torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1830 of 5267

INSTALLATION - CAMSHAFT

CAUTION: 5.7L engines equipped with MDS uses a

unique camshaft for use with the Multi Displace-

ment System. When installing a new camshaft, the

replacement camshaft must be compatible with

the Multi Displacement System.

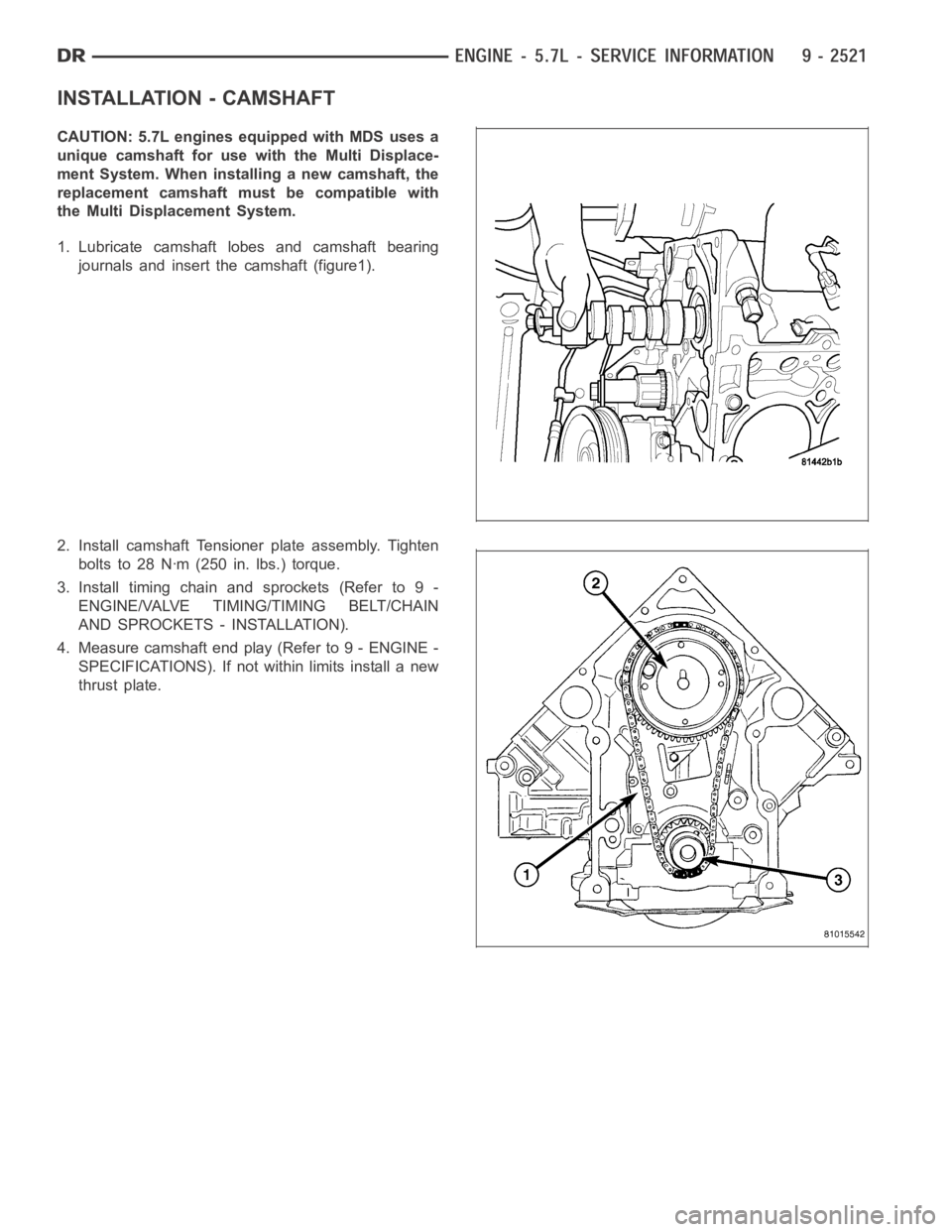

1. Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft (figure1).

2. Install camshaft Tensioner plate assembly. Tighten

bolts to 28 Nꞏm (250 in. lbs.) torque.

3. Install timing chain and sprockets (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION).

4. Measure camshaft end play (Refer to 9 - ENGINE -

SPECIFICATIONS). If not within limits install a new

thrust plate.

Page 1841 of 5267

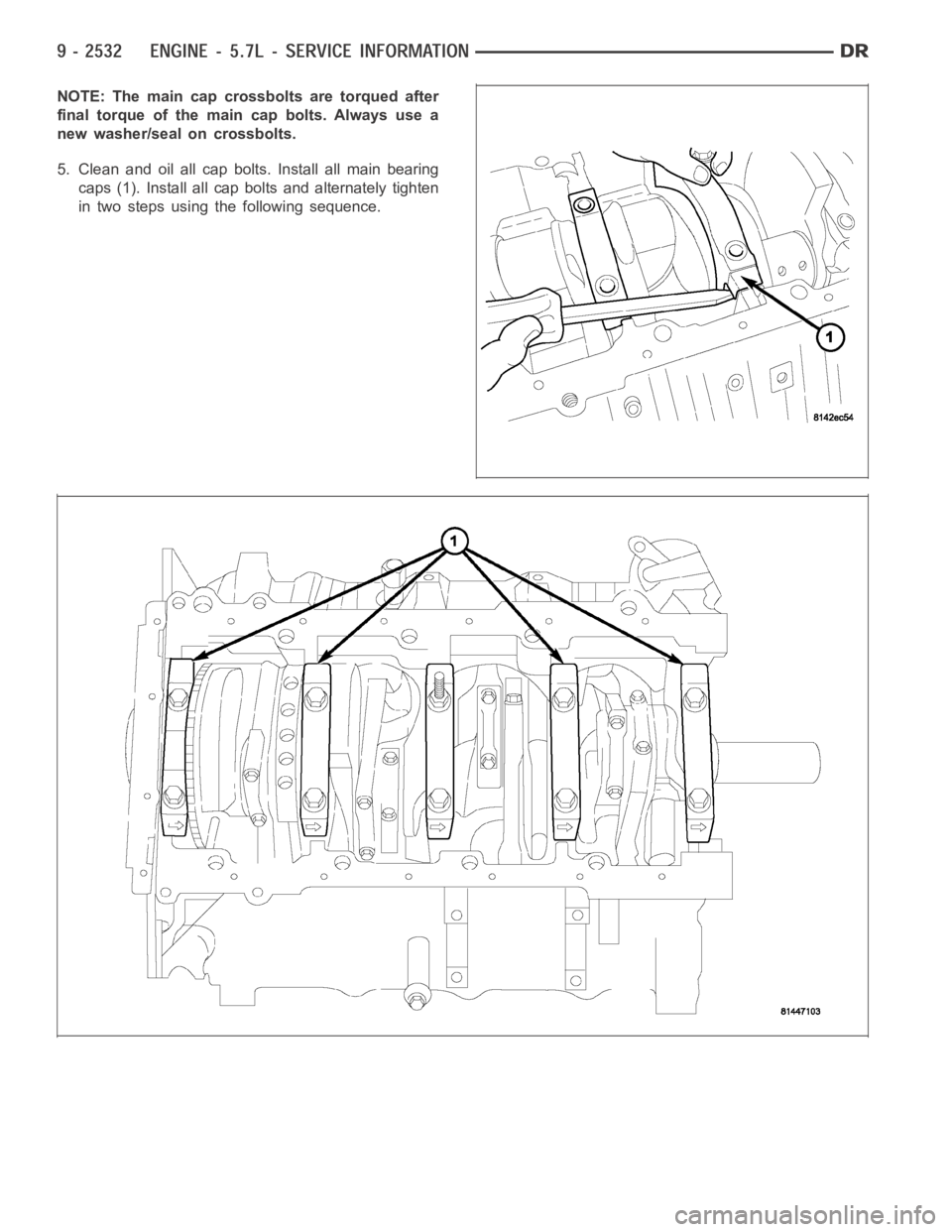

NOTE: The main cap crossbolts are torqued after

final torque of the main cap bolts. Always use a

new washer/seal on crossbolts.

5. Clean and oil all cap bolts. Install all main bearing

caps (1). Install all cap bolts and alternately tighten

in two steps using the following sequence.

Page 1842 of 5267

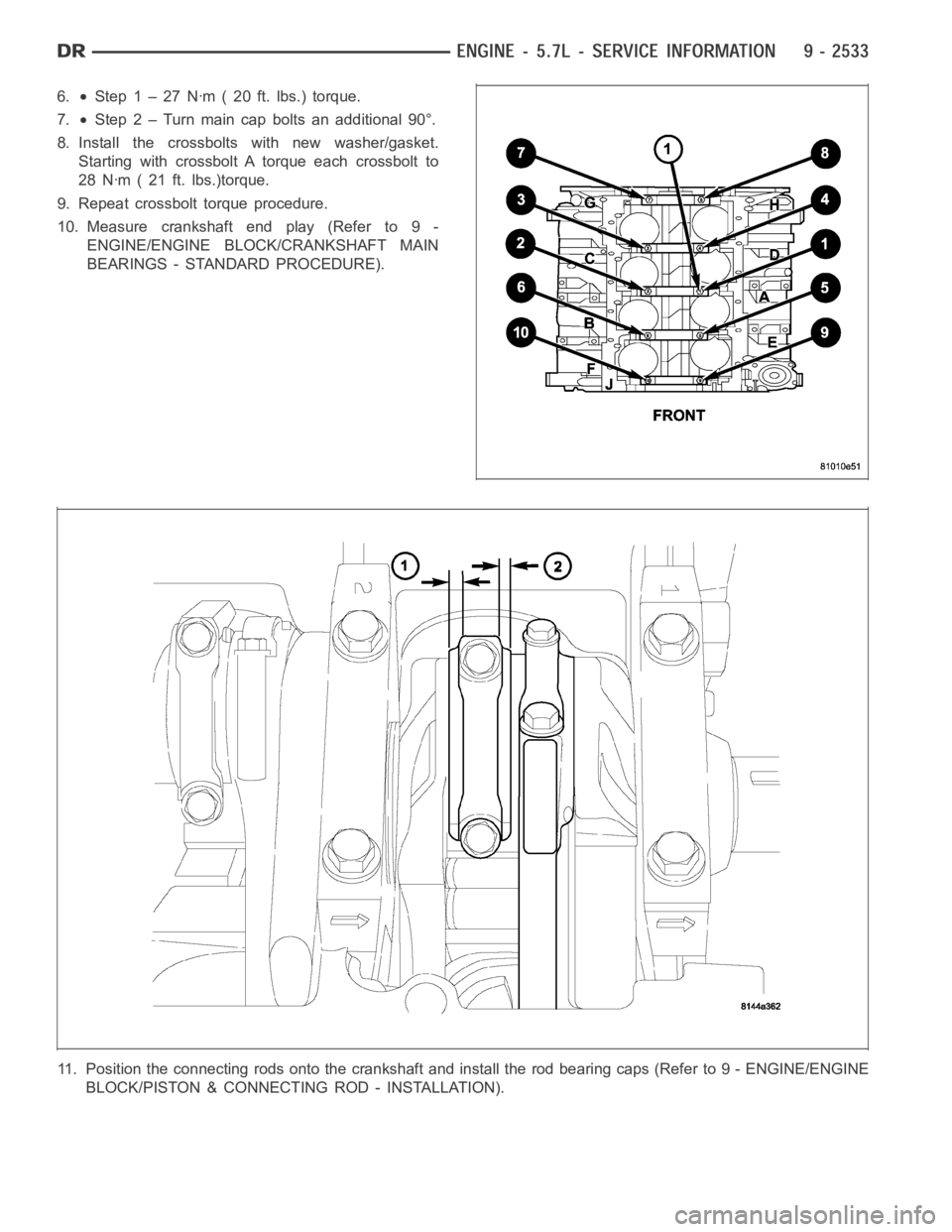

6.Step 1 – 27 Nꞏm ( 20 ft. lbs.) torque.

7.

Step 2 – Turn main cap bolts an additional 90°.

8. Install the crossbolts with new washer/gasket.

Starting with crossbolt A torque each crossbolt to

28 Nꞏm ( 21 ft. lbs.)torque.

9. Repeat crossbolt torque procedure.

10. Measure crankshaft end play (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE).

11. Position the connecting rods onto the crankshaft and install the rod bearing caps (Refer to 9 - ENGINE/ENGINE

BLOCK/PISTON & CONNECTING ROD - INSTALLATION).

Page 1848 of 5267

SEAL - CRANKSHAFT OIL - REAR

DIAGNOSIS AND TESTING - REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, camshaft bore cup plugs, oil

galley pipe plugs, oil filter runoff, and main bearing cap to cylinder block mating surfaces. See Engine, for

proper repair procedures of these items.

4. If no leaks are detected, pressurized the crankcase as outlined in the section, Inspection (Engine oil Leaks in

general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled. (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING), under the Oil Leak row, for components inspections on possible

causes and corrections.

7. After the oil leak root cause and appropriate corrective action have been identified, (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR - REMOVAL).

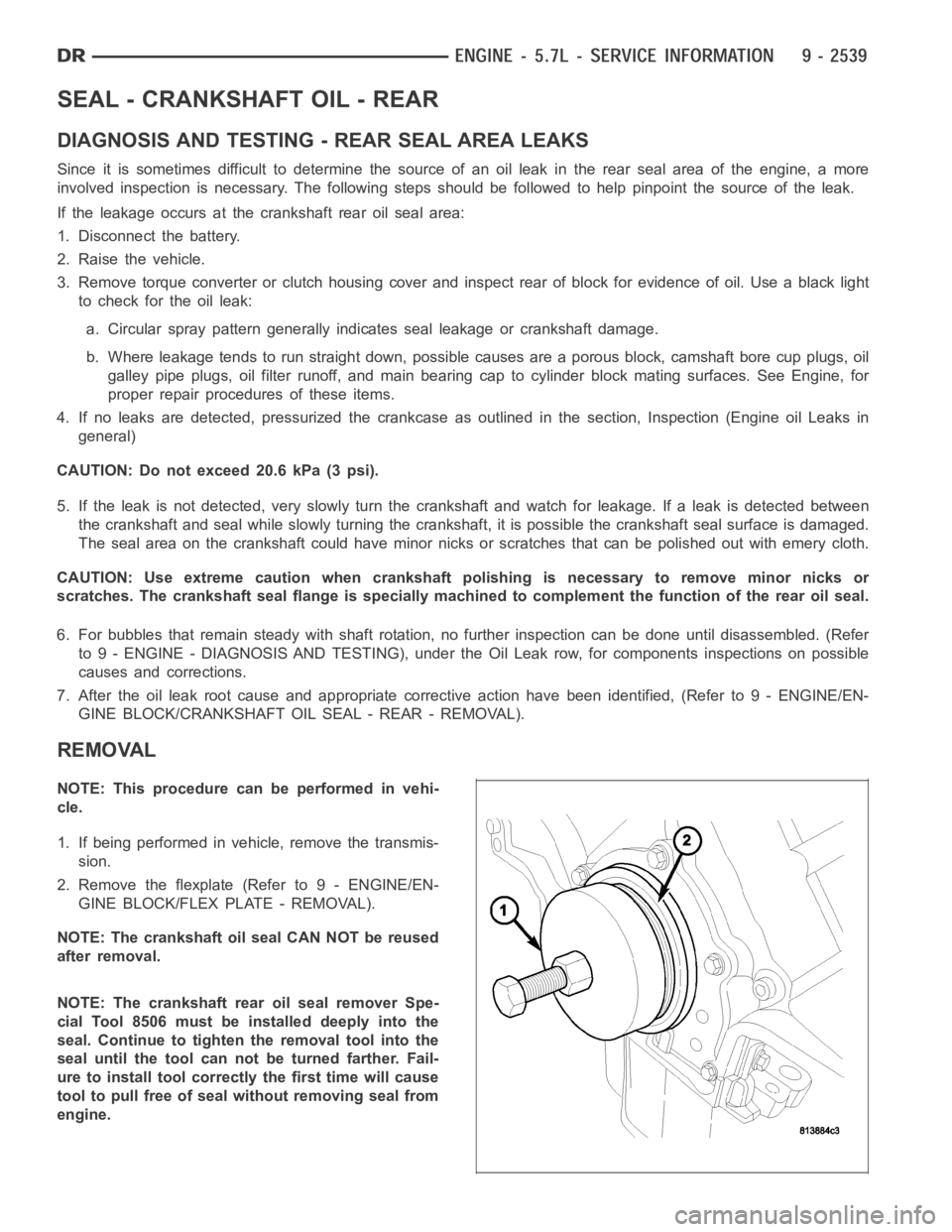

REMOVAL

NOTE: This procedure can be performed in vehi-

cle.

1. If being performed in vehicle, remove the transmis-

sion.

2. Remove the flexplate (Refer to 9 - ENGINE/EN-

GINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Spe-

cial Tool 8506 must be installed deeply into the

seal. Continue to tighten the removal tool into the

seal until the tool can not be turned farther. Fail-

ure to install tool correctly the first time will cause

tool to pull free of seal without removing seal from

engine.

Page 1854 of 5267

CAUTION: 5.7L engines equipped with MDS uses both standard roller tappetsand deactivating roller tap-

pets, for use with the Multi Displacement System. The deactivating rollertappets must be used in cylinders

1,4,6,7. The deactivating tappets can be identified by the two holes in theside of the tappet body, for the

latching pins.

2. Install tappets in their original positions.

3. Install tappet retainer (1). Install the tappet retainer bolt and tighten to 12 Nꞏm (106 in. lbs.) torque.

4. Install cylinder head (Refer to 9 - ENGINE/CYLINDER HEAD - INSTALLATION).

5. Install pushrods and rocker arm assembly (Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - INSTALLATION).

6. Install cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

7. Install intake manifold (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD-INSTALLATION).

8. Install the air cleaner (Refer to 9 - ENGINE/AIR INTAKE SYSTEM - INSTALLATION).

9. Connect the negative cable to the battery.

CAUTION: To prevent damage to valve mechanism, engine must not be run abovefast idle until all hydrau-

lic tappets have filled with oil and have become quiet.

10. Road test vehicle and check for leaks.

Page 1859 of 5267

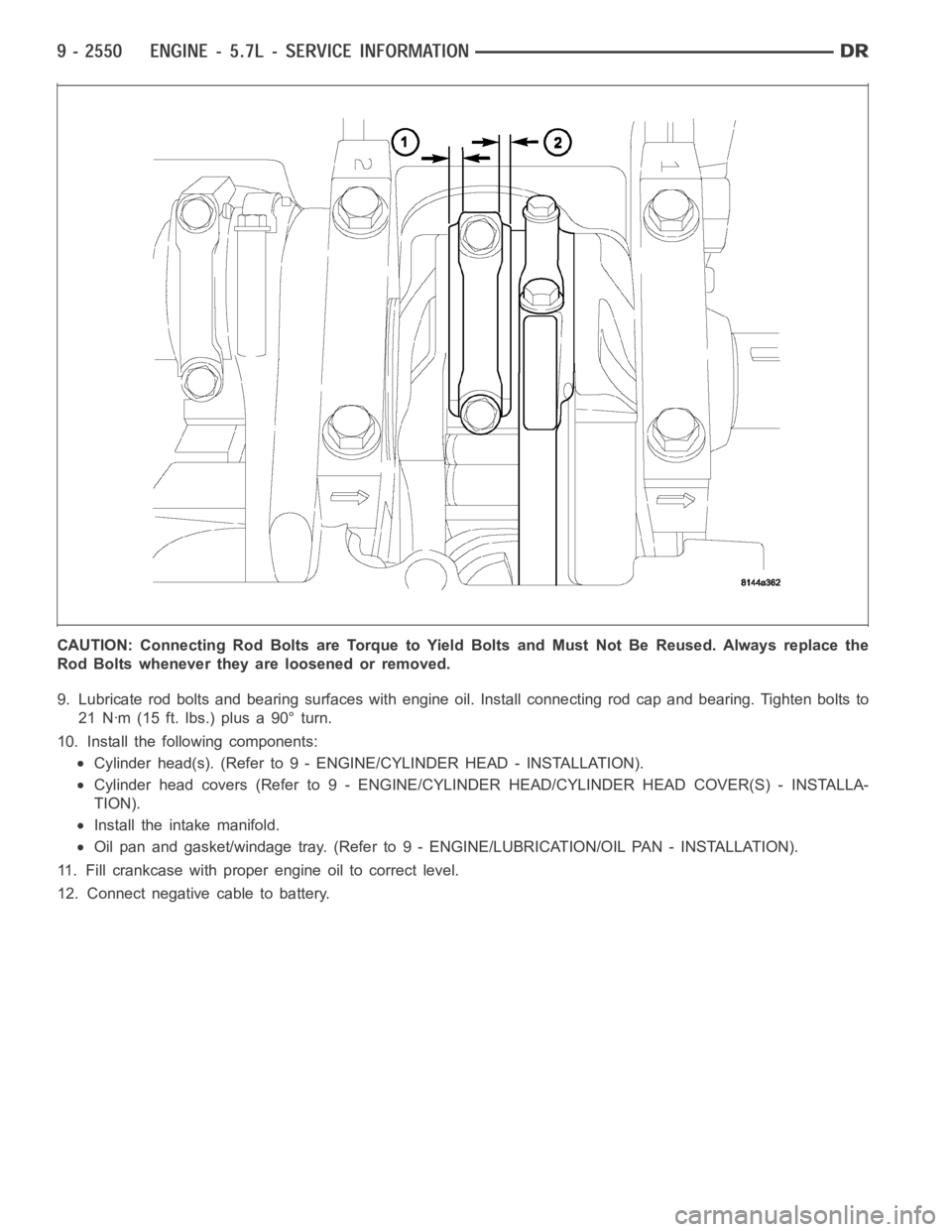

CAUTION: Connecting Rod Bolts are Torque to Yield Bolts and Must Not Be Reused. Always replace the

Rod Bolts whenever they are loosened or removed.

9. Lubricate rod bolts and bearing surfaces with engine oil. Install connecting rod cap and bearing. Tighten bolts to

21 Nꞏm (15 ft. lbs.) plus a 90° turn.

10. Install the following components:

Cylinder head(s). (Refer to 9 - ENGINE/CYLINDER HEAD - INSTALLATION).

Cylinderheadcovers(Referto9-ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

Install the intake manifold.

Oil pan and gasket/windage tray. (Refer to 9 - ENGINE/LUBRICATION/OIL PAN- INSTALLATION).

11. Fill crankcase with proper engine oil to correct level.

12. Connect negative cable to battery.

Page 1866 of 5267

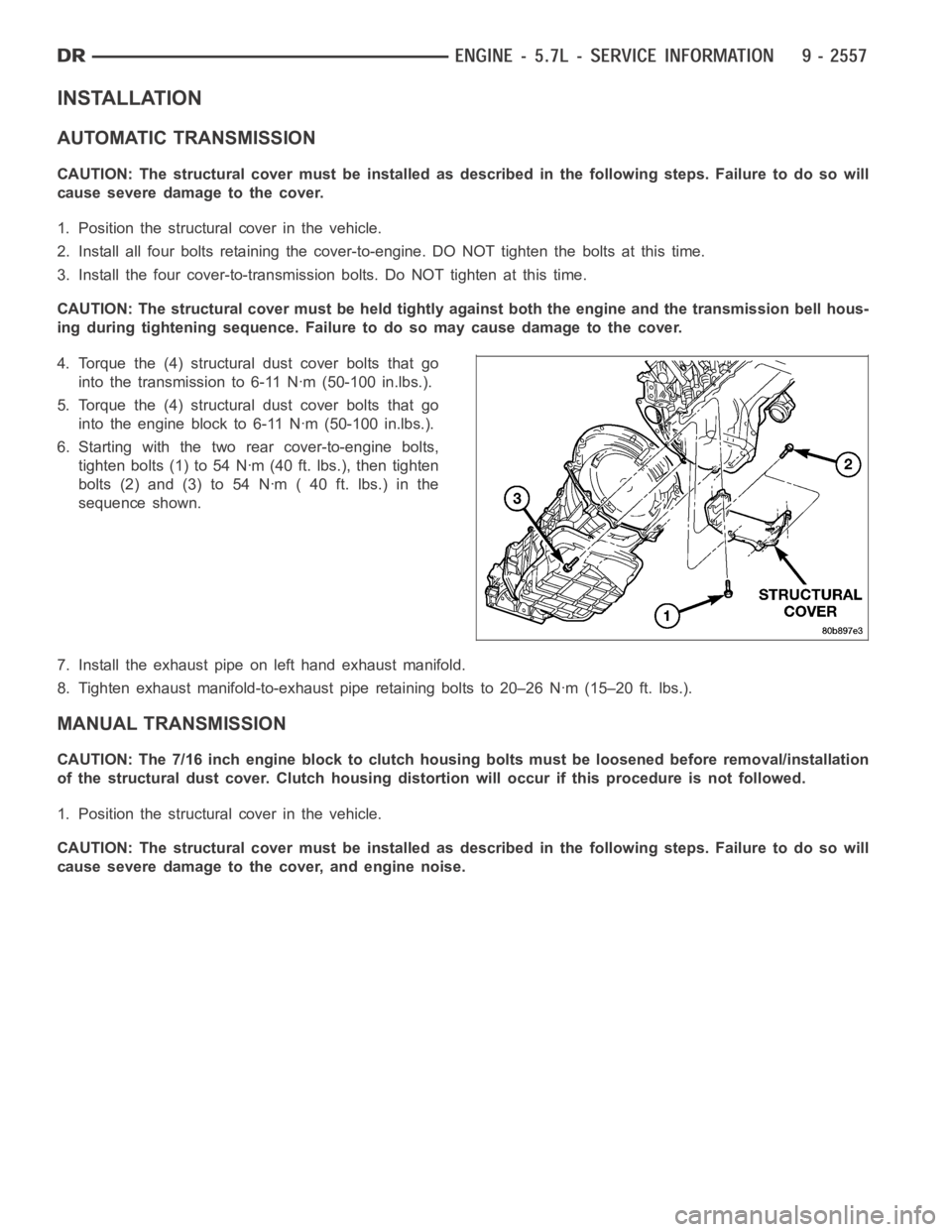

INSTALLATION

AUTOMATIC TRANSMISSION

CAUTION: The structural cover must be installed as described in the following steps. Failure to do so will

cause severe damage to the cover.

1. Position the structural cover in the vehicle.

2. Install all four bolts retaining the cover-to-engine. DO NOT tighten the bolts at this time.

3. Install the four cover-to-transmission bolts. Do NOT tighten at this time.

CAUTION: The structural cover must be held tightly against both the engineand the transmission bell hous-

ing during tightening sequence. Failure to do so may cause damage to the cover.

4. Torque the (4) structural dust cover bolts that go

intothetransmissionto6-11Nꞏm(50-100in.lbs.).

5. Torque the (4) structural dust cover bolts that go

into the engine block to 6-11 Nꞏm (50-100 in.lbs.).

6. Starting with the two rearcover-to-engine bolts,

tighten bolts (1) to 54 Nꞏm (40 ft. lbs.), then tighten

bolts(2)and(3)to54Nꞏm(40ft.lbs.)inthe

sequence shown.

7. Install the exhaust pipe on left hand exhaust manifold.

8. Tighten exhaust manifold-to-exhaust pipe retaining bolts to 20–26 Nꞏm(15–20 ft. lbs.).

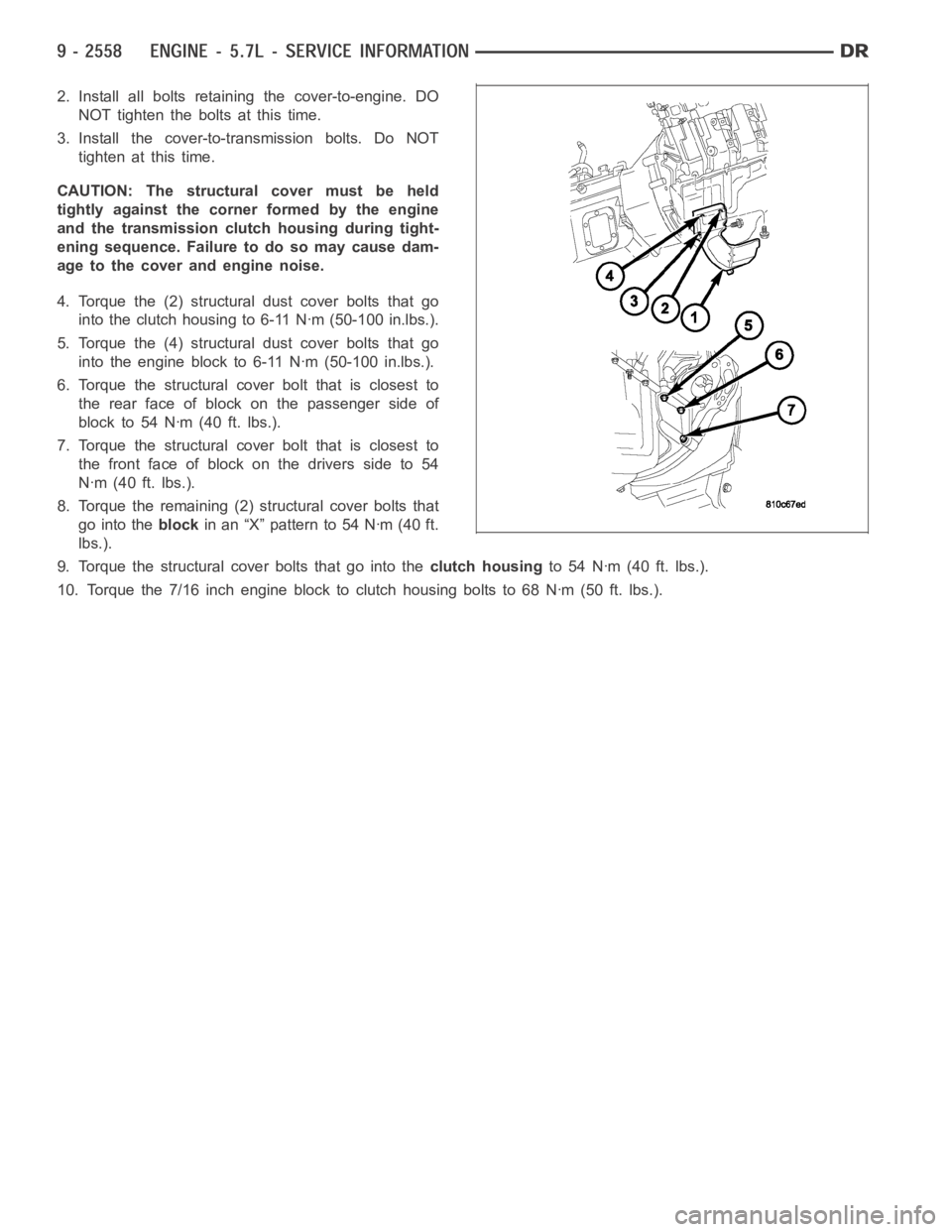

MANUAL TRANSMISSION

CAUTION: The 7/16 inch engine block to clutch housing bolts must be loosened before removal/installation

of the structural dust cover. Clutch housing distortion will occur if thisprocedure is not followed.

1. Position the structural cover in the vehicle.

CAUTION: The structural cover must be installed as described in the following steps. Failure to do so will

cause severe damage to the cover, and engine noise.

Page 1867 of 5267

2. Install all bolts retaining the cover-to-engine. DO

NOT tighten the bolts at this time.

3. Install the cover-to-transmission bolts. Do NOT

tighten at this time.

CAUTION: The structural cover must be held

tightly against the corner formed by the engine

and the transmission clutch housing during tight-

ening sequence. Failure to do so may cause dam-

age to the cover and engine noise.

4. Torque the (2) structural dust cover bolts that go

into the clutch housing to 6-11 Nꞏm (50-100 in.lbs.).

5. Torque the (4) structural dust cover bolts that go

into the engine block to 6-11 Nꞏm (50-100 in.lbs.).

6. Torque the structural cover bolt that is closest to

the rear face of block on the passenger side of

blockto54Nꞏm(40ft.lbs.).

7. Torque the structural cover bolt that is closest to

the front face of block on the drivers side to 54

Nꞏm (40 ft. lbs.).

8. Torque the remaining (2) structural cover bolts that

go into theblockin an “X” pattern to 54 Nꞏm (40 ft.

lbs.).

9. Torque the structural cover bolts that go into theclutch housingto 54 Nꞏm (40 ft. lbs.).

10. Torque the 7/16 inch engine block to clutch housing bolts to 68 Nꞏm (50 ft.lbs.).

Page 1869 of 5267

REMOVAL

1. Disconnect the negative battery cable.

2. Remove the intake manifold. (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

3. Remove wiring harness connectors from the MDS solenoids.

4. Remove hold down bolt from MDS solenoid.

5. Remove MDS solenoid.

INSTALLATION

1. Verify that MDS bores are free of debris, before solenoid installation.

2. Install MDS solenoid fully into block.

3. Install hold down bolt and torque to 11 Nꞏm (97 in. lbs.).

4. Reconnect the MDS wiring harness to the solenoids.

5. Install the intake manifold. (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - INSTALLATION).

Page 1872 of 5267

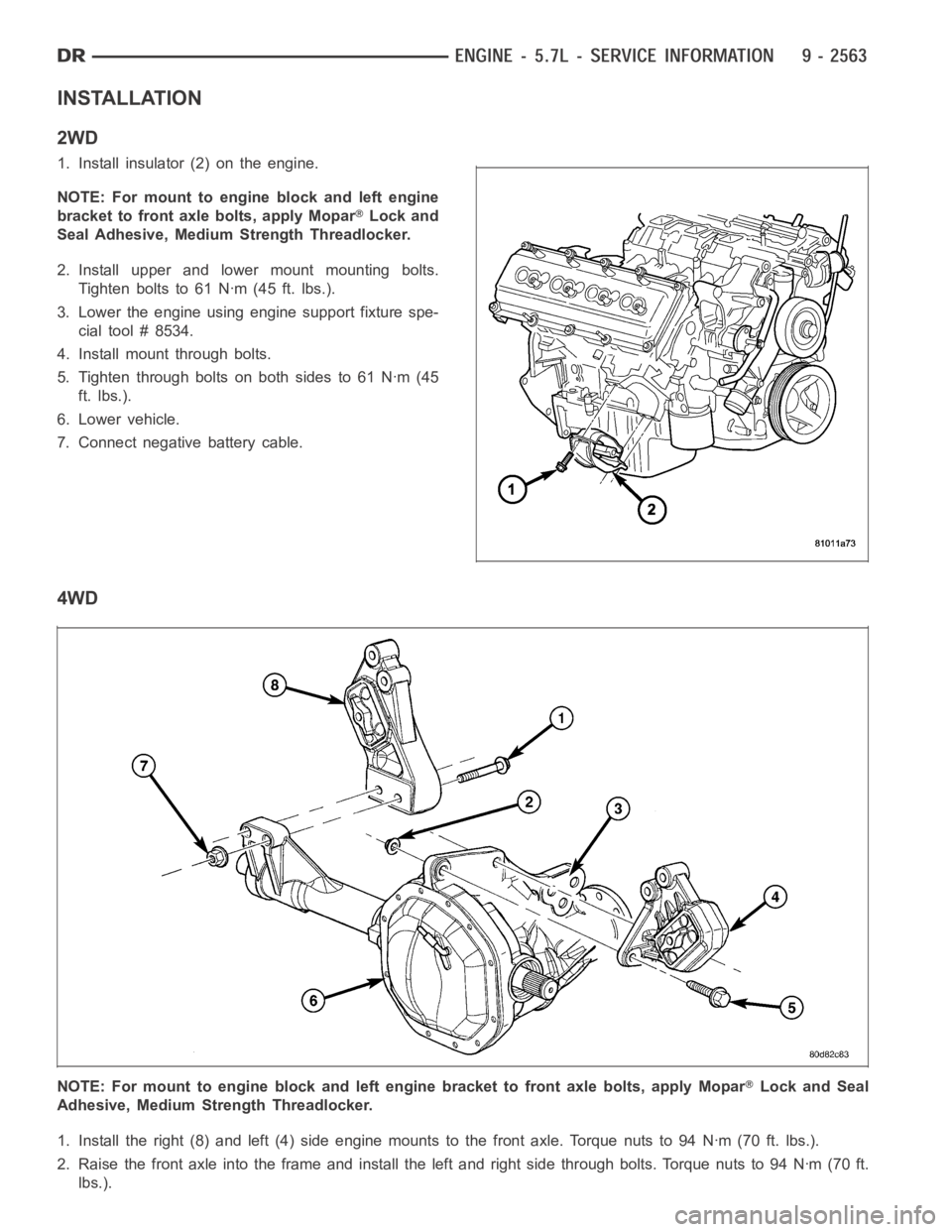

INSTALLATION

2WD

1. Install insulator (2) on the engine.

NOTE: For mount to engine block and left engine

bracket to front axle bolts, apply Mopar

Lock and

Seal Adhesive, Medium Strength Threadlocker.

2. Install upper and lower mount mounting bolts.

Tighten bolts to 61 Nꞏm (45 ft. lbs.).

3. Lower the engine using engine support fixture spe-

cial tool # 8534.

4. Install mount through bolts.

5. Tighten through bolts on both sides to 61 Nꞏm (45

ft. lbs.).

6. Lower vehicle.

7. Connect negative battery cable.

4WD

NOTE: For mount to engine block and left engine bracket to front axle bolts,apply MoparLock and Seal

Adhesive, Medium Strength Threadlocker.

1. Install the right (8) and left (4) side engine mounts to the front axle. Torque nuts to 94 Nꞏm (70 ft. lbs.).

2. Raise the front axle into the frame and install the left and right side through bolts. Torque nuts to 94 Nꞏm (70 ft.

lbs.).