relay DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2281 of 5267

page page

PEDAL - ACCELERATOR

REMOVAL .................................... 46

INSTALLATION ............................... 46

SENSOR-ACCELERATOR PEDAL POSITION

DESCRIPTION ................................ 47

OPERATION .................................. 47

REMOVAL .................................... 47

INSTALLATION ............................... 48

SENSOR-CRANKSHAFT POSITION

DESCRIPTION

3.7L V-6 .................................... 49

4.7L V-8 .................................... 49

5.7L V-8 .................................... 50

OPERATION

3.7L V-6 .................................... 50

4.7L V-8 .................................... 51

5.7L V-8 .................................... 51

REMOVAL

3.7L V-6 .................................... 52

4.7L V-8 .................................... 52

5.7L V-8 .................................... 53

8.3L - SRT-10 ............................... 53

INSTALLATION

3.7L V-6 .................................... 54

4.7L V-8 .................................... 55

5.7L V-8 .................................... 55

8.3L - SRT-10 ............................... 55

INJECTOR - FUEL

DESCRIPTION ................................ 56

OPERATION

FUEL INJECTOR ............................ 56

PCM OUTPUT .............................. 56

REMOVAL

3.7/4.7/ 5.7L ................................ 57

8.3L - SRT-10 ............................... 57

INSTALLATION

3.7/ 4.7/ 5.7L ............................... 60

8.3L - SRT-10 ............................... 60

RELAY - FUEL PUMP

DESCRIPTION ................................ 61

OPERATION .................................. 61

REMOVAL .................................... 61

INSTALLATION ............................... 61

MOTOR-IAC

DESCRIPTION

3.7L, 4.7L, 5.7L ............................. 62

8.3L - SRT-10 ............................... 63

OPERATION

3.7L V-6/4.7L V-8 ............................ 63

REMOVAL

3.7L V-6 .................................... 644.7L V-8 .................................... 65

5.7L V-8 .................................... 65

8.3L - SRT-10 ............................... 65

INSTALLATION

3.7L V-6 .................................... 66

4.7L V-8 .................................... 66

5.7L V-8 .................................... 66

8.3L - SRT-10 ............................... 67

SENSOR - INLET AIR TEMPERATURE

REMOVAL — 8.3L ............................. 68

INSTALLATION ............................... 68

SENSOR-INTAKE AIR TEMPERATURE

DESCRIPTION

3.7L V-6 .................................... 69

4.7L V-8 .................................... 69

5.7L V-8 .................................... 70

OPERATION .................................. 70

REMOVAL

3.7L V-6 .................................... 71

4.7L V-8 .................................... 72

5.7L V-8 .................................... 73

INSTALLATION

3.7L V-6 .................................... 74

4.7L V-8 .................................... 75

5.7L V-8 .................................... 75

SENSOR-MAP

DESCRIPTION

3.7L V-6 .................................... 76

4.7L V-8 .................................... 76

5.7L V-8 .................................... 77

8.3L - SRT-10 ............................... 77

OPERATION .................................. 77

REMOVAL

3.7L V-6 .................................... 79

4.7L V-8 .................................... 80

5.7L V-8 .................................... 80

8.3 L - SRT-10 .............................. 81

INSTALLATION

3.7L V-6 .................................... 81

4.7L V-8 .................................... 82

5.7L V-8 .................................... 83

8.3L - SRT-10 ............................... 83

SENSOR - OXYGEN

DESCRIPTION ................................ 84

REMOVAL .................................... 84

INSTALLATION ............................... 85

SWITCH-PTO

DESCRIPTION ................................ 86

OPERATION .................................. 86

THROTTLE BODY

DESCRIPTION ................................ 87

Page 2293 of 5267

INJECTOR - FUEL

DESCRIPTION

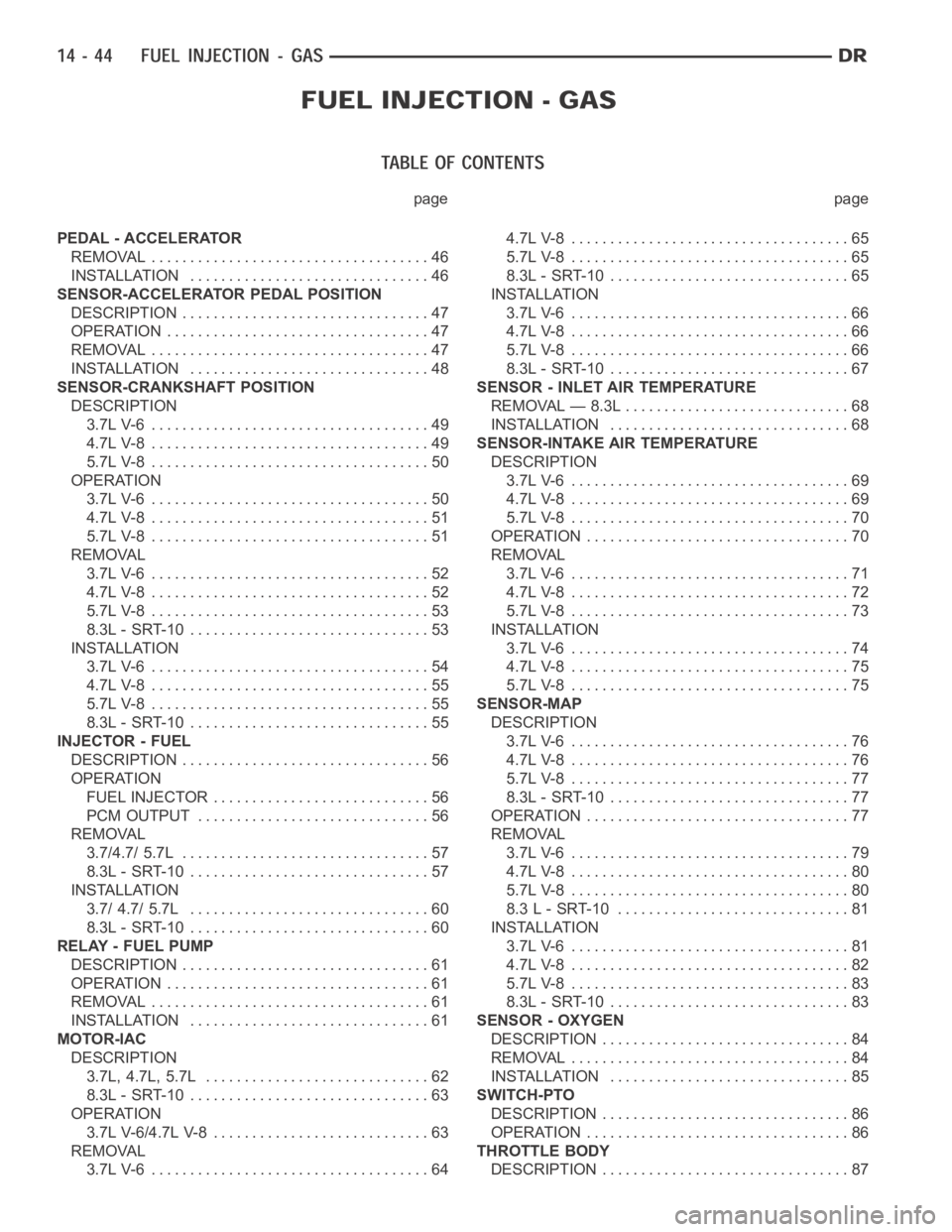

An individual fuel injector (1) is used for each individ-

ual cylinder.

OPERATION

FUEL INJECTOR

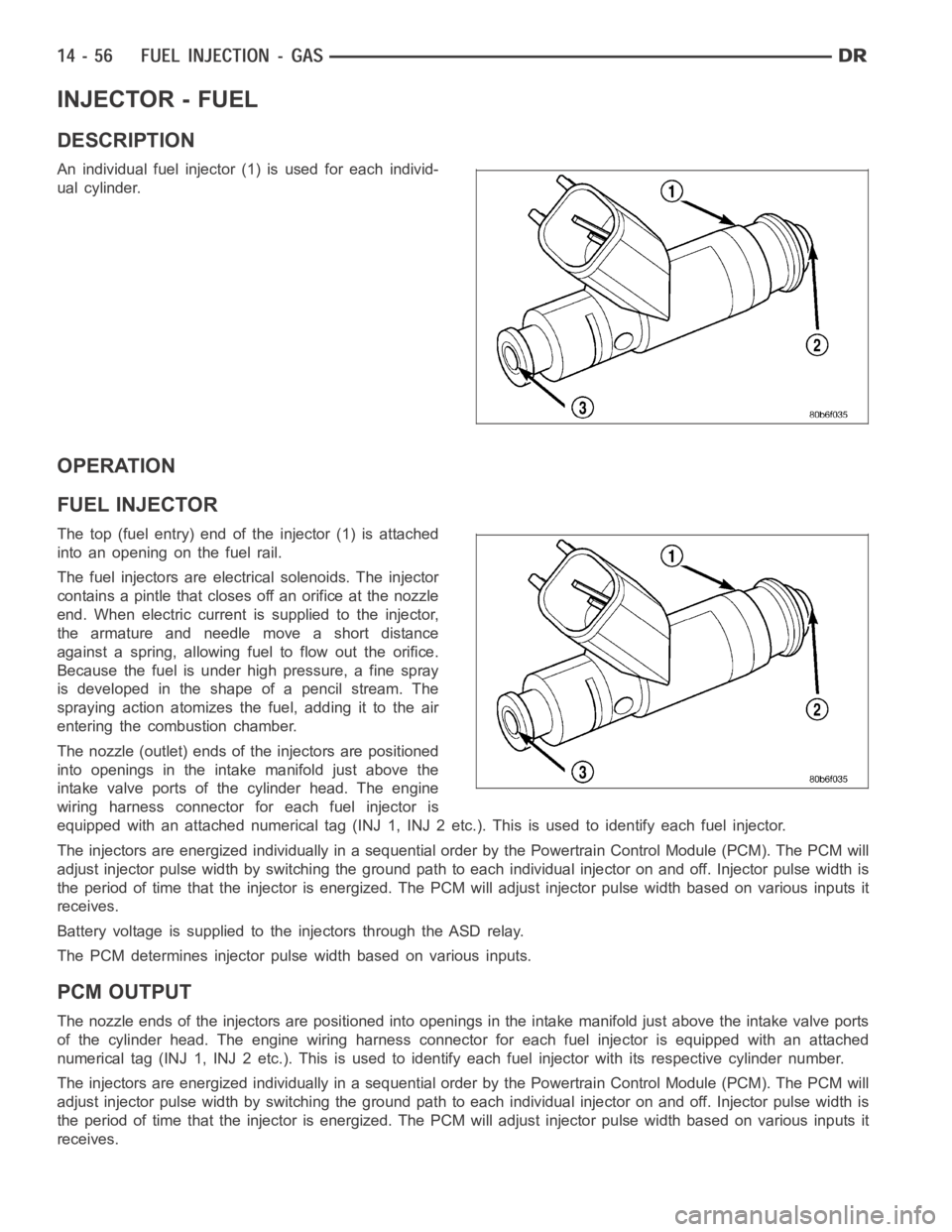

The top (fuel entry) end of the injector (1) is attached

into an opening on the fuel rail.

The fuel injectors are electrical solenoids. The injector

contains a pintle that closes off an orifice at the nozzle

end. When electric current is supplied to the injector,

the armature and needle move a short distance

against a spring, allowing fuel to flow out the orifice.

Because the fuel is under high pressure, a fine spray

is developed in the shape of a pencil stream. The

spraying action atomizes the fuel, adding it to the air

entering the combustion chamber.

The nozzle (outlet) ends of the injectors are positioned

into openings in the intake manifold just above the

intake valve ports of the cylinder head. The engine

wiring harness connector for each fuel injector is

equipped with an attached numerical tag (INJ 1, INJ 2 etc.). This is used to identify each fuel injector.

The injectors are energized individually in a sequential order by the Powertrain Control Module (PCM). The PCM will

adjust injector pulse width by switching the ground path to each individual injector on and off. Injector pulse width is

the period of time that the injector isenergized. The PCM will adjust injector pulse width based on various inputs it

receives.

Battery voltage is supplied to the injectors through the ASD relay.

The PCM determines injector pulse width based on various inputs.

PCM OUTPUT

The nozzle ends of the injectors are positioned into openings in the intakemanifold just above the intake valve ports

of the cylinder head. The engine wiring harness connector for each fuel injector is equipped with an attached

numerical tag (INJ 1, INJ 2 etc.). This is used to identify each fuel injector with its respective cylinder number.

The injectors are energized individually in a sequential order by the Powertrain Control Module (PCM). The PCM will

adjust injector pulse width by switching the ground path to each individual injector on and off. Injector pulse width is

the period of time that the injector isenergized. The PCM will adjust injector pulse width based on various inputs it

receives.

Page 2294 of 5267

Battery voltage (12 volts +) is supplied to the injectors through the ASD relay. The ASD relay will shut-down the 12

volt power source to the fuel injectors if the PCM senses the ignition is on,but the engine is not running. This

occurs after the engine has not been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width) based on various inputs.

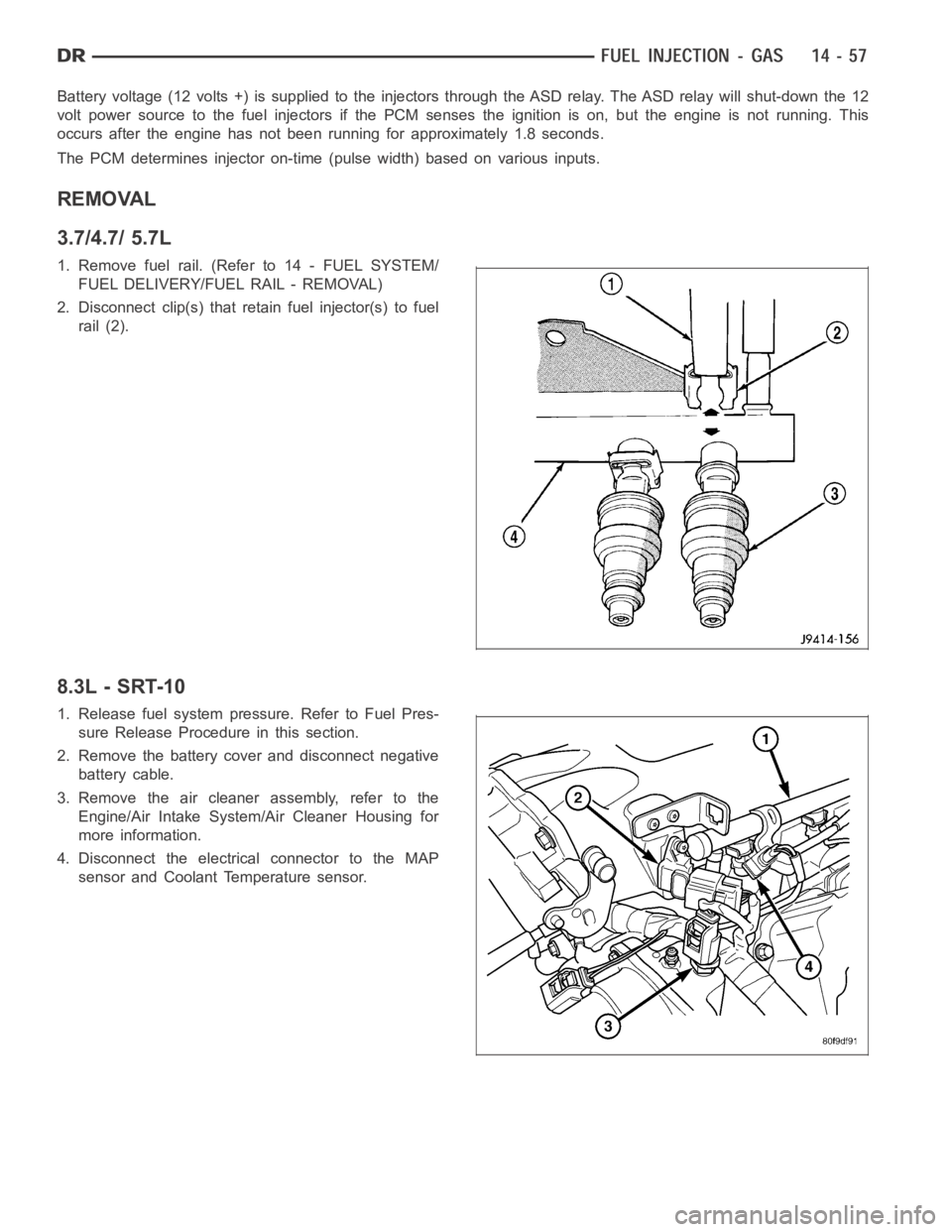

REMOVAL

3.7/4.7/ 5.7L

1. Remove fuel rail. (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - REMOVAL)

2. Disconnect clip(s) that retain fuel injector(s) to fuel

rail (2).

8.3L - SRT-10

1. Release fuel system pressure. Refer to Fuel Pres-

sure Release Procedure in this section.

2. Remove the battery cover and disconnect negative

battery cable.

3. Remove the air cleaner assembly, refer to the

Engine/Air Intake System/Air Cleaner Housing for

more information.

4. Disconnect the electrical connector to the MAP

sensor and Coolant Temperature sensor.

Page 2298 of 5267

RELAY - FUEL PUMP

DESCRIPTION

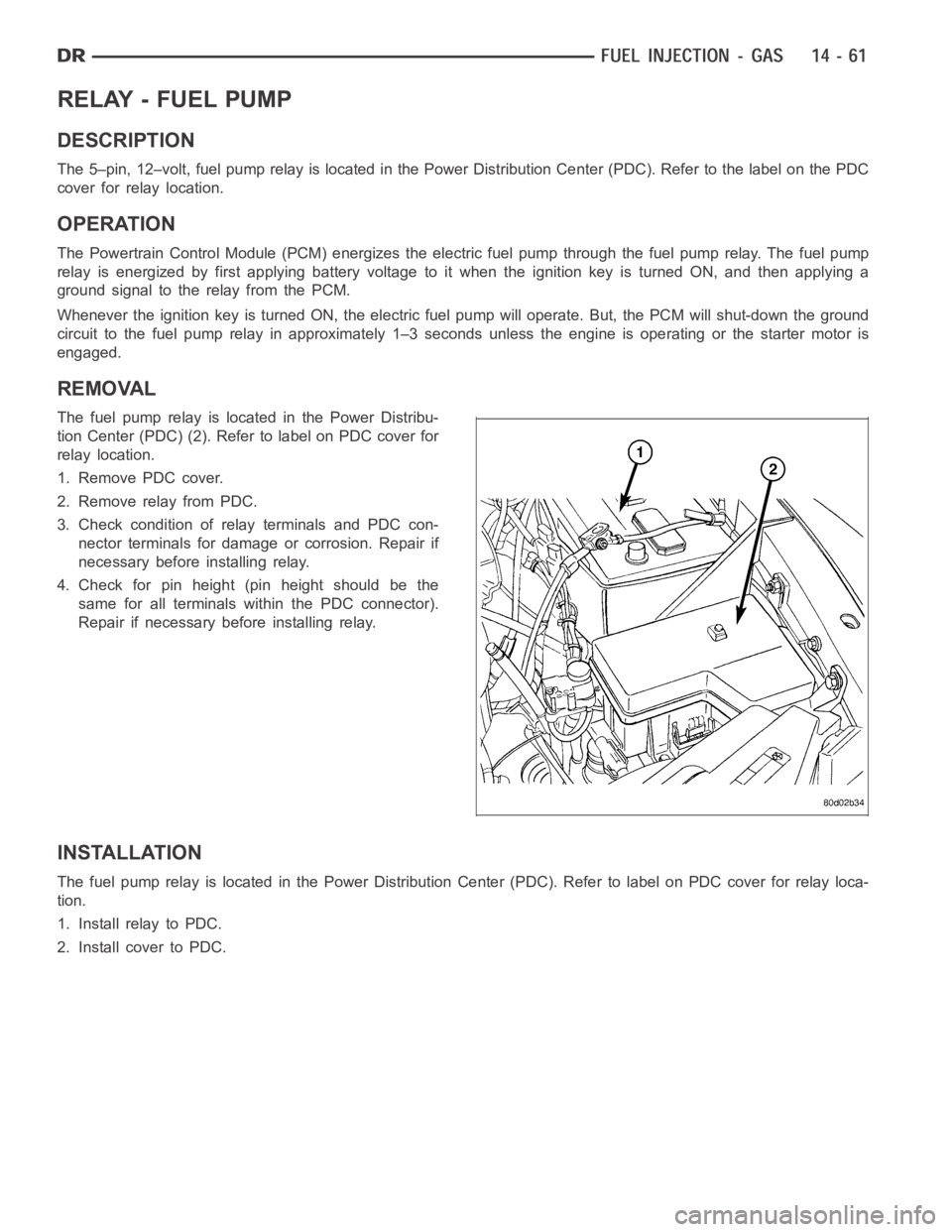

The 5–pin, 12–volt, fuel pump relay is located in the Power Distribution Center (PDC). Refer to the label on the PDC

cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes the electric fuel pump through the fuel pump relay. The fuel pump

relay is energized by first applying battery voltage to it when the ignition key is turned ON, and then applying a

ground signal to the relay from the PCM.

Whenever the ignition key is turned ON, the electric fuel pump will operate. But, the PCM will shut-down the ground

circuit to the fuel pump relay in approximately 1–3 seconds unless the engine is operating or the starter motor is

engaged.

REMOVAL

The fuel pump relay is located in the Power Distribu-

tion Center (PDC) (2). Refer to label on PDC cover for

relay location.

1. Remove PDC cover.

2. Remove relay from PDC.

3. Check condition of relay terminals and PDC con-

nector terminals for damage or corrosion. Repair if

necessary before installing relay.

4. Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distribution Center (PDC). Refer to label on PDC cover for relay loca-

tion.

1. Install relay to PDC.

2. Install cover to PDC.

Page 2342 of 5267

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM

WARNING: High-pressure fuel lines deliver diesel

fuel under extreme pressure from the injection

pump to the fuel injectors. This may be as high as

160,000 kpa (23,206 psi). Use extreme caution

when inspecting for high-pressure fuel leaks.

Inspect for high-pressure fuel leaks with a sheet of

cardboard. High fuel injection pressure can cause

personal injury if contact is made with the skin.

The fuel system used on the Cummins engine is an electronically controlled, Bosch HPCR (High-Pressure Common

Rail) system. The HPCR system consists of five main components:

Electric Fuel Transfer (lift) Pump Located in the Fuel Tank

Fuel Pump/Gear Pump (attached to fuel injection pump)

High-Pressure Fuel Injection Pump

Fuel Injection Rail

Fuel Injectors

Also to be considered as part of the overall fuel system are:

Accelerator Pedal

Air Cleaner Housing/Element

Check Valve Banjo Fitting at Rear of Cylinder Head

Fuel Connector Tubes

Fuel Drain Manifold (passage)

Fuel Drain Valve (at filter)

Fuel Filter/Water Separator

Fuel Heater

Fuel Heater Relay

Fuel Transfer Pump Relay

Fuel Level (gauge) Sending Unit

Fuel Pressure Limiting Valve

Fuel Tank

Fuel Tank Module (containing a fuel gauge sending unit, separate fuel filter located at bottom of tank module,

and fuel transfer pump)

Fuel Tank Filler/Vent Tube Assembly

Fuel Tank Filler Tube Cap

Fuel Tubes/Lines/Hoses

High-Pressure Fuel Injector Lines

In-Tank Fuel Filter (at bottom of fuel tank module)

Low-Pressure Fuel Supply Lines

Low-Pressure Fuel Return Lines

Overflow Valve

Quick-Connect Fuel Line Fittings

Accelerator Pedal Position Sensor (APPS) Located in Cab

Water Draining (maintenance)

Water-In-Fuel (WIF) Sensor

Screened Banjo Bolt (22)

The fuel injection pump supplies high pressure to the fuel rail independent of engine speed. This high pressure fuel

is then accumulated in the fuel rail. High pressure fuel is constantly supplied to the injectors by the fuel rail. The

Engine Control Module (ECM) controls the fueling and timing of the engine by actuating the injectors.

Page 2352 of 5267

HEATER-FUEL

DESCRIPTION

The fuel heater assembly is located on the side of the fuel filter housing and internal to the fuel filter housing .

The heater/element assembly is equipped with a temperature sensor (thermostat) that senses fuel temperature. This

sensor is attached to the fuel heater/element assembly.

OPERATION

The fuel heater is used to prevent diesel fuel from waxing during cold weather operation.

When the fuel temperature is below 45° ±8 F (7°C), the temperature sensor allows current to flow to the heater

element warming the fuel. When the fuel temperature is above 75° ±8 F (24°C), the sensor stops current flow to the

heater element.

Battery voltage to operate the fuel heater element is supplied from the ignition switch and through a solid stated

device in the IPM.The fuel heater element and

solid state device in IPMinstead offuel heater relayare not

computer controlled.

The heater element operates on 12 volts, 300 watts at 0° F (-18° C).

DIAGNOSIS AND TESTING

FUEL HEATER

The fuel heater is used to prevent diesel fuel from waxing during cold weather operation.

NOTE: The fuel heater element,

solid state device in IPMinstead offuel heater relayand fuel heater tem-

perature sensor are not controlled by the Engine Control Module (ECM).

A malfunctioning fuel heater can cause a wax build-up in the fuel filter/water separator. Wax build-up in the filter/

separator can cause engine starting problems and prevent the engine from revving up. It can also cause blue or

white fog-like exhaust. If the heater is not operating in cold temperatures, the engine may not operate due to fuel

waxing.

The fuel heater assembly is located on the side of fuel filter housing and internal to the fuel filter housing.

The heater assembly is equipped with a built-in fuel temperature sensor (thermostat) that senses fuel temperature.

When fuel temperature drops below 45° ± 8° F (7° C), the sensor allows current to flow to built-in heater element

to warm fuel. When fuel temperature rises above 75 °± 8° F (24° C), the sensorstops current flow to heater ele-

ment (circuit is open).

Voltage to operate fuel heater element is supplied from ignition switch, through

solid state device in IPM,tofuel

temperature sensor and on to fuel heater element.

The heater element operates on 12 volts, 300 watts at 0 °F (-18° C). As temperature increases, power requirements

decrease.

A minimum of 7 volts is required to operate the fuel heater. The resistance value of the heater element is less than

1 ohm (cold) and up to 1000 ohms warm.

TESTING

1. Disconnect electrical connector from thermostat.

Ambient temperature must be below the circuit close temperature. If necessary, induce this ambient temperature by

placing ice packs on thermostat to produce an effective ambient temperature below circuit close temperature.

Measure resistance across two pins. Operating range is 0.3 - 0.45 Ohms.

2. If resistance is out of range, remove thermostat and check resistance across terminal connections of heater. The

heater can be checked at room temperature. Operating range is 0.3 - 0.45 Ohms.

3. Replace heater if resistance is not within operating range.

4. If heater is within operating range, replace heater thermostat.

Page 2373 of 5267

PUMP - FUEL TRANSFER

DESCRIPTION

The fuel transfer pump (fuel lift pump) is part of the fuel pump module. The fuel pump module is located in the fuel

tank. The 12–volt electric pump is operated and controlled by the Engine Control Module (ECM). The ECM controls

a relay in the Intelligent Power Module(IPM) for transfer pump operation.

OPERATION

The purpose of the fuel transfer pump is to supply (transfer) a low-pressure fuel source:fromthe fuel tank,through

the fuel filter/water separator andtothe fuel injection pump. Here, the low-pressure is raised to a high-pressure by

the fuel injection pump for operation of the high-pressure fuel injectors. Check valves within the pump, control direc-

tion of fuel flow and prevent fuel bleed-back during engine shut down.

Maximum current flow to the pump is 5 amperes.

With the engine running, the pump has a 100 percent duty-cycle.

The transfer pump is self-priming: When the key is first turned on (withoutcranking engine), the pump will operate

for approximately 2 seconds and then shut off (Note: When ambient temperatures are cold enough to cause the

intake air heaters to operate, the fuel lift pump will operate during the entire intake air pre-heat cycle). The pump will

also operate for up to 25 seconds after the starter is engaged, and then disengaged and the engine is not running.

The pump shuts off immediately if the key is on and the engine stops running.

The fuel volume of the transfer pump will always provide more fuel than the fuel injection pump requires. Excess

fuel is returned from the injection pump through an overflow valve, and then back to the fuel tank.

REMOVAL

The fuel transfer pump (fuel lift pump) is a part of the fuel tank module. It is not serviced separately. Refer to Fuel

Tank Module Removal or Installation for procedures (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL TANK

MODULE - REMOVAL).

INSTALLATION

The fuel transfer pump (fuel lift pump) is a part of the fuel tank module. It is not serviced separately (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL TANK MODULE - INSTALLATION).

Page 2377 of 5267

page page

SENSOR-ACCELERATOR PEDAL POSITION

DESCRIPTION ............................... 141

OPERATION ................................. 141

REMOVAL ................................... 141

INSTALLATION .............................. 142

SENSOR-CAMSHAFT POSITION

DESCRIPTION ............................... 143

OPERATION ................................. 143

REMOVAL ................................... 143

INSTALLATION .............................. 144

SENSOR-CRANKSHAFT POSITION

DESCRIPTION ............................... 145

OPERATION ................................. 145

REMOVAL ................................... 146

INSTALLATION .............................. 146

ACTUATOR - FUEL CONTROL

DESCRIPTION ............................... 147

OPERATION ................................. 147

REMOVAL ................................... 147

INSTALLATION .............................. 147

INJECTOR - FUEL

DESCRIPTION ............................... 148

OPERATION ................................. 149

REMOVAL ................................... 149

INSTALLATION .............................. 153

FUEL INJECTOR RAIL

DESCRIPTION ............................... 155

OPERATION ................................. 155REMOVAL ................................... 155

INSTALLATION .............................. 156

SENSOR-TEMPERATURE/PRESSURE-INTAKE

DESCRIPTION ............................... 157

OPERATION ................................. 157

REMOVAL ................................... 157

INSTALLATION .............................. 159

HEATER - INTAKE AIR

DESCRIPTION ............................... 160

OPERATION ................................. 160

REMOVAL ................................... 160

INSTALLATION .............................. 162

RELAY - INTAKE AIR HEATER

DESCRIPTION ............................... 163

OPERATION ................................. 163

REMOVAL ................................... 163

INSTALLATION .............................. 164

SENSOR-TEMPERATURE/PRESSURE-MAP

DESCRIPTION ............................... 165

OPERATION ................................. 165

REMOVAL ................................... 165

INSTALLATION .............................. 166

SENSOR-MAP

DESCRIPTION ............................... 167

SWITCH - PTO

DESCRIPTION ............................... 168

OPERATION ................................. 168

Page 2397 of 5267

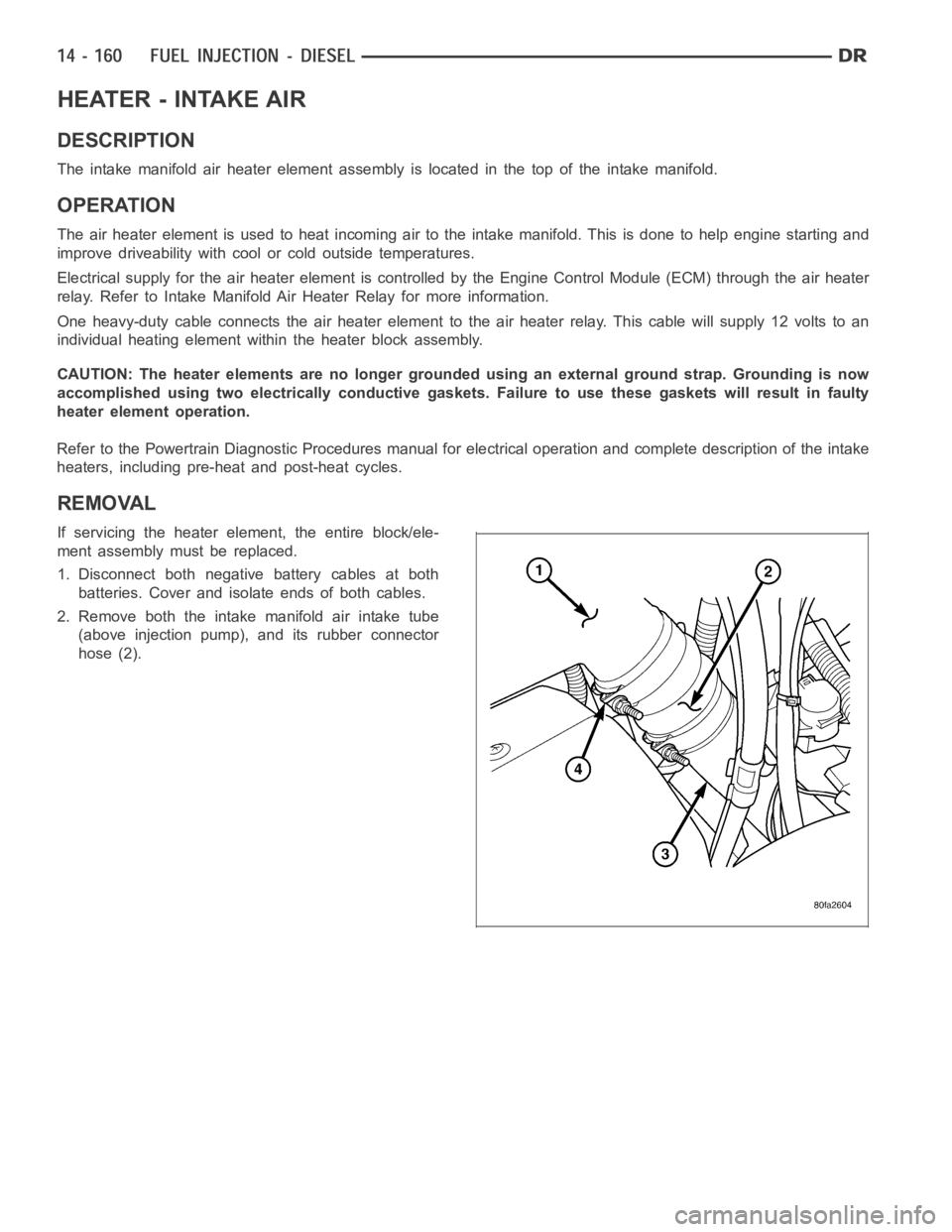

HEATER - INTAKE AIR

DESCRIPTION

The intake manifold air heater element assembly is located in the top of theintake manifold.

OPERATION

The air heater element is used to heat incoming air to the intake manifold. This is done to help engine starting and

improve driveability with cool or cold outside temperatures.

Electrical supply for the air heater element is controlled by the Engine Control Module (ECM) through the air heater

relay. Refer to Intake Manifold Air Heater Relay for more information.

One heavy-duty cable connects the air heater element to the air heater relay. This cable will supply 12 volts to an

individual heating element within the heater block assembly.

CAUTION: The heater elements are no longer grounded using an external ground strap. Grounding is now

accomplished using two electrically conductive gaskets. Failure to use these gaskets will result in faulty

heater element operation.

Refer to the Powertrain Diagnostic Procedures manual for electrical operation and complete description of the intake

heaters, including pre-heat and post-heat cycles.

REMOVAL

If servicing the heater element, the entire block/ele-

ment assembly must be replaced.

1. Disconnect both negative battery cables at both

batteries. Cover and isolate ends of both cables.

2. Remove both the intake manifold air intake tube

(above injection pump), and its rubber connector

hose (2).

Page 2400 of 5267

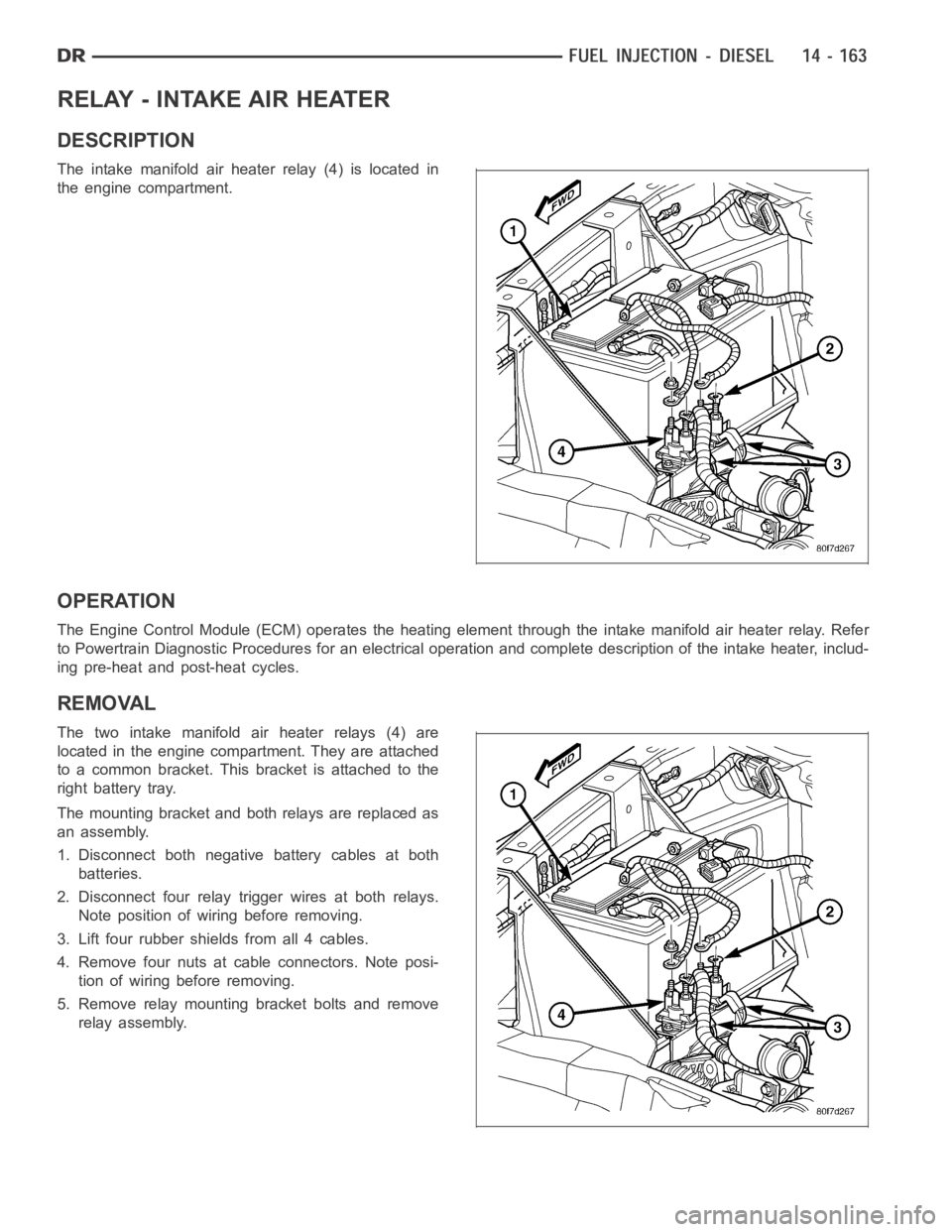

RELAY - INTAKE AIR HEATER

DESCRIPTION

The intake manifold air heater relay (4) is located in

the engine compartment.

OPERATION

The Engine Control Module (ECM) operates the heating element through the intake manifold air heater relay. Refer

to Powertrain Diagnostic Procedures for an electrical operation and complete description of the intake heater, includ-

ing pre-heat and post-heat cycles.

REMOVAL

The two intake manifold air heater relays (4) are

located in the engine compartment. They are attached

to a common bracket. This bracket is attached to the

right battery tray.

The mounting bracket and both relays are replaced as

an assembly.

1. Disconnect both negative battery cables at both

batteries.

2. Disconnect four relay trigger wires at both relays.

Note position of wiring before removing.

3. Lift four rubber shields from all 4 cables.

4. Remove four nuts at cable connectors. Note posi-

tion of wiring before removing.

5. Remove relay mounting bracket bolts and remove

relay assembly.