torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2040 of 5267

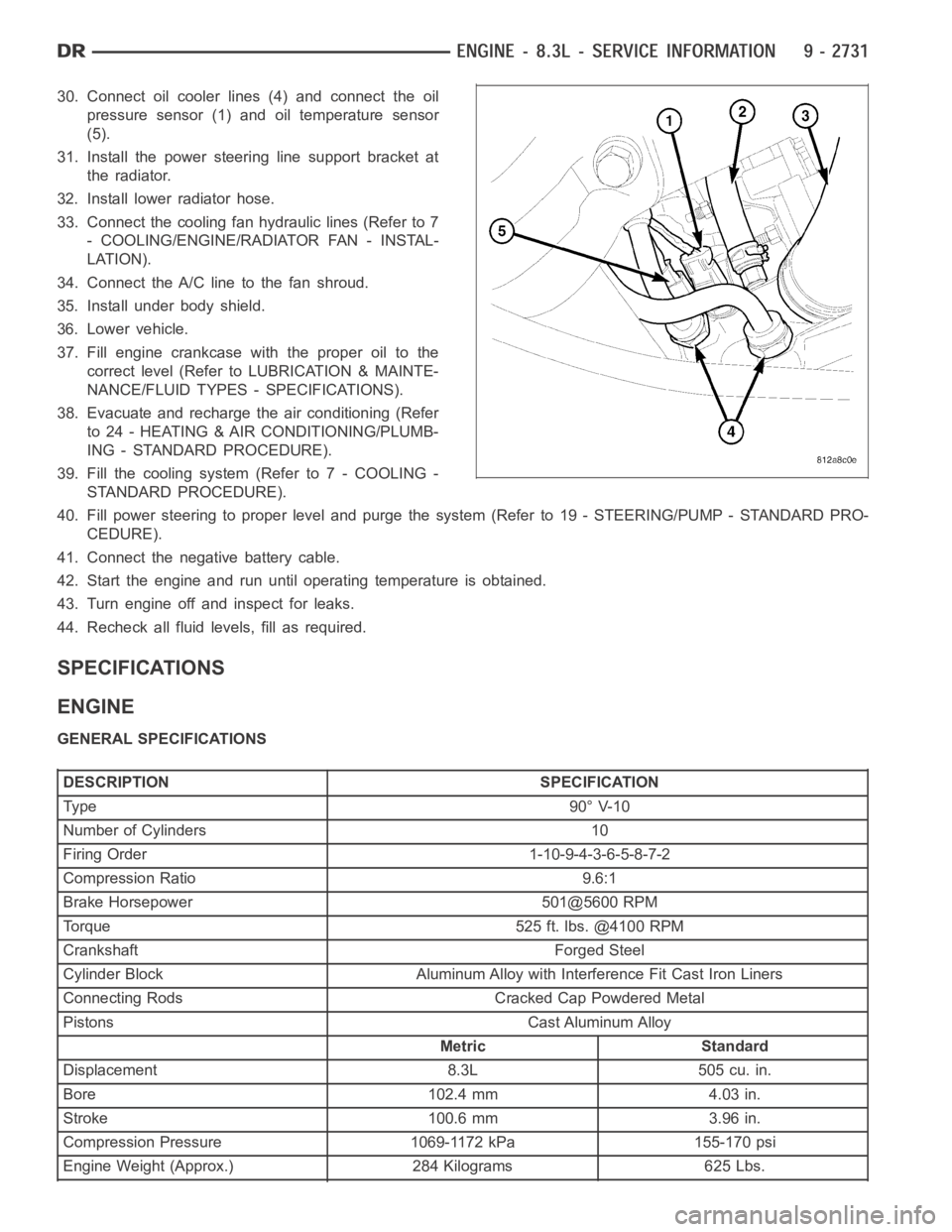

30. Connect oil cooler lines (4) and connect the oil

pressure sensor (1) and oil temperature sensor

(5).

31. Install the power steering line support bracket at

the radiator.

32. Install lower radiator hose.

33. Connect the cooling fan hydraulic lines (Refer to 7

- COOLING/ENGINE/RADIATOR FAN - INSTAL-

LATION).

34. Connect the A/C line to the fan shroud.

35. Install under body shield.

36. Lower vehicle.

37. Fill engine crankcase with the proper oil to the

correct level (Refer to LUBRICATION & MAINTE-

NANCE/FLUID TYPES - SPECIFICATIONS).

38. Evacuate and recharge the air conditioning (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE).

39. Fill the cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

40. Fill power steering to proper leveland purge the system (Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE).

41. Connect the negative battery cable.

42. Start the engine and run until operating temperature is obtained.

43. Turn engine off and inspect for leaks.

44. Recheck all fluid levels, fill as required.

SPECIFICATIONS

ENGINE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Ty pe 9 0° V-1 0

Number of Cylinders 10

Firing Order 1-10-9-4-3-6-5-8-7-2

Compression Ratio 9.6:1

Brake Horsepower 501@5600 RPM

Torque 525 ft. lbs. @4100 RPM

Crankshaft Forged Steel

Cylinder Block Aluminum Alloy with Interference Fit Cast Iron Liners

Connecting Rods Cracked Cap Powdered Metal

Pistons Cast Aluminum Alloy

Metric Standard

Displacement 8.3L 505 cu. in.

Bore 102.4 mm 4.03 in.

Stroke 100.6 mm 3.96 in.

Compression Pressure 1069-1172 kPa 155-170 psi

Engine Weight (Approx.) 284 Kilograms 625 Lbs.

Page 2045 of 5267

DESCRIPTIONSPECIFICATION

Metric Standard

Clearance Over Rotors (Max.) 0.077 mm 0.003 in.

Cover Out-Of-Flat (Max.) 0.076 mm 0.003 in.

Inner Rotor Thickness (Min.) 18.92 mm 0.744 in.

Clearance (Max.) 0.19 mm 0.007 in.

Diameter (Min.) 82.45 mm 3.246 in.

Thickness (Min.) 18.92 mm 0.744 in.

Tip Clearance Between Rotors

(Max)0.150 mm 0.0068 in.

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Bolts-A/C Compressor Mounting 23 - 200

Bolts-A/C Compressor Bracket 23 - 200

Bolt-Camshaft Position Sensor 11 - 95

Bolts-Camshaft Sprocket 23 - 200

Bolts-Camshaft Thrust Plate 24 - 210

Bolts-Connecting Rod Cap 68 50 -

Bolts-Crankshaft Main Bearing Cap (Refer to CRANKSHAFT -

INSTALLATION)

Nuts-Crankshaft Oil Scraper 23 - 200

Bolts-Crankshaft Pulley 23 - 200

Bolt-Crankshaft Vibration Damper 176 130 -

Bolts-Cylinder Head (Refer to CYLINDER HEAD -

INSTALLATION)

Bolts/Studs-Cylinder Head Cover 11 - 95

Exhaust Manifold 23 - 200

Exhaust Pipe to Exhaust Manifold 34 25 -

Bolts-Engine Mount Bracket-to-Block 41 30 -

Nuts-Engine Mount Insulator 102 75 -

Bolts-Flywheel to Crankshaft 75 55 -

Bolts-Generator Mounting 41 30 -

Bolts-Intake Manifold 11 - 95

Bolts-Oil Cooler 5 - 40

Oil Cooler Line Fitting 68 50 -

Bolts-Oil Pan

1/4–20 11 - 95

5/16–18 23 - 200

Plug-Oil Pan Drain 34 25 -

Plug-Oil Pressure Relief Valve 34 25 -

Bolts-Oil Pump Cover 23 - 200

Oil Pump Pick-up Tube

Bolt 1/4–20 11 - 95

Nut 5/16–18 23 - 200

Page 2067 of 5267

CLEANING

CLEANING AND INSPECTION

1. Before cleaning, check for leaks, damage and

cracks.

2. Clean cylinder head and oil passages.

3. Check cylinder head for flatness.

4. Inspect all surfaces with a straightedge (2) if there

is any reason to suspect leakage. If out-of-flatness

exceeds 0.019 mm (0.00075 in.) times the span

length in inches in any direction, either replace

head or lightly machine the head surface. As an

example, if a 12.0 inch span is 1.0 mm (0.004 in.)

out-of-flat, allowable is 12 x 0.019 mm (0.00075 in.)

equals 0.22 mm (0.009 in.). This amount of out-of-

flat is acceptable. *Maximum of 0.2 mm (0.008 in.)

for grinding is permitted.

CAUTION: This is a combined total dimension of

stock removal from cylinder head surface.

INSTALLATION - CYLINDER HEAD(S)

NOTE: This procedure covers either the left or

right cylinder head.

1. Clean all surfaces of engine block and cylinder

heads (Refer to 9 - ENGINE - STANDARD PRO-

CEDURE - ENGINE GASKET SURFACE PREPA-

RATION).

CAUTION: Remove all gasket material from cylin-

der head and block using a plastic scraper only.

DO NOT use a metal scraper, as damage to seal-

ing surface may occur.

NOTE: A multi-layer steel head gasket is used.

2. Install new gasket(s) on the engine block. Assure all coolant passages and bolt holes align properly..

CAUTION: Cylinder head bolts are coated, DO NOT

oil.

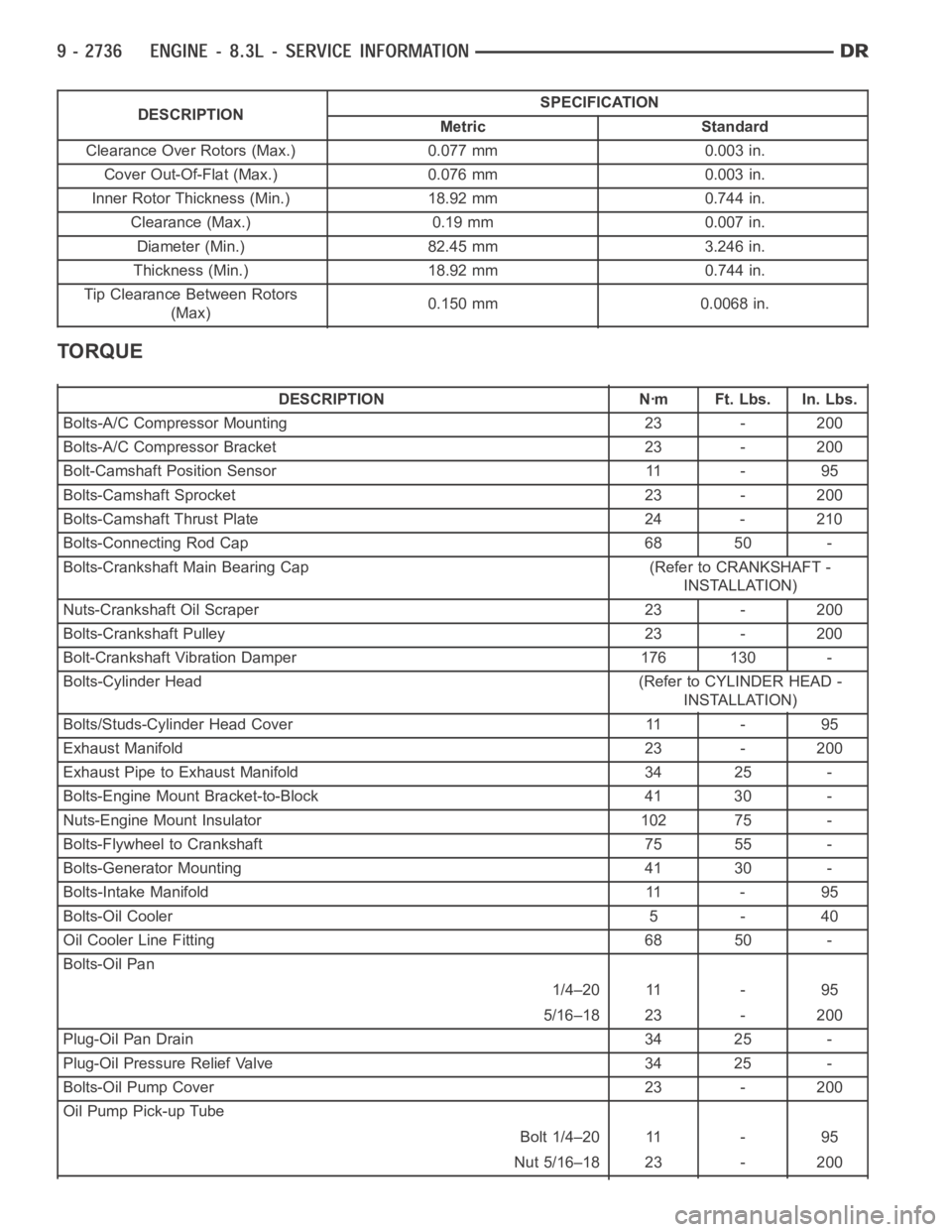

3. Install cylinder head(s) over dowel pins. Install cyl-

inder head bolts 1–12. Tighten cylinder head bolts

1–12 in the sequence shown in using a two step

torque sequence:

a. Firstto47Nꞏm(35ft.lbs.).

b. Second to 122 Nꞏm (90 ft. lbs.).

4. After cylinder head bolts 1-12 have been tightened

to specifications, install and tighten cylinder head tappet gallery bolts A-H in sequence shown to 11 Nꞏm (95 in.

lbs.).

Page 2071 of 5267

ARMS-ROCKER

REMOVAL

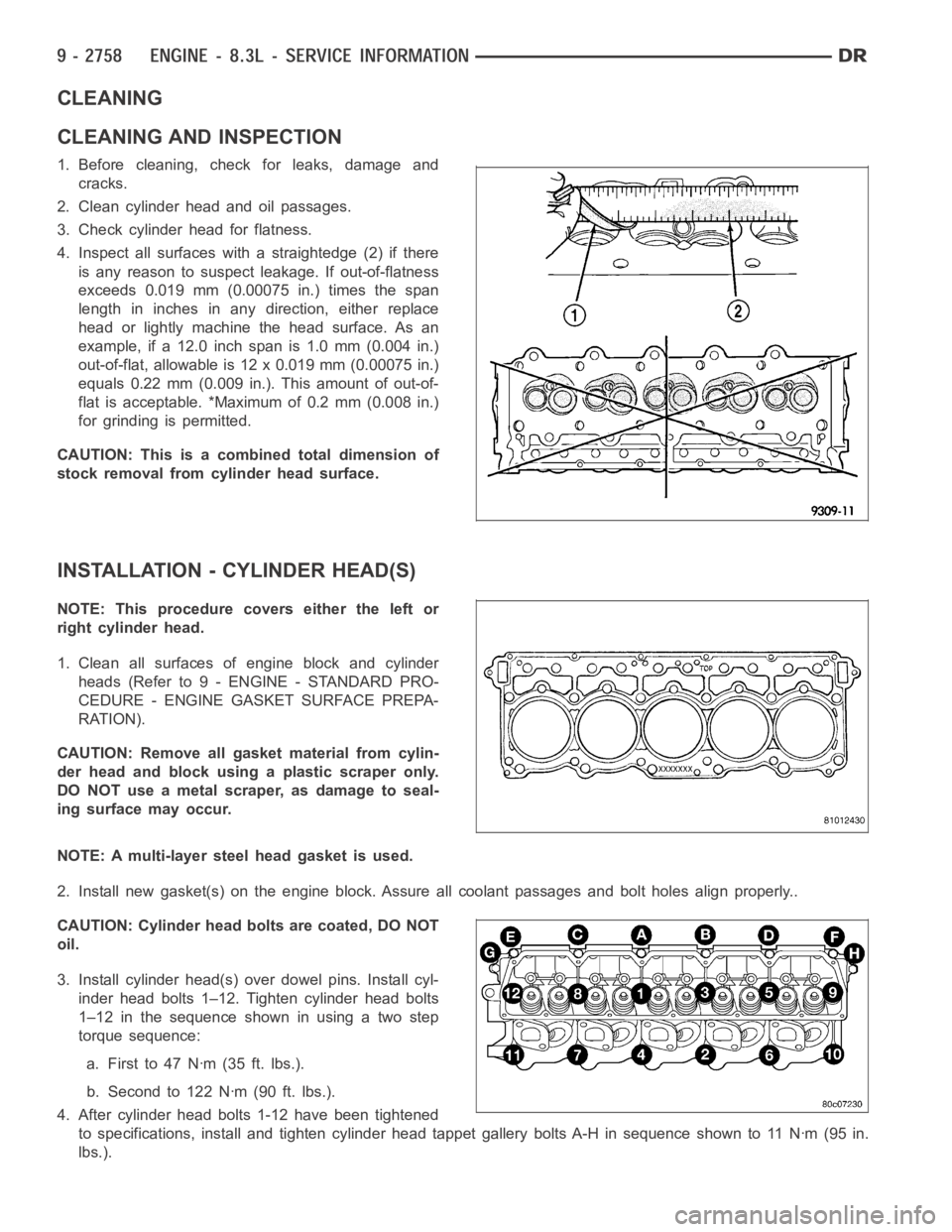

NOTE: Before replacing parts, inspect all related

valvetrain components for damage to prevent

engine misfire.

1. Remove cylinder head cover(s) (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

2. Remove two rocker pedestal bolts per each cylin-

der.

3. Remove rocker arm assemblies as a pair.

4. If rocker arm assemblies are disassembled for

cleaning or replacement, reassemble rocker arms

in their original position.

INSTALLATION

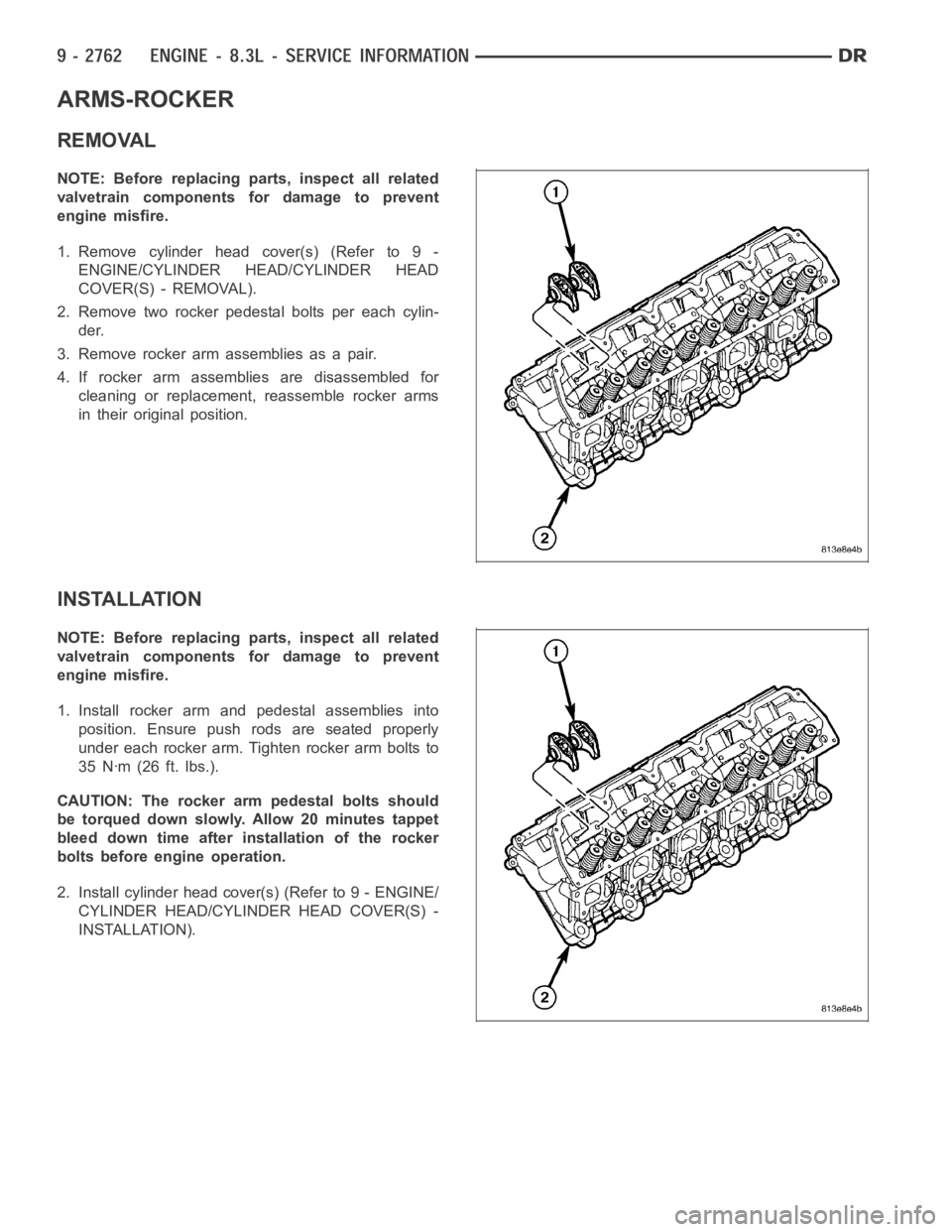

NOTE: Before replacing parts, inspect all related

valvetrain components for damage to prevent

engine misfire.

1. Install rocker arm and pedestal assemblies into

position. Ensure push rods are seated properly

under each rocker arm. Tighten rocker arm bolts to

35 Nꞏm (26 ft. lbs.).

CAUTION: The rocker arm pedestal bolts should

be torqued down slowly. Allow 20 minutes tappet

bleed down time after installation of the rocker

bolts before engine operation.

2. Install cylinder head cover(s) (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

Page 2072 of 5267

SPRINGS/SEALS-VALVE

DIAGNOSIS AND TESTING

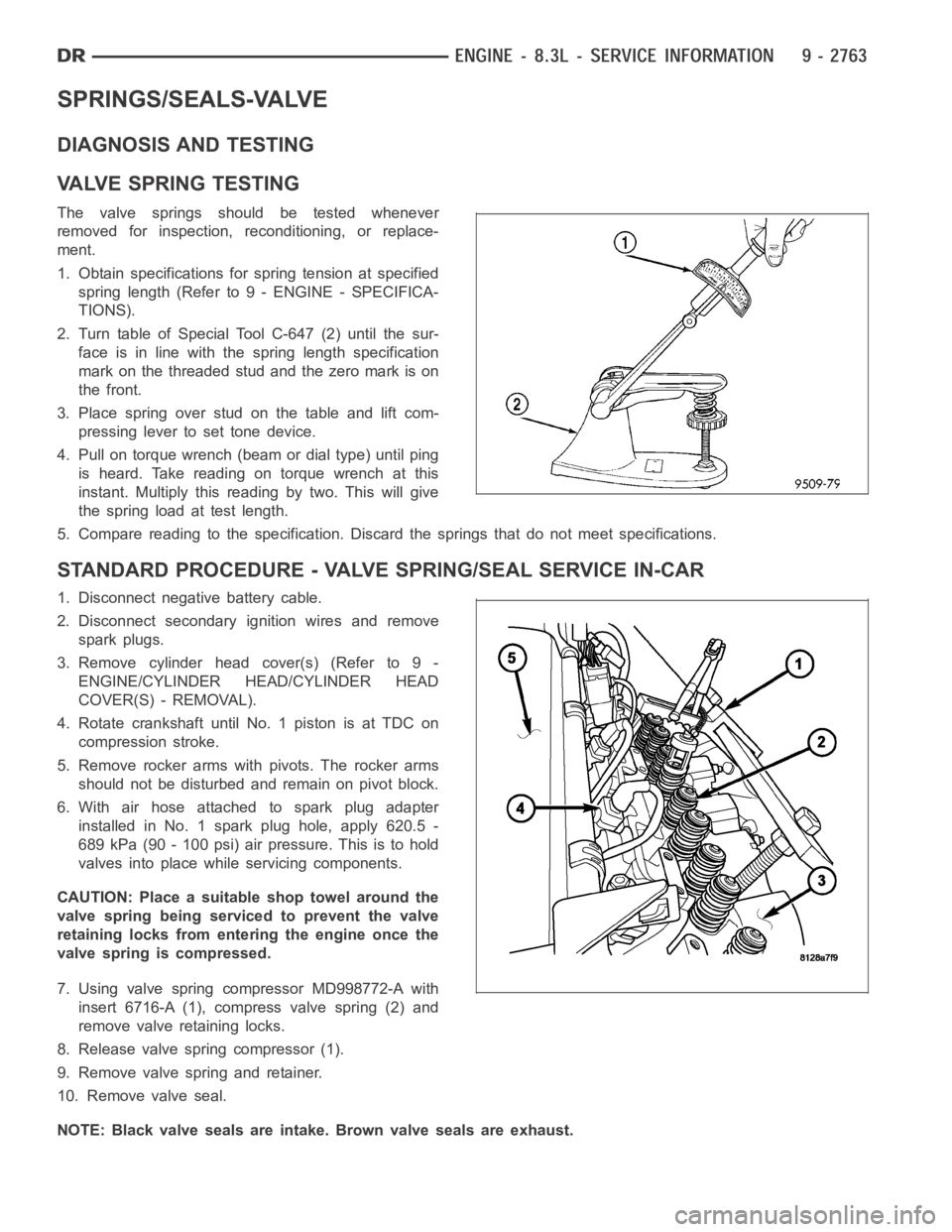

VA LV E S P R I N G T E S T I N G

The valve springs should be tested whenever

removed for inspection, reconditioning, or replace-

ment.

1. Obtain specifications for spring tension at specified

spring length (Refer to 9 - ENGINE - SPECIFICA-

TIONS).

2. Turn table of Special Tool C-647 (2) until the sur-

face is in line with the spring length specification

mark on the threaded stud and the zero mark is on

the front.

3.Placespringoverstudonthetableandliftcom-

pressing lever to set tone device.

4. Pull on torque wrench (beam or dial type) until ping

is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give

the spring load at test length.

5. Compare reading to the specification. Discard the springs that do not meet specifications.

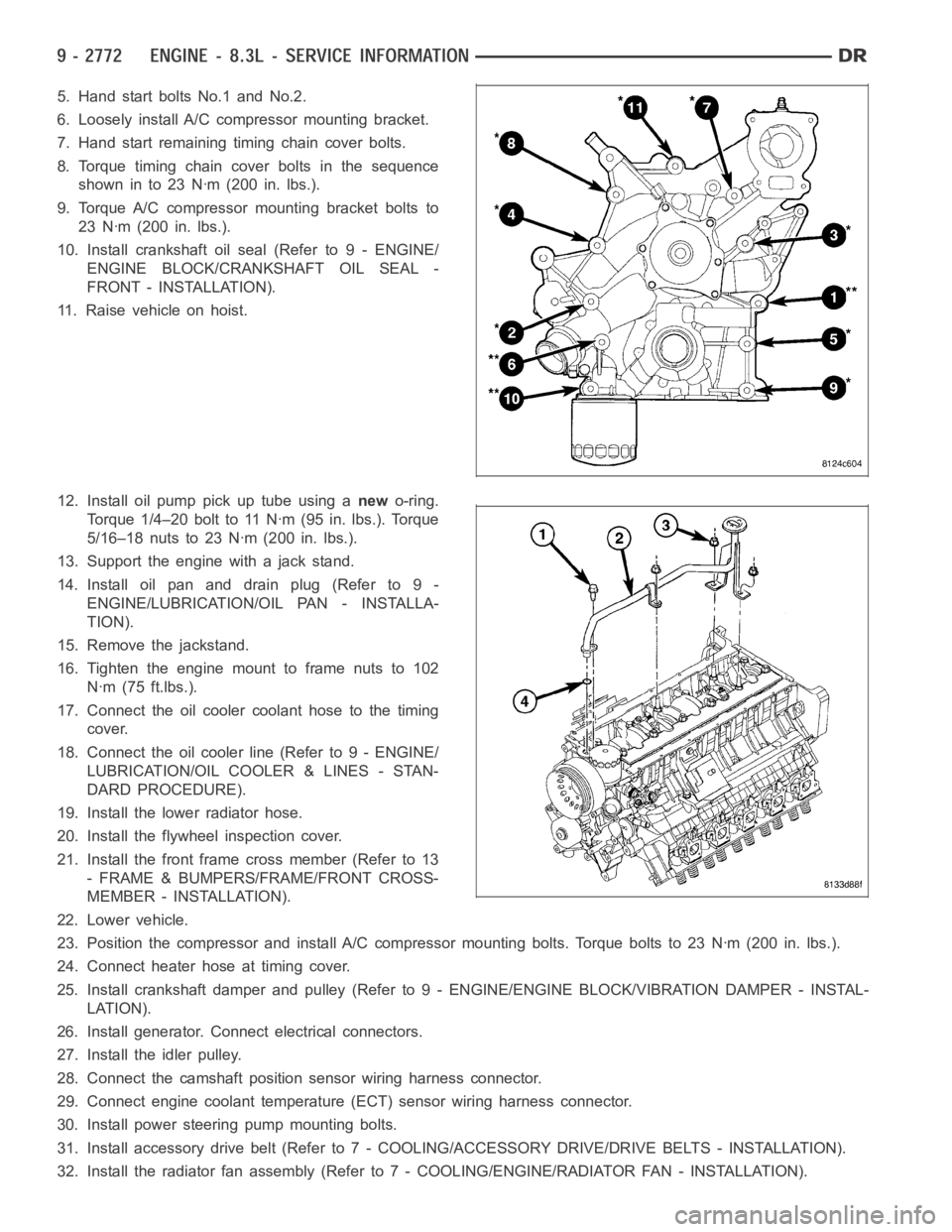

STANDARD PROCEDURE - VALVE SPRING/SEAL SERVICE IN-CAR

1. Disconnect negative battery cable.

2. Disconnect secondary ignition wires and remove

spark plugs.

3. Remove cylinder head cover(s) (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

4. Rotate crankshaft until No. 1 piston is at TDC on

compression stroke.

5. Remove rocker arms with pivots. The rocker arms

should not be disturbed and remain on pivot block.

6. With air hose attached to spark plug adapter

installed in No. 1 spark plug hole, apply 620.5 -

689 kPa (90 - 100 psi) air pressure. This is to hold

valves into place while servicing components.

CAUTION: Place a suitable shop towel around the

valve spring being serviced to prevent the valve

retaining locks from entering the engine once the

valve spring is compressed.

7. Using valve spring compressor MD998772-A with

insert 6716-A (1), compress valve spring (2) and

remove valve retaining locks.

8. Release valve spring compressor (1).

9. Remove valve spring and retainer.

10. Remove valve seal.

NOTE: Black valve seals are intake. Brown valve seals are exhaust.

Page 2081 of 5267

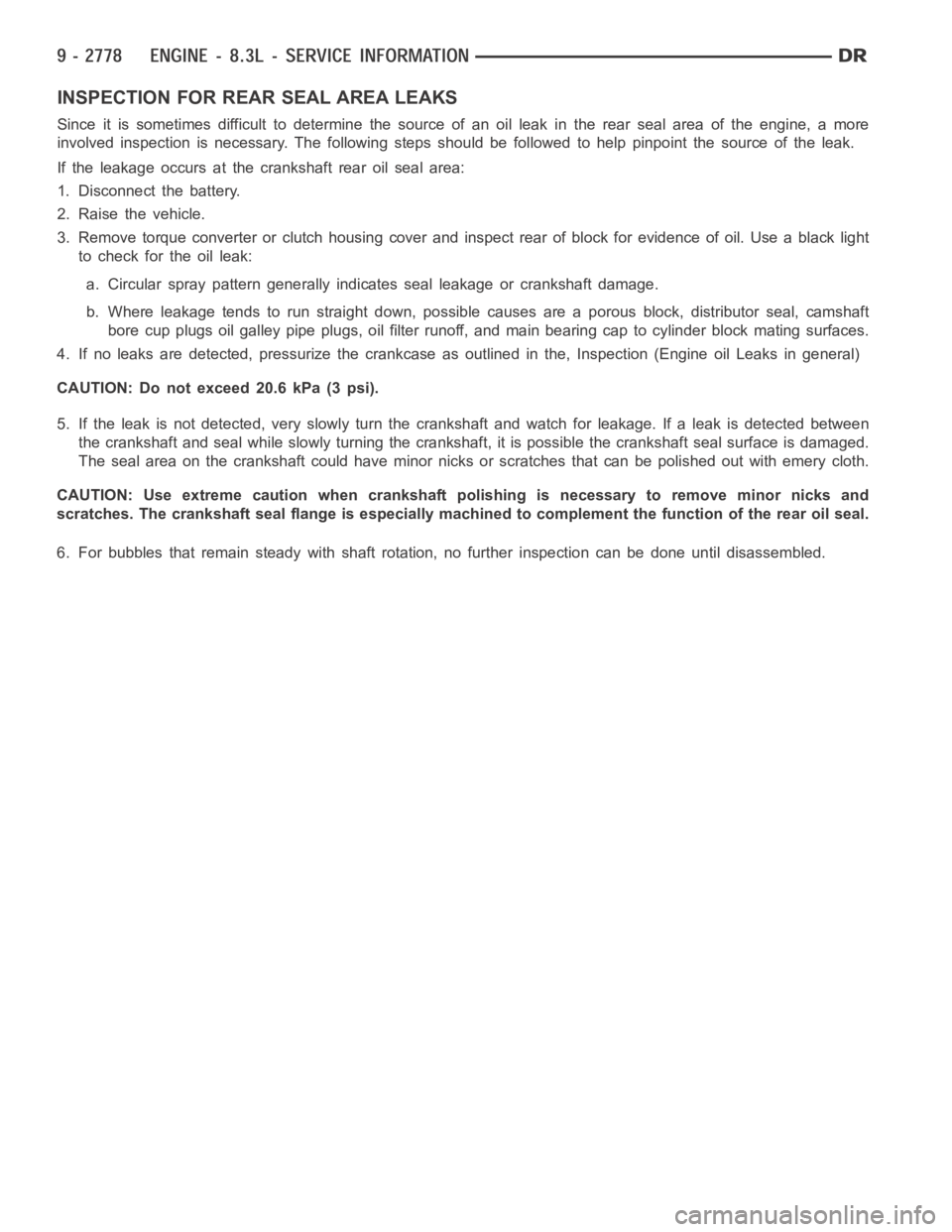

5. Hand start bolts No.1 and No.2.

6. Loosely install A/C compressor mounting bracket.

7. Hand start remaining timing chain cover bolts.

8. Torque timing chain cover bolts in the sequence

showninto23Nꞏm(200in.lbs.).

9. Torque A/C compressor mounting bracket bolts to

23 Nꞏm (200 in. lbs.).

10. Install crankshaft oil seal (Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT OIL SEAL -

FRONT - INSTALLATION).

11. Raise vehicle on hoist.

12. Install oil pump pick up tube using anewo-ring.

Torque 1/4–20 bolt to 11 Nꞏm (95 in. lbs.). Torque

5/16–18 nuts to 23 Nꞏm (200 in. lbs.).

13. Support the engine with a jack stand.

14. Install oil pan and drain plug (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

15. Remove the jackstand.

16. Tighten the engine mount to frame nuts to 102

Nꞏm (75 ft.lbs.).

17. Connect the oil cooler coolant hose to the timing

cover.

18. Connect the oil cooler line (Refer to 9 - ENGINE/

LUBRICATION/OIL COOLER & LINES - STAN-

DARD PROCEDURE).

19. Install the lower radiator hose.

20. Install the flywheel inspection cover.

21. Install the front frame cross member (Refer to 13

- FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

22. Lower vehicle.

23. Position the compressor and install A/C compressor mounting bolts. Torque bolts to 23 Nꞏm (200 in. lbs.).

24. Connect heater hose at timing cover.

25. Install crankshaft damper and pulley (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

26. Install generator. Connect electrical connectors.

27. Install the idler pulley.

28. Connect the camshaft position sensor wiring harness connector.

29. Connect engine coolant temperature (ECT) sensor wiring harness connector.

30. Install power steering pump mounting bolts.

31. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

32. Install the radiator fan assembly (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION).

Page 2087 of 5267

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, distributor seal, camshaft

bore cup plugs oil galley pipe plugs, oil filter runoff, and main bearing cap to cylinder block mating surfaces.

4. If no leaks are detected, pressurize the crankcase as outlined in the, Inspection (Engine oil Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled.

Page 2095 of 5267

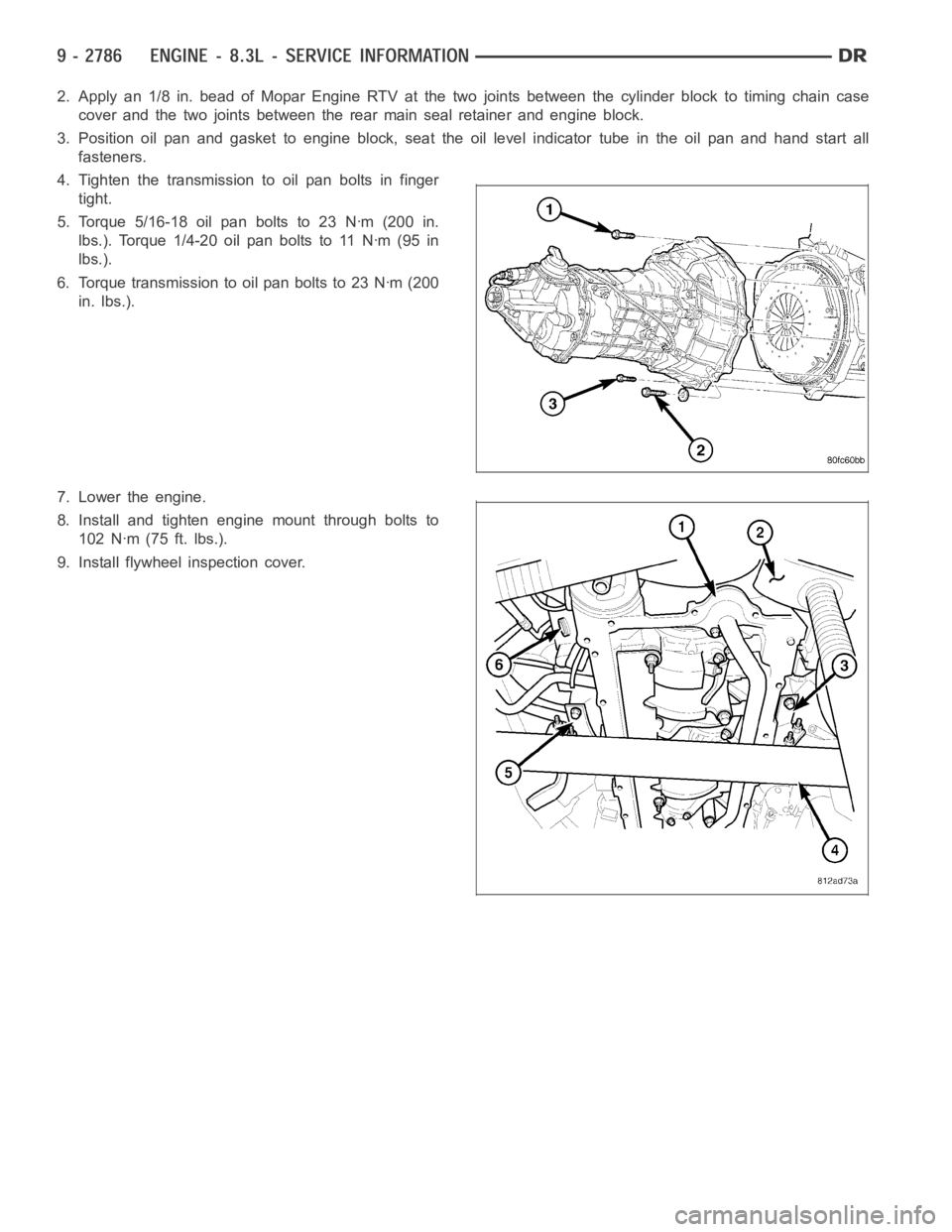

2. Apply an 1/8 in. bead of Mopar Engine RTV at the two joints between the cylinder block to timing chain case

cover and the two joints between the rear main seal retainer and engine block.

3. Position oil pan and gasket to engine block, seat the oil level indicatortube in the oil pan and hand start all

fasteners.

4. Tighten the transmission to oil pan bolts in finger

tight.

5. Torque 5/16-18 oil pan bolts to 23 Nꞏm (200 in.

lbs.). Torque 1/4-20 oil pan bolts to 11 Nꞏm (95 in

lbs.).

6. Torque transmission to oil pan bolts to 23 Nꞏm (200

in. lbs.).

7. Lower the engine.

8. Install and tighten engine mount through bolts to

102 Nꞏm (75 ft. lbs.).

9. Install flywheel inspection cover.

Page 2100 of 5267

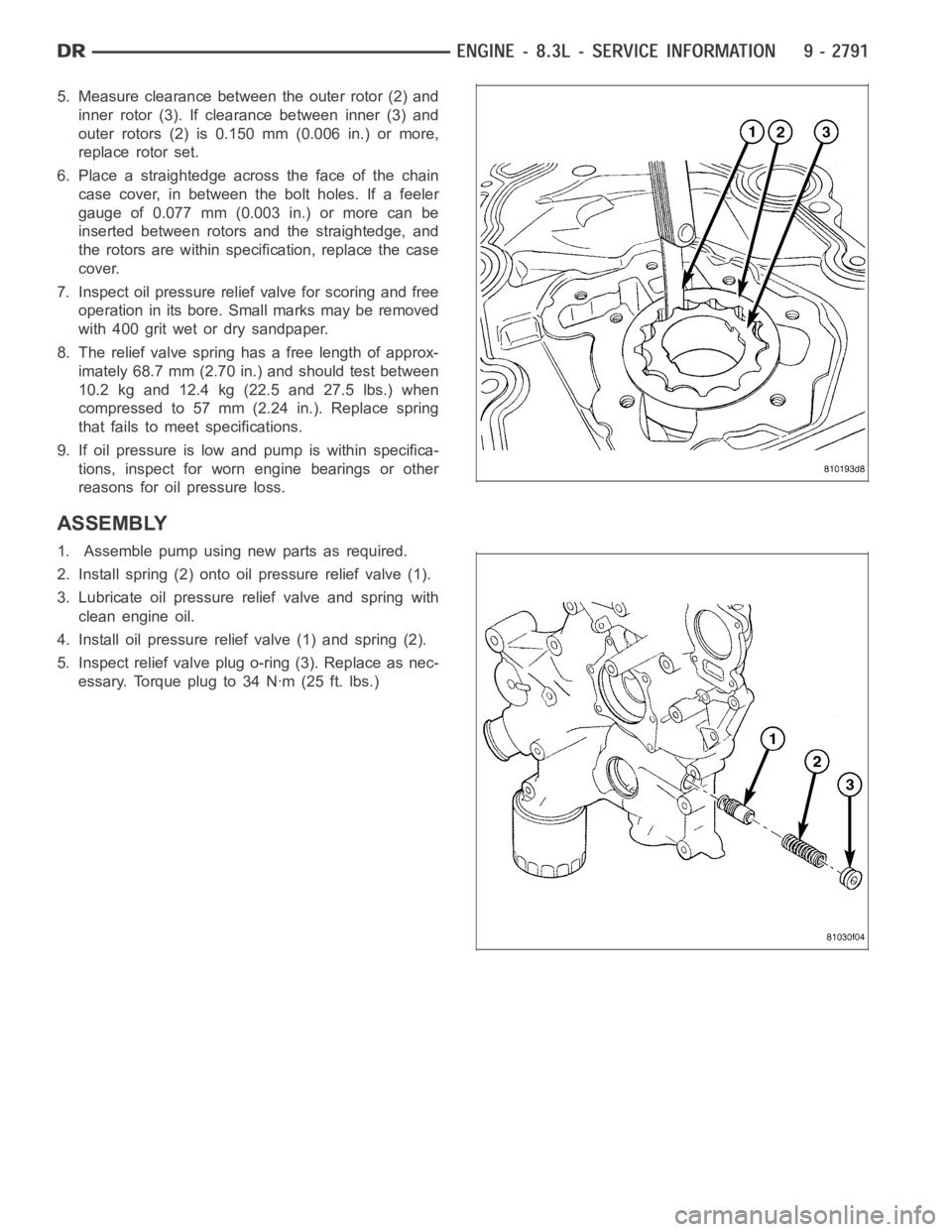

5. Measure clearance between the outer rotor (2) and

inner rotor (3). If clearance between inner (3) and

outer rotors (2) is 0.150 mm (0.006 in.) or more,

replace rotor set.

6. Place a straightedge across the face of the chain

case cover, in between the bolt holes. If a feeler

gauge of 0.077 mm (0.003 in.) or more can be

inserted between rotors and the straightedge, and

the rotors are within specification, replace the case

cover.

7. Inspect oil pressure relief valve for scoring and free

operation in its bore. Small marks may be removed

with 400 grit wet or dry sandpaper.

8. The relief valve spring has a free length of approx-

imately 68.7 mm (2.70 in.) and should test between

10.2 kg and 12.4 kg (22.5 and 27.5 lbs.) when

compressedto57mm(2.24in.). Replace spring

that fails to meet specifications.

9. If oil pressure is low and pump is within specifica-

tions, inspect for worn engine bearings or other

reasons for oil pressure loss.

ASSEMBLY

1. Assemble pump using new parts as required.

2. Install spring (2) onto oil pressure relief valve (1).

3. Lubricate oil pressure relief valve and spring with

clean engine oil.

4. Install oil pressure relief valve (1) and spring (2).

5. Inspect relief valve plug o-ring (3). Replace as nec-

essary. Torque plug to 34 Nꞏm (25 ft. lbs.)

Page 2114 of 5267

PISTON

1. Inspect all piston surfaces for nicks and scuffs.

2. Inspect piston and ring grooves for wear.

INSTALLATION

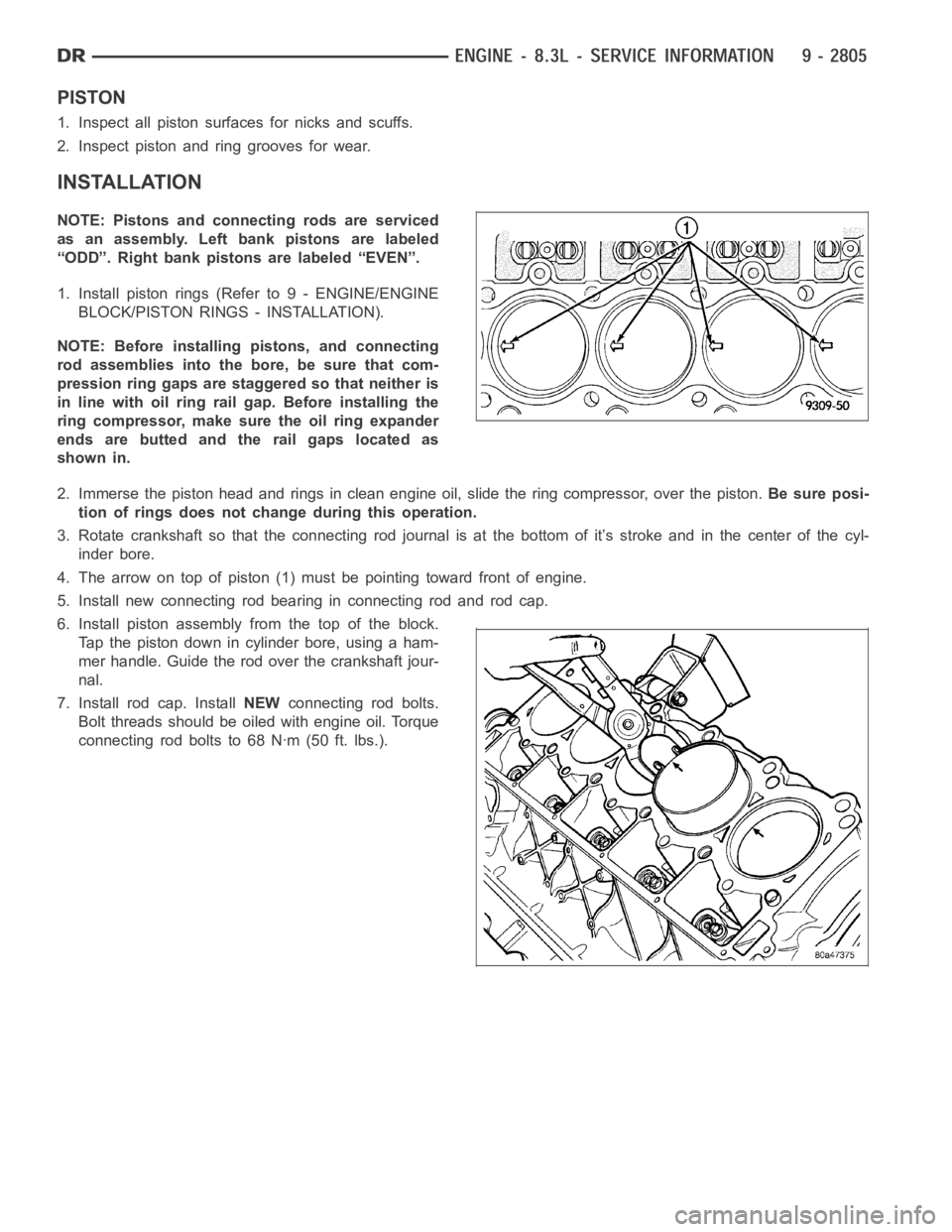

NOTE: Pistons and connecting rods are serviced

as an assembly. Left bank pistons are labeled

“ODD”. Right bank pistons are labeled “EVEN”.

1. Install piston rings (Refer to 9 - ENGINE/ENGINE

BLOCK/PISTON RINGS - INSTALLATION).

NOTE: Before installing pistons, and connecting

rod assemblies into the bore, be sure that com-

pression ring gaps are staggered so that neither is

in line with oil ring rail gap. Before installing the

ring compressor, make sure the oil ring expander

ends are butted and the rail gaps located as

shown in.

2. Immerse the piston head and rings in clean engine oil, slide the ring compressor, over the piston.Be sure posi-

tion of rings does not change during this operation.

3. Rotate crankshaft so that the connecting rod journal is at the bottom of it’s stroke and in the center of the cyl-

inder bore.

4. The arrow on top of piston (1) must be pointing toward front of engine.

5. Install new connecting rod bearing in connecting rod and rod cap.

6. Install piston assembly from the top of the block.

Tap the piston down in cylinder bore, using a ham-

mer handle. Guide the rod over the crankshaft jour-

nal.

7. Install rod cap. InstallNEWconnecting rod bolts.

Bolt threads should be oiled with engine oil. Torque

connecting rod bolts to 68 Nꞏm (50 ft. lbs.).