check engine DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 28 of 5267

Theory of Operation

The Park Neutral switch rationality test is enabled only for vehicles equipped with a 4/5 speed automatic transmis-

sion. This diagnostic checks if the park/neutral switch is incorrectly stuck in the neutral position during driving con-

ditions by comparing Vehicle Speed, Engine Speed, Throttle Position, andPressure Ratio to the fail thresholds and

by looking at the state of the Park/Neutral Switch. The stuck in drive condition is not explicitly checked as the starter

relay does not energize and therefore render the vehicle inoperable.

When Monitored:

Continuously with the transmission in Park, Neutral, or Drive and NOT in Limp-in mode.

Set Condition:

This code will set if the PCM detects an incorrect Park/Neutral switch state for a given mode of vehicle oper-

ation. One trip fault. Three good trips to turn off the MIL.

Possible Causes

TRS (T41) SENSE (P/N SENSE) CIRCUIT OPEN

TRS (T41) SENSE (P/N SENSE) CIRCUIT SHORTED TO GROUND

TRANSMISSION RANGE SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.P/N AND D/R NOT IN CORRECT POSITION

NOTE: Check the TCM for DTCs, if P0706 is set in the TCM diagnose the TCM code before continuing.

Ignition on, engine not running.

With the scan tool, read the Park/Neutral Position Switch input state.

While moving the gear selector through all gear positions (Park to 1 and back to Park), monitor the scan tool dis-

play.

Did the scan tool display show P/N and D/R in the correct gear positions?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

Page 30 of 5267

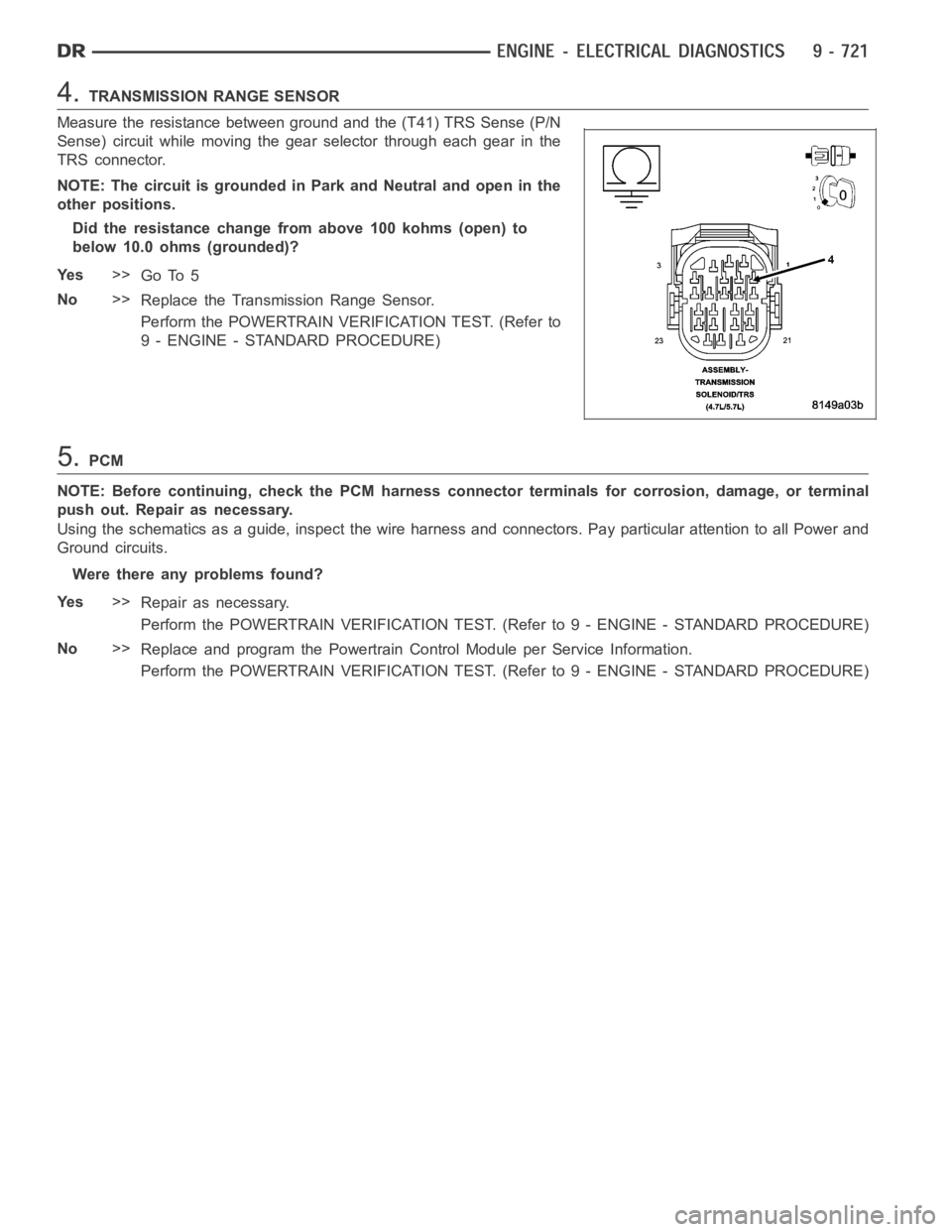

4.TRANSMISSION RANGE SENSOR

Measure the resistance between ground and the (T41) TRS Sense (P/N

Sense) circuit while moving the gear selector through each gear in the

TRS connector.

NOTE: The circuit is grounded in Park and Neutral and open in the

other positions.

Did the resistance change from above 100 kohms (open) to

below 10.0 ohms (grounded)?

Ye s>>

Go To 5

No>>

Replace the Transmission Range Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

5.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 36 of 5267

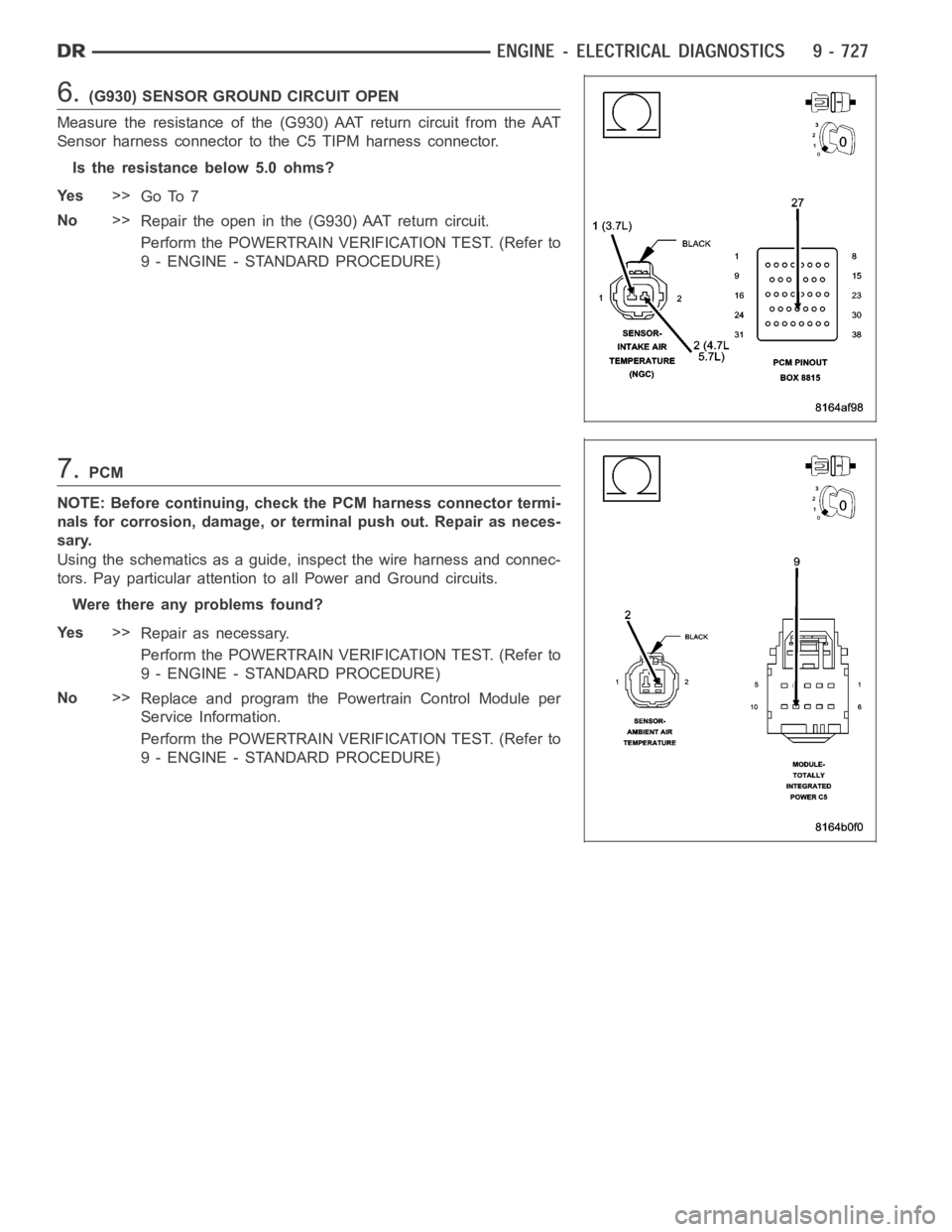

6.(G930) SENSOR GROUND CIRCUIT OPEN

Measure the resistance of the (G930) AAT return circuit from the AAT

Sensor harness connector to the C5 TIPM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the open in the (G930) AAT return circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.PCM

NOTE: Before continuing, check the PCM harness connector termi-

nals for corrosion, damage, or terminal push out. Repair as neces-

sary.

Using the schematics as a guide, inspect the wire harness and connec-

tors. Pay particular attention to all Power and Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per

Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 39 of 5267

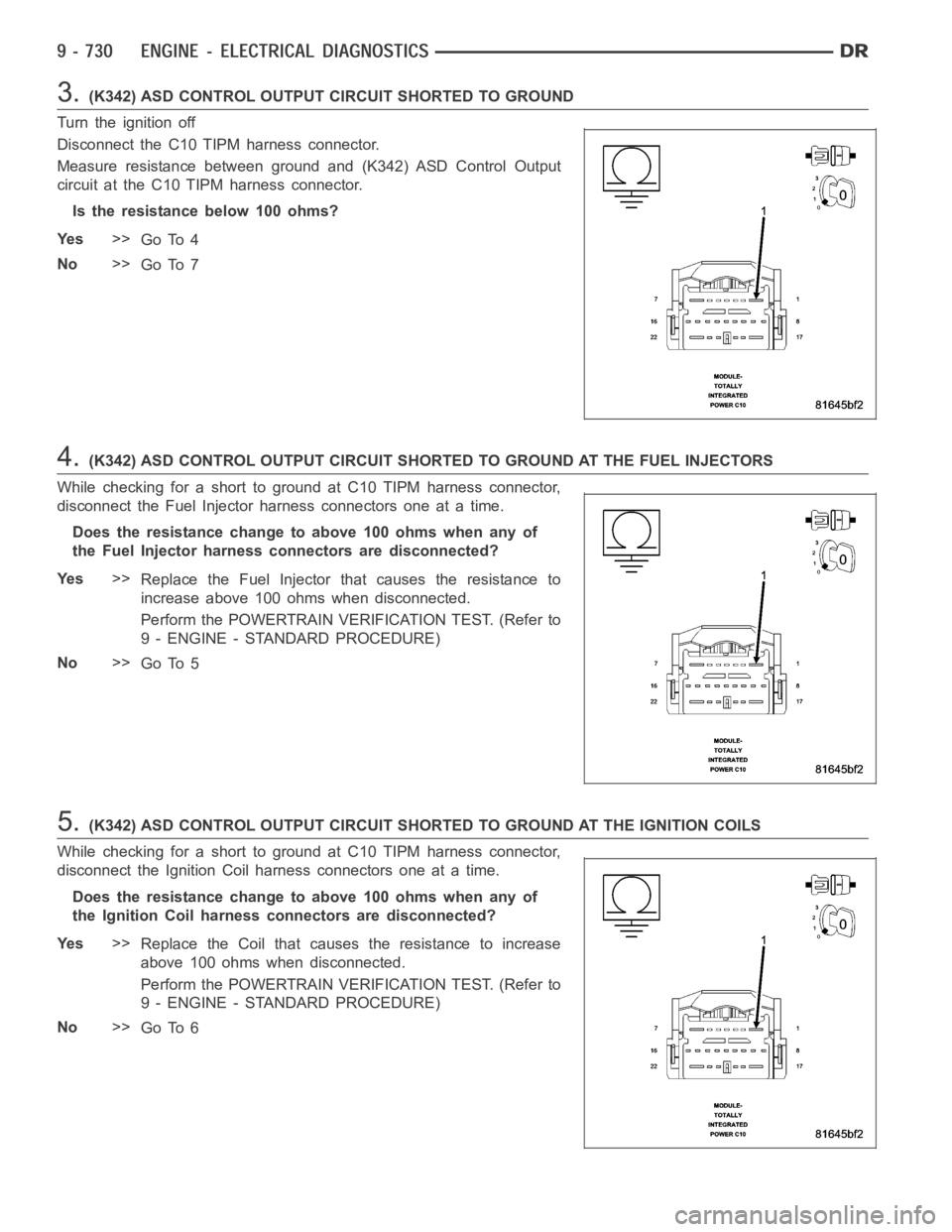

3.(K342) ASD CONTROL OUTPUT CIRCUIT SHORTED TO GROUND

Turn the ignition off

Disconnect the C10 TIPM harness connector.

Measure resistance between ground and (K342) ASD Control Output

circuit at the C10 TIPM harness connector.

Istheresistancebelow100ohms?

Ye s>>

Go To 4

No>>

Go To 7

4.(K342) ASD CONTROL OUTPUT CIRCUIT SHORTED TO GROUND AT THE FUEL INJECTORS

While checking for a short to ground at C10 TIPM harness connector,

disconnect the Fuel Injector harness connectors one at a time.

Does the resistance change to above 100 ohms when any of

the Fuel Injector harness connectors are disconnected?

Ye s>>

Replace the Fuel Injector that causes the resistance to

increase above 100 ohms when disconnected.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.(K342) ASD CONTROL OUTPUT CIRCUIT SHORTED TO GROUND AT THE IGNITION COILS

While checking for a short to ground at C10 TIPM harness connector,

disconnect the Ignition Coil harness connectors one at a time.

Does the resistance change to above 100 ohms when any of

the Ignition Coil harness connectors are disconnected?

Ye s>>

Replace the Coil that causes the resistance to increase

above 100 ohms when disconnected.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

Page 40 of 5267

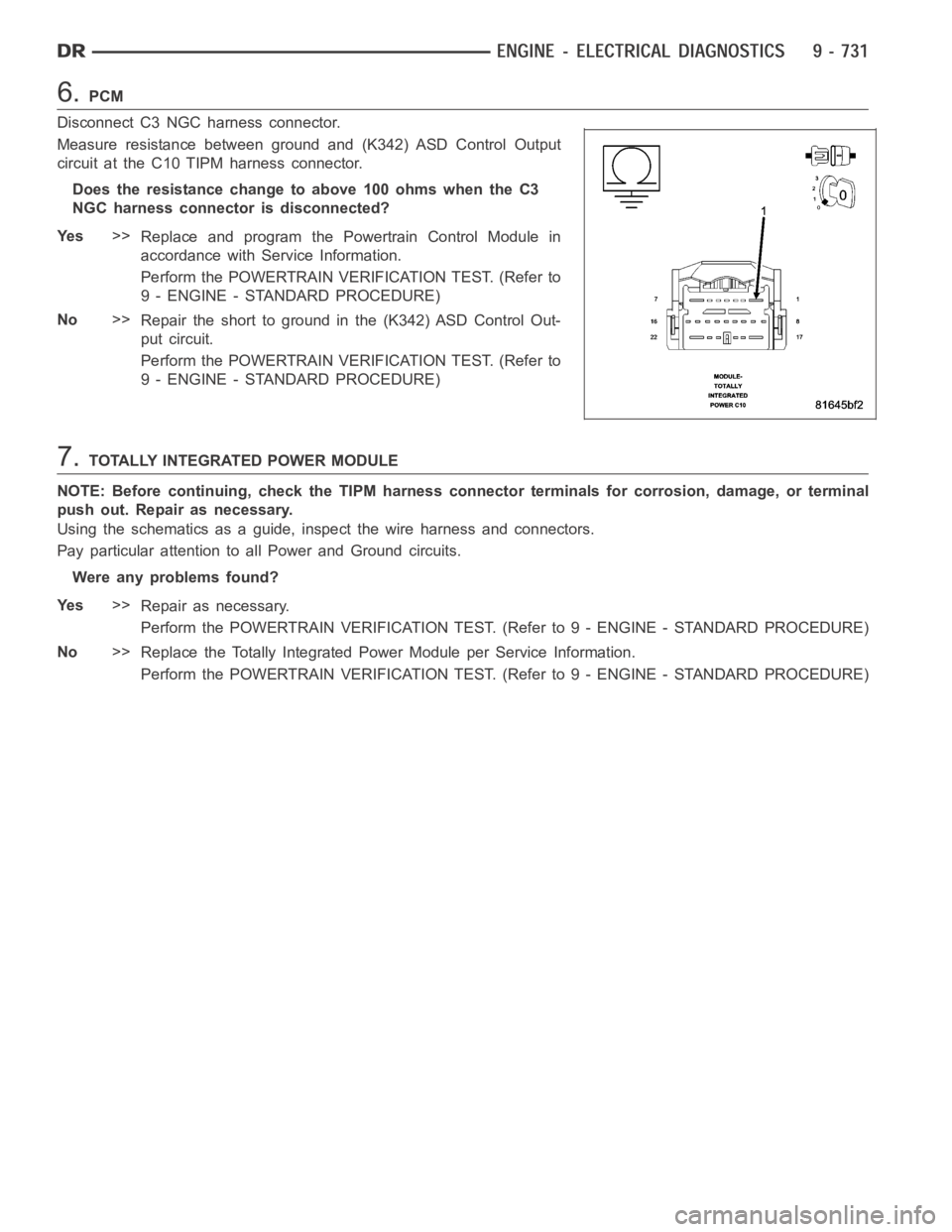

6.PCM

Disconnect C3 NGC harness connector.

Measure resistance between ground and (K342) ASD Control Output

circuit at the C10 TIPM harness connector.

Does the resistance change to above 100 ohms when the C3

NGC harness connector is disconnected?

Ye s>>

Replace and program the Powertrain Control Module in

accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Repair the short to ground in the (K342) ASD Control Out-

put circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 43 of 5267

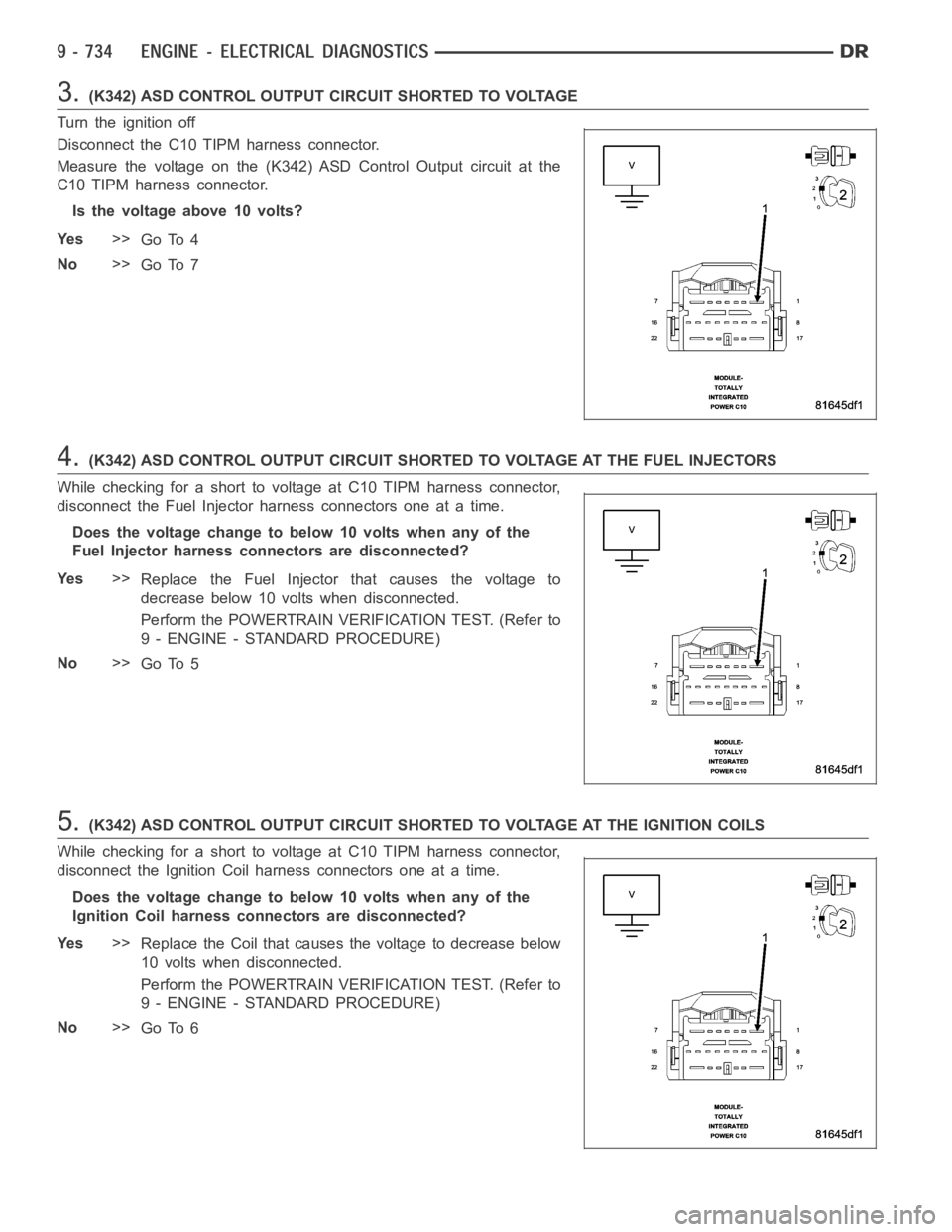

3.(K342) ASD CONTROL OUTPUT CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off

Disconnect the C10 TIPM harness connector.

Measure the voltage on the (K342) ASD Control Output circuit at the

C10 TIPM harness connector.

Is the voltage above 10 volts?

Ye s>>

Go To 4

No>>

Go To 7

4.(K342) ASD CONTROL OUTPUT CIRCUIT SHORTED TO VOLTAGE AT THE FUEL INJECTORS

While checking for a short to voltage at C10 TIPM harness connector,

disconnect the Fuel Injector harness connectors one at a time.

Does the voltage change to below 10 volts when any of the

Fuel Injector harness connectors are disconnected?

Ye s>>

Replace the Fuel Injector that causes the voltage to

decrease below 10 volts when disconnected.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.(K342) ASD CONTROL OUTPUT CIRCUIT SHORTED TO VOLTAGE AT THE IGNITION COILS

While checking for a short to voltage at C10 TIPM harness connector,

disconnect the Ignition Coil harness connectors one at a time.

Does the voltage change to below 10 volts when any of the

Ignition Coil harness connectors are disconnected?

Ye s>>

Replace the Coil that causes the voltage to decrease below

10 volts when disconnected.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

Page 44 of 5267

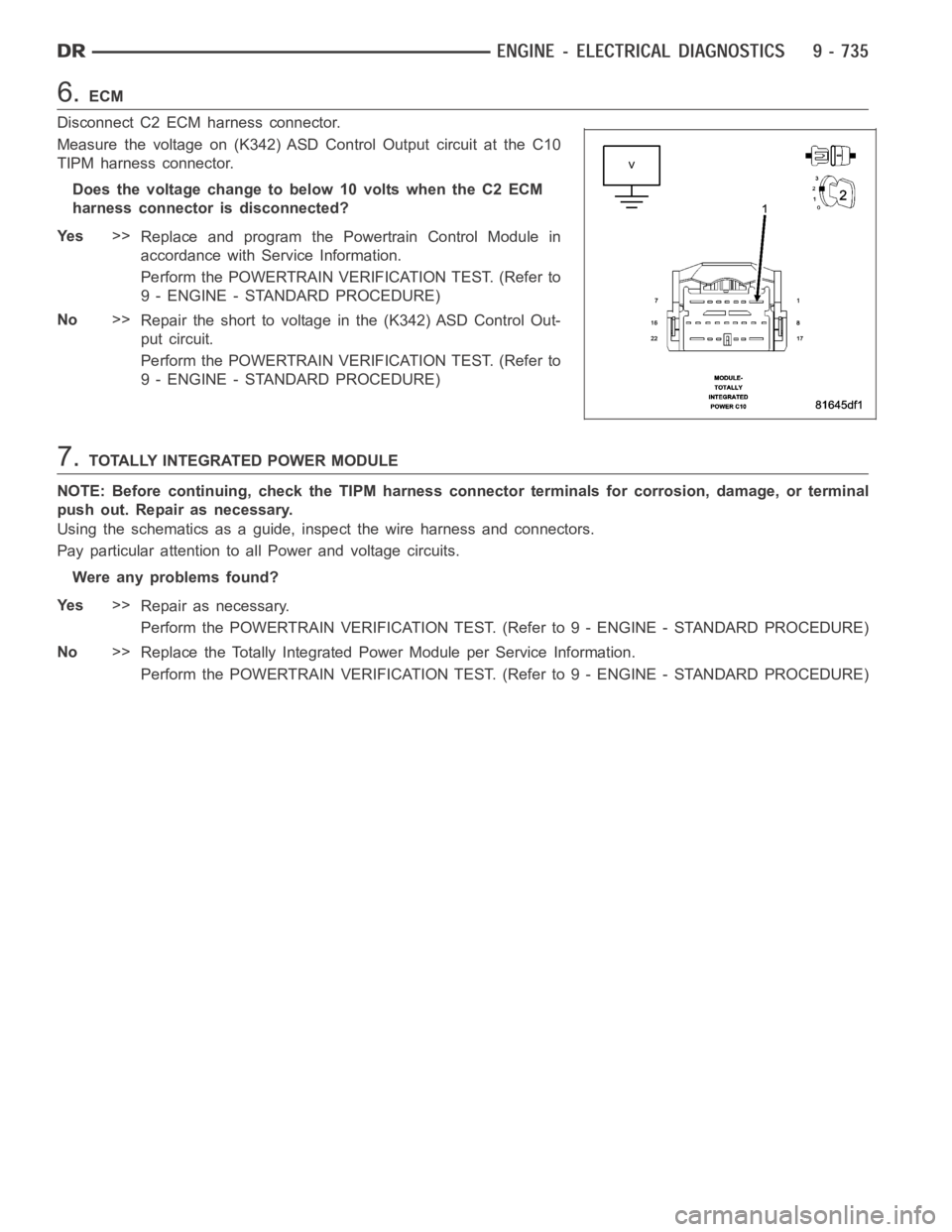

6.ECM

Disconnect C2 ECM harness connector.

Measure the voltage on (K342) ASD Control Output circuit at the C10

TIPM harness connector.

Does the voltage change to below 10 volts when the C2 ECM

harness connector is disconnected?

Ye s>>

Replace and program the Powertrain Control Module in

accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Repair the short to voltage in the (K342) ASD Control Out-

put circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 48 of 5267

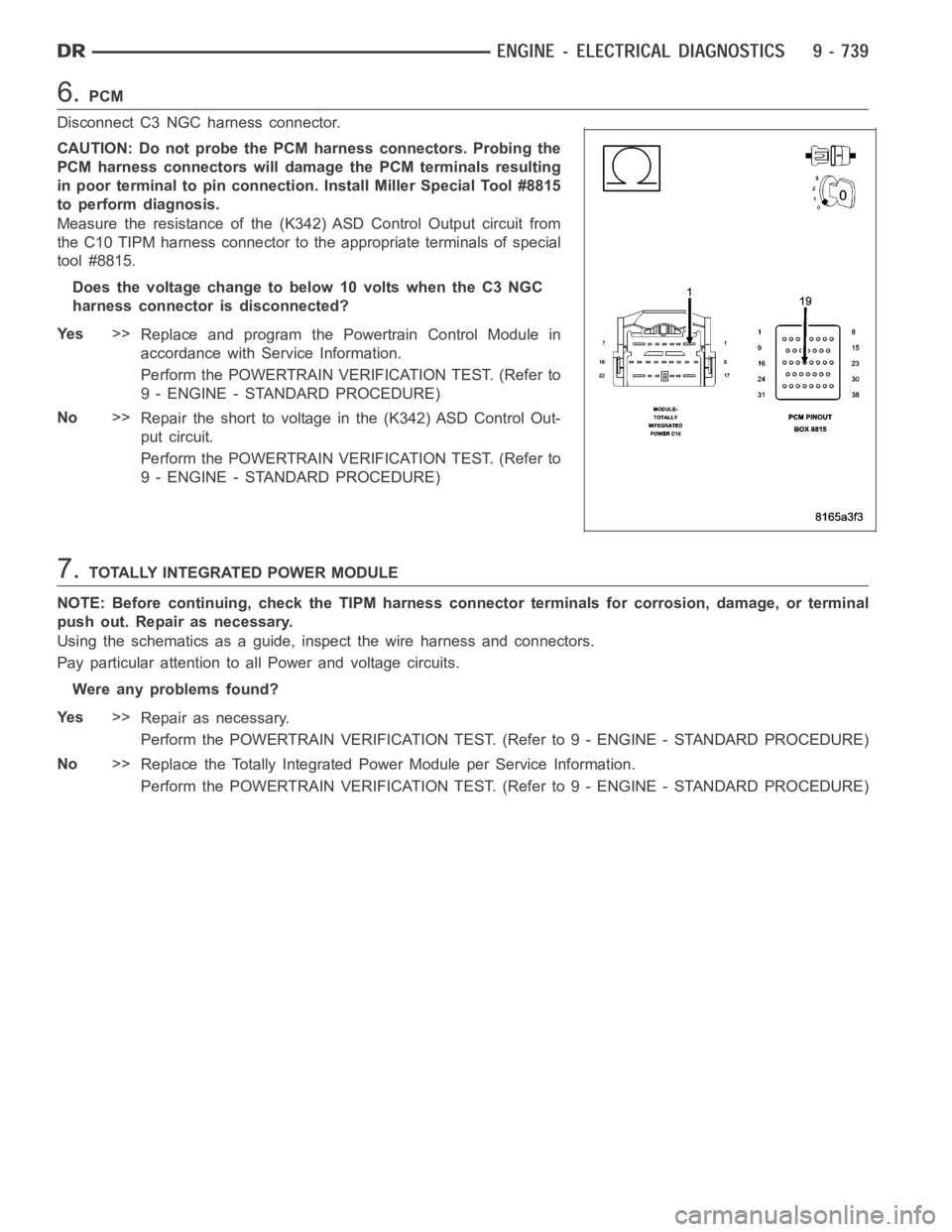

6.PCM

Disconnect C3 NGC harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (K342) ASD Control Output circuit from

the C10 TIPM harness connector to the appropriate terminals of special

tool #8815.

Does the voltage change to below 10 volts when the C3 NGC

harness connector is disconnected?

Ye s>>

Replace and program the Powertrain Control Module in

accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Repair the short to voltage in the (K342) ASD Control Out-

put circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 52 of 5267

6.PCM Turn the ignition off.

Disconnect C3 NGC harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage

the PCM terminals resulting in poor terminal to pin connection. Install Miller Special Tool #8815 and #8815-1

to perform diagnosis.

With a voltmeter, use Negative lead of the voltmeter along with terminal probe tool #6801, probe the (K342) ASD

Control Output circuit at the appropriate terminals of special tool #8815.

With the Positive lead of the voltmeter along with terminal probe tool #6801, back probe the (K342) ASD Control

Output circuit at the C10 TIPM harness connector.

Start the engine and allow it to idle.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Measure the voltage of the (K342) ASD Control Output circuit.

Is the voltage above 0.001 of a volt (1.0mV) for any of the Ignition Coil ASD Control Output circuits?

Ye s>>

Repair the excessive resistance in the (K342) ASD Control Output circuit tothePCM.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module in accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 55 of 5267

3.(C3) A/C CLUTCH CONTROL OUTPUT CIRCUIT SHORTED TO GROUND

Turn the ignition off

Disconnect the C9 TIPM harness connector.

Disconnect the A/C Compressor Clutch harness connector.

Measure the resistance between ground and the (C3) A/C Clutch Con-

trol Output circuit at the A/C Compressor Clutch harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (C3) A/C Clutch Control

Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.A/C COMPRESSOR CLUTCH

Connect the C2 and C9 TIPM harness connectors.

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the A/C Clutch.

With a 12-volt test light connected to ground, probe the (C3) A/C Clutch

Control Output circuit at the A/C Compressor Clutch harness connector.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Replace the A/C Compressor Clutch per Service Informa-

tion.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES - STANDARD PROCEDURE)