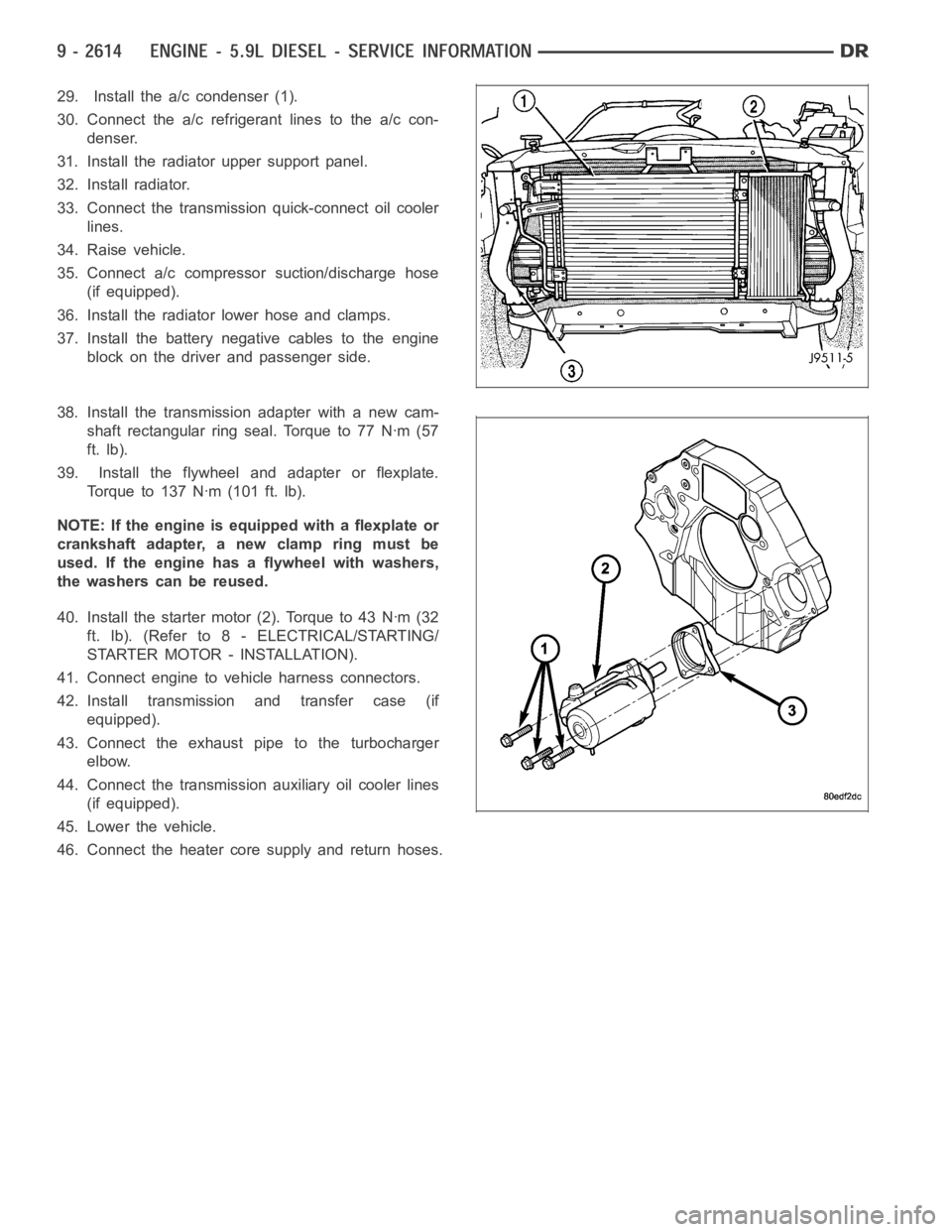

29. Install the a/c condenser (1).

30. Connect the a/c refrigerant lines to the a/c con-

denser.

31. Install the radiator upper support panel.

32. Install radiator.

33. Connect the transmission quick-connect oil cooler

lines.

34. Raise vehicle.

35. Connect a/c compressor suction/discharge hose

(if equipped).

36. Install the radiator lower hose and clamps.

37. Install the battery negative cables to the engine

block on the driver and passenger side.

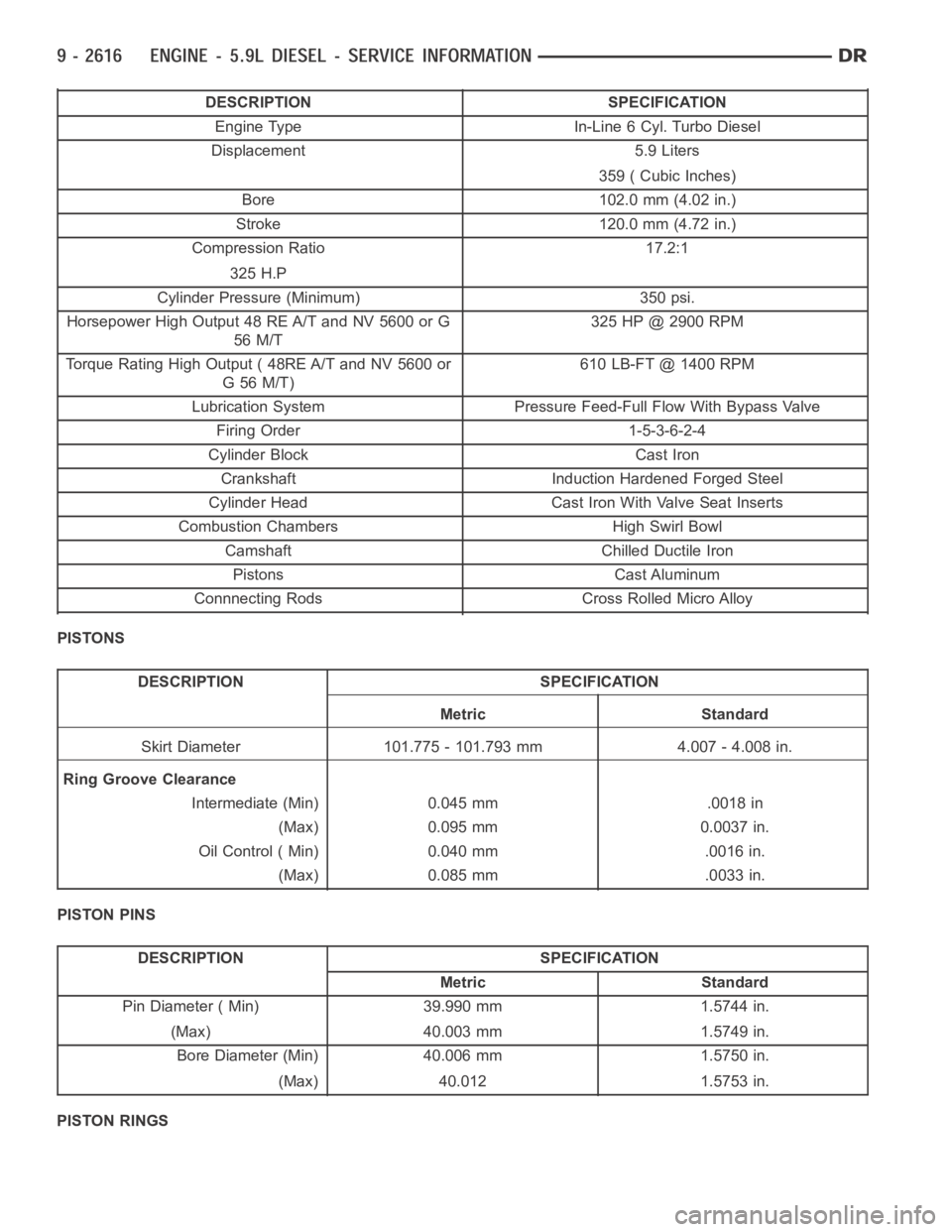

38. Install the transmission adapter with a new cam-

shaft rectangular ring seal. Torque to 77 Nꞏm (57

ft. lb).

39. Install the flywheel and adapter or flexplate.

Torque to 137 Nꞏm (101 ft. lb).

NOTE: If the engine is equipped with a flexplate or

crankshaft adapter, a new clamp ring must be

used. If the engine has a flywheel with washers,

the washers can be reused.

40. Install the starter motor (2). Torque to 43 Nꞏm (32

ft. lb). (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

41. Connect engine to vehicle harness connectors.

42. Install transmission and transfer case (if

equipped).

43. Connect the exhaust pipe to the turbocharger

elbow.

44. Connect the transmission auxiliary oil cooler lines

(if equipped).

45. Lower the vehicle.

46. Connect the heater core supply and return hoses.

Page 1925 of 5267

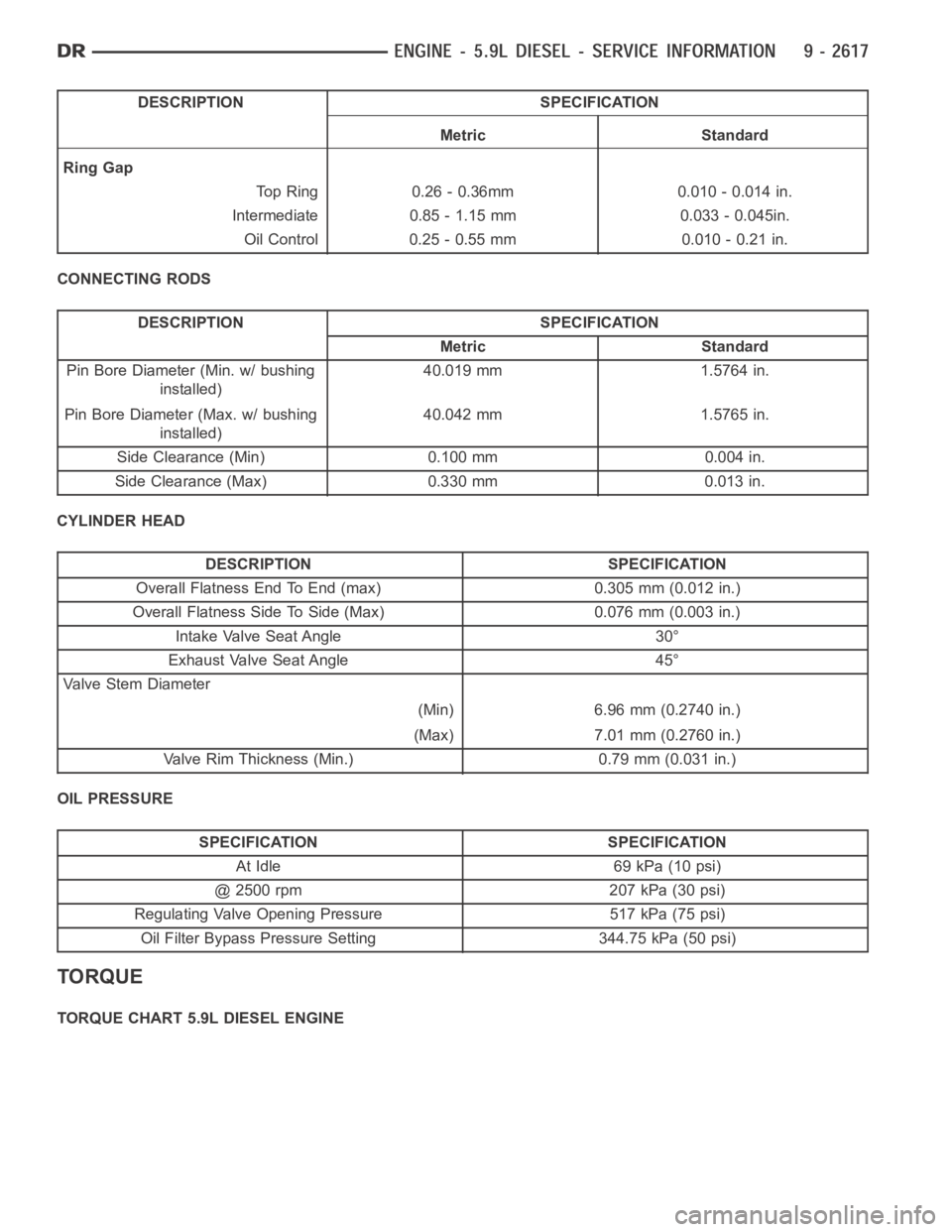

DESCRIPTION SPECIFICATION

Engine Type In-Line 6 Cyl. Turbo Diesel

Displacement 5.9 Liters

359 ( Cubic Inches)

Bore 102.0 mm (4.02 in.)

Stroke 120.0 mm (4.72 in.)

Compression Ratio 17.2:1

325 H.P

Cylinder Pressure (Minimum) 350 psi.

Horsepower High Output 48 RE A/T and NV 5600 or G

56 M/T325 HP @ 2900 RPM

Torque Rating High Output ( 48RE A/T and NV 5600 or

G56M/T)610 LB-FT @ 1400 RPM

Lubrication System Pressure Feed-Full Flow With Bypass Valve

Firing Order 1-5-3-6-2-4

Cylinder Block Cast Iron

Crankshaft Induction Hardened Forged Steel

Cylinder Head Cast Iron With Valve Seat Inserts

Combustion Chambers High Swirl Bowl

Camshaft Chilled Ductile Iron

Pistons Cast Aluminum

Connnecting Rods Cross Rolled Micro Alloy

PISTONS

DESCRIPTION SPECIFICATION

Metric Standard

Skirt Diameter 101.775 - 101.793 mm 4.007 - 4.008 in.

Ring Groove Clearance

Intermediate (Min) 0.045 mm .0018 in

(Max) 0.095 mm 0.0037 in.

Oil Control ( Min) 0.040 mm .0016 in.

(Max) 0.085 mm .0033 in.

PISTON PINS

DESCRIPTION SPECIFICATION

Metric Standard

Pin Diameter ( Min) 39.990 mm 1.5744 in.

(Max) 40.003 mm 1.5749 in.

Bore Diameter (Min) 40.006 mm 1.5750 in.

(Max) 40.012 1.5753 in.

PISTON RINGS

Page 1926 of 5267

DESCRIPTION SPECIFICATION

Metric Standard

Ring Gap

Top Ring 0.26 - 0.36mm 0.010 - 0.014 in.

Intermediate 0.85 - 1.15 mm 0.033 - 0.045in.

Oil Control 0.25 - 0.55 mm 0.010 - 0.21 in.

CONNECTING RODS

DESCRIPTION SPECIFICATION

Metric Standard

Pin Bore Diameter (Min. w/ bushing

installed)40.019 mm 1.5764 in.

Pin Bore Diameter (Max. w/ bushing

installed)40.042 mm 1.5765 in.

Side Clearance (Min) 0.100 mm 0.004 in.

Side Clearance (Max) 0.330 mm 0.013 in.

CYLINDER HEAD

DESCRIPTION SPECIFICATION

Overall Flatness End To End (max) 0.305 mm (0.012 in.)

Overall Flatness Side To Side (Max) 0.076 mm (0.003 in.)

Intake Valve Seat Angle 30°

Exhaust Valve Seat Angle 45°

Va l v e S t e m D i a m e t e r

(Min) 6.96 mm (0.2740 in.)

(Max) 7.01 mm (0.2760 in.)

Valve Rim Thickness (Min.) 0.79 mm (0.031 in.)

OIL PRESSURE

SPECIFICATION SPECIFICATION

At Idle 69 kPa (10 psi)

@ 2500 rpm 207 kPa (30 psi)

Regulating Valve Opening Pressure 517 kPa (75 psi)

Oil Filter Bypass Pressure Setting 344.75 kPa (50 psi)

TORQUE

TORQUE CHART 5.9L DIESEL ENGINE

Page 1935 of 5267

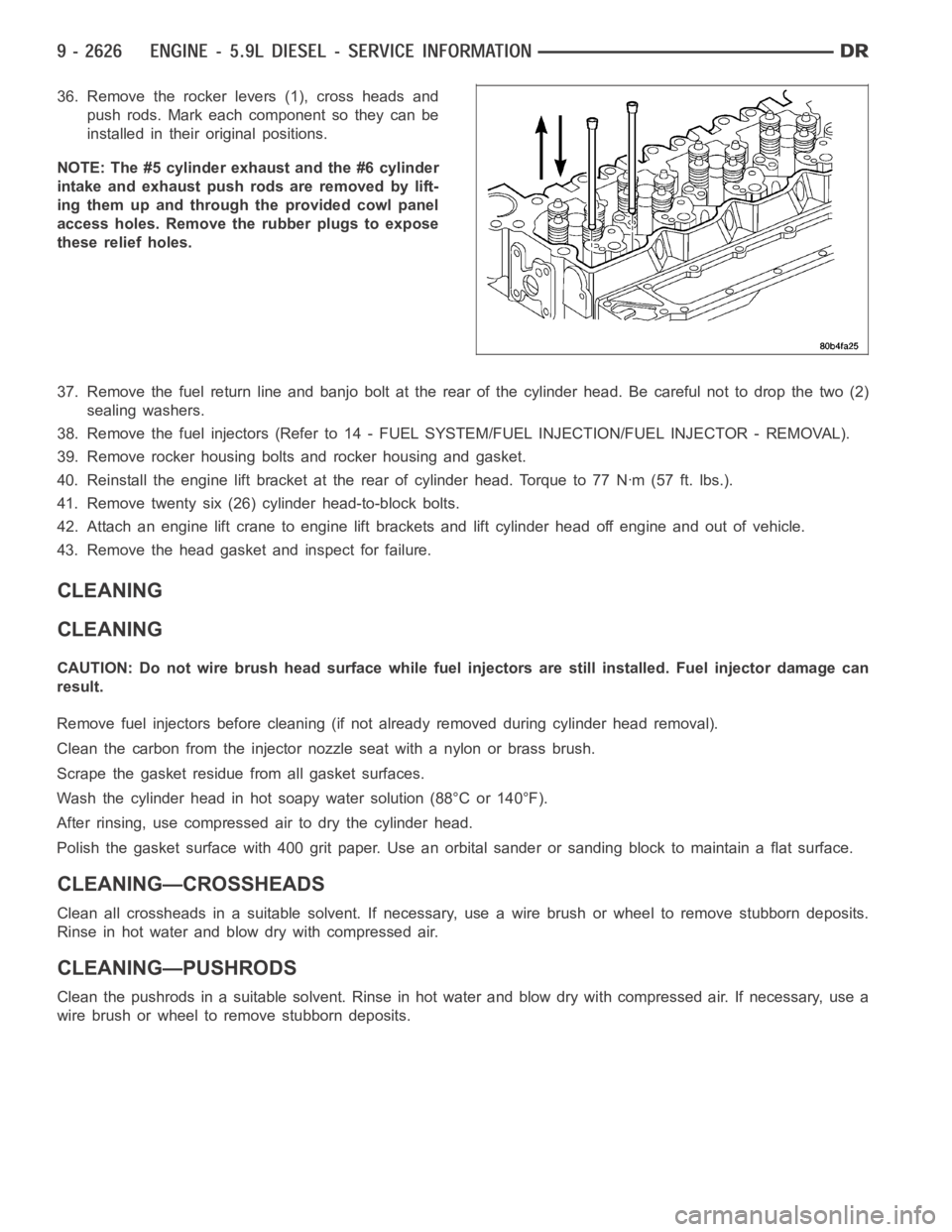

36. Remove the rocker levers (1), cross heads and

push rods. Mark each component so they can be

installed in their original positions.

NOTE: The #5 cylinder exhaust and the #6 cylinder

intake and exhaust push rods are removed by lift-

ing them up and through the provided cowl panel

access holes. Remove the rubber plugs to expose

these relief holes.

37. Remove the fuel return line and banjo bolt at the rear of the cylinder head. Be careful not to drop the two (2)

sealing washers.

38. Remove the fuel injectors (Refer to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL INJECTOR - REMOVAL).

39. Remove rocker housing bolts and rocker housing and gasket.

40. Reinstall the engine lift bracket at the rear of cylinder head. Torque to77Nꞏm(57ft.lbs.).

41. Remove twenty six (26) cylinder head-to-block bolts.

42. Attach an engine lift crane to engine lift brackets and lift cylinder head off engine and out of vehicle.

43. Remove the head gasket and inspect for failure.

CLEANING

CLEANING

CAUTION: Do not wire brush head surface while fuel injectors are still installed. Fuel injector damage can

result.

Remove fuel injectors before cleaning (if not already removed during cylinder head removal).

Clean the carbon from the injector nozzle seat with a nylon or brass brush.

Scrape the gasket residuefrom all gasket surfaces.

Wash the cylinder head in hot soapy water solution (88°C or 140°F).

After rinsing, use compressed air to dry the cylinder head.

Polish the gasket surface with 400 grit paper. Use an orbital sander or sanding block to maintain a flat surface.

CLEANING—CROSSHEADS

Clean all crossheads in a suitable solvent. If necessary, use a wire brush or wheel to remove stubborn deposits.

Rinse in hot water and blow dry with compressed air.

CLEANING—PUSHRODS

Clean the pushrods in a suitable solvent. Rinse in hot water and blow dry with compressed air. If necessary, use a

wire brush or wheel to remove stubborn deposits.

Page 1937 of 5267

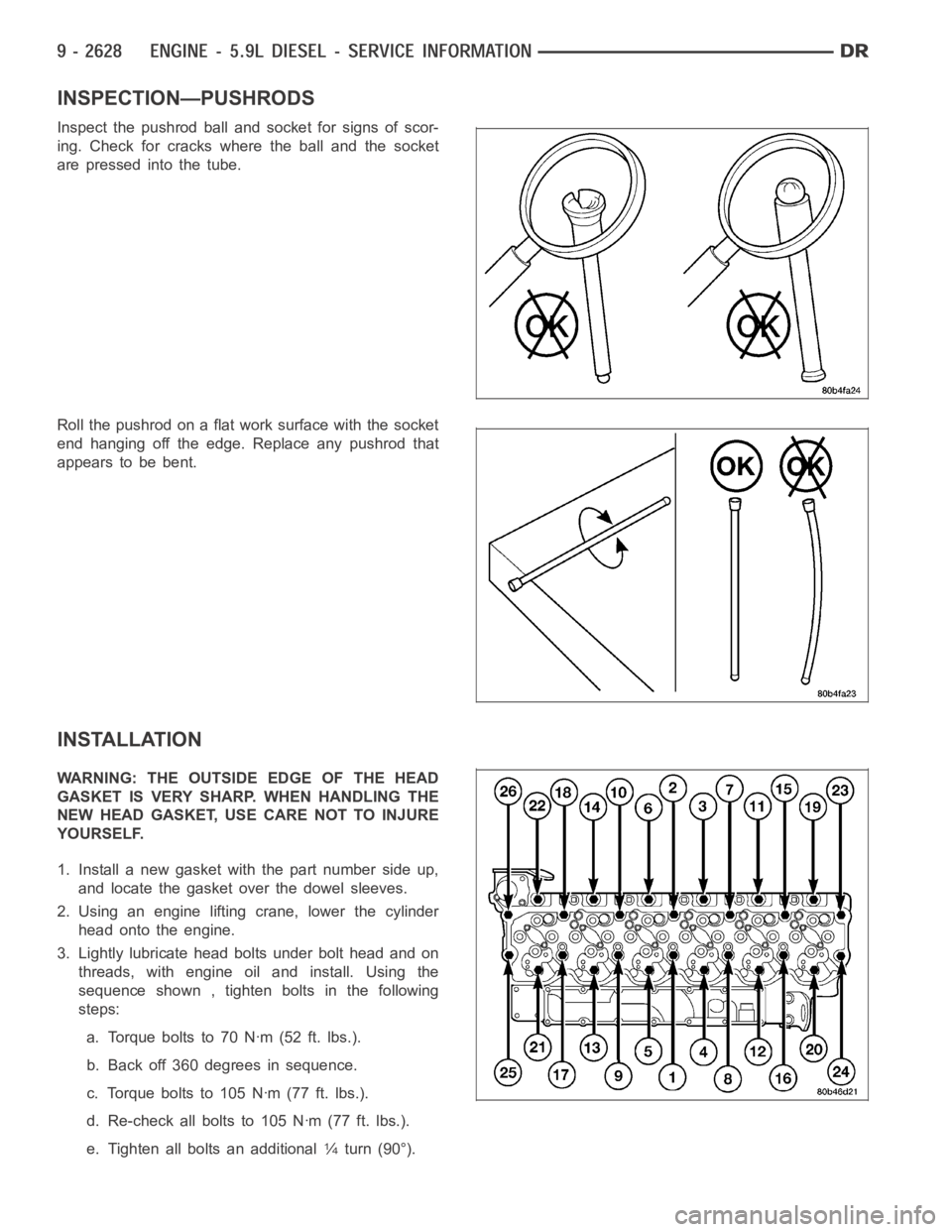

INSPECTION—PUSHRODS

Inspect the pushrod ball and socket for signs of scor-

ing. Check for cracks where the ball and the socket

are pressed into the tube.

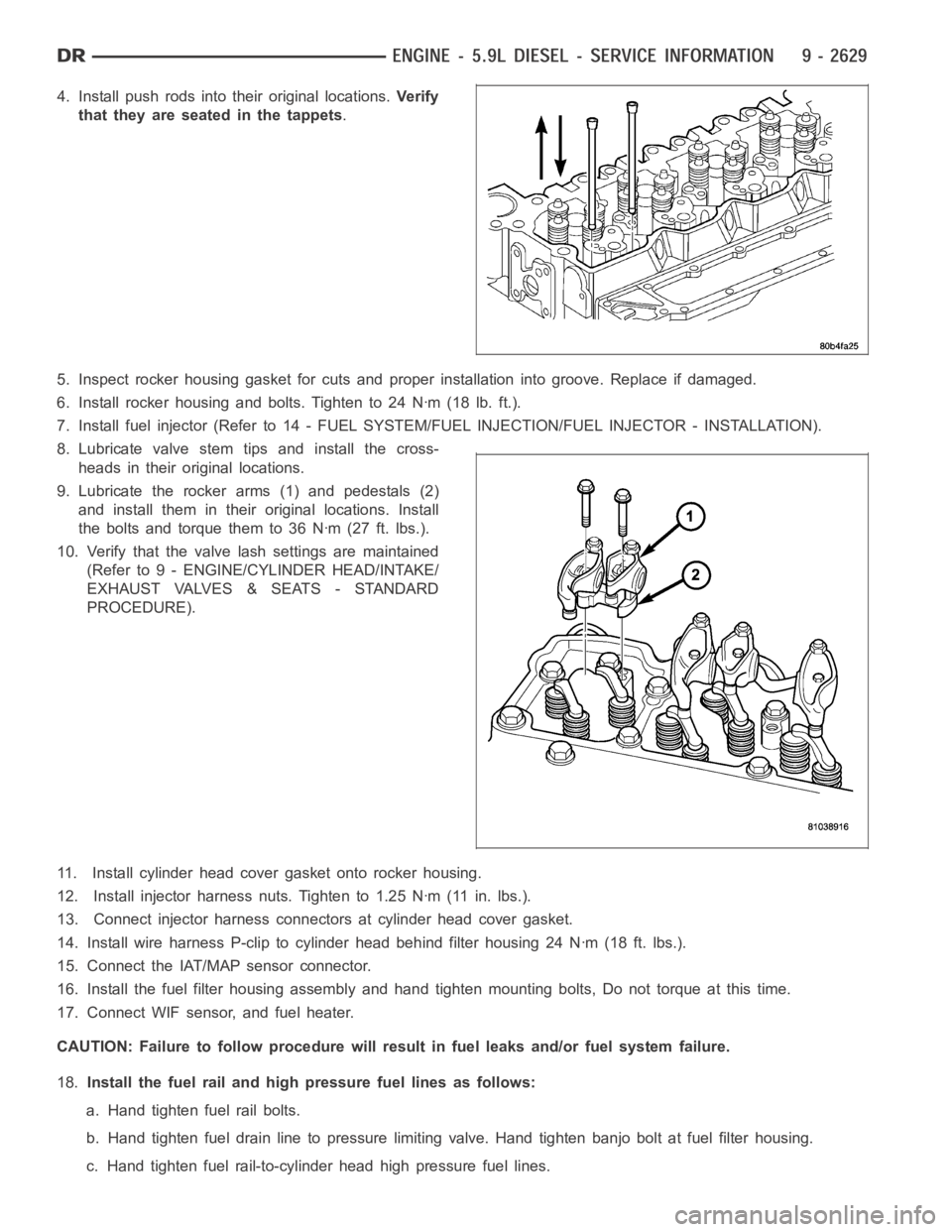

Roll the pushrod on a flat work surface with the socket

end hanging off the edge. Replace any pushrod that

appears to be bent.

INSTALLATION

WARNING: THE OUTSIDE EDGE OF THE HEAD

GASKET IS VERY SHARP. WHEN HANDLING THE

NEW HEAD GASKET, USE CARE NOT TO INJURE

YOURSELF.

1. Install a new gasket with the part number side up,

and locate the gasket over the dowel sleeves.

2. Using an engine lifting crane, lower the cylinder

head onto the engine.

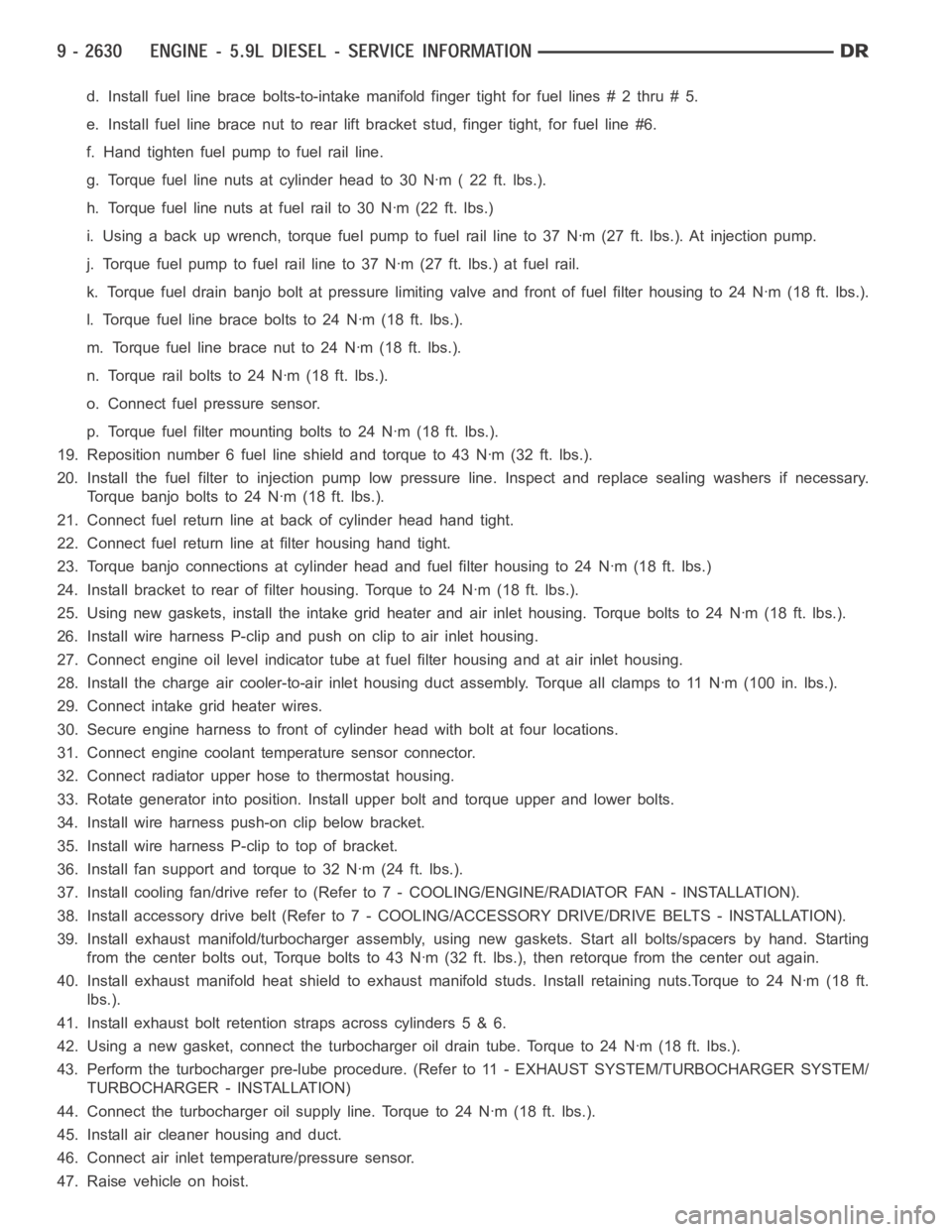

3. Lightly lubricate head bolts under bolt head and on

threads, with engine oil and install. Using the

sequence shown , tighten bolts in the following

steps:

a. Torqueboltsto70Nꞏm(52ft.lbs.).

b. Back off 360 degrees in sequence.

c. Torque bolts to 105 Nꞏm (77 ft. lbs.).

d. Re-check all bolts to 105 Nꞏm (77 ft. lbs.).

e. Tighten all bolts an additional

1⁄4turn (90°).

Page 1938 of 5267

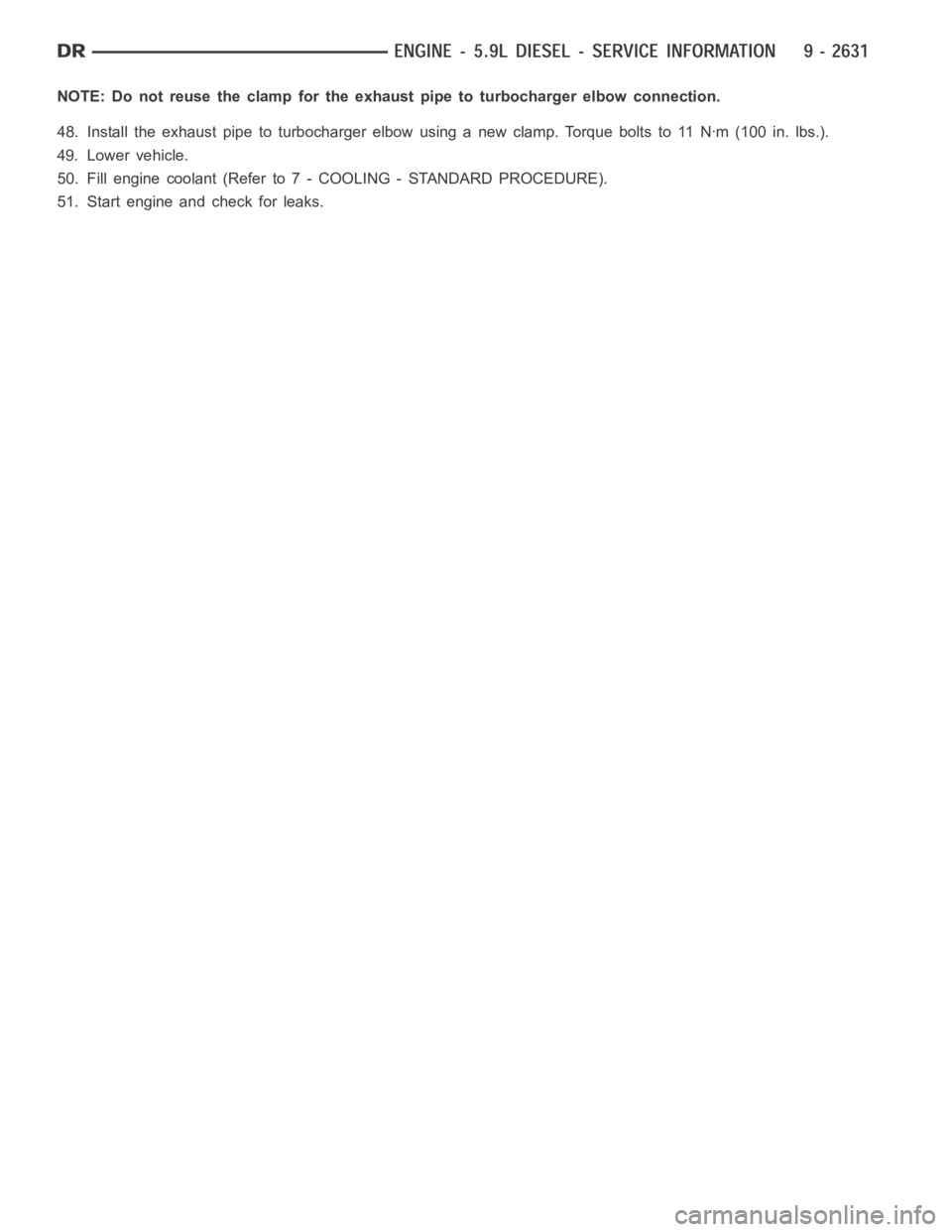

4. Install push rods into their original locations.Ve r i f y

that they are seated in the tappets.

5. Inspect rocker housing gasket for cuts and proper installation into groove. Replace if damaged.

6. Install rocker housing and bolts. Tighten to 24 Nꞏm (18 lb. ft.).

7. Install fuel injector (Refer to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL INJECTOR - INSTALLATION).

8. Lubricate valve stem tips and install the cross-

heads in their original locations.

9. Lubricate the rocker arms (1) and pedestals (2)

and install them in their original locations. Install

the bolts and torque them to 36 Nꞏm (27 ft. lbs.).

10. Verify that the valve lash settings are maintained

(Refer to 9 - ENGINE/CYLINDER HEAD/INTAKE/

EXHAUST VALVES & SEATS - STANDARD

PROCEDURE).

11. Install cylinder head cover gasket onto rocker housing.

12. Install injector harness nuts. Tighten to 1.25 Nꞏm (11 in. lbs.).

13. Connect injector harness connectors at cylinder head cover gasket.

14. Install wire harness P-clip to cylinder head behind filter housing 24 Nꞏm (18 ft. lbs.).

15. Connect the IAT/MAP sensor connector.

16. Install the fuel filter housing assembly and hand tighten mounting bolts, Do not torque at this time.

17. Connect WIF sensor, and fuel heater.

CAUTION: Failure to follow procedure will result in fuel leaks and/or fuelsystem failure.

18.Install the fuel rail and high pressure fuel lines as follows:

a. Hand tighten fuel rail bolts.

b. Hand tighten fuel drain line to pressure limiting valve. Hand tighten banjo bolt at fuel filter housing.

c. Hand tighten fuel rail-to-cylinder head high pressure fuel lines.

Page 1939 of 5267

d. Install fuel line brace bolts-to-intake manifold finger tight for fuellines#2thru#5.

e. Install fuel line brace nut to rear lift bracket stud, finger tight, for fuel line #6.

f. Hand tighten fuel pump to fuel rail line.

g. Torque fuel line nuts at cylinder head to 30 Nꞏm ( 22 ft. lbs.).

h. Torque fuel line nuts at fuel rail to 30 Nꞏm (22 ft. lbs.)

i. Usingabackupwrench,torquefuelpumptofuelraillineto37Nꞏm(27ft.lbs.). At injection pump.

j. Torque fuel pump to fuel rail line to 37 Nꞏm (27 ft. lbs.) at fuel rail.

k. Torque fuel drain banjo bolt at pressure limiting valve and front of fuelfilter housing to 24 Nꞏm (18 ft. lbs.).

l. Torque fuel line brace bolts to 24 Nꞏm (18 ft. lbs.).

m. Torque fuel line brace nut to 24 Nꞏm (18 ft. lbs.).

n. Torque rail bolts to 24 Nꞏm (18 ft. lbs.).

o. Connect fuel pressure sensor.

p. Torque fuel filter mounting bolts to 24 Nꞏm (18 ft. lbs.).

19. Reposition number 6 fuel line shield and torque to 43 Nꞏm (32 ft. lbs.).

20. Install the fuel filter to injection pump low pressure line. Inspect and replace sealing washers if necessary.

Torque banjo bolts to 24 Nꞏm (18 ft. lbs.).

21. Connect fuel return line at back of cylinder head hand tight.

22. Connect fuel return line at filter housing hand tight.

23. Torque banjo connections at cylinder head and fuel filter housing to 24Nꞏm (18 ft. lbs.)

24. Install bracket to rear of filter housing. Torque to 24 Nꞏm (18 ft. lbs.).

25. Using new gaskets, install the intake grid heater and air inlet housing. Torque bolts to 24 Nꞏm (18 ft. lbs.).

26. Install wire harness P-clip and push on clip to air inlet housing.

27. Connect engine oil level indicator tube at fuel filter housing and at air inlet housing.

28. Install the charge air cooler-to-air inlet housing duct assembly. Torque all clamps to 11 Nꞏm (100 in. lbs.).

29. Connect intake grid heater wires.

30. Secure engine harness to front of cylinder head with bolt at four locations.

31. Connect engine coolant temperature sensor connector.

32. Connect radiator upper hose to thermostat housing.

33. Rotate generator into position. Install upper bolt and torque upper and lower bolts.

34. Install wire harness push-on clip below bracket.

35. Install wire harness P-clip to top of bracket.

36. Install fan support and torque to 32 Nꞏm (24 ft. lbs.).

37. Install cooling fan/drive refer to (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION).

38. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

39. Install exhaust manifold/turbocharger assembly, using new gaskets.Start all bolts/spacers by hand. Starting

from the center bolts out, Torque bolts to 43 Nꞏm (32 ft. lbs.), then retorque from the center out again.

40. Install exhaust manifold heat shield to exhaust manifold studs. Install retaining nuts.Torque to 24 Nꞏm (18 ft.

lbs.).

41. Install exhaust bolt retention straps across cylinders 5 & 6.

42. Using a new gasket, connect the turbocharger oil drain tube. Torque to 24Nꞏm(18ft.lbs.).

43. Perform the turbocharger pre-lube procedure. (Refer to 11 - EXHAUST SYSTEM/TURBOCHARGER SYSTEM/

TURBOCHARGER - INSTALLATION)

44. Connect the turbocharger oil supply line. Torque to 24 Nꞏm (18 ft. lbs.).

45. Install air cleaner housing and duct.

46. Connect air inlet temperature/pressure sensor.

47. Raise vehicle on hoist.

Page 1940 of 5267

NOTE: Do not reuse the clamp for the exhaust pipe to turbocharger elbow connection.

48. Install the exhaust pipe to turbocharger elbow using a new clamp. Torque bolts to 11 Nꞏm (100 in. lbs.).

49. Lower vehicle.

50. Fill engine coolant (Refer to 7 - COOLING - STANDARD PROCEDURE).

51. Start engine and check for leaks.

Page 1944 of 5267

CAUTION: When installing rocker housing onto cylinder head, do not slide housing from side to side, The

gasket could fall out or be damaged.

3. Install the rocker housing. Carefully guide the rocker housing evenly down onto the cylinder head.

4. Install rocker housing bolts and tighten finger tight.

5. Torque bolts, working from center out, to 24 Nꞏm (18 ft. lbs.).

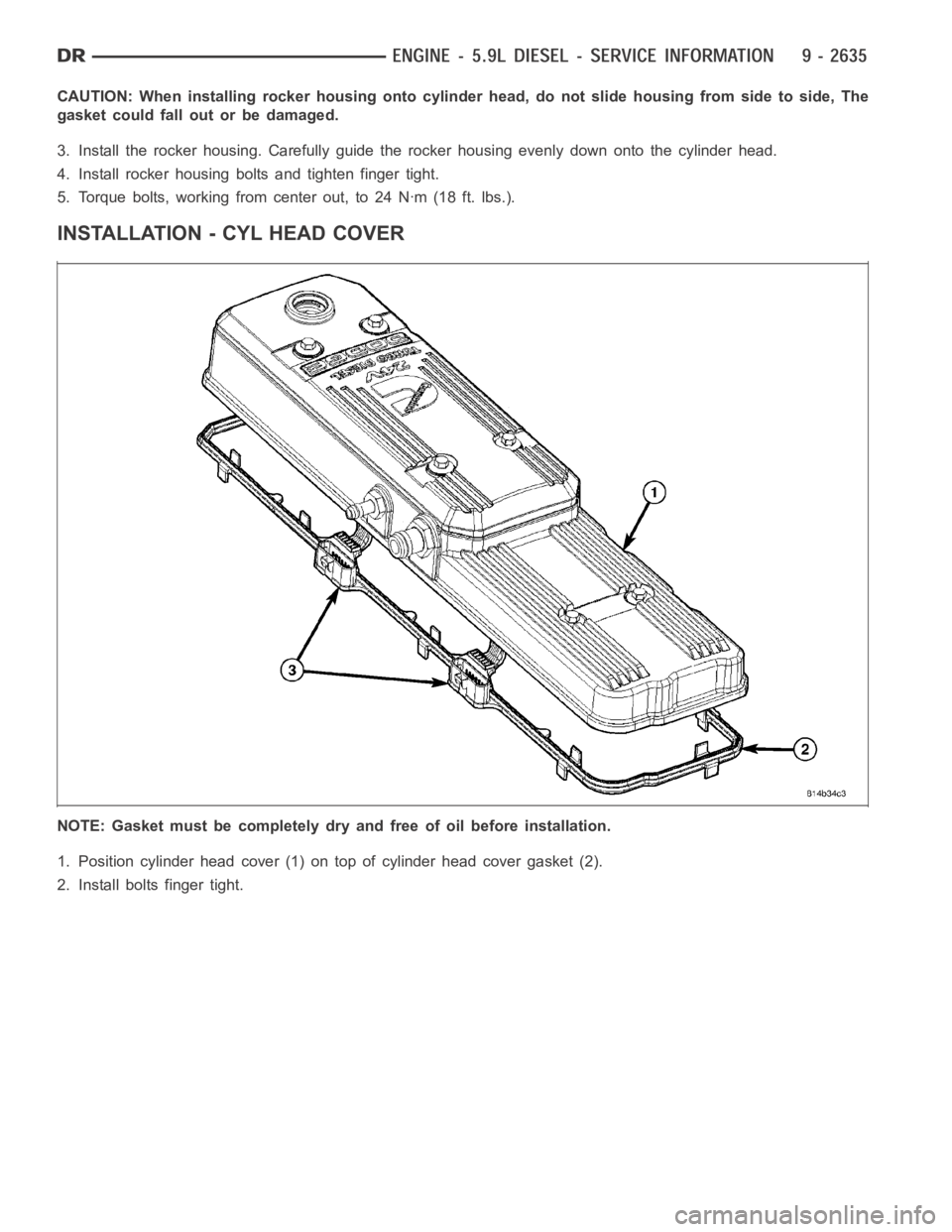

INSTALLATION - CYL HEAD COVER

NOTE: Gasket must be completely dry and free of oil before installation.

1. Position cylinder head cover (1) on top of cylinder head cover gasket (2).

2. Install bolts finger tight.

Page 1945 of 5267

3. Starting with the center bolt, torque bolts (1) to 24

Nꞏm ( 18 ft. lbs. ).

4. Install breather tube (3) to cylinder head cover (2).

5. Install breather drain tube (4) to cylinder head

cover (2).

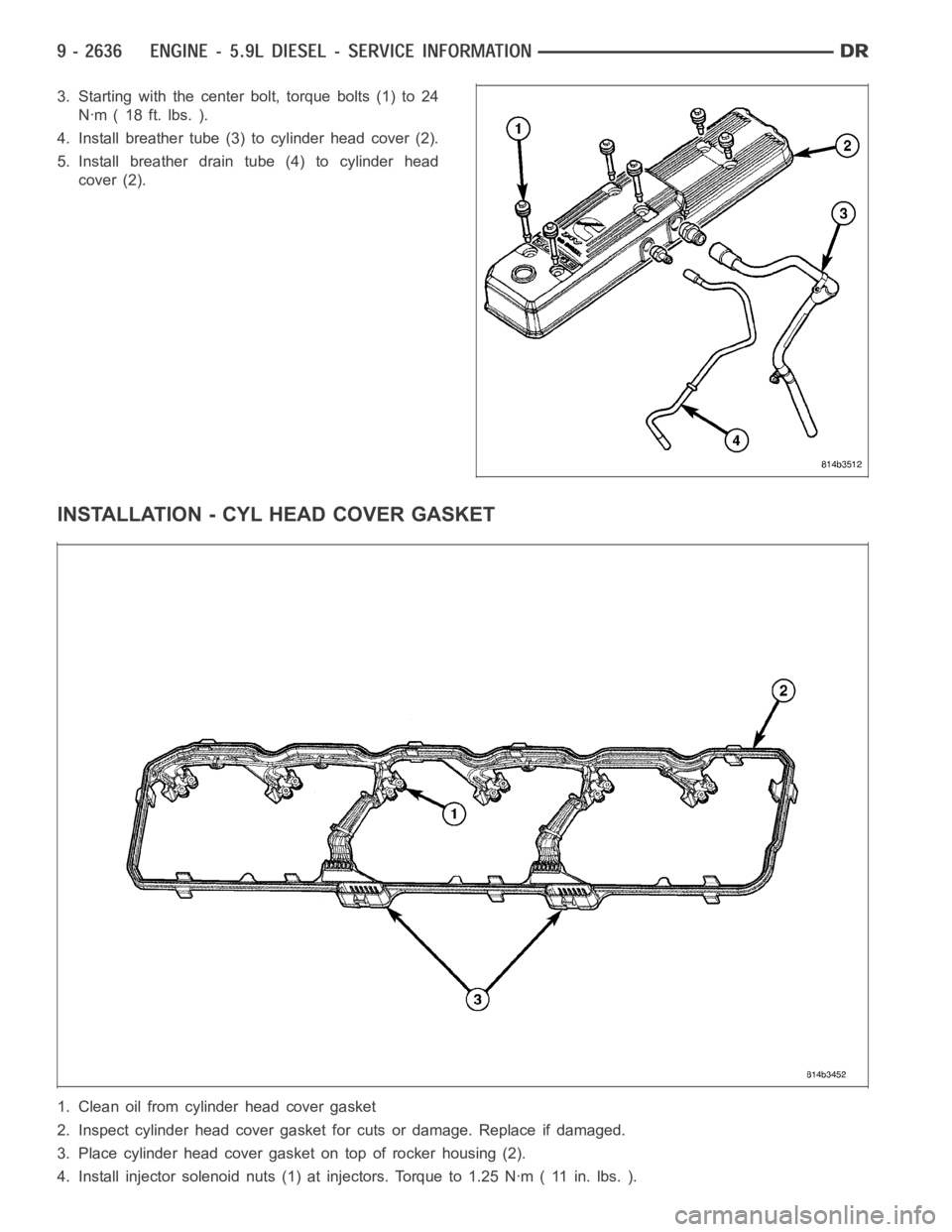

INSTALLATION - CYL HEAD COVER GASKET

1. Clean oil from cylinder head cover gasket

2. Inspect cylinder head cover gasket for cuts or damage. Replace if damaged.

3. Place cylinder head cover gasket on top of rocker housing (2).

4. Install injector solenoid nuts (1) at injectors. Torque to 1.25 Nꞏm ( 11 in. lbs. ).