DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Page 1788 of 5267

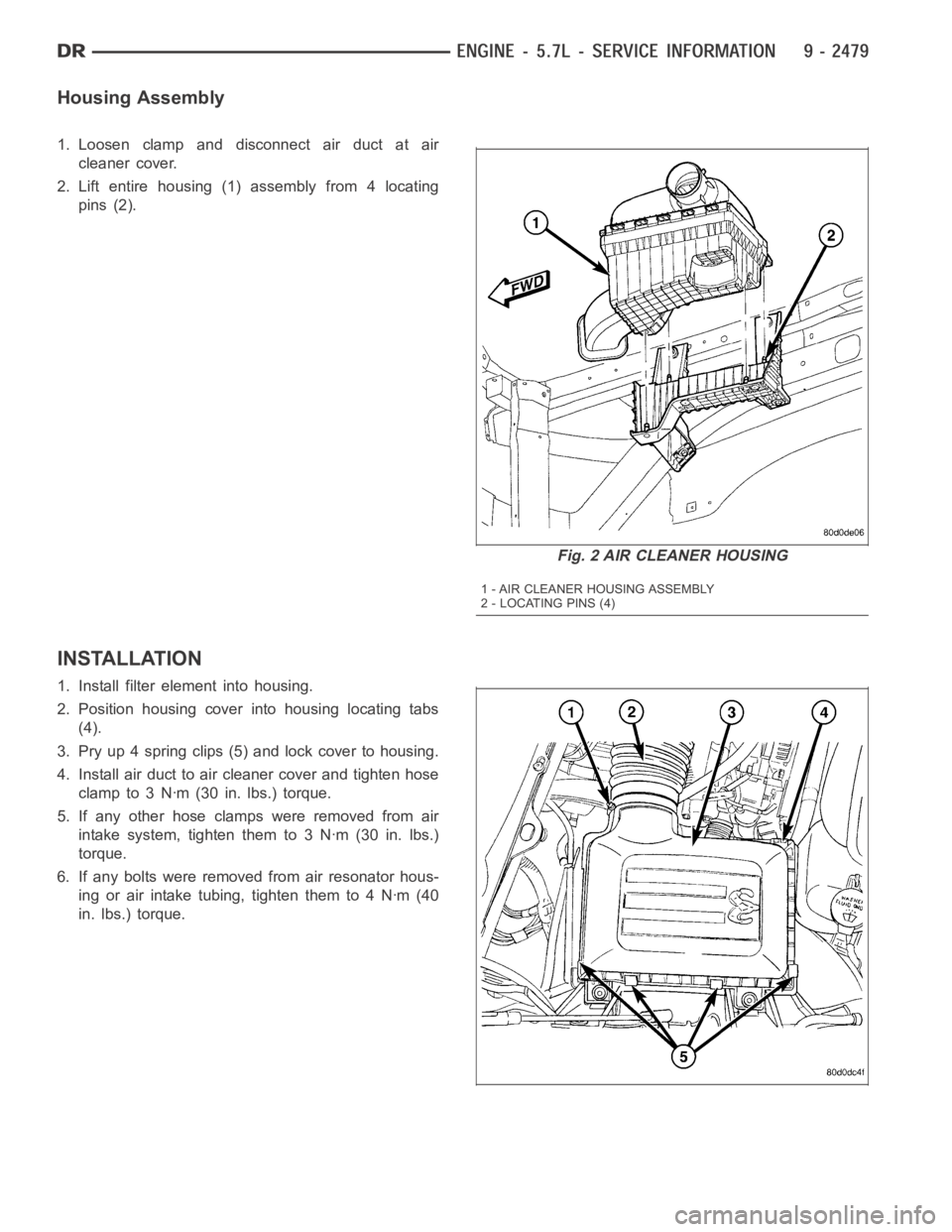

Housing Assembly

1. Loosen clamp and disconnect air duct at air

cleaner cover.

2. Lift entire housing (1) assembly from 4 locating

pins (2).

INSTALLATION

1. Install filter element into housing.

2. Position housing cover into housing locating tabs

(4).

3. Pry up 4 spring clips (5) and lock cover to housing.

4. Install air duct to air cleaner cover and tighten hose

clamp to 3 Nꞏm (30 in. lbs.) torque.

5. If any other hose clamps were removed from air

intake system, tighten them to 3 Nꞏm (30 in. lbs.)

torque.

6. If any bolts were removed from air resonator hous-

ing or air intake tubing, tighten them to 4 Nꞏm (40

in. lbs.) torque.

Fig. 2 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

Page 1796 of 5267

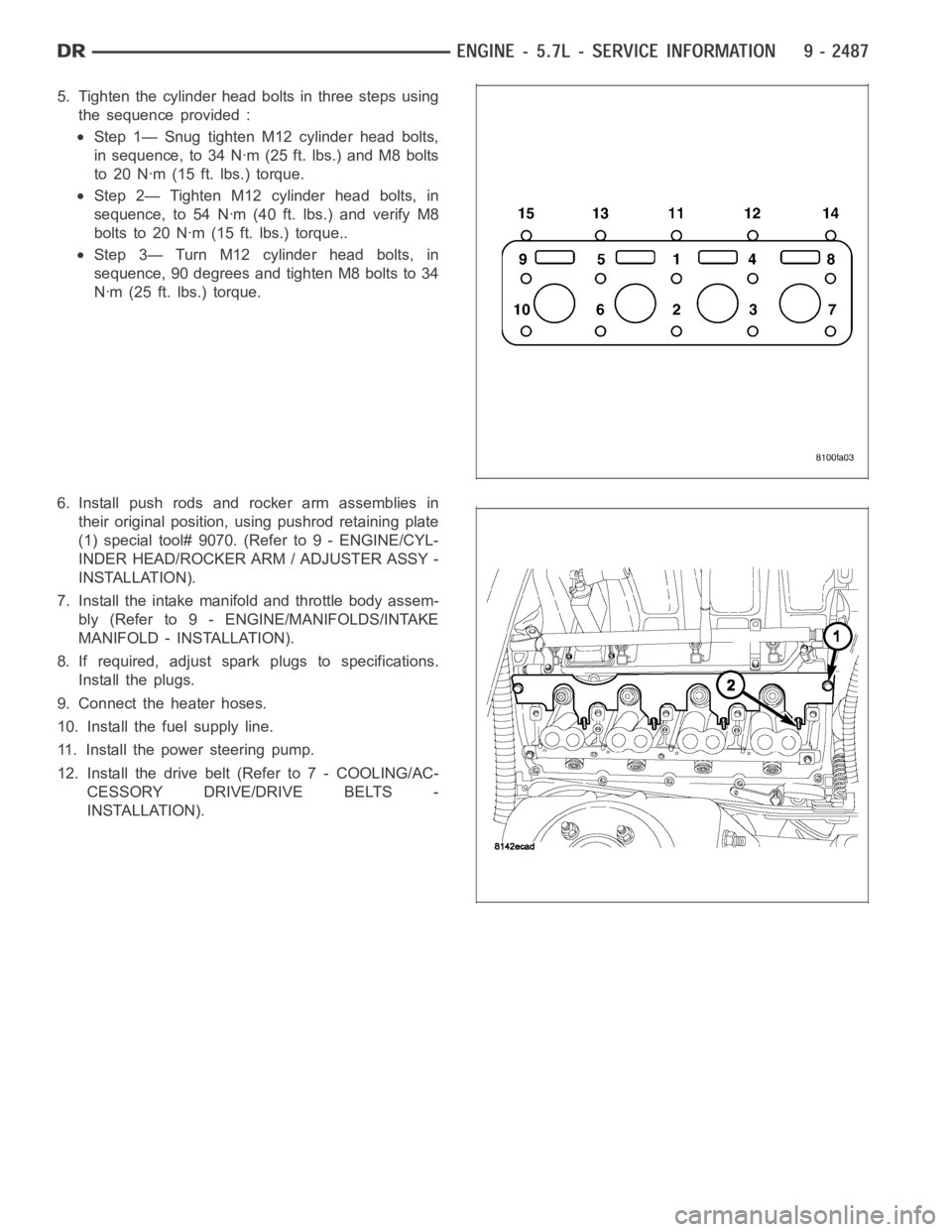

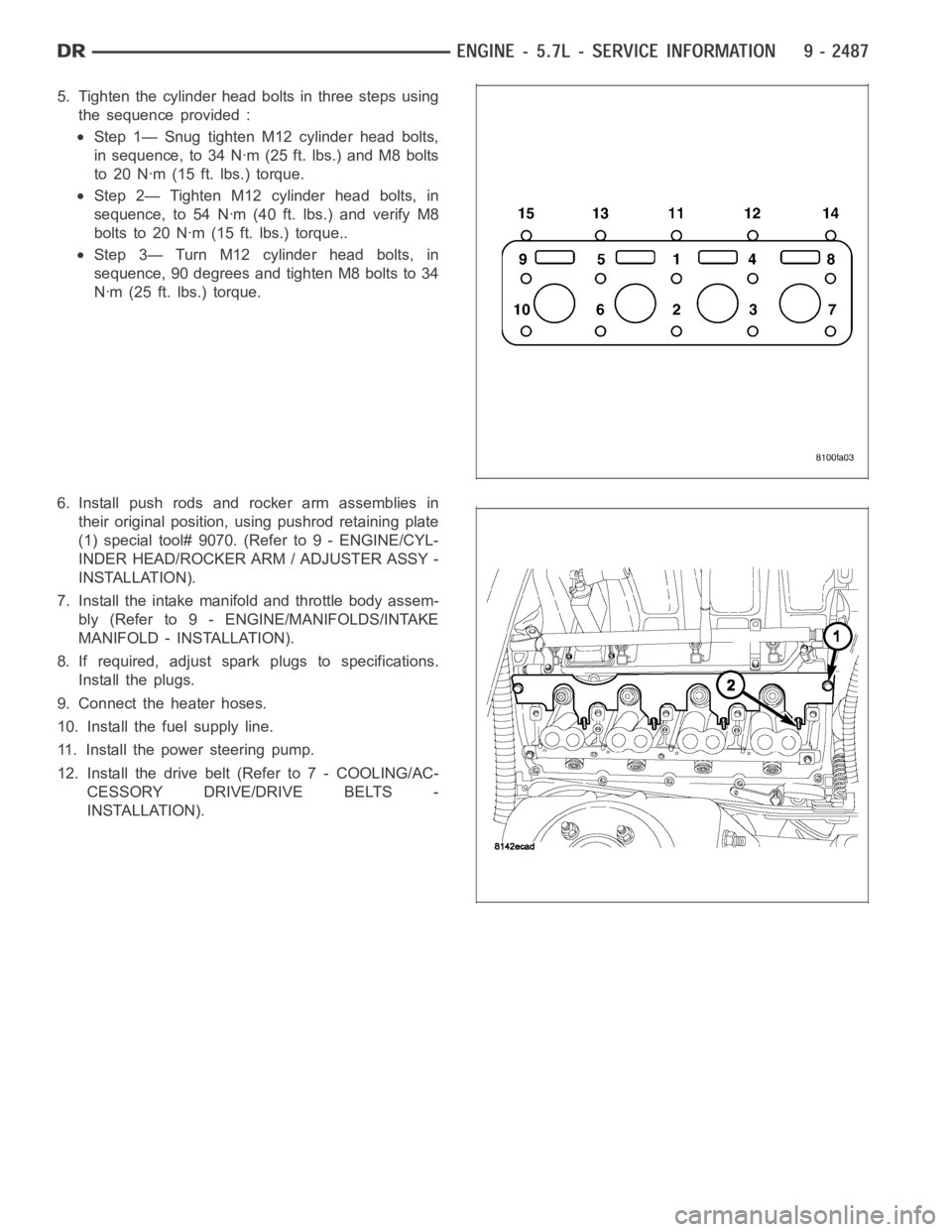

5. Tighten the cylinder head bolts in three steps using

the sequence provided :

Step 1— Snug tighten M12 cylinder head bolts,

in sequence, to 34 Nꞏm (25 ft. lbs.) and M8 bolts

to 20 Nꞏm (15 ft. lbs.) torque.

Step 2— Tighten M12 cylinder head bolts, in

sequence, to 54 Nꞏm (40 ft. lbs.) and verify M8

bolts to 20 Nꞏm (15 ft. lbs.) torque..

Step 3— Turn M12 cylinder head bolts, in

sequence, 90 degrees and tighten M8 bolts to 34

Nꞏm (25 ft. lbs.) torque.

6. Install push rods and rocker arm assemblies in

their original position, using pushrod retaining plate

(1) special tool# 9070. (Refer to 9 - ENGINE/CYL-

INDER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

7. Install the intake manifold and throttle body assem-

bly (Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - INSTALLATION).

8. If required, adjust spark plugs to specifications.

Install the plugs.

9. Connect the heater hoses.

10. Install the fuel supply line.

11. Install the power steering pump.

12. Install the drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Page 1803 of 5267

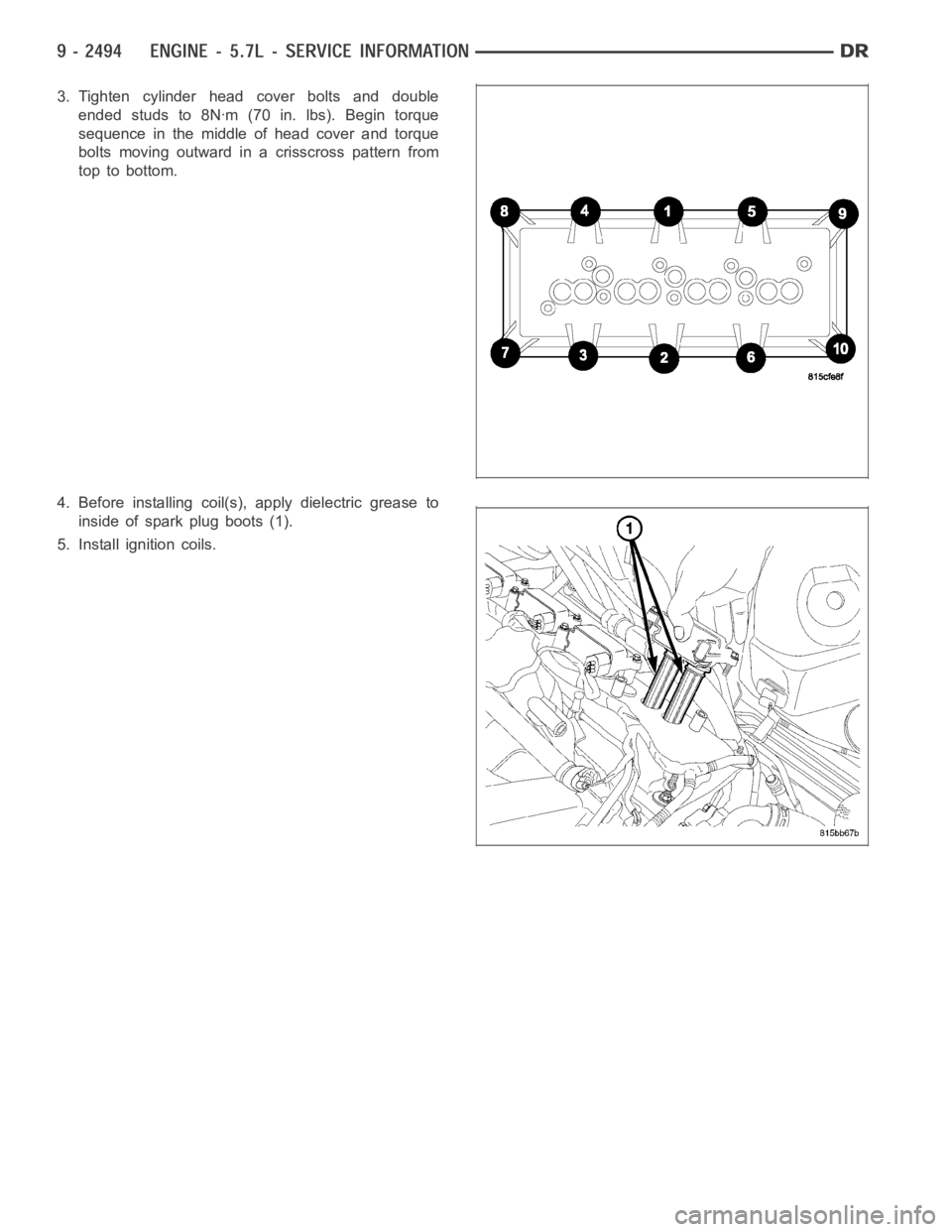

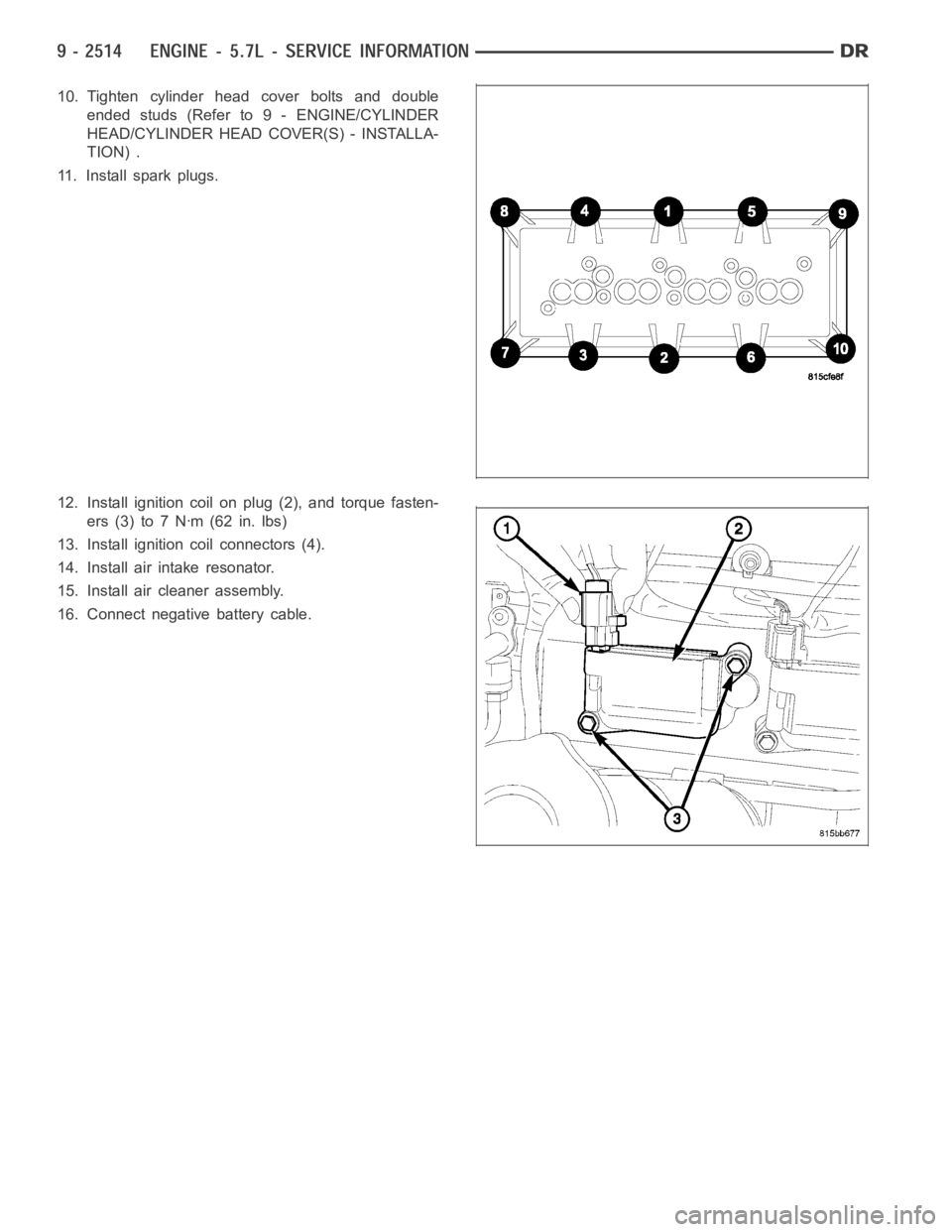

3. Tighten cylinder head cover bolts and double

ended studs to 8Nꞏm (70 in. lbs). Begin torque

sequence in the middle of head cover and torque

bolts moving outward in a crisscross pattern from

top to bottom.

4. Before installing coil(s), apply dielectric grease to

inside of spark plug boots (1).

5. Install ignition coils.

Page 1804 of 5267

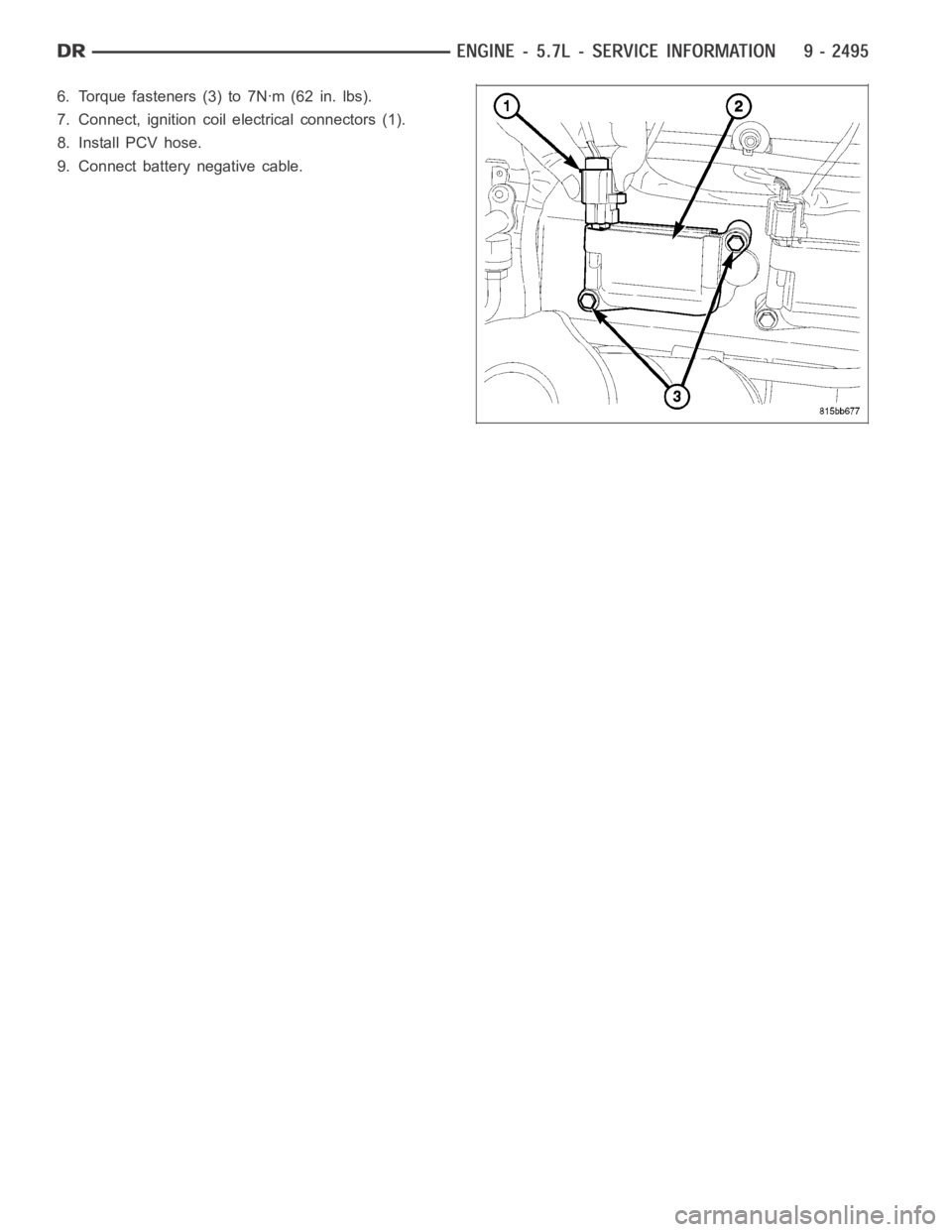

6. Torque fasteners (3) to 7Nꞏm (62 in. lbs).

7. Connect, ignition coil electrical connectors (1).

8. Install PCV hose.

9. Connect battery negative cable.

Page 1809 of 5267

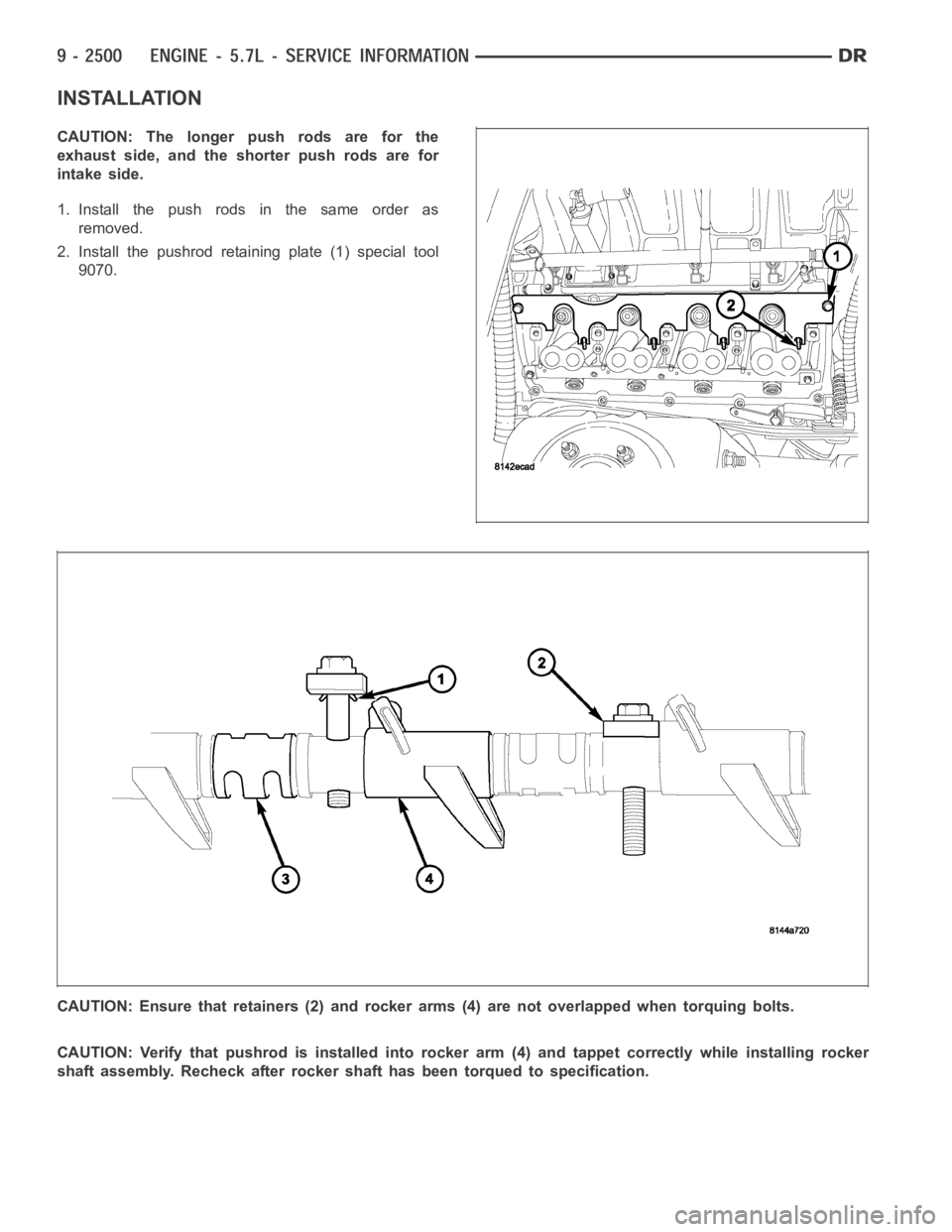

INSTALLATION

CAUTION: The longer push rods are for the

exhaust side, and the shorter push rods are for

intake side.

1. Install the push rods in the same order as

removed.

2. Install the pushrod retaining plate (1) special tool

9070.

CAUTION: Ensure that retainers (2) and rocker arms (4) are not overlapped when torquing bolts.

CAUTION: Verify that pushrod is installed into rocker arm (4) and tappet correctly while installing rocker

shaft assembly. Recheck after rocker shaft has been torqued to specification.

Page 1810 of 5267

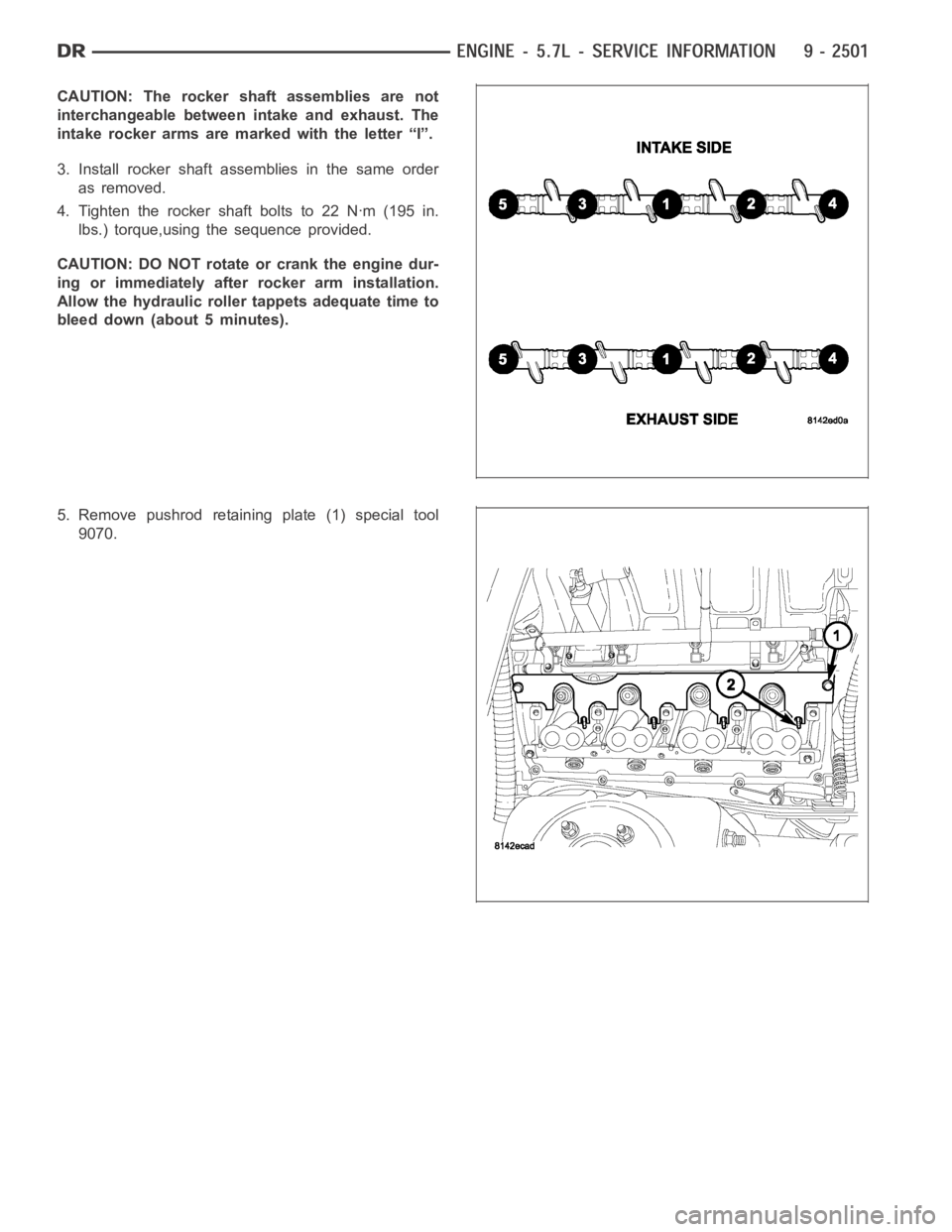

CAUTION: The rocker shaft assemblies are not

interchangeable between intake and exhaust. The

intake rocker arms are marked with the letter “I”.

3. Install rocker shaft assemblies in the same order

as removed.

4. Tighten the rocker shaft bolts to 22 Nꞏm (195 in.

lbs.) torque,using the sequence provided.

CAUTION: DO NOT rotate or crank the engine dur-

ing or immediately after rocker arm installation.

Allow the hydraulic roller tappets adequate time to

bleed down (about 5 minutes).

5. Remove pushrod retaining plate (1) special tool

9070.

Page 1820 of 5267

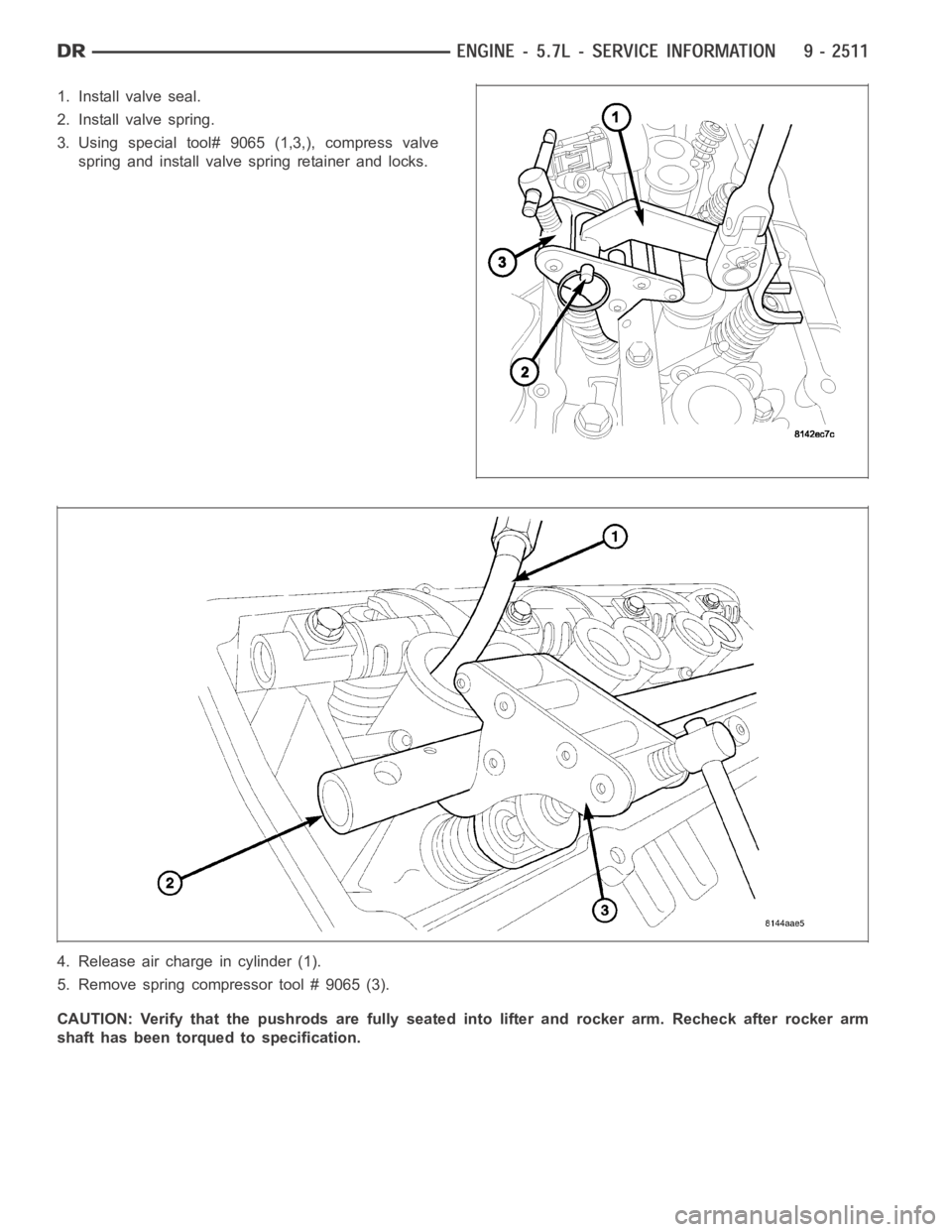

1. Install valve seal.

2. Install valve spring.

3. Using special tool# 9065 (1,3,), compress valve

spring and install valve spring retainer and locks.

4. Release air charge in cylinder (1).

5. Remove spring compressor tool # 9065 (3).

CAUTION: Verify that the pushrods are fully seated into lifter and rocker arm. Recheck after rocker arm

shaft has been torqued to specification.

Page 1821 of 5267

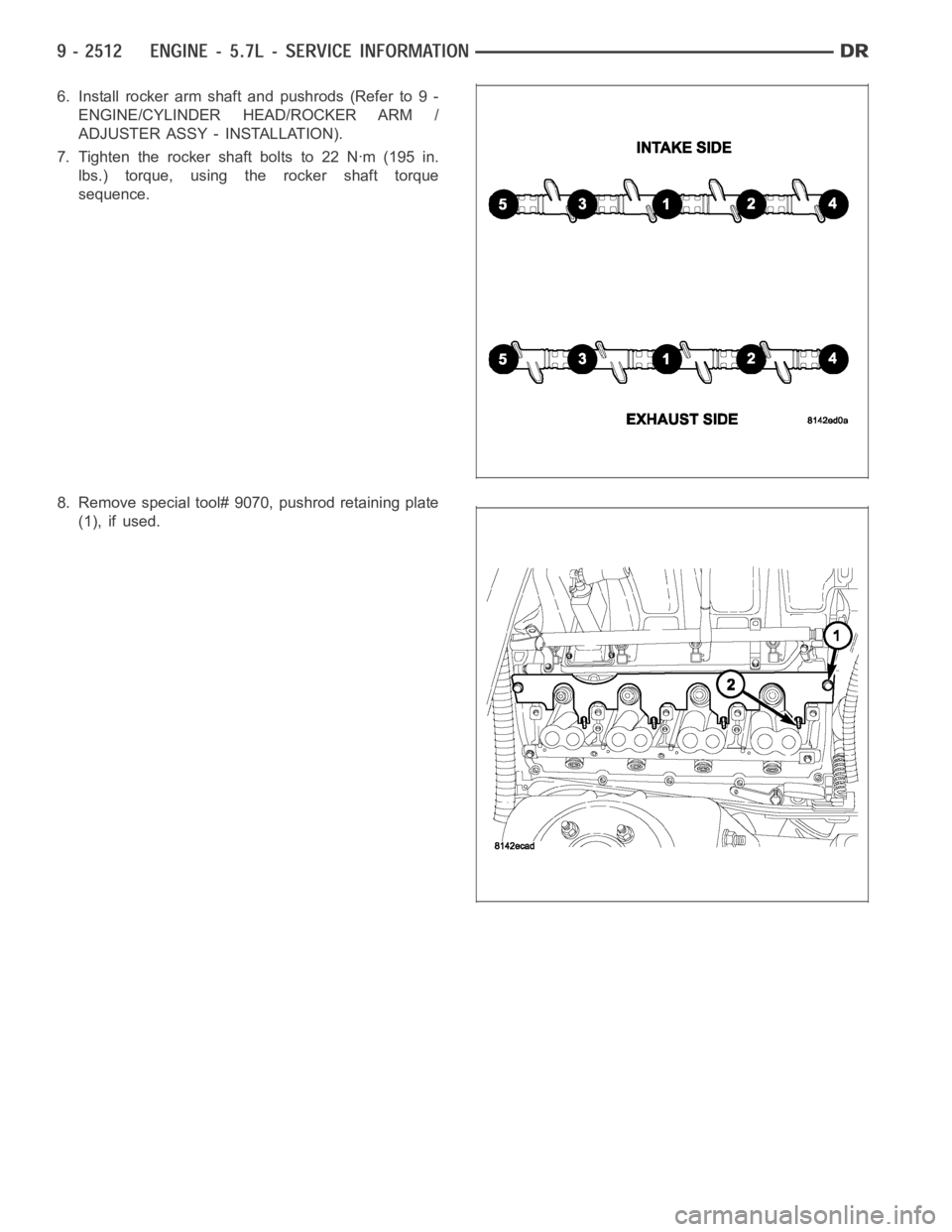

6. Install rocker arm shaft and pushrods (Refer to 9 -

ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - INSTALLATION).

7. Tighten the rocker shaft bolts to 22 Nꞏm (195 in.

lbs.) torque, using the rocker shaft torque

sequence.

8. Remove special tool# 9070, pushrod retaining plate

(1), if used.

Page 1823 of 5267

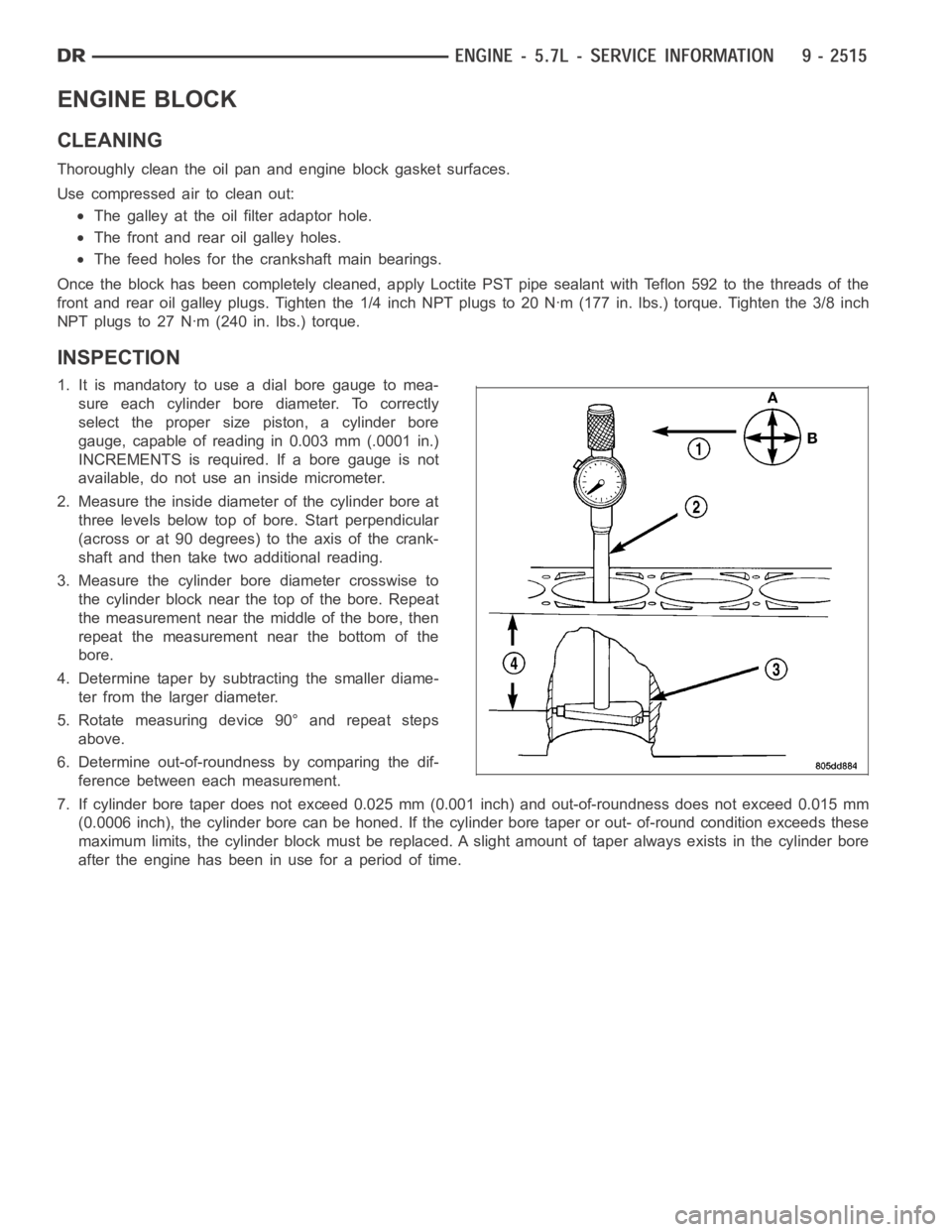

10. Tighten cylinder head cover bolts and double

ended studs (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION) .

11. Install spark plugs.

12. Install ignition coil on plug (2), and torque fasten-

ers (3) to 7 Nꞏm (62 in. lbs)

13. Install ignition coil connectors (4).

14. Install air intake resonator.

15. Install air cleaner assembly.

16. Connect negative battery cable.

Page 1824 of 5267

ENGINE BLOCK

CLEANING

Thoroughly clean the oil pan and engine block gasket surfaces.

Use compressed air to clean out:

The galley at the oil filter adaptor hole.

The front and rear oil galley holes.

The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply Loctite PST pipe sealantwith Teflon 592 to the threads of the

front and rear oil galley plugs. Tighten the 1/4 inch NPT plugs to 20 Nꞏm (177in. lbs.) torque. Tighten the 3/8 inch

NPT plugs to 27 Nꞏm (240 in. lbs.) torque.

INSPECTION

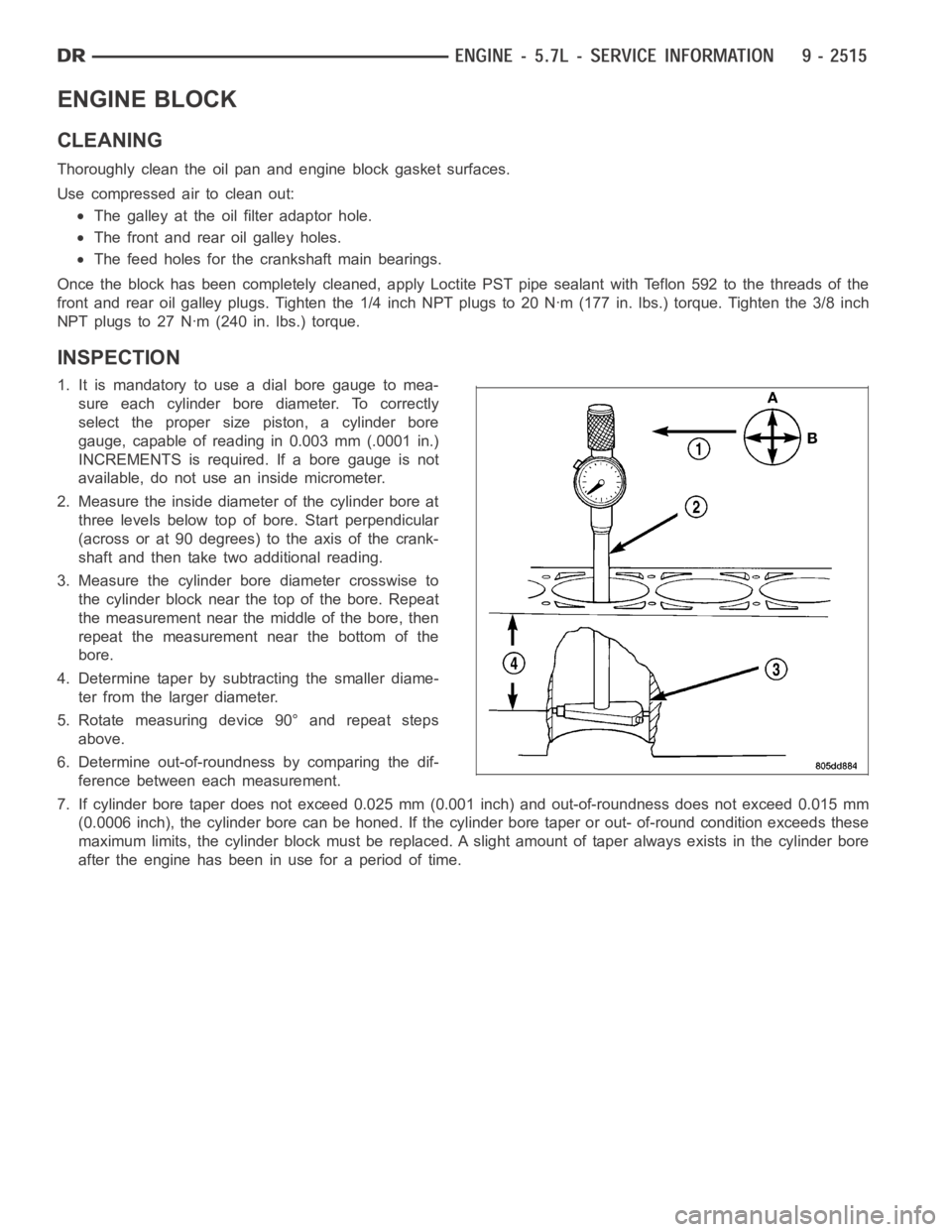

1. It is mandatory to use a dial bore gauge to mea-

sure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore

gauge, capable of reading in 0.003 mm (.0001 in.)

INCREMENTS is required. If a bore gauge is not

available, do not use an inside micrometer.

2. Measure the inside diameter of the cylinder bore at

three levels below top of bore. Start perpendicular

(across or at 90 degrees) to the axis of the crank-

shaft and then take two additional reading.

3. Measure the cylinder bore diameter crosswise to

the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the

bore.

4. Determine taper by subtracting the smaller diame-

ter from the larger diameter.

5. Rotate measuring device 90° and repeat steps

above.

6. Determine out-of-roundness by comparing the dif-

ference between each measurement.

7. If cylinder bore taper does not exceed 0.025 mm (0.001 inch) and out-of-roundness does not exceed 0.015 mm

(0.0006 inch), the cylinder bore can be honed. If the cylinder bore taper orout- of-round condition exceeds these

maximum limits, the cylinder block must be replaced. A slight amount of taper always exists in the cylinder bore

after the engine has been in use for a period of time.