relay DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2887 of 5267

3.PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the Transmission Simulator, turn the Pressure Switch selector switchtoL/R.

With the scan tool, monitor the L/R Pressure Switch State while pressing the Pressure Switch Test button.

Did the Pressure Switch state change from open to closed when the test button was pressed?

Ye s>>

Repair internal transmission as necessary per the Service Information. Inspect the Solenoid Switch

Valve per the Service Information and repair or replace as necessary. If noproblems are found, replace

the Transmission Solenoid/Pressure Switch Assembly.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Go To 4

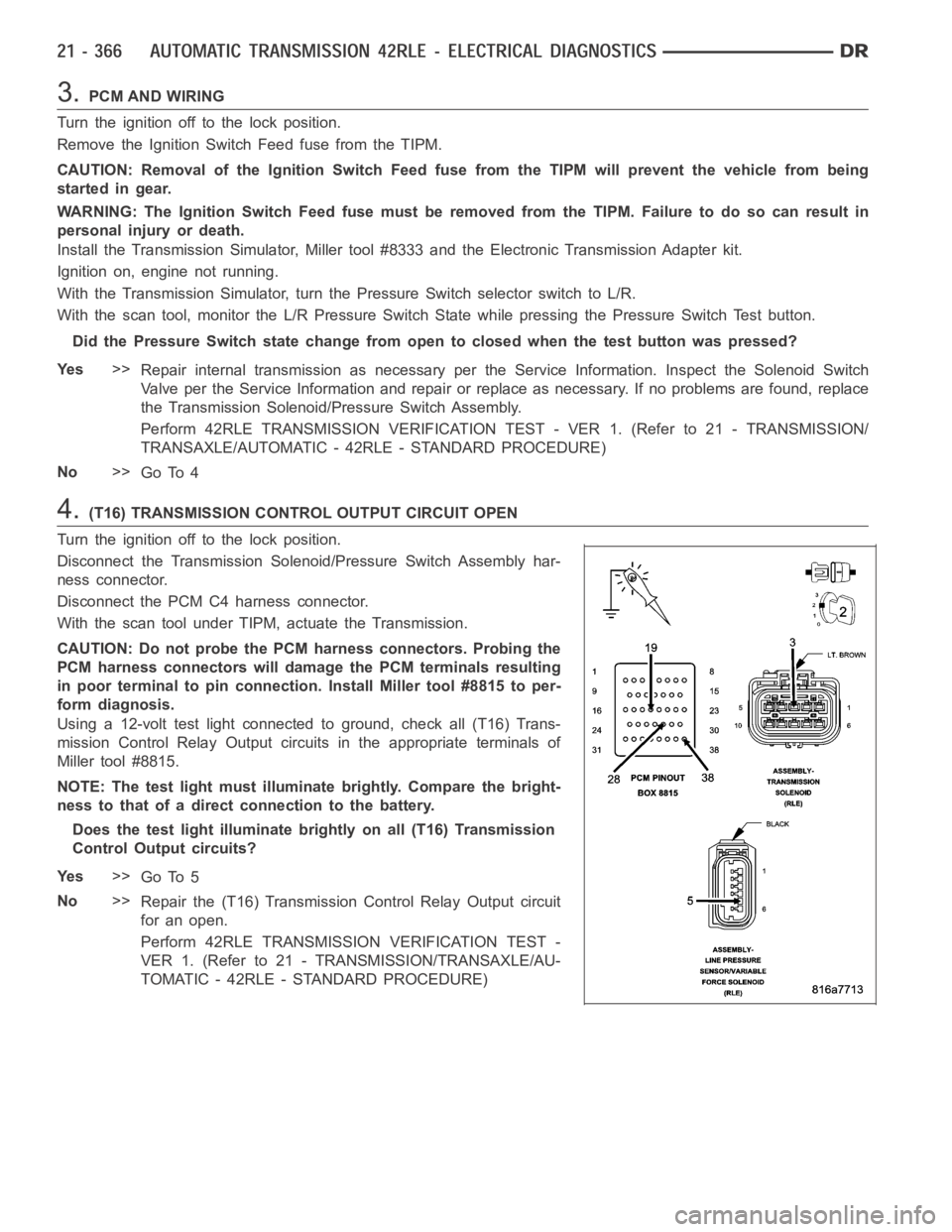

4.(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid/Pressure Switch Assembly har-

ness connector.

Disconnect the PCM C4 harness connector.

With the scan tool under TIPM, actuate the Transmission.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Using a 12-volt test light connected to ground, check all (T16) Trans-

mission Control Relay Output circuits in the appropriate terminals of

Miller tool #8815.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly on all (T16) Transmission

Control Output circuits?

Ye s>>

Go To 5

No>>

Repair the (T16) Transmission Control Relay Output circuit

for an open.

Perform 42RLE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2911 of 5267

MECHANISM-SHIFT

DESCRIPTION ............................... 536

OPERATION ................................. 536

SOLENOID

DESCRIPTION ............................... 537

OPERATION ................................. 538

ASSEMBLY-TRANSMISSION SOLENOID/

PRESSURE SWITCH

DESCRIPTION ............................... 539

OPERATION ................................. 539

REMOVAL ................................... 540

INSTALLATION .............................. 541

CONVERTER-TORQUE

DESCRIPTION ............................... 542

OPERATION ................................. 546

REMOVAL ................................... 548

INSTALLATION .............................. 549

SWITCH-TOW/HAUL OVERDRIVE

DESCRIPTION ............................... 550

OPERATION ................................. 550REMOVAL ................................... 550

INSTALLATION .............................. 551

RELAY-TRANSMISSION CONTROL

DESCRIPTION ............................... 552

OPERATION ................................. 552

SENSOR-TRANSMISSION RANGE

DESCRIPTION ............................... 553

OPERATION ................................. 553

REMOVAL ................................... 554

INSTALLATION .............................. 555

SENSOR-TRANSMISSION TEMPERATURE

DESCRIPTION ............................... 556

OPERATION ................................. 556

BODY-VALVE

DESCRIPTION ............................... 557

OPERATION ................................. 558

REMOVAL ................................... 562

DISASSEMBLY .............................. 564

ASSEMBLY .................................. 571

INSTALLATION .............................. 578

Page 2914 of 5267

The 42RLE is a four-speed transmission that is a conventional hydraulic/mechanical assembly controlled with adap-

tive electronic controls and monitors. The hydraulic system of the transmission consists of the transmission fluid,

fluid passages, hydraulic valves, and various line pressure control components. An input clutch assembly which

houses the underdrive, overdrive, and reverse clutches is used. It also utilizes separate holding clutches: 2nd/4th

gear and Low/Reverse. The primary mechanical components of the transmission consist of the following:

Three multiple disc input clutches

Two multiple disc holding clutches

Four hydraulic accumulators

Two planetary gear sets

Hydraulic oil pump

Valve body

Solenoid/Pressure switch assembly

Control of the transmission is accomplished by fully adaptive electronics. Optimum shift scheduling is accomplished

through continuous real-time sensor feedback information provided to the Transmission Control Module (TCM) por-

tion of the Powertrain Control Module (PCM).

The TCM is the heart of the electronic control system and relies on information from various direct and indirect

inputs (sensors, switches, etc.) to determine driver demand and vehicle operating conditions. With this information,

the TCM can calculate and perform timely and quality shifts through various output or control devices (solenoid

pack, transmission control relay, etc.).

The TCM also performs certain self-diagnostic functions and provides comprehensive information (sensor data,

DTC’s, etc.) which is helpful in proper diagnosis and repair. This informationcanbeviewedwiththescantool.

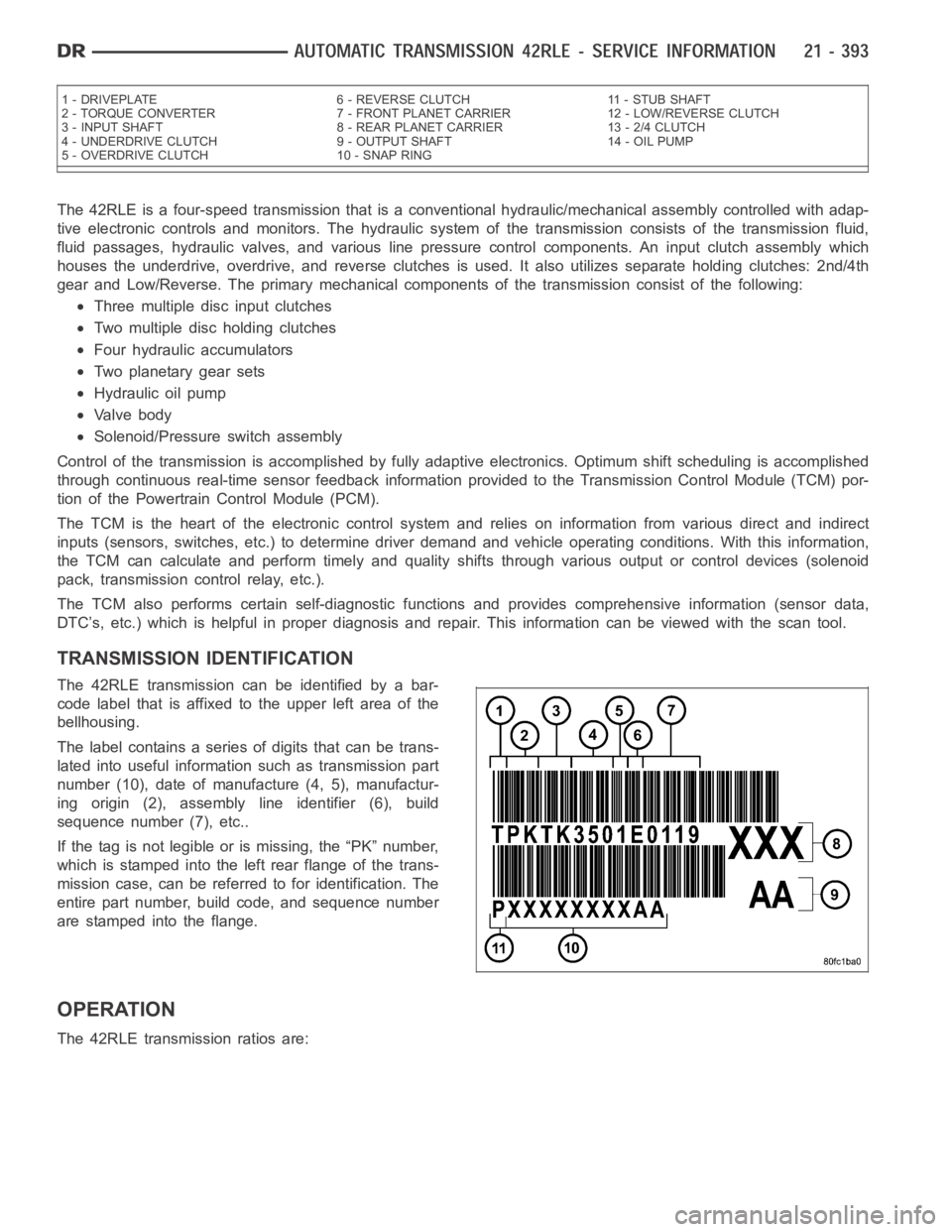

TRANSMISSION IDENTIFICATION

The 42RLE transmission can be identified by a bar-

code label that is affixed to the upper left area of the

bellhousing.

The label contains a series of digits that can be trans-

lated into useful information such as transmission part

number (10), date of manufacture (4, 5), manufactur-

ing origin (2), assembly line identifier (6), build

sequence number (7), etc..

If the tag is not legible or is missing, the “PK” number,

which is stamped into the left rear flange of the trans-

mission case, can be referred to for identification. The

entire part number, build code, and sequence number

are stamped into the flange.

OPERATION

The 42RLE transmission ratios are:

1 - DRIVEPLATE 6 - REVERSE CLUTCH 11 - STUB SHAFT

2 - TORQUE CONVERTER 7 - FRONT PLANET CARRIER 12 - LOW/REVERSE CLUTCH

3 - INPUT SHAFT 8 - REAR PLANET CARRIER 13 - 2/4 CLUTCH

4 - UNDERDRIVE CLUTCH 9 - OUTPUT SHAFT 14 - OIL PUMP

5 - OVERDRIVE CLUTCH 10 - SNAP RING

Page 3060 of 5267

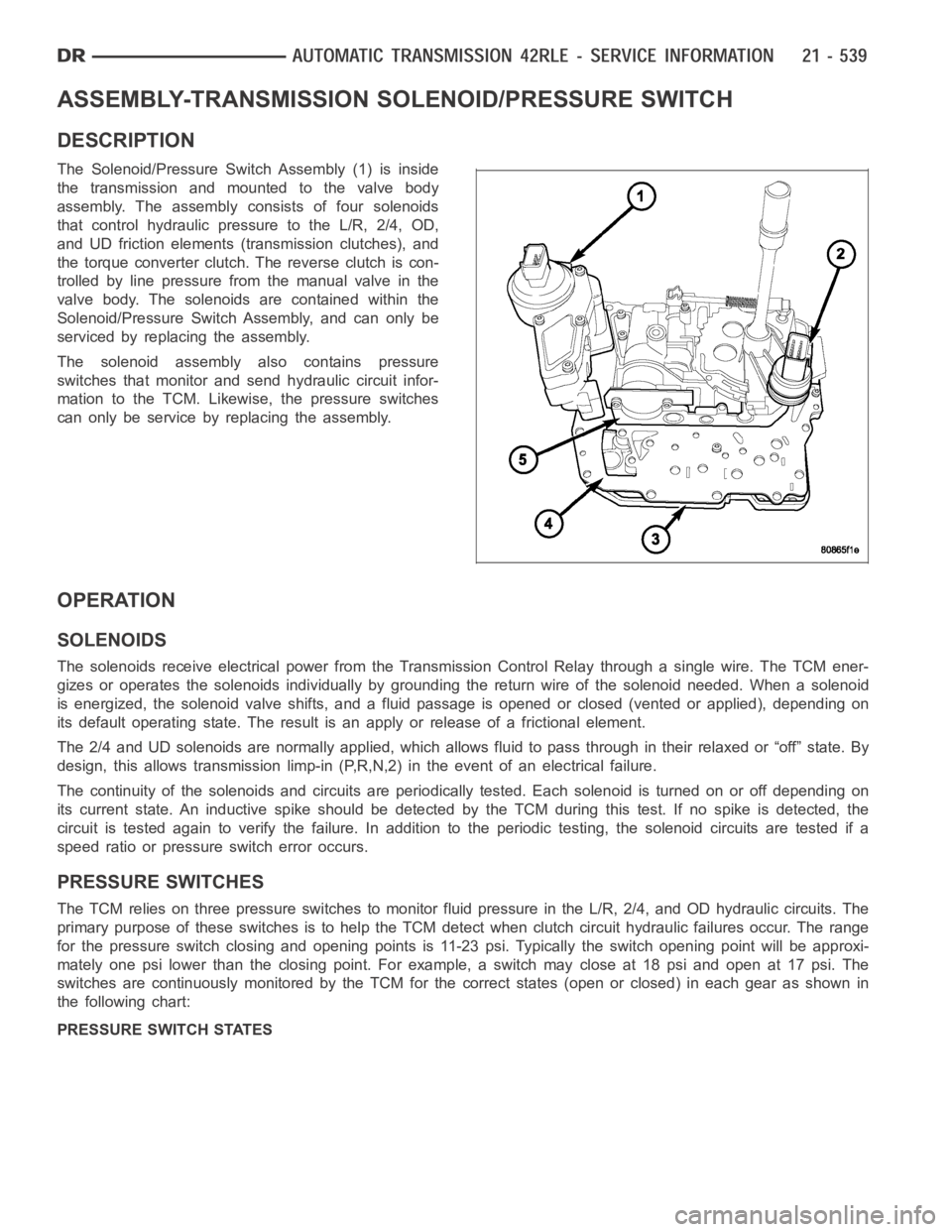

ASSEMBLY-TRANSMISSION SOLENOID/PRESSURE SWITCH

DESCRIPTION

The Solenoid/Pressure Switch Assembly (1) is inside

the transmission and mounted to the valve body

assembly. The assembly consists of four solenoids

that control hydraulic pressure to the L/R, 2/4, OD,

and UD friction elements (transmission clutches), and

the torque converter clutch. The reverse clutch is con-

trolled by line pressure from the manual valve in the

valve body. The solenoids are contained within the

Solenoid/Pressure Switch Assembly, and can only be

serviced by replacing the assembly.

The solenoid assembly also contains pressure

switches that monitor and send hydraulic circuit infor-

mation to the TCM. Likewise, the pressure switches

can only be service by replacing the assembly.

OPERATION

SOLENOIDS

The solenoids receive electrical power from the Transmission Control Relay through a single wire. The TCM ener-

gizes or operates the solenoids individually by grounding the return wireof the solenoid needed. When a solenoid

is energized, the solenoid valve shifts, and a fluid passage is opened or closed (vented or applied), depending on

its default operating state. The result is an apply or release of a frictional element.

The 2/4 and UD solenoids are normally applied, which allows fluid to pass throughintheirrelaxedor“off”state.By

design, this allows transmission limp-in (P,R,N,2) in the event of an electrical failure.

The continuity of the solenoids and circuits are periodically tested. Each solenoid is turned on or off depending on

its current state. An inductive spike should be detected by the TCM during this test. If no spike is detected, the

circuit is tested again to verify the failure. In addition to the periodic testing, the solenoid circuits are tested if a

speed ratio or pressure switch error occurs.

PRESSURE SWITCHES

The TCM relies on three pressure switches to monitor fluid pressure in the L/R, 2/4, and OD hydraulic circuits. The

primary purpose of these switches is to help the TCM detect when clutch circuit hydraulic failures occur. The range

for the pressure switch closing and opening points is 11-23 psi. Typicallythe switch opening point will be approxi-

mately one psi lower than the closing point. For example, a switch may closeat 18 psi and open at 17 psi. The

switches are continuously monitored by the TCM for the correct states (open or closed) in each gear as shown in

the following chart:

PRESSURE SWITCH STATES

Page 3073 of 5267

RELAY-TRANSMISSION CONTROL

DESCRIPTION

The relay is supplied fused B+ voltage, energized by the TCM, and is used to supply power to the solenoid pack

when the transmission is in normal operating mode.

OPERATION

When the relay is “off”, no power is supplied to the solenoid pack and the transmission is in “limp-in” mode. After a

controller reset, the TCM energizes the relay. Prior to this, the TCM verifies that the contacts are open by checking

for no voltage at the switched batteryterminals. After this is verified, the voltage at the solenoid pack pressure

switches is checked. After the relay is energized, the TCM monitors the terminals to verify that the voltage is greater

than 3 volts.

Page 3111 of 5267

When Monitored:

With the engine running and the PCM has closed the Transmission Control Relay.

Set Condition:

If the battery voltage of the Transmission Output circuit(s) to the PCM is less than 10.0 volts for the period of

15 seconds. Note: P0562 generally indicates a gradually falling battery voltage or a resistive connection(s) to

the PCM. The DTC will also set if the battery voltage sensed at the PCM is lessthan 6.5-volts for 200ms or

where the Transmission Output circuits are less than 7.2-volts for 200ms.

Possible Causes

RELATED CHARGING SYSTEM DTC’S

(Z904, Z908, Z977) GROUND CIRCUITS OPEN OR HIGH RESISTANCE

(T16) TIPM OUTPUT CIRCUIT OPEN OR HIGH RESISTANCE

TOTALLY INTEGRATED POWER MODULE (TIPM)

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Friction element distress could result from an insufficient supply voltage to properly control the solenoids. To prevent

this possibility, the battery voltage is monitored and the system is placed in logical limp-in if the battery voltage

drops below the limit.

Diagnostic Test

1.RELATED CHARGING SYSTEM DTCS

With the scan tool, read the Engine DTCs.

Are there any related Charging System DTCs also present?

Ye s>>

Refer to the Charging System category and repair any Engine Charging System DTCs, before testing

DTC P0562. NOTE: After repairing the Engine Charging System DTC’s, perform the Transmission Ver-

ification test to verify the transmission control systemwas not damaged.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 2

2.CHECK FOR TIPM DTCS

NOTE: Generator, battery, and charging system must be fully functional before performing this test.

With the scan tool, read TIPM DTCs.

Are there any TCM TIPM DTCs present.

Ye s>>

Refer to the Transmission category and perform the appropriate symptom. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - DIAGNOSIS AND TESTING)

No>>

Go To 3

Page 3116 of 5267

P0604-INTERNAL CONTROL MODULE RAM

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

After the controller is reset (ignition turned to the RUN position), the microprocessor checks the integrity of each

RAM location by writing to it and reading back from it. The read value shouldbe same as value written.

When Monitored:

One time after the controller is reset (ignition turned to the RUN position).

Set Condition:

Whenever the Powertrain Control Module (PCM) detects an internal controller problem.

Possible Causes

POWERORGROUNDCIRCUIT

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK WIRING AND CONNECTORS FOR INTERMITTENT OPERATION

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and ground circuits.

NOTE: Due to the integration of the Powertrain and Transmission Control Modules, the transmission part of

the PCM has it’s own specific power and ground circuits.

Wiggle the wires while checking for shorted and open circuits.

Check for any Service Bulletins that may apply.

Were there any problems found?

Ye s>>

Repair the power and/or ground circuits to the PCM and Transmission Control Relay as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the PCM per the Service Information. With the scan tool, perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3118 of 5267

P0613-INTERNAL TCM

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The internal Watchdog (WD) is a separate hardware circuit that continuously monitors the microprocessor. To insure

the proper operation of the Transmission controller the watchdog must receive a signal from the microprocessor

within a specific time window (14 msec ± 1 msec) to prevent a system shutdownafter a short delay (570 msec).

The microprocessor periodically tests the WD’s ability to provide this shutdown function using a three phase test;

1) Send the signal too late > 15 msec

2) Send the signal too early < 13 msec

3) Delay test < 590 msec

If the watchdog input signal arrives too early or too late, the Watchdog Fault line will go low and the watchdog delay

will start to time out. The delay will be reset by the correct timing of watchdog signal sent during subsequent oper-

ations.

The Delay Test checks the delay time out. The Delay Monitor line is pulled low, which forces the delay to start timing

out. At the end of the delay time the Transmission Relay will be turned off. The delay test, upon detection of the

relay turning off, will immediately turn the relay back on before shutdowncan occur.

When Monitored:

1) One time after the controller is reset (ignition turned to the RUN position) and every 60 seconds thereafter.

The Delay Test is executed after a reset only.

2) 2 seconds after an invalid test.

Set Condition:

If either of the following conditions occur 3 times:

1) The watchdog fault line remains high after the period has elapsed for thetoo early - too late watchdog test.

2) The Transmission Control Relay remains on after the watchdog delay expired.

Possible Causes

POWERORGROUNDCIRCUIT

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK THE WIRING AND CONNECTORS

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and ground circuits.

NOTE: Due to the integration of the Powertrain and Transmission Control Modules, the transmission part of

the PCM has it’s own specific power and ground circuits.

Wiggle the wires while checking for shorted and open circuits.

Check for any Service Bulletins that may apply.

Were there any problems found?

Ye s>>

Repair the power and/or ground circuits as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the PCM per the Service Information. With the scan tool, perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3225 of 5267

When Monitored:

Continuously while driving in a forward gear.

Set Condition:

The PCM continuously monitors Actual Line Pressure. If the Actual Line Pressure reading is greater than the

highest Desired Line Pressure ever used in the current gear, while the Pressure Control Solenoid duty cycle is

at or near its maximum value (which should result in minimum line pressure), the DTC will set.

Possible Causes

(F856) 5-VOLT SUPPLY CIRCUIT OPEN

LINE PRESSURE SENSOR CONNECTION

(T118) PRESSURE CONTROL SOLENOID CONTROL CIRCUIT OPEN

(F856) 5-VOLT SUPPLY CIRCUIT SHORT TO GROUND

(T118) PRESSURE CONTROL SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION CONTROL RELAY OUTPUT CIRCUIT

LINE PRESSURE SENSOR

STUCK OR STICKING MAIN REGULATOR VALVE

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is measured by the Line Pressure Sensor (LPS) and regulationis achieved by changing the duty

cycle of the Pressure Control Solenoid (PCS) controlled by the Transmission Control System. (5% duty cycle =

solenoid off = Max line pressure, 62%duty cycle = solenoid on = Min line pressure). The Transmission Control

System calculates the desired line pressure based on inputs from both the engine and transmission.

The Transmission Control System calculates torque input to the transmission and uses it as the primary input to the

desired line pressure calculation. This is called Torque Based Line Pressure. In addition, the line pressure is set to

a preset level 827 or 931 kPa (120 or 135 psi) during shifts and in Park and Neutral to ensure consistent shift

quality. The desired line pressure is continuously being compared to the actual line pressure. If the actual line pres-

sure is consistently higher than the highest desired line pressure ever used in the current gear, the line pressure

high DTC P0869 will set.

Diagnostic Test

1.CHECKFORRELATEDDTC’S

With the scan tool, check for other Transmission DTC’s

Is the DTC P0932 or P0882 present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, check the STARTS SINCE SET counter for P0869.

Is the STARTS SINCE SET COUNTER 2 or less?

Ye s>>

Go To 3

No>>

Go To 10

Page 3231 of 5267

When Monitored:

In any forward gear with engine speed above 1000 RPM shortly after a shift and every minute thereafter.

Set Condition:

After a shift into a forward gear, with engine speed above 1000 RPM, the PCM momentarily turns on element

pressure to the Clutch circuits that don’t have pressure to identify the correct Pressure Switch closes. If the

Pressure Switch does not close 2 times, the DTC sets.

Possible Causes

LINE PRESSURE SENSOR

TRANSMISSION FLUID CONTAMINATION

RELATED DTC’S PRESENT

TRANSMISSION SOLENOID/TRS ASSEMBLY

EXCESSIVE DEBRIS IN OIL PAN

POOR LINE PRESSURE SENSOR CONNECTION

(T9) OD PRESSURE SWITCH SENSE CIRCUIT OPEN

TRANSMISSION CONTROL RELAY DTCS PRESENT

(T9) OD PRESSURE SWITCH SENSE CIRCUIT OPEN

(F856) 5-VOLT SUPPLY CIRCUIT OPEN

TRANSMISSION CONTROL RELAY OUTPUT CIRCUIT OPEN

(T9) OD PRESSURE SWITCH SENSE CIRCUIT SHORT TO GROUND

(F856) 5-VOLT SUPPLY CIRCUIT SHORT TO GROUND

(T9) OD PRESSURE SWITCH SENSE CIRCUIT SHORT TO OTHER CIRCUITS

TRANSMISSION SOLENOID/TRS ASSEMBLY

INTERNAL TRANSMISSION

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System tests the pressure switches when they areoff. The test verifies that the switches

are operational (They will close with pressure applied). The Transmission Control System verifies that the switch

closes when the corresponding element is applied. If a switch fails to close, it is re-tested. If it fails the second test,

the DTC will set, the MIL will illuminate and the transmission system will default to the orderly Shutdown routine.

Diagnostic Test

1.CHECK IF RELATED DTCS ARE PRESENT

With the scan tool, check for other transmission DTCs.

Is there any Loss of Prime, Transmission Control Relay, and/or Line Pressure Sensor DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom. If the DTC, P0944-LOSS OF

PRIME is present, perform its respective test first.

No>>

Go To 2